Rice finish machining system

A rice and rubber roller technology, applied in agricultural machinery and equipment, grain degermination, grain processing, etc., can solve the problems of poor flexibility and single rice production line, and achieve the effects of simple combination, improved storage effect, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

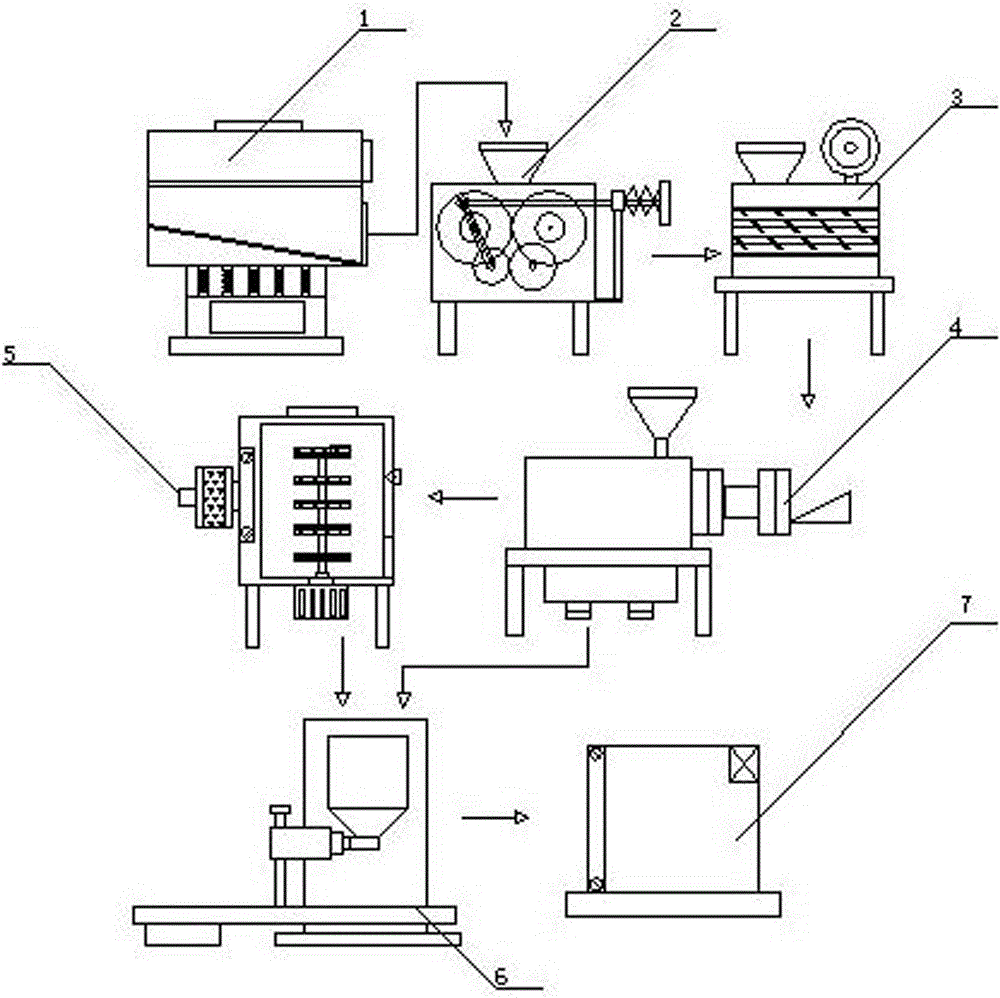

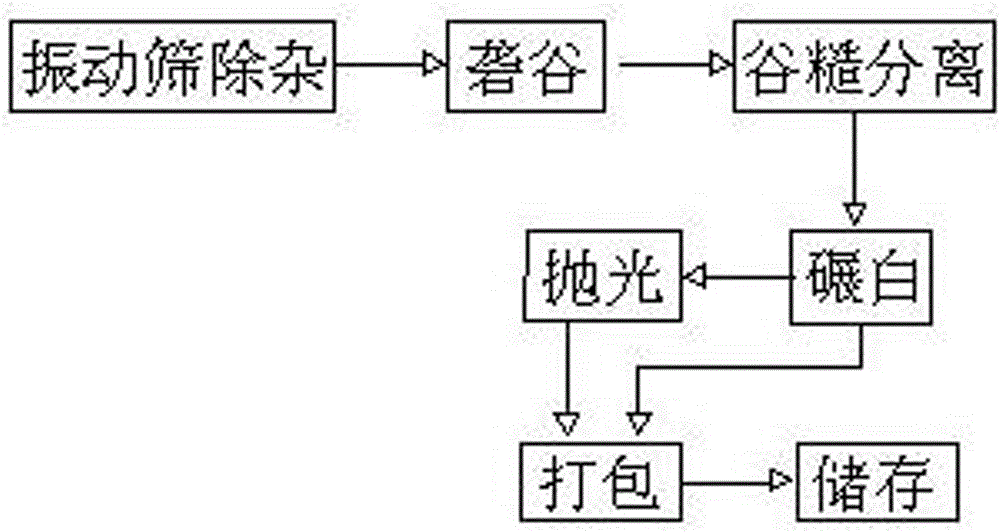

[0019] As shown in the figure, a rice finishing system includes a finishing system body, and the finishing system body is composed of a vibrating screen 1, a rubber roller hulling device 2, a paddy separating device 3, a rice milling device 4, The polishing device 5, the packaging machine 6, and the storage bin 7 are composed of the vibrating screen 1 connected with the rubber roller hulling device 2, the rubber roller hulling device 2 connected with the paddy separating device 3, and the paddy separating device 3 connected with the rice paddy Rice device 4, the rice milling device 4 is connected to a polishing device 5, the rice milling device 1 is connected to a packaging machine 6, the polishing device 5 is connected to a packaging machine 6, and the packaging machine 6 is connected to a storage bin 7.

[0020] The upper end of the vibrating screen 1 is equipped with a screening chamber, the lower end of the vibrating screen 1 is equipped with a vibrating mechanism; the top ...

Embodiment 2

[0028] Further, the sequence among the vibrating screen 1, the rubber roller hulling device 2, the paddy separating device 3, the rice milling device 4, the polishing device 5, the packaging machine 6 and the storage bin 7 can be freely combined.

Embodiment 3

[0030] Working principle: A rice finishing system. When finishing rice, the raw grain is put into the vibrating screen 1. After the impurities are removed by vibration, the large particles of impurities in the raw grain are removed, and the raw materials after the removal of impurities enter the rubber roller husking device 2. After being treated by movable rollers and fixed rollers, the rice enters the paddy-rough separation device 3, and the separated rice enters the rice milling device 4 for whitening, and then enters the polishing device 5 for polishing and packaging or directly enters the packaging machine 6 for packaging. Be bagged, and the packed rice enters the storage bin 7 for storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com