Quick cleaning method for quartz sand acid pickling

A quartz sand and pickling technology, applied in the direction of silicon dioxide and silicon oxide, can solve the problems of producing a large amount of waste acid and waste water, polluting the environment, difficult to purify quartz, etc., reducing acid content, convenient operation and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

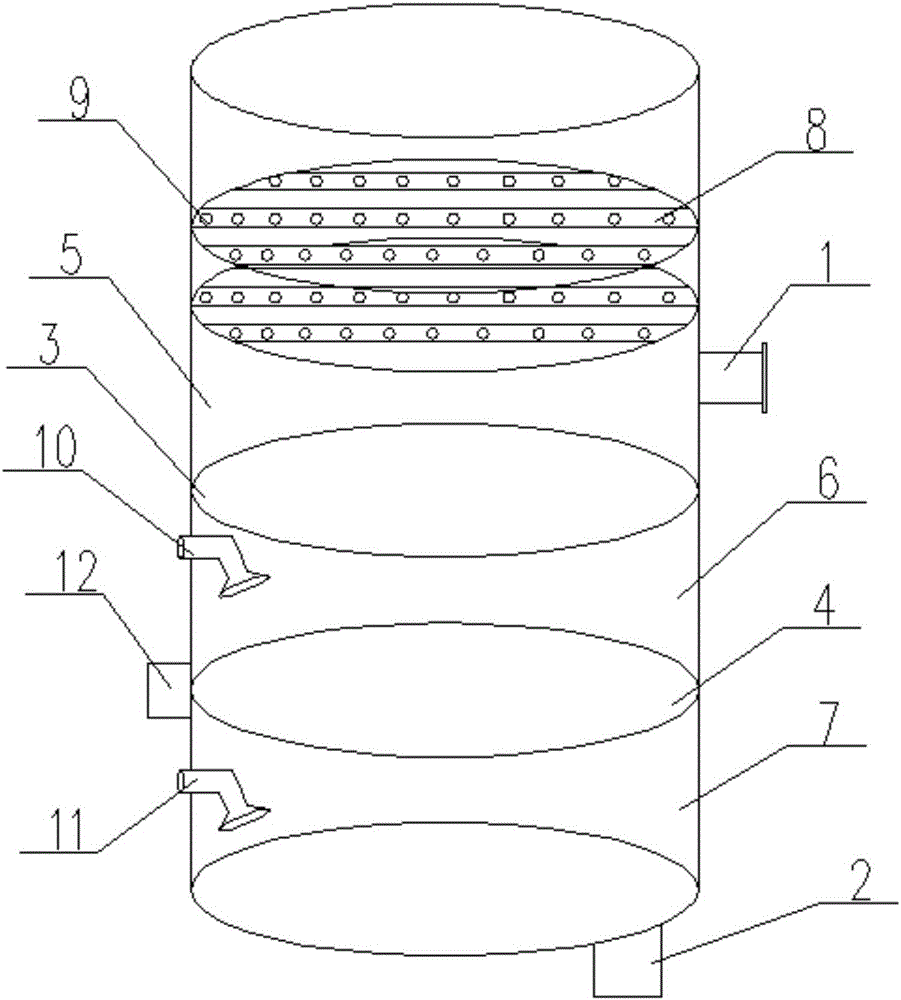

Image

Examples

Embodiment 1

[0034] A method for quickly cleaning pickling quartz sand, comprising the following steps:

[0035] Step 1. Put the quartz sand to be pickled into the pickling purification device, add pickling liquid, heat the temperature in the pickling purification device to 60°C, and open the circulation system to circulate the hot pickling liquid for dynamic pickling Quartz sand, after pickling for 3 hours, take out and collect the pickling solution;

[0036] Wherein, the pickling solution is composed of 2 parts by weight of hydrofluoric acid, 5 parts by weight of fluosilicic acid, 4 parts by weight of oxalic acid, 1 part by weight of hydrochloric acid and 50 parts by weight of water;

[0037] Step 2. Send the pickled quartz sand to the water washing device, and bury a plurality of adsorption bags in the quartz sand. The buried density of the adsorption bags is 30g / piece. Take out all the adsorption bags after 10 minutes, and add them to the water washing device. Soak in clean water for ...

Embodiment 2

[0050] A method for quickly cleaning pickling quartz sand, comprising the following steps:

[0051] Step 1. Put the quartz sand to be pickled into the pickling purification device, add pickling liquid, heat the temperature in the pickling purification device to 73°C, and open the circulation system to make the hot pickling liquid circulate and pickle dynamically Quartz sand, after pickling for 5 hours, take out and collect the pickling solution;

[0052] Wherein, the pickling solution is composed of 9 parts by weight of hydrofluoric acid, 13 parts by weight of fluosilicic acid, 14 parts by weight of oxalic acid, 5 parts by weight of hydrochloric acid and 70 parts by weight of water;

[0053] Step 2. Send the pickled quartz sand to the water washing device, and bury a plurality of adsorption bags in the quartz sand. The buried density of the adsorption bags is 30g / piece. Take out all the adsorption bags after 15 minutes, and add them to the water washing device. Soak in clean ...

Embodiment 3

[0066] A method for quickly cleaning pickling quartz sand, comprising the following steps:

[0067] Step 1. Put the quartz sand to be pickled into the pickling purification device, add pickling liquid, heat the temperature in the pickling purification device to 85°C, and open the circulation system to make the hot pickling liquid circulate and pickle dynamically Quartz sand, after pickling for 6 hours, it will be removed and the pickling solution will be collected;

[0068] Wherein, the pickling solution is composed of 15 parts by weight of hydrofluoric acid, 20 parts by weight of fluosilicic acid, 25 parts by weight of oxalic acid, 8 parts by weight of hydrochloric acid and 90 parts by weight of water;

[0069] Step 2. Send the pickled quartz sand to the water washing device, and bury a plurality of adsorption bags in the quartz sand. The buried density of the adsorption bags is 30g / piece. Take out all the adsorption bags after 20 minutes, and add them to the water washing de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com