Patents

Literature

225 results about "COCONUT ACID" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

About COCONUT ACID: Coconut Acid is a mixture of fatty acids derived from Cocos Nucifera (Coconut) Oil (q.v.). Function(s): Surfactant - Cleansing AgentSurfactant-Cleansing Agent is included as a function for the soap form of Coconut Acid.;

Water-soluble washing agent composition

ActiveCN101434890AMildImprove wettabilityInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsAlcoholPhosphate

A water-soluble cleaning agent composition comprises an alkaline compound, polyoxyethylene laurylether phosphate salt, lauric acid diethanolamide, lower alcohol and water; taking the total weight of the composition as benchmark, the content of the alkaline compound is 0.01-5 percent by weight, the content of the polyoxyethylene laurylether phosphate salt is 0.01-5 percent by weight, the content of the lauric acid diethanolamide is 0.01-5 percent by weight, the content of the lower alcohol is 0.1-40 percent by weight, and the rest is the water. The cleaning agent composition is easy to be dissolved in a water-organic matter system, can be dissolved in water by any proportion and has strong oil-removing and cleaning ability at normal temperature without causing residual surfactant on the surface of the cleaned object.

Owner:BYD CO LTD

Water-soluble metal polishing agent

The invention relates to a water-soluble metal polishing agent which is characterized by comprising the following ingredients in percentage by weight: 5-10% of coconut acid ethanediol amide, 4-8% of alkylphenol polyoxyethylene, 3-6% of ethylenediamine tetraacetic acid disodium salt, 1-3% of sodium butter fatty acid ester, 0.5-1.5% of a surfactant, 0.2-0.6% of a corrosion inhibitor, 0.1-0.3% of an antirust agent and the balance of water. The water-soluble metal polishing agent has the characteristics of wide application range, stable polishing effect, convenience in use, high efficiency and the like.

Owner:佛山市中成不锈钢管业有限公司

Composite ceramic filter core and preparation method thereof

ActiveCN103382127AImprove mechanical propertiesEfficient Adsorption RemovalCeramicwareClaywaresAir filtrationSodium metasilicate

The invention provides a composite ceramic filter core and a preparation method thereof. The composite ceramic filter core is prepared from 12 to 14 parts of diatomite, 36 to 38 parts of active carbon, 2 to 3 parts of a carbon nanotube, 1 to 2 parts of silver nitrate, 4 to 5 parts of coconut oil monoethanolamide, 7 to 9 parts of sodium metasilicate, 8 to 10 parts of propylene glycol, 3 to 5 parts of starch, 3 to 4 parts of ammonium bicarbonate, 20 to 25 parts of modified bentonite and a proper amount of water. The carbon nanotube used in the invention can improve mechanical properties of the ceramic filter core; meanwhile, the multiwalled carbon nanotube has a mesoporous structure and can effectively absorb and remove heavy metal ions in water. The composite ceramic filter core provided by the invention can be used for air filtration of an air-conditioning system, water filtration and inhalation filtration of an automobile filter and is applicable to a variety of places with a severe environment.

Owner:ANHUI PHOENIX INT CO LTD

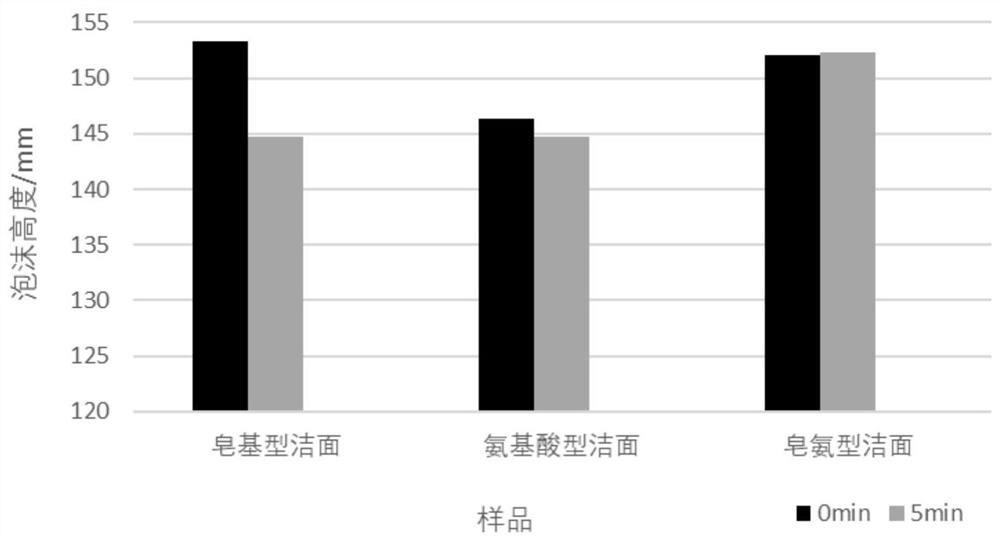

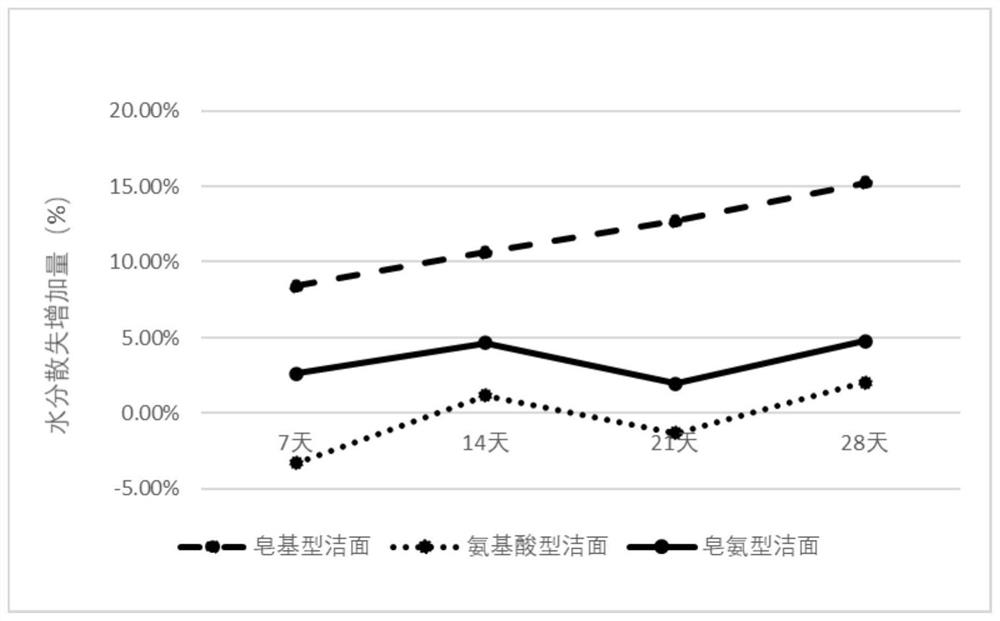

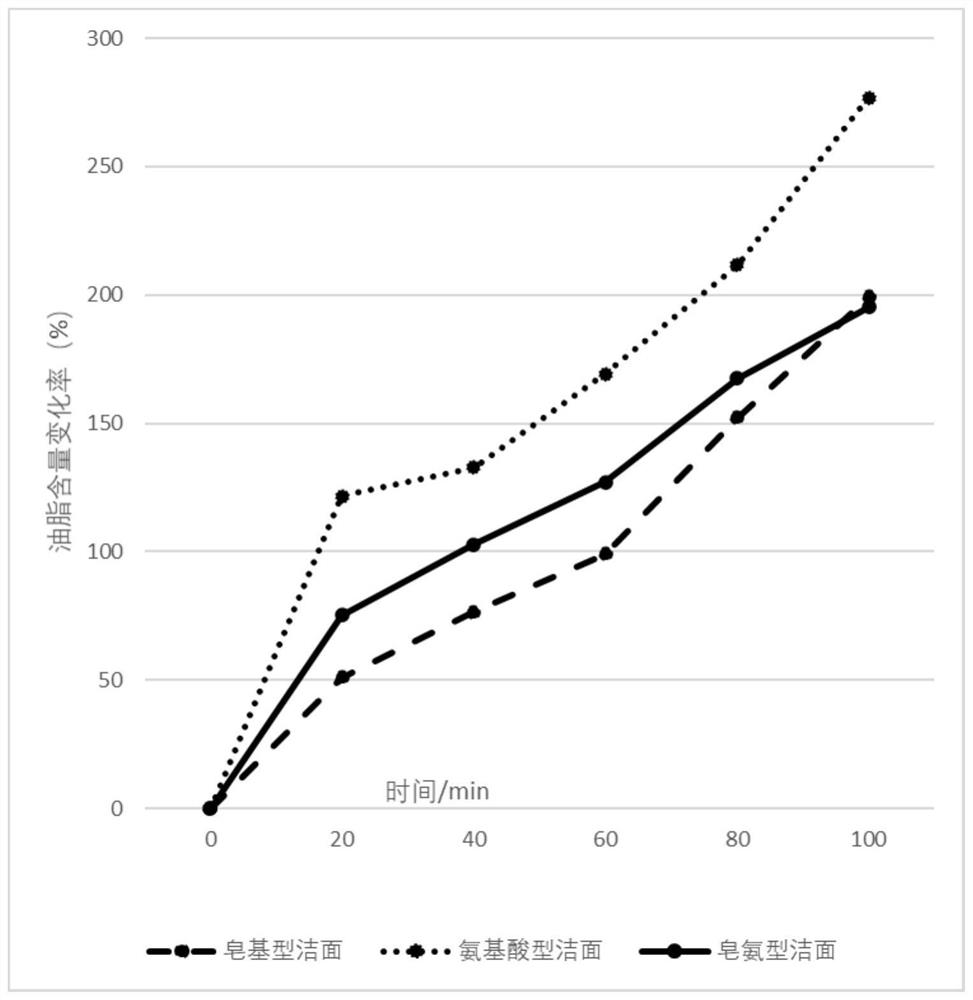

Soap ammonia type facial cleansing product and preparation method thereof

ActiveCN111631974AFine foamLess irritatingCosmetic preparationsToilet preparationsSodium acetatePOTASSIUM STEARATE

The invention relates to a soap ammonia type facial cleansing product and a preparation method thereof. The product comprises an amino acid surfactant, a soap-based surfactant, an auxiliary surfactant, an auxiliary agent and a solvent, wherein the amino acid surfactant is at least one selected from potassium cocoyl glycinate, sodium cocoyl glycinate, sodium lauroyl sarcosine, TEA-cocoyl alaninate,sodium cocoyl glutamate, TEA-lauroyl glutamate, sodium lauroyl glutamate and sodium palmitoleyl glutamate; the soap-based surfactant is at least one selected from potassium cocoate, potassium laurate, potassium myristate, potassium palmitate and potassium stearate; and the auxiliary surfactant is at least one selected from sodium lauroamphoacetate, lauryl hydroxyl sulphobetaine, cocamidopropyl betaine, lauryl glucoside, decyl glucoside, cocamidopropyl betaine, cocamide, dodecyl dimethyl betaine and palm kernelamide. The cleaning agent has the characteristics of low irritation, high cleaning efficiency, rich foam and good use feeling.

Owner:HUNAN YUJIA COSMETICS MFG CO LTD

Combined shower gel for both hair washing and bathing

InactiveCN103181871AThe formula is scientific and reasonableEasy to cleanCosmetic preparationsHair cosmeticsShower gelGlycerol

The invention discloses a combined shower gel for both haring washing and bathing. The shower gel comprises, by weight, 5 to 10% of cocamidopropyl betaine, 2 to 5% of coconut acid diethanolamide, 5 to 15% of ammonium lauryl sulfate, 5 to 20% of sodium carboxymethyl cellulose, 1 to 10% of distearic acid glycol ester, 2 to 5% of glycerol, 1to 5% of fruit essence, 0.5 to 5% of an aloe extract, 0.5 to 2% of menthol and 2 to 5% of sodium chloride, with the balance being deionized water. The combined shower gel provided by the invention has the advantages of a reasonable and scientific formula, a good cleaning effect, functions of both hair washing and bathing and convenience in usage and carrying.

Owner:黄佩英

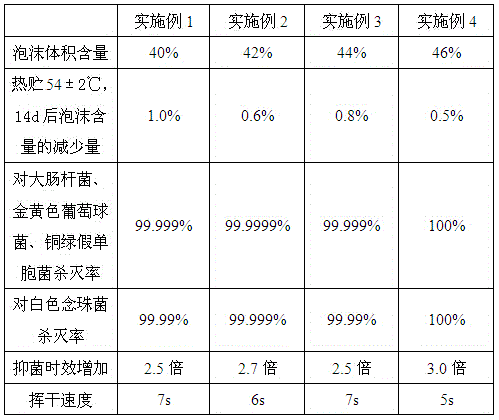

Foam disinfectant for medical use and preparation process of foam disinfectant

InactiveCN105456548ARich foamImprove disinfection effectAntibacterial agentsAntimycoticsBiotechnologyChlorhexidine Acetate

The invention provides a foam disinfectant for medical use. The foam disinfectant consists of chlorhexidine acetate, glycerol, alcohol, grape seed essential oil, an emulsifier op, betaine cocoate, tocopherol, lavender essential oil and de-ionized water. The invention also provides a preparation method of the disinfectant. The foam disinfectant prepared by the invention is rich in foam amount, and the volume content of foam is 40-46%; when the foam disinfectant is heat-stored at 52-56 DEG C, only 0.5-1.0% of foam is reduced after 14d; the foam disinfectant is good in disinfecting effect, and when the foam disinfectant is used for disinfecting skin of hands of a human body, a killing rate on escherichia coli, staphylococcus aureus and pseudomonas aeruginosa within 30s is 99.999-100%, and a killing rate on candida albicans reaches 99.99-100%; the foam disinfectant is long in antibacterial duration, and compared with disinfection with simple using of alcohol, the effective antibacterial duration of the foam disinfectant is increased by 2.5-3 times; and the disinfection is high in volatilizing speed, and the disinfection, after being smeared to the hands, volatilizes within 5-7s without residue on the hands.

Owner:郭健

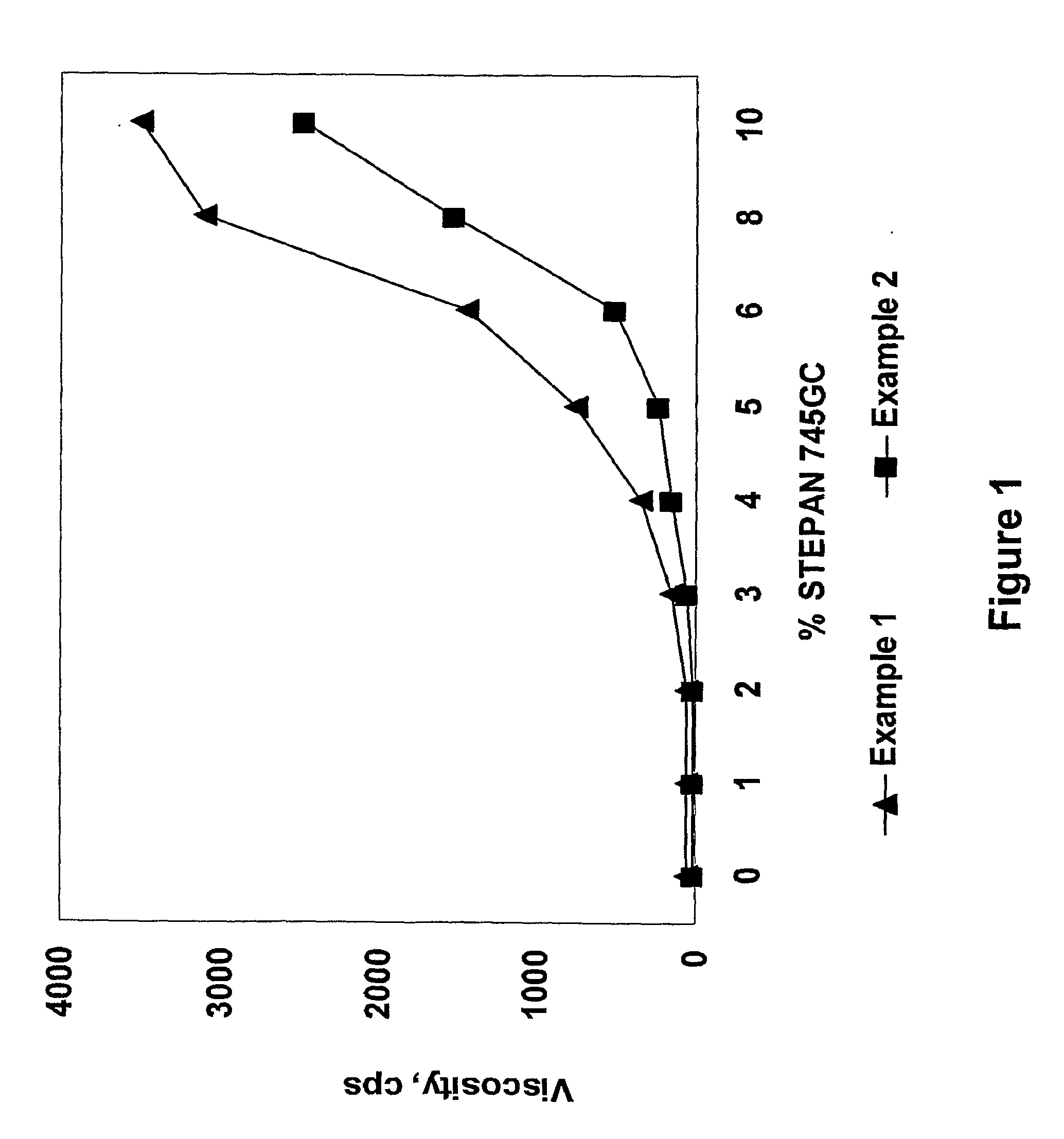

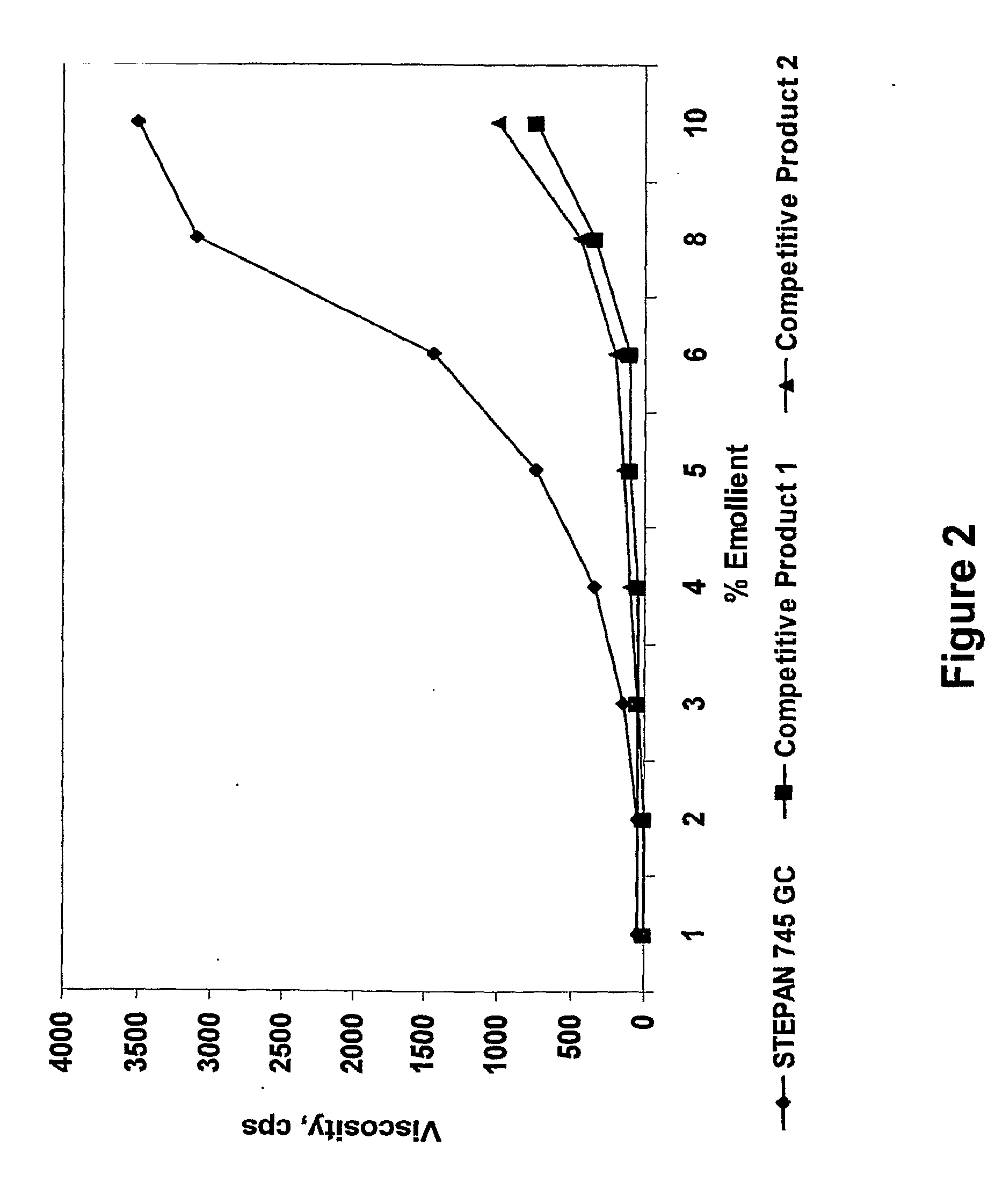

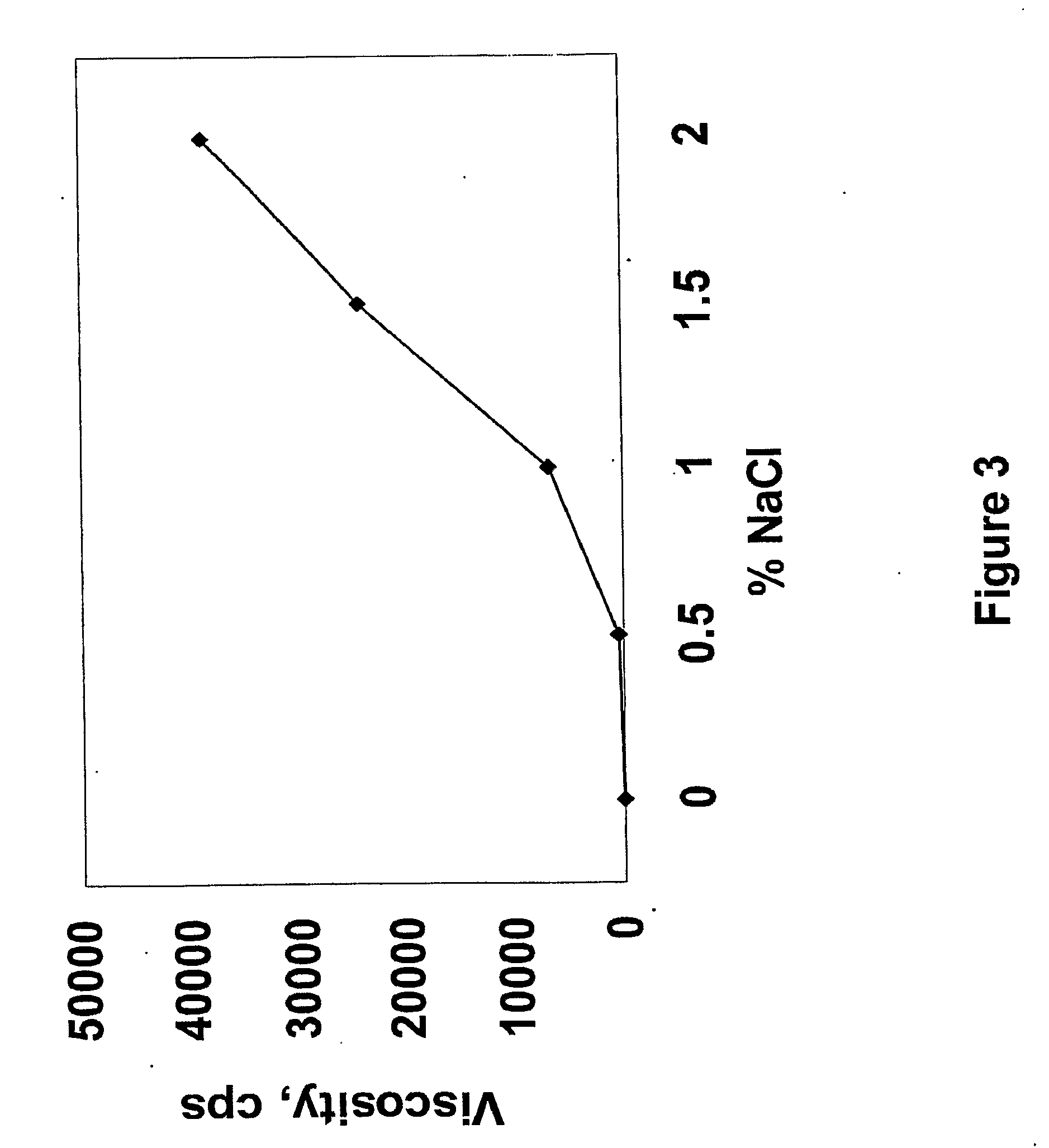

Water compatible emollient for cleansing products

ActiveUS20090181873A1Improved performance characteristicsImprove featuresCosmetic preparationsHair removalCleansers skinGlyceryl Cocoate

A cleansing composition comprising a water-compatible emollient that provides enhanced skin-feel characteristics, as well as viscosity-building properties. The water-compatible emollient is an alkoxylated derivative of glyceryl cocoate containing both propylene oxide and ethylene oxide groups in the molecular structure. The cleansing composition also comprises one or more surfactants, and optional additives, and can be formulated into a body wash, shampoo, facial cleanser, liquid hand soap, dish detergent or car wash detergent.

Owner:STEPAN COMPANY

Synthesizing method of cocoyl amino acid sodium

InactiveCN102863352AReasonable workmanshipHigh reaction yieldOrganic compound preparationCarboxylic acid amides preparationPtru catalystActive agent

The invention relates to a synthesizing method of cocoyl amino acid sodium. The synthesizing method of the cocoyl amino acid sodium comprises the following steps of: taking cocinic acid and phosgene as raw materials, reacting the cocinic acid and the phosgene for 1-20 hours at a temperature of 60-100 DEG C at the presence of an organic amide catalyst, distilling reaction products in an vacuum environment after the reaction to obtain acyl chloride, and dropping the oleoyl chloride obtained through the phosgenation into amino acid sodium solution for reaction, wherein the pH value is controlled to 8-10, the reaction temperature is 15-20 DEG C, and the reaction time is 4-5 hours. The synthesizing method of the cocoyl amino acid sodium provided by the invention has the advantages of reasonable process, high reaction yield, high product quality, substantially no three wastes, no residual phosphorus and sulfur in the product, capability of being widely applied to the production of high-end surfactant, higher practical value as well as higher social and economical benefits.

Owner:CHANGSHA PUJI BIOTECH

A kind of disinfectant and preparation method thereof

InactiveCN102293199AEfficient killingPrevention and Control of TransmissionSoap detergents with organic compounding agentsBiocideDisinfectantPotassium hydroxide

The invention relates to a disinfectant and a preparation method thereof. The formula of the disinfectant is: p-chloro-m-xylenol, coconut oleic acid, potassium hydroxide, isopropanol, pine oil and deionized water, and its weight percentage is, 5.0 -7.0: 6.5-9.5: 3.7-5.4: 15.0-25.0: 3.0-6.0: margin. The preparation includes: (1) adding deionized water and potassium hydroxide, stirring, heating up to 90°C-100°C, and then adding coconut oleic acid to make potassium coconut oleate soap; (2) mixing p-chloro-m-xylenol with Mix isopropanol, heat up to dissolve, then add deionized water and the above-mentioned potassium coconut oleate soap, stir; cool to 30°C-35°C, add pine oil, stir, add deionized water and continue stirring, and the product is ready. The disinfectant solution of the invention can effectively kill 99.999% of intestinal pathogenic bacteria, pyogenic cocci and pathogenic yeasts; the preparation method is simple, the cost is low, and it is suitable for industrial production.

Owner:SHANGHAI SOAP GRP RUGAO

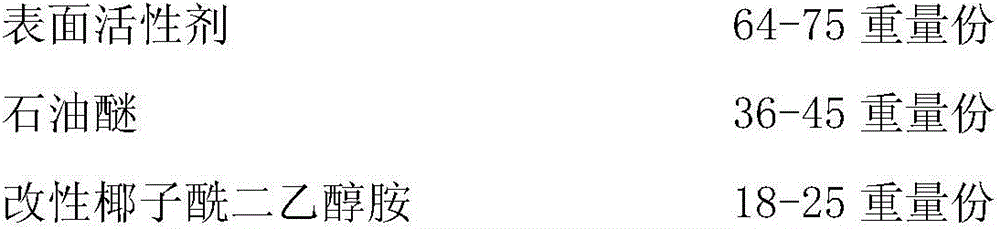

Cleanser for effectively removing asphalt on paver

InactiveCN106118894AEfficient removalEasy to cleanInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsRoad engineeringCleansing Agents

The invention provides a cleaning agent for effectively removing asphalt from pavers, which is composed of surfactant, petroleum ether, modified cocoyl diethanolamine, diethylene glycol ethyl ether, isopropanol, trichloroethylene, potassium pyrophosphate and water. The beneficial effects of the invention are: compared with the traditional cleaning agent, the asphalt cleaning agent has good cleaning effect, high utilization rate, simple preparation process, lower price and less environmental pollution, and can be widely used in construction machinery in the road engineering industry. Surface cleaning of asphalt dirt.

Owner:TIANJIN KANGYUAN ENG MACHINERY

Wild camellia oil shampoo

InactiveCN102488634AMoisturizingHas the function of black hair and beautyCosmetic preparationsHair cosmeticsToxicologyMethyl polysiloxane

The invention relates to a wild camellia oil shampoo, which comprises 1-3 percent by weight of refined wild camellia oil, 40-50 percent by weight of deionized water and the balance of aid, wherein the balance of aid comprises 18-25 percent by weight of sodium lauryl sulfoacetate, 3-6 percent by weight of sodium cocoamphoacetate, 3-5 percent by weight of glucoside lauryl sulfate, 1-2 percent by weight of coconut acid diethanolamide, 3-6 percent by weight of cocamidopropyl betaine, 1-3 percent by weight of polyquaternium, 0.1-0.2 percent by weight of guar hydroxypropyltrimonium chloride, 2-4 percent by weight of dimethyl polysiloxane, 1-2 percent by weight of ethylene glycol monostearate, 0.2-0.3 percent by weight of DMDM (Dimethylol Dimethyl) hydantoin, 0.05-0.07 percent by weight of Katho-CG and 0.1-1 percent by weight of essence. The wild camellia seed oil shampoo has an insecticidal effect, and can be used for resisting bacteria and viruses, killing fungi, preventing phalacrosis, removing scurf and stopping head itching; and the wild camellia seed oil shampoo has the effects of moisturizing, moistening, blackening hair and beautifying, and can be used for preventing the hairs from being fractured when applied to hair protection.

Owner:广东富然农科有限公司

Plant environment-friendly type cleaning agent and processing method thereof

InactiveCN101550379AWith adsorptionWith emulsificationInorganic/elemental detergent compounding agentsSurface-active detergent compositionsSoftened waterCleansing Agents

The invention discloses a plant environment-friendly type cleaning agent, which is prepared by the following raw materials in weight percentages of: fatty alcohol polyoxyethylene ether (degree of polymerization n is 6-18) 20%-30%, coconut acid diethanolamide essential oil 20%-30%, sodium carbonate 3%-8%, propylene glycol 8%-13%, and the balance amount of softened water. The invention further discloses the processing method of the plant environment-friendly type cleaning agent. The cleaning agent of the present invention is safe to human, animal and working environment; achieves the advantages of nontoxic, no side-effect, no excitant, excellent cleaning performance and wide adaptation range; has potential economic benefits.

Owner:ZHEJIANG LORPAR ENVIRONMENT TECH

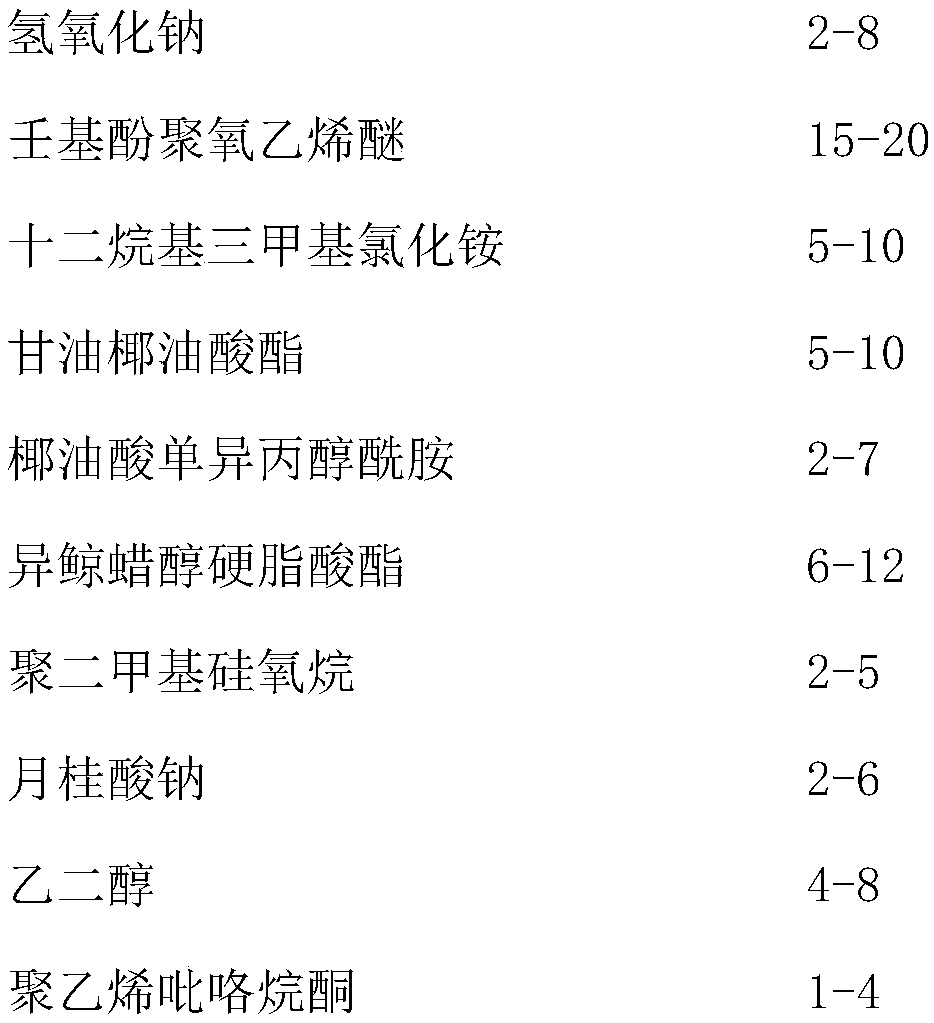

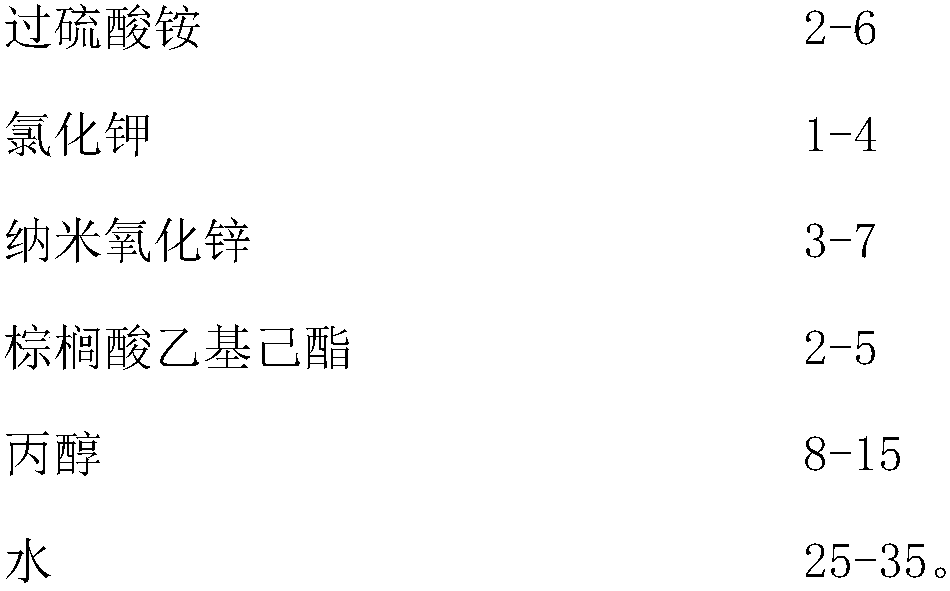

Novel desizing agent and preparation method thereof

ActiveCN108505318AWith desizing effectImprove desizing effectDry-cleaning apparatus for textilesGrip property fibresEthylhexyl palmitatePotassium

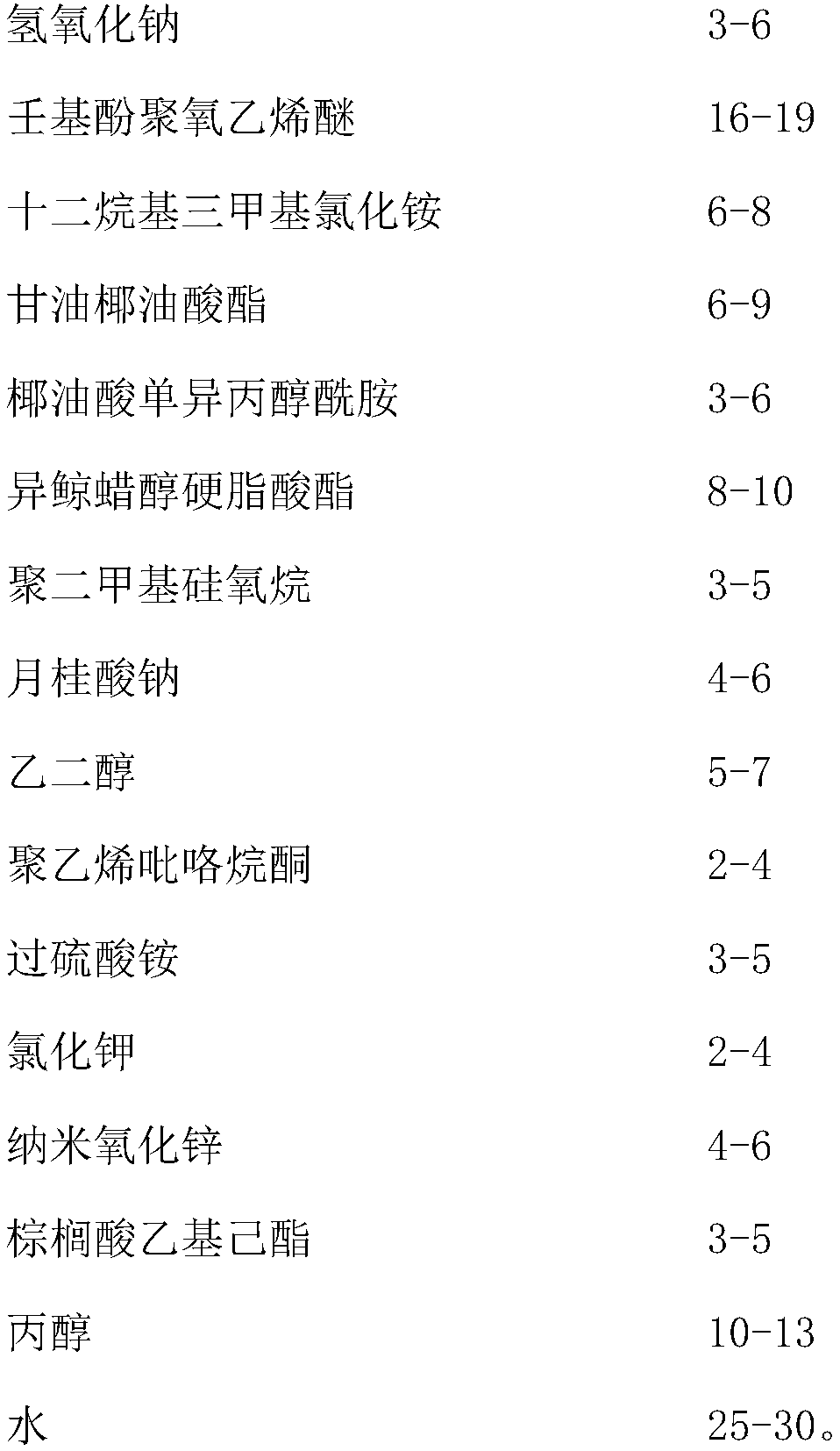

The invention aims at overcoming the defects in the prior art, and provides a desizing agent with the advantages that the desizing effect is good; the damage on fabrics is small; the treated fabrics have a good wool effect, hand feeling and whiteness; in addition, the seepage performance and the dispersion performance are good; the refining effect is achieved. The invention provides the desizing agent, which is prepared from the following ingredients in parts by weight: 2 to 8 parts of sodium hydroxide, 15 to 20 parts of nonylphenol polyoxyethylene ether, 5 to 10 parts of dodecyl trimethyl ammonium chloride, 5 to 10 parts of glyceryl cocoate, 2 to 7 parts of coconut acid monoisopropanolamide, 6 to 12 parts of isocetyl stearate, 1 to 3 parts of polydimethylsiloxane, 2 to 6 parts of sodium laurate, 4 to 8 parts of glycol, 1 to 4 parts of polyvinylpyrrolidone, 2 to 6 parts of ammonium persulfate, 1 to 4 parts of potassium chloride, 1 to 4 parts of nano-zinc oxide, 2 to 5 parts of ethylhexyl palmitate, 8 to 15 parts of propyl alcohol and 25 to 35 parts of water. The desizing rate of the fabrics treated by the desizing agent provided by the invention is 96.1 percent or higher; in addition, the fabrics cannot be damaged.

Owner:多恩生物科技有限公司

Fast dissolving roll paper and production method thereof

InactiveCN104313935AFast dissolutionLow costNon-macromolecular organic additionPaper/cardboardBetainePolyvinyl alcohol

The invention relates to the technical field of paper for daily use, in particular to fast dissolving roll paper and a production method thereof. The fast dissolving roll paper comprises, by weight, 80-120 parts of pulp, 8-12 parts of polyvinyl alcohol, 5-10 parts of dispersing agent, 5-10 parts of sodium dodecyl sulfate, 4-8 parts of glucoside, 4-8 parts of corn starch, 4-8 parts of nonylphenol polyoxyethylene ether, 1-5 parts of fatty alcohol-polyoxyethylene ether, 1-5 parts of dodecyl dimethyl betaine, 1-3 parts of ethylene diamine tetraacetic acid, 1-3 parts of coco fatty acid diethanol amide and 1-3 parts of propylene glycol. The production method includes pulping, degritting, pulp screening, pulp spraying, dewatering, drying, stripping, rolling and packaging to obtain the fast dissolving roll paper. The fast dissolving roll paper has good fast dissolving property, used waste paper can be dissolved in water quickly, and environmental protection and low cost are realized. The production method is simple in technology, convenient to operate and control, stable in quality, high in production efficiency, energy saving and environmentally friendly.

Owner:GUANGDONG BILUN HOUSEHOLD PAPER IND

Rust-proof pigment

InactiveCN104789049ALarge specific surface areaImprove corrosion resistanceAnti-corrosive paintsPigment pastesFatty acidPetroleum

The invention discloses a rust-proof pigment. The rust-proof pigment comprises the following raw materials in parts by weight: 30-50 parts of scale-shaped zinc powder, 2-10 parts of modified aluminum tripolyphosphate, 15-20 parts of titanium dioxide powder, 30-35 parts of zinc phosphate, 1-2 parts of calcium phosphate, 8-10 parts of calcium carbonate, 2-7 parts of a pigment dispersing agent, 2-5 parts of a silicane coupling agent, 3-7 parts of ammonium molybdate, 1-2 parts of coconut fatty acid diethanol amide, 10-15 parts of a dinonylnaphthalene sulfonic acid, 5-10 parts of ethyl orthosilicate, 0.5-0.9 part of a polyaspartic acid and 0.5-0.7 part of petroleum sodium sulfonate, and further comprises 1.5-3.2 parts of sepiolite powder. The rust-proof pigment disclosed by the invention is low in production cost; environmental pollution is avoided, that is, an environmental protection function is achieved; the rust-proof pigment is high in storage stability and cost performance, and has a certain of rust-proof and comprehensive performance.

Owner:SHUANGLE CHEM PIGMENT YANGZHOU CITY

High-strength silica-based graphene conductive material and preparation method thereof

The invention discloses a high-strength silica-based graphene conductive material. The high-strength silica-based graphene conductive material is prepared from the following raw materials in parts by weight: 0.3 to 1 part of coconut acid diethanolamide, 3 to 4 parts of wollastonite powder, 5 to 6 parts of ethylhexyl epoxy tetrahydrophthalate, 1 to 2 parts of chlorination-1-allyl-3-methylimidazole, 1.7 to 2 parts of phosphoric acid, 2 to 3 parts of lithium hydroxide, 0.8 to 1 part of ferrous sulfate, 0.1 to 0.2 part of glucose, 6 to 7 parts of acetylene carbon black, 81 to 90 parts of unsaturated polyester resin, 600 to 700 parts of N,N-dimethylformamide, 27 to 30 parts of graphene oxide, 26 to 30 parts of hydrazine hydrate, 7 to 10 parts of tetraethyl orthosilicate, 0.8 to 1 part of zinc acetylacetonate, 0.1 to 0.2 part of 1,2-dimethylimidazole, 1 to 2 parts of aluminum magnesium silicate, 1 to 2 parts of ammonium octamolybdate and 1 to 2 parts of polyacrylamide. Chlorination modified grapheme has good conductivity, is blended with the acetylene carbon black, and can be well dispersed in the unsaturated polyester resin to form a composite material with high conductivity.

Owner:SUZHOU ZIJIN PLASTIC

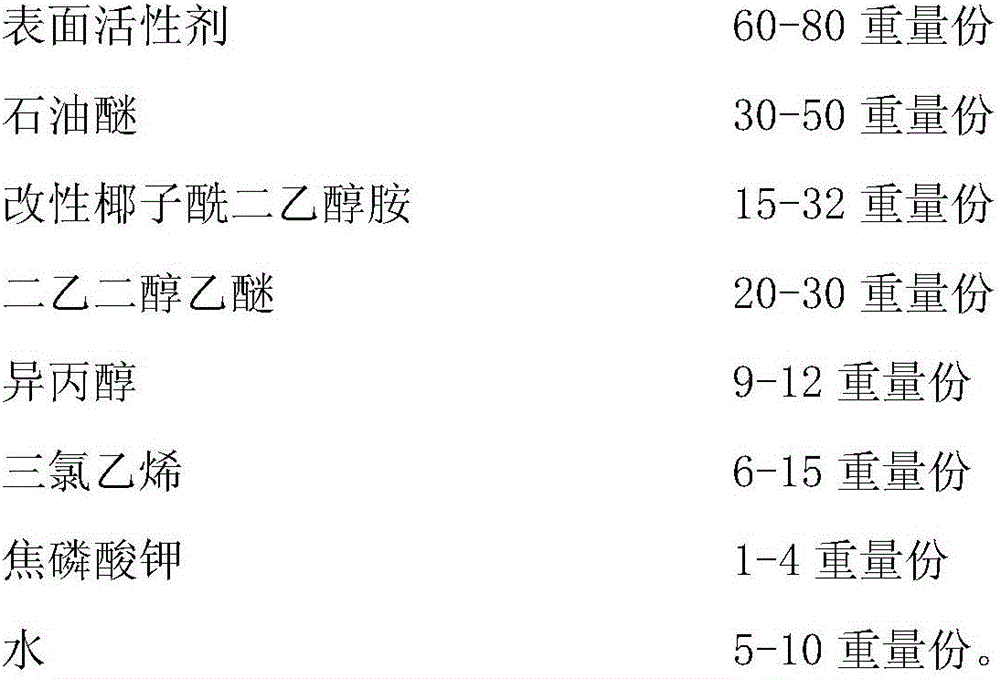

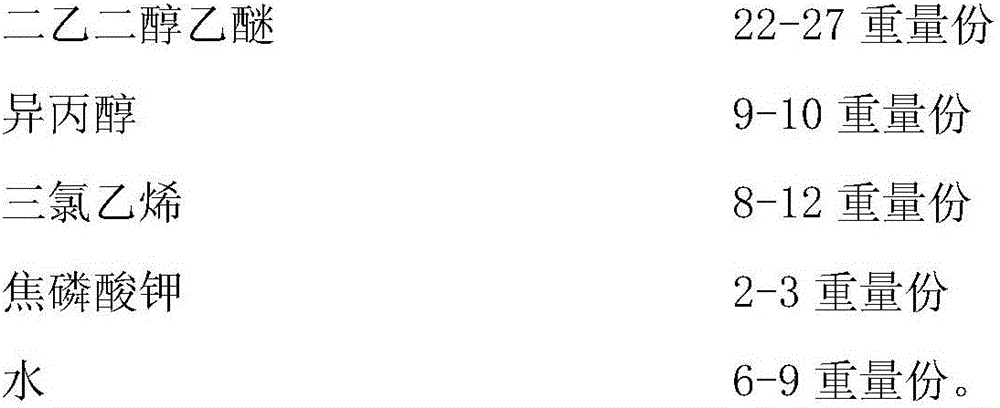

Method for preparing asphalt cleaners capable of effectively removing residual asphalt

InactiveCN106047537AEfficient removalEasy to cleanInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsDiethylene glycol diethyl etherCOCONUT ACID

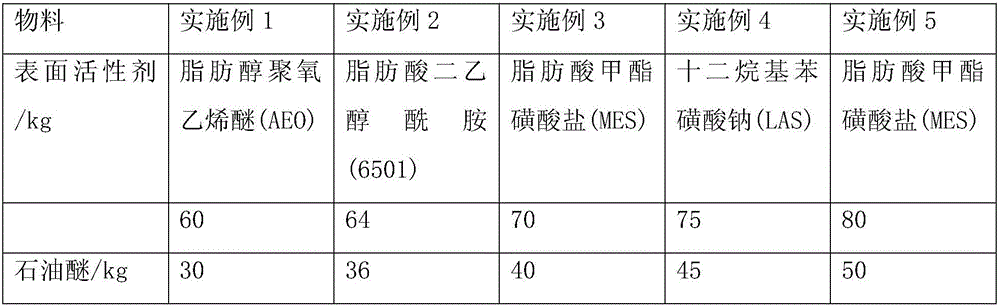

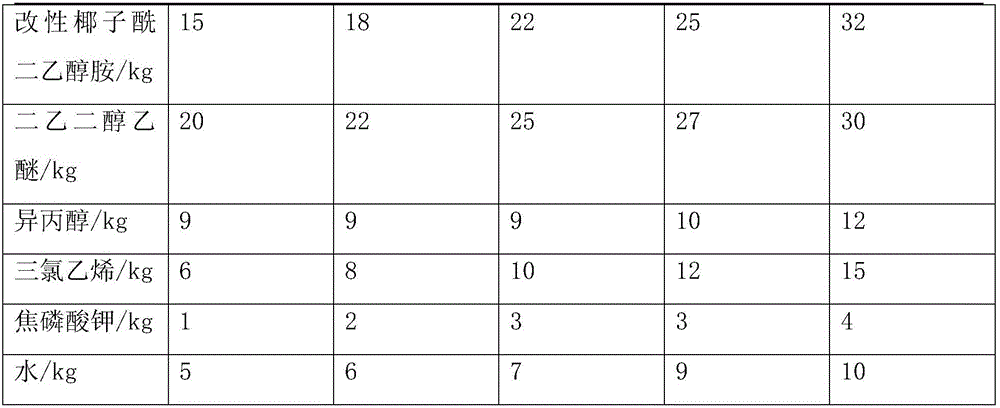

The invention provides a method for preparing asphalt cleaners capable of effectively removing residual asphalt. The method includes adding, by weight, 5-10 parts of water into a container at first, then sequentially adding, by weight, 60-80 parts of surfactants and 30-50 parts of petroleum ether into the container and stirring the water, the surfactants and the petroleum ether for 3-5 min to obtain preliminary mixed liquid; sequentially adding, by weight, 15-32 parts of modified coconut acid diethanolamide and 9-12 parts of isopropyl alcohol into the preliminary mixed liquid and mechanically stirring the modified coconut acid diethanolamide, the isopropyl alcohol and the preliminary mixed liquid for 10-20 min to obtain mixed liquid; adding, by weight, 20-30 parts of diethylene glycol diethyl ether into the mixed liquid, uniformly mixing the diethylene glycol diethyl ether and the mixed liquid with each other, then sequentially adding, by weight, 6-15 parts of trichlorethene and 1-4 parts of potassium pyrophosphate into the mixed liquid and manually stirring the diethylene glycol diethyl ether, the mixed liquid, the trichlorethene and the potassium pyrophosphate to obtain the asphalt cleaners. The method has the advantages that good cleaning effects can be realized by the asphalt cleaners, the asphalt cleaners are high in utilization rate, low in cost and little in environmental pollution, and processes for preparing the asphalt cleaners are simple.

Owner:TIANJIN KANGYUAN ENG MACHINERY

High-low temperature and static resistant PE corrugated pipe filling master batch as well as preparation method thereof

InactiveCN105131399AIncreased ring stiffnessHigh strengthLow-density polyethyleneCoconut diethanolamide

The invention discloses a high-low temperature and static resistant PE corrugated pipe filling master batch which is prepared from the following raw material components in parts by weight: 50-60 parts of low density polyethylene, 30-40 parts of carbon black, 4-6 parts of silicon-calcium-magnesium (SCM) whiskers, 1-2 parts of coconut diethanolamide, 1-2 parts of lauric diethanolamide,1-2 parts of sodium gluconate, 0.1-0.5 part of a coldproof plasticizer, 1-2 parts of barium stearate, 5-8 parts of talcum powder, 0.2-0.4 part of an anti-oxidant 215 and 10-15 parts of an enhancer. The master batch can be subjected to extruding pelletization by a conventional double-screw extruder, and added for processing of a corrugated pipe, so that the processed corrugated pipe has the advantages of being resistant to high-low temperature, high in ring stiffness, light in weight, high in oxidation resistance, low in material consumption, convenient for construction and mounting, and high in static-resistant performance.

Owner:安徽玉发塑业有限公司

Kitchen oil stain cleaning agent and preparation method thereof

InactiveCN103952249AEasy to cleanGood degreasing powerSurface-active non-soap compounds and soap mixture detergentsVegetable oilHazardous substance

The invention relates to the technical field of daily chemical living cleaning, and discloses a kitchen oil stain cleaning agent and a preparation method thereof. The kitchen oil stain cleaning agent is characterized in that the kitchen oil stain cleaning agent comprises the following raw materials by weight: 10-25% of a surfactant, 5-15% of propanediol butyl ether, 3-7% of a coconut acid diethanolamine condensation compound, 3-7% of sodium carbonate, 3-10% of potassium laurate, 1-10% of sodium silicate, 0.1-1% of essence, 0.1-1% of a chelating gent, 0.1-1% of a dispersant, and the balance of deionized water. The kitchen oil stain cleaning agent has the following advantages that: the oil stain cleaning is rapid, the heavy oil scale dissolving is complete, no insoluble substance is remained on the surface of the cleaned object during the cleaning process, and no new stain is produced; the banana peel extract and the coconut acid diethanolamine condensation compound are added so as to effectively clean the oil stain, and the coconut acid diethanolamine condensation compound provides good oil removing capability for animal and vegetable oils and mineral oils, and has effects of significant scale suspending effect, skin protection, thickening and foam stabilizing; and the kitchen oil stain cleaning agent has the low cost, and does not produce toxic or harmful substances.

Owner:侯鸣

Rust-resistant concrete mold release agent and preparation method thereof

InactiveCN104479843AExcellent anti-rustImprove high temperature resistanceLubricant compositionMaterials scienceTert-butyl acrylate

The invention discloses a rust-resistant concrete mold release agent and a preparation method thereof. The rust-resistant concrete mold release agent comprises the following components as raw materials in parts by weight: 50-55 parts of modified glycerin, 25-30 parts of coconut acid monoethanolamide, 0.3-0.5 part of zinc dialkyl dithiophosphate, 8-10 parts of rosin resin, 0.4-0.6 part of t-butyl acrylate, 2-3 parts of sodium tripolyphosphate, 1.5-1.8 parts of lauryl diethanolamide, 6-8 parts of purified benzene emulsion, 0.3-0.5 part of sodium tripolyphosphate, 0.1-0.2 part of sodium benzoate and 300-330 parts of deionized water. By adopting modified glycerin as main base oil, the difficulty of emulsification is decreased; the rust-resistant agent and multiple additives are added, so that the rust-resistant concrete mold release agent has good rust resistance, high temperature resistance and the like on the surface of a concrete member and the concrete member has smooth surface, the secondary treatment is not needed and the construction cost is decreased.

Owner:蒙城县科技创业服务中心

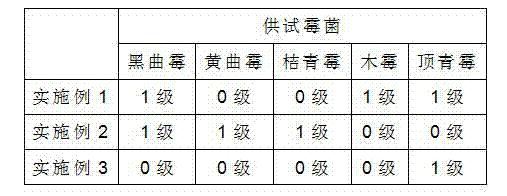

Leather mildew-proof fat-liquoring agent and preparation method thereof

The invention relates to a leather mildew-proof fat-liquoring agent and a preparation method thereof, and belongs to the technical field of fine chemical industry. The mildew-proof fat-liquoring agent comprises the following components in parts by weight: 10-20 parts of jojoba oil, 30-50 parts of palm oil, 3-6 parts of sodium N-lauroyl-L-valinate, 2-5 parts of coco fatty acid diethanol amide, 1-3 parts of 10,10'-oxybisphenoxarsine, 2-4 parts of a thickening agent, and 50-70 parts of water. The product has good acid resistance, good alkali resistance and good salt resistance, strong permeability and good mildew proof; after fat liquoring by using the product, finished leather has good elasticity and small contractility, and is not easy to mildew; and at the same time, the product is simple in preparation method, and easy to popularize and apply.

Owner:ZIBO LURUI FINE CHEM CO LTD

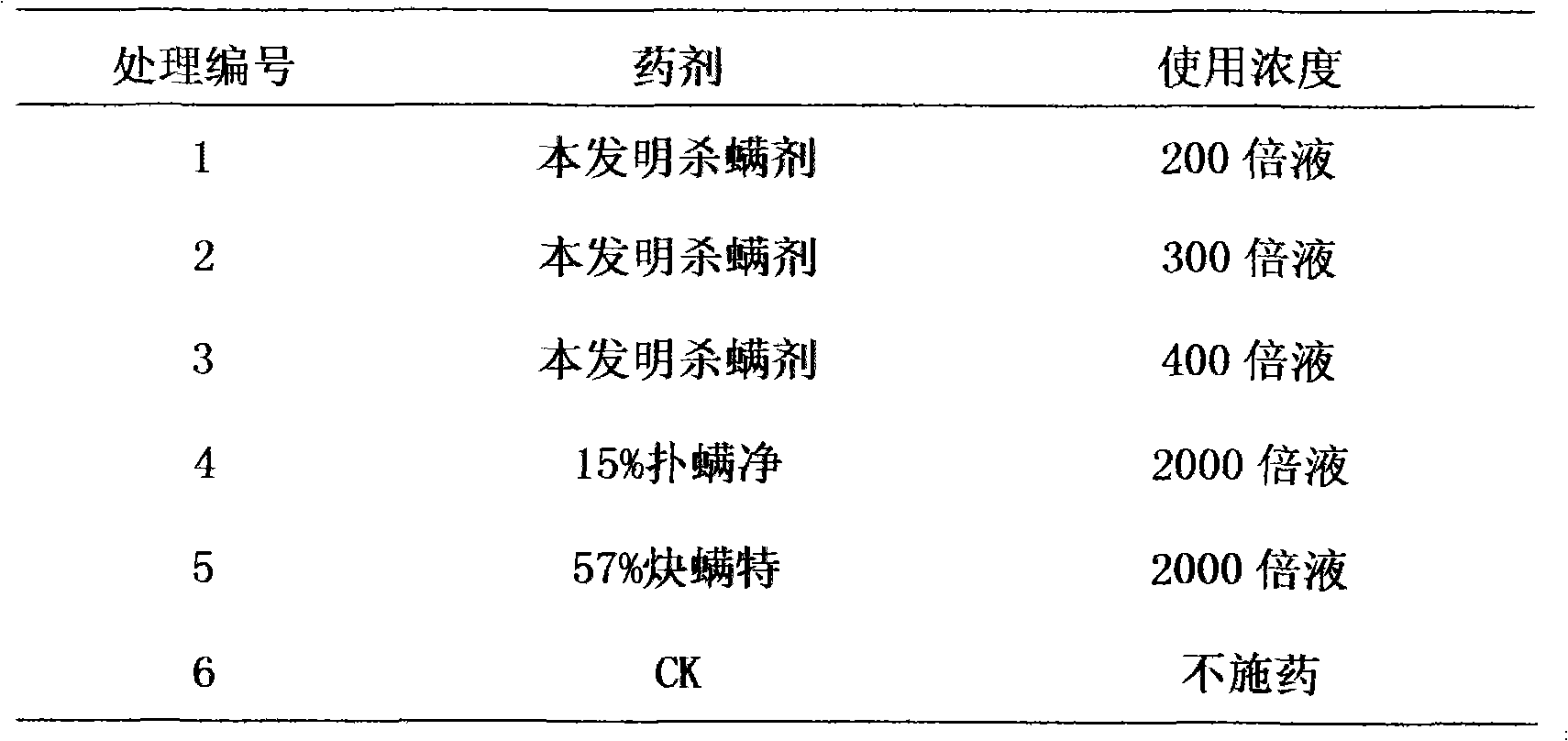

Safe environment-friendly acaricide

InactiveCN101869105AImprove qualityReduce the frequency of sprayingBiocideFungicidesPesticide residuePollution

The invention provides a safe environment-friendly acaricide. The formula of the acaricide comprises the following components in weight percentage: 1.0-10.0 percent of ethoxylated lauryl alcohol sulfates, 1.0-10.0 percent of coconut acid glycol amide, 1.0-10.0 percent of sodium dodecyl benzene sulfonate, 0.5 percent of NaOH, 1.0 percent of salt, 0.1-0.5 percent of Kathon and 68-95.4 percent of water; the best formula comprises the following components in weight percentage: 5 percent of ethoxylated lauryl alcohol sulfates, 5 percent of coconut acid glycol amide, 4 percent of sodium dodecyl benzene sulfonate, 0.5 percent of NaOH, 1.0 percent of salt, 0.2 percent of Kathon and 84.3 percent of water. The acaricide only takes the action of contace poison on the larvae of insects and mites, hasthe function of controlling fungous and bacterial diseases and has no toxin on other animals of people, fowls, beasts and the like. Grain, fruits and vegetables applying the reagent do not have pesticide residues, and therefore, the acaricide can be applied at any time and the grain, the fruits and the vegetables can be eaten at any time. By using the acaricide to control the harmful mites, the labour strength of fruit farmers can be relieved, the agricultural production cost can be reduced and the pollutions of pesticide to the environment can be reduced to let consumers have ease food. The popularization and the application of the reagent have good social benefits and huge economic benefits.

Owner:HUBEI UNIV

Multifunctional water-based cleaning agent

InactiveCN105695119AQuality improvementAnti-corrosionOrganic detergent compounding agentsSurface-active detergent compositionsWater basedPreservative

The invention discloses a multifunctional water-based cleaning agent. The multifunctional water-based cleaning agent is composed of a surfactant, a thickener, an emulsifier, a stabilizer, a detergent builder, a preservative and water. Sodium cocoyl isethionate serves as the surfactant, coconut diethanolamide serves as the thickener, octylphenol polyoxyethylene ether serves as the emulsifier, triphenyl phosphite serves as the stabilizer, sodium tripolyphosphate serves as the detergent builder, and ethyl p-hydroxybenzoate serves as the preservative. The multifunctional water-based cleaning agent which is composed of the surfactant, the thickener, the emulsifier, the stabilizer, the detergent builder, the preservative and water has the advantages of high cleaning efficiency, excellent detergency, corrosion resistance, high stability, stable quality, low cost, high safety and excellent utilization effects.

Owner:SUZHOU LOTTE CHEM TECH

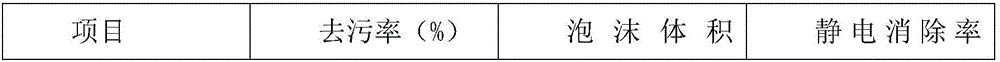

Antistatic detergent used for carpet and preparation method thereof

InactiveCN106244348AStrong decontaminationImprove washing effectNon-ionic surface-active compoundsOrganic detergent compounding agentsPhosphateFatty alcohol

The invention discloses an antistatic detergent used for a carpet and a preparation method thereof. The antistatic detergent is composed of the following raw materials in parts by weight: 8 to 13 parts of polyoxyethylene fatty alcohol sodium sulfate, 4 to 7 parts of sodium lauroyl sarcosine, 5 to 9 parts of alpha-sulfo fatty acid alkyl ester salt, 7 to 11 parts of hydrogenated castor oil polyoxypropylene ester, 9 to 15 parts of alkylamine oxide polyoxyethylene ether, 3 to 6 parts of coconut acid diethanolamide, 6 to 9 parts of phosphate polyoxyethylene nonyl phenol, 2 to 5 parts of dodecyl dimethyl benzyl ammonium bromide and 60 to 80 parts of water. The detergent prepared by using the method provided by the invention has strong detergency and good washing effect, and can guarantee that the carpet does not generate electrostatic phenomenon, so dust adsorption is reduced.

Owner:合肥永佳新材料科技有限公司

Antifreezing glass cleaning liquid

InactiveCN104342293AImprove low temperature resistanceImprove performanceInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSalicylic acidGlycerol

The invention provides antifreezing glass cleaning liquid prepared from the following raw materials in parts by weight: 6-10 parts of ethylenediamine tetramethylenephosphonic acid sodium, 3-8 parts of tripropylene glycol monomethyl ether, 5-9 parts of monoethanolamine, 6-8 parts of glycerindiacetate, 5-9 parts of coconut oil fatty acid, 4-8 parts of salicylic acid, 5-8 parts of urea, 7-9 parts of sodium hydroxide, 5-10 parts of silicone emulsion, 2-6 parts of saponin glue, 7-11 parts of propylene glycol, 6-8 parts of kudzu glue, 3-6 parts of silicon dioxide, 1-5 parts of wax and 30 parts of water. The antifreezing glass cleaning liquid has the beneficial effects of being used normally at a low temperature and having good low-temperature resistance, a good antifreezing effect and excellent performance.

Owner:QINGDAO KELIKE INFORMATION TECH

Foundry modeling facing sand and preparation method thereof

InactiveCN104475644AImprove high temperature resistanceGood collapsibilityFoundry mouldsFoundry coresFoundrySodium Bentonite

The invention relates to foundry modeling facing sand, which is prepared from the following raw materials by weight: 3-4 parts of sodium fluorosilicate, 18-22 parts of metal silicon powder, 10-15 parts of kyanite, 6-8 parts of biotite, 3-5 parts of hydrophobic carbon black, 1-2 parts of coconut acid, 1-2 parts of calcium phosphate, 3-4 parts of methanol, 2-3 parts of castor oil borate, 1-2 parts of sodium stearate, 4-5 parts of iron oxide red, 3-4 parts of organic bentonite, 220-240 parts of clay, a proper amount of water, and 20-30 parts of an auxiliary agent. According to the foundry modeling facing sand of the present invention, the metal silicon powder is used, such that the high temperature resistance of the molding sand is increased, and the collapsibility of the molding sand is good; the sodium fluorosilicate, the sodium stearate, the iron oxide red and the organic bentonite are used, such that the adhesion is good, the demolding property is good, and the shakeout is prevented; the clay is used so as to provide advantages of suitable particle size, good gas permeability, good fluidity and good dispersion, the cast surface is smooth, and the recycling can be achieved; and the molding sand is suitable for facing sand, the cast surface is smooth, and the shakeout is not easily produced.

Owner:繁昌县琦祥铸造厂(普通合伙)

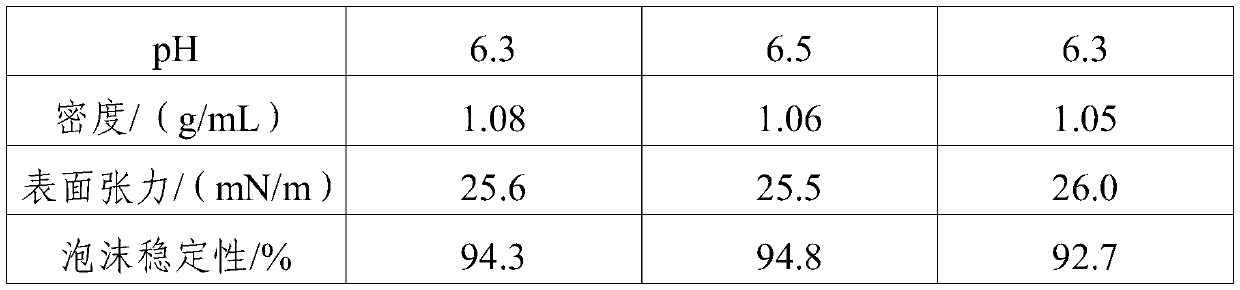

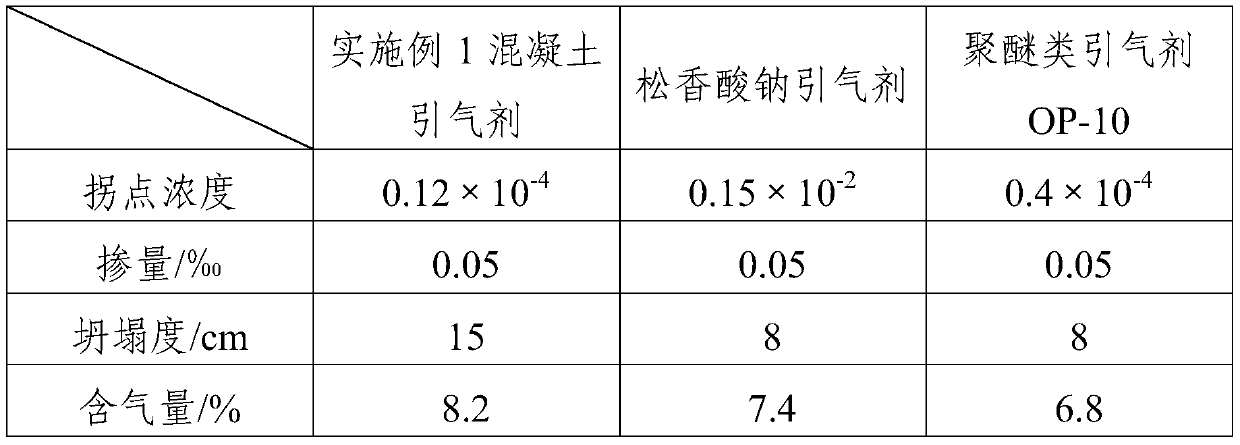

Efficient composite concrete air entraining agent and preparation method thereof

The invention provides an efficient composite concrete air entraining agent and a preparation method thereof, and relates to the field of concrete admixtures. The efficient composite concrete air entraining agent is prepared from the following components in parts by weight: 30-40 parts of sapogenin, 30-40 parts of sapindus saponin, 10-15 parts of sodium dodecyl benzene sulfonate, 5-10 parts of coco fatty acid diethanolamide, 3-6 parts of orange essential oil, 3-5 parts of itaconic anhydride, 2-4 parts of sodium alcohol ether sulphate, 0.1-0.5 parts of sulfonated castor alcohol sodium salt, 0.1-0.5 part of carboxymethyl cellulose, 5-15 parts of nano powder, 0.01-0.1 parts of a water reducing agent, 0.01-0.1 parts of a foam stabilizer, 10-15 parts of polyethylene glycol, 2-4 parts of pentaerythritol and 130-150 parts of water. The efficient composite concrete air entraining agent can effectively improve slump, fluidity and plasticity of concrete, can reduce bleeding and segregation of the concrete, can improve homogeneity of the concrete, can reduce thermal diffusion and conduction coefficient of the concrete, can improve volume stability of the concrete and can enhance weather resistance of a field structure.

Owner:安徽信聪数据科技有限公司

Automobile lubricating oil additive

InactiveCN104974821AImprove viscosity indexImprove the lubrication effectAdditivesPhosphoric Acid EstersOil additive

An automobile lubricating oil additive is composed of the following raw materials in parts by weight: 3 to 6 parts of phosphorodithioate, 2 to 4 parts of random polypropylene, 1.2 to 3 parts of oligomer of trimethyl hydrogen quinazoline, 4 to 6 parts of phenothiazine, 5 to 8 parts of phenyl-2-naphthylamine, 2 to 4 parts of methyl silicone oil, 3 to 5 parts of calcium oxide, 1 to 2 parts of succinate, 4 to 7 parts of mesembryanthemoidigenic acid, 3 to 6 parts of glycerin acrylate, 7 to 10 parts of lupeol palmitate, 5 to 8 parts of linolenic acid, 6 to 9 parts of coconut diethanolamide, 5 to 8 parts of inositol hexaphosphate, 2 to 4 parts of calcium chloride, 6 to 10 parts of polyacrylic acid, 4 to 7 parts of sodium dodecyl benzene sulfonate, 2 to 6 parts of tetrahydropalmatine, 3 to 5 parts of lupeol palmitate, 8 to 16 parts of benzyl alcohol, and 7 to 12 parts of sulfurized calcium alkyl phenate. The provided automobile lubricating oil additive has an improved viscosity index and a good lubricating performance, can effectively prevent lubricating oil from being oxidized or degraded, and prolongs the service life of lubricating oil.

Owner:QINGDAO YUXING INTELLIGENT TECH DEV CO LTD

Improved plastic anti-aging auxiliary

Disclosed is an improved plastic anti-aging auxiliary. The improved plastic anti-aging auxiliary is made from, by weight part, 1-3 parts of inorganic salt, 4-9 parts of aluminum oxide, 6-8 parts of calcium and zinc poly-fatty-acid resinate, 2-8 parts of zinc oxide, 5-9 parts of modified calcium carbonate, 3-6 parts of methacrylate, 3-7 parts of sodium carbonate, 4-11 parts of maize straw extracts, 3-5 parts of coconut oil monoethanolamide, 6-8 parts of moxa leaf alcohol extracts, 5-9 parts of coffee extracts and 1-5 parts of towel gourd seed extracts. The improved plastic anti-aging auxiliary has the advantages of being capable retarding aging of plastics, long in effect time and small in influence on the environment.

Owner:QINGDAO BAOLIKANG NEW MATERIALS

Fragrance type hand sterilizer for children

InactiveCN102871873AGood hand washing habitsElasticCosmetic preparationsToilet preparationsMonoglycerideMugwort

The invention discloses a fragrance type hand sterilizer for children. The hand sterilizer is characterized by being prepared from the following raw materials in part by weight: 2 to 8 parts of Chinese mugwort leaf monoglyceride, 3 to 5 parts of polyoxyethylene, 2 to 5 parts of bactericide, 5 to 10 parts of glycerin, 5 to 10 parts of sodium chloride, 2 to 5 parts of pigments, 2 to 5 parts of solid essence, 5 to 10 parts of coconut acid monoglyceride and 2 to 5 parts of ionized water. The fragrance type hand sterilizer for children is reasonable in formula, low in cost and convenient to use, is fragrant, and has an effect of sterilizing bacteria and viruses.

Owner:QINGDAO SANDING SANITARY PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com