Nanometer heat-insulating outer wall coating and preparation method thereof

An exterior wall coating and heat insulation technology, applied in the direction of coating, etc., can solve the problems of poor heat preservation effect, long construction period, poor fire performance, etc., and achieve the effect of thin construction layer, high cost performance, and good safety and fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

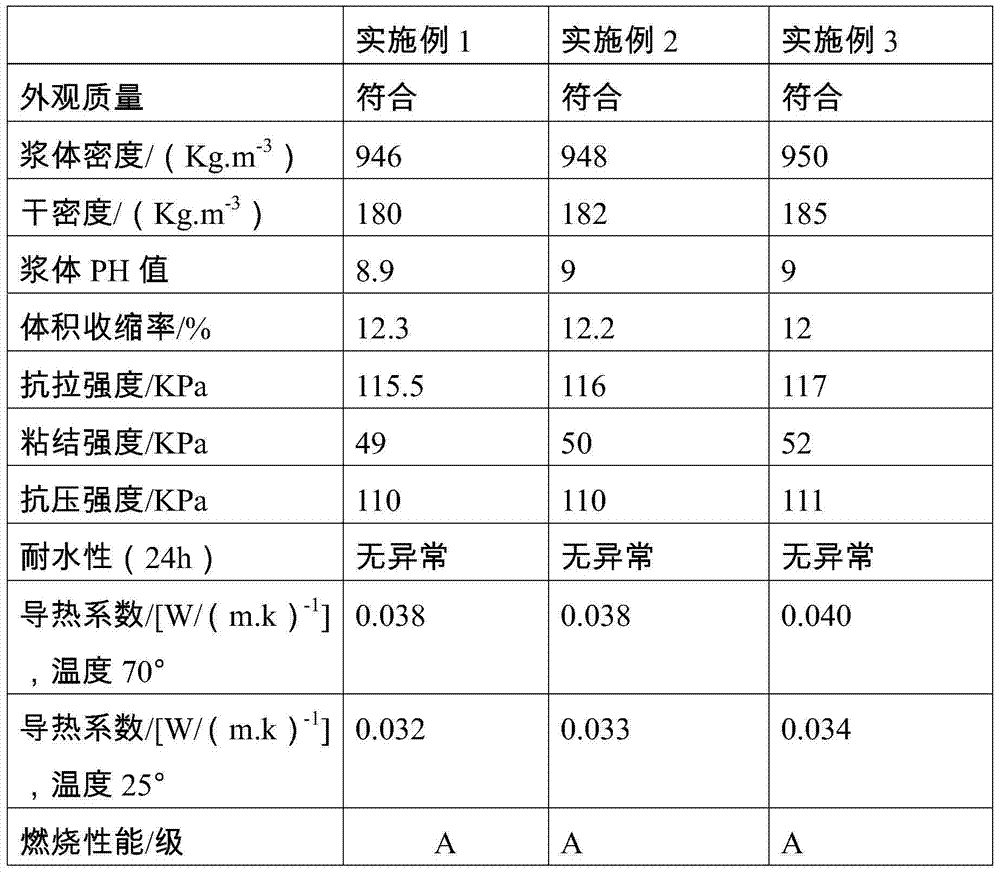

Examples

preparation example Construction

[0042] The embodiment of the present invention also provides a preparation method of the nano-insulation exterior wall coating, comprising the following steps:

[0043] Step 1, preparing 20% silica airgel aqueous slurry;

[0044] The specific preparation steps are: in 80 parts by mass of deionized water, add 2-3 parts of wetting agent, 2-3 parts of dispersing agent, 0.3-0.5 parts of defoaming agent, 1-2 parts of leveling agent and stir evenly, Add 20 parts of silica airgel, disperse at high speed for 20-40 minutes, then oscillate ultrasonically for 20-40 minutes, and then grind with a grinder until the particle size is less than 100nm;

[0045] Described dispersant, wetting agent, defoamer, thickener, anticorrosion agent etc. all are auxiliary agents for conventional water-based coatings, do not repeat them here;

[0046] Step 2, adding diatomaceous earth into the reaction kettle and vacuumizing, removing the vacuuming device, adding 20% silica airgel water-based slurry, ...

Embodiment 1

[0049] Weigh 5kg of deionized water, 1kg of ethylene glycol, 3kg of aluminum silicate chopped fibers, 3kg of diatomaceous earth, 30kg of self-crosslinking elastic acrylic emulsion, 15kg of hollow glass microspheres, 20kg of 20% silica airgel aqueous slurry, 0.4kg dispersant 5040, 0.1kg wetting agent X405, 0.1kg multifunctional amine additive AMP-95, 0.2kg defoamer NXZ, 0.1kg preservative LXE, 0.2kg thickener TT935, 0.3kg leveling agent RM -2020.

[0050] The preparation steps are as follows:

[0051] The preparation process of 20% silica airgel water-based slurry is as follows: in 80kg deionized water, add 2kg wetting agent X405, 2kg dispersant 5040, 0.3kg defoamer NXZ, 1kg leveling agent RM- 2020 Stir evenly, add 20 parts of silica airgel, disperse at high speed for 30 minutes, then oscillate with ultrasonic waves for 30 minutes, and then grind with a blue grinder until the particle size is less than 100nm.

[0052] Add diatomaceous earth into the reaction kettle and vacuum...

Embodiment 2

[0054] The preparation steps are as follows: Weigh 7kg of deionized water, 1.5kg of ethylene glycol, 4kg of chopped aluminum silicate fibers, 4kg of diatomaceous earth, 35kg of self-crosslinking elastic acrylic emulsion, 20kg of hollow glass microspheres, and 30kg of 20% silica gas Gel water-based slurry, 0.6kg dispersant 5040, 0.15kg wetting agent X405, 0.15kg multifunctional amine additive AMP-95, 0.3kg defoamer NXZ, 0.2kg preservative LXE, 0.3kg thickener TT935, 0.4 kg leveling agent RM-2020.

[0055] The preparation process of 20% silica airgel water-based slurry is as follows: in 80kg deionized water, add 2.5kg wetting agent X405, 2.5kg dispersant 5040, 0.4kg defoamer NXZ, 1.5kg leveling agent Mix the agent RM-2020 evenly, add 20 parts of silica airgel, disperse at high speed for 30 minutes, then oscillate with ultrasonic waves for 30 minutes, and then grind with a blue mill until the particle size is less than 100nm.

[0056] Add diatomaceous earth into the reaction ket...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com