Manufacturing technology for half-axis sleeve tube

A manufacturing process and a technology for a half-shaft casing, which is applied in the field of automobile half-shaft casing production and manufacturing technology, can solve the problems of difficult quality assurance, high tool requirements, time-consuming and other problems, so as to achieve less machining allowance and reduce processing procedures and man-hours. , The effect of saving tool cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

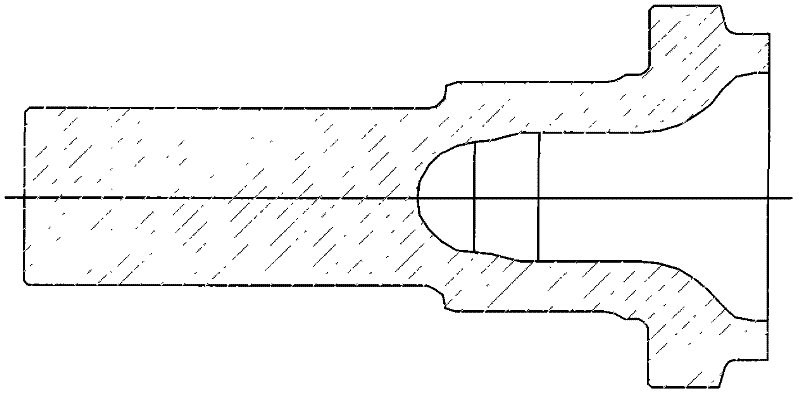

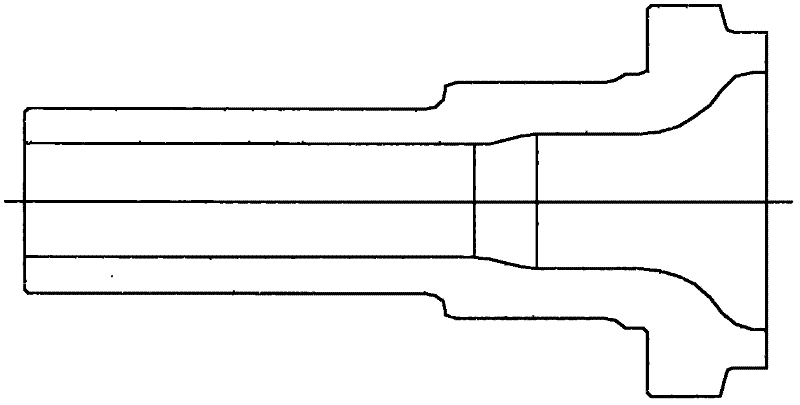

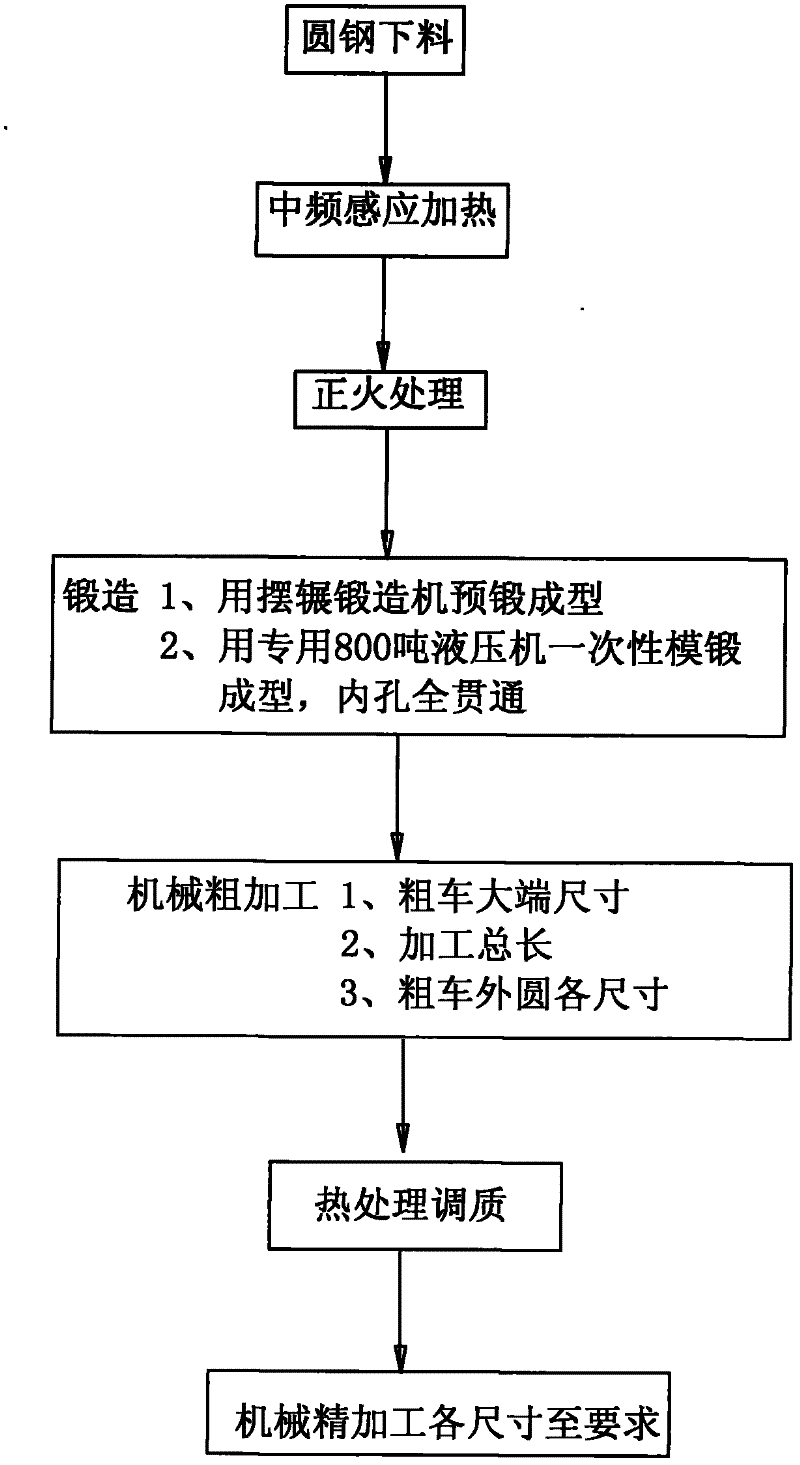

[0013] Such as Figures 2 to 3 As shown, the manufacturing process steps of the semi-shaft casing of the present invention are as follows: 1. Blanking with round steel with a weight of 25 kg; 2. Heating the round steel with medium frequency induction to a predetermined temperature of 1200 ° C; 3. Forging with a swing roller Machine pre-forging, namely figure 1 State as shown; 4. Then use 800 tons of special hydraulic press to form a one-time die forging to figure 2 In the state shown, the inner hole is fully penetrated and reaches the required size. The misalignment between the outer circle and the inner hole is not more than φ0.4, and the machining allowance is small, which reduces the processing procedures and man-hours, and greatly saves tool consumption and processing man-hours.

[0014] From the comparison of the two processes, the new process can save 10kg of material for the half-shaft parts of the same specification, and use a special 800-ton hydraulic press to forge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com