Patents

Literature

74 results about "Ethanolamide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

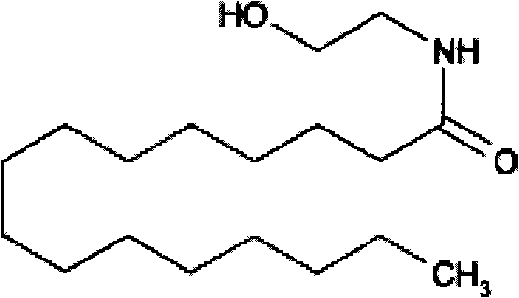

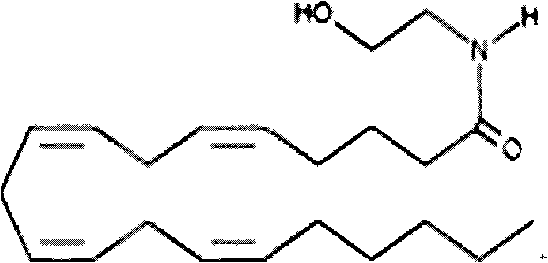

Ethanolamides are chemical compounds which are amides formed from carboxylic acids and ethanolamine. Some ethanolamides are naturally occurring, such as anandamide, palmitoylethanolamide and prostamides, which play physiological roles as lipid neurotransmitters and autacoids.

Methods for identification of modulators of OSGPR116 activity

InactiveUS7083933B1Improve developmentCell receptors/surface-antigens/surface-determinantsBiological material analysisDiabetes mellitusDisease

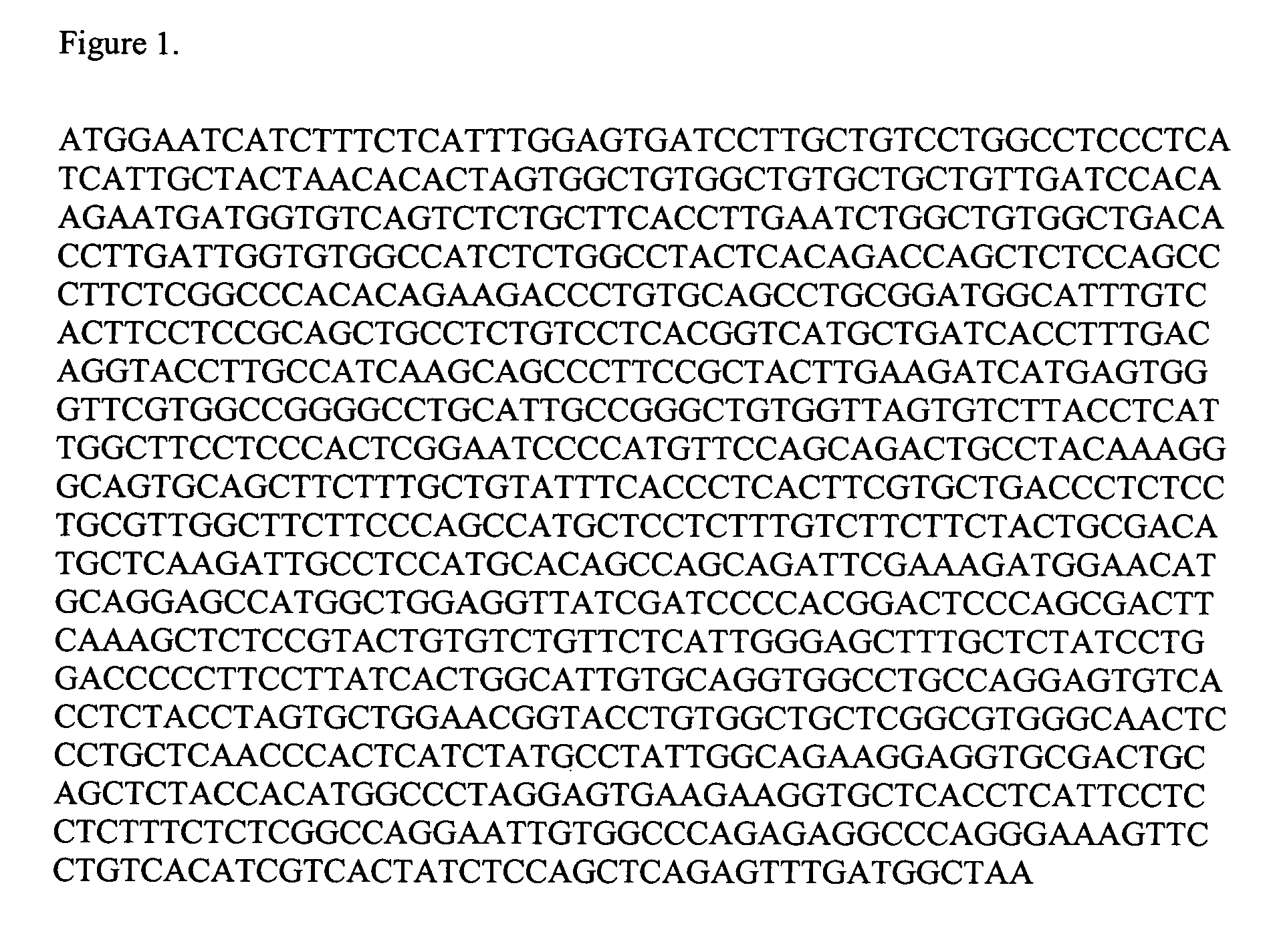

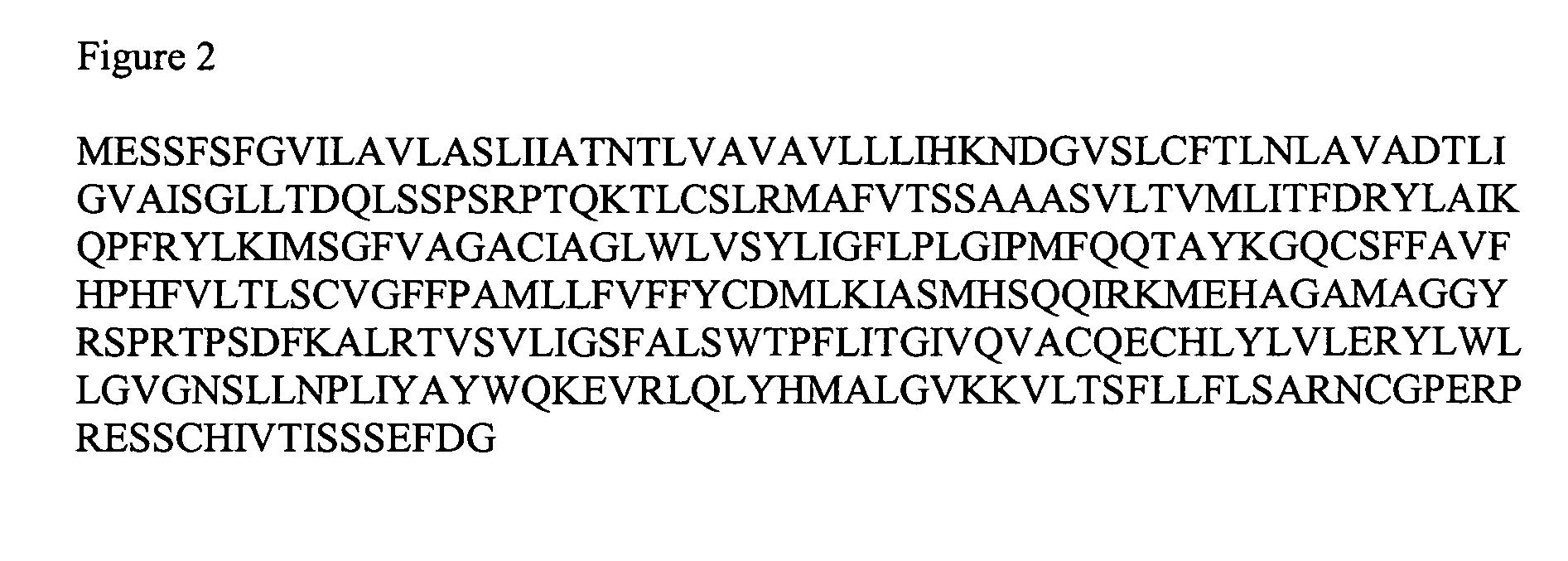

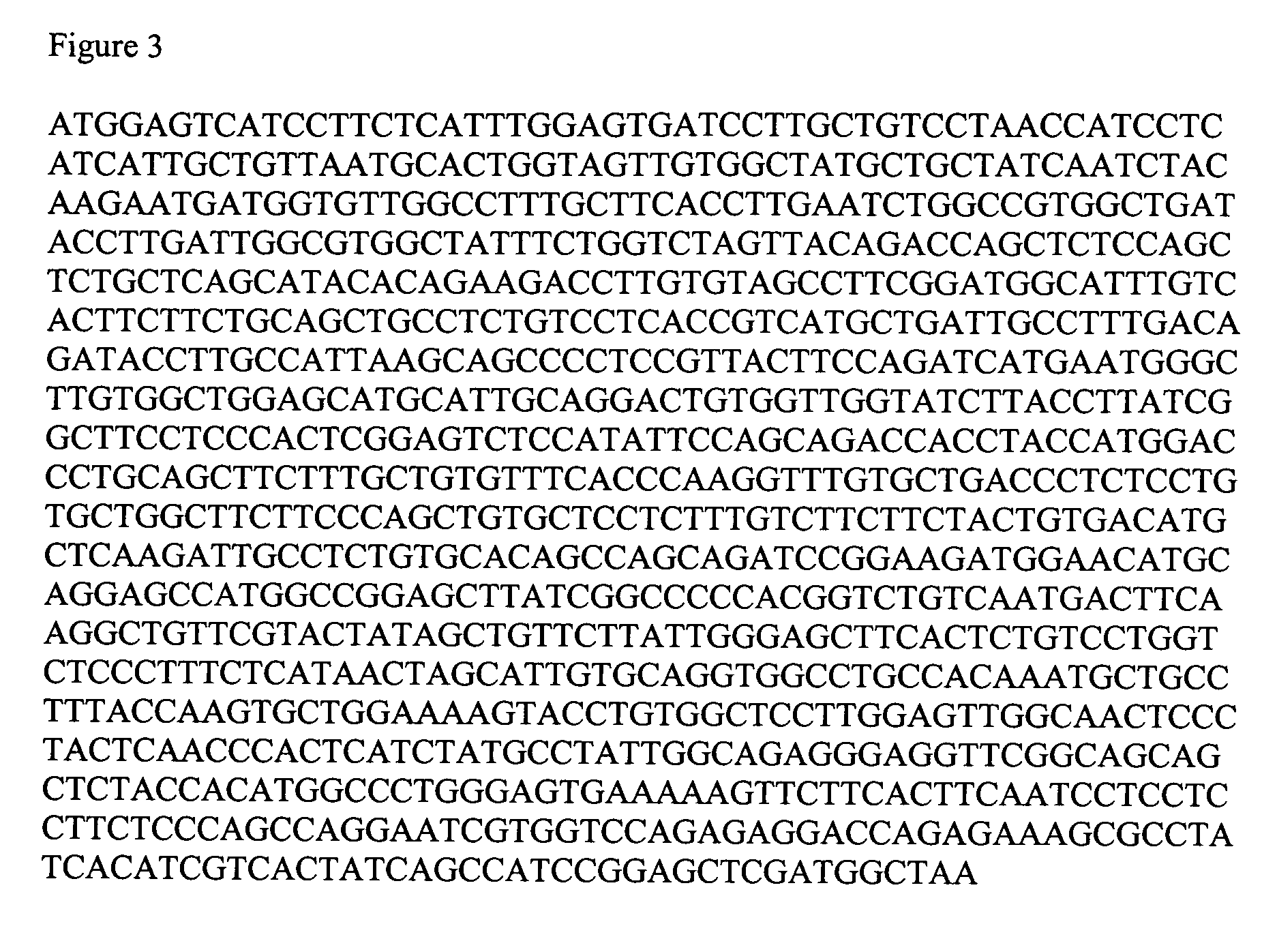

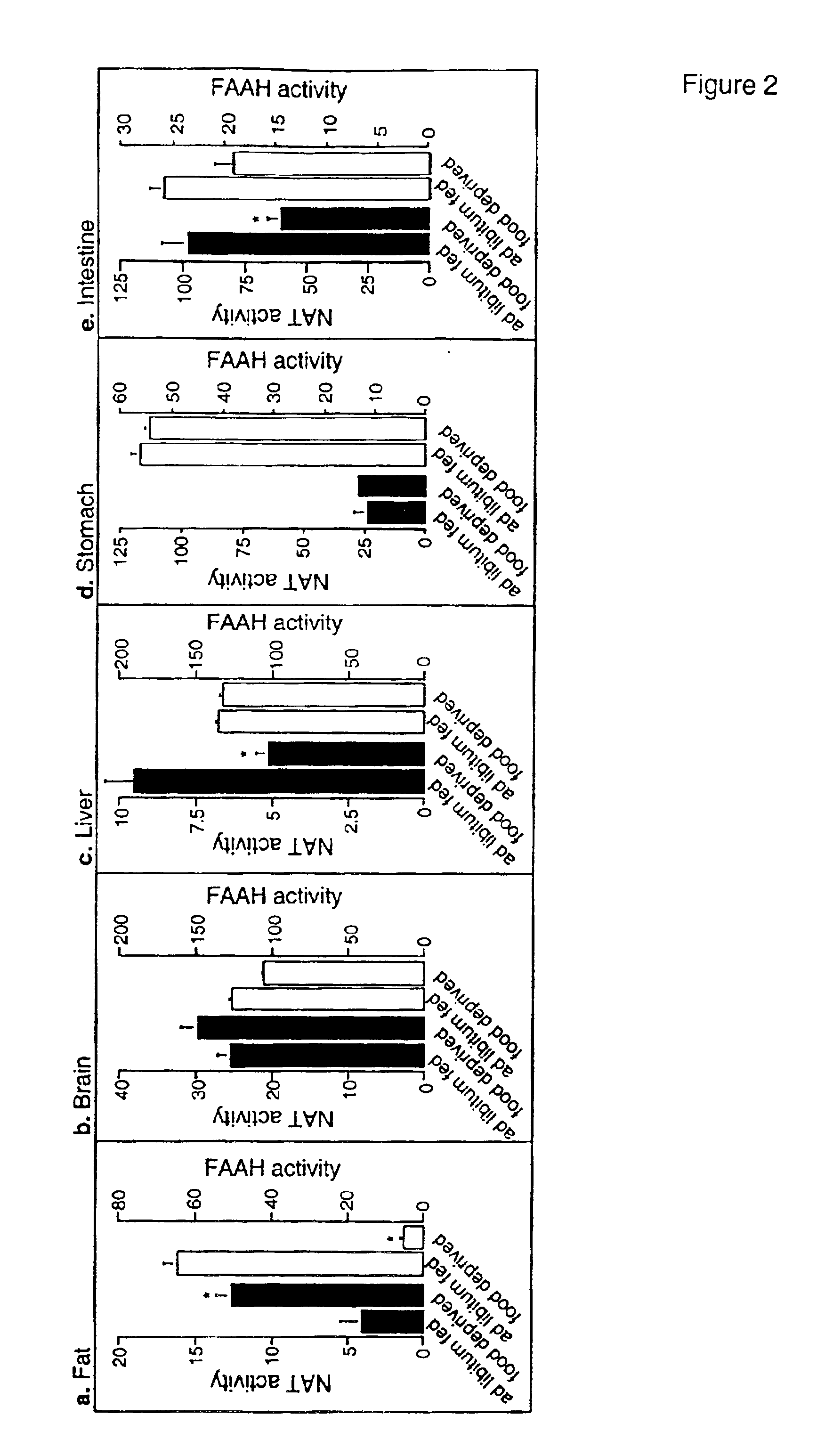

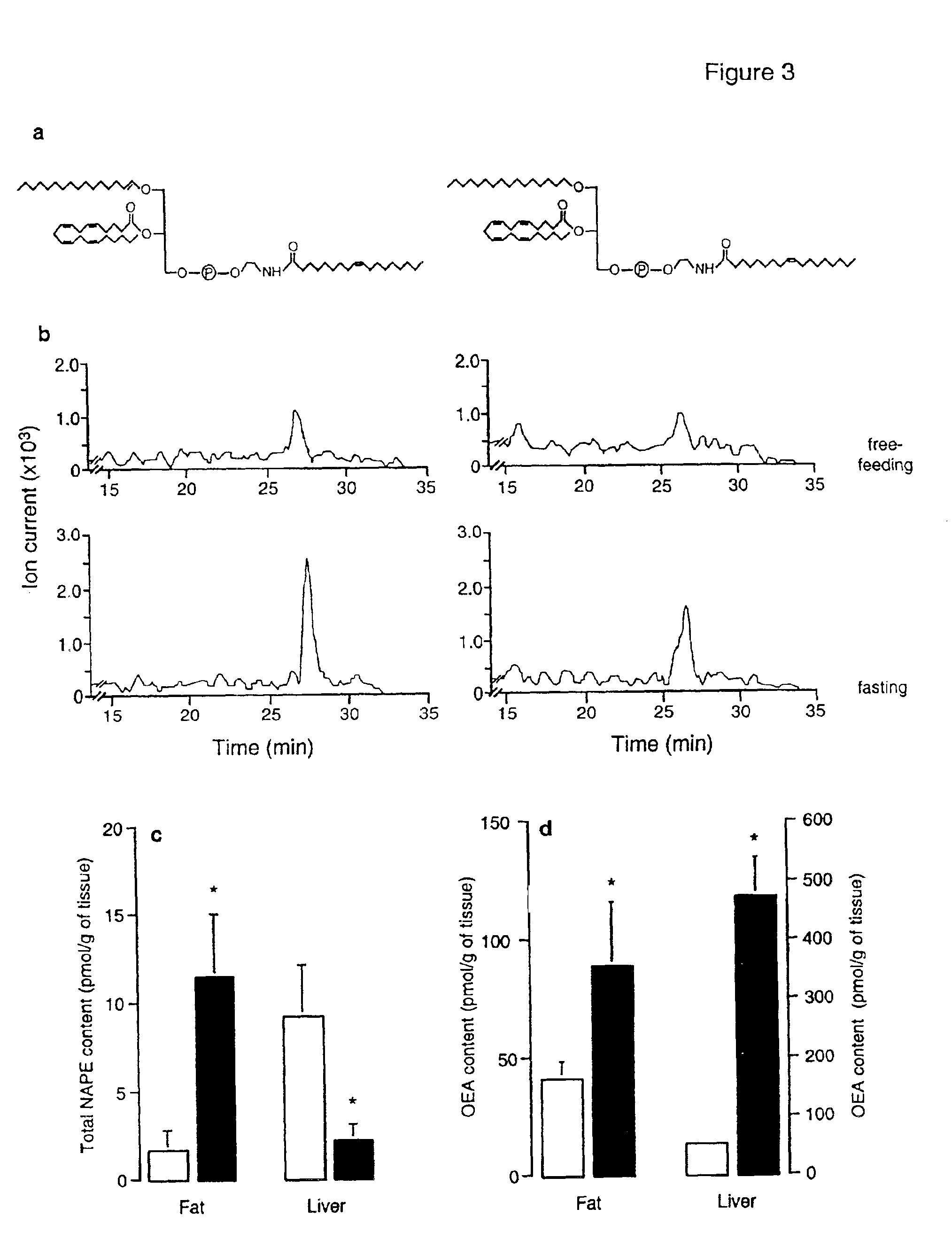

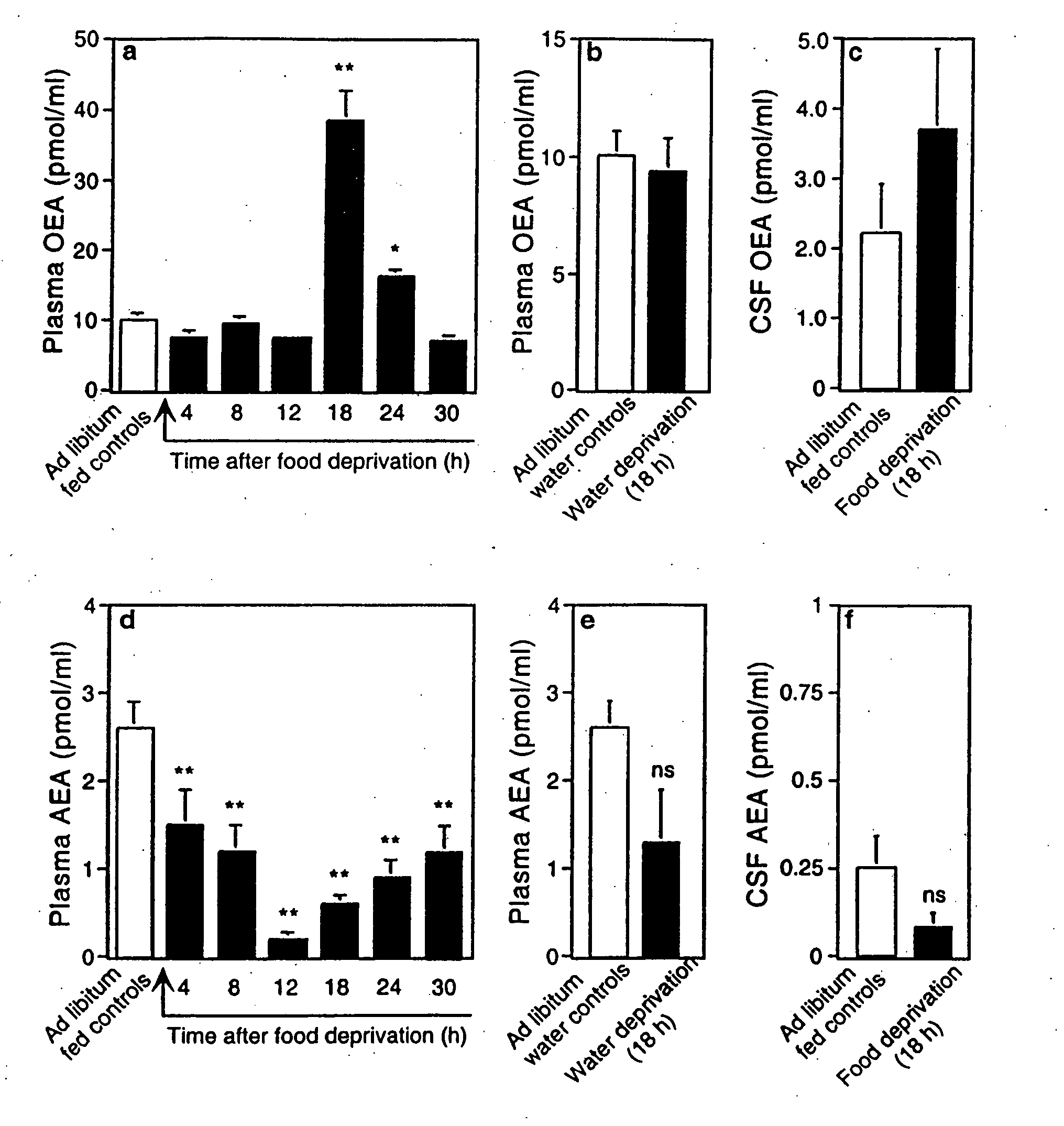

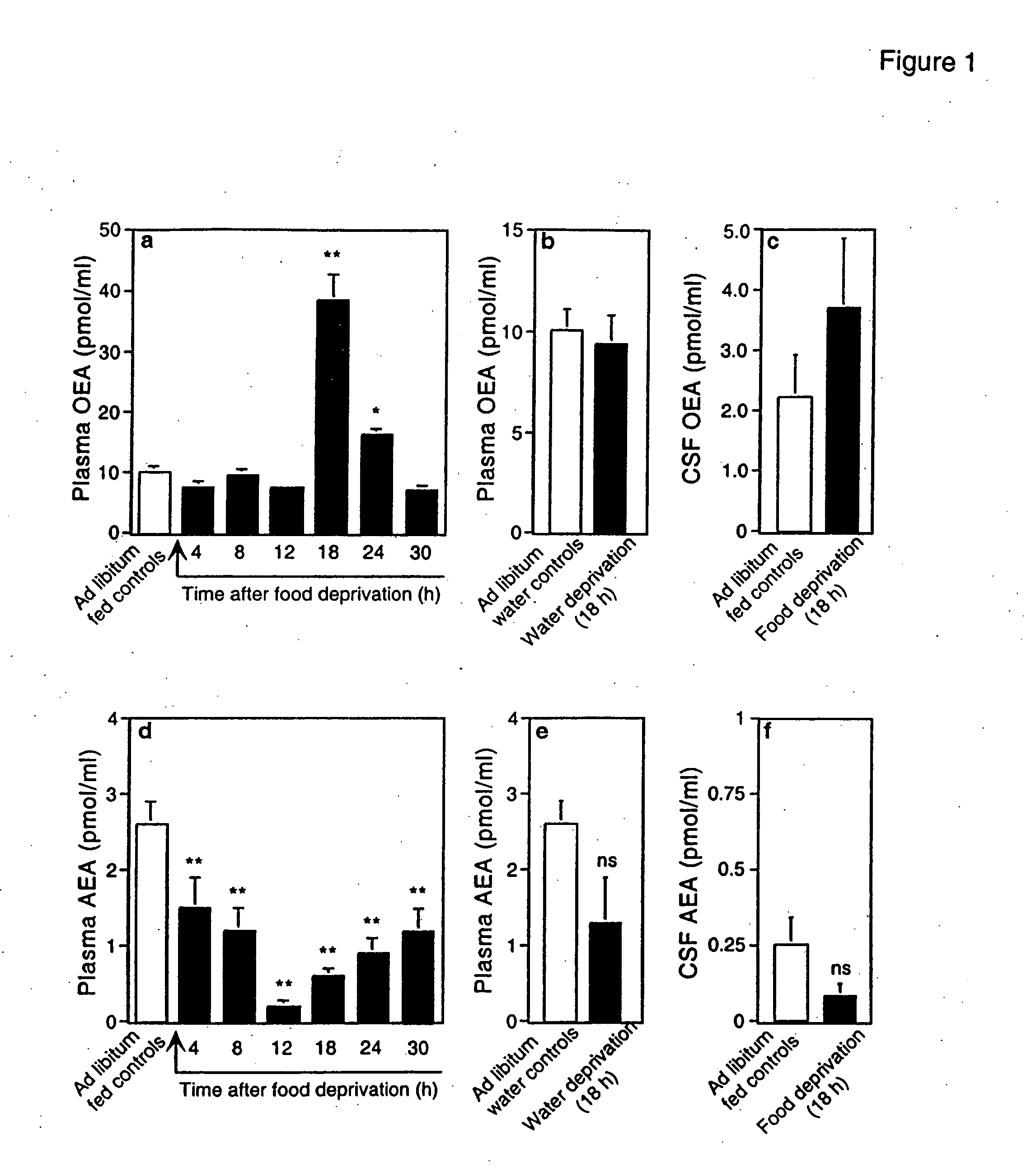

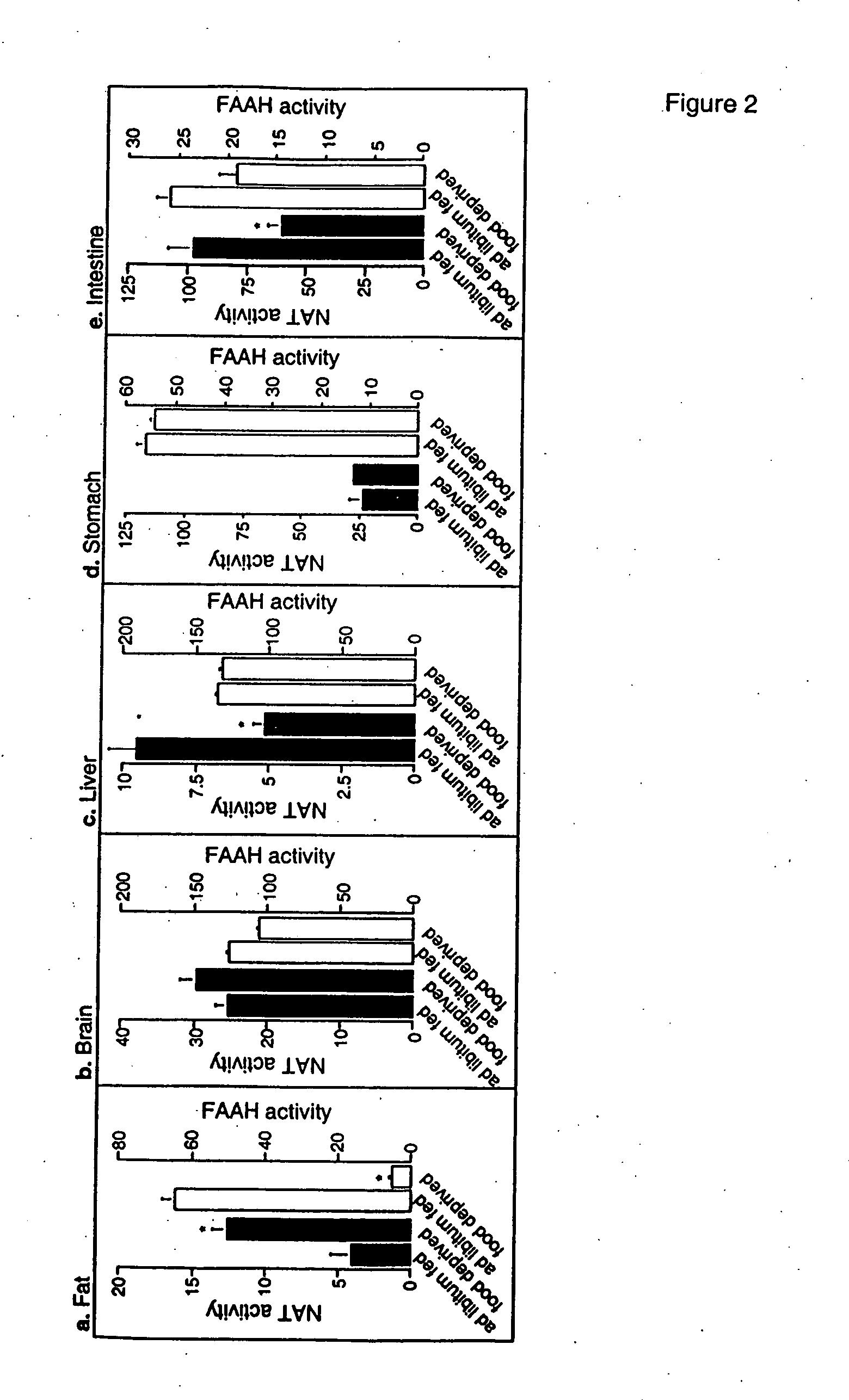

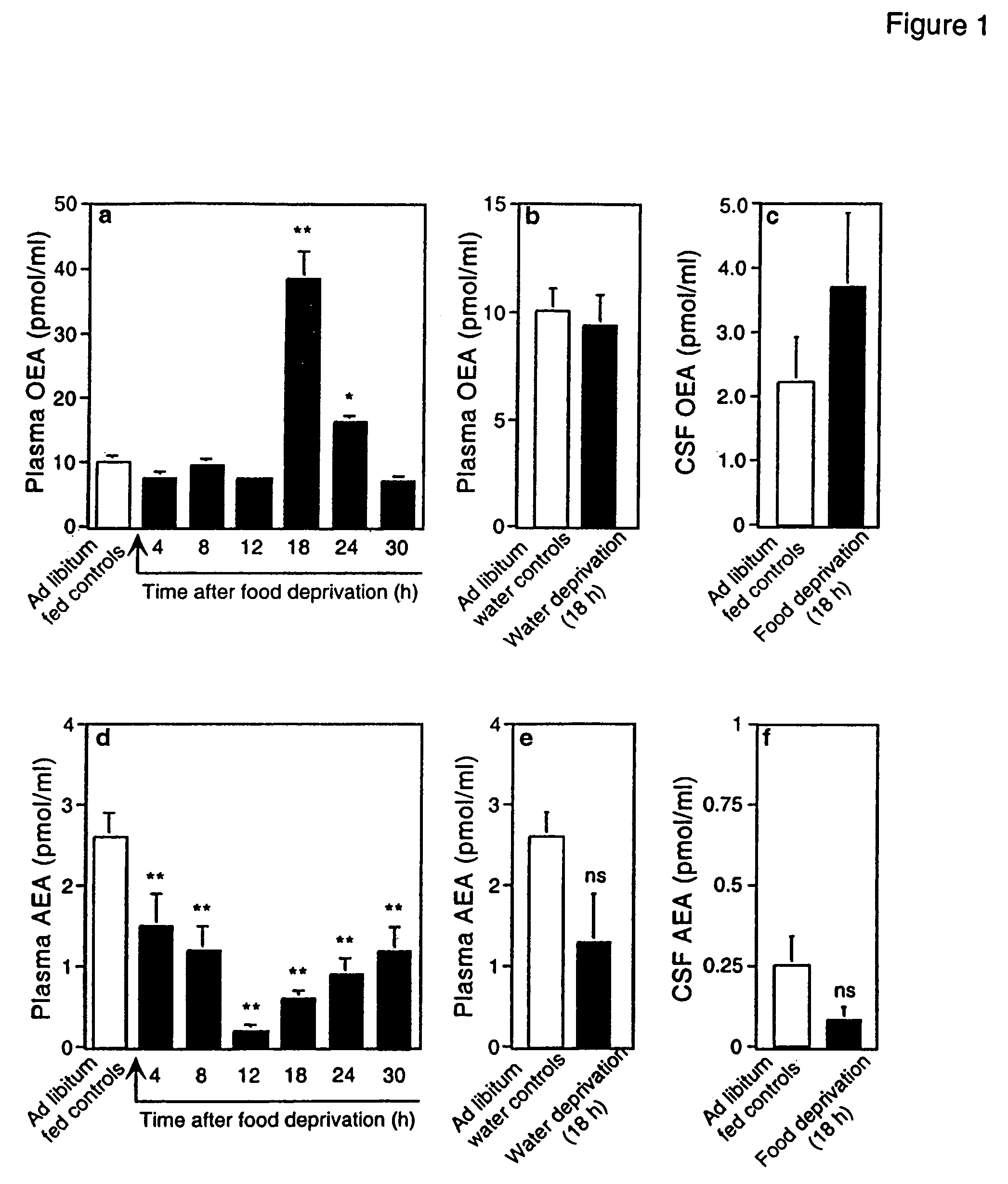

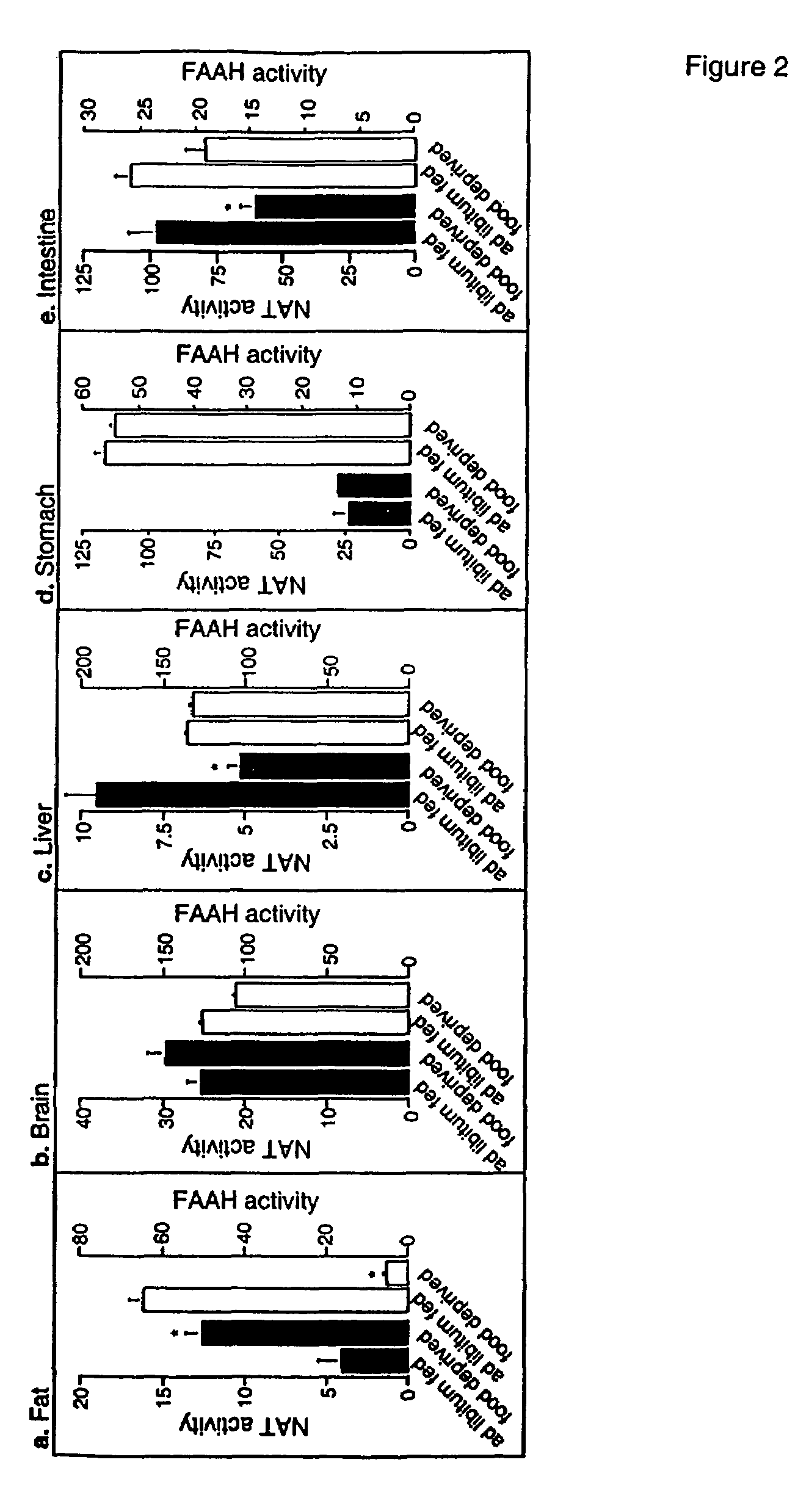

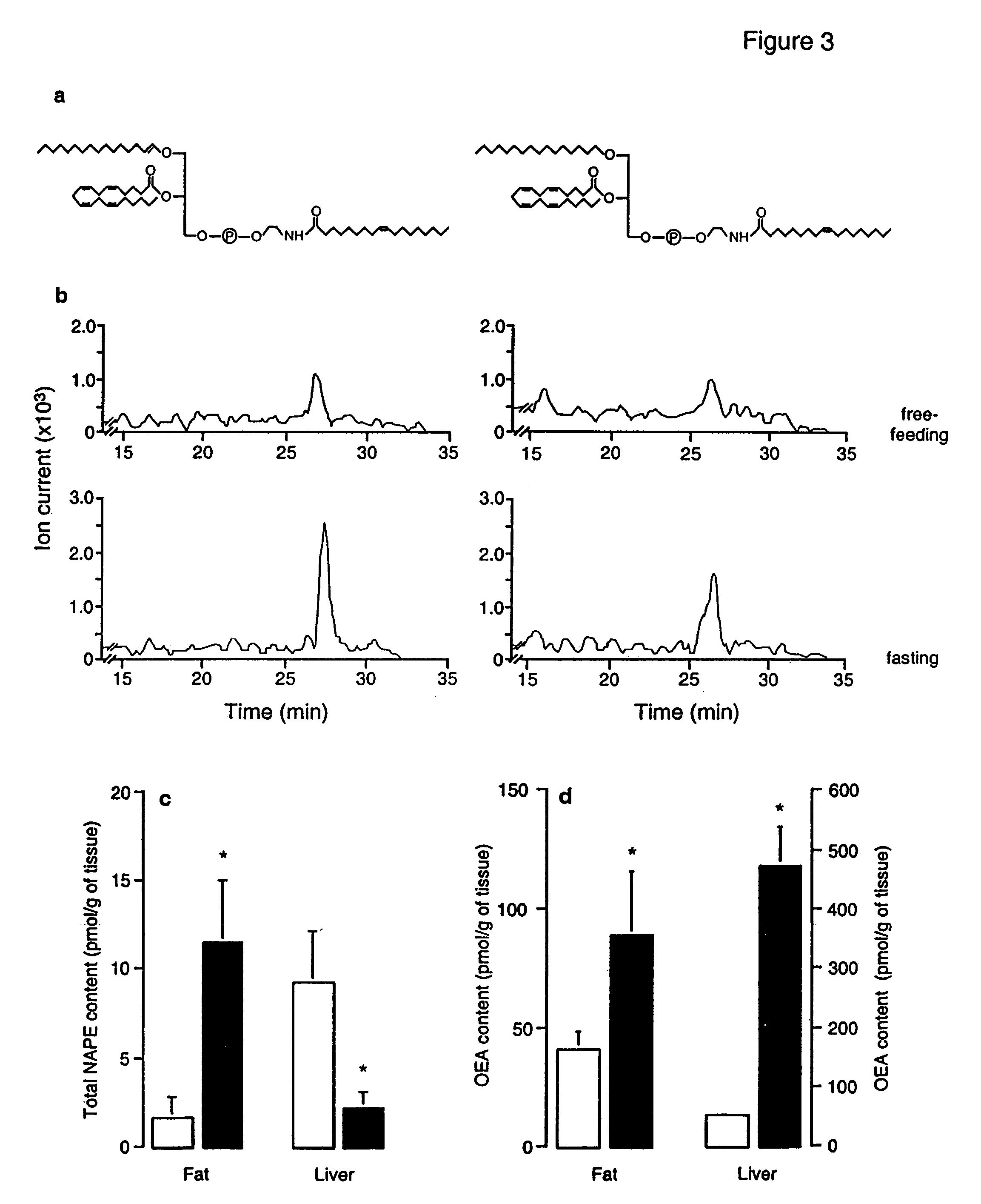

This invention relates to the identification of fatty acid or lipid amides that decrease food intake in mammals, including fatty acid ethanolamides, as ligands for the G-protein coupled receptor OSGPR116, and describes the first demonstration of a specific G-protein coupled receptor that is activated by fatty acid ethanolamides that inhibit feeding. The invention is directed to new methods for screening candidate drugs for their ability to modulate the activity of OSGPR116, and new pharmaceutical agents identified by these methods. It is also directed to the use of such agents in the manufacture of medicaments for the treatment of OSGPR116 mediated diseases, and methods of treating diseases such as obesity and diabetes by administering to an individual a therapeutic amount of a modulator of OSGPR116 identified by these methods.

Owner:PROSIDLON LTD

Methods, compounds, and compositions for reducing body fat and modulating fatty acid metabolism

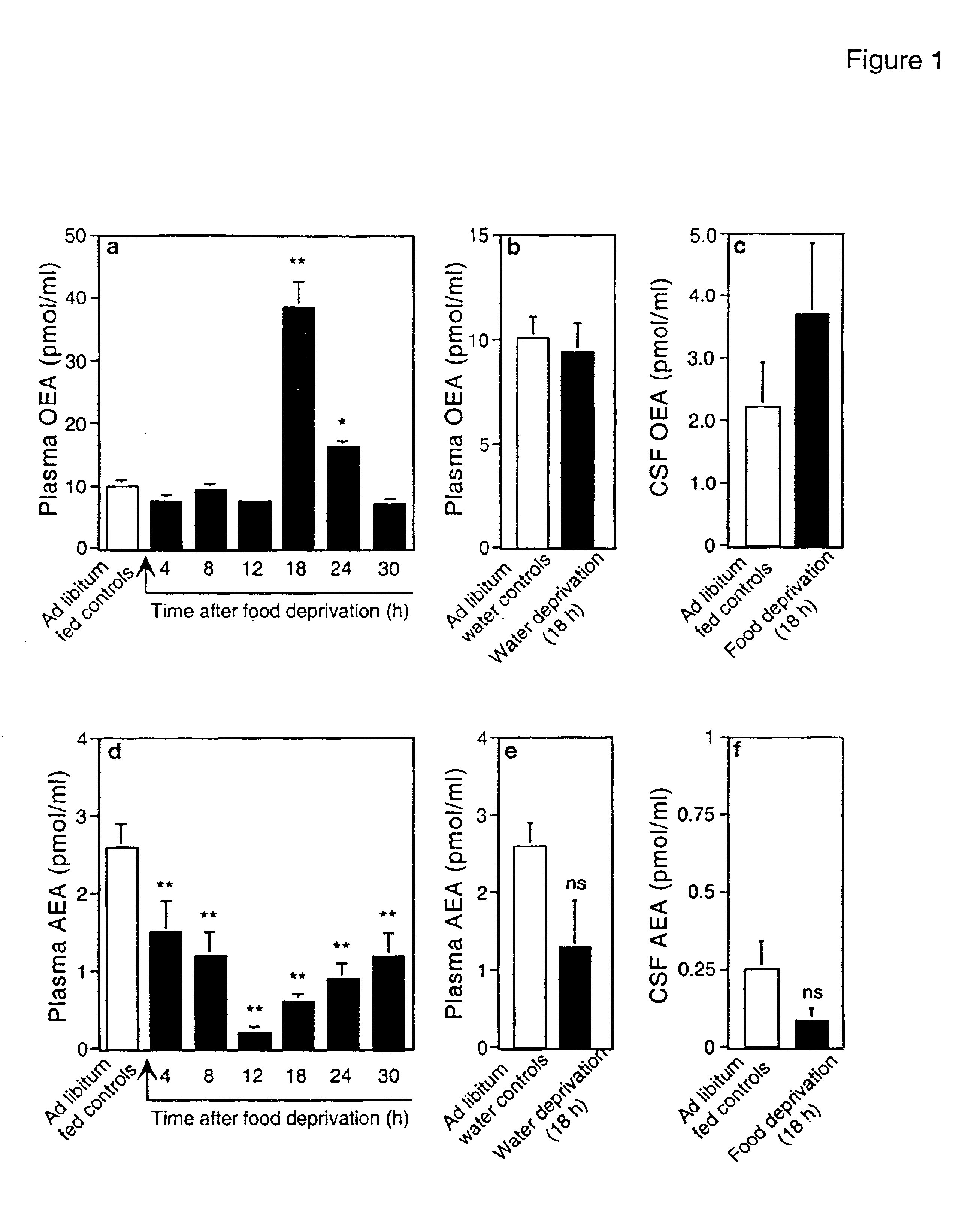

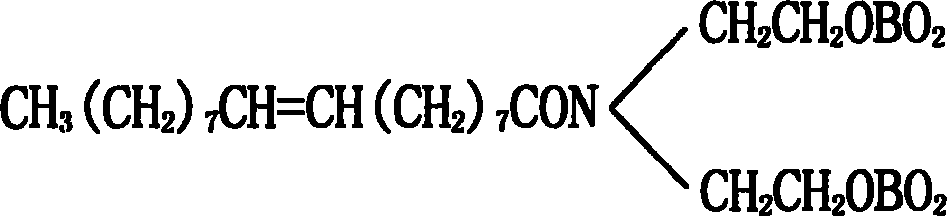

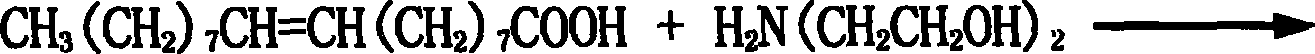

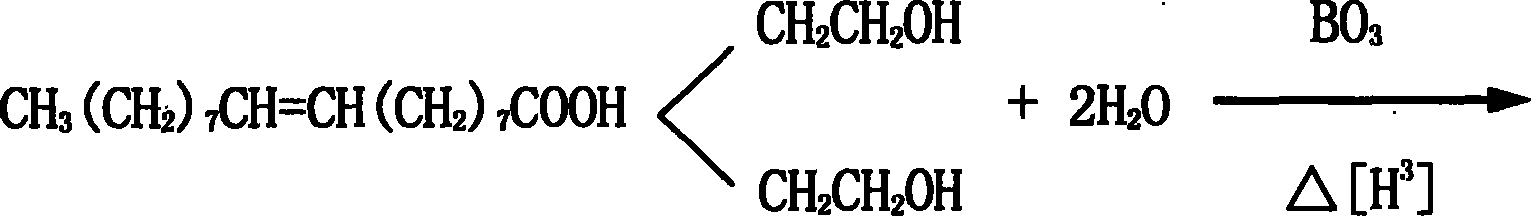

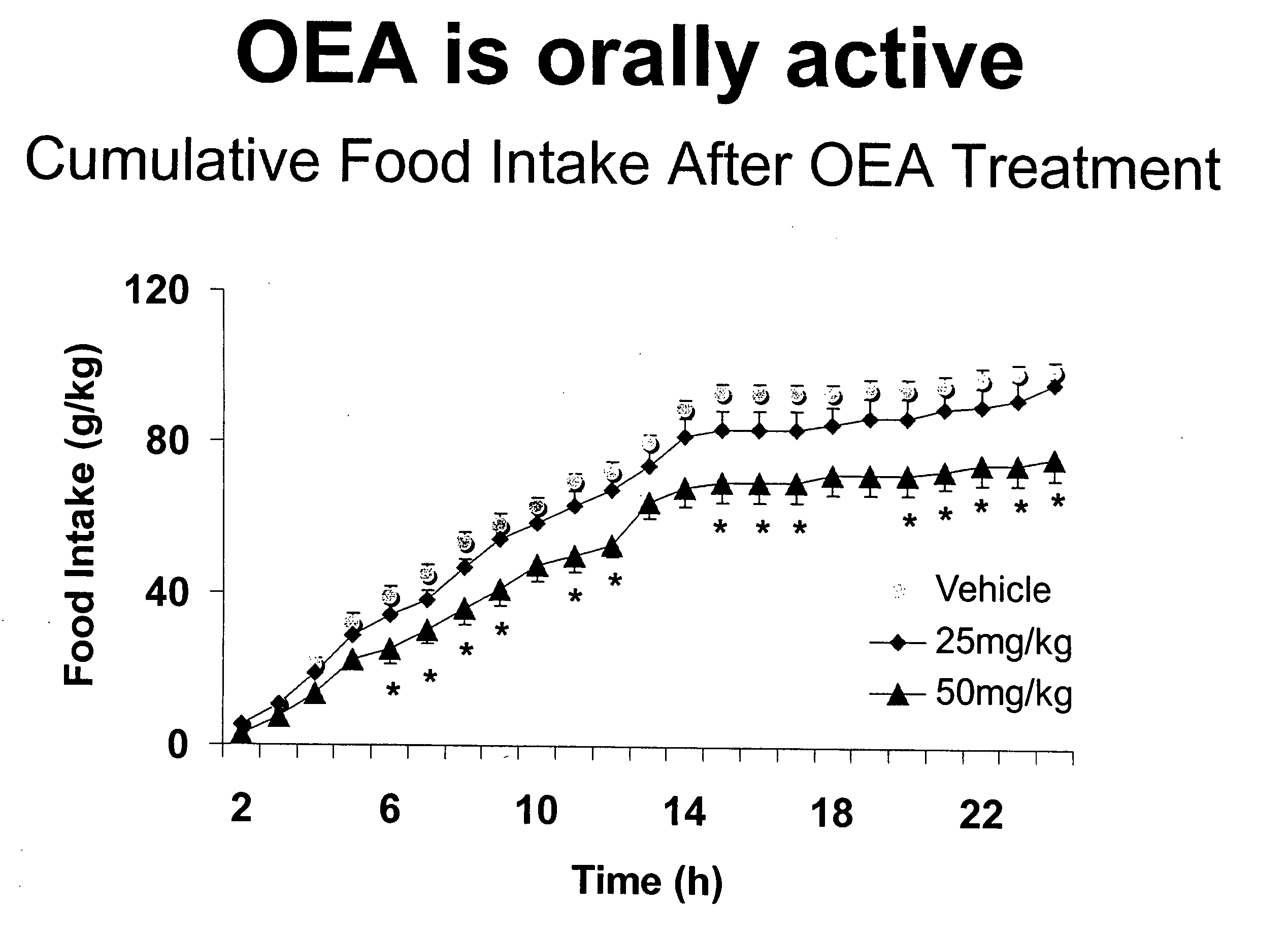

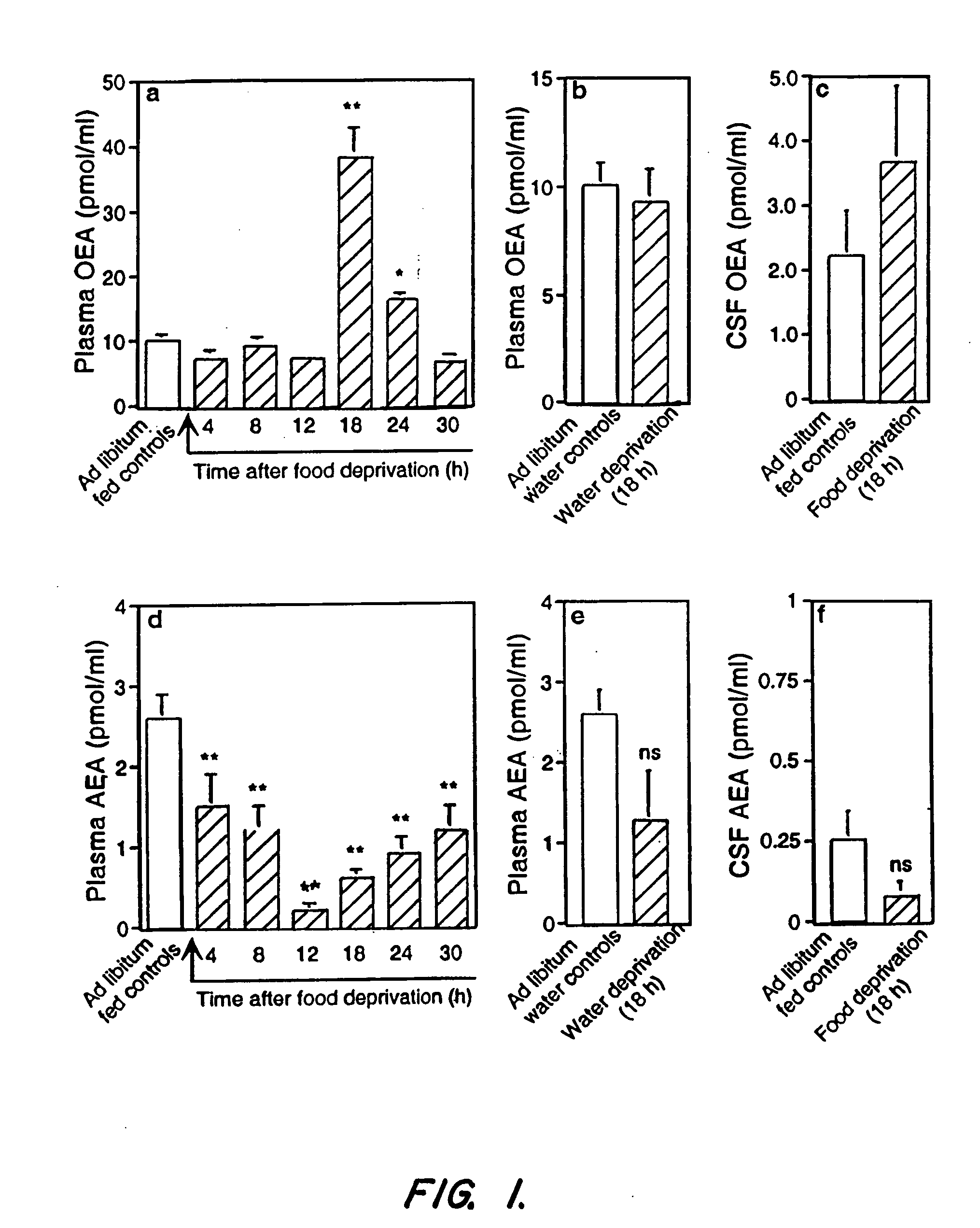

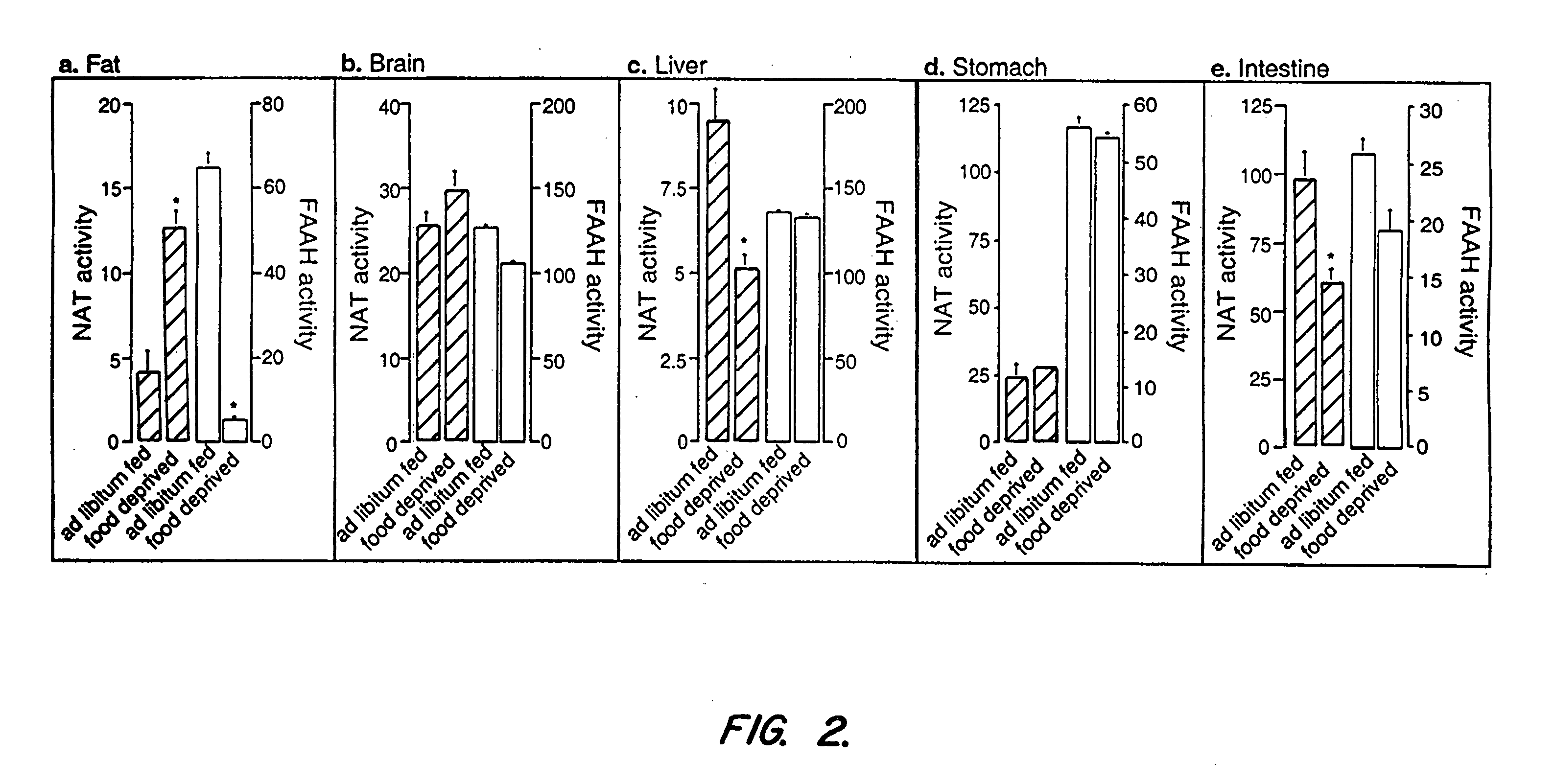

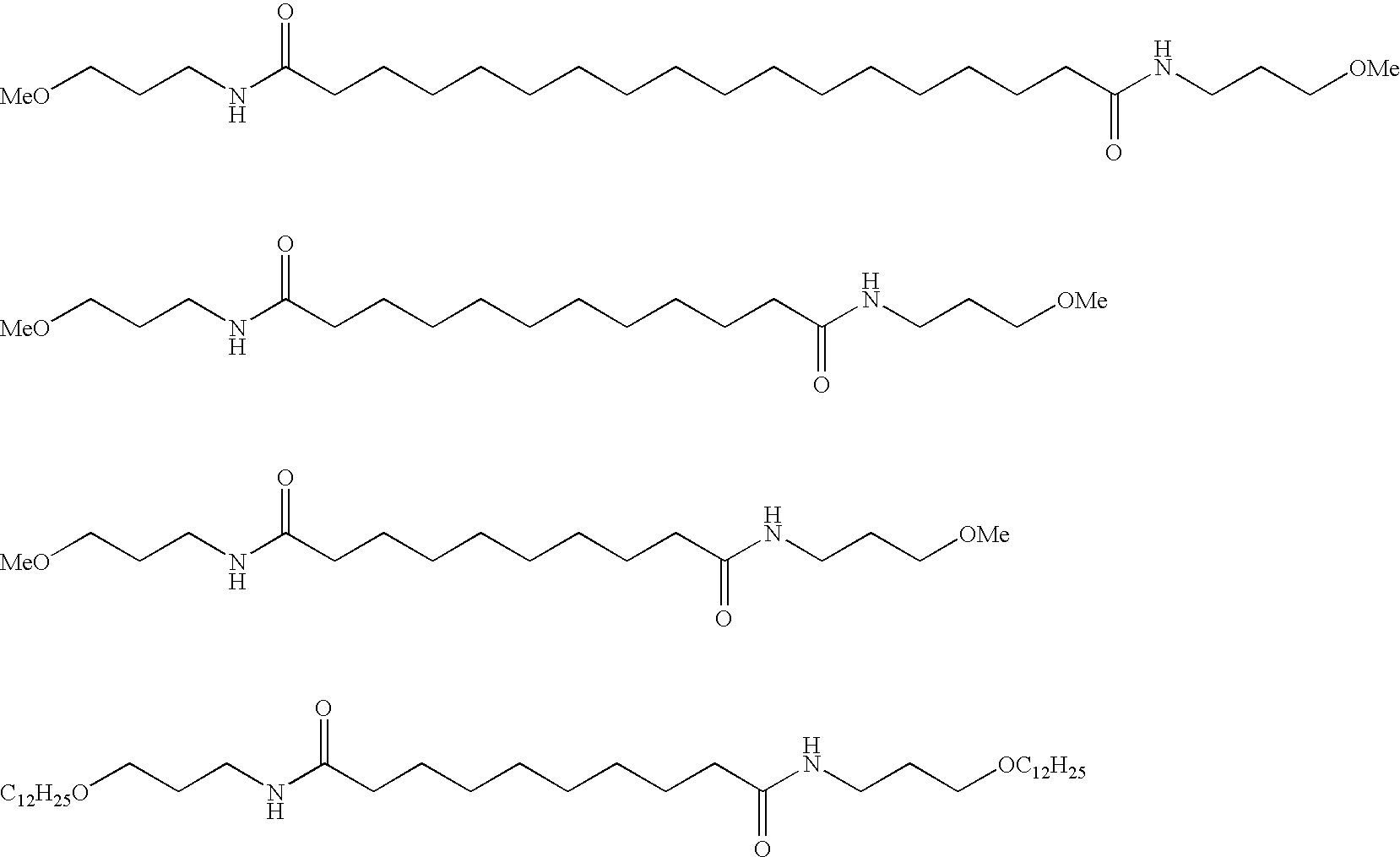

Methods, pharmaceutical compositions, and compounds for reducing body weight, modulating body lipid metabolism, and reducing food intake in mammals are provided. The compounds of the invention include fatty acid ethanolamide compounds, homologues and analogs of which the prototype is the endogenous fatty acid ethanolamide, oleoylethanolamide.

Owner:RGT UNIV OF CALIFORNIA

Oil soluble compound highly effective antirust additive and preparation method thereof

The invention discloses an oil soluble built high effective antirust additive and preparing method, which comprises the following steps: allocating 12-30 wt polyhydroxy carboxylic acids, 40-60 wt oleic acid acetal amide boric acid ester, 3-6 wt bromide triethyl cetyl ammonium, 2-6 wt alkyl group bromine generation ammonium salt, 10-30 wt dioctyl regular sebacate, 20-30 wt trolamine, 0. 7-1. 3 wt wool alcohol; getting the product. This product possesses good oil solubility, which can be used as antirust agent for ferrous metal and non-ferrous metals.

Owner:BEIJING TIANBAO TONGHUI MATERIAL PROTECTION TECH

Dietary and other compositions, compounds, and methods for reducing body fat, controlling appetite, and modulating fatty acid metabolism

InactiveUS20050154064A1Inhibit liver fat accumulationLower Level RequirementsBiocidePeptide/protein ingredientsDietary supplementIngested food

Methods, pharmaceutical, dietary supplement, and nutraceutical compositions, and compounds for reducing body weight, modulating body lipid metabolism, and reducing food intake in mammals are provided. The compounds of the invention include fatty acid ethanolamide compounds, homologues and analogs of which the prototype is the endogenous fatty acid ethanolamide, oleoylethanolamide.

Owner:RGT UNIV OF CALIFORNIA

Herbal medicine flower foam shower agent and skin care capsule

InactiveCN101559033AGood for healthSuitable for useCosmetic preparationsToilet preparationsSide effectAngelica dahurica

The invention provides a method for preparing a herbal medicine flower foam shower agent and a skin care capsule, belonging to the technical field of production of cleaning products and skin care products for daily use. The herbal medicine flower foam shower agent of the invention is prepared from the components of Chinese violet, Chinese ixora, campsis grandiflora, vervain, coconut fatty acid mono ethanolamide of 1:1 type, borneol, sodium carboxymethyl cellulose, flavoring rose essence, etc. The skin care capsule of the invention is prepared from angelica dahurica extract, bee honey, vitamin E, vanishing cream, etc. The products are handy, delicate, safe and reliable, and have no side effect; and the products of the invention clean and protect the skin and are matched with each other to use, thereby providing convenience for users and benefiting the health.

Owner:黎秋萍

Water-soluble washing agent composition

ActiveCN101434890AMildImprove wettabilityInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsAlcoholPhosphate

A water-soluble cleaning agent composition comprises an alkaline compound, polyoxyethylene laurylether phosphate salt, lauric acid diethanolamide, lower alcohol and water; taking the total weight of the composition as benchmark, the content of the alkaline compound is 0.01-5 percent by weight, the content of the polyoxyethylene laurylether phosphate salt is 0.01-5 percent by weight, the content of the lauric acid diethanolamide is 0.01-5 percent by weight, the content of the lower alcohol is 0.1-40 percent by weight, and the rest is the water. The cleaning agent composition is easy to be dissolved in a water-organic matter system, can be dissolved in water by any proportion and has strong oil-removing and cleaning ability at normal temperature without causing residual surfactant on the surface of the cleaned object.

Owner:BYD CO LTD

Metal polishing agent

The invention relates to a metal polishing agent, which is prepared from the following components in percentage by weight: 2 to 7 percent of dodecyl benzene sulfonic acid sodium, 1.5 to 5 percent of sodium oleate, 8 to 15 percent of ethanol, 4 to 8 percent of emulsifying agent NP-10, 5 to 8 percent of emulsifying agent TW-80, 0.2 to 0.8 percent of oleic acid triamide alcohol, 1 to 4 percent of coconut oil alkyl alcohol amide phosphate, 1 to 4 percent of antifoaming agent, 0.5 to 2.5 percent of sodium phosphate, 1 to 3 percent of sodium citrate, 0.3 to 1.2 percent of cysteine LBGAS, 0.35 to 1 percent of potassium hydroxide, and the balance of water. A method for preparing the metal polishing agent comprises the following steps: putting the prepared metal polishing agent components into a temperature adjustable reaction kettle in turn, heating the components to between 30 and 80 DEG C, and stirring the components for 3 hours under the condition of heat preservation to obtain a finished product. The polishing agent is stable, has strong brightness coverage capability, can increase the brightness of a metal surface, has little decomposed product, has no corrosive gas, and is favorable for environmental protection and body health of workers.

Owner:刘丽

Aerosol cosmetic composition

Provided is an aerosol cosmetic composition containing, in a pressure container, a stock solution containing (A) 0.5 to 10 wt. % of a hair styling polymer, (B) 1 to 25 wt. % of a solvent having at least 2 hydroxy groups, having a molecular weight of 62 or greater but not greater than 1000 and being in the liquid form at 30° C., (C) 0.1 to 20 wt. % of a nonionic surfactant having an HLB of from 2.8 to 20 and being in the liquid form at 30° C. and / or N-acetyl ethanolamide, and (D) ethanol and / or water, and (E) a propellant, a weight ratio of the components (A) / (B) falling within a range of from 0.42 to 2.3. In the aerosol cosmetic composition of the present invention, the stock solution sprayed to the hair forms thereover a tacky film made of fine droplets, and spot-bonds individual hairs without firmly sticking, whereby the hair is able to acquire a soft and light finish and moreover, can be re-styled.

Owner:KAO CORP

Method for preparing compounded collecting agent of vegetable fatty acid diethanolamide ester soap

The invention relates to a method for preparing a compounded collecting agent of vegetable fatty acid diethanolamide ester soap. The method comprises the following steps of: 1) performing amide esterification reaction on fatty acid with an iodine value of 85 to 135 and diethanolamine, performing saponification reaction on an obtained reaction product and 30 mass percent of sodium hydroxide solution, and thus obtaining fatty acid diethanolamine and a fatty acid soap mixture thereof; 2) performing the saponification reaction on raw materials such as the fatty acid with the iodine value of 120 to 135 and sodium hydroxide or sodium carbonate, and thus obtaining fatty acid soap; and 3) mixing the fatty acid diethanolamine and the fatty acid soap mixture thereof obtained in the step 1) with the fatty acid soap obtained in the step 2) to obtain fatty acid diethanolamide ester soap, compounding a surfactant into the fatty acid diethanolamide ester soap, and thus obtaining the compounded collecting agent of the vegetable fatty acid diethanolamide ester soap. By adoption of the method, phosphorus selectivity is obviously improved, flotation temperature is reduced, floatation efficiency is high, and the raw materials are easy to purchase and low in cost.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +2

Aerosol cosmetic composition

Provided is an aerosol cosmetic composition containing, in a pressure container, a stock solution containing (A) 0.5 to 10 wt. % of a hair styling polymer, (B) 1 to 25 wt. % of a solvent having at least 2 hydroxy groups, having a molecular weight of 62 or greater but not greater than 1000 and being in the liquid form at 30° C., (C) 0.1 to 20 wt. % of a nonionic surfactant having an HLB of from 2.8 to 20 and being in the liquid form at 30° C. and / or N-acetyl ethanolamide, and (D) ethanol and / or water, and (B) a propellant, a weight ratio of the components (A) / (B) falling within a range of from 0.42 to 2.3.In the aerosol cosmetic composition of the present invention, hair is able to acquire a soft and light finish and moreover, can be re-styled.

Owner:KAO CORP

Synthesis method of fatty acid monoethanal acid amide

InactiveCN102093240AHigh purityQuality improvementOrganic compound preparationTransportation and packagingSynthesis methodsDecomposition

The invention discloses a synthesis method of fatty acid monoethanal acid amide. In the method, fatty acid and monoethanal amide are used as raw materials, wherein the molar ratio of the fatty acid to the monoethanal amide is 1:(1.05-1.30). The method is characterized by comprising the following steps of: (A) amidation reaction: slowly dripping monoethanol amine which is 44-77 percent of the total quantity of the raw materials to fatty acid under nitrogen environment for reacting at 130-160 DEG C; sampling, measuring the acid value, and stopping reacting when the acid value is smaller than 2 (mgKOH / g) to generate amide ester; and (B) amine decomposition reaction of the amide ester: adding residual monoethanol amine to the amide ester obtained in the step (A), and reacting for 1-3 hours at 70-90 DEG C in the presence of a potassium hydroxide catalyst to obtain the fatty acid monoethanal acid amide. Compared with the prior art, the method disclosed by the invention has the characteristics of high purity of the prepared product, stable product quality, and the like and the advantages of environmental friendliness and simple process.

Owner:ZHEJIANG HUANGMA TECH

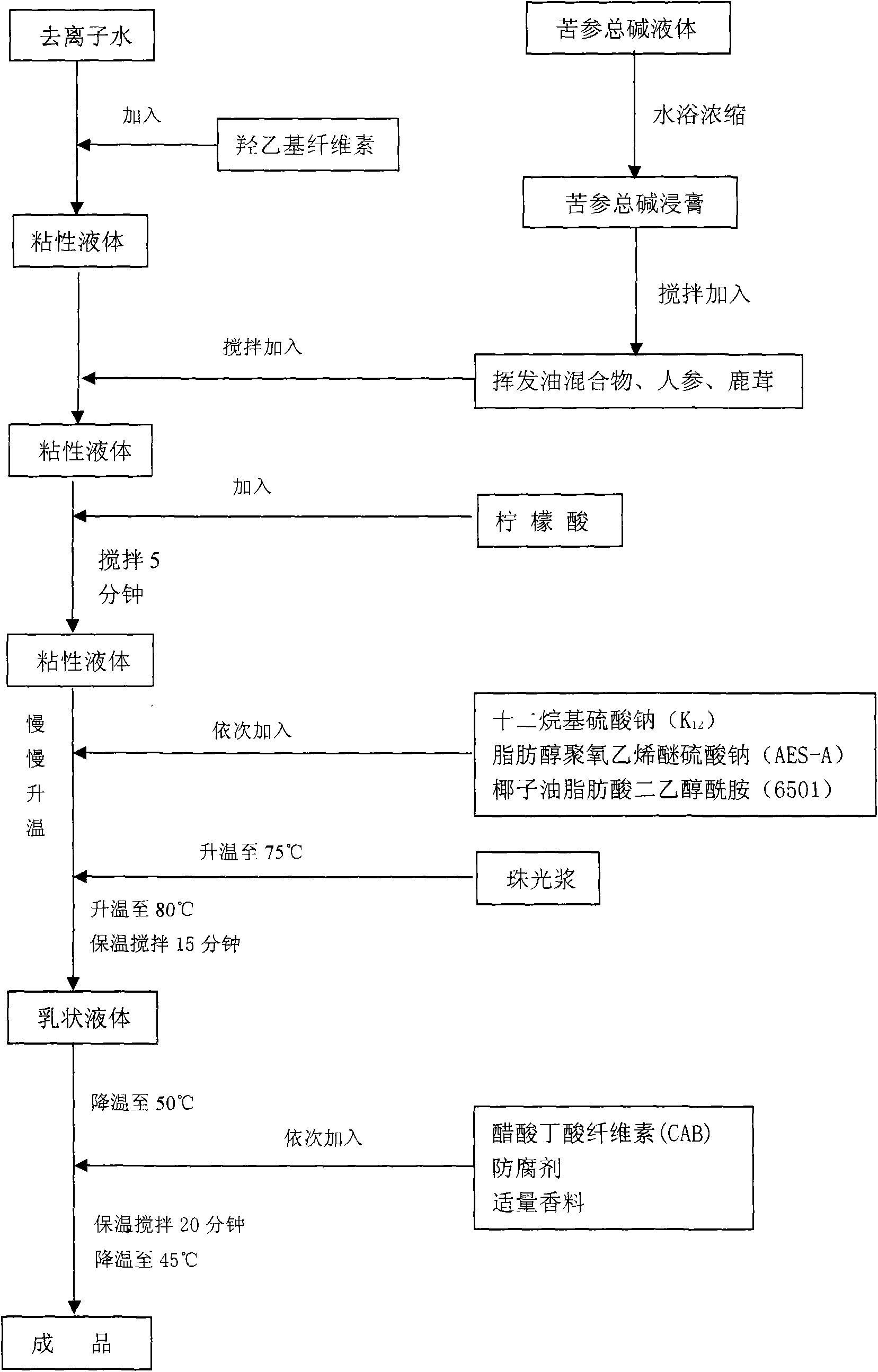

Production method of sophora alopecuroide bacteriostatic bath foam

ActiveCN101658480AEnhanced inhibitory effectIncrease drynessCosmetic preparationsToilet preparationsIrritationDissolution

The invention discloses a production method of sophora alopecuroide bacteriostatic bath foam. The main technique processes comprise: extracting cartialgenous with ethanol; extracting ginseng with distilled water; extracting essential oil from clove and angelica sinensis with distilled water; mixing the essential oil and extracted liquid medicine, adding total matrines extractum to make liquid traditional Chinese medicine, putting de-ionized water in a reaction vessel, adding hydroxyethyl cellulose, stirring evenly, adding mixed liquid traditional Chinese medicine, heating and adding dodecyl sodium sulfate, coconut oil fatty acid ethanolamide sulfosuccinates, fatty alcohol-polyoxyethylene ether sodium sulfate and pearly-luster slurry to stir for dissolution, heating to certain temperature,stirring to be dissolved, cooling, adding cellulose acetate butyrate and glycerine for stirring, and obtaining a finished product after passing inspection. The production method extracts essence fromsophora alopecuroide, ginseng, cartialgenous, angelica sinensis and clove, the produced finished product is pure natural plant effective bacteriostatic bath foam which has no irritation to skin, has the functions of invigorating circulation of blood, detoxicating, moistening skin and beautifying, and is a good bath product for effectively activating activity of dormant cells.

Owner:内蒙古永业生物技术有限责任公司

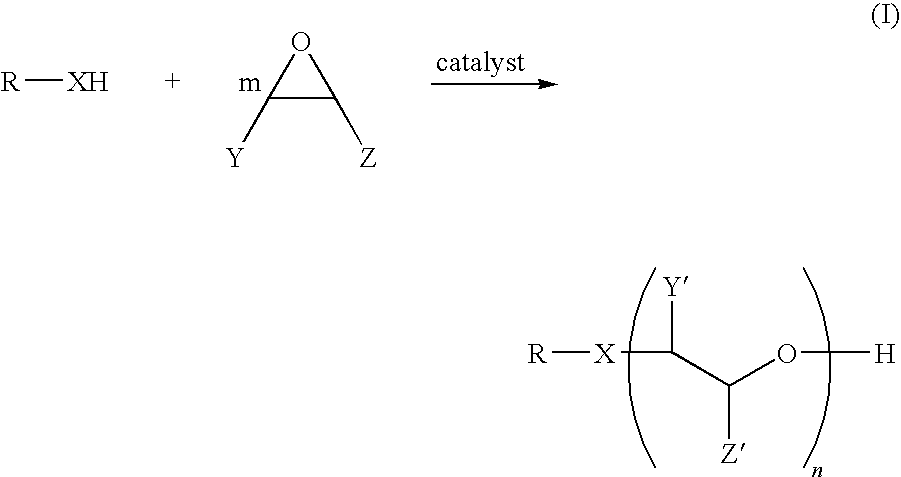

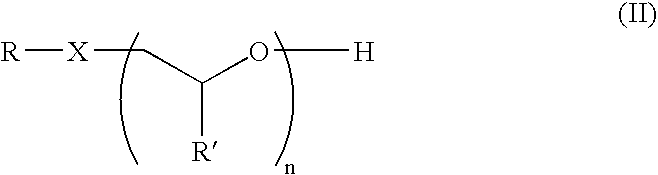

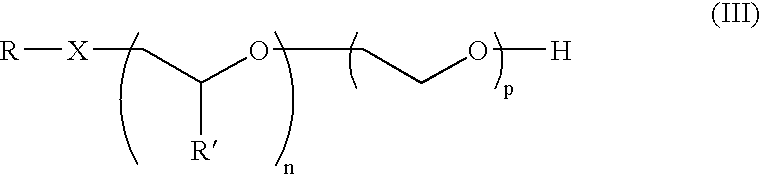

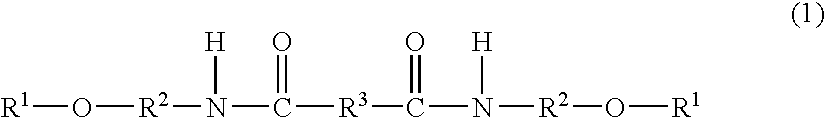

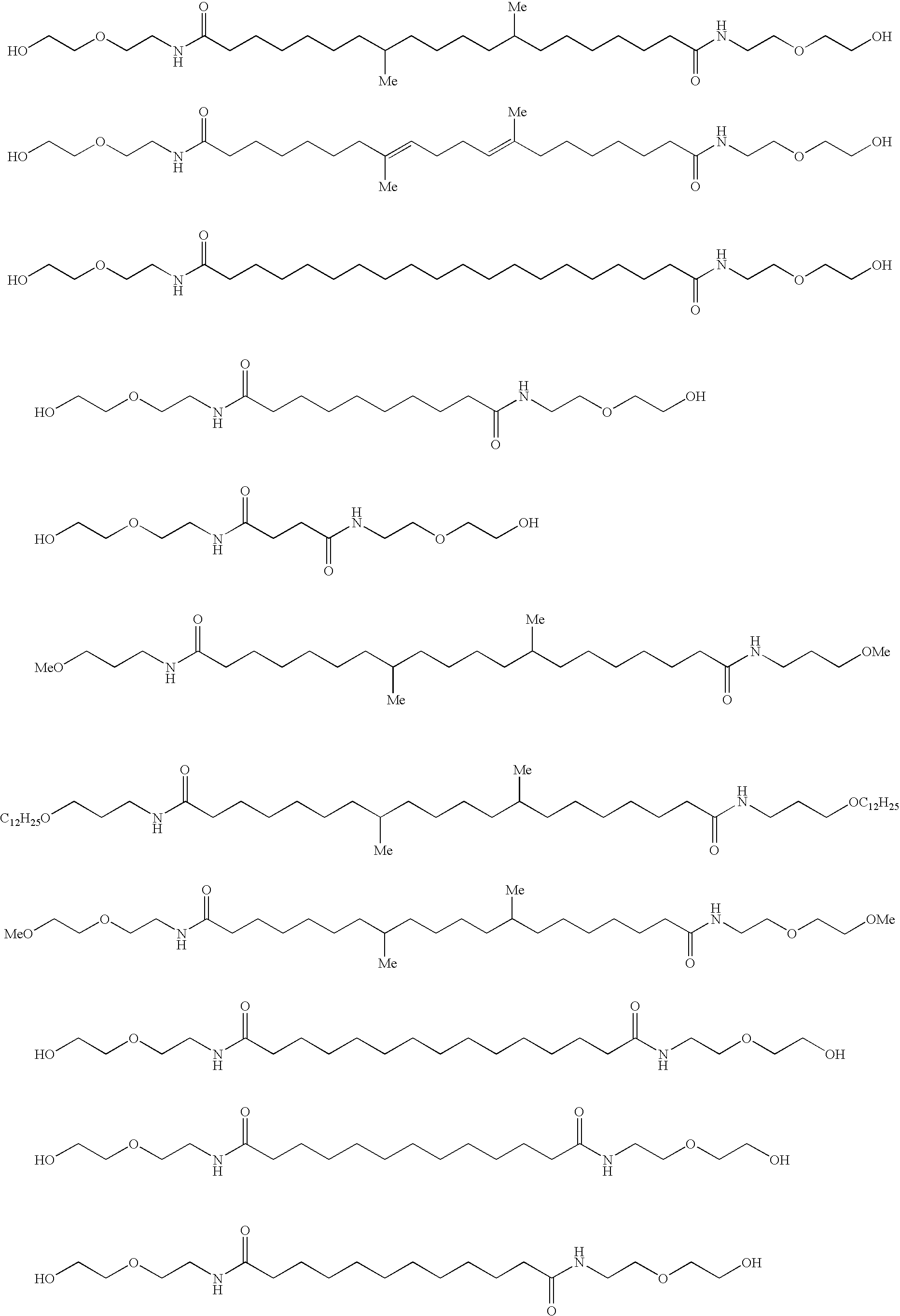

Alkoxylate composition and a process for preparing the same

InactiveUS20090057608A1Oxygen-containing compound preparationOrganic compound preparationCyanideHydrogen

A process for the preparation of an alkoxylate composition, said process comprising the steps of: (a) introducing into a reactor system one or more compounds with one or more active hydrogen atoms, selected from the group comprising alkanoic acids, alkanoic amides, alkanoic ethanolamides, alcohols and alkylmercaptans, and a double metal cyanide catalyst; (b) contacting the one or more compounds with one or more active hydrogen atoms and the double metal cyanide catalyst with propylene oxide and / or butylene oxide to form a first product mixture comprising double metal cyanide catalyst and compounds formed by the addition of one of more propylene oxide and / or butylene oxide units to the one or more compounds with one or more active hydrogen atoms; and (c) contacting the first product mixture with ethylene oxide to form a second product mixture comprising compounds formed by the addition of one of more ethylene oxide units to the compounds formed in step (b).

Owner:SHELL OIL CO

Methods, compounds, and compositions for reducing body fat and modulating fatty acid metabolism

Methods, pharmaceutical compositions, and compounds for reducing body weight, modulating body lipid metabolism, and reducing food intake in mammals are provided. The compounds of the invention include fatty acid ethanolamide compounds, homologues and analogs of which the prototype is the endogenous fatty acid ethanolamide, oleoylethanolamide.

Owner:RGT UNIV OF CALIFORNIA

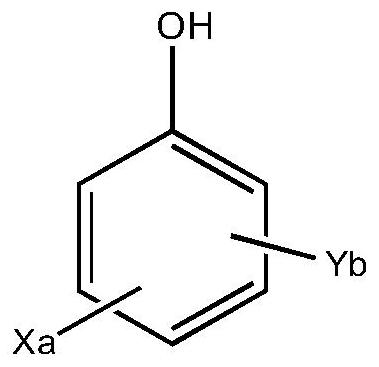

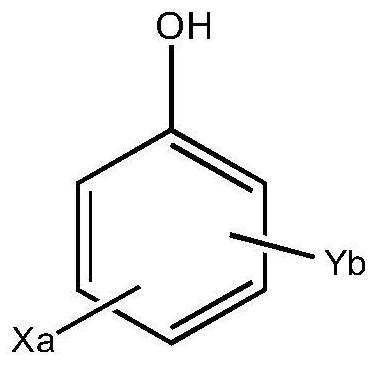

Antimicrobial softener composition

ActiveCN112227071AImprove deposition efficiencySignificant and long-lasting antimicrobial effectBiochemical fibre treatmentGrip property fibresBiotechnologyPolyester

The invention relates to the field of detergents, and discloses an antimicrobial softener composition. The antimicrobial softener composition comprises 0.1%-5% of polyester polyether polymers, 0.01%-5% of an antimicrobial agent with a halogenated phenol structure, 1%-10% of a cationic surfactant, 0.1%-5% of emulsifier, 0.1%-5% of a thickener, a pH regulator and a solvent. The pH value of a 1% deionized water solution of the antimicrobial softener composition is 3.0-6.0. The polyester polyether polymers are introduced into the antimicrobial softener composition so that the deposition efficiencyof the antimicrobial agent on fabric can be improved. It is found that any one of urea, amine oxide and fatty acid ethanolamide is added into the composition, the deposition efficiency of the antimicrobial agent can be further improved, finally, the fabric has a remarkable and lasting antimicrobial effect, the addition amount of the antimicrobial agent can be reduced on the basis that the excellent antimicrobial and bacteriostatic effects are kept, and the product cost is reduced.

Owner:NICE ZHEJIANG TECH CO LTD +1

Hair cosmetic composition

Provided is a hair cosmetic composition containing (A) from 0.001 to 10 wt. % of an amphipathic amide lipid, and (B): from 0.05 to 10 wt. % of a dialkyl ether or ethylene glycol dialkyl ether with an alkyl group having from 18 to 22 carbon atoms, or an ethylene glycol monofatty acid ester, ethylene glycol difatty acid ester, fatty acid monoethanolamide or acylated beta-alanine with an acyl group having from 18 to 22 carbon atoms. The hair cosmetic composition of the present invention for example, protects the hair from physical or chemical stimulation, prevents appearance of split ends and broken hair, imparts natural smoothness, moist feeling, resilience and strength, and moisture retention property to the hair after treatment (shampooing), and at the same time has excellent storage stability.

Owner:KAO CORP

Workshop floor cleaner

InactiveCN104845748AEasy to cleanShort cleaning timeNon-ionic surface-active compoundsDetergent compounding agentsVegetable oilCleansing Agents

Disclosed is a workshop floor cleaner. Raw materials of the cleaner include, by weight: 2.4 to 3.2 parts of benzene sulfonate, 2.5 to 6.5 parts of polyacrylamide, 1.3 to 4.2 parts of amido-sulfonic acid, 2 to 5 parts of sodium silicate, 2.5 to 3.2 parts of potassium chloride, 4.5 to 7.5 parts of aspartic acid, 2 to 3.5 parts of cleaning aids, 2.6 to 4.5 parts of fatty acid diethanolamide, 0.5 to 1.2 part of dehydroascorbate, 0.8 to 1.4 part of tertiary butylhydroquinone, 2.5 to 4.5 parts of naphthenic acid, 4.5 to 6 parts of triethylene glycol alkyl ether, 2 to 5 parts of benzotriazole, 0.2 to 1.5 part of molybdate and 8 to 14 parts of hydroxyethylidene diphosphonic acid. The workshop floor cleaner has the advantages that the cleaning effect of mineral oil, vegetable oil and mixed oil is fine, cleaning time is short, and labor force and working time are saved.

Owner:QINGDAO DONGCHANGRUI TEXTILE

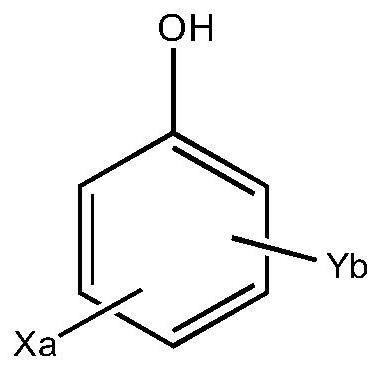

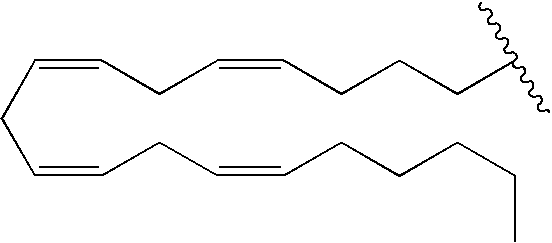

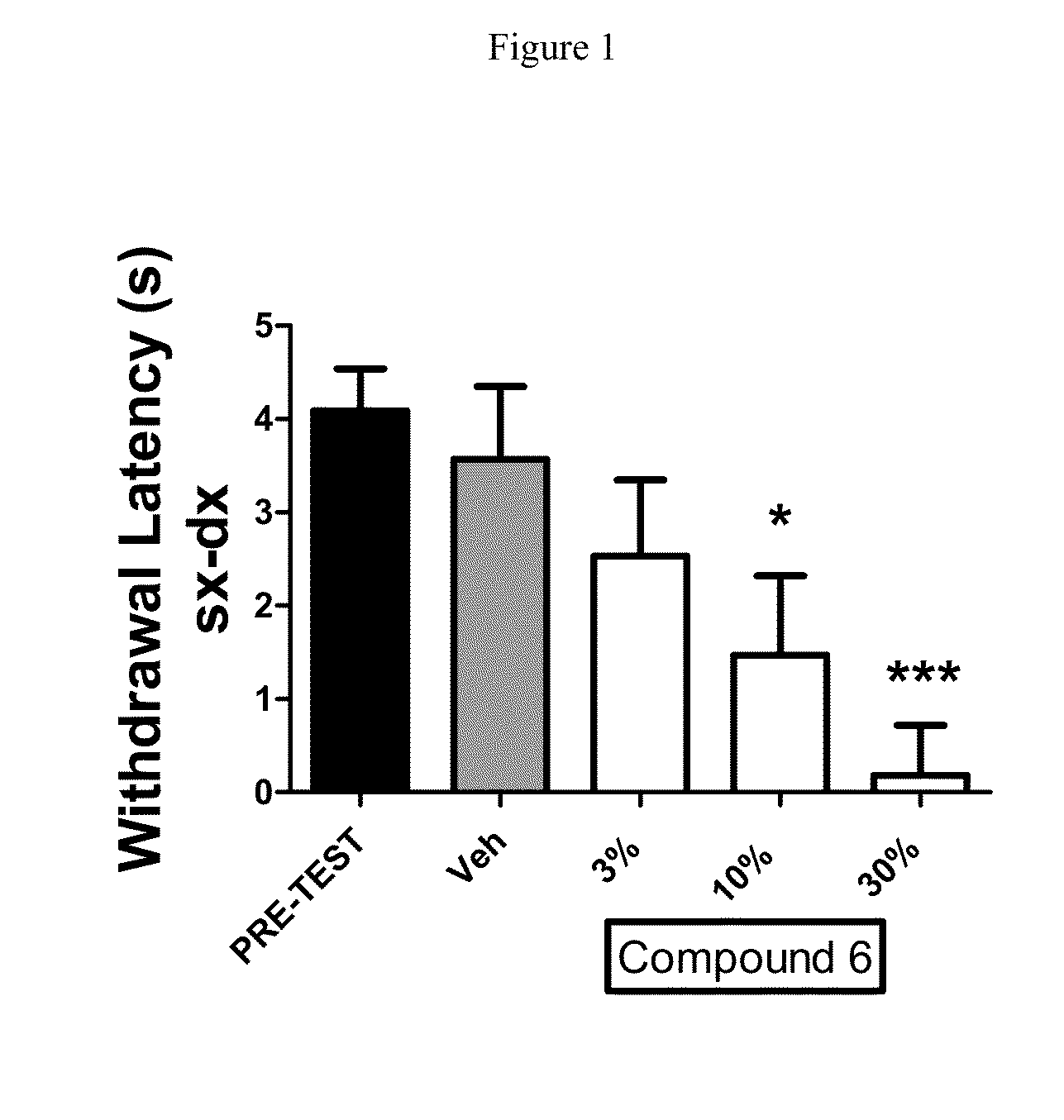

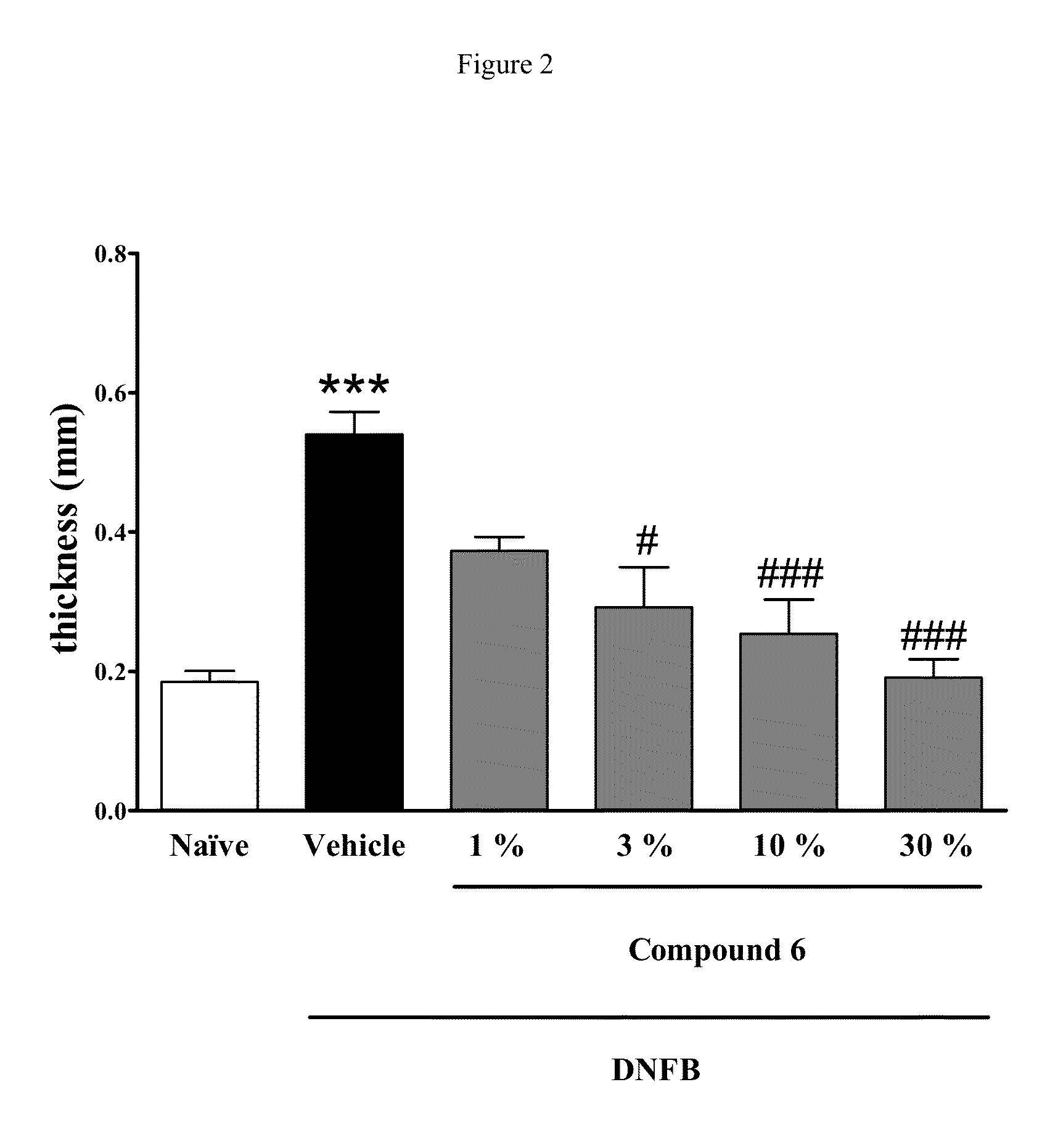

Cannabimimetic lipid amides as useful medications

InactiveUS7161016B1High affinityHigh selectivityFatty acid chemical modificationOrganic compound preparationCancer and nauseaMetabolic stability

Novel analogs of arachidonylethanolamide are presented which have higher affinities for the cannabinoid CB1 and / or CB2 receptor sites. Further, most of the analogs exhibit greater metabolic stability than arachidonylethanolamide. The improved receptor affinity and selectivity and / or greater metabolic stability make these analogs therapeutically useful as medications for relief of pain caused by cancer and nausea caused by chemotherapy, as well as for peripheral pain. The compounds may also be useful as oral and topical contraceptives, in suppression of the immune system, enhancement of appetite and in treatment of psychomotor disorders, multiple sclerosis and hypertension.

Owner:UNIV OF CONNECTICUT

Lubricating oil antifriction additive and preparation method thereof

The invention belongs to the field of lubricating oil and in particular relates to a lubricating oil antifriction additive and a preparation method thereof, wherein the lubricating oil antifriction additive comprises an antifriction agent, a clean dispersing agent and an antioxidant preservative. The preparation method of the lubricating oil antifriction additive comprises the following steps: evenly mixing diglycolamide oleate borate, dibutyl phosphite and cyclohexyloxy cupric borate in advance at normal temperature and normal pressure to prepare the antifriction agent for later use; evenly mixing amine polybutylene, polyisobutylene carbamate and diaminopyridin to prepare the clean dispersing agent for later use; and adding the clean dispersing agent into the antifriction agent, and then adding the preservative boride butadiene imide, and quickly stirring to prepare the lubricating oil antifriction additive. The preparation method is simple and easy to operate; and the additive is good in antifriction effect, long in service life, small in adding amount in the lubricating oil and economical.

Owner:JINAN DEV ZONE XINGHUO SCI & TECH RES INST

Damage-free detergent for metal equipment

The invention discloses a damage-free detergent for metal equipment, which is prepared from the following raw materials in parts by weight: 4.3-6.2 parts of coconut oil monoethanolamide, 5.1-7.3 parts of polymaliec acid anhydride, 3.4-5.3 parts of tetrasodium ethylenediamine tetraacetate, 4.4-7.5 parts of 2-carboxyethylphosphonic acid, 7.3-10.4 parts of alkylphenol polyoxyethylene, 2.3-4.2 parts of surfactant and 3.7-5.4 parts of ethanolamine-triethanolamine mixture. The detergent has the cleaning effects of high economy and high efficiency, belongs to a concentrated product, and can be used after being diluted to a low concentration; all the components are combined effectively to generate an excellent synergic enhancement effect, so the detergent has favorable oil removal and antirust effects, and the average cleaning cost is low; the detergent has high safety performance, and does not pollute the environment; the detergent has the advantages of energy saving and low cleaning cost; and the detergent does not damage the metal equipment in the cleaning process, and does not corrode the metal equipment after cleaning.

Owner:QINGDAO HUIERTONG TRADING

An extract

InactiveCN101641089AIncrease contentGood for joint flexibilityNervous disorderAntipyreticMusselFatty acid amide

The invention relates to compositions that include an oil extract rich in fatty acid amide compounds including N-acylethanolamine (NAE) compounds such as N-palmitoylethanolamide (PEA) and N-arachidonoylethanolamide (AEA). The composition may be derived from marine materials including mussel meat.

Owner:SEPEREX NUTRITIONALS

Concrete block and manufacturing method thereof

The invention provides a concrete block and a manufacturing method thereof. The manufacturing method comprises the following steps: selecting waste asphalt, crushing the waste asphalt into particles of 5-15 mm, performing washing with water and sun-curing on the waste asphalt, and then soaking the waste asphalt in a pretreatment solution. According to the manufacturing method provided by the invention, coconut diethanolamide, n-octyl alcohol and behenyl palmitate are used as main active ingredients, so that the defoaming efficiency of the concrete block is reduced sufficiently and brought into full play sufficiently; and with the use of span-80, the permeation of defoaming components in a foam liquid membrane can be well promoted, thereby destroying stability of the foam liquid membrane, and improving the defoaming rate.

Owner:浙江万寿建筑工业科技有限公司

Methods, compounds, and compositions for reducing body fat and modulating fatty acid metabolism

Methods, pharmaceutical compositions, and compounds for reducing body weight, modulating body lipid metabolism, and reducing food intake in mammals are provided. The compounds of the invention include fatty acid ethanolamide compounds, homologues and analogs of which the prototype is the endogenous fatty acid ethanolamide, oleoylethanolamide.

Owner:RGT UNIV OF CALIFORNIA

Synthetic cutting fluid

InactiveCN104789343AEasy to cleanImprove the lubrication effectLubricant compositionBenzoic acidEpoxy

The invention relates to a synthetic cutting fluid which is prepared from the following raw materials in parts by weight: 3.2-4.5 parts of nonionic surfactant, 2.1-3.2 parts of benzotriazole, 7-8 parts of coconut oil acetal amide, 4-8 parts of sodium chloride, 3-7 parts of epoxy resin, 4.2-5.6 parts of polyacrylamide, 6-12 parts of polymer latex, 8-14 parts of paranitrobenzoic acid, 6-9 parts of imidazolidinyl urea, 6-11 parts of mixed alkylol amine, 4-6 parts of sodium molybdate, 5-8 parts of Tween, 8-10 parts of fatty alcohol polyethenoxy ether, 4-6 parts of sodium salicylate and 20-26 parts of deionized water. The synthetic cutting fluid has improved cleaning and lubricating effects, can form a protective film on the metal surface, and reduces the abrasion.

Owner:QINGDAO DEXITUOCHUANG HIGH TECH CO LTD

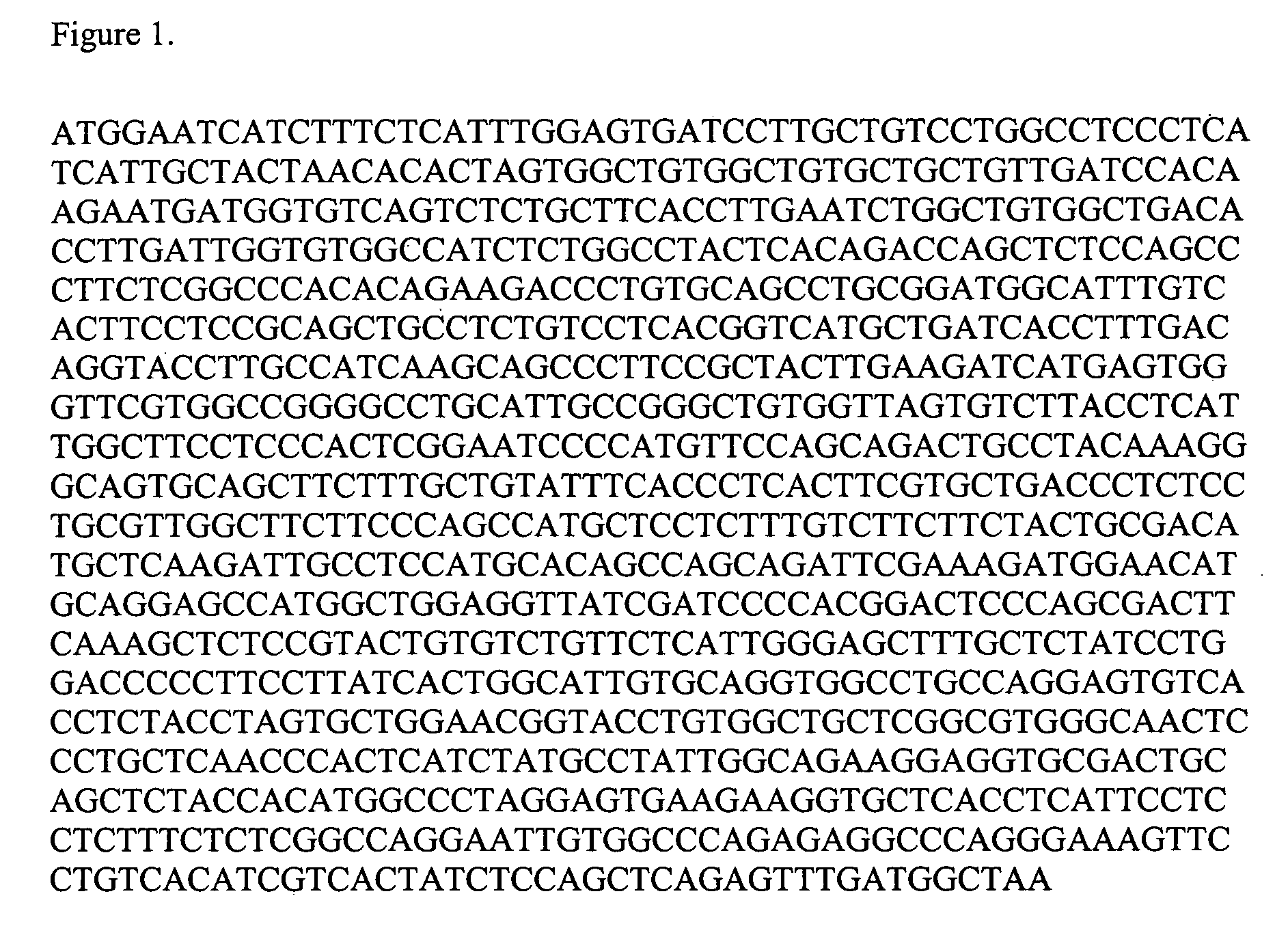

Methods for identification of modulators of OSGPR116 activity, and their use in the treatment of disease

This invention relates to the identification of fatty acid or lipid amides that decrease food intake in mammals, including fatty acid ethanolamides, as ligands for the G-protein coupled receptor OSGPR116, and describes the first demonstration of a specific G-protein coupled receptor that is activated by fatty acid ethanolamides that inhibit feeding. The invention is directed to new methods for screening candidate drugs for their ability to modulate the activity of OSGPR116, and new pharmaceutical agents identified by these methods. It is also directed to the use of such agents in the manufacture of medicaments for the treatment of OSGPR116 mediated diseases, and methods of treating diseases such as obesity and diabetes by administering to an individual a therapeutic amount of a modulator of OSGPR116 identified by these methods.

Owner:GRIFFIN GRAEME

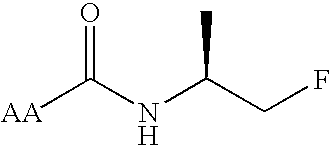

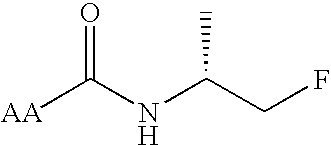

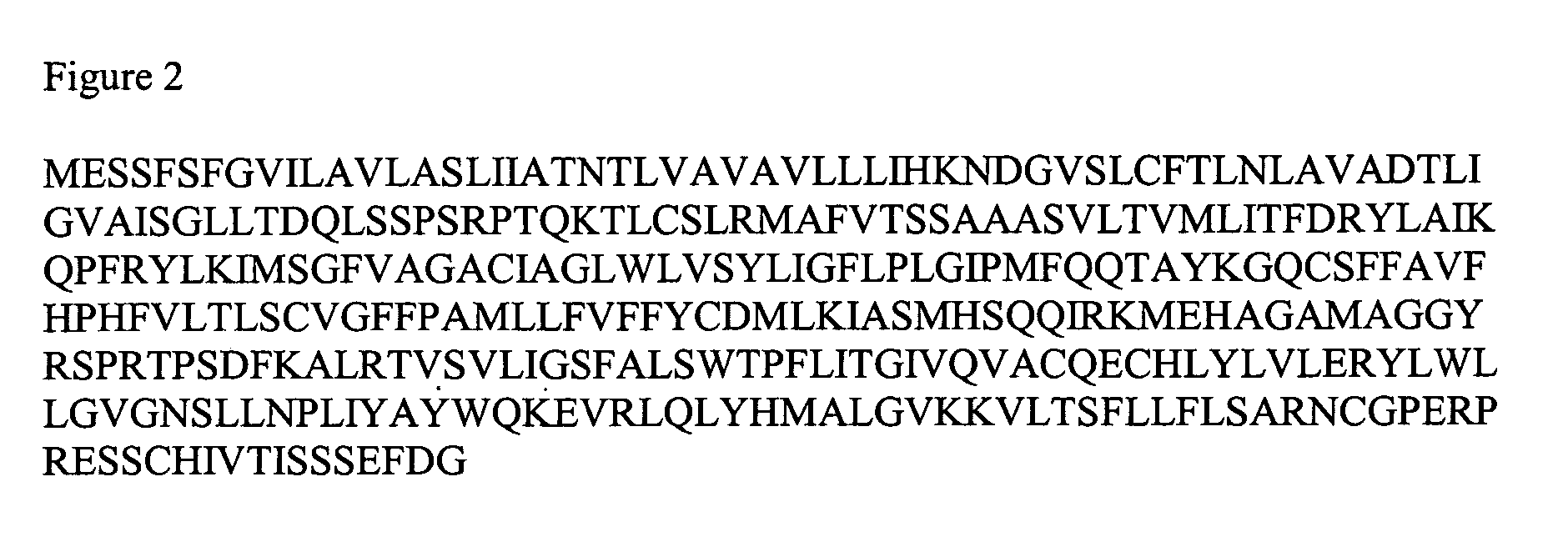

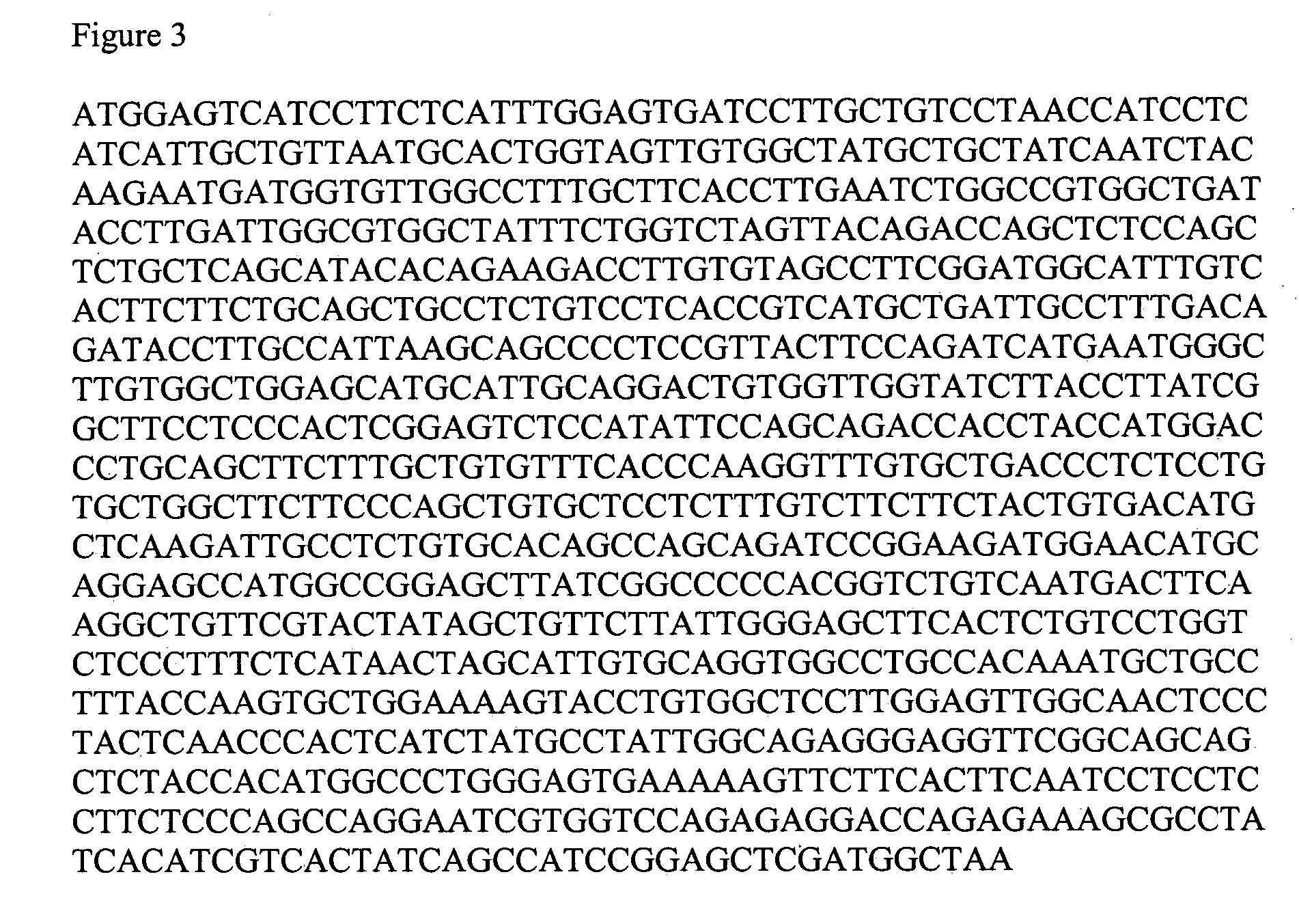

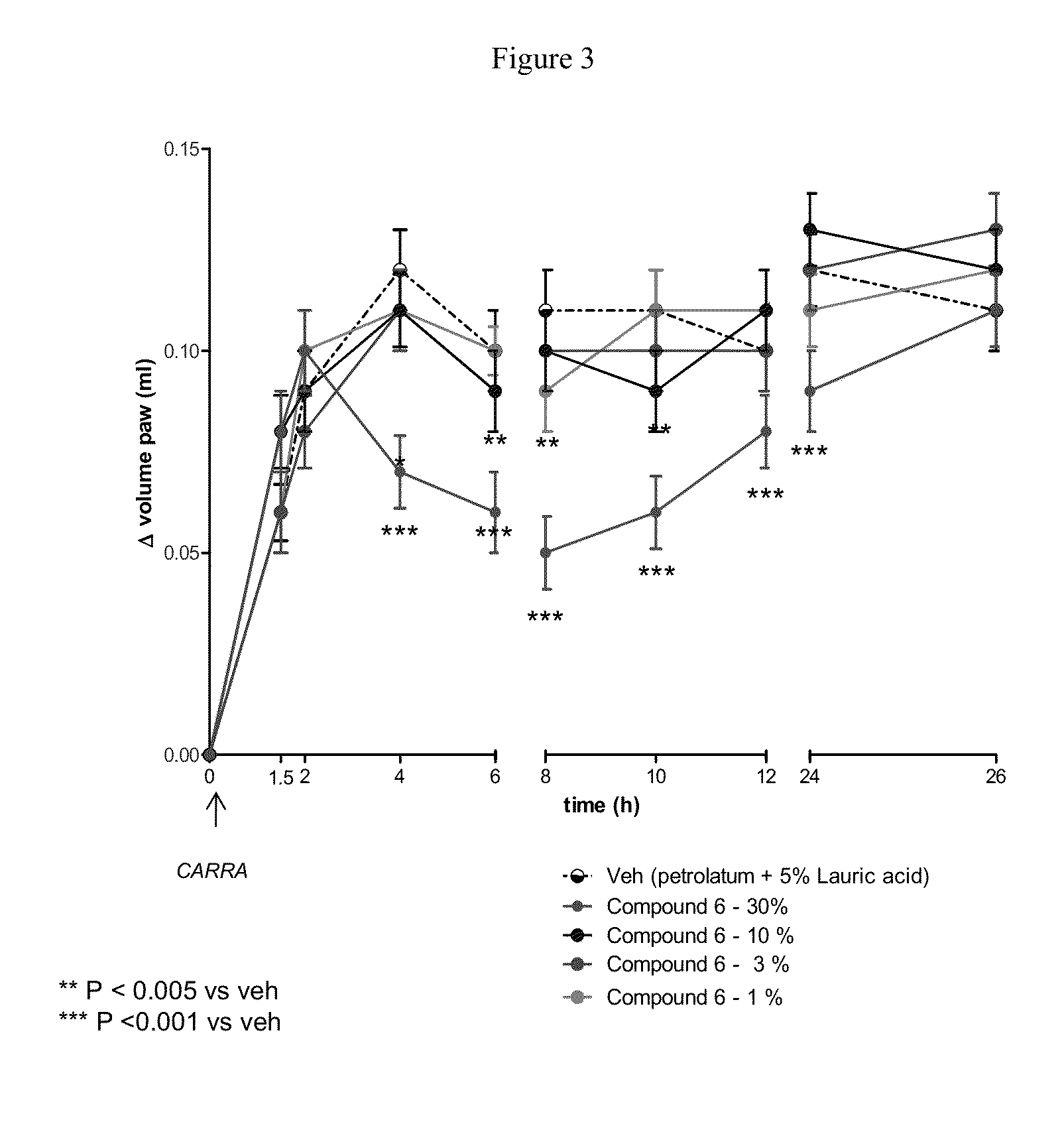

Disubstituted beta-lactones as inhibitors of N-acylethanolamine acid amidase (NAAA)

The present invention provides compounds and pharmaceutical compositions for inhibiting N-acylethanolamine acid amidase (NAAA). Inhibition of NAAA is contemplated as a method to sustain the levels of palmitoylethanolamide (PEA) and oleylethanolamide (OEA), two substrates of NAAA, in conditions characterized by reduced concentrations of PEA and OEA. The invention also provides methods for treating inflammatory diseases and pain, and other disorders in which decreased levels of PEA and OEA are associated with the disorder.

Owner:FOND INST ITAL DI TECH +2

Improved fatty acid monoethanolamide synthesis method

ActiveCN107188816AHigh yieldMild reaction conditionsOrganic compound preparationCarboxylic acid amides preparationPtru catalystFluid phase

The invention relates to an improved fatty acid monoethanolamide synthesis method, which comprises: 1) preparing a polystyrene resin containing a carboxyl activating agent; 2) carrying out a condensation reaction on the polystyrene resin obtained in the step (1) and fatty acid in the presence of a catalyst to obtain an immobilized active ester; and (3) in the presence of a solvent, carrying out a reaction on the immobilized active ester obtained in the step 2) and ethanolamine, carrying out simple filtration or centrifugation to remove the resin after completing the reaction, carrying out pressure reducing concentration on the obtained liquid phase, and carrying out vacuum drying to obtain the high-quality fatty acid monoethanolamide product. According to the present invention, the condensation reaction is performed under the normal temperature condition, the generation of the by-product is substantially reduced through the selection of the catalyst and the reaction parameters, and the yield of the reaction and the purity of the product are maximized; and with the synthesis method, the defects of more by-products, difficult purification and the like caused by unstable raw material, poor selectivity to ethanolamine and alkali high temperature condition in the prior art are overcome.

Owner:上海欧睿生物科技有限公司

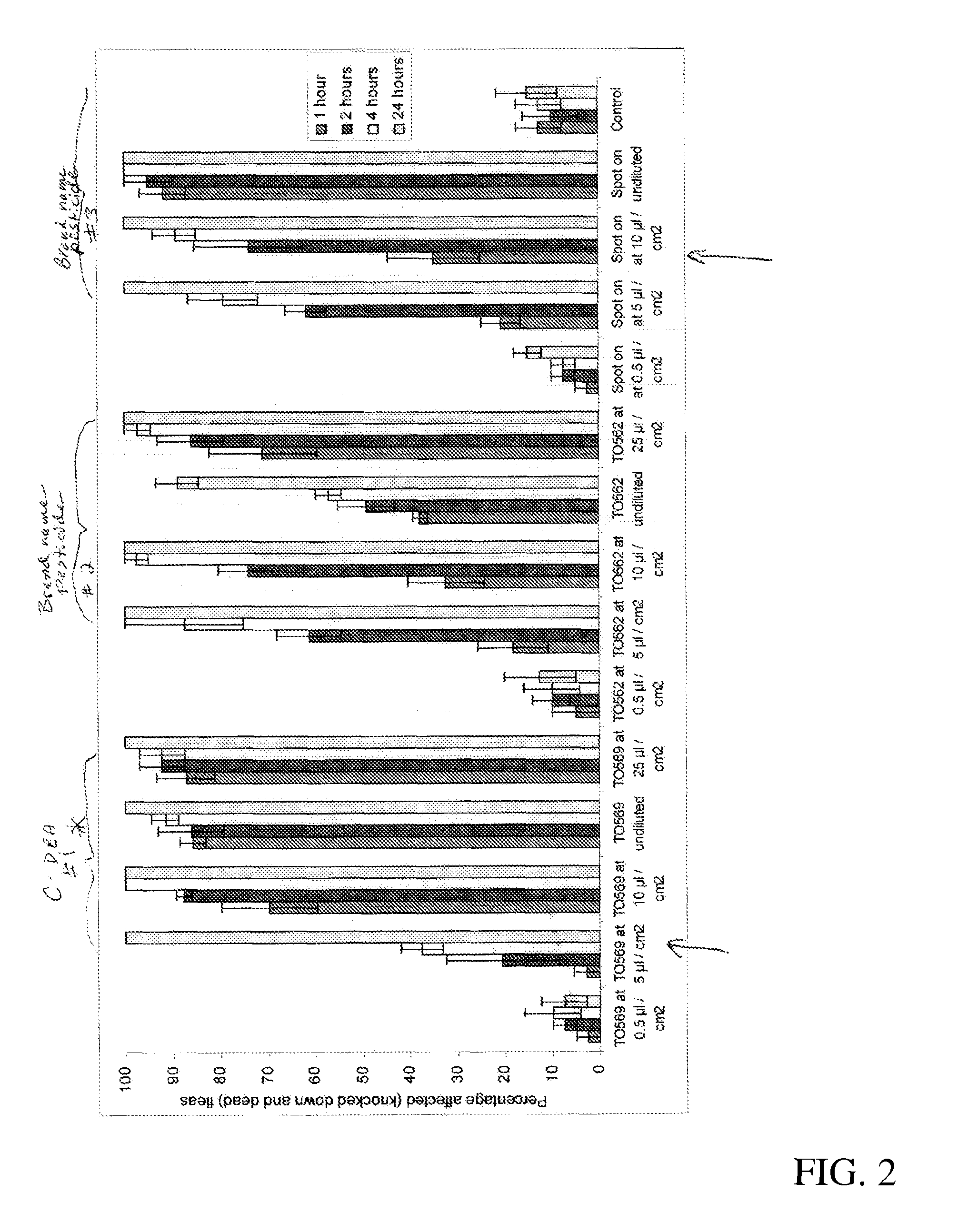

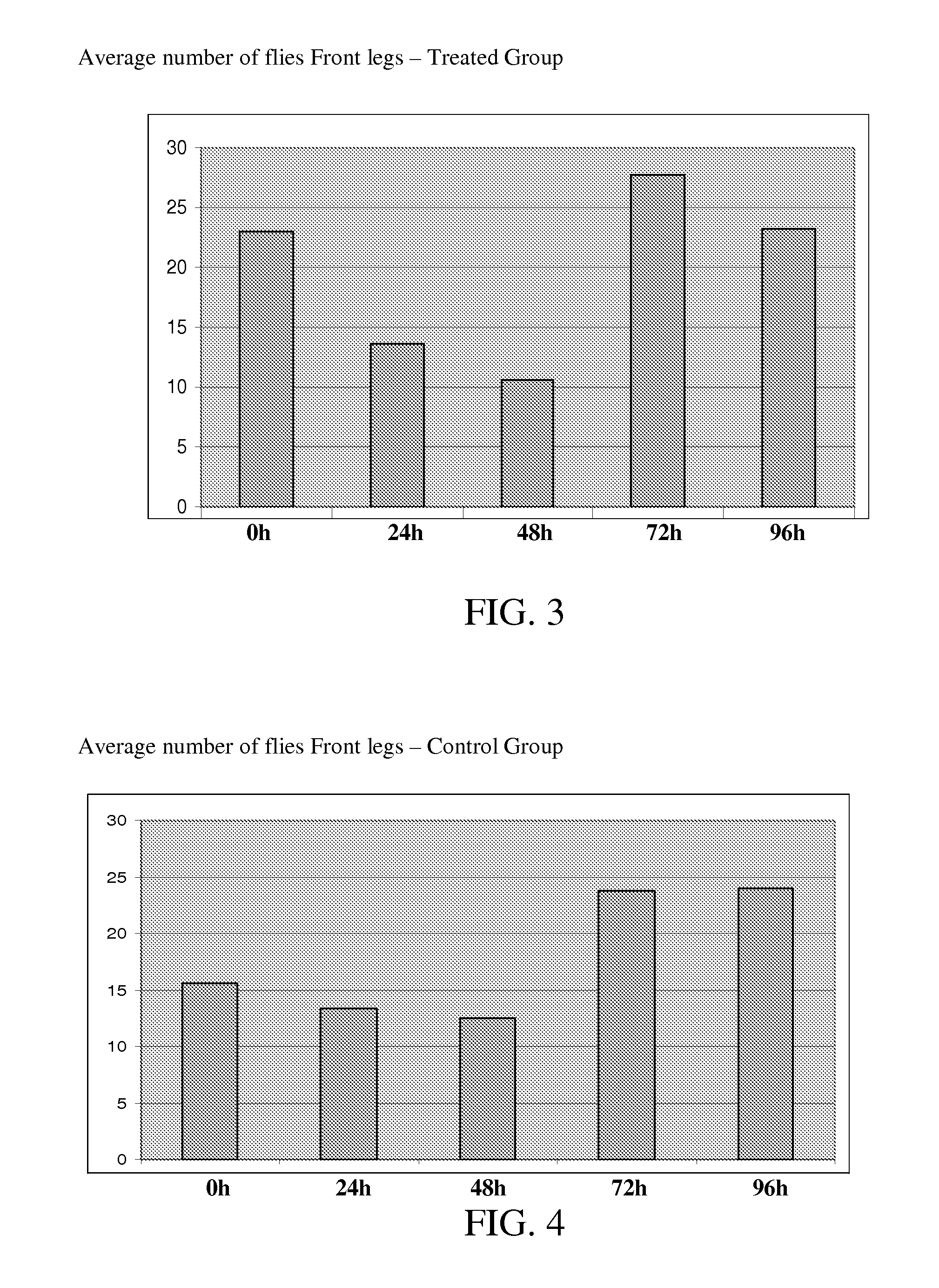

Compositions for internal and external insecticides, ovicides, repellents and wound healing

Exemplary embodiments of the present invention relate to pesticides, insecticides, insect repellant, insect anti-feeding, cleaning, glue dissolving and anti-irritation and wound healing compositions for humans and animals and, more particularly, to such compositions which are effective in killing, removing and / or repelling a wide range of endoparasites, ectoparasites and insects while also being non-toxic to humans, animals, and the environment. An exemplary embodiment of the present invention is directed to an aqueous composition including a mixture of at least one ethanolamide and at least one esterified fatty acid. Another exemplary embodiment of the present invention is directed to an aqueous composition including at least one esterified fatty acid in water and at least one emulsifier. The aqueous compositions may be used as a cleaning composition, insecticide, insect repellant, glue solvent or to relieve irritation from and / or promote healing of insect bites, skin abrasions superficial burns and wounds.

Owner:NATUREZA

Facial cleanser with N-lauroyl-L-alanine sodium salt or potassium salt as surfactant

ActiveCN103126926AImprove decontamination abilityStrong decontaminationCosmetic preparationsToilet preparationsBetainePotassium

The invention discloses a facial cleanser with N-lauroyl-L-alanine sodium salt or potassium salt as a surfactant, which comprises the following components by mass: 10%-20% of N-lauroyl-L-alanine sodium salt or potassium salt; 5.0%-6.0% of cocoamidopropyl betaine; 4.0%-5.0% of disodium lauroyl ether sulfosuccinate; 6.0%-8.0% of lauryl acetate sodium sulfonate; 2.0%-3.0% of coconutt diethanol amide; 0.1%-0.2% of polyquaternium; 3.0%-5.0% of propylene glycol; 1.0%-2.0% of emulsified silicone oil; 0.2%-0.5% of urea formaldehyde; 50%-60% of deionized water; 0.1%-0.5% of essence; and the balance of citric acid. The invention has the following advantages of: strong decontamination capability, very good compatibility, green and environmental protection, less skin irritation, and low cost.

Owner:SUZHOU WEIMEI BIOLOGICAL TECH

Preparation method of oil displacement type water-based fracturing fluid

The invention provides the preparation method of the oil displacement type water-based fracturing fluid, the oil displacement type water-based fracturing fluid has dual effects of fracturing fluid and an oil displacement agent, the problem of adsorbability damage of a conventional cationic VES clean fracturing fluid in the oil and gas reservoir exploitation process is solved, the single well fracturing oil increasing efficiency is improved, and the oil displacement type water-based fracturing fluid has good actual operability. The oil displacement type water-based fracturing fluid is prepared from a nonionic surfactant, an amphoteric surfactant, an anionic surfactant, a chelating agent, inorganic salt, water and a nano material. The nonionic surfactant is one of palm oil diethanolamide or coconut oil diethanolamide; the ampholytic surfactant is one or two of hydroxysulfobetaine or carboxyl betaine; the anionic surfactant is one or two of triethanolamine petroleum sulfonate, dodecylbenzene sulfonic acid or sodium dodecyl sulfate; the chelating agent is sodium ethylene diamine tetracetate; the inorganic salt is potassium chloride or ammonium chloride; and the particle size of the nano material is 10-50nm.

Owner:XI'AN PETROLEUM UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com