Method for preparing asphalt cleaners capable of effectively removing residual asphalt

A cleaning agent and bitumen technology, applied in the field of cleaning, can solve problems such as difficult treatment of bitumen layer, and achieve the effects of less environmental pollution, low price and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

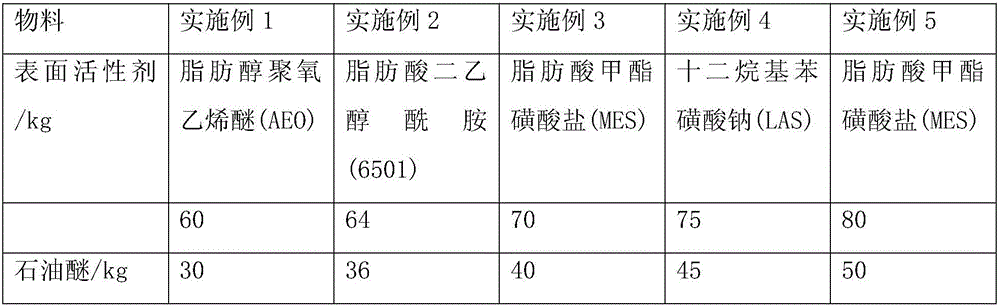

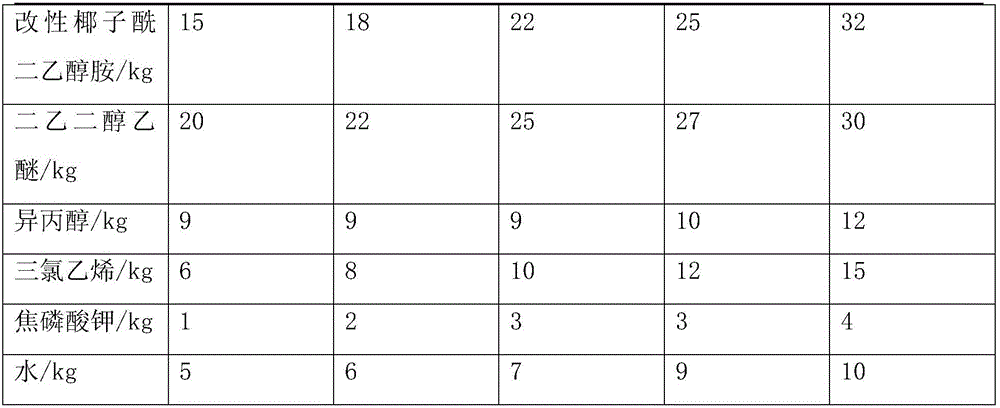

[0016] The technical solutions of the present invention will be further described below through specific examples.

[0017] A preparation method of an asphalt cleaner capable of effectively removing residual asphalt is carried out according to the following steps:

[0018] Step 1, first add water to the container, then add surfactant and petroleum ether to the above container in turn, and stir for 3-5 minutes to obtain a preliminary mixed solution;

[0019] Step 2, adding modified cocoamide diethanolamine and isopropanol successively to the preliminary mixed solution prepared in step 1, and mechanically stirring for 10-20 minutes to obtain the mixed solution;

[0020] Step 3: Add diethylene glycol ethyl ether to the mixed liquid prepared in Step 2, mix evenly, then add trichlorethylene and potassium pyrophosphate in sequence, and manually stir for 5-10 minutes to obtain an asphalt cleaner.

[0021] Material addition is shown in the table below in each embodiment:

[0022] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com