Patents

Literature

77 results about "Esterified fatty acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

EstraFlex™ CMO is a proprietary blend of esterified fatty acid carbons (EFAC), also known as cetylated fatty acids, including cetyl myristate, cetyl myristoleate, cetyl oleate, cetyl palmitoleate, and cetyl palmitate.

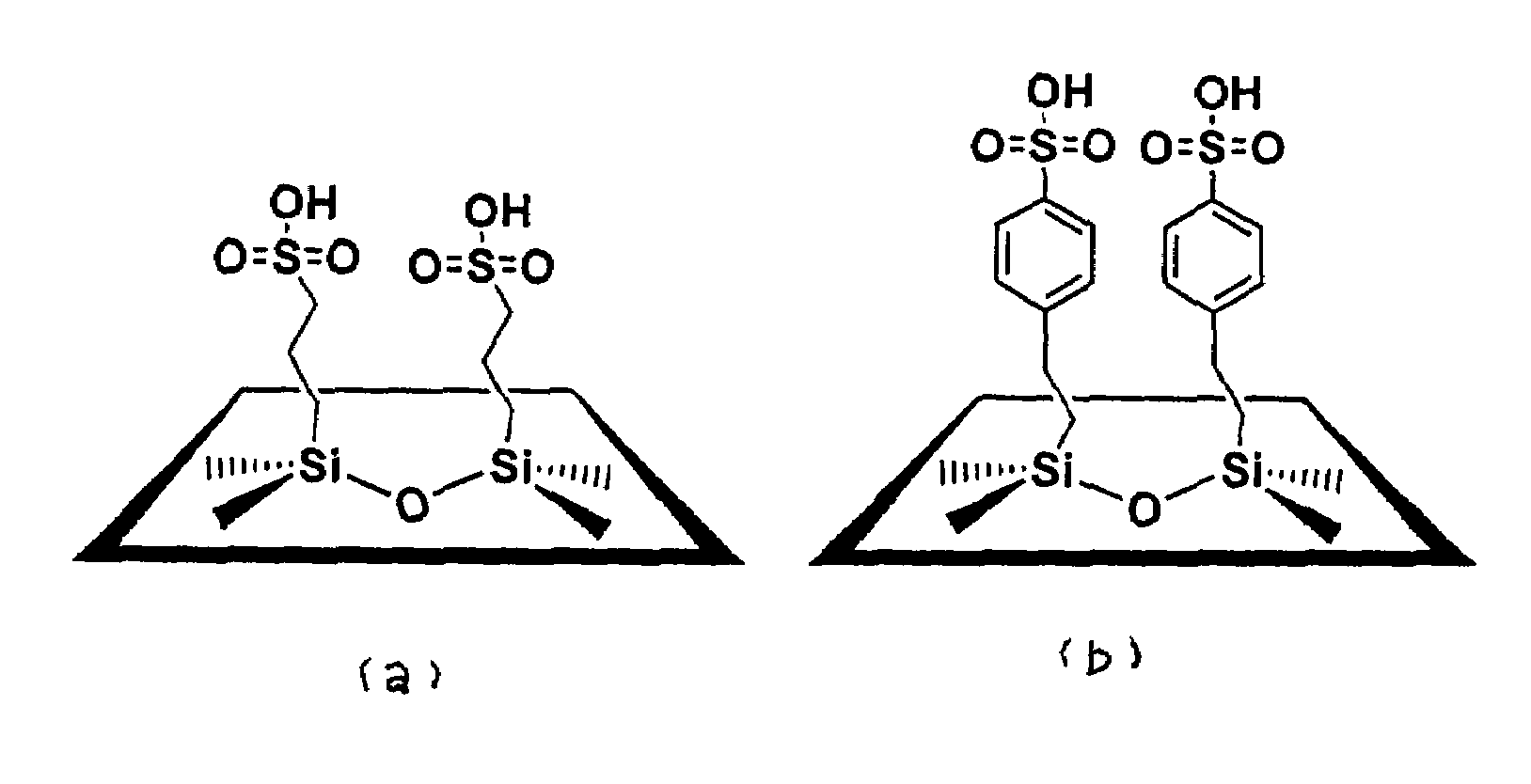

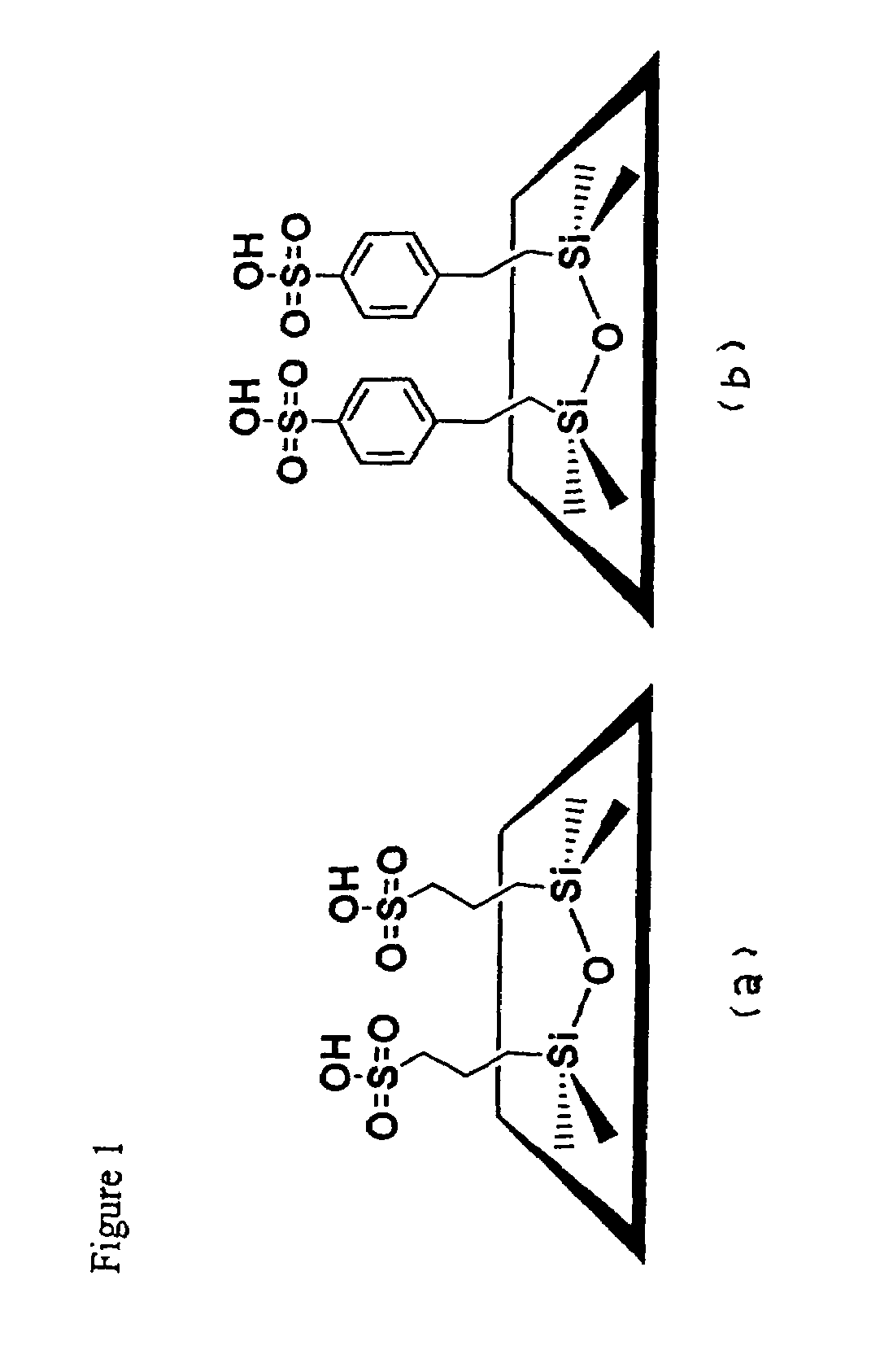

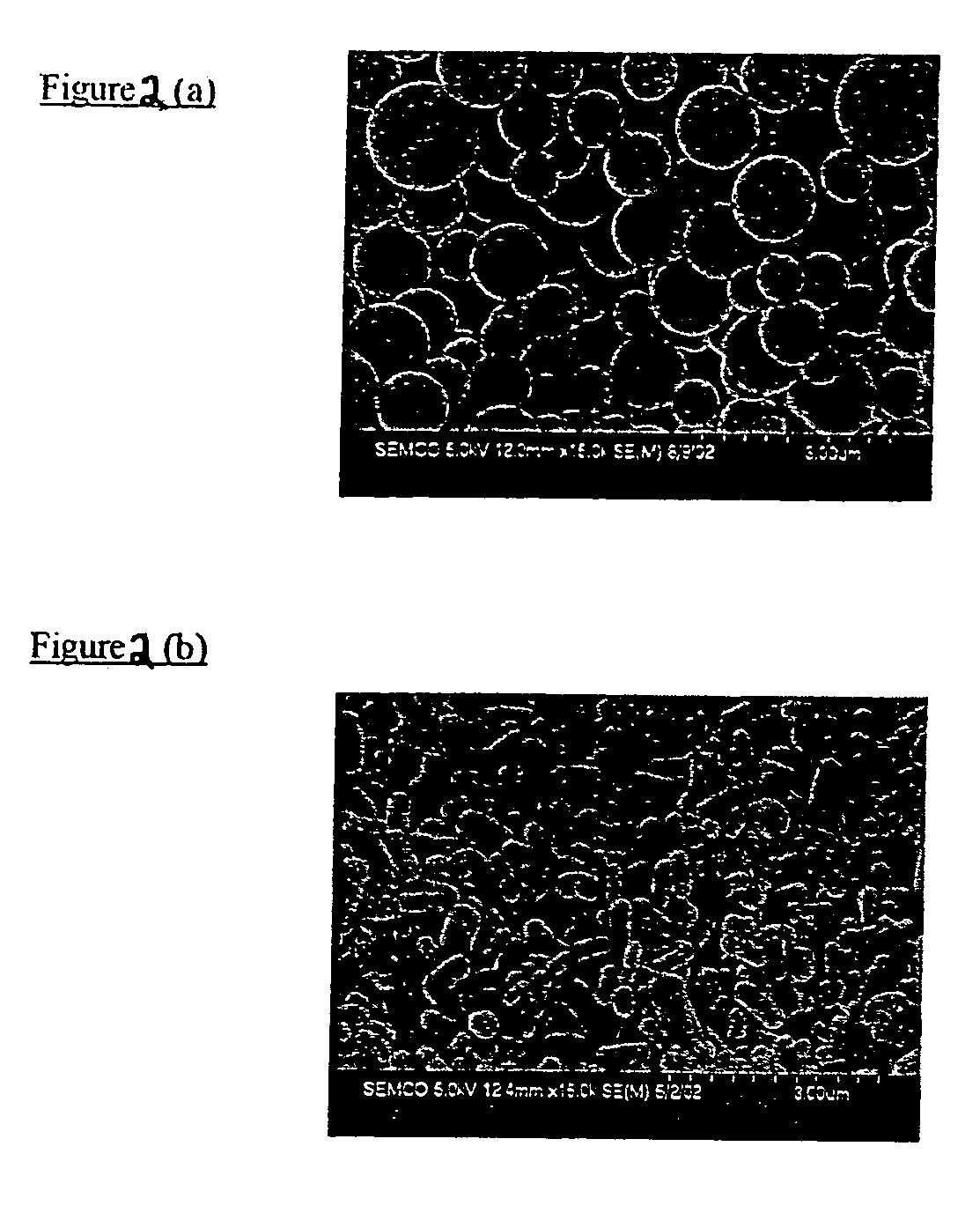

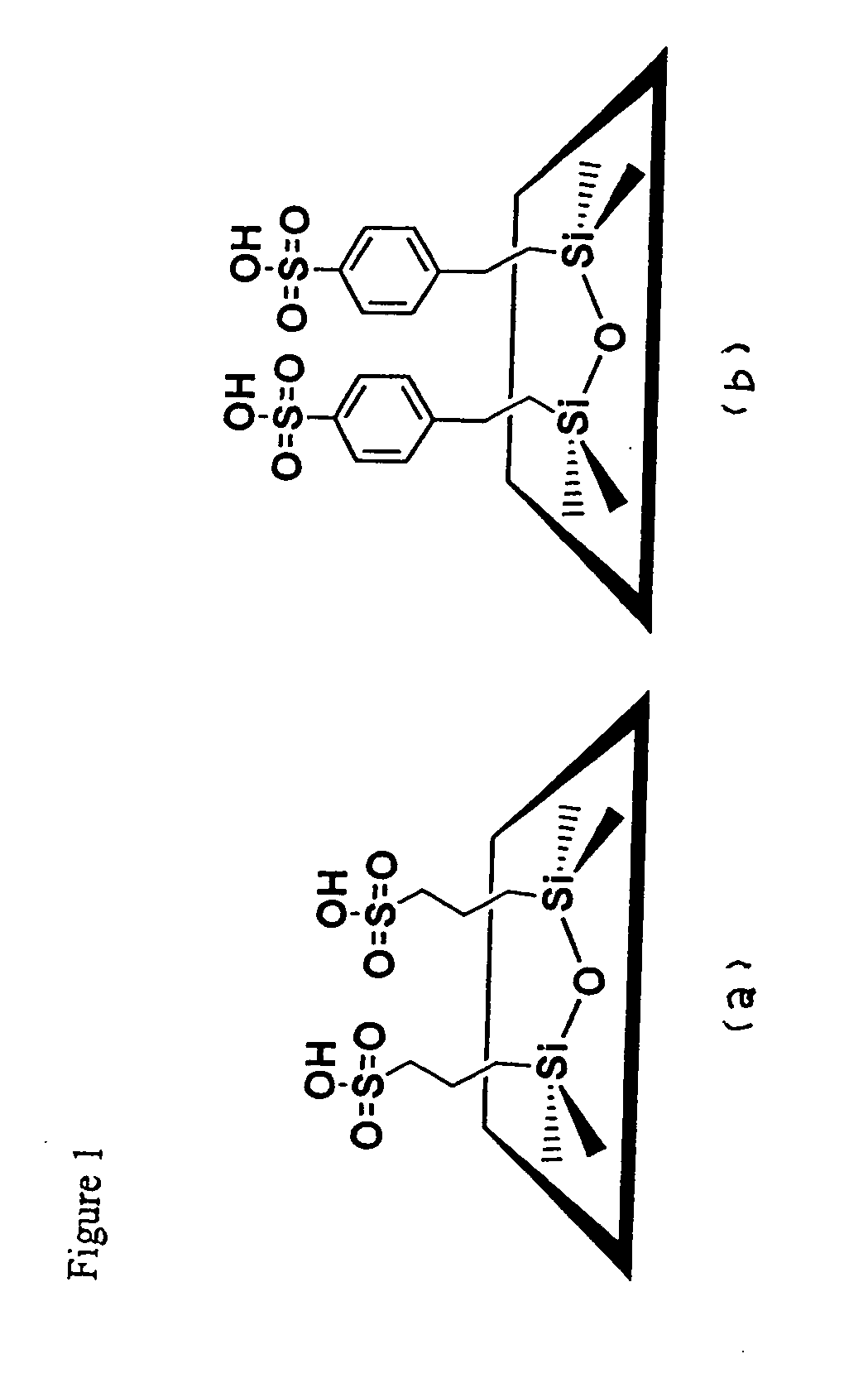

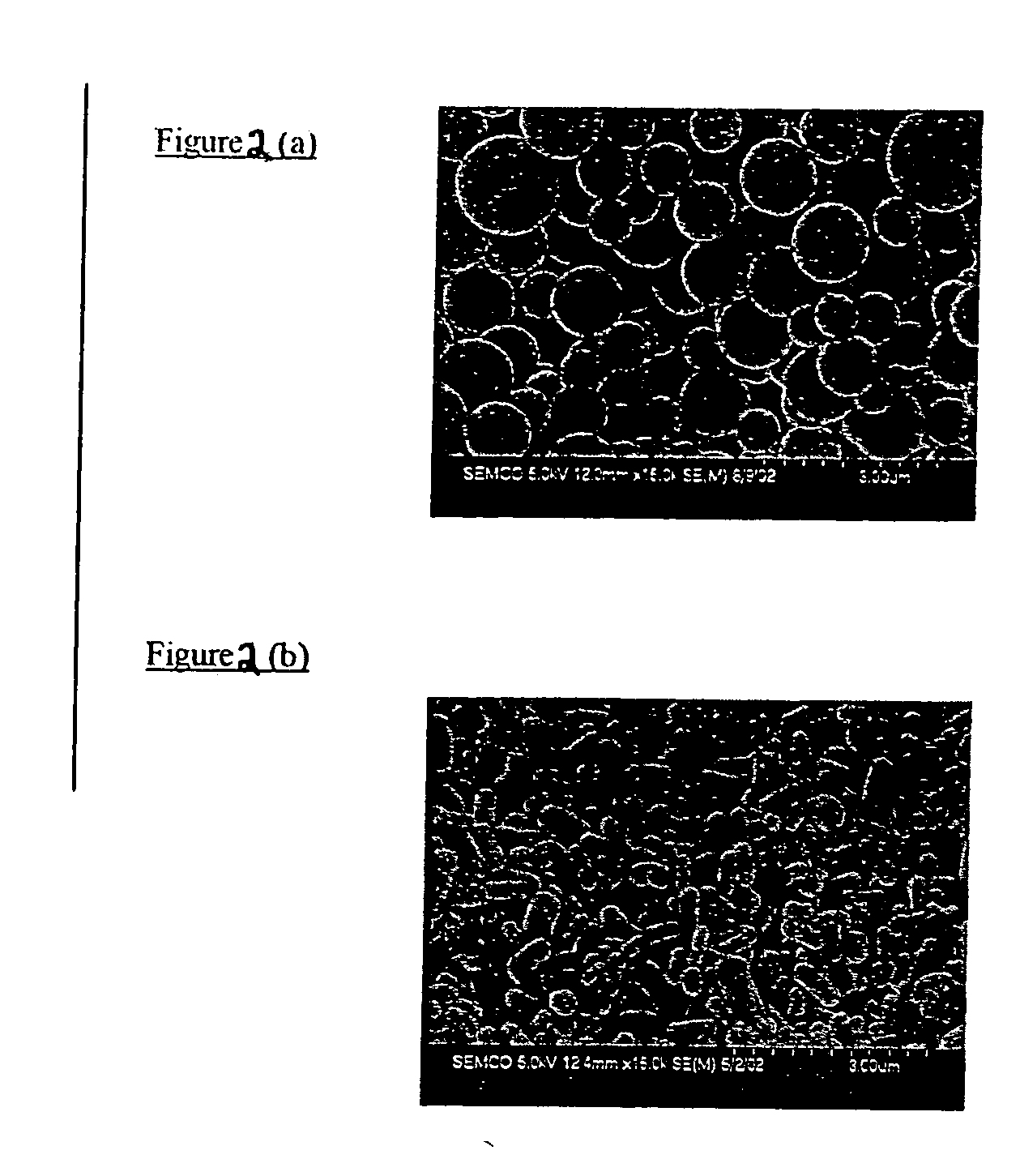

Use of functionalized mesoporous silicates to esterify fatty acids and transesterify oils

InactiveUS7122688B2Permit releaseEasy to separateFatty oils/acids recovery from wasteFatty acid chemical modificationIodo fatty acidMonoglyceride

The present invention provides a method to prepare a fatty acid lower alkyl esters from a feedstock, such as a vegetable or an animal oil, comprising one or more fatty acid glycerol esters such as mono-, di- or tri-glycerides, and free fatty acids, comprising combining the feedstock, a lower alcohol and an acidic mesoporous silicate under conditions wherein the mesoporous silicate catalyzes the formation of the corresponding fatty acid lower alkyl ester of the free fatty acids an optionally glycerol.

Owner:IOWA STATE UNIV RES FOUND

Enzymatic antioxidant of allene oxide for lipid peroxidation in biological systems

InactiveUS6132711ABeneficial antioxidativeExtend effective lifeSugar derivativesPeptide/protein ingredientsLipid formationFatty acid

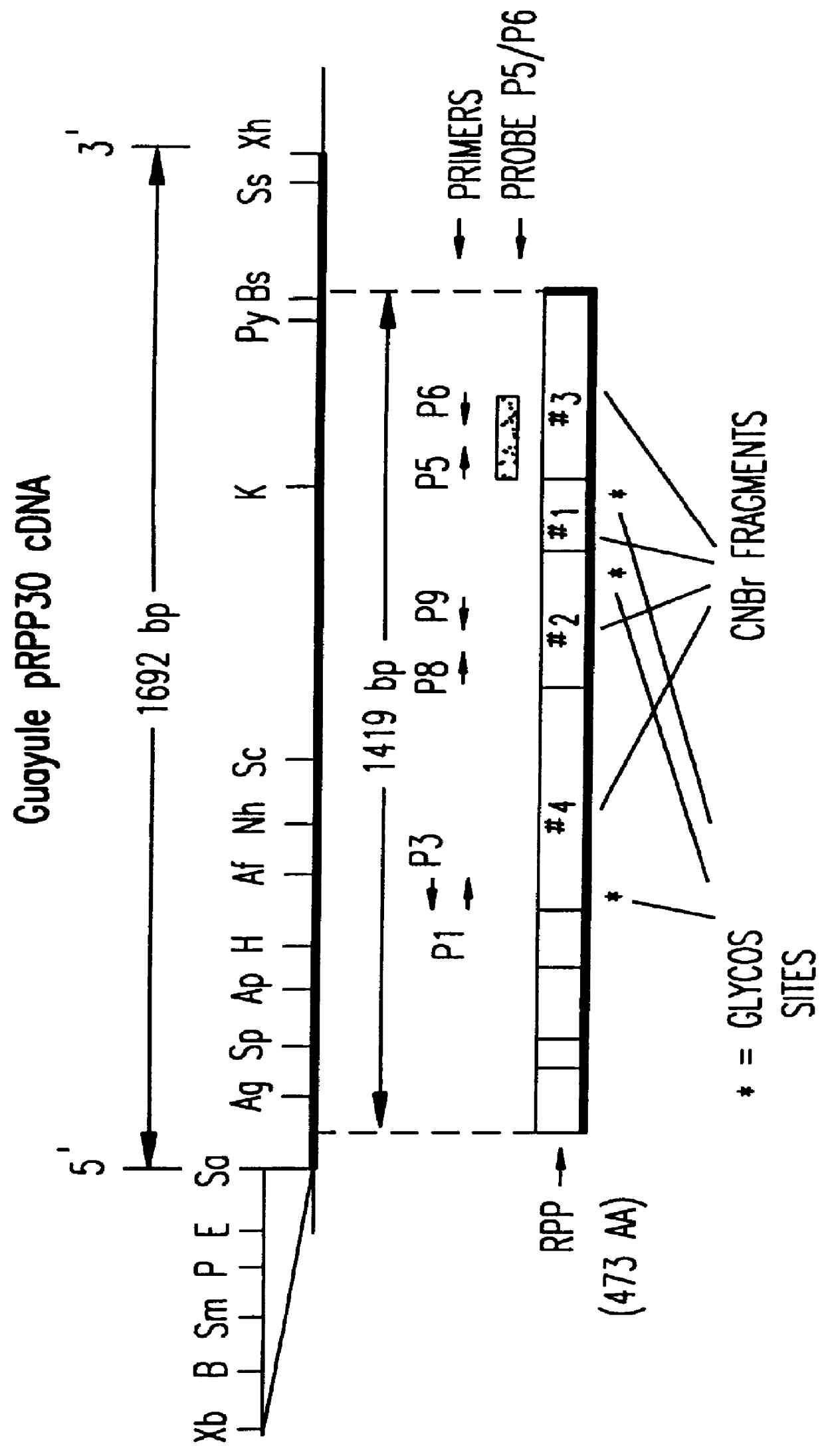

The present invention relates to the isolation and use of an allene oxide synthase enzyme as an antioxidant of lipid peroxides in biological systems. It is based, at least in part, on the discovery that antioxidation is accomplished enzymatically by RPP, a species of allene oxide synthase, in guayule, and on the discovery that the allene oxide synthase RPP disrupts the chain reaction and propagation steps of lipid peroxidation. The present further invention relates to the use of an allene oxide synthase to result in a time-dependent disappearance of conjugated dienes (i.e. lipid hydroperoxides). The allene oxide synthase rapidly converts free or esterified fatty acid peroxides or hydroperoxides into their corresponding epoxides, which, in turn are converted to ketols. The lipid peroxide and hydroperoxide substrates for this enzyme are known to be toxic to biological organisms and can generate additional peroxides by chain propagation reactions. In the presence of an allene oxide synthase these compounds are rapidly and effectively converted to allene oxides (the epoxide), thus breaking the chain reaction.

Owner:ARIZONA STATE UNIVERSITY

Use of functionalized mesoporous silicates to esterify fatty acids and transesterify oils

InactiveUS20050107624A1Valid conversionLarge specific surface areaFatty oils/acids recovery from wasteFatty acid chemical modificationAlcoholGlycerol

The present invention provides a method to prepare a fatty acid lower alkyl esters from a feedstock, such as a vegetable or an animal oil, comprising one or more fatty acid glycerol esters such as mono-, di- or tri-glycerides, and free fatty acids, comprising combining the feedstock, a lower alcohol and an acidic mesoporous silicate under conditions wherein the mesoporous silicate catalyzes the formation of the corresponding fatty acid lower alkyl ester of the free fatty acids an optionally glycerol.

Owner:IOWA STATE UNIV RES FOUND

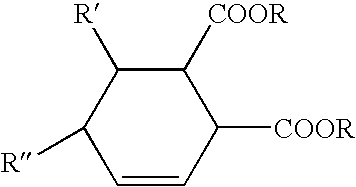

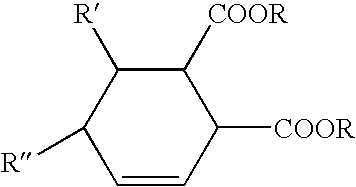

Esterified Fatty Acids for Pvc Plasticization

InactiveUS20080200595A1Improve compatibilityAvoid problemsChloroprene adhesivesPlasticizerOleic Acid Triglyceride

At least one esterified fatty acid, particularly a fatty acid from tall oil that undergoes a Diels-Alder reaction or a fatty acid from oleic sunflower oil that undergoes an epoxydation reaction, is used as a PVC plasticizer, particularly for floor coverings.

Owner:GERFLOR

Esterified fatty acid composition

ActiveUS20050208162A1Improve efficacyImprove stabilityBiocideHalogenated hydrocarbon active ingredientsSide effectArthritis

The invention is directed to compositions comprising lecithin, olive oil, esterified fatty acids and mixed tocophenols for use in the treatment and prevention of various types of arthritis and other inflammatory joint conditions, periodontal diseases and psoriasis, which avoid many of the side effects associated with known treatments. The compositions of the present invention have the advantage of increased stability, a reduction of arachidonic acid in cells, a reduction in eicosanoid production and enhanced cell regulation and communication. Also disclosed are methods for using the compositions for treatment and prevention.

Owner:TRIPHARMA LLC

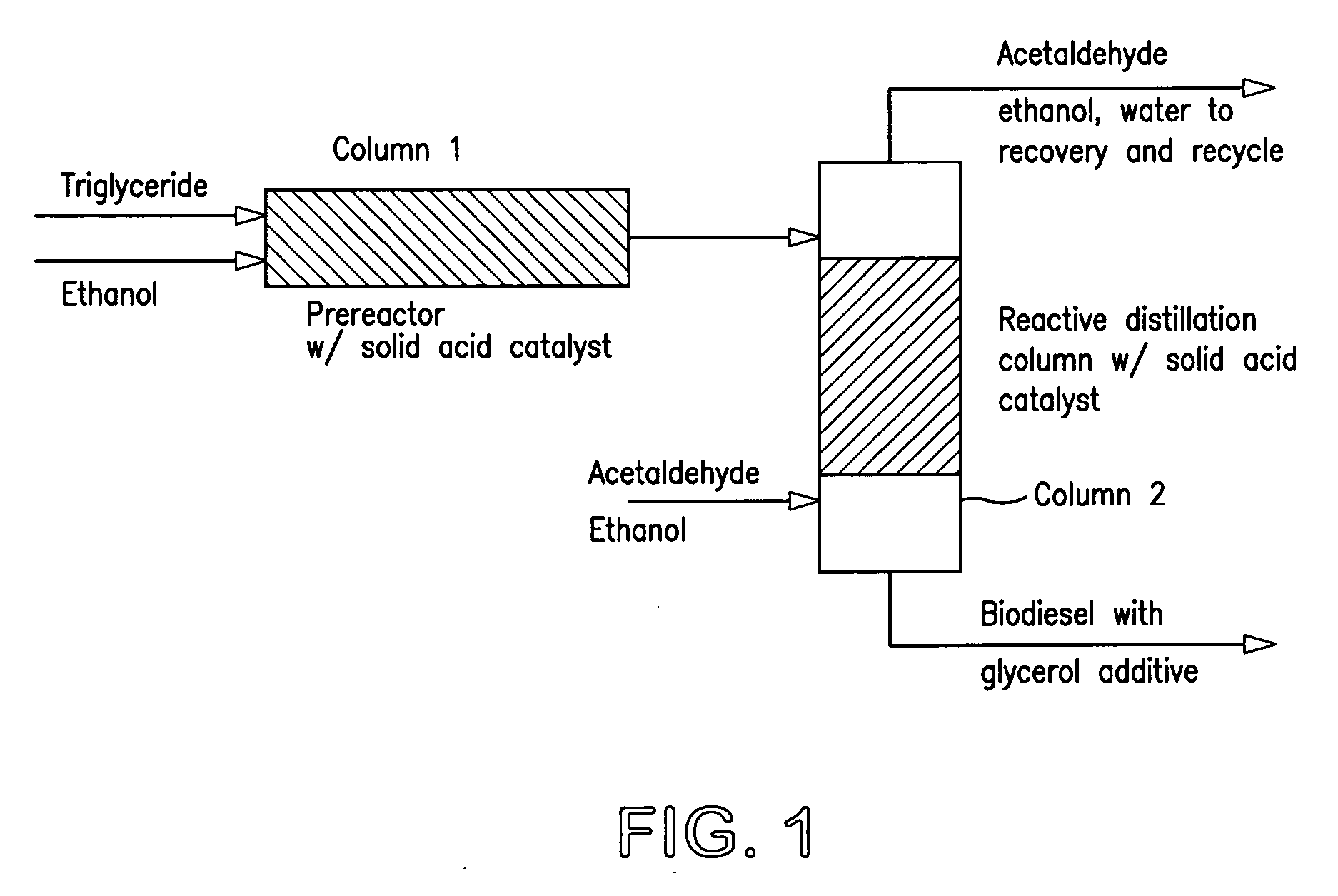

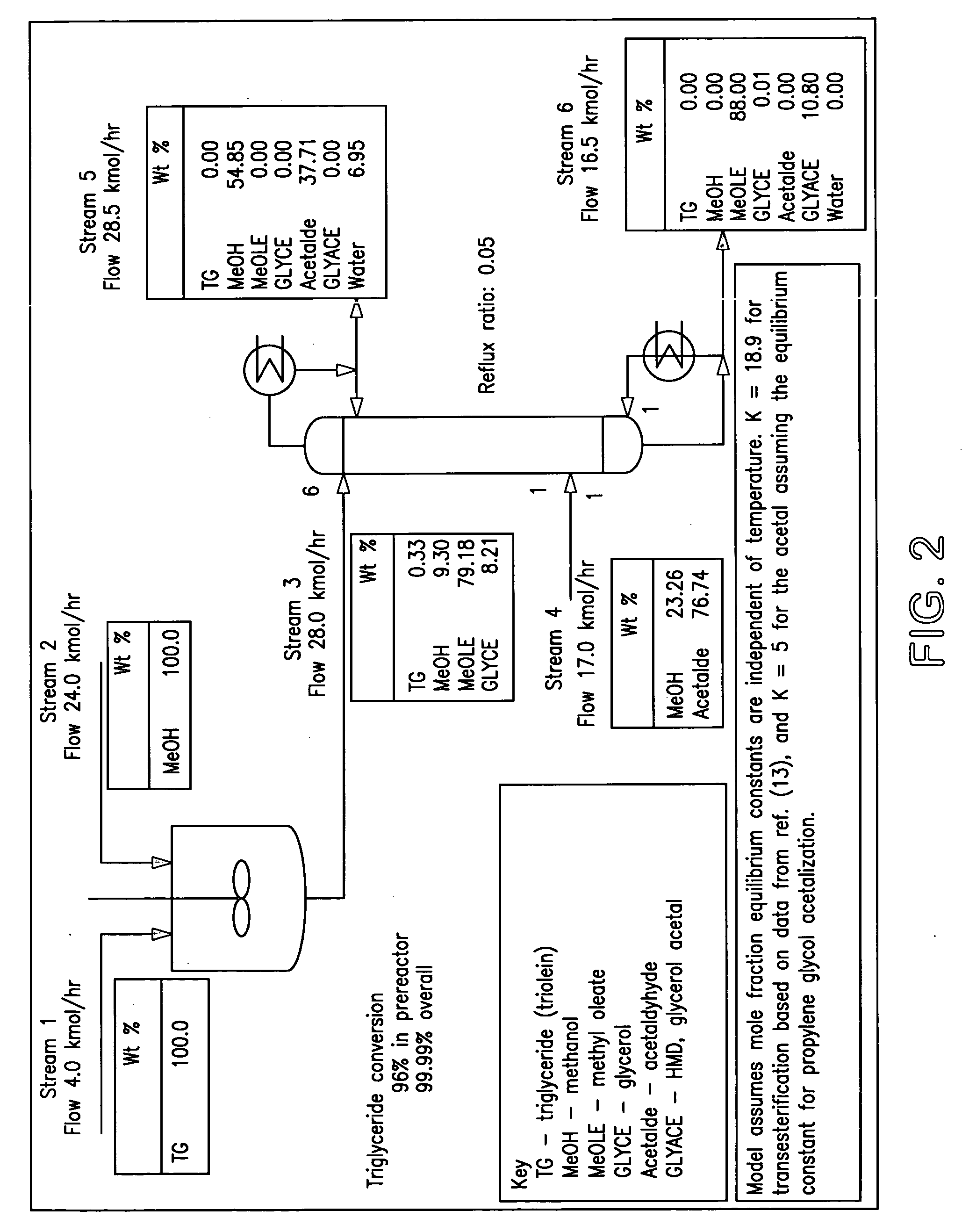

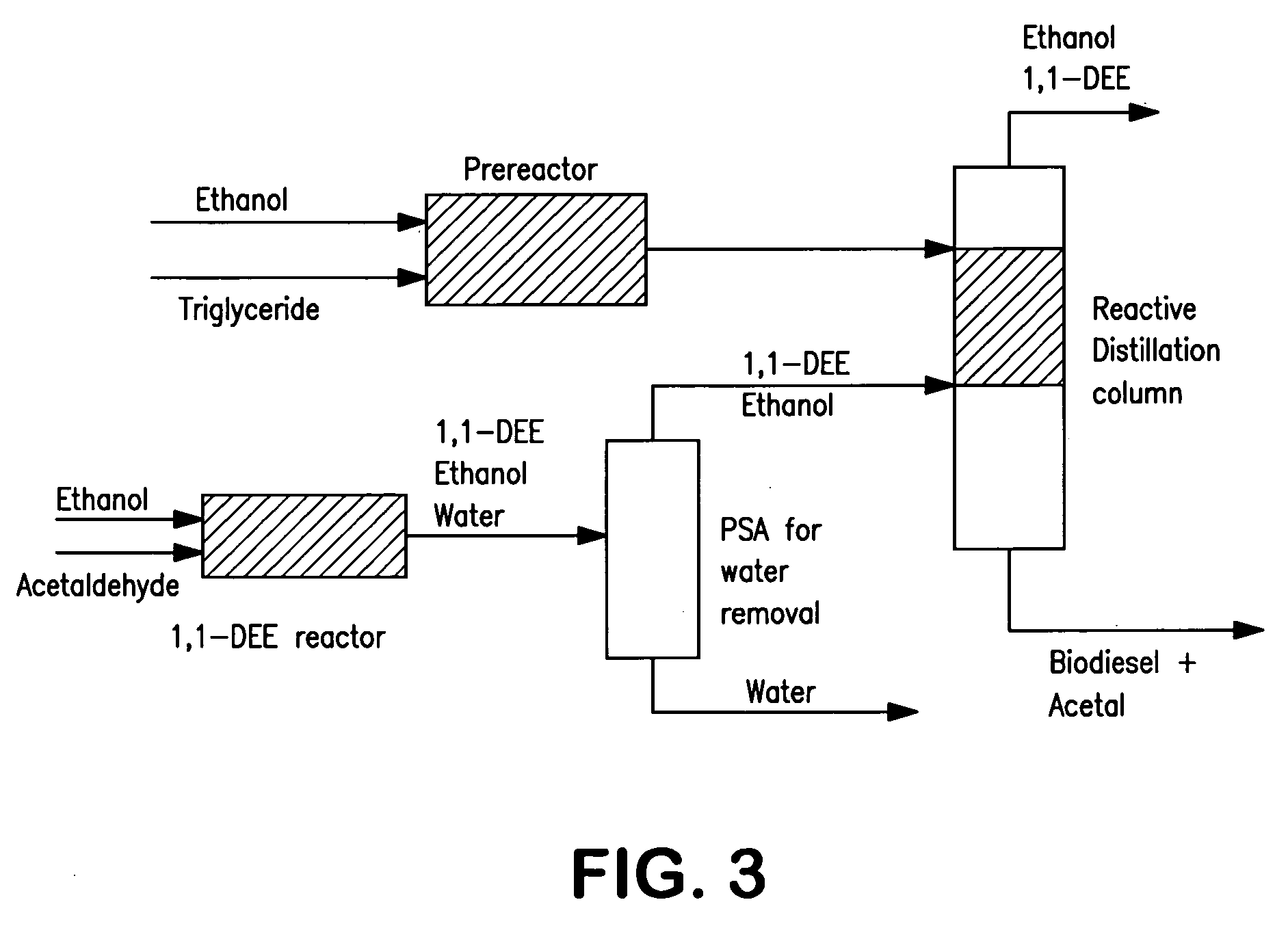

Process for production of a composition useful as a fuel

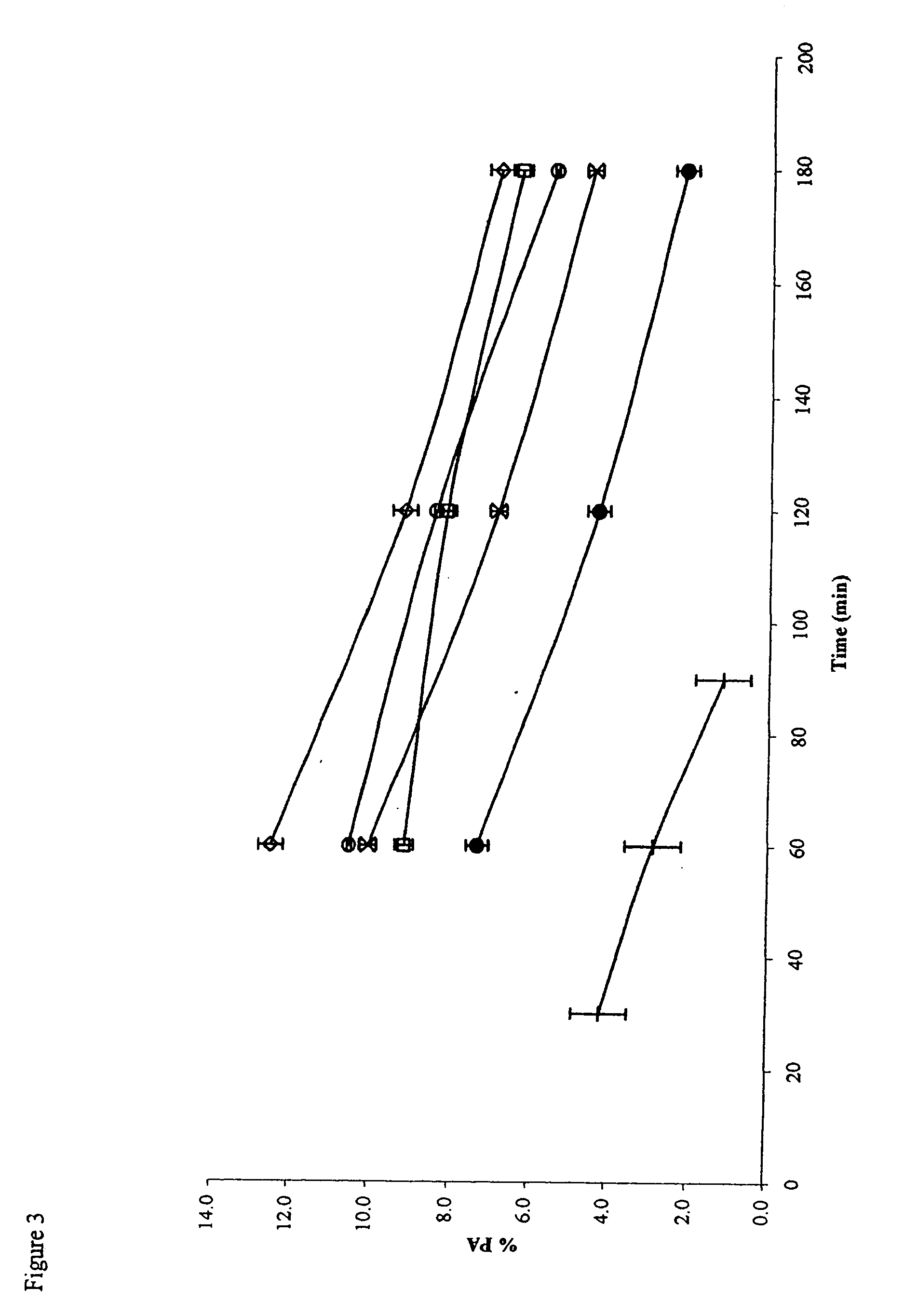

InactiveUS20060199970A1Easy to operateImprove solubilityFatty oils/acids recovery from wasteFatty acid esterificationHeating oilGlycerol

A process for the preparation of a fuel oil (diesel fuel or heating oil) composition which is a mixture of an alkanol tranesterified fatty acid ester triglyceride and an acetal of glycerol is described. The process preferably provides a prestep of the formation of at least some of the alkanol transesterified triglyceride containing the glycerol for use in the formation of the acetal of glycerol. The composition can also be formed from a reaction of 1,1- dimethoxy- or 1,1-diethoxyethane and glycerol to form the acetal in the alkanol transesterified triglyceride.

Owner:MICHIGAN STATE UNIV

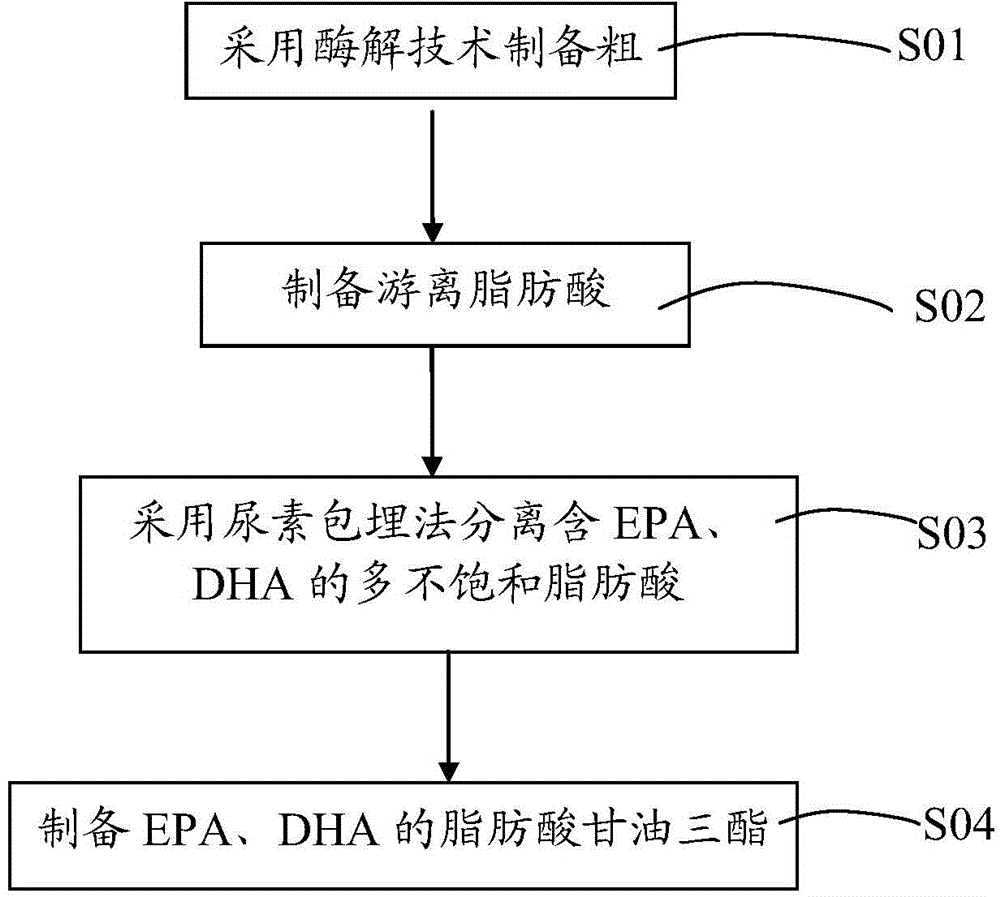

Method of extracting DHA and EPA in type of triglyceride from deep-sea fish

ActiveCN104651422AIncrease contentLow acid valueFermentationBulk chemical productionTriglycerideFish oil

The invention belongs to the technical field of biopharmacy and provides a method of extracting DHA and EPA in the type of triglyceride from deep-sea fish. The method includes steps of: preparing crude fish oil with enzymolysis technology, preparing free fatty acid, separating poly-unsaturated fatty acids containing the EPA and the DHA through a urea-embedding method, and preparing the fatty acid triglyceride of the DHA and the EPA. The method can effectively extract and enrich the DNA and the EPA from the deep-sea fish. The obtained crude fish oil is low in acidic value and is high in hydrolysis degree of esterified fatty acids. The finally products of the DHA and the EPA are in the type of triglyceride with the contents of the DHA and the EPA are in the type of triglyceride being high.

Owner:SHENZHEN HAIYOUKANG BIOTECH CO LTD

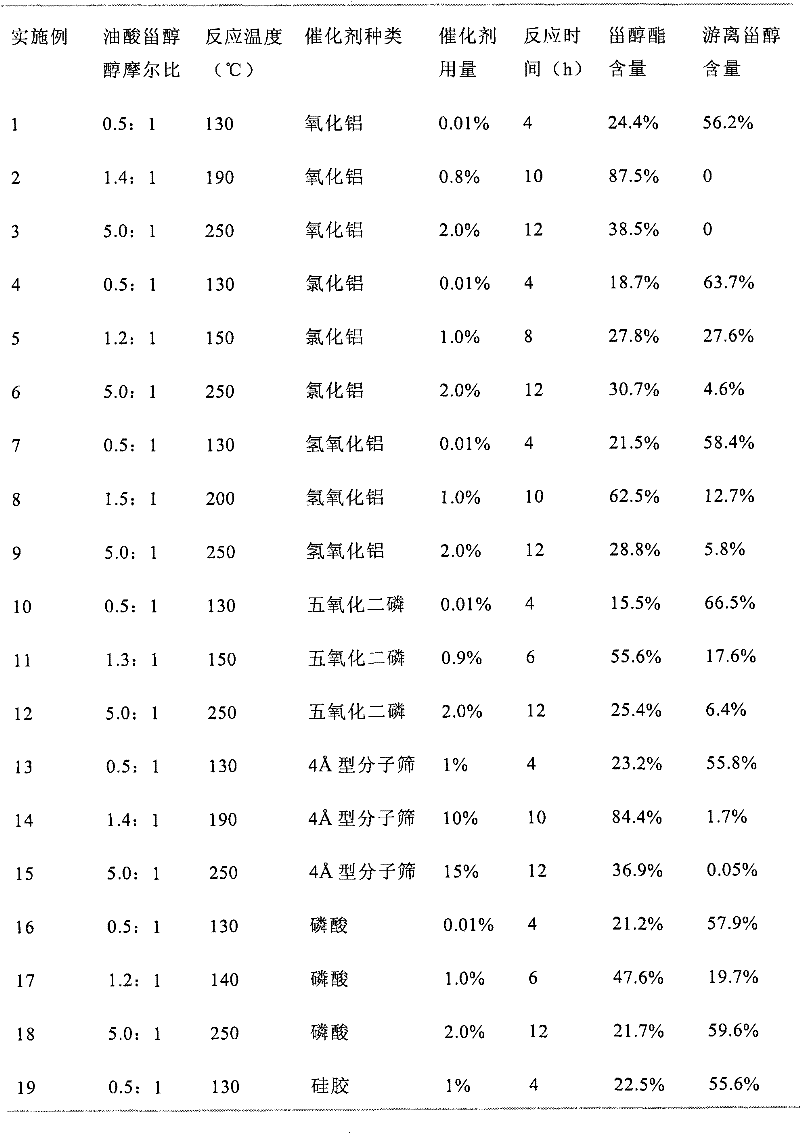

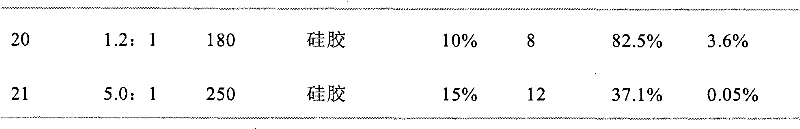

Method for preparing fatty acid phytosterol esters

The invention relates to a method for preparing fatty acid phytosterol esters, which comprises the following step of: esterifying fatty acid and phytosterol in the presence of one or more catalysts such as alumina, aluminum hydroxide, aluminum salt (such as aluminum chloride, aluminum sulfate, aluminum silicate and the like), oxide of other elements in IIIA family, phosphorus pentoxide, phosphoric acid, phosphate (such as sodium dihydrogen phosphate, dipotassium phosphate and the like), a molecular sieve and silica gel in effective catalysis amount. The invention also relates to the fatty acid phytosterol esters prepared by the method, and foods, soft capsules and cosmetics containing the phytosterol esters.

Owner:丰益生物科技(江苏)有限公司

Method of making alkyl esters

InactiveUS7795460B2Recovery be complicateFatty oils/acids recovery from wasteFatty acid esterificationSolid acidEsterified fatty acid

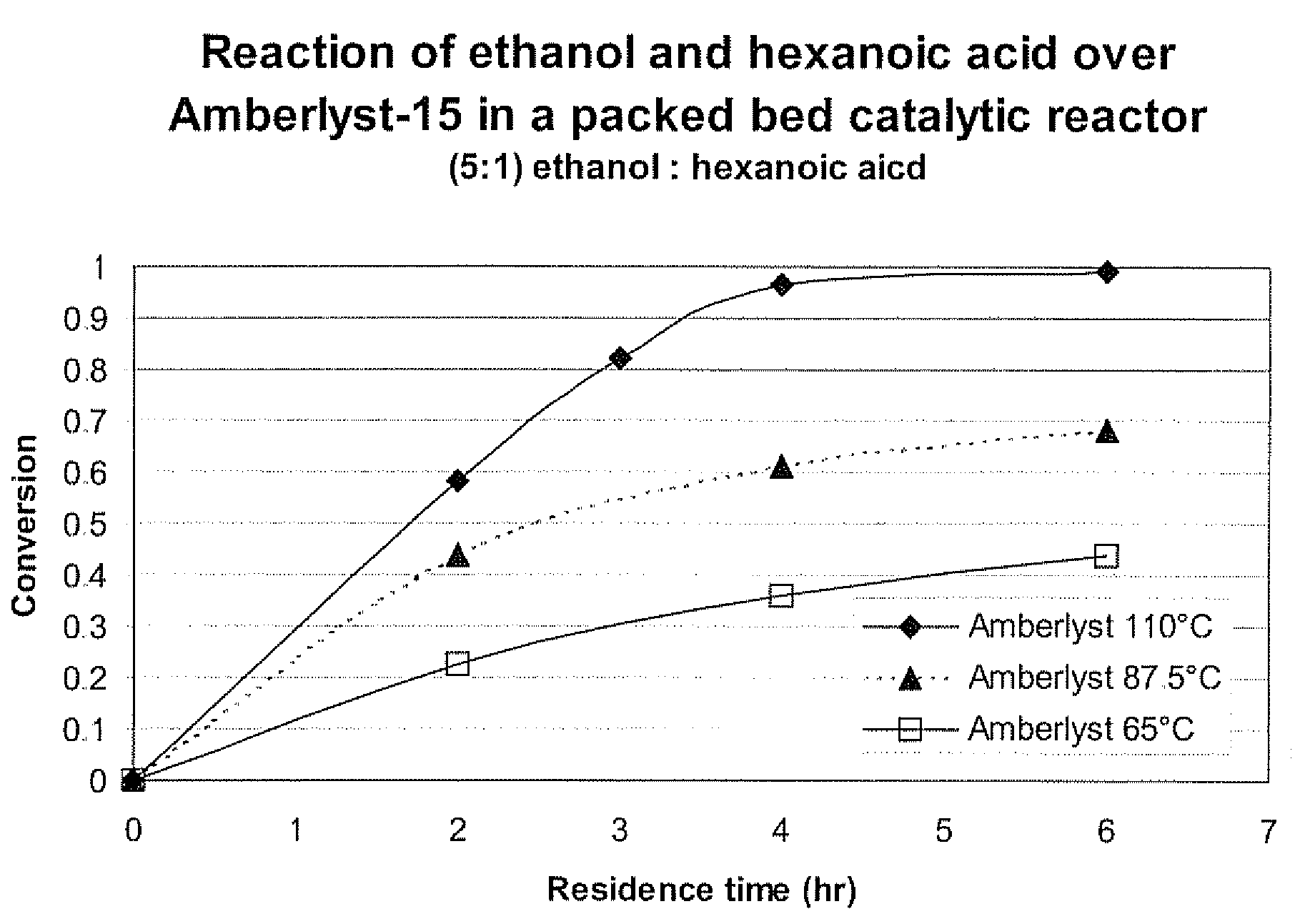

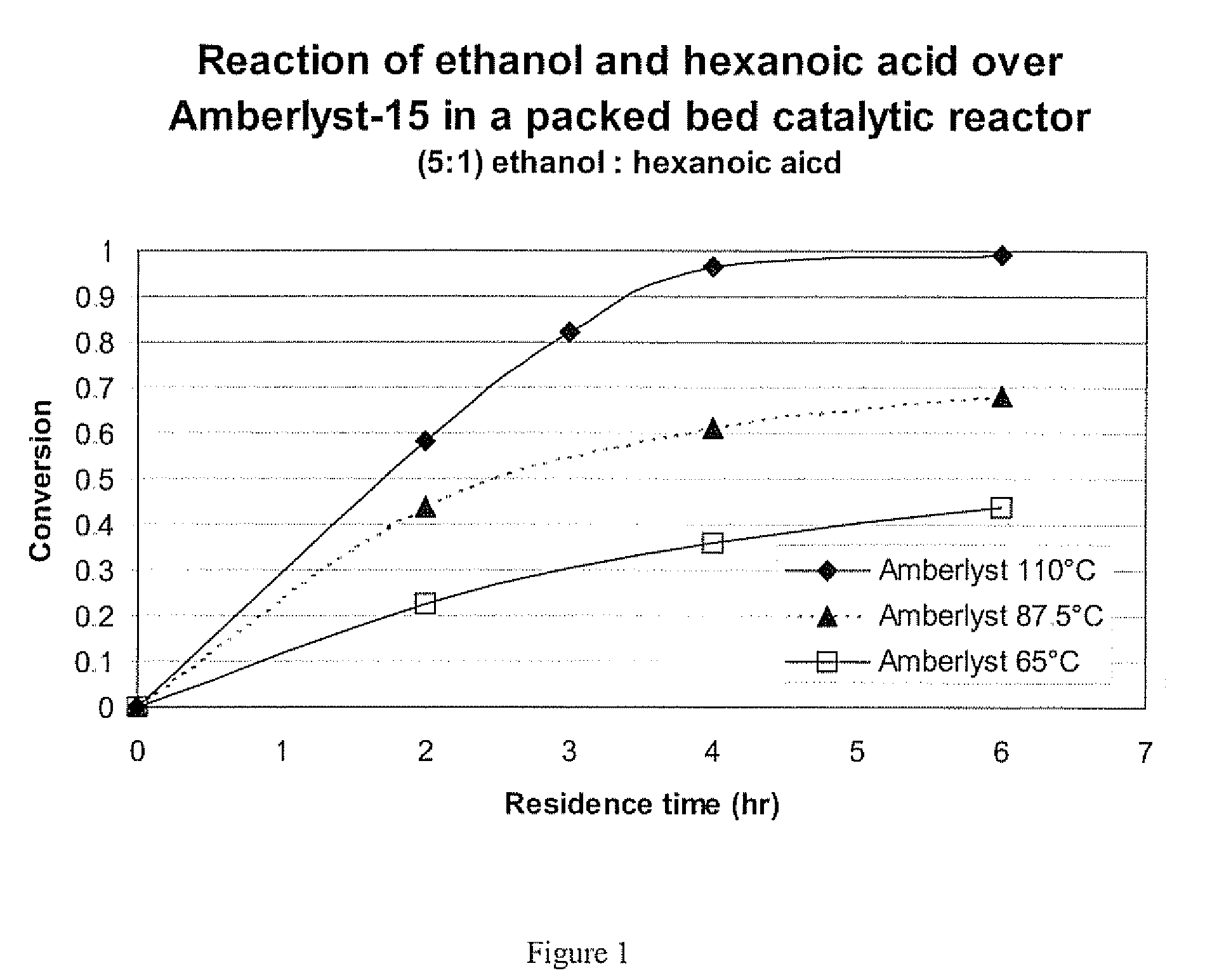

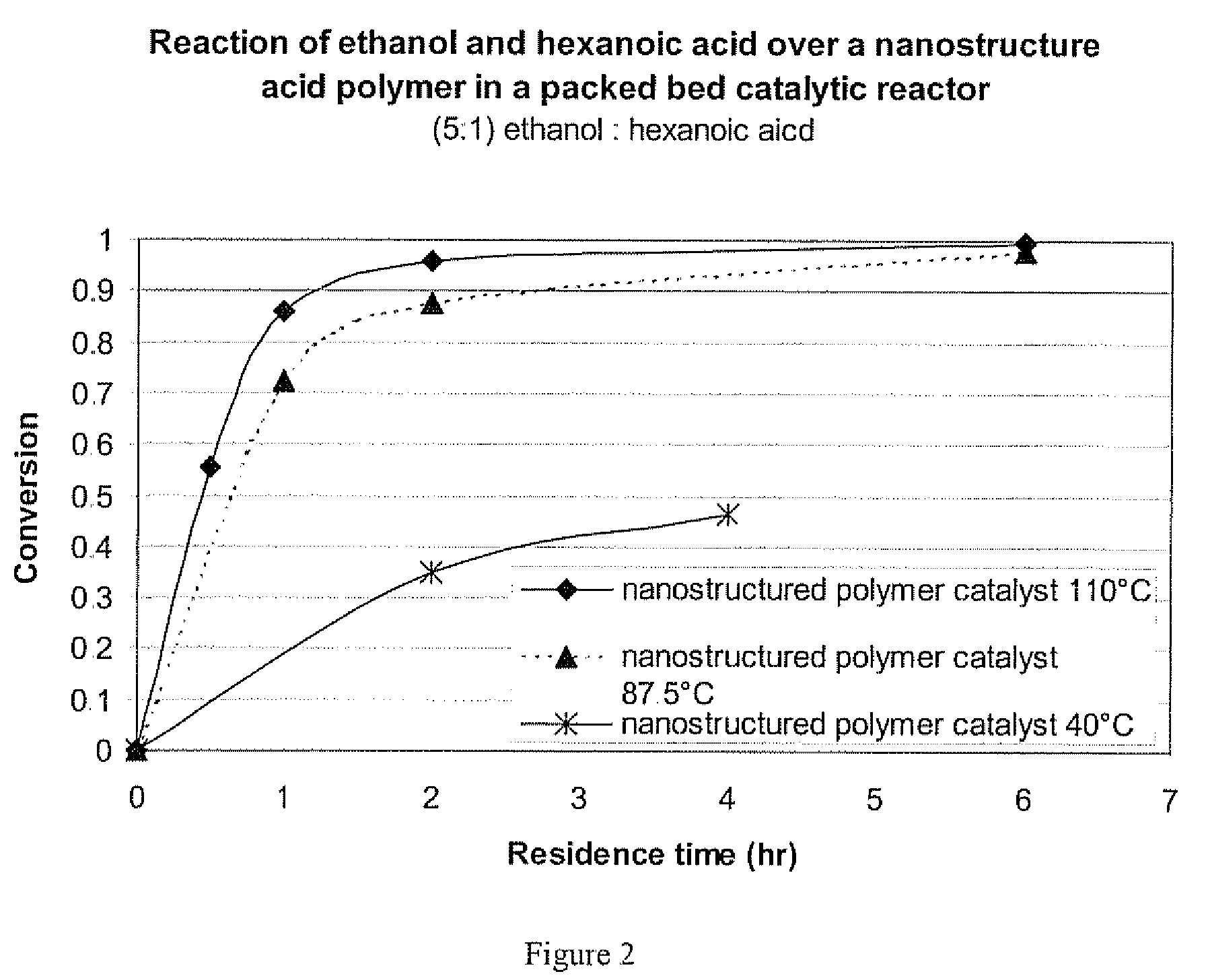

Methods of making alkyl esters are described herein. The methods are capable of using raw, unprocessed, low-cost feedstocks and waste grease. Generally, the method involves converting a glyceride source to a fatty acid composition and esterifying the fatty acid composition to make alkyl esters. In an embodiment, a method of making alkyl esters comprises providing a glyceride source. The method further comprises converting the glyceride source to a fatty acid composition comprising free fatty acids and less than about 1% glyceride by mass. Moreover, the method comprises esterifying the fatty acid composition in the presence of a solid acid catalyst at a temperature ranging firm about 70° C. to about 120° C. to produce alkyl esters, such that at least 85% of the free fatty acids are converted to alkyl esters. The method also incorporates the use of packed bed reactors for glyceride conversion and / or fatty acid esterification to make alkyl esters.

Owner:TDA RES

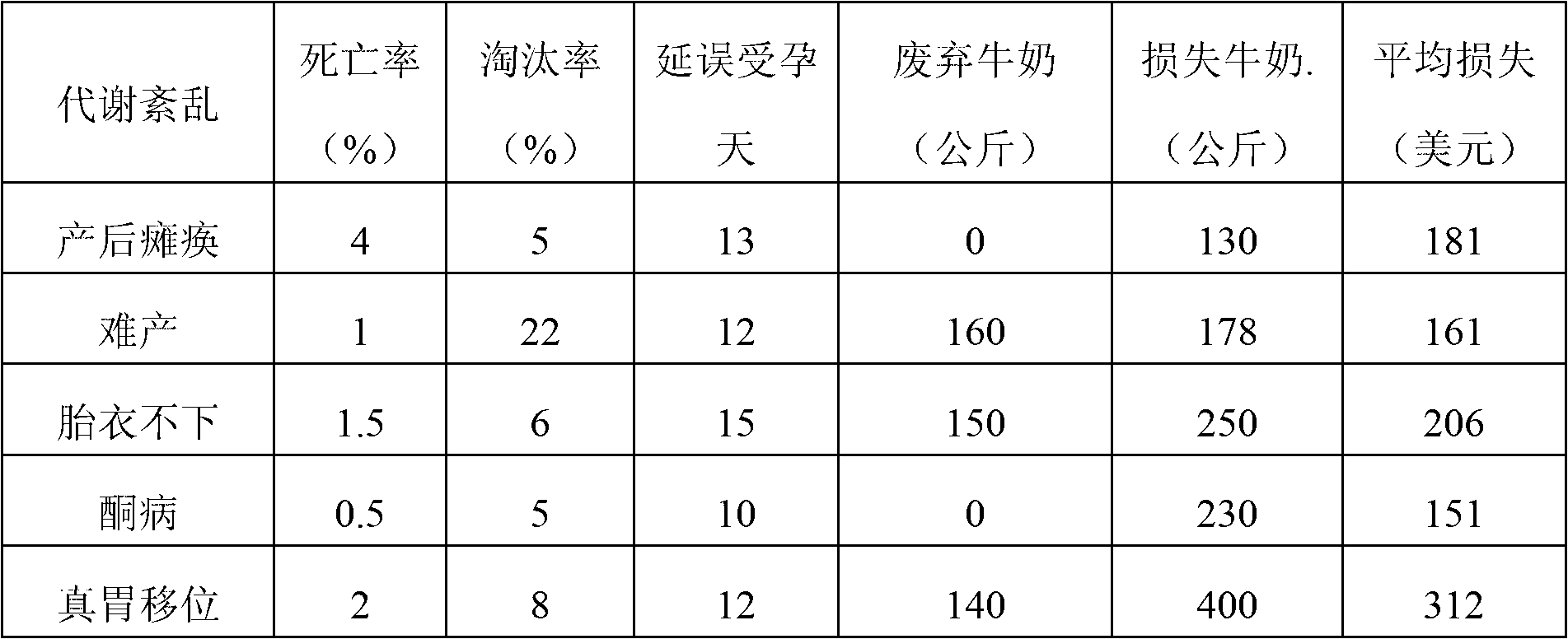

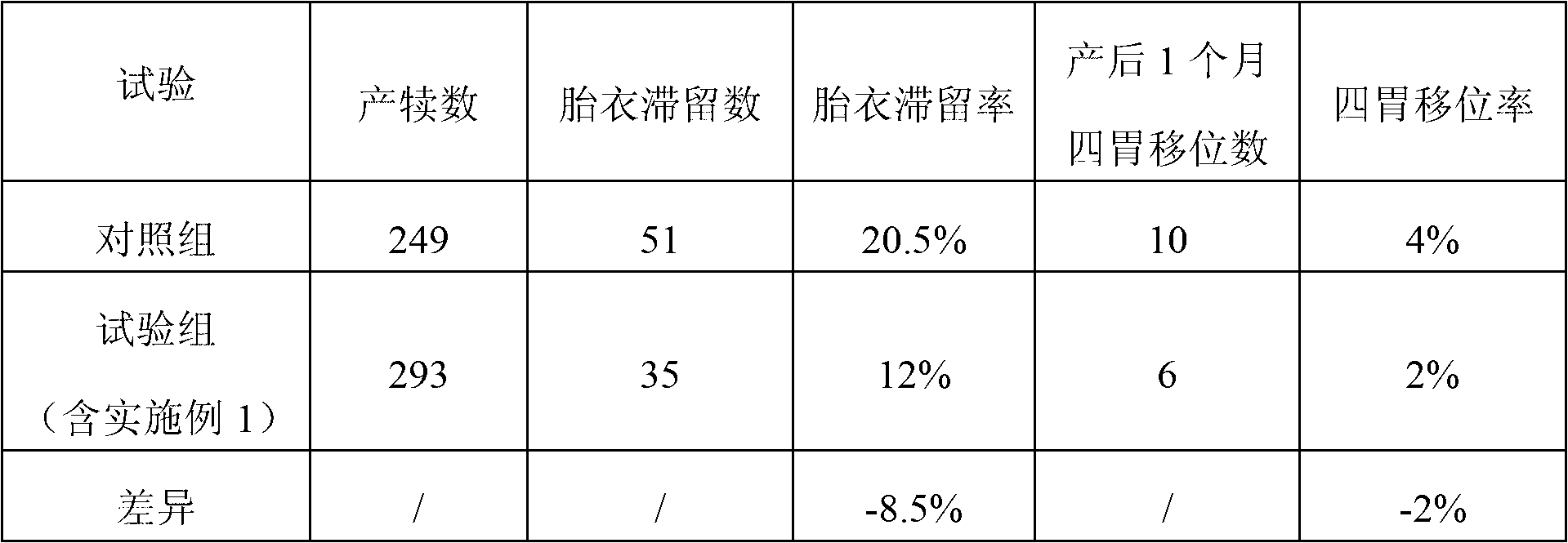

Postpartum dairy cow drenching nutritious supplementary and application method thereof

InactiveCN103340317AEffective maintenance levelLower levelAnimal feeding stuffDiseaseBeta-Hydroxybutyric acid

The invention discloses a postpartum new dairy cow drenching nutritious supplementary and application thereof in a nutritious supplementary for treating postpartum hypocalcemia, abomasum displacement or ketosis disease of dairy cow. The nutritious supplementary provided by the invention is capable of effectively maintaining the levels of blood calcium, blood magnesium and glucose and reducing the levels of NEFA (Non-Esterified Fatty Acid) and beta-hydroxybutyric acid, thereby effectively reducing the occurrence rate of metabolic diseases of postpartum paralysis, ketosis, abomasum displacement and the like of new dairy cow. As a result, the dairy cow can be rehabilitated in physical power and food intake quickly, and the health condition of the dairy cow can be improved and the milk yield of the dairy cow can be increased; and good economic benefit can be achieved.

Owner:CHANGCHUN BORUI FEED

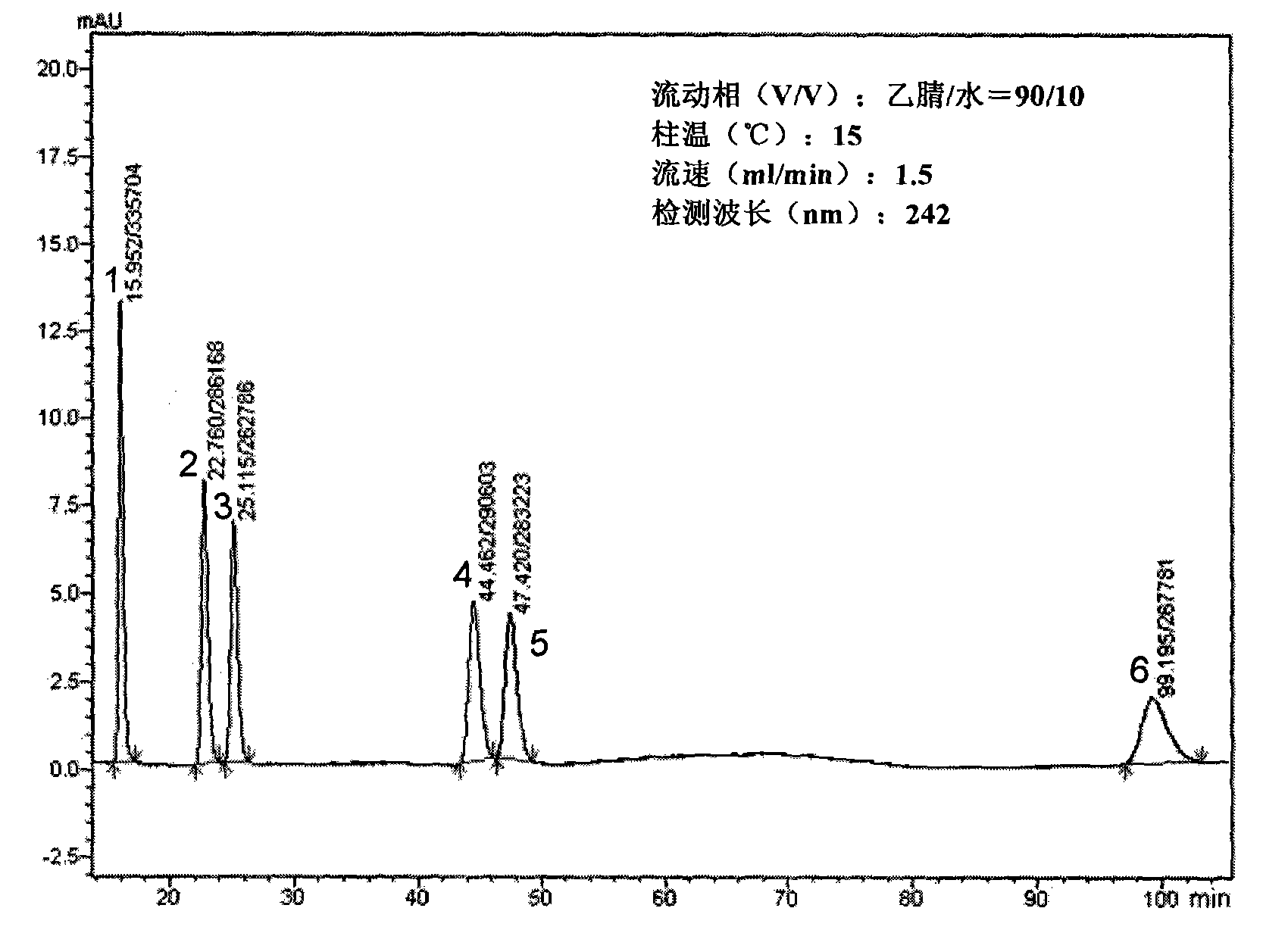

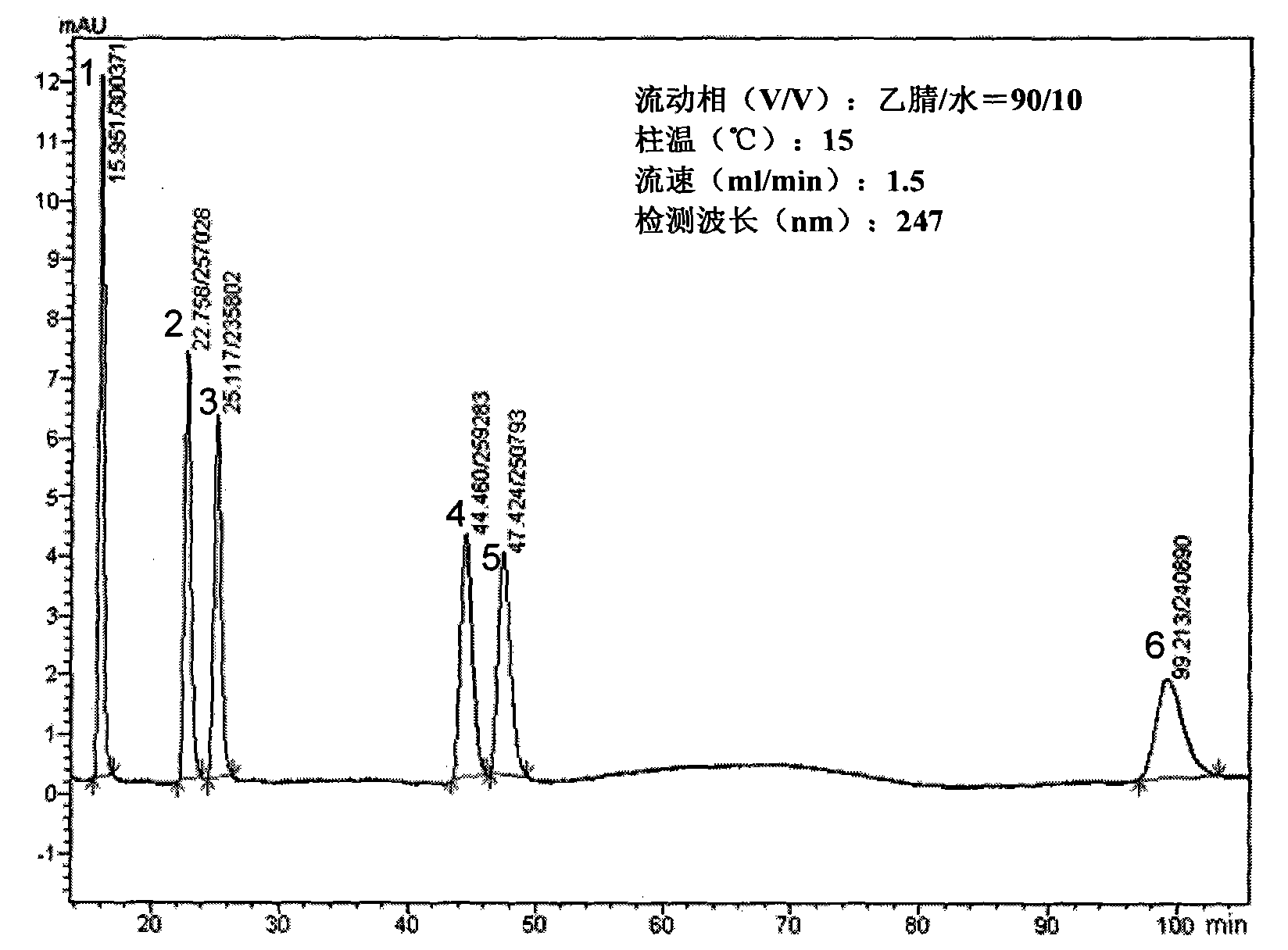

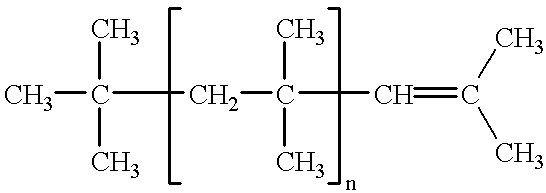

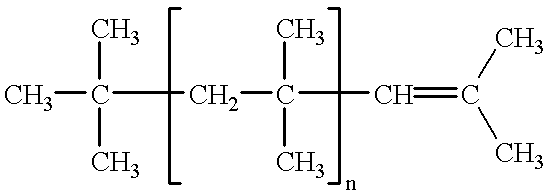

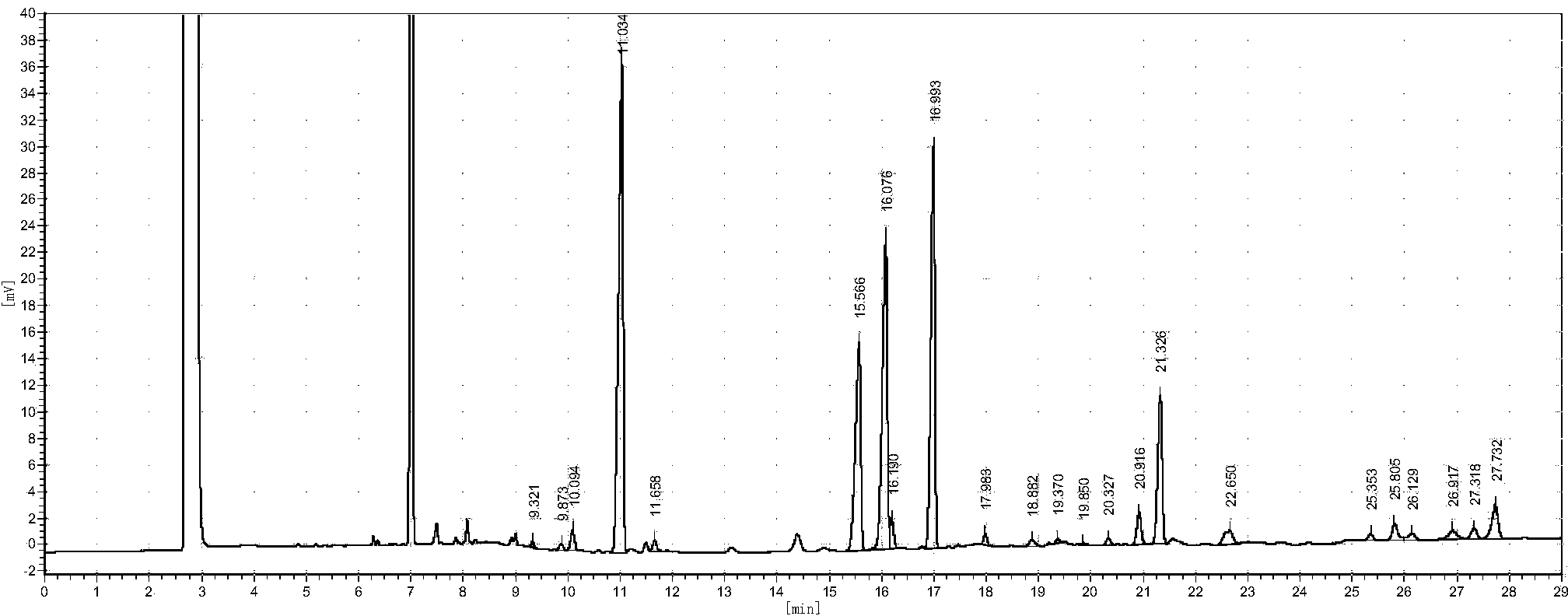

Mixed fatty acid high performance liquid phase chromatography method and application

InactiveCN101776666AImprove efficiencyShort separation timeComponent separationStearic acidPalmitoleic acid

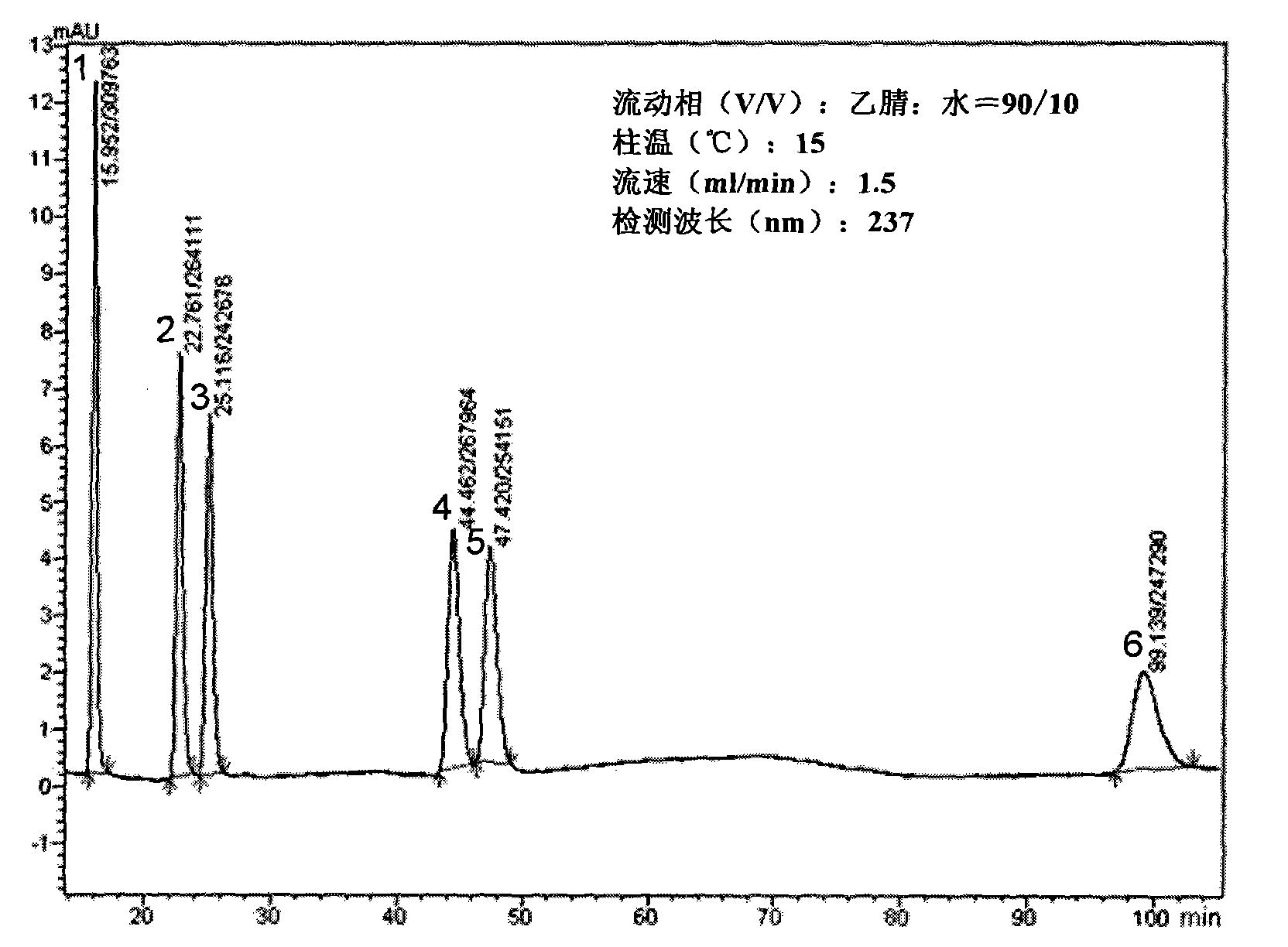

The invention discloses a mixed fatty acid high performance liquid phase chromatography method and application thereof. In order to solve the problems that the prior art has single method in separating linolenic acid, palmitic acid, linoleic acid and other three fatty acid mixtures with very similar chemical and physical properties with HPLC, and defects in elution method, mobile phase composition selection and the like, the invention provides a method for simultaneously separating six fatty acid mixtures, i.e. linolenic acid, palmitic acid, linoleic acid, oleic acid, palmitic acid and stearic acid with HPLC. The method esterifies fatty acid solution to be tested with the acetone solution of omega-bromoacetophenone and the acetone solution of triethanolamine, and separates the solution with HPLC. The HPLC adopts an isocratic elution method, and the mixture of acetonitrile and CTAB solution or acetonitrile-water solution is selected to serve as the mobile phase. Compared with the priorart, the invention has the advantages of simple and feasible operation, good separation effect, high detection sensitivity, accurate and reliable results, and simultaneous separation of 6 fatty acids.

Owner:SICHUAN AGRI UNIV

Chinese air-dry fish fermented sausage and preparation method thereof

The invention provides a Chinese air-dry fish fermented sausage and a preparation method thereof. The Chinese air-dry fish fermented sausage comprises the following components in percentage by weight: 10 to 95 percent of fish, 0.1 to 18 percent of ferment agent, 1 to 25 percent of auxiliary flavouring, and the rest of water. The Chinese air-dry fish fermented sausage of the invention has special flavor. Mainly the enzymes generated by the metabolism of the histenzyme of the fish and the microorganism decompose carbohydrate, fat, protein and the like to form the flavor components. The substances have important effect on formation of the flavor, and particularly the fat and the protein provide precursor substances, i.e. non-esterified fatty acid and free amino acid, of mass flavor substrates. Moreover, the Maillard reaction, the non-enzyme reactions, such as fat oxidation and the like, and a plurality of flavouring substrates added manually also make an important contribution to the formation of the flavor of the fermented sausage.

Owner:青岛农博农食品科技有限公司

Homogeneous, essentially nonaqueous adjuvant compositions with buffering capability

InactiveUSRE37313E1Evenly distributedImprove permeabilityBiocideHydrocarbon active ingredientsAdjuvantFatty acid

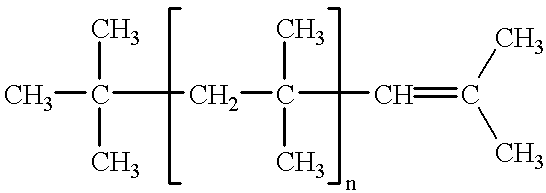

A homogeneous, essentially nonaqueous adjuvant composition containing at least one spray oil selected from the group consisting of:(a) vegetable oils;(b) fatty acids and blends thereof;(c) esterified fatty acids or blends thereof;(d) saponified fatty acids or blends thereof;(e) N,N-dimethylamide of the formula(f) polybutenes of the following formula a surfactant in an effective amount to emulsify said composition and a buffering agent in amount sufficient to reduce the pH to below about 7.

Owner:HELENA HLDG

Stable NEFA (non-esterified fatty acid) measuring kit

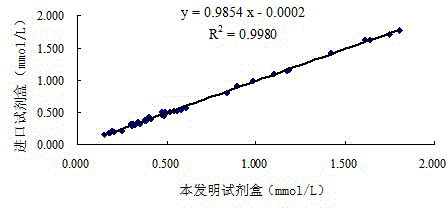

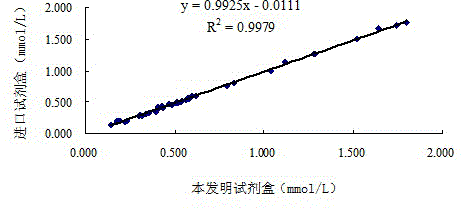

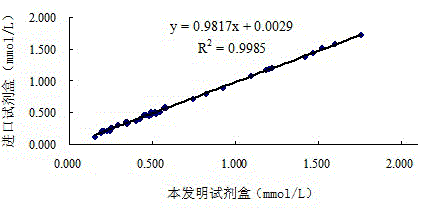

ActiveCN105203472AGood correlationExcellent linear fit correlation coefficientColor/spectral properties measurementsBiological testingBlood lipidsFatty acid

The invention relates to a stable kit for measuring NEFA (non-esterified fatty acid) through an enzymic method. The kit comprises two separate liquid reagents, namely, a reagent 1 and a reagent 2 which are respectively placed, and is good in stability and anti-interference performance. The enzymic method is adopted to measure NEFA, and the method is easy, convenient and easy to operate. According to the kit, novel chromogen is selected, and anti-interference agents such as ascorbic acid oxidase and potassium ferrocyanide are added into the formula at the same time, so that the reagent has the characteristics of being high in sensitivity and anti-interference performance; a liquid stabilization technology is adopted, and a series of special stabilizers, chelating agents and enzymatic protective agents are added, so that the reagent is good in stability, and can be widely applied to most semi / full automatic biochemical analyzers, and used for monitoring human body fat metabolic status, lipid level, and the like, and clinical popularization is facilitated.

Owner:北京万泰德瑞诊断技术有限公司

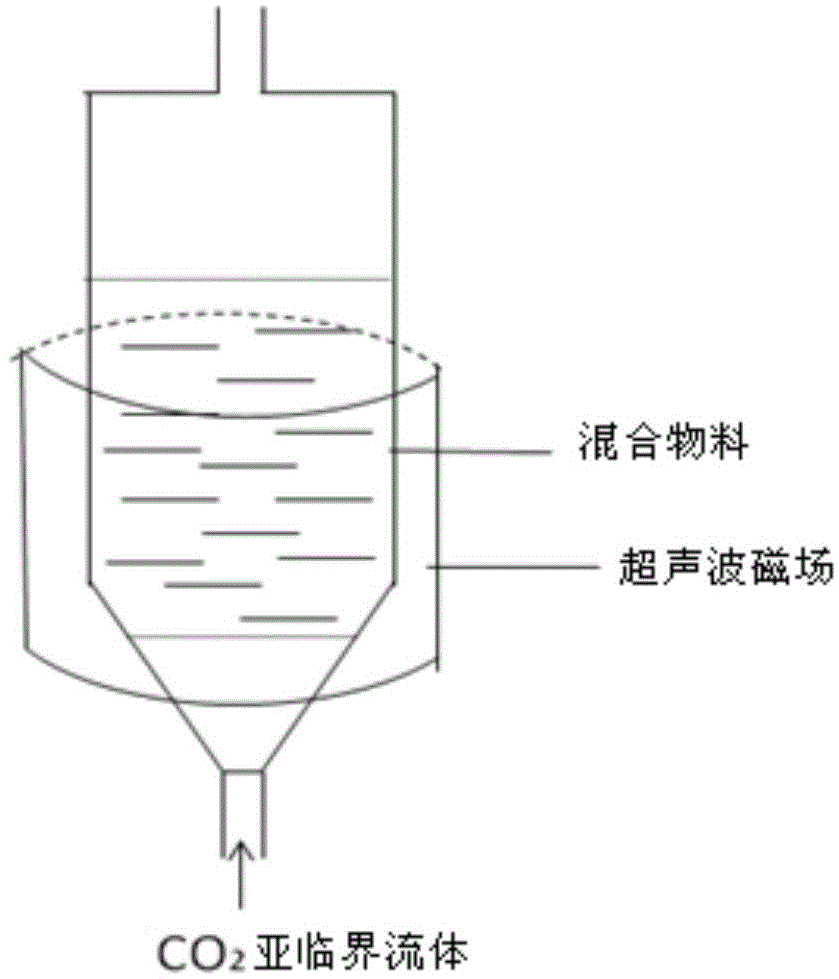

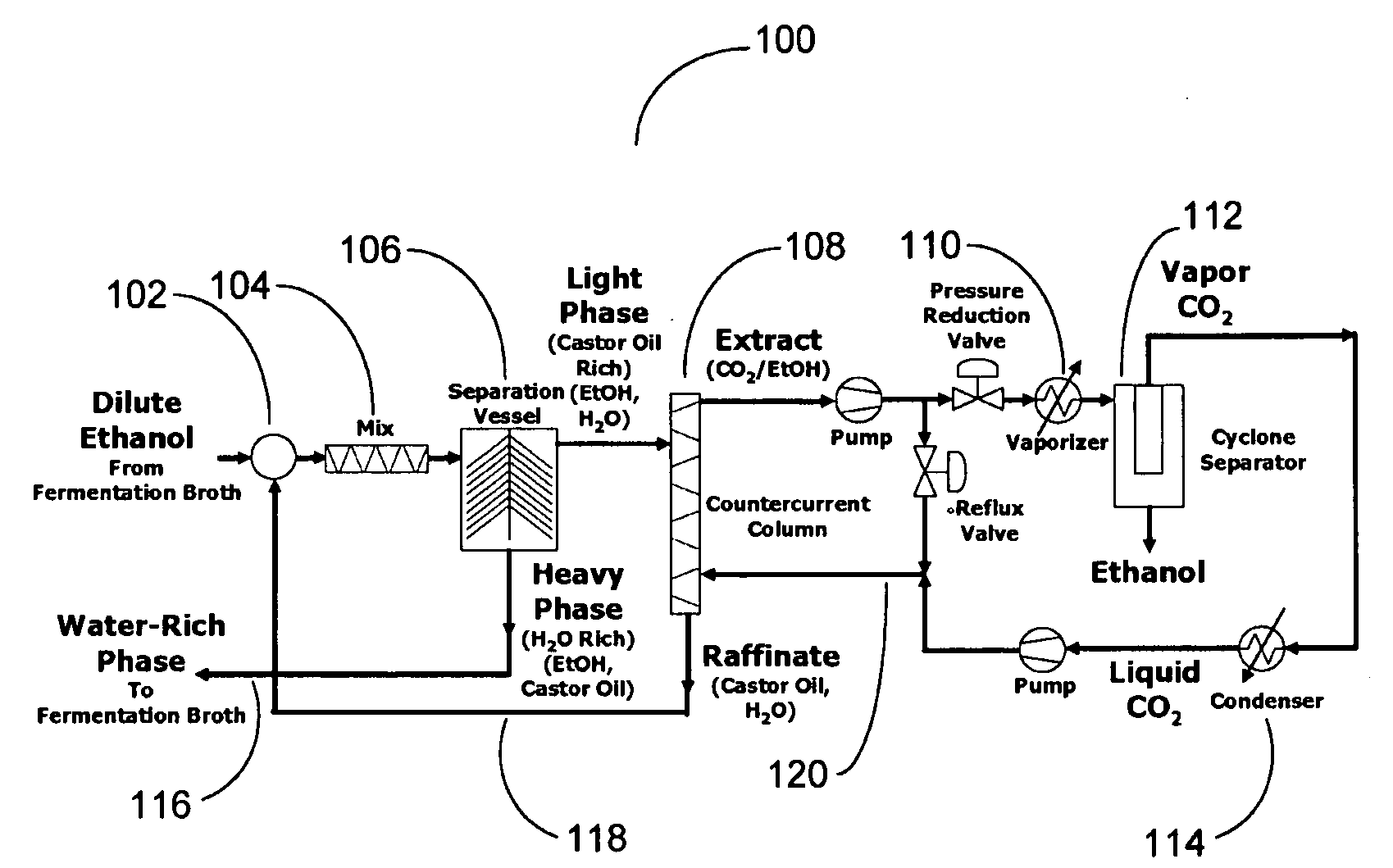

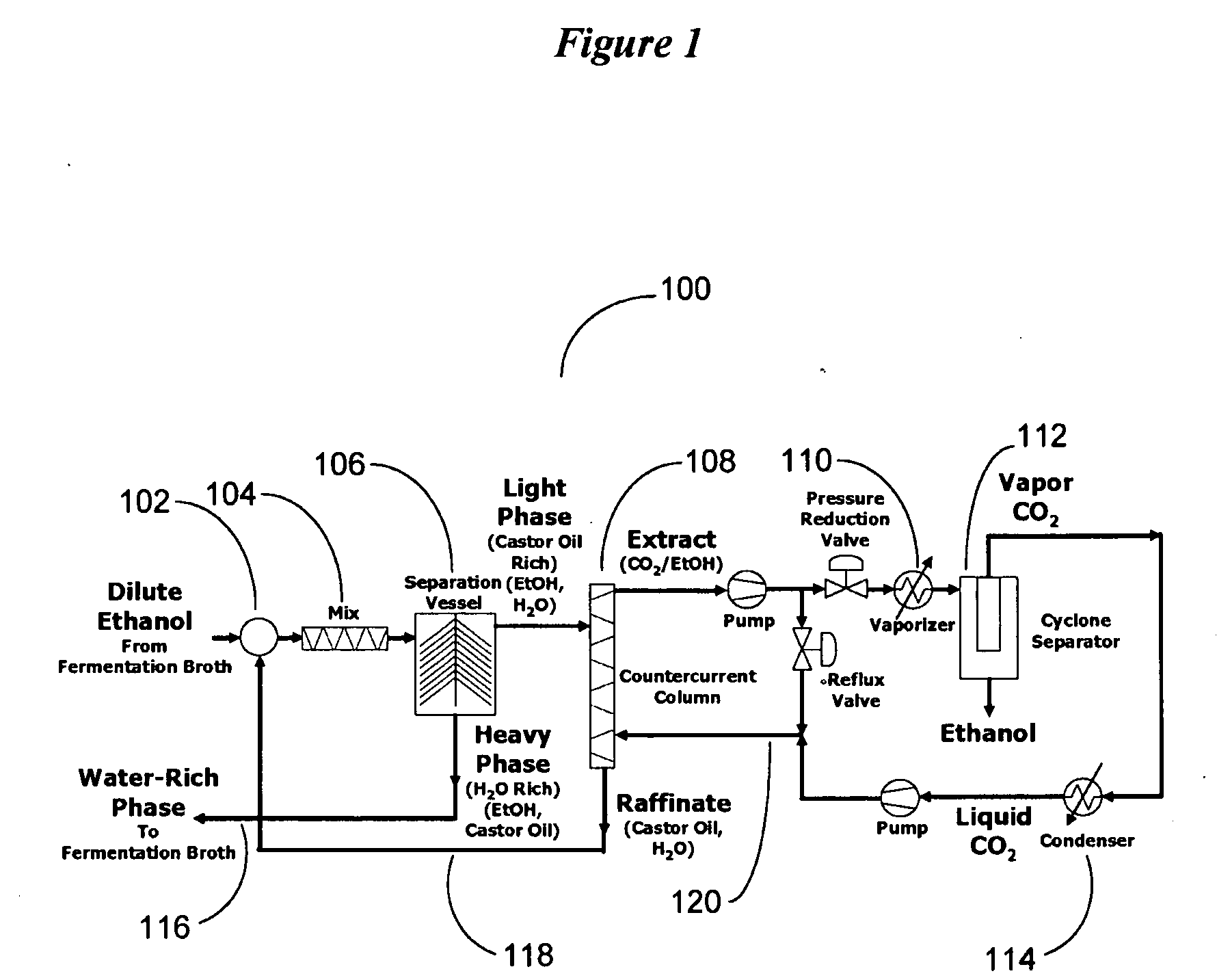

Energy Efficient Separation of Ethanol From Aqueous Solution

The present invention provides methods and systems for extracting ethanol from an ethanol-water solution comprising (1) extracting ethanol from an ethanol-water solution with a first solvent comprising an esterified fatty acid, wherein the esterified fatty acid comprises a hydroxylated fatty acid component and an alcohol component such that the alcohol component is a C3-6 alcohol, such that the distribution coefficient for ethanol in the mixture of the ethanol-water solution and the first solvent is at least 0.02 favoring the transfer of ethanol from the ethanol-water solution to the first solvent, thereby extracting the ethanol from the ethanol-water solution into the first solvent, and (2) extracting the ethanol-enriched first solvent with carbon dioxide, such that the carbon dioxide is at a liquid or near supercritical phase, wherein the distribution coefficient for ethanol in a mixture of the first solvent and the carbon dioxide is at least 0.1 favoring the transfer of ethanol from the first solvent to the carbon dioxide.

Owner:DYNASEP

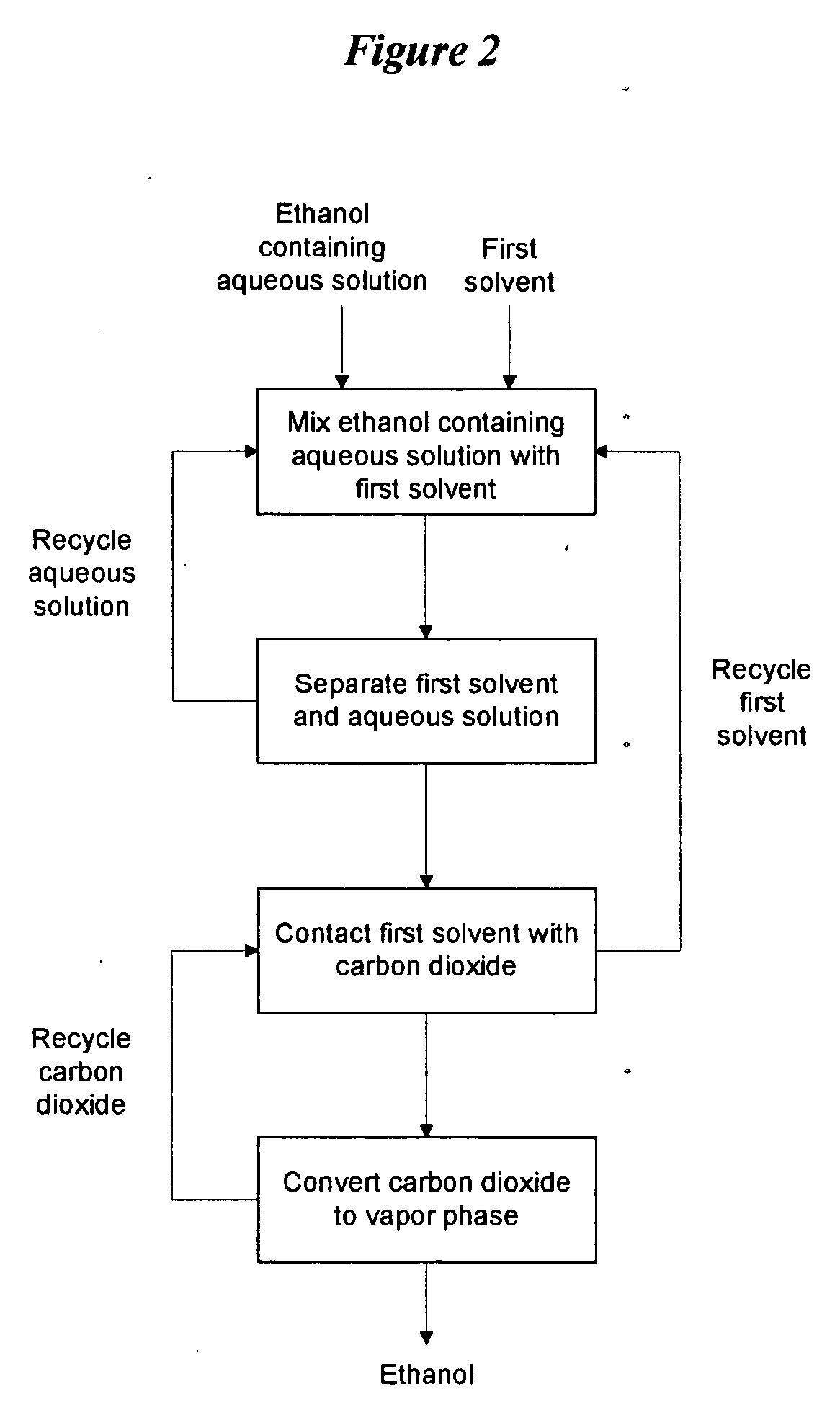

Method for preparing biodiesel by taking pupal oil as production raw material

InactiveCN101691519ABroaden source channelsAvoid pollutionFatty acid esterificationBiofuelsWater bathsBiodiesel

The invention provides a method for preparing biodiesel by taking pupal oil as a production raw material, comprising the following steps: extracting crude pupal oil from pupal powder by petroleum ether or normal hexane through a heat refluxing method; mixing the crude pupal oil with the solution of NaOH and ethanol; stirring in water bath; adding petroleum ether or normal hexane; adding hydrochloric acid into a saponified fluid for acidification to obtain non-esterified fatty acid; extracting fatty acid by petroleum ether or normal hexane; standing and layering; mergering petroleum ether layers or normal hexane layers; washing by water to be neutral; drying; filtering to obtain the mixed fatty acid; stirring the mixed fatty acid with low alcohol saturated solution of urea to obtain clathrate compound; cooling, crystallizing and filtering the obtained clathrate compound; filtering; extracting the obtained filtrate by petroleum ether or normal hexane; washing by water and drying the extract; carrying out reduced pressure distillation on solvent to obtain unsaturated fatty acid; placing the rest pupal fatty acid into a reactor, adding solid base catalyst and stirring, adding methanol, filtering the reaction liquid after reaction, standing and laying the reaction liquid; and carrying out reduced pressure distillation on crude biodiesel to obtain the biodiesel product.

Owner:JIANGSU UNIV OF SCI & TECH

Technique for producing fatty acid methyl ester

InactiveCN101215233AImprove use valueWide range of usesPreparation by ester-hydroxy reactionBiofuelsPlasticizerBoiling point

The invention relates to a manufacturing technique of fatty acid ester, which employs polished fat to generate sulfated oil or crude fatty acids of leftovers. Glyceride is generated by the reaction of non-esterified fatty acid and glycerol, in the sulfated oil or the crude fatty acids, unsaponifiable doesn't react with glycerol, unsaponifiable and acylglycerol are seperated by employing the different boiling points of both, the boiling point of non-esterified fatty acid which does not react is lower than that of acylglycerol, and the non-esterified fatty acid which does not react is also separated, the purified acylglycerol is obtained, then, acylglycerol is used to react with methanol, and the fatty acid ester with relatively high purity can be obtained. sulfated oil and crude fatty acids are used to separate unsaponifiable via pre-esterification, the process of pre-esterification doesn't need catalyst, the content of the obtained fatty acid ester is not less than 98%, and the cost is low, and thereby the invention can be widely used in the field of biodiesel, fine chemicals and plasticizer. The invention not only recycles and reuses waste, but also decreases environmental pollution, simultaneously the invention has relatively high economic value.

Owner:江门市江海区嘉诺化工发展有限公司

Composition Comprising a Powder Containing Microencapsulated Polyunsaturated Long-Chain Esterified Fatty Acids Distributed in an Effervescent Base

InactiveUS20080279935A1Easy to swallowUnpleasant textureBiocidePill deliveryFatty acids.polyunsaturatedEsterified fatty acid

The invention relates to a composition being substantially free from water comprising a powder containing microencapsulated polyunsaturated long-chain esterified fatty acids (PUFA), wherein said PUPA content of said powder is from about 5 to about 50% (w / w), said powder being homogenously distributed in an effervescent base, wherein said effervescent base is from about 20 to about 75% (w / w) of said composition. The invention also relates to a process for the production of said composition as well as tablets, granules and powders comprising said composition and does unites as well as containers comprising said composition, tablet, granules or powders and the use of said products.

Owner:DELANTE HEALTH

Method for preparing biodiesel

The invention relates to a method for preparing biodiesel, which comprises the following steps: a raw oil material reacts with C1-C6 monohydric alcohol in a reactor under the existence of an extra non-esterified fatty acid source; and the biodiesel is obtained by separating fatty acid ester from reacted materials, wherein the content of non-esterified fatty acid in the non-esterified fatty acid source is 2-100 wt percent and higher than that of the non-esterified fatty acid in the raw oil material. The method can improve the yield and purity of biodiesel of raw oil material low in reaction activity, and the raw material has strong suitability.

Owner:CHINA PETROLEUM & CHEM CORP +1

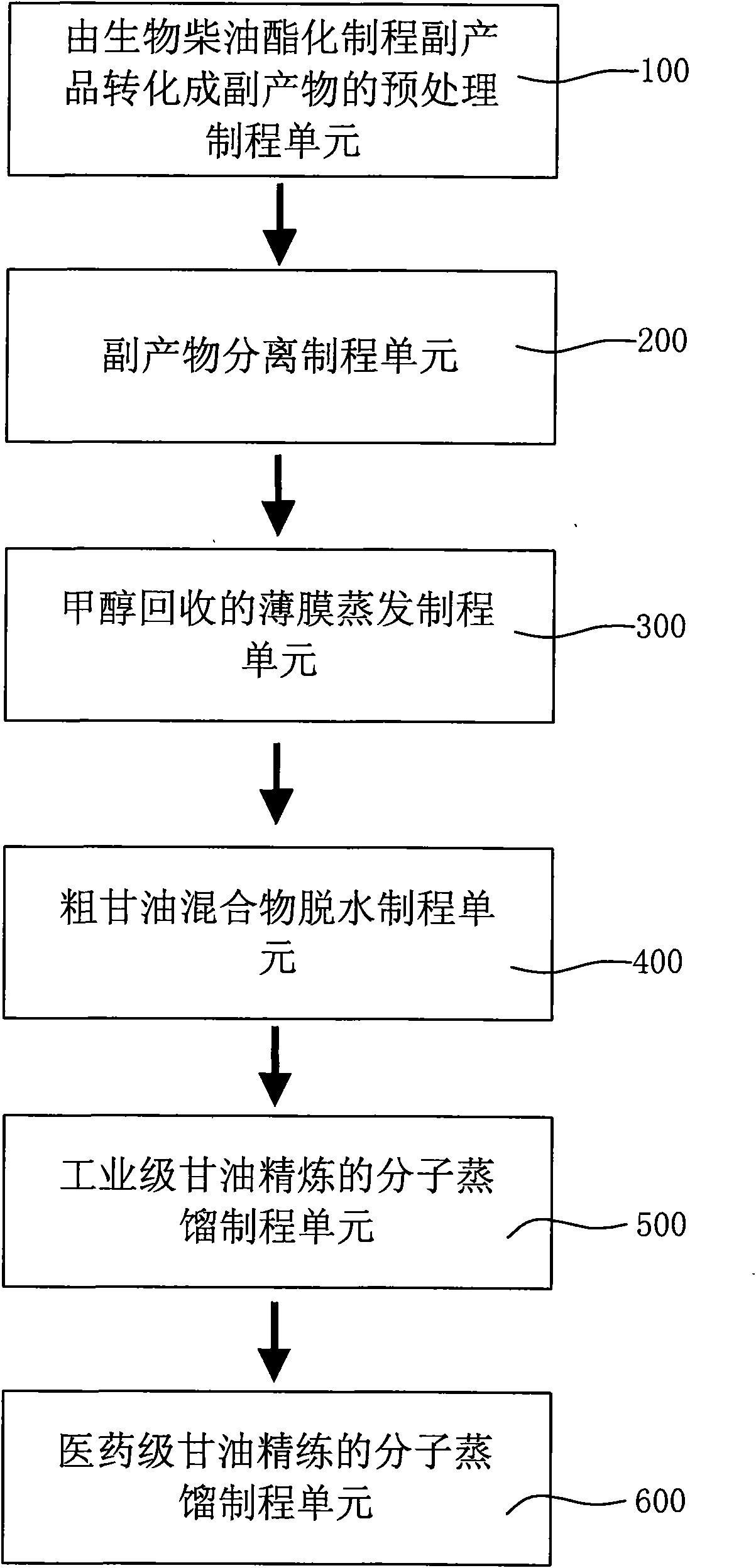

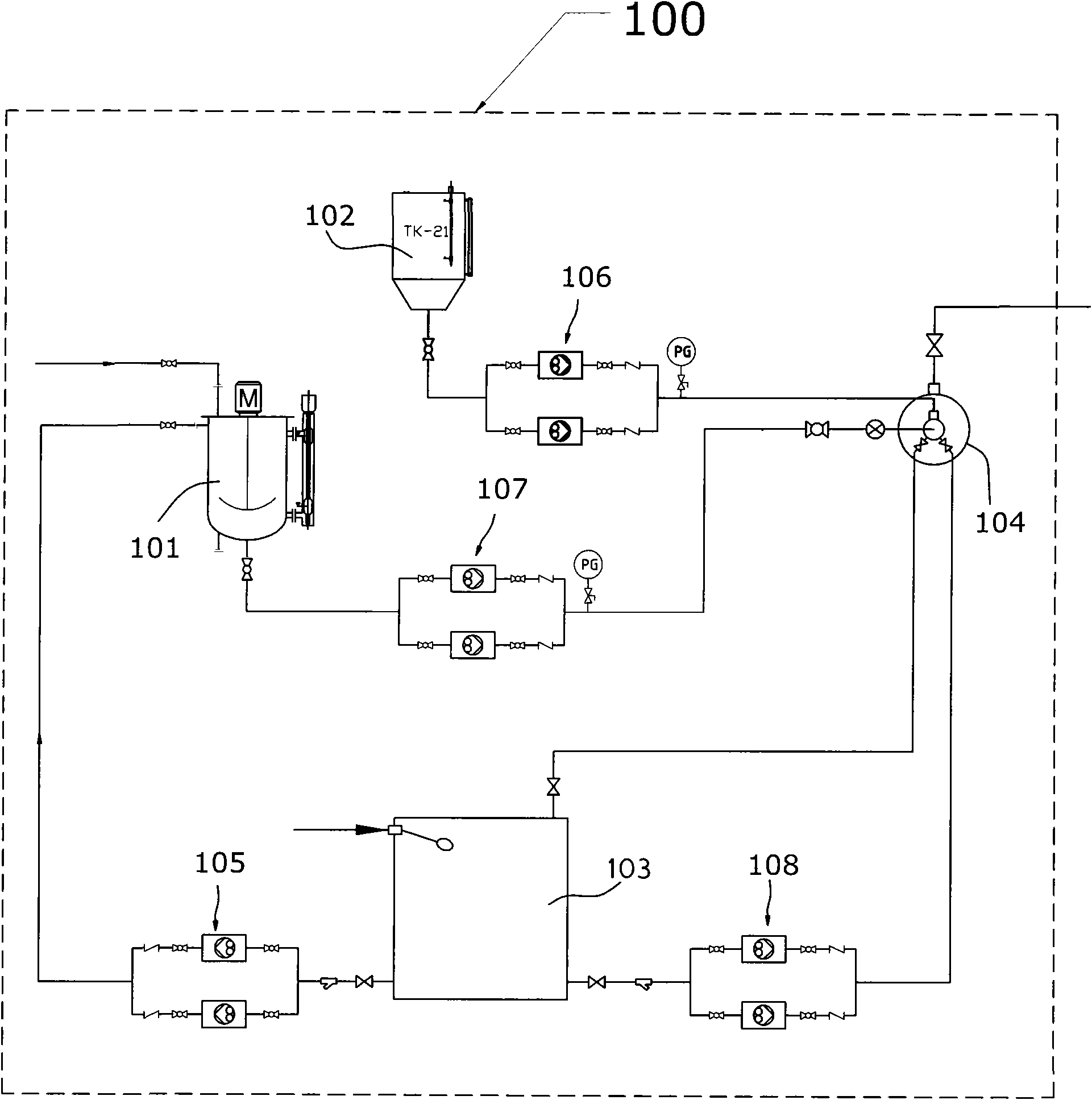

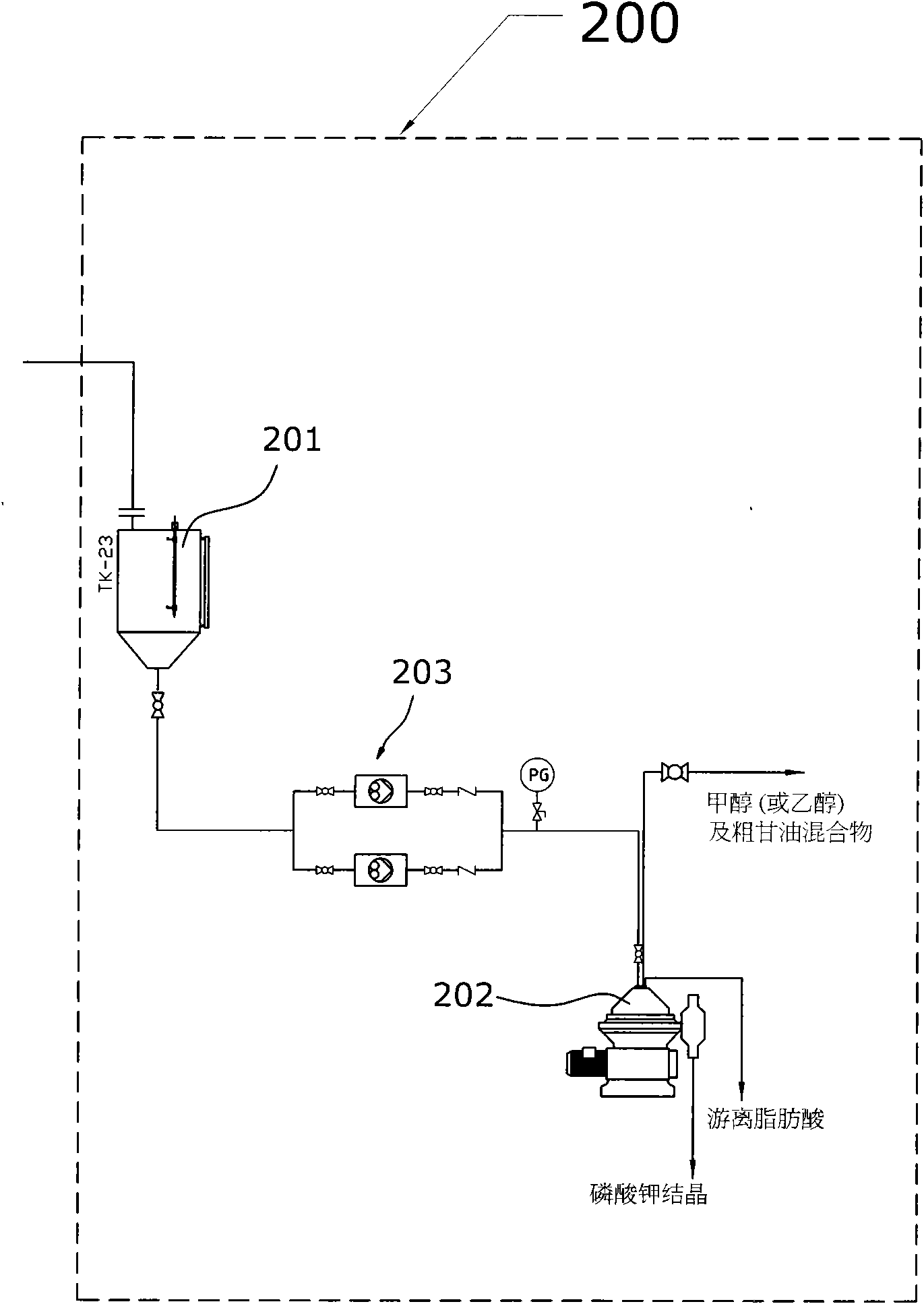

Method for preparing glycerin from byproduct in manufacture procedure of biodiesel

The invention discloses a method for preparing glycerin from a byproduct in a manufacture procedure of biodiesel, which comprises that: phosphoric acid is put into a phosphoric acid storage tank; the byproduct generated in the esterification manufacture procedure of the biodiesel is sent into a blending tank, and clear water in certain ratio is introduced to a temporary storage tank, and mixed and stirred with the byproduct in the esterification manufacture procedure; the stirred byproduct in the esterification manufacture procedure is sent into a homogenizer for conversion treatment through a delivery pump, and simultaneously the delivery pump is started; the phosphoric acid is sent into the homogenizer in specific ratio and is subjected to mixing and conversion with the byproduct in the esterification manufacture procedure, and a mixture of the byproduct in the esterification manufacture procedure after the mixing and conversion is temporarily placed in the material temporary storage tank; and the material in the material temporary storage tank is converted, sticky and thick non-esterified fatty acid, a particle crystalloid potassium phosphate compound, and farrago of liquid crude glycerine, water content and methanol are separated out, and the separated substances are subjected to three-phase separation by a three-phase centrifuge.

Owner:张伟民 +4

Method for preparing texture phospholipid and lecithin

ActiveCN101701229AWill not damage the structureFull of nutritionFermentationPhospholipidUnsaturated Oils

The invention discloses a method for preparing texture phospholipid and lecithin, comprising the following steps: mixing concentrated phospholipids and unsaturated oil and adding lipase for catalyzing phospholipid for ester exchange reaction; inactivating lipase after reaction, removing non-esterified fatty acid, concentrating and drying to obtain powder texture phospholipid crude product; and further extracting, decoloring and concentrating the powder texture phospholipid crude product to obtain pasty texture lecithin, freezing and drying to obtain the powder texture phospholipid product B. For the texture lecithin prepared by the invention, ester exchange occurs at saturated fatty acid at 1 and 3 of phospholipid positions at the same time and are all replaced by unsaturated fatty acid, thus having abundant nutrition and being healthy for human bodies; the method in the invention has the advantages of mild reaction conditions and no damage of product structure, especially can protect unsaturated bonds in unsaturated fatty acid well.

Owner:广州海莎生物科技有限公司

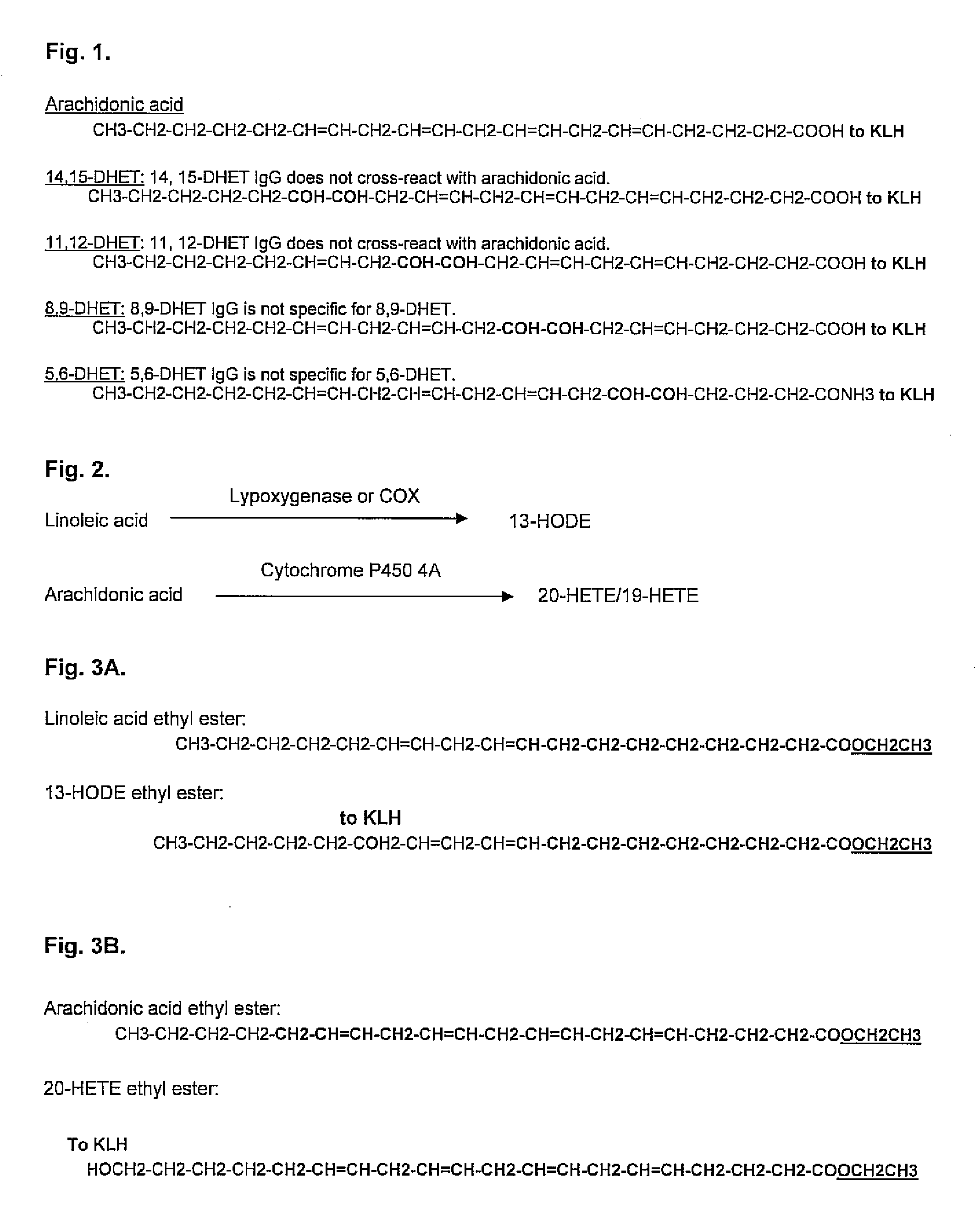

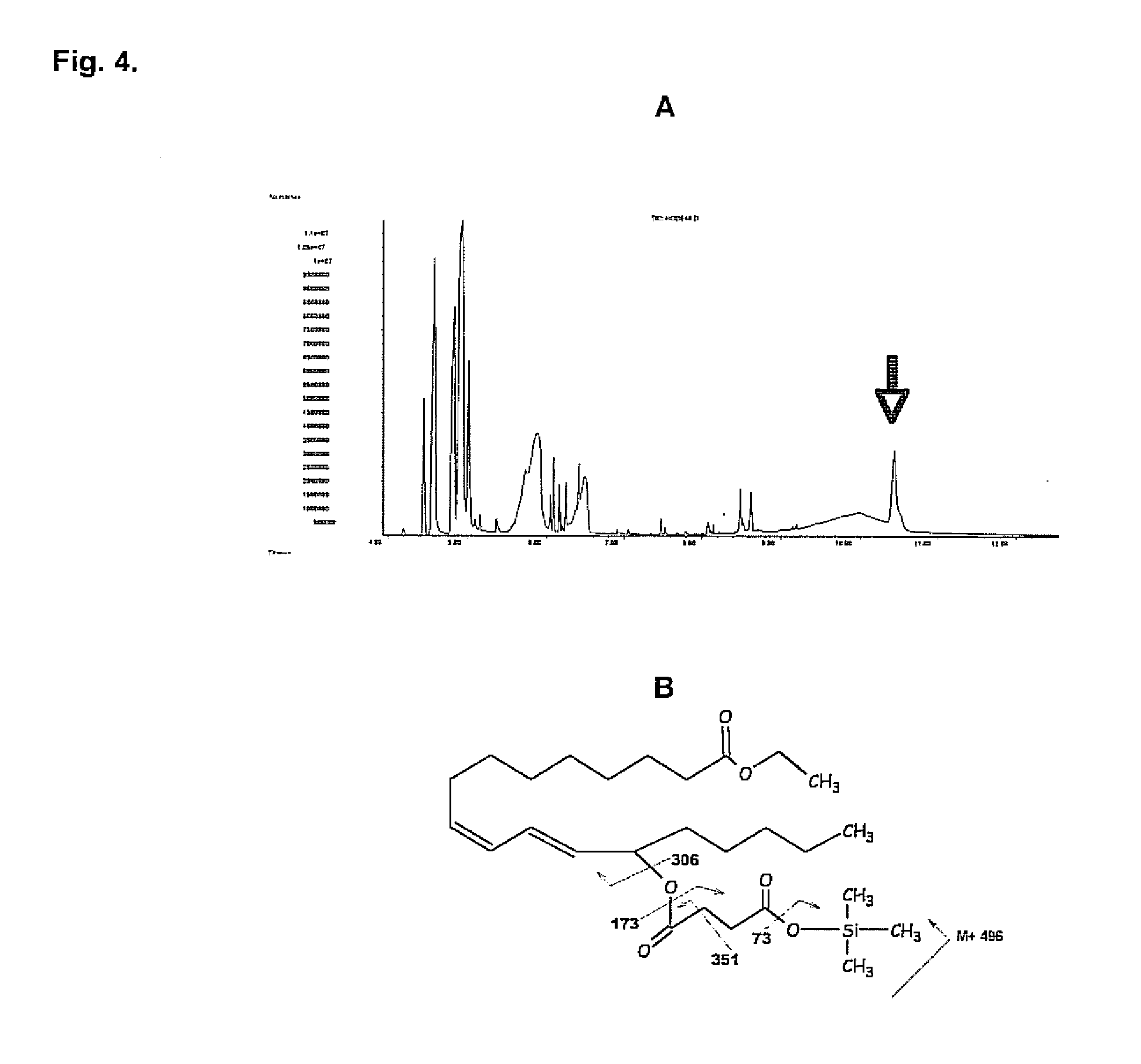

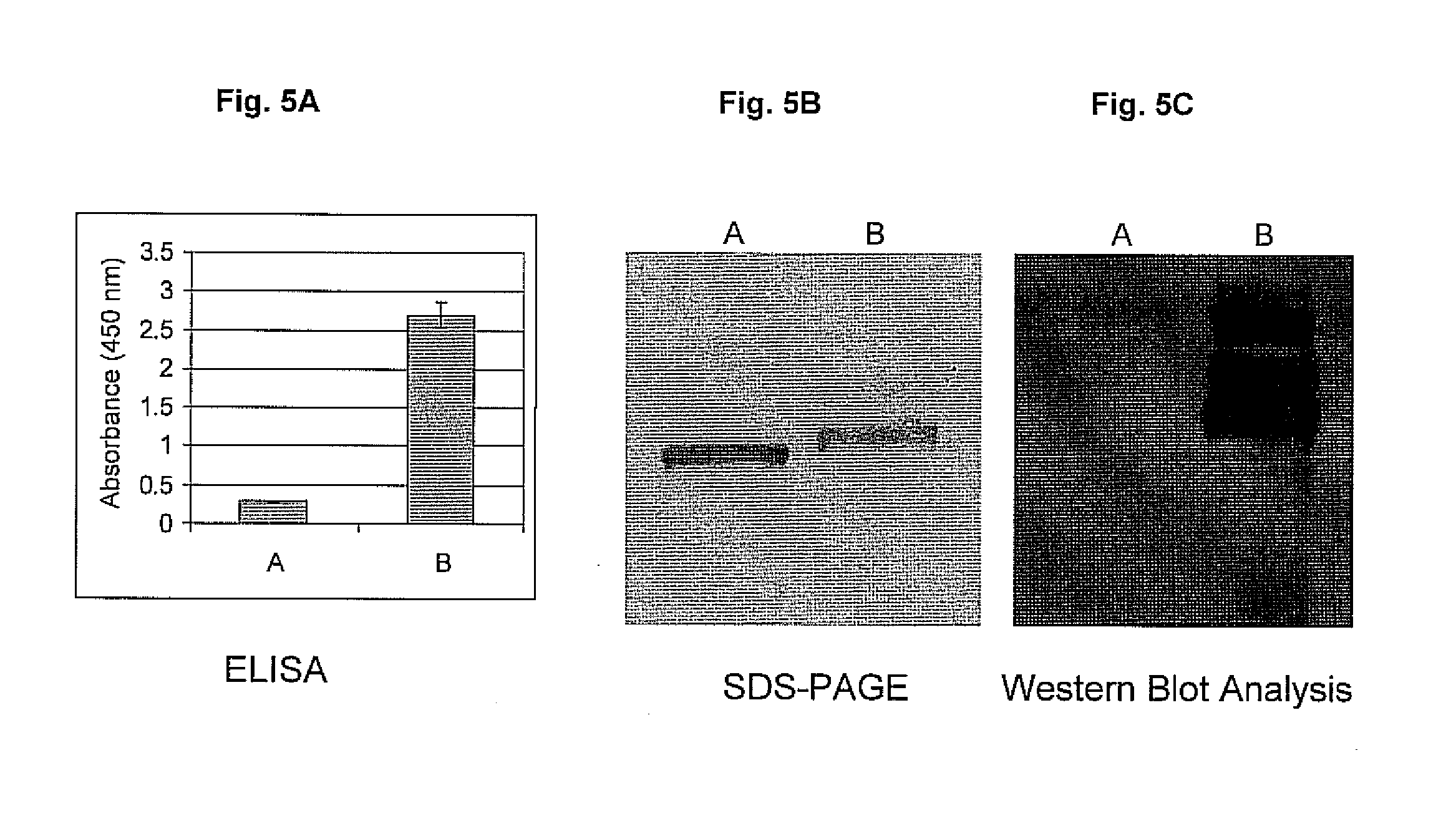

Detection of alcohol-esterified fatty acids

A method of producing an antibody recognizing a target fatty acid alcohol ester by immunizing an animal with a carrier protein conjugated with a derivative of the target fatty acid alcohol ester. A method of estimating alcohol consumption of an individual by quantitating levels of molecules which bind to antibodies produced with a derivative of a target fatty acid alcohol ester conjugated to a carrier protein in a biological sample obtained from the individual. A kit for estimating alcohol consumption of an individual including means for quantitating levels of molecules which bind to antibodies produced with a derivative of a target fatty acid alcohol ester conjugated to a carrier protein in a biological sample obtained from the individual.

Owner:DETROIT R&D

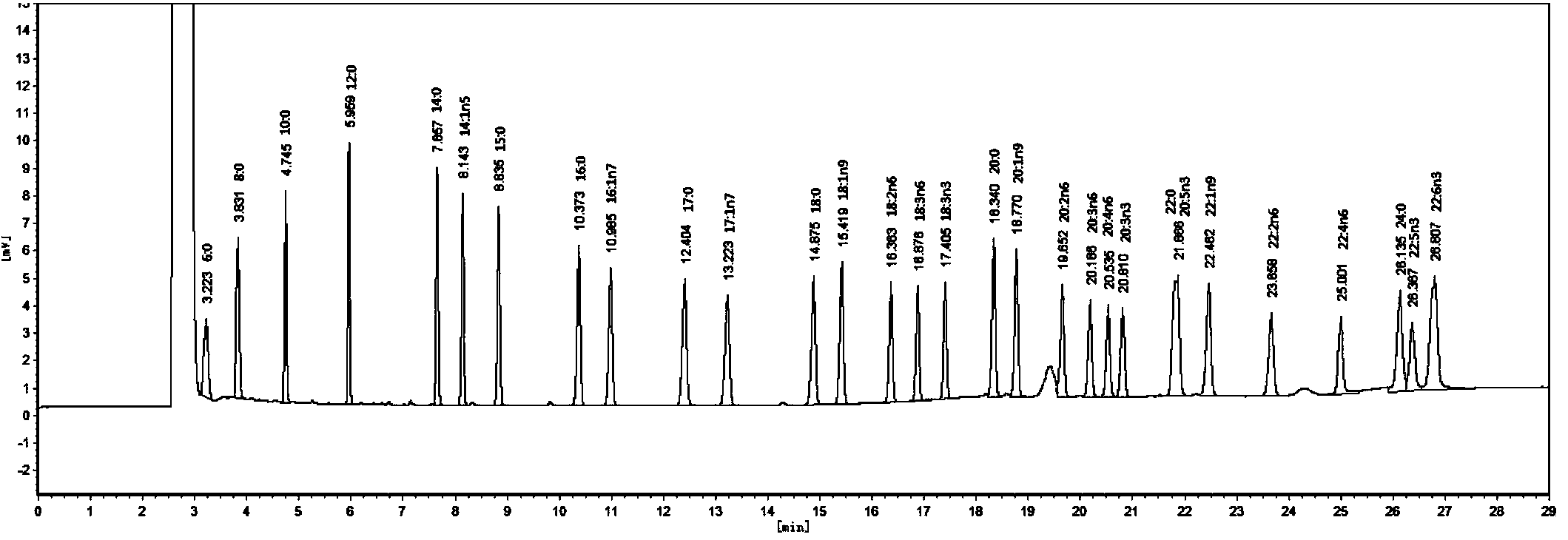

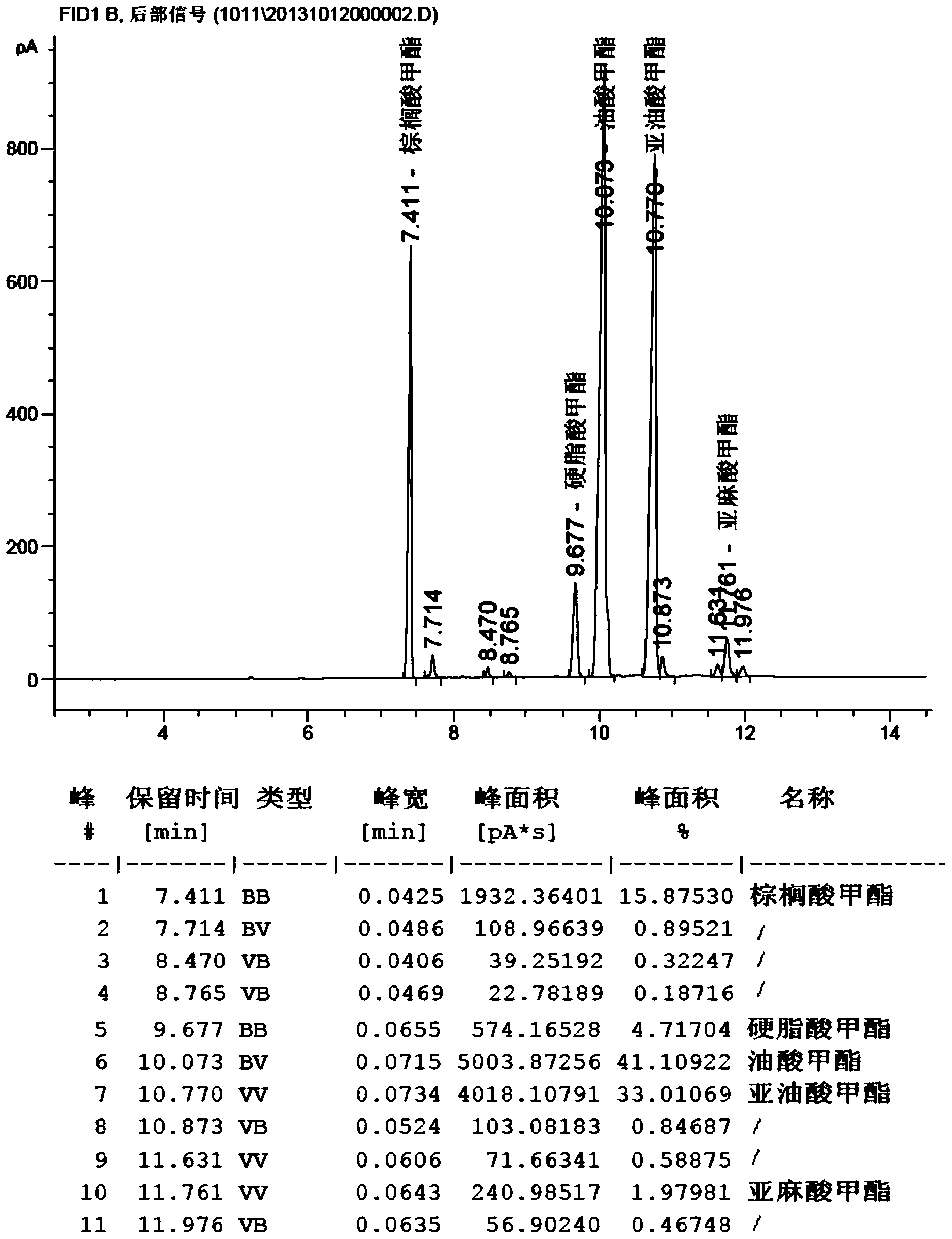

Method for establishing blood correlated fatty acid spectrum

InactiveCN103616465AEffective way to buildTrusted establishment methodComponent separationLipid formationFat intake

The invention discloses a method for establishing a blood correlated fatty acid spectrum. The method comprises the following steps: 1) choosing a research object, and carrying out extraction, separation and concentration on plasma, serum or platelet disengaged from the body of the research object, so as to obtain total lipids; 2) separating phospholipids and triglycerides from the total lipids by a thin-layer chromatography method; 3) conducting methyl esterification on the separated phospholipids and triglycerides; 4) determining fatty acid components in the fatty acid subjected to methyl esterification by a gas chromatography method; 5) carrying out atlas analysis and SPSS data statistical analysis on the fatty acid; and 6) systemizing and summarizing the analysis data. The invention creates a simple, effective and practical method for establishing fatty acid spectrum; and a fatty acid spectrum of healthy people with current chronic diseases is established, so as to provide potent guidance for the health of human and fat intake.

Owner:ZHEJIANG UNIV

Method for producing edible lipid containing docosahexenoic acid by lipase-catalyzed ester exchange

The invention provides a method for producing edible fat containing docosahexenoic acid by enzyme process and ester exchange. The method comprises the following steps: (1) putting DHA fat into the edible fat to add enzyme; (2) vacuumizing and heating a closed container to be stirred; and (3) charging nitrogen into the closed container after a reaction is completed, filtering to obtain the edible fat after ester exchange, obtaining finished product fat after molecular distillation, or removing non-esterified fatty acid after alkali refining, and deodorizing to obtain the finished product fat. The method has the advantages that the edible fat and the docosahexenoic acid (DHA for short) fat are catalyzed to carry out ester exchange by 1,3-selective immobilized lipase so as to produce the edible vegetable fat with rich docosahexenoic acid (short for DHA) and with high added value; the edible fat with rich docosahexenoic acid (short for DHA) is sealed in a proper packaging container, afterthe container is vacuumized and charged with nitrogen, the container is placed at room temperature for 18 to 24 months, the peroxide number of the edible fat is stilled maintained at less than or equal to 10meq / kg, and the oxidative stabilization of the fat is obviously improved.

Owner:罗盖特生物营养品(武汉)有限公司

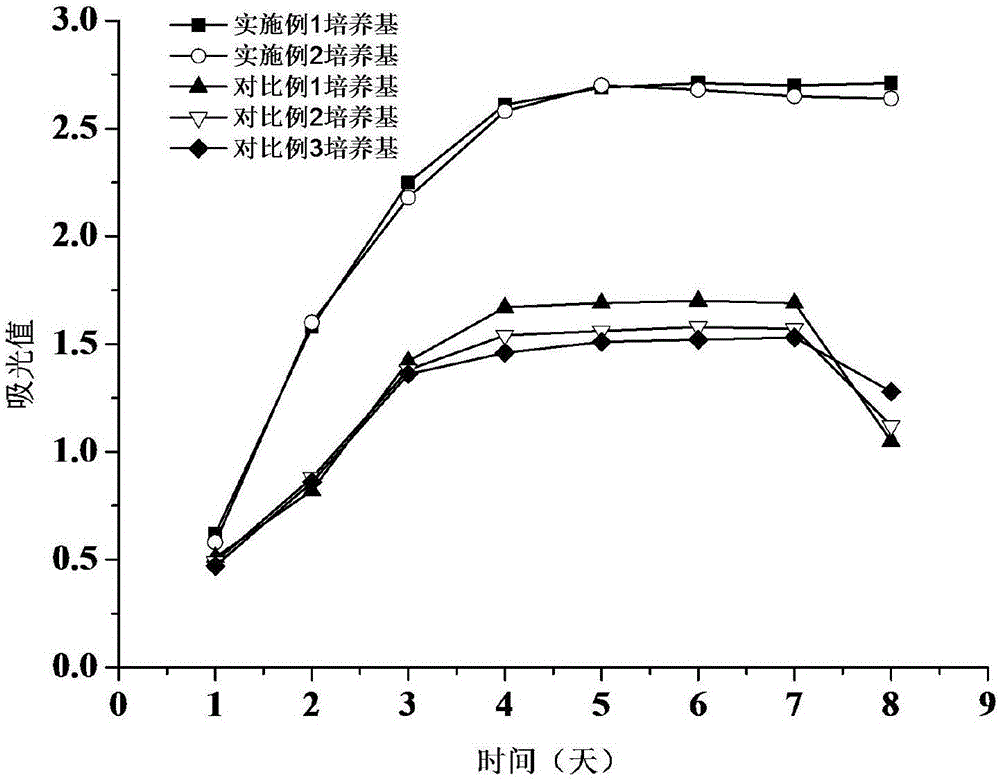

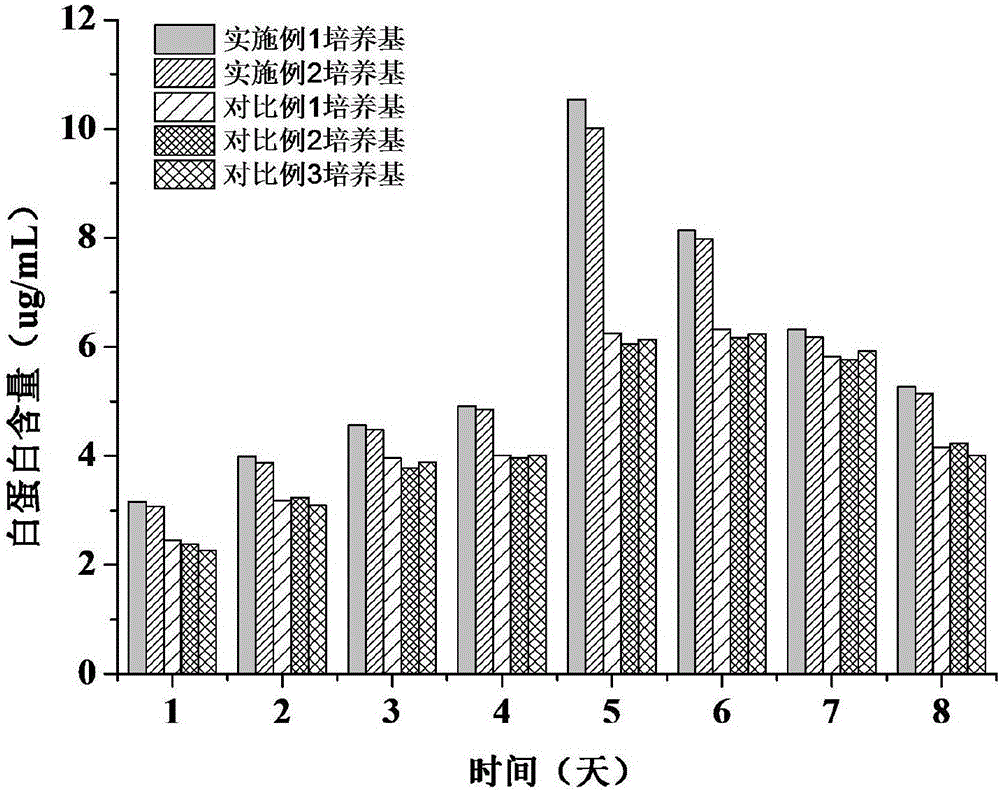

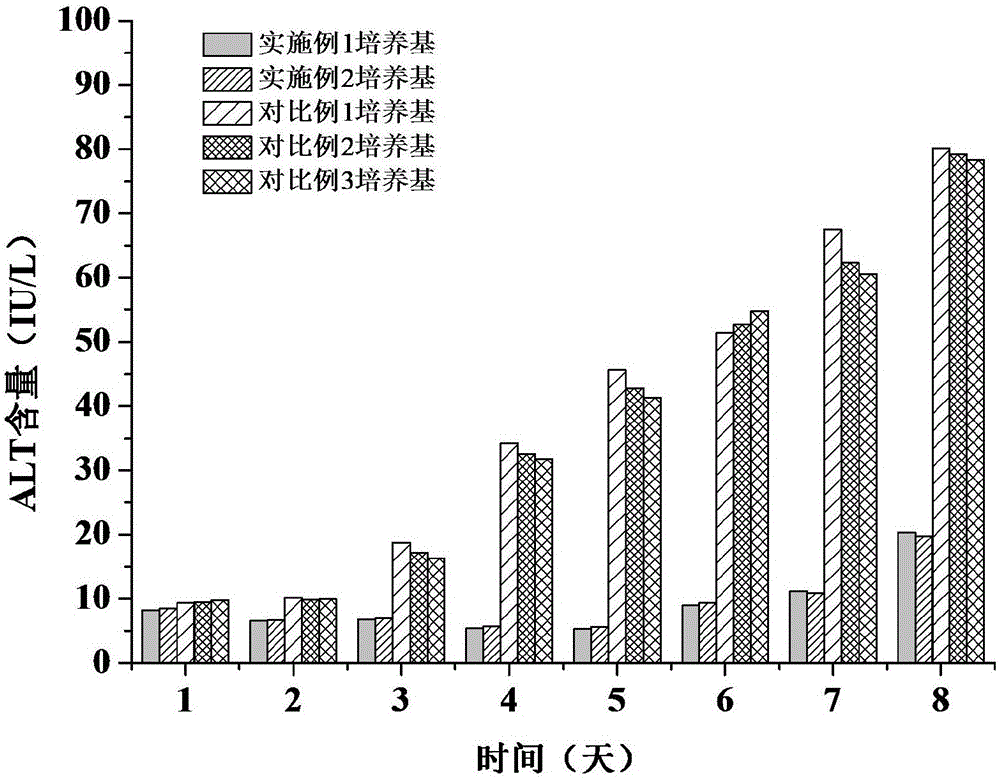

Serum-free hepatocyte culture medium and preparation method thereof

InactiveCN106754643APromote growthKeep activeVertebrate cellsArtificial cell constructsSodium bicarbonateCell culture media

The invention relates to a culture medium for cell culture, and concretely relates to a serum-free hepatocyte culture medium and a preparation method thereof. The culture medium provided by the invention comprises a basic culture medium and additive components, wherein the additive components comprise insulin, transferrin, sodium selenite, epidermal growth factors, hepatocyte growth factors, laminin, dexamethasone, non-esterified fatty acid, sodium bicarbonate, tanshinone IIA and cryptotanshinone. The culture medium can promote the cell growth, and unexpectedly, the serum-free hepatocyte culture medium provided by the invention can greatly promote synthesis of albumin, and can maintain cell activity for a long time.

Owner:严志海

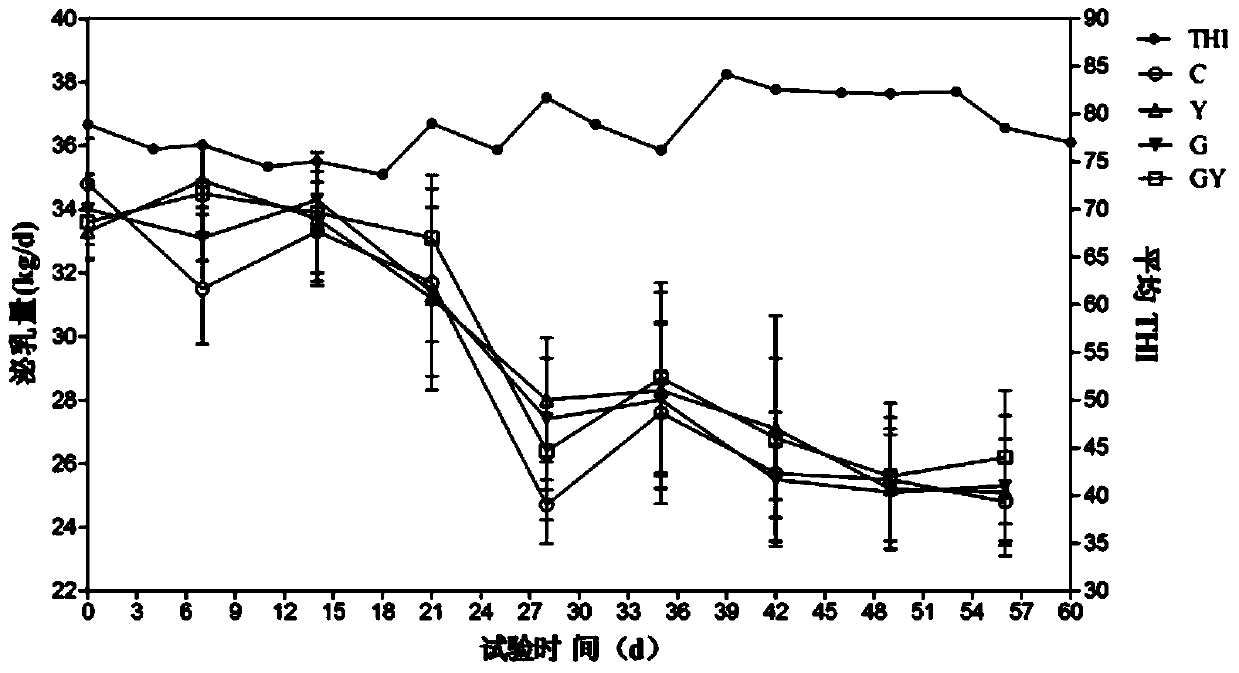

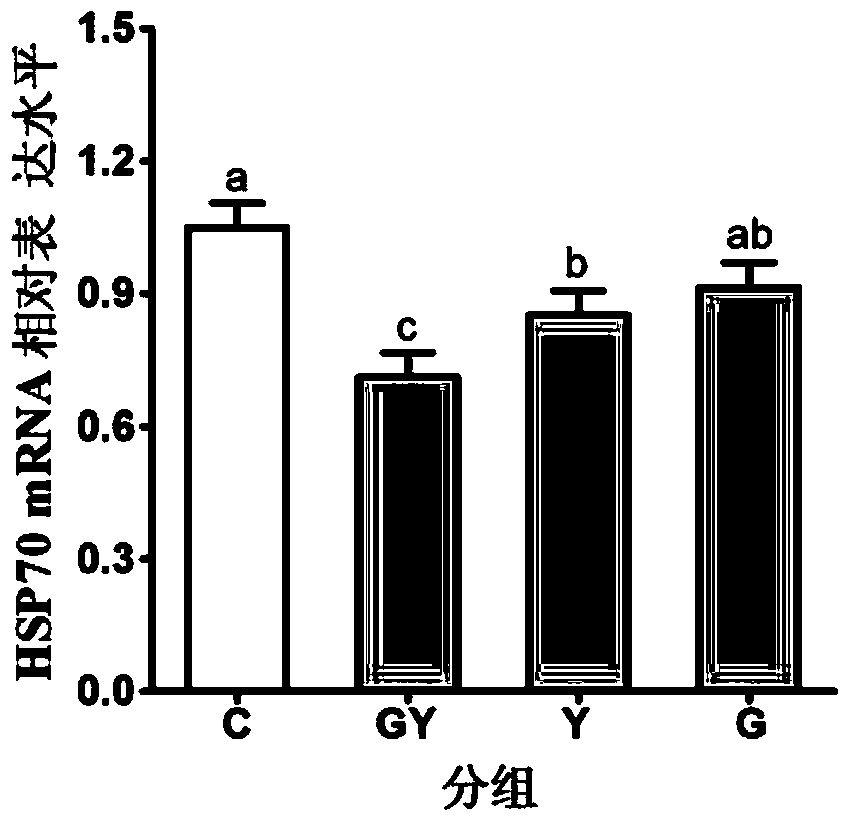

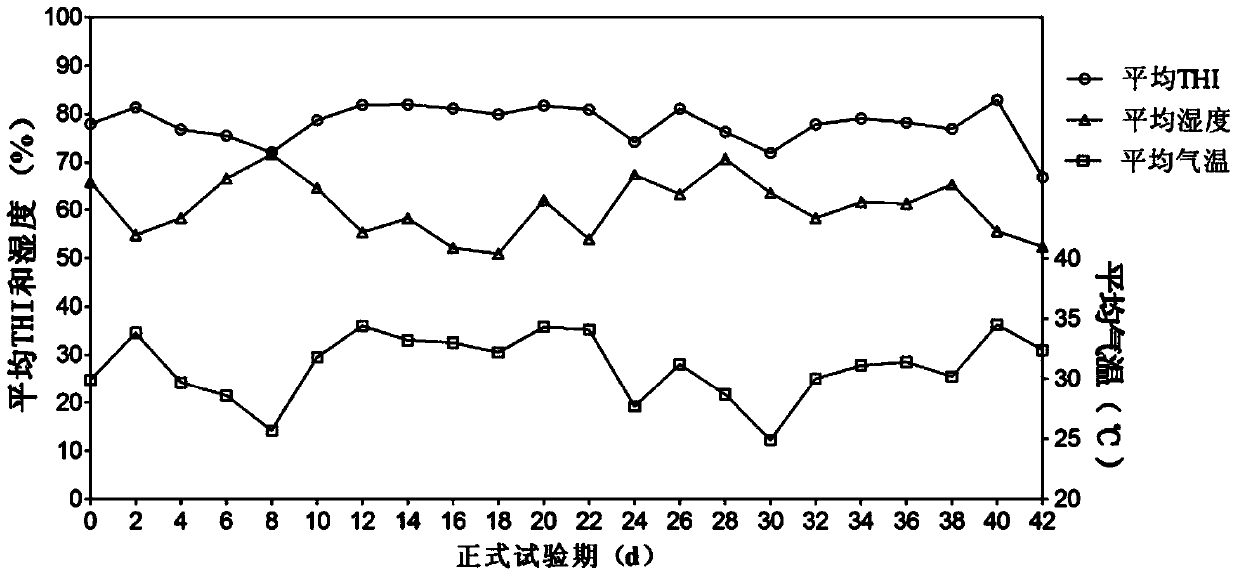

Cow heat-stress resistant feed additive

The invention discloses a cow heat-stress resistant feed additive. Saccharomyces cerevisiae (Sc) NAU-ZH-GY1 is applicable to prepare the cow heat-stress-resistant feed additive. The cow heat-stress-resistant feed additive, which is rich in glycerin, yeast live bacteria and microbial metabolites such as amino acids, vitamins and the like, is produced under the high-permeability condition by employing a continuously feeding manner for fermentation; and the cow heat-stress resistant feed additive is capable of cooperatively perform dual efficacy of glycerin and yeast, and is capable of substantially improving lactation yield, 4% fat corrected milk yield and milk fat percentage of cow under heat-stress condition, improving blood sugar concentration, reducing somatic cell number, concentration of non-esterified fatty acid and concentration of urea nitrogen in milk, supplementing energy for cows, alleviating body weight reduction, enhancing antioxidation capability, reducing HSP70mRNA level and effectively alleviating heat stress of cows.

Owner:NANJING AGRICULTURAL UNIVERSITY

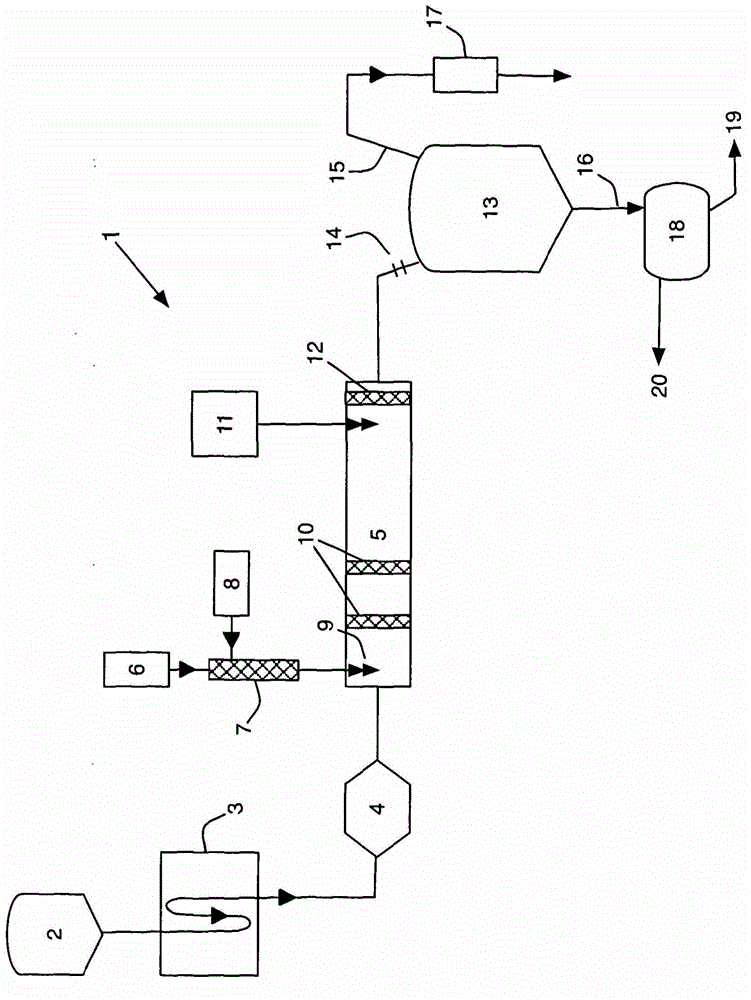

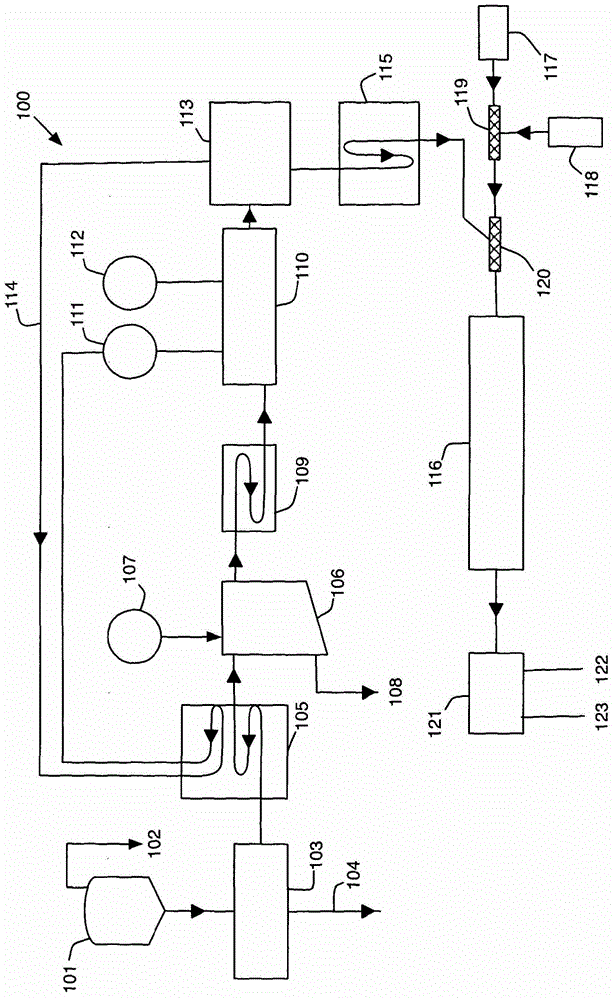

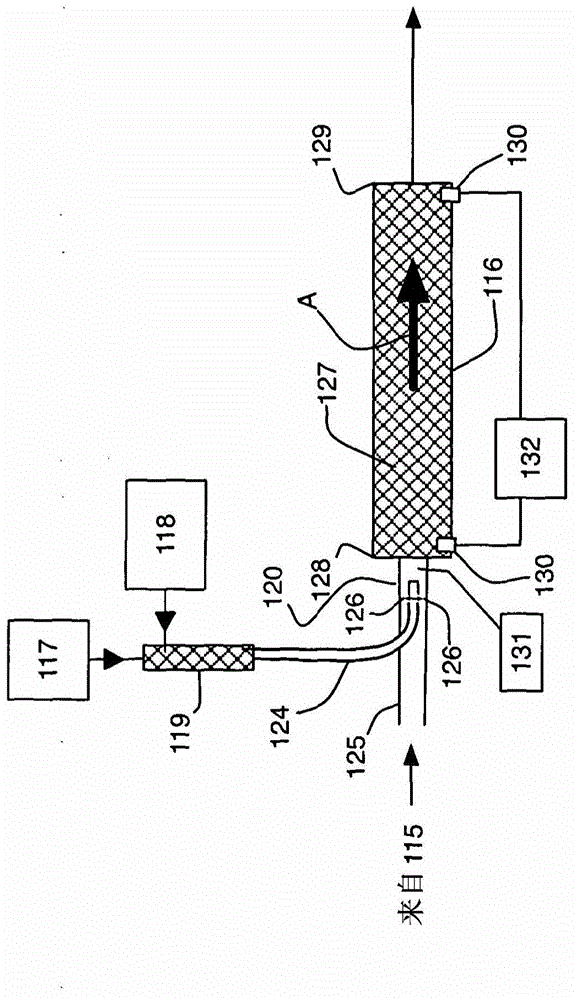

Method and apparatus for esterifying fatty acid

InactiveCN102753263AEnhanced mixing processImprove responseFatty acid esterificationOrganic compound preparationAlcoholReaction temperature

A method of esterifying free fatty acid in natural oil comprises heating the natural oil (2) to a first temperature above a reaction temperature, feeding the heated natural oil into an acid-resistant pipe reactor (5), providing a mixture of acid catalyst (6) and short chain alcohol (8) at a second temperature below the reaction temperature, and feeding the mixture of acid catalyst and short chain alcohol into the natural oil in the pipe reactor (5). The short chain alcohol and free fatty acid react at the reaction temperature to form an ester.

Owner:RENEWABLE HLDG LTD

Concentrate supplement for dairy cows in early peripartum and using method thereof

InactiveCN102907574AIncrease blood calcium concentrationImprove immunityAnimal feeding stuffAdditive ingredientMilk cow's

The invention discloses concentrate supplement for dairy cows in early peripartum and a using method thereof. A formula of the concentrate supplement contains 17.5% of protein, 4% of fiber, 2.5% of fat, 12% of ash, 3% of calcium, 0.5% of phosphorus, 0.6% of magnesium, 0.8% of potassium, 0.6% of sulphur, 0.1% of sodium and 0.9% of chlorine, wherein the percentages are mass percentages of all the components in the total weight of the concentrate supplement for dairy cows in early peripartum; and the formula also contains 75mg / kg of manganese, 120mg / kg of iron, 32mg / kg of copper, 2.5mg / kg of cobalt, 125mg / kg of zinc, 0.5mg / kg of selenium, 3mg / kg of iodine, 42000IU of vitamin A, 10000IU of vitamin D, 420IU of vitamin E and 50ppm of rumensin. The using method is that the concentrate supplement for dairy cows in early peripartum is used together with corn silage and tall oat grass or hay. The concentrate supplement can improve the blood calcium concentration of cows, provide available energy, reduce energy negative balance, improve fat metabolism, and reduce blood NEFA (Non Esterified Fatty Acid) concentration so as to effectively guarantee the smooth transition of the production phase of the cows.

Owner:上海延华生物科技股份有限公司

Lactation promoting feed for sow and preparation method of feed

InactiveCN106974104AReasonable formulaPromote secretionFood processingAnimal feeding stuffBiotechnologyCyclodextrin

The invention discloses lactation promoting feed for sow and a preparation method of the feed and belongs to the technical field of feed. The lactation promoting feed is prepared from raw materials in parts by weight as follows: 50-80 parts of wheat bran, 40-60 parts of corn flour, 20-30 parts of apple pomace, 20-30 parts of black soya beans, 15-30 parts of maifanite, 15-30 parts of fishbone meal, 15-25 parts of mushroom dregs, 15-20 parts of calcium citrate, 15-20 parts of platycodon roots, 10-20 parts of dried small shrimps, 5-10 parts of suberect spatholobus stems and 5-10 parts of a lactation promotion inducer; the lactation promotion inducer is prepared from raw materials in parts by weight as follows: 30-50 parts of cyclodextrin, 10-15 parts of puerarin, 8-12 parts of ginsenoside, 8-10 parts of flos lonicerae, 8-10 parts of NEFA (non-esterified fatty acid), 5-10 parts of peony roots, 3-8 parts of cassia twigs, 2-5 parts of red dates and 1-3 parts of poria cocos. The feed adopts a reasonable formula, has a good lactation promoting effect, can increase the milk production of the sow and prolong the milk production period, has no adverse effects on the health of the sow and is beneficial to body recovery of the sow after delivery.

Owner:元谋朝阳牧业有限公司

Method for extracting fatty acid methyl ester from vegetable pitch

ActiveCN103666769ALow reaction temperatureReduce difficultyFatty acid esterificationLiquid carbonaceous fuelsAfter treatmentReaction temperature

The invention discloses a method for extracting fatty acid methyl ester from vegetable pitch. The method comprises the following steps: (1) adding methanol into the vegetable pitch for the first time, and esterifying fatty acids in the vegetable pitch at the temperature of 60-100 DEG C under the action of an acid catalyst; and (2) adding methanol into the solution in the system for the second time for diluting after the esterification reaction is finished, performing centrifugal separation, collecting light components, steaming to remove the solvent to obtain crude fatty acid methyl ester, and regulating the acid value of the crude fatty acid methyl ester to be 1mgKOH / g below, thus obtaining the fatty acid methyl ester. According to the method for extracting fatty acid methyl ester from vegetable pitch, the esterification reaction and the centrifugal separation are combined, the reaction temperature and the reaction difficulty are greatly reduced, and the method is low in equipment requirement, simple in after treatment and suitable for industrial production.

Owner:浙江嘉澳环保科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com