A multi-stage eddy current electromagnetic ultrafine dust flue gas processor for methanol cracking reaction

A methanol cracking and flue gas treatment technology, applied in the direction of using liquid separation agent, chemical instruments and methods, separation methods, etc., can solve environmental pollution, without considering waste heat recovery, heat transfer optimization, compact structure, impurity removal and purification, architecture Instability and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

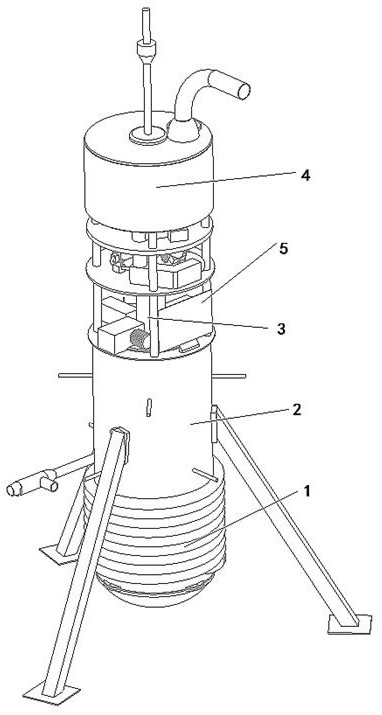

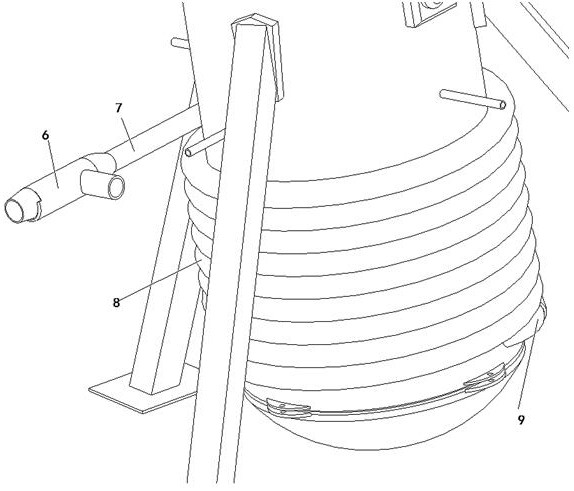

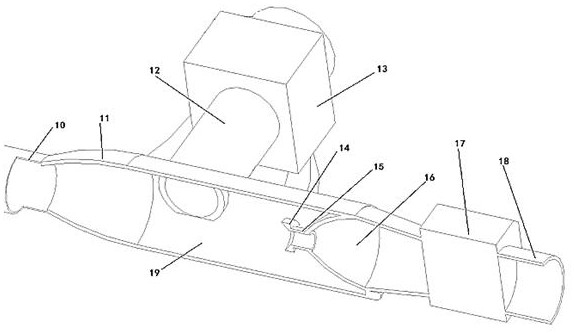

[0064] Embodiment 1: as Figure 1-11 As shown, a multi-stage eddy current electromagnetic ultra-fine dust flue gas processor for methanol cracking reaction, including high-speed spiral copper tube pretreatment system 1, spray impurity removal system 2, central impurity removal system 3, double dust removal system 4, The support column III70, the spray impurity removal system 2 is fixedly installed on the top of the support column III70, the high-speed spiral copper tube pretreatment system 1 is fixedly wound and installed on the bottom outer wall of the spray impurity removal system 2, and the central impurity removal system 3 is fixedly installed on the spray impurity removal system In the inner center of system 2, the double dedusting system 4 is fixed above the spraying impurity removal system 2, and the high-speed spiral copper tube pretreatment system 1, the spraying impurity removal system 2, the central impurity removal system 3, and the double dedusting system 4 are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com