Liquid composite cement grinding aid and preparation method thereof

A technology for compounding cement and grinding aid, which is applied in the field of cement admixtures, can solve the problems of rapid growth in the early strength of cement of various mineral components of cement, poor performance in terms of cement performance and quality, and slow growth in later strength. and over-grinding phenomenon, various performance and quality improvement, and the effect of increasing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

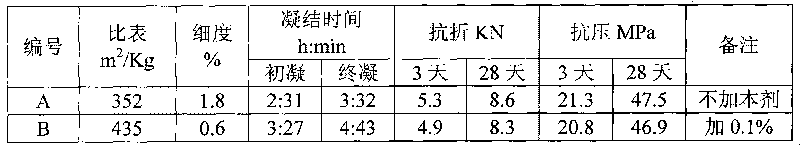

Examples

Embodiment 1

[0019] Example 1: 1 kg per serving

[0020] A kind of liquid composite cement grinding aid, is made up of the raw material of following parts by weight: 200 kilograms of coconut acid diethanolamide, 300 kilograms of water, 100 kilograms of acetic acid, 50 kilograms of melamine, 10 kilograms of sodium nitrite, 20 kilograms of sodium acetate, 20 kilograms of sodium thiosulfate, 20 kilograms of molasses, 20 kilograms of sodium hexametaphosphate, 10 kilograms of calcium lignosulfonate, 4 kilograms of soaps, and preparation method comprises the following steps: (1) earlier sodium nitrite, sodium acetate, thiosulfuric acid Sodium, sodium hexametaphosphate, and calcium lignosulfonate were mixed into water in proportion to prepare solution A; (2) Then, coconut acid diethanolamide, acetic acid, melamine, and molasses were added in proportion to the reaction tank and stirred, and the temperature was controlled at 40°C , stirred at constant temperature for 25 minutes, and at the same tim...

Embodiment 2

[0021] Example 2: 1 kg per serving

[0022] A kind of liquid composite cement grinding aid, is made up of the raw material of following parts by weight: 600 kilograms of cocoate diethanolamide, 600 kilograms of water, 300 kilograms of acetic acid, 150 kilograms of melamine, 15 kilograms of sodium nitrite, 30 kilograms of sodium acetate, 50 kilograms of sodium thiosulfate, 60 kilograms of molasses, 30 kilograms of sodium hexametaphosphate, 30 kilograms of calcium lignosulfonate, 5 kilograms of soaps, and preparation method comprises the following steps: (1) earlier sodium nitrite, sodium acetate, thiosulfuric acid Sodium, sodium hexametaphosphate, and calcium lignosulfonate were mixed into water in proportion to prepare solution A; (2) Then, coconut acid diethanolamide, acetic acid, melamine, and molasses were added in proportion to the reaction tank and stirred, and the temperature was controlled at 60°C , stirred at constant temperature for 40 minutes, and at the same time, c...

Embodiment 3

[0023] Example 3: 1 kg per serving

[0024] A kind of liquid composite cement grinding aid, is made up of the raw material of following weight in kilograms: 200 kilograms of coconut acid diethanolamide, 600 kilograms of water, 100 kilograms of acetic acid, 50 kilograms of melamine, 15 kilograms of sodium nitrite, 20 kilograms of sodium acetate, 45 kilograms of sodium thiosulfate, 30 kilograms of molasses, 30 kilograms of sodium hexametaphosphate, 10 kilograms of calcium lignosulfonate, 4 kilograms of soaps, and preparation method comprises the following steps: (1) earlier make sodium nitrite, sodium acetate, thiosulfuric acid Sodium, sodium hexametaphosphate, and calcium lignosulfonate were mixed into water in proportion to prepare solution A; (2) Then, coconut acid diethanolamide, acetic acid, melamine, and molasses were added in proportion to the reaction tank and stirred, and the temperature was controlled at 40°C , stirred at constant temperature for 30 minutes, and at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com