Method for preparing fatty acid phytosterol esters

A technology of phytosterol ester and phytosterol, which is applied in the preparation of steroids, food preparation, chemical instruments and methods, etc., can solve the problems of high demand pressure, complex catalyst preparation, and great influence on catalytic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0093] In the method for preparing fatty acid phytosterol esters of the present application, the fatty acid and phytosterol can be heated first to form a uniform oily substance. It can be heated by conventional technical means. For example, depending on the selected fatty acids and phytosterols, the heating temperature may vary from, for example, about 100-180°C, 110-150°C, 110-130°C.

[0094] The phytosterols suitable for each method of the present application may include one or a mixture of more than one of sitosterol, stigmasterol, campesterol, and brassicasterol in any proportion. Preferred is β-sitosterol, or a mixture of several sterols. For example, the phytosterol suitable for each method of the present application may be a mixture of β-sitosterol, stigmasterol, campesterol or brassicasterol in any proportion. For example, based on the total weight of the mixture, the mixture contains 40-50% β-sitosterol, 20-28% stigmasterol, 20-28% campesterol and 0.5-5% brassicaste...

Embodiment 1~21

[0140] Embodiment 1~21: the preparation of sterol ester

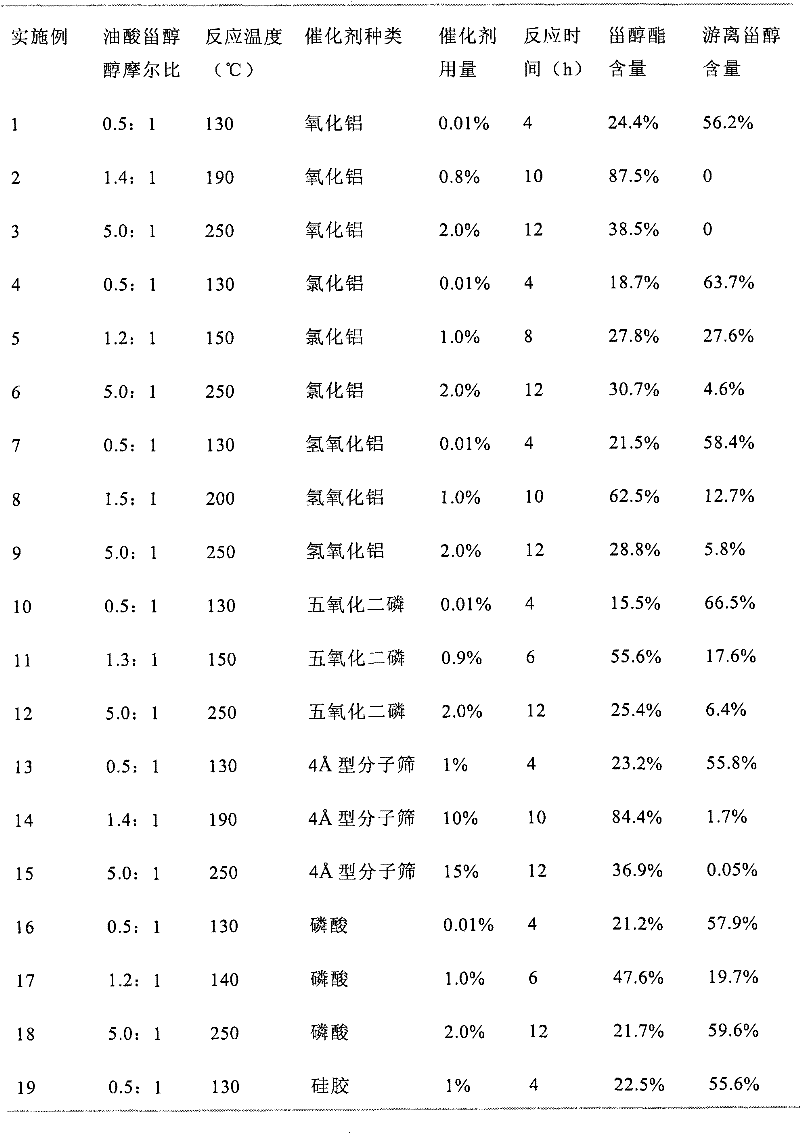

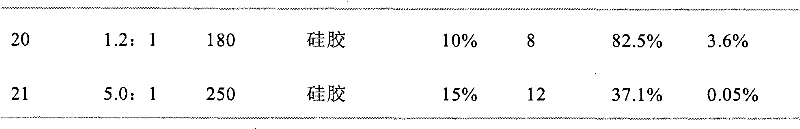

[0141] By the molar ratio shown in table 1, phytosterol (the mixed sterol of 43.48% β-sitosterol, 25.06% stigmasterol, 25.90% campesterol, 1.01% brassicasterol, this mixed sterol purity is 95.45%) and oleic acid are added Put it into a clean and dry three-neck flask, heat it to 130°C, and continue heating until it becomes a uniform oily substance. Then, add the catalyst in the amount shown in Table 1, be heated to the reaction temperature shown in Table 1, and the whole process remains in a vacuum and stirring state until the reaction is completed, and the degree of completion can be monitored by HPLC.

[0142] Table 1: Contents of sterol esters and free sterols after esterification under different reaction conditions

[0143]

[0144]

Embodiment 22

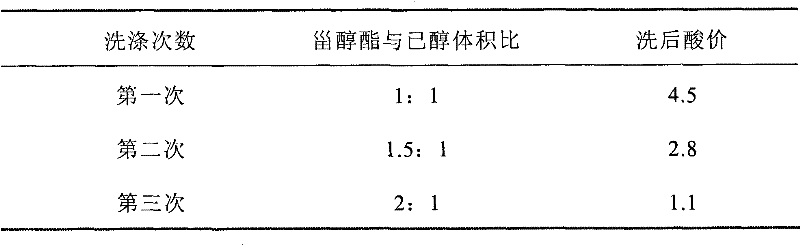

[0146] About 200 g of the reaction solution obtained by the esterification operation in Example 14 was cooled to 100° C., the catalyst was filtered off while hot, and 195 g of the filtrate was collected for purification.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com