Lubricating oil antifriction additive and preparation method thereof

An additive and lubricating oil technology, applied in the field of lubricating oil, to achieve good anti-rust performance, improve operating environment, and good thermal oxidation stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

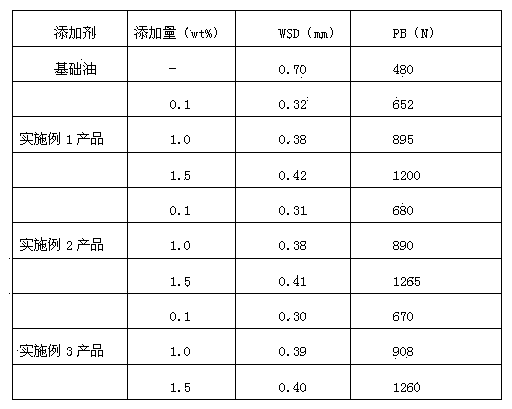

Embodiment 1

[0036] Get the raw material of following parts by weight:

[0037] 5 parts of oleic acid diethanolamide borate;

[0038] 5 parts of di-n-butyl phosphite;

[0039] 5 parts of copper cyclohexyl borate;

[0040] 2 parts of polybutenylamine;

[0041] 5 parts of polyisobutylene urethane;

[0042] 3 parts of diaminopyridine;

[0043] 6 parts of borated succinimide.

[0044] Its preparation process is as follows:

[0045] (1) Under normal temperature and pressure, 5 parts of oleic acid diethanolamide borate, 5 parts of di-n-butyl phosphite and 5 parts of cyclohexyloxycopper borate are uniformly mixed in advance to prepare an anti-wear agent for use; 1 part of polybutene amine, 5 parts of polyisobutylene urethane and 3 parts of diaminopyridine were mixed uniformly to prepare a clean dispersant for future use.

[0046] (2) Add detergent and dispersant to the anti-wear agent, then add 6 parts of boronated succinimide, and stir rapidly (1500r / min) for 10min. The entire preparati...

Embodiment 2

[0054] Get the raw material of following parts by weight:

[0055] 15 parts of acid diethanolamide borate;

[0056] 10 parts of di-n-butyl phosphite;

[0057] 10 parts of copper cyclohexyl borate;

[0058] 6 parts of polybutenylamine;

[0059] 7 parts of polyisobutylene urethane;

[0060] 5 parts of diaminopyridine;

[0061] Borated succinimide 10 parts.

[0062] Its preparation process is as follows:

[0063] (1) Under normal temperature and pressure, 15 parts of oleic acid diethanolamide borate, 10 parts of di-n-butyl phosphite and 10 parts of cyclohexyloxycopper borate are uniformly mixed in advance to prepare an anti-wear agent for use; 1 part of polybutene amine, 7 parts of polyisobutylene urethane and 5 parts of diaminopyridine were mixed uniformly to prepare a clean dispersant for future use.

[0064] (2) Add detergent and dispersant to the antiwear agent, then add 10 parts of boronated succinimide, and stir rapidly (1800r / min) for 20min. The entire preparation...

Embodiment 3

[0071] Get the raw material of following parts by weight:

[0072] 20 parts of acid diethanolamide borate;

[0073] 15 parts of di-n-butyl phosphite;

[0074] 15 parts of copper cyclohexyl borate;

[0075] 10 parts of polybutenylamine;

[0076] 15 parts of polyisobutylene urethane;

[0077] 10 parts of diaminopyridine;

[0078] Borated succinimide 15 parts.

[0079] Its preparation process is as follows:

[0080] (1) Under normal temperature and pressure, 20 parts of oleic acid diethanolamide borate, 15 parts of di-n-butyl phosphite and 15 parts of cyclohexyloxycopper borate are uniformly mixed in advance to prepare an anti-wear agent for use; 1 part of polybutene amine, 15 parts of polyisobutylene urethane and 10 parts of diaminopyridine were mixed uniformly to prepare a clean dispersant for future use.

[0081] (2) Add detergent and dispersant to the anti-wear agent, then add 15 parts of boronated succinimide, and stir rapidly (2000r / min) for 30min. The entire prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com