Preparation method of aluminum-alloy gas meter end cover

A gas meter and aluminum alloy technology, which is applied in liquid/fluid solid measurement, measurement capacity, instruments, etc., can solve the gas meter end cover that cannot meet the requirements of air tightness and mechanical properties, cannot improve material performance, and increases product manufacturing costs and other issues, to achieve the effect of improving material utilization, light weight, and reducing product manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: The preparation method of a G1 type aluminum alloy gas meter end cover is:

[0021] a. The mass percentages of aluminum alloy materials are: Si: 6.0%, Mg: 0.2%, Ti: 0.1%, and the rest is Al;

[0022] b. Put the prepared pure aluminum ingot, aluminum-titanium alloy and aluminum-silicon alloy into the melting furnace for heating. After the alloy is completely melted, adjust the temperature of the aluminum liquid to 650°C and add Mg. Continue to heat up to 700°C and add 0.3% hexachloroethane to refine for 8 minutes, and let it stand for 15 minutes to skimmer and wait for pouring;

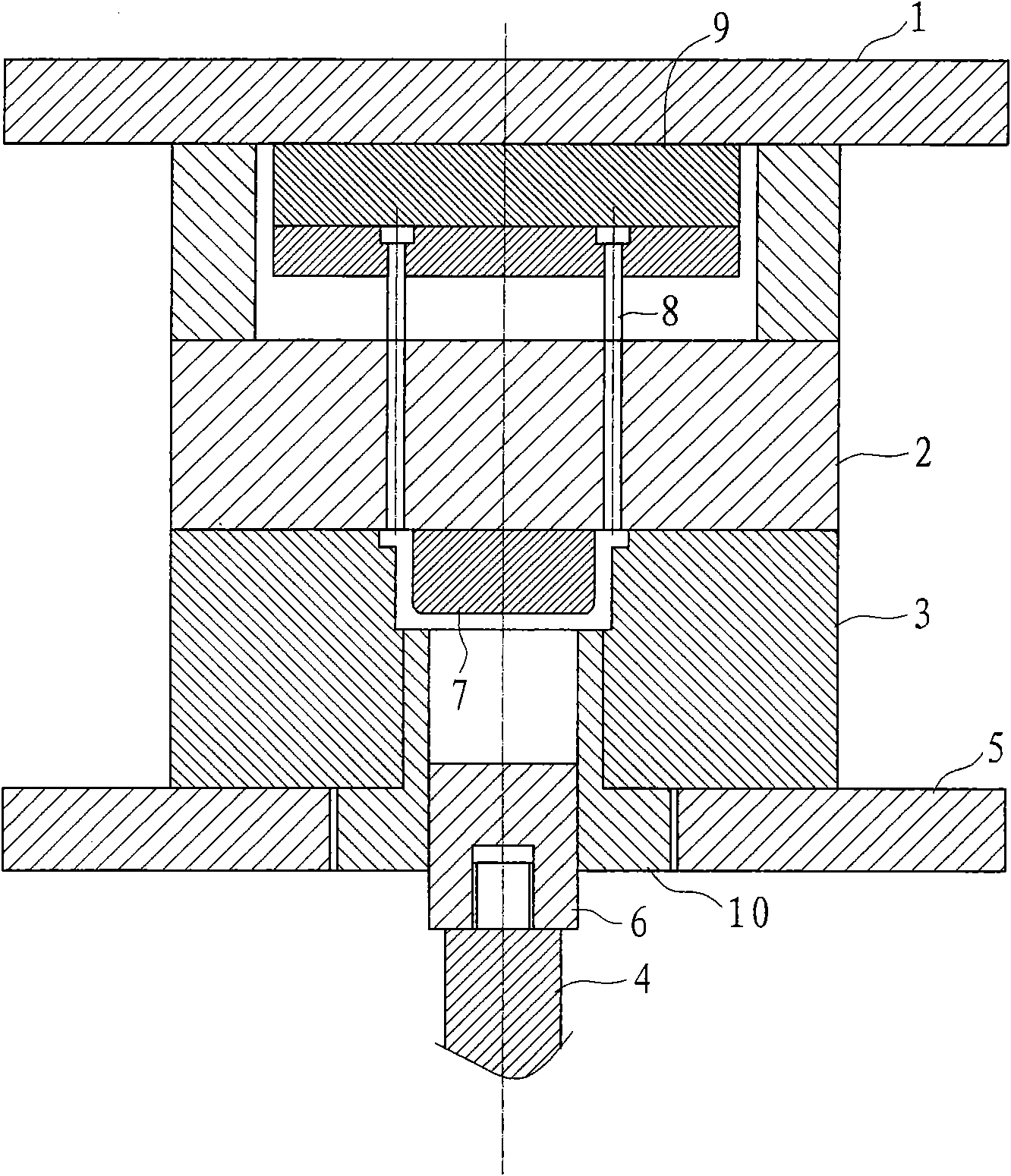

[0023] c. Before using the prefabricated gas meter end cover indirect squeeze casting mold, the internal cavity should be cleaned, and preheated to 100°C, and then spray graphite evenly inside the cavity;

[0024] d. When the temperature of the aluminum alloy melt is adjusted to 700℃, a certain amount of melt is quickly and smoothly poured into the squeeze casting mold bearing cylinder pr...

Embodiment 2

[0031] A preparation method of the G2 type aluminum alloy gas meter end cover is:

[0032] a. The mass percentages of aluminum alloy material components are: Si: 8.0%, Mg: 0.5%, Ti: 0.3%, and the rest is Al;

[0033] b. Put the prepared pure aluminum ingot, aluminum-titanium alloy and aluminum-silicon alloy into the melting furnace for heating. After the alloy is completely melted, adjust the temperature of the aluminum liquid to 680°C and add Mg. Continue to heat up to 720°C and add 0.6% hexachloroethane to refine for 9 minutes, and let it stand for 18 minutes to skimmer and wait for pouring;

[0034] c. The prefabricated gas meter end cover indirect squeeze casting mold needs to be cleaned of its internal cavity before use, and preheated to 200°C, and then spray graphite evenly inside the cavity;

[0035] d. When the temperature of the aluminum alloy melt is adjusted to 720°C, a certain amount of melt is quickly and smoothly poured into the squeeze casting mold bearing cylinder ...

Embodiment 3

[0041] A preparation method of the G4 type aluminum alloy gas meter end cover is as follows:

[0042] a. The mass percentages of aluminum alloy material components are: Si: 10.0%, Mg: 0.8%, Ti: 0.5%, and the rest is Al;

[0043]b. Put the prepared pure aluminum ingot, aluminum-titanium alloy and aluminum-silicon alloy into the melting furnace for heating. After the alloy is completely melted, the temperature of the aluminum liquid is adjusted to 700°C, and Mg is added. Continue to heat up to 730°C and add 0.8% hexachloroethane for refining for 10 minutes, and let it stand for 20 minutes to skimmer and wait for pouring;

[0044] c. Before using the prefabricated gas meter end cover indirect squeeze casting mold, the internal cavity should be cleaned, and preheated to 300℃, and then spray graphite evenly inside the cavity;

[0045] d. When the temperature of the aluminum alloy melt is adjusted to 740℃, a certain amount of melt is quickly and smoothly poured into the squeeze casting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com