Biomass fodder compressing device

A compression device and biomass technology, applied in the direction of feed, material forming presses, presses, etc., can solve the problems that the uniformity of feeding is greatly affected, affects production efficiency, and is prone to traffic jams, etc., to solve the problem of uneven compression density Low compression quality, easy maintenance, and energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

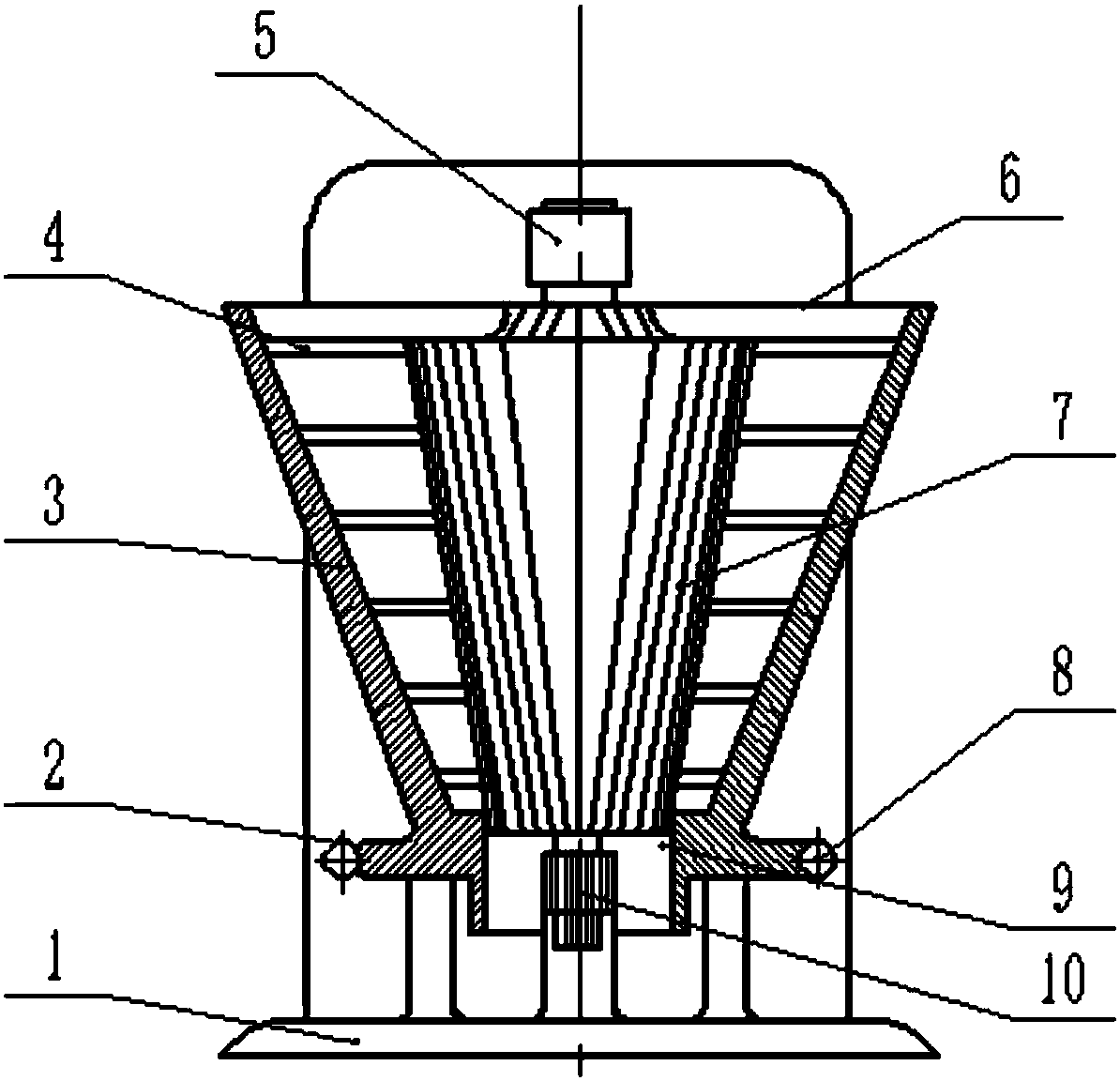

[0015] like figure 1 As shown, the biomass feed compression device is characterized in that its structure includes a device body 1, a worm 2, a chuck 3, a spiral convex groove 4, a motor 5, a feed port 6, a conical pressure roller 7, and a worm wheel 8 , the discharge port 9 and the fixed end 10, the upper side of the device body 1 is provided with a worm 2, the upper side of the worm 2 is provided with a chuck 3, the inner side of the chuck 3 is provided with a spiral convex groove 4, and the spiral convex groove 4 The upper side is provided with a feed port 6, the upper side of the feed port 6 is provided with a motor 5, the lower side of the motor 5 is provided with a conical nip roller 7, and the lower side of the conical nip roller 7 is provided with a discharge port 9, A worm wheel 8 is arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com