Leather mildew-proof fat-liquoring agent and preparation method thereof

A fatliquor and anti-mildew technology, which is applied in the field of leather anti-mold fatliquor and its preparation, can solve the problems of unsatisfactory leather processing technology, poor stability and permeability, and no anti-mildew effect, so that it is not easy to mildew , small shrinkage, easy to popularize and apply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] A leather anti-mildew fatliquoring agent, comprising the following components in parts by weight: 10 parts of jojoba oil, 30 parts of palm oil, 3 parts of N-lauroyl-L-valine sodium, dicocoyl 2 parts of ethanolamide, 1 part of 10,10'-oxobisphenoxarpine, 2 parts of hydroxyethyl cellulose, 50 parts of water.

[0012] The preparation method of the leather anti-mildew fatliquoring agent of this embodiment is to add N-lauroyl-L-valine, cocoic acid diethanolamide and hydroxyethyl cellulose in water, stir until evenly mixed, and then heat to 40 Jojoba oil, palm oil and 10,10'-oxobisphenoxarsen were added thereto at a temperature of °C, and the stirring was continued until the mixture was evenly mixed, and the mixture was lowered to room temperature, and the leather anti-mildew fatliquoring agent of this embodiment was obtained.

Embodiment 2

[0014] A leather anti-mildew fatliquoring agent, comprising the following components in parts by weight: 20 parts of jojoba oil, 50 parts of palm oil, 6 parts of N-lauroyl-L-valine sodium, dicocoyl 5 parts of ethanolamide, 3 parts of 10,10'-oxobisphenoxarsenic, 4 parts of hydroxyethyl cellulose, 70 parts of water.

[0015] The preparation method of the leather anti-mildew fatliquoring agent of this embodiment is to add N-lauroyl-L-valine, cocoic acid diethanolamide and hydroxyethyl cellulose in water, stir until evenly mixed, and then heat to 50 Jojoba oil, palm oil and 10,10'-oxobisphenoxarsen were added thereto at a temperature of °C, and the stirring was continued until the mixture was evenly mixed, and the mixture was lowered to room temperature, and the leather anti-mildew fatliquoring agent of this embodiment was obtained.

Embodiment 3

[0017] A leather anti-mildew fatliquoring agent, comprising the following components in parts by weight: 15 parts of jojoba oil, 40 parts of palm oil, 5 parts of N-lauroyl-L-valine sodium, dicocoyl 4 parts of ethanolamide, 2 parts of 10,10'-oxobisphenoxarsenic, 3 parts of hydroxyethyl cellulose, 60 parts of water.

[0018] The preparation method of the leather anti-mildew fatliquoring agent of this embodiment is to add N-lauroyl-L-valine, cocoic acid diethanolamide and hydroxyethyl cellulose in water, stir until evenly mixed, and then heat to 45 Jojoba oil, palm oil and 10,10'-oxobisphenoxarsen were added thereto at a temperature of °C, and the stirring was continued until the mixture was evenly mixed, and the mixture was lowered to room temperature, and the leather anti-mildew fatliquoring agent of this embodiment was obtained.

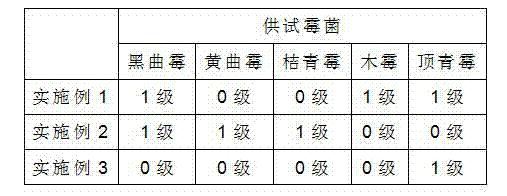

[0019] Spray the skin piece (2.5cm×5.0cm) treated with the leather anti-mildew fatliquoring agent of Examples 1~3 of the present invention on the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com