Cold extrusion mold for ball stud

A technology of cold extrusion and ball studs, which is applied in the direction of metal extrusion dies, etc., can solve the problems of reduced shear resistance of bending machines, large machining allowances, and large cutting volumes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

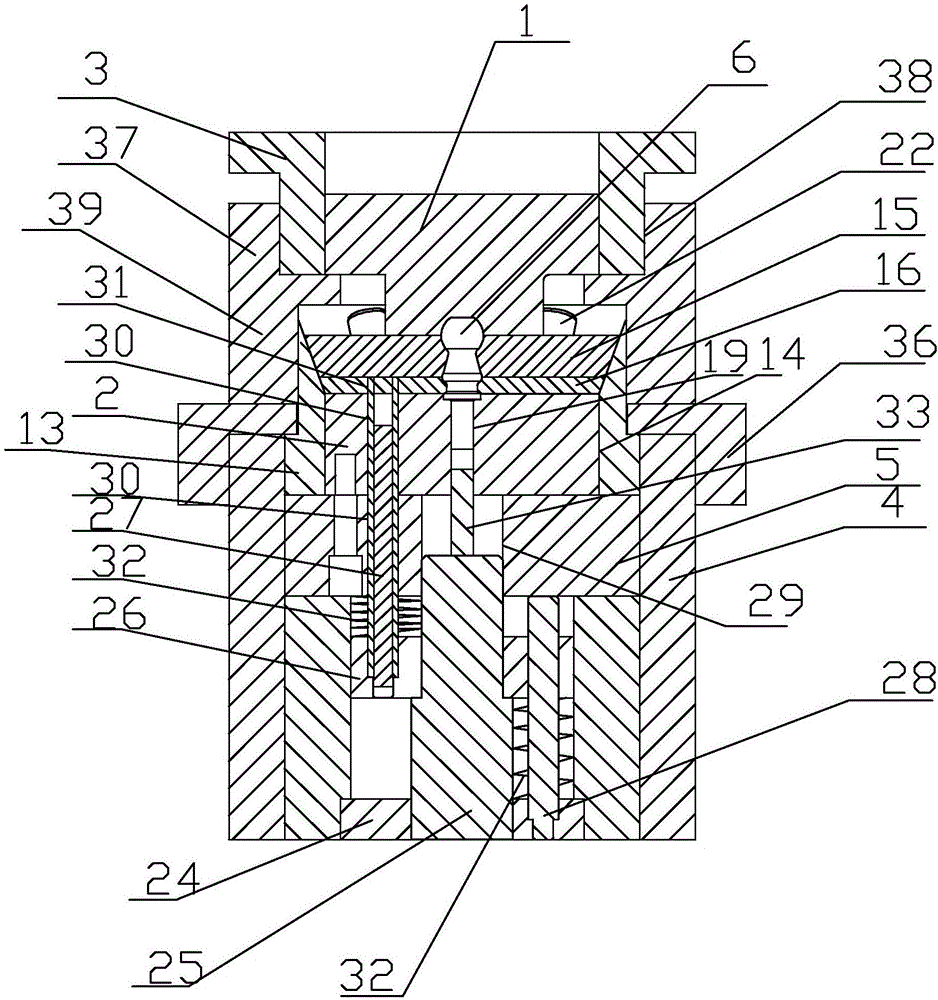

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

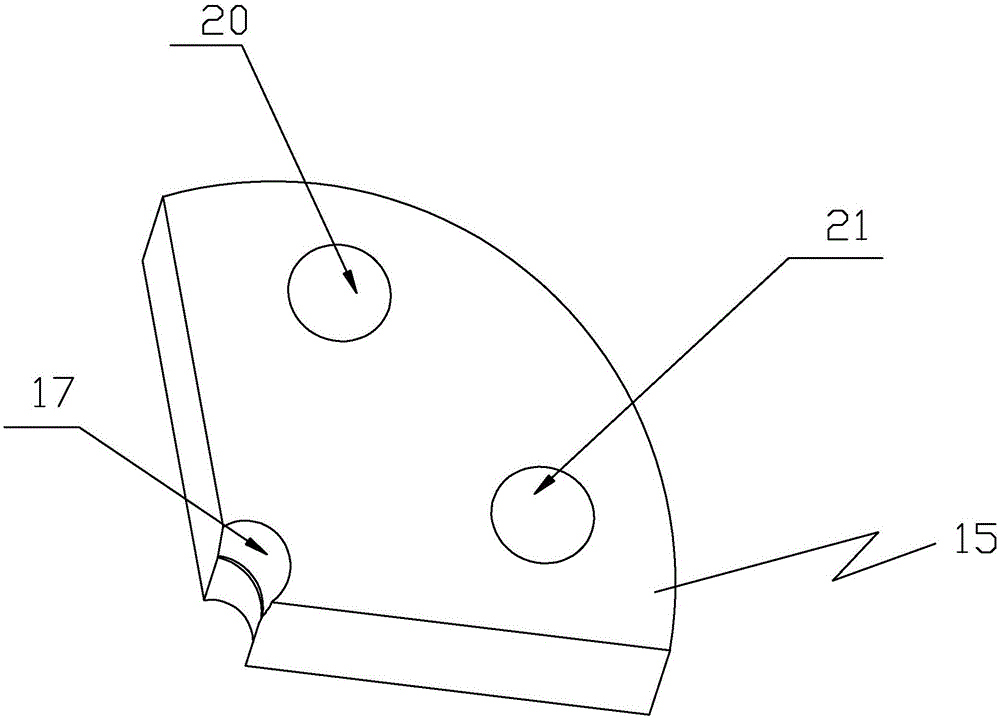

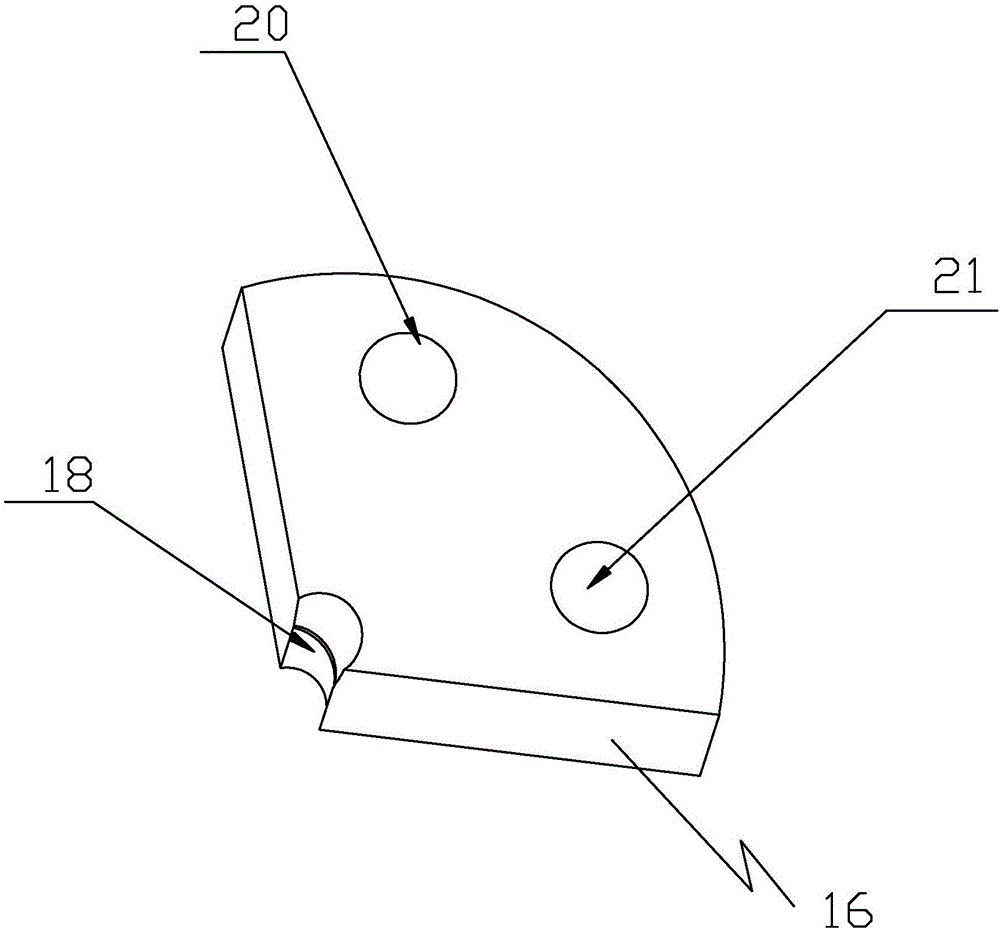

[0025] As shown in the figure, the present invention provides a ball stud cold extrusion die, including an upper die 1, a lower die 2, an upper die set 3, a lower die set 4 and a product 6, and the upper die 1 is fixed on the upper die In the cover 3, the lower mold 2 is fixed in the lower mold cover 4, and the lower mold cover 4 is provided with a lower mold backing plate 5, and the lower mold backing plate 5 is located at the bottom of the lower mold 2. The product 6 includes a ball head 7, a neck 8 and a stem 9, the stem 9 is provided with a first protrusion 10 and a second protrusion 11, and the first protrusion 10 is located between the neck 8 and the Between the second protrusions 11, a groove 12 is provided between the first protrusion 10 and the second protrusion 11, the diameter of the neck 8 increases from the upper end to the lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com