Rapid demolding method after press quenching of synchronous ring and synchronous ring press quenching device thereof

A synchronous ring and demoulding technology, which is applied in the direction of quenching device, process efficiency improvement, furnace, etc., can solve problems affecting product quality, mandrel and workpiece damage, and affecting production progress, so as to maintain heat treatment quality and achieve huge economic benefits , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In the method of rapid demoulding of the synchronous ring after press quenching in this embodiment, the outer end of the synchronous ring workpiece after press quenching is heated by a quenching inductor, the heating temperature is 110~130°C, and the heating time is 10~30S. In the example, the preferred heating temperature is 120°C and the heating time is 15S. After heating, pull the mandrel with external force and pull out the synchronous ring workpiece.

Embodiment 2

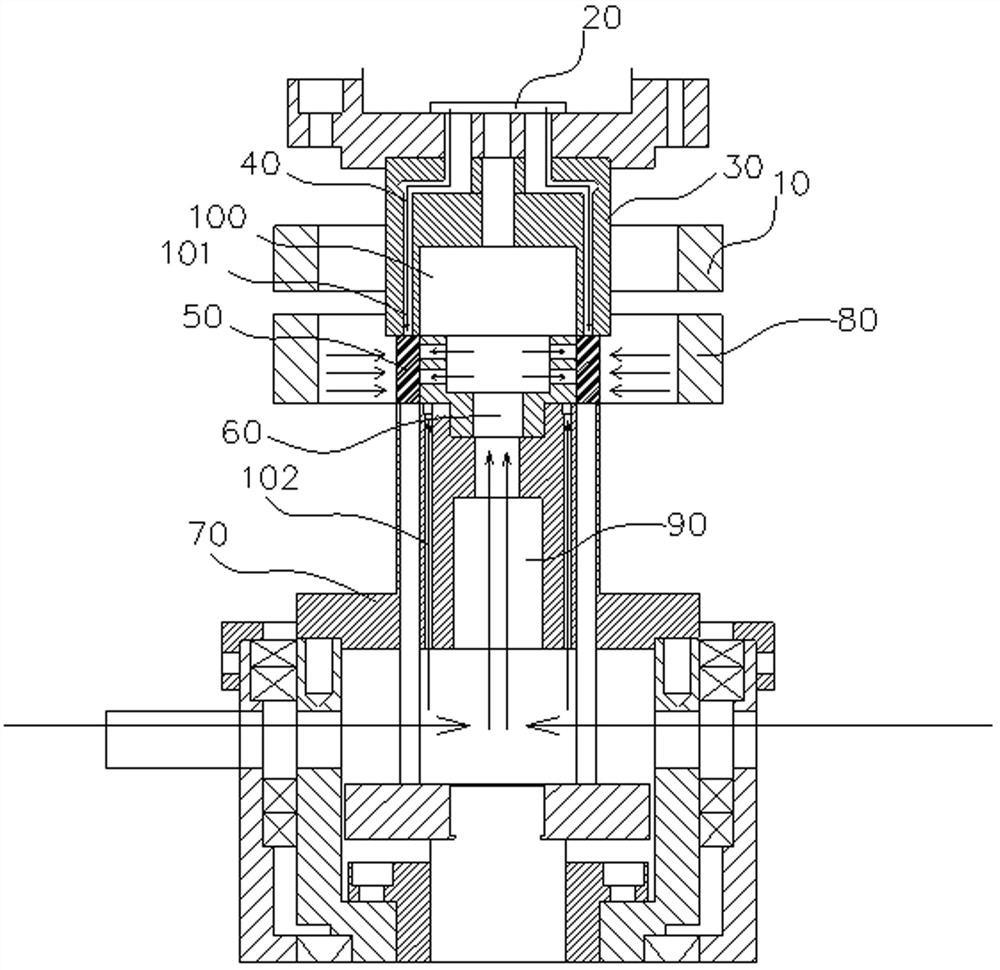

[0026] Such as figure 1 As shown, the synchronous ring press quenching device in this embodiment includes a lower die 70, an upper die 30 and a quenching mandrel 60; , the bottom of the upper mold 30 is provided with a core mold 60, the upper mold is provided with a cooling water channel 40, the outer periphery of one end of the upper mold 30 close to the core mold 60 is provided with an inductor 10 electrically connected to the power supply transformer, and the outer periphery of the core mold is provided with a spray nozzle. Water circle 80, water spray circle 80 comprises inner circle and outer circle, and inner circle and outer circle form annular quenching spray chamber, and the water spray velocity and water spray time of water spray circle 80 are controlled by controller.

[0027] The outer side of the lower die 70 is provided with a push rod 90, and the push rod 90 pushes out the mandrel 60 through the cylinder, so that the synchronized ring workpiece 50 to be quenched...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com