Preparation method of oil displacement type water-based fracturing fluid

A water-based fracturing and oil displacement technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of low-temperature gel breaking, low porosity, low flowback efficiency, etc., to meet the requirements of fracturing and The effect of dual action of oil displacement, improvement of oil displacement efficiency and improvement of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment relates to a method for preparing oil displacement fracturing fluid, comprising the following steps:

[0041] Step 1: Mix 15g sulfobetaine C18, 5g coconut oil diethanolamide; 5g sodium edetate and 25g water at 50°C, stir for 1 hour and cool to room temperature, called liquid A.

[0042] Step 2: Add 5g of sodium lauryl sulfate; 10g of triethanolamine petroleum sulfonate to 35g of water at 50°C, then add 5g of isopropanol and 0.3g of 20nm silicon dioxide, stir for 3 hours, then cool to room temperature , denoted as liquid B;

[0043] Step 3: Mix liquid A, liquid B with 0.5% ammonium chloride or potassium chloride aqueous solution according to the volume ratio: 5:1.5:50 to obtain oil displacement fracturing fluid.

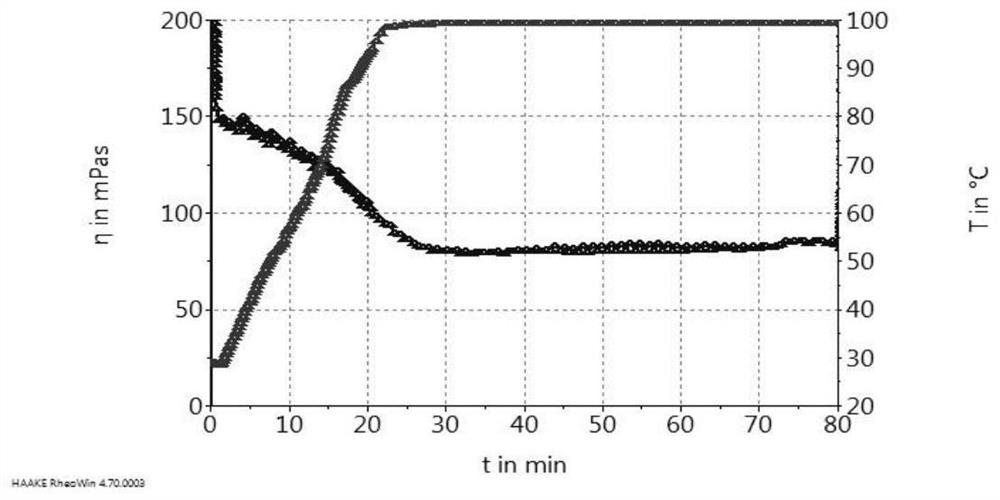

[0044] Performance Testing:

[0045] Test instruments: MARS60 rheometer of German HAAKE company, measuring system is D100 / 200, rotor is P38; spinning drop interfacial tensiometer SITE100 of German KRUSS company; surface tensiometer SIGMA700 of...

Embodiment 2

[0052] This embodiment relates to a method for preparing oil displacement fracturing fluid, comprising the following steps:

[0053]Step 1: Mix 8g of hydroxysultaine C18, 7.0g of carboxysultaine C12, 5g of sodium edetate, and 35g of water at 50°C, stir for 1 hour, then cool to room temperature, and call it liquid A .

[0054] Step 2, at 50°C, add 15g of petroleum sulfonic acid triethanolamine salt into 30g of water, then add 0.25g of 10nm nano-silica, stir for 3h, cool to room temperature, and record as B liquid;

[0055] Step 3: Mix liquid A, liquid B and 0.5% potassium chloride aqueous solution according to the volume ratio: 5:1.5:50 to obtain oil displacement fracturing fluid.

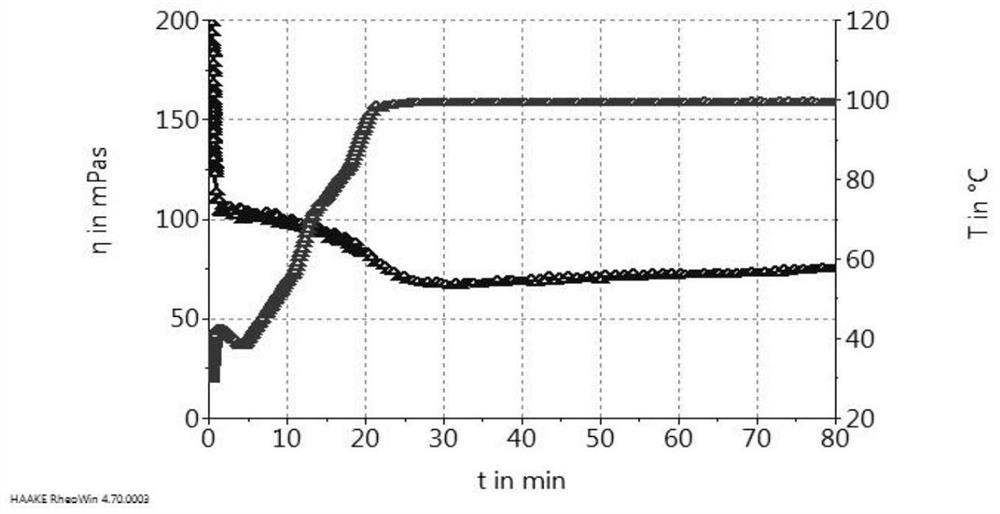

[0056] Performance Testing:

[0057] Test instruments: MARS60 rheometer of German HAAKE company, measuring system is D100 / 200, rotor is P38; spinning drop interfacial tensiometer SITE100 of German KRUSS company; surface tensiometer SIGMA700 of Swiss company Bioling;

[0058] Test temperature: fra...

Embodiment 3

[0064] This embodiment relates to a method for preparing oil displacement fracturing fluid, comprising the following steps:

[0065] Step 1: Mix 13g of sulfobetaine C18, 2g of palm oil diethanolamide; 5g of sodium edetate and 35g of water at 50°C, stir for 1 hour, then cool to room temperature, and call it A solution.

[0066] Step 2, at 50°C, add 2g of sodium dodecylsulfate; 13g of sodium dodecylbenzenesulfonate into 30g of water, then add 0.25g of 20nm silicon dioxide, stir for 3h, then cool to room temperature, Recorded as liquid B;

[0067] Step 3: Mix liquid A, liquid B with 0.5% ammonium chloride or potassium chloride aqueous solution according to the volume ratio: 5:1.5:50 to obtain oil displacement fracturing fluid.

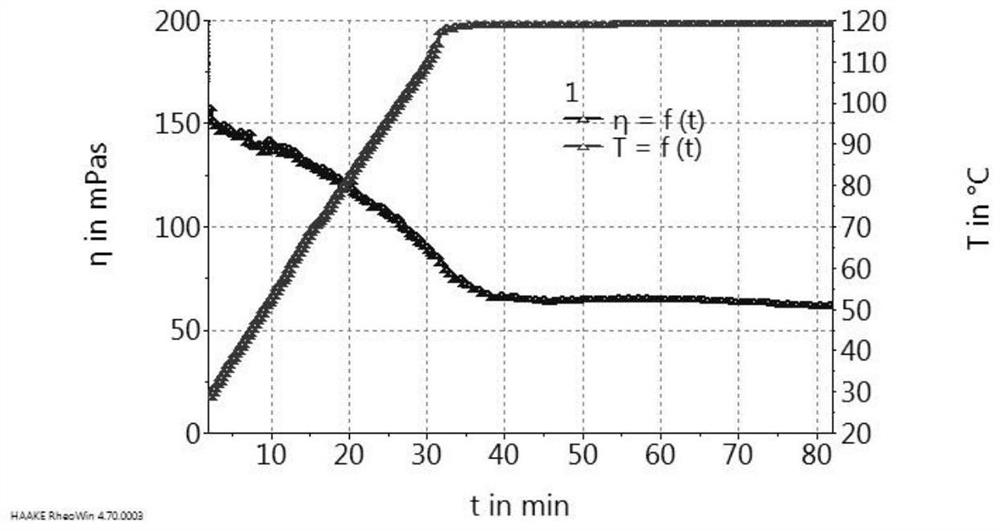

[0068] Performance Testing:

[0069] Test instruments: MARS60 rheometer of German HAAKE company, measuring system is D100 / 200, rotor is P38; spinning drop interfacial tensiometer SITE100 of German KRUSS company; surface tensiometer SIGMA700 of Swiss com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com