Quick quenching furnace

A quenching furnace, fast technology, applied in the direction of quenching device, heat treatment equipment, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

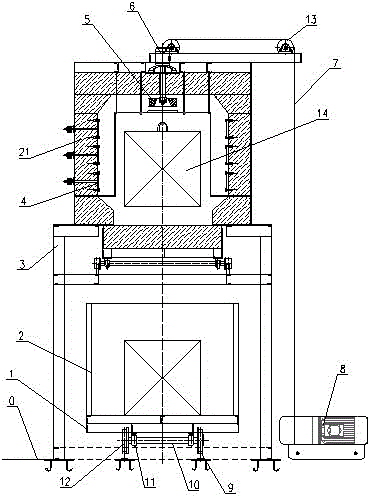

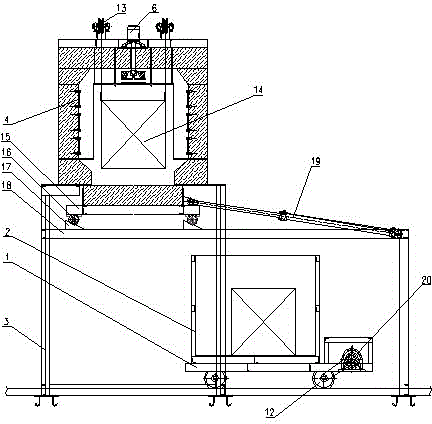

[0012] refer to figure 1 and figure 2 As shown, a rapid quenching furnace of the present invention comprises a furnace frame 3, a body of furnace 21, a furnace door 15, a cylinder 19, a track 18, a water tank car and a track 9, the frame 3 is fixed on the ground 0, and the body of furnace 21 is made of insulating material Building, fixedly installed on the top of the grate 3, the furnace mouth is downward. A heating element 4 is fixed in the hearth of the body of furnace 21, and a blower fan 5 driven by a motor 6 is fixedly installed to uniform the temperature in the furnace. A pulley 13 is fixed on the furnace body 21 or the furnace frame 3, and the motor 8 fixed on the ground 0 or the furnace frame 3 is fixedly connected to one end of the hoisting chain 7 treated with high manganese steel quenched and tempered, and the other end of the hoisting chain 7 is wound around Enter the furnace through the pulley 13, and lift the workpiece 21. Also be fixed with track 18 and cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com