Welding and assembling thermal treatment method for martensite heat-resistant steel G115 large-diameter thick-wall pipeline

A heat treatment method and heat-resistant steel technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of inclusions, unfused, and tungsten welding materials in the fusion zone, and improve the utilization rate of heat treatment equipment. Guarantee the quality of welding and heat treatment, and the effect of ensuring the quality of weld heat treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

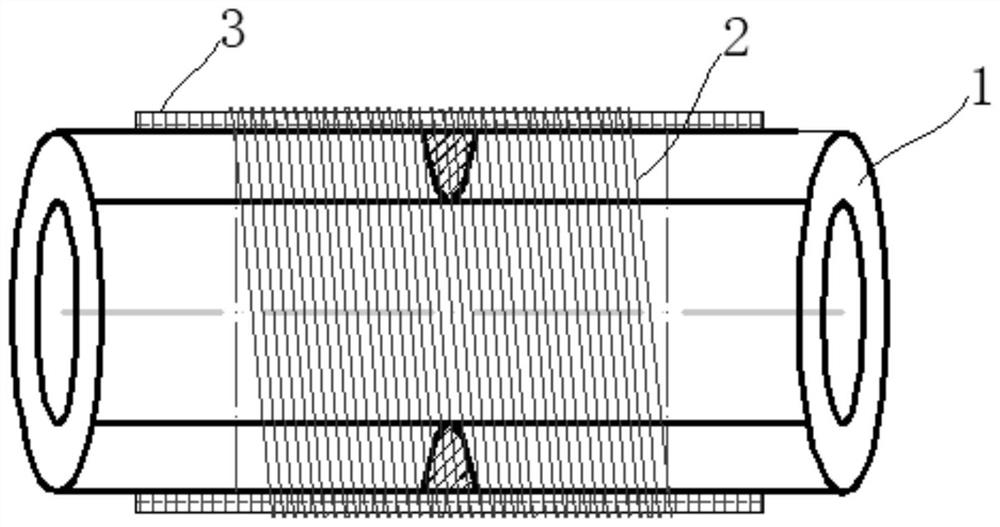

[0039]A martensitic heat-resistant steel G115 large-diameter thick-walled pipe welding and combined heat treatment method, taking G115 steel pipe 1 with a diameter of 530 mm and a wall thickness of 115 mm as an example, the ambient temperature for welding is not lower than 5°C, and the wind speed in the welding area is ≤ 2m / s. Specifically, the method includes the steps of:

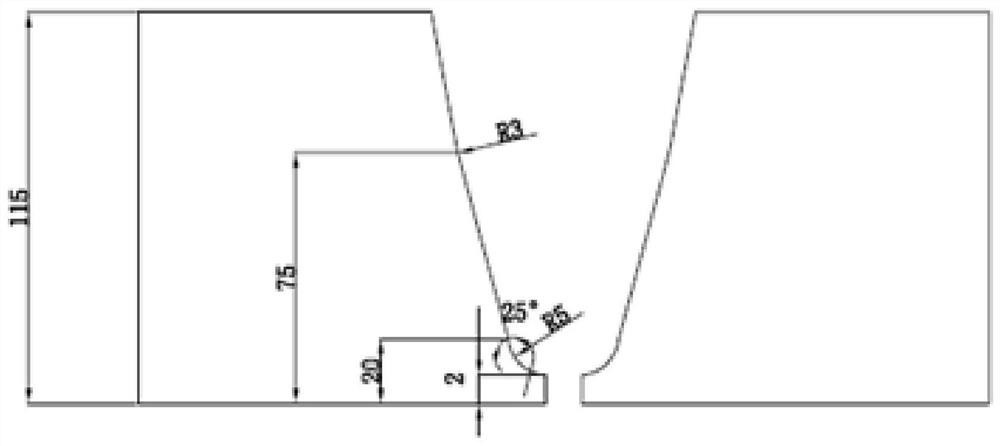

[0040] (1) Groove preparation: according to figure 1 Process U-shaped grooves, and then pair them to form grooves.

[0041] (2) Preheating before welding: Preheating is performed by flexible ceramic resistance heating before welding. The heating width of each side is not less than 4 times the wall thickness. During the preheating process, the temperature control thermocouple should be arranged within the heating area. The monitoring thermocouple should be as close as possible to the groove to be welded. The preheating rate is 60°C / h. Use a temperature measuring pen to measure the preheating temperature ...

no. 2 example

[0051] A martensitic heat-resistant steel G115 large-diameter thick-walled pipe welding and combined heat treatment method, taking G115 steel pipe 1 with a diameter of 530 mm and a wall thickness of 115 mm as an example, the ambient temperature for welding is not lower than 5°C, and the wind speed in the welding area is ≤ 2m / s. Specifically, the method includes the steps of:

[0052] (1) Groove preparation: according to figure 1 Process U-shaped grooves, and then pair them to form grooves.

[0053] (2) Preheating before welding: Preheating is performed by flexible ceramic resistance heating before welding. The heating width of each side is not less than 4 times the wall thickness. During the preheating process, the temperature control thermocouple should be arranged within the heating area. The monitoring thermocouple should be as close as possible to the groove to be welded. The preheating rate is 55°C / h. Use a temperature measuring pen to measure the preheating temperature...

no. 3 example

[0063] A martensitic heat-resistant steel G115 large-diameter thick-walled pipe welding and combined heat treatment method, taking G115 steel pipe 1 with a diameter of 530 mm and a wall thickness of 115 mm as an example, the ambient temperature for welding is not lower than 5°C, and the wind speed in the welding area is ≤ 2m / s. Specifically, the method includes the steps of:

[0064] (1) Groove preparation: according to figure 1 Process U-shaped grooves, and then pair them to form grooves.

[0065] (2) Preheating before welding: Preheating is performed by flexible ceramic resistance heating before welding. The heating width of each side is not less than 4 times the wall thickness. During the preheating process, the temperature control thermocouple should be arranged within the heating area. The monitoring thermocouple should be as close as possible to the groove to be welded. The preheating speed is 80°C / h. Use a temperature measuring pen to measure the preheating temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com