Patents

Literature

45results about How to "No local overheating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

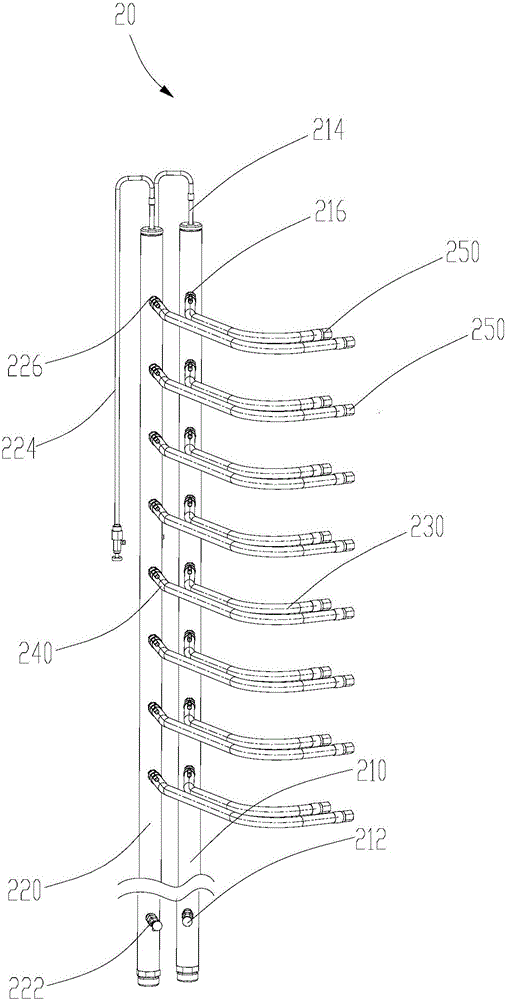

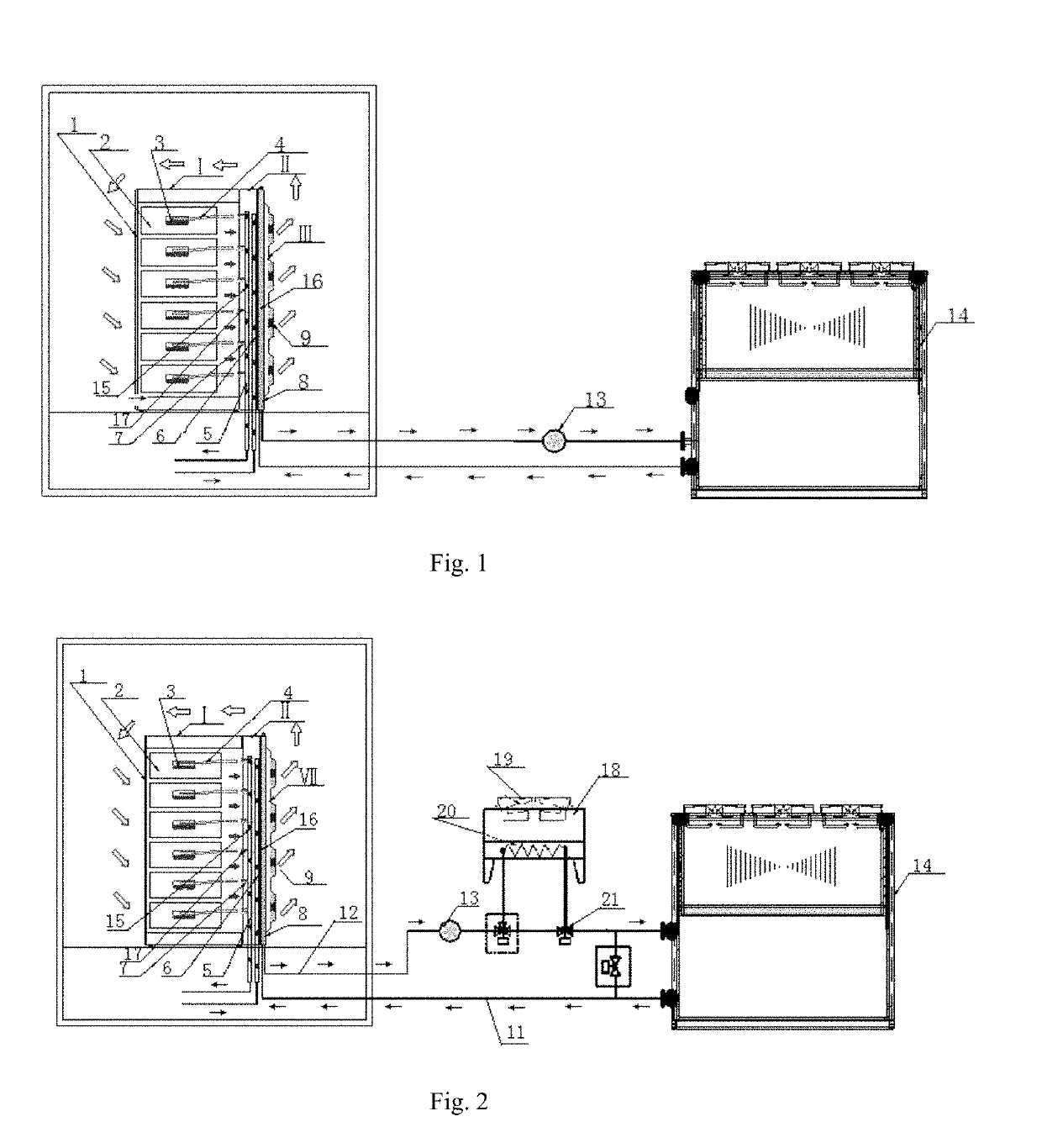

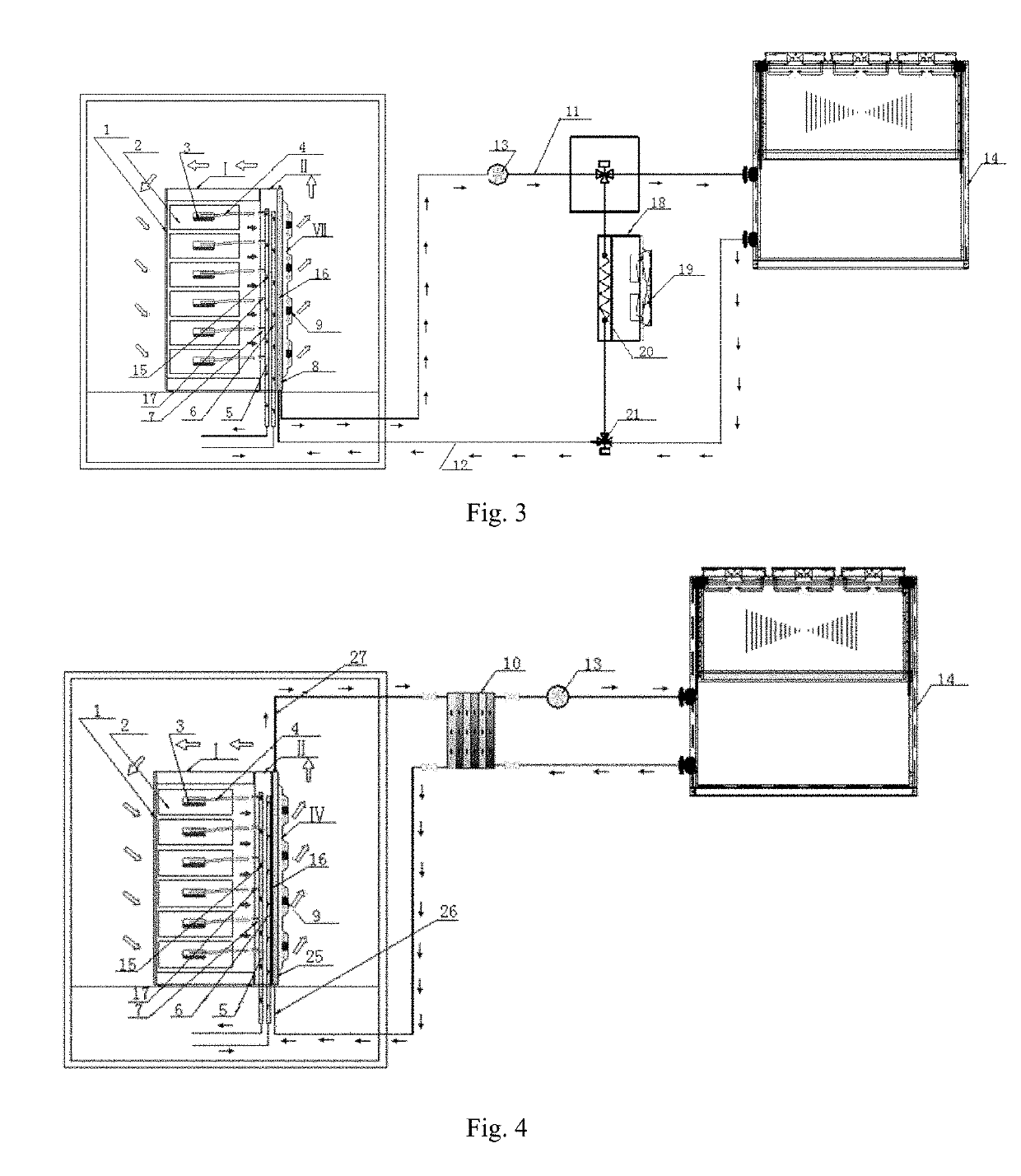

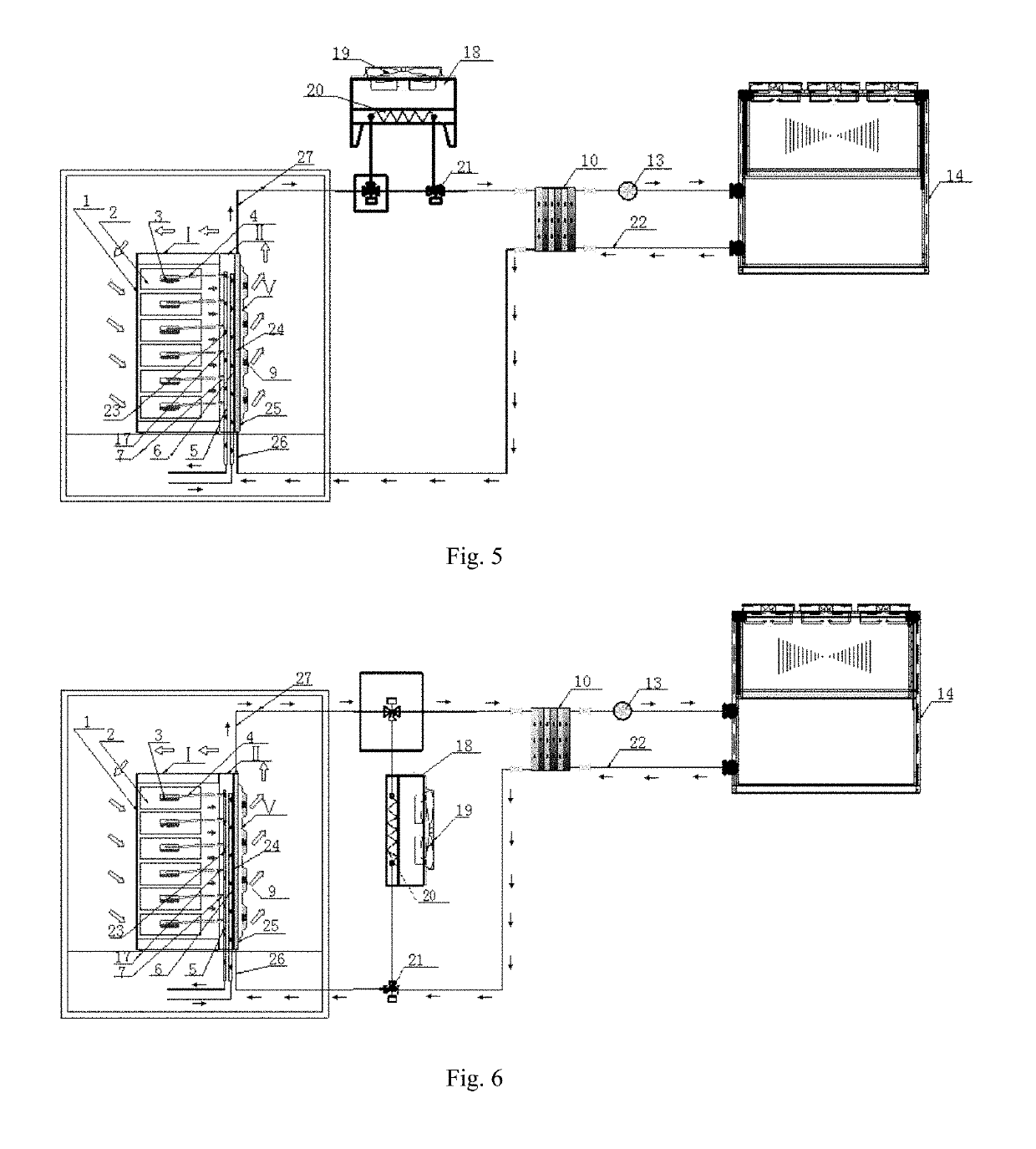

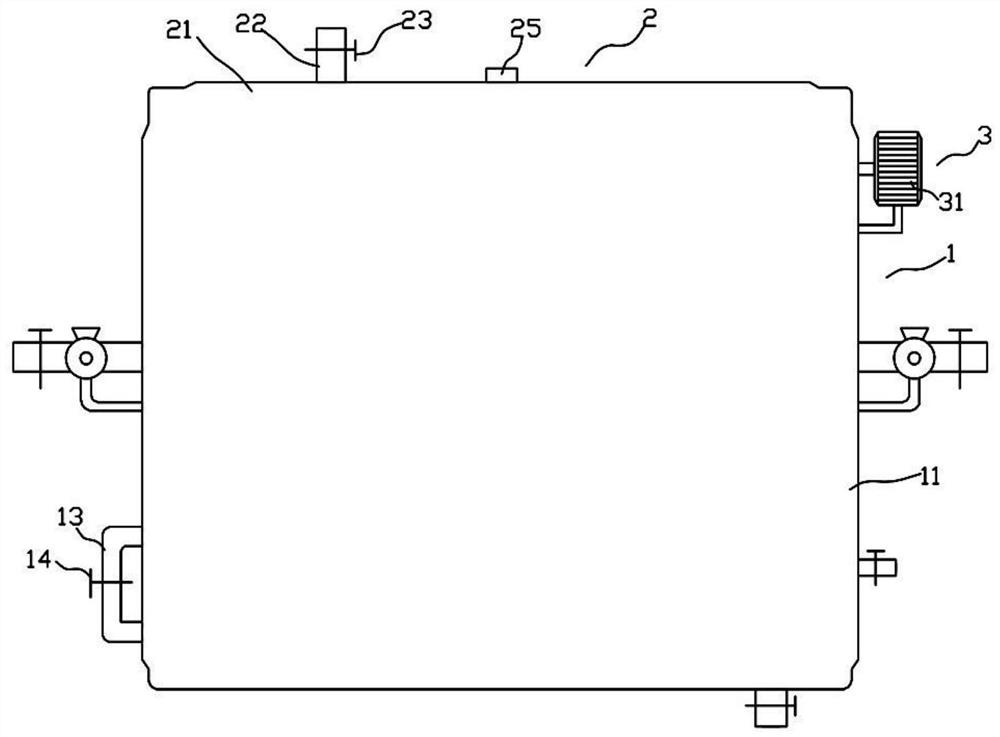

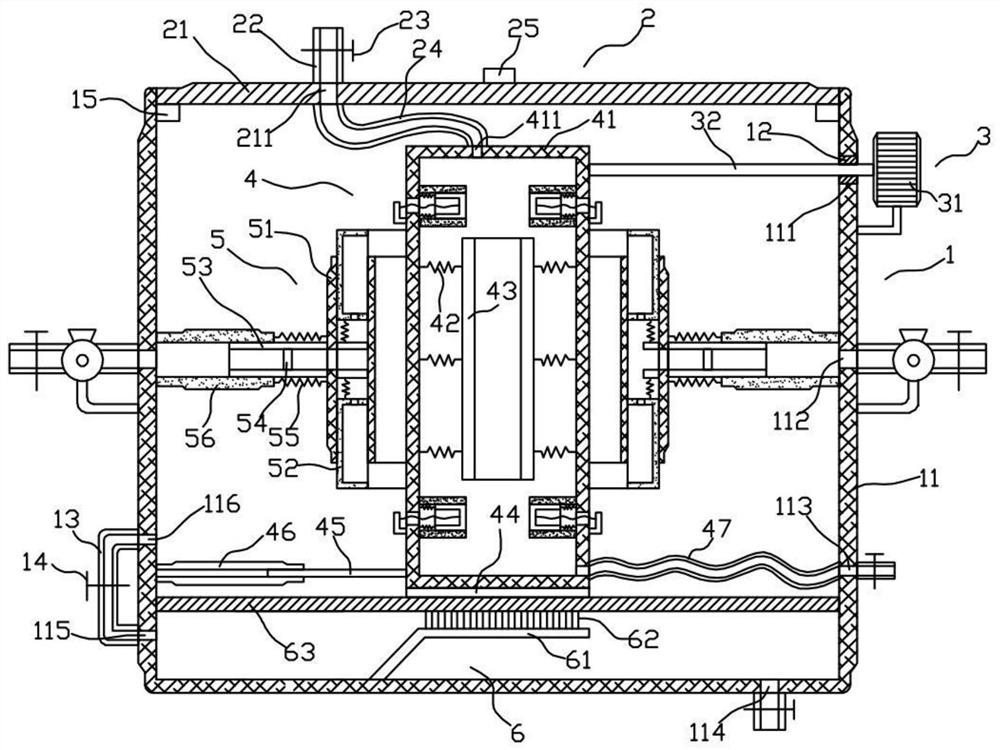

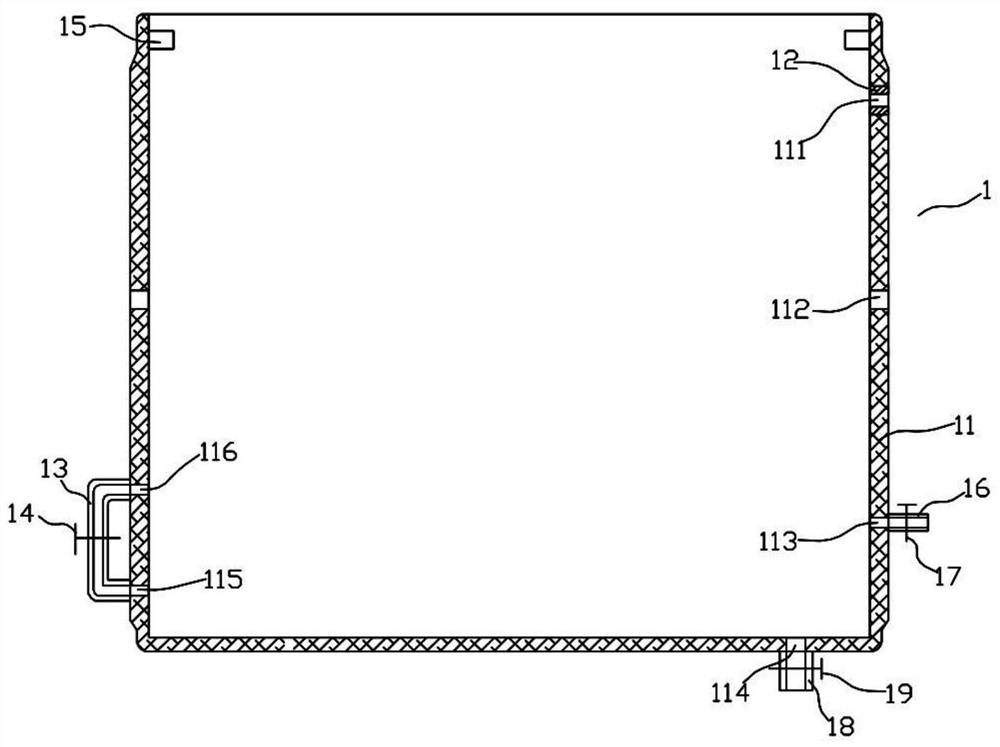

Server rack heat sink system with combination of liquid cooling device and auxiliary heat sink device

ActiveUS20180042140A1Cool efficiency be highGood effectModifications using liquid coolingEnergy efficient computingHeat sinkEngineering

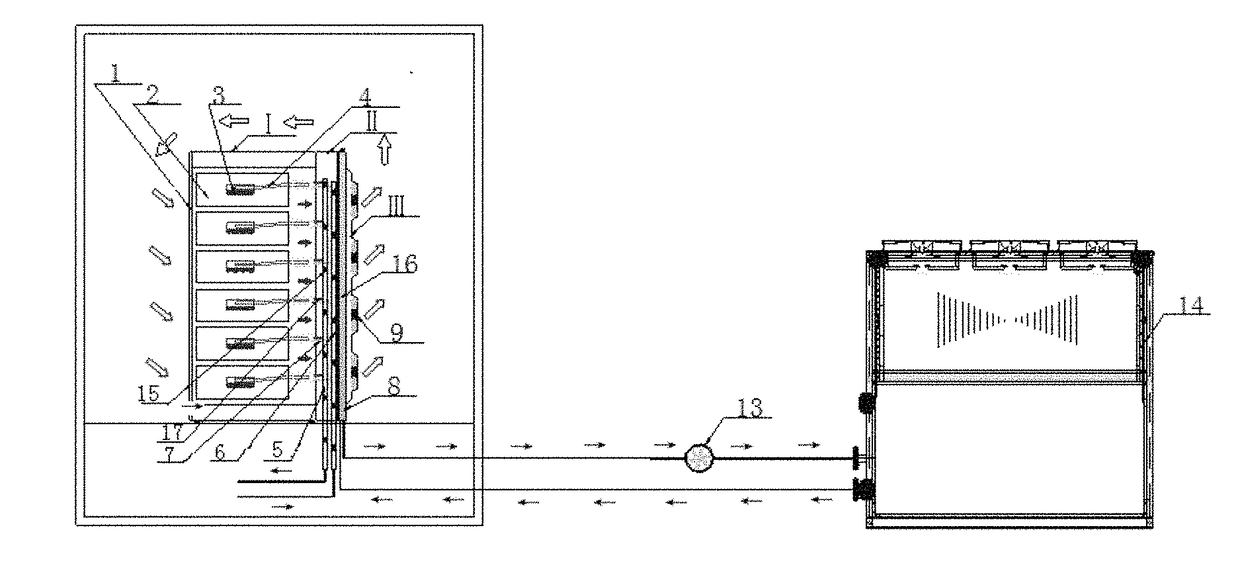

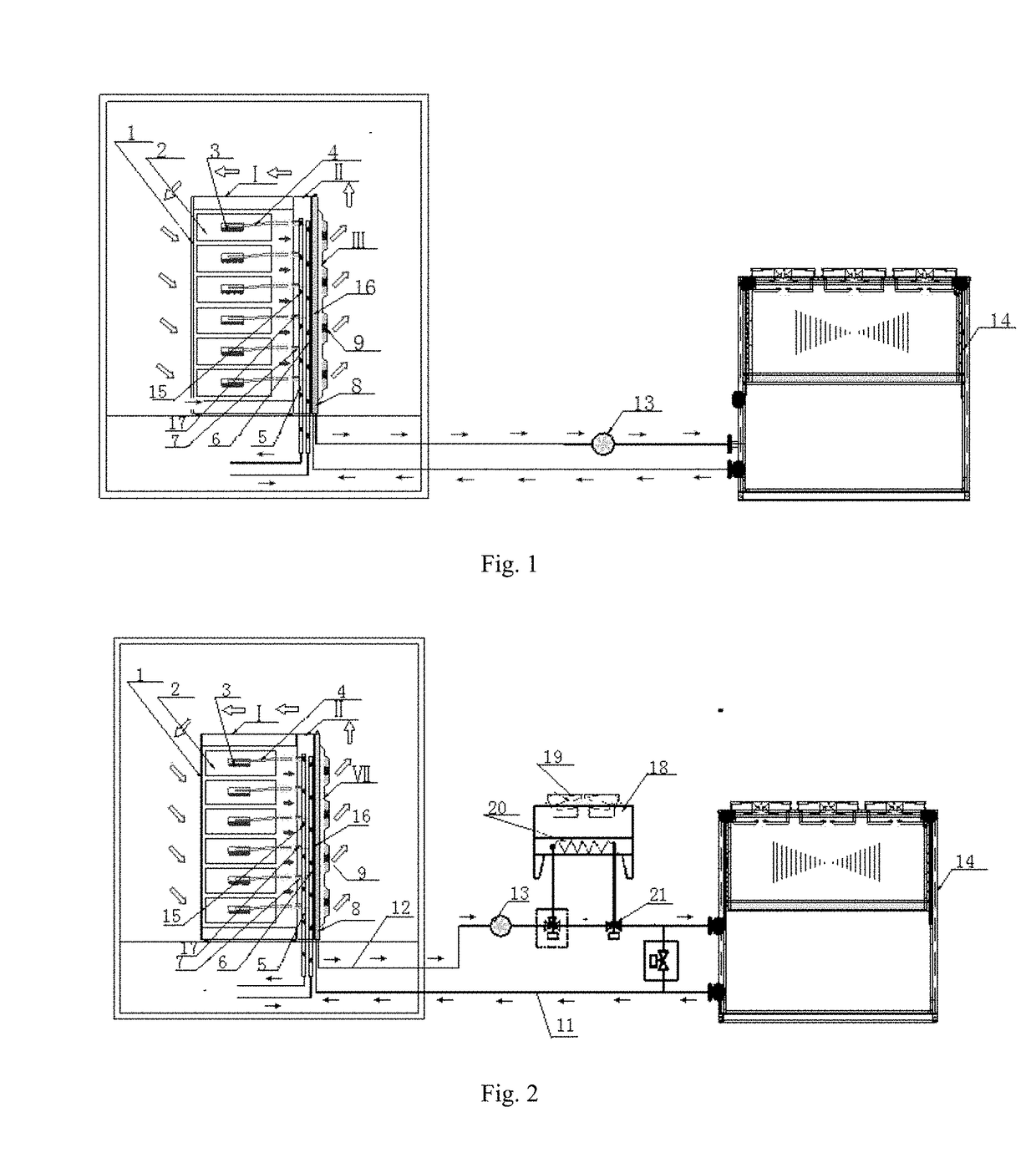

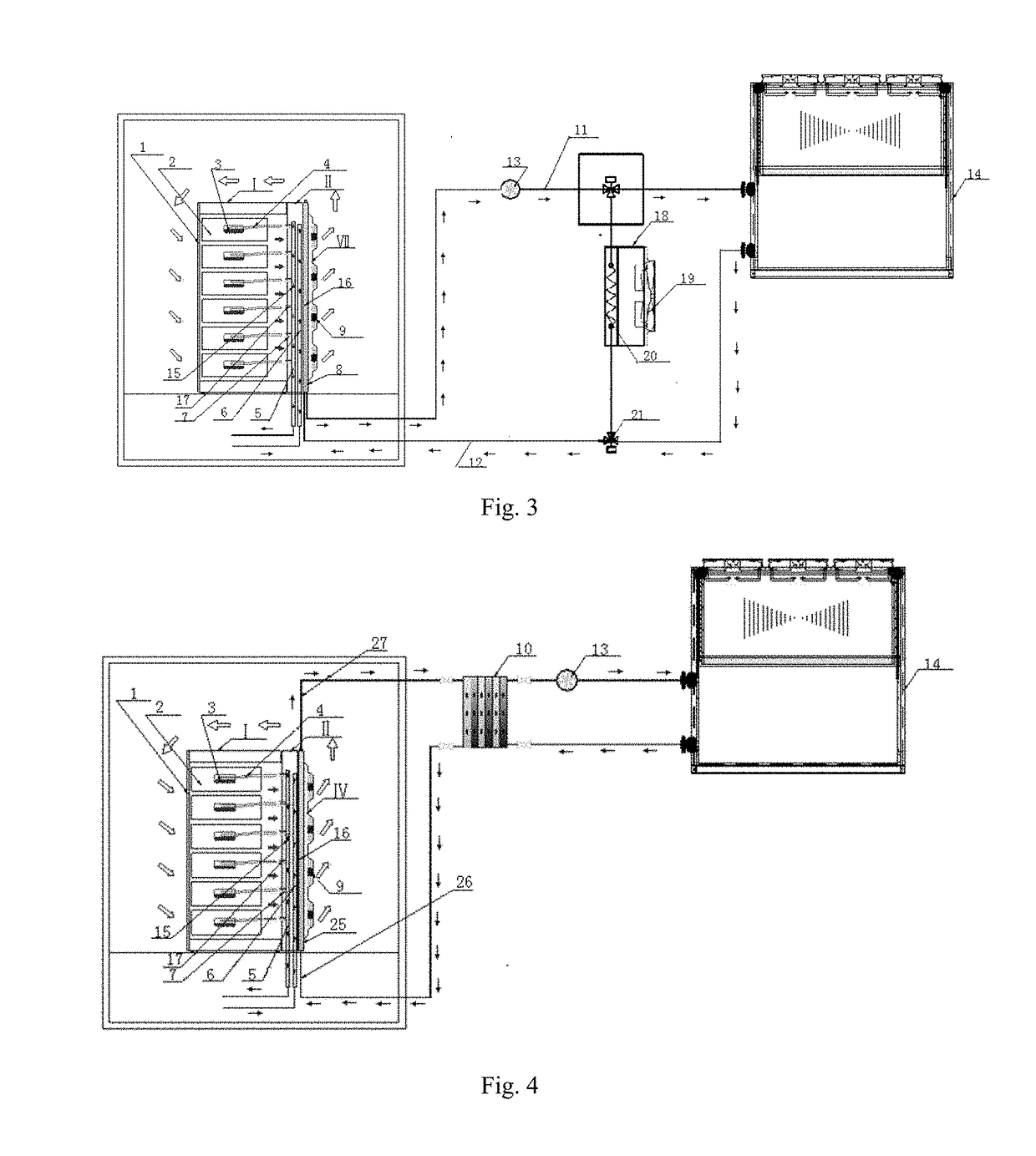

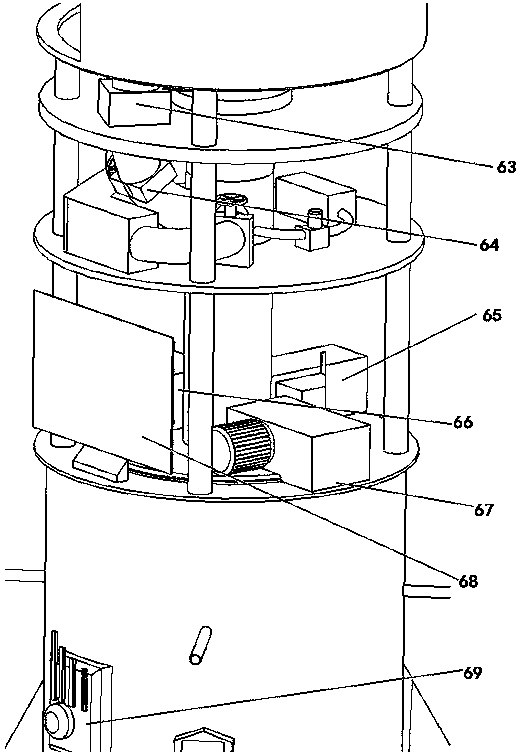

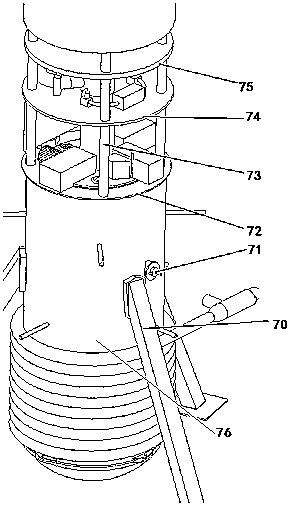

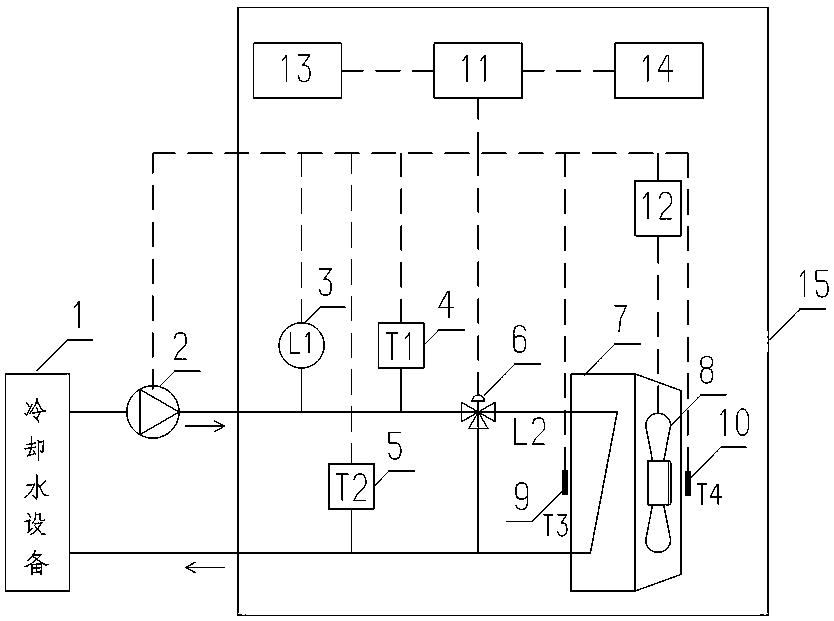

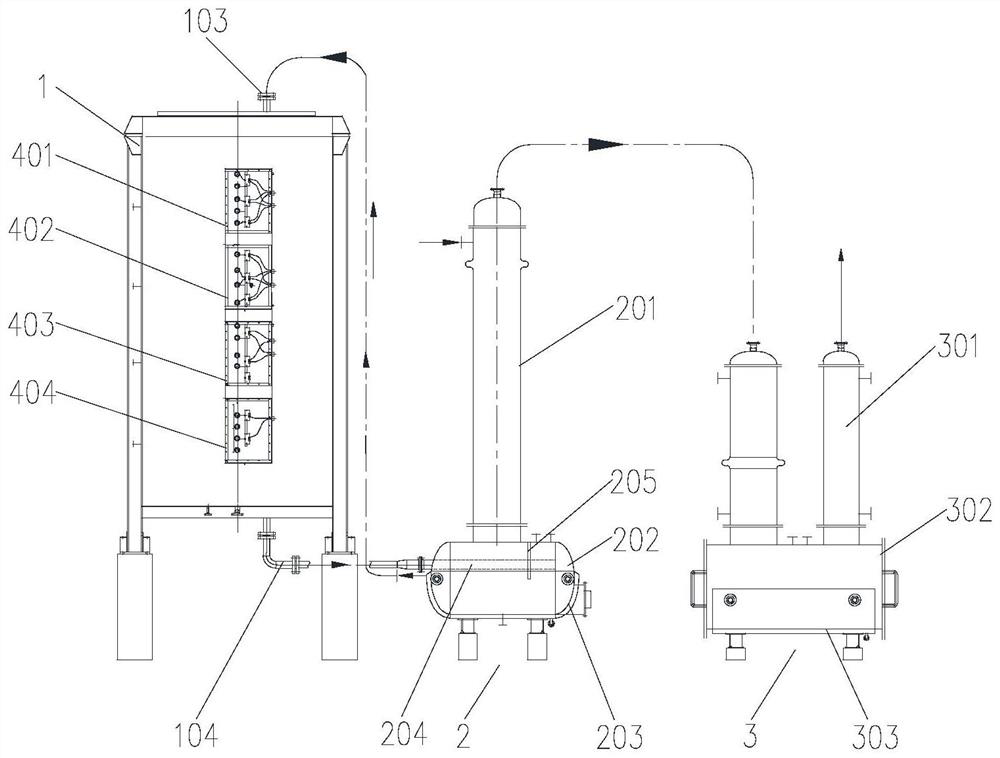

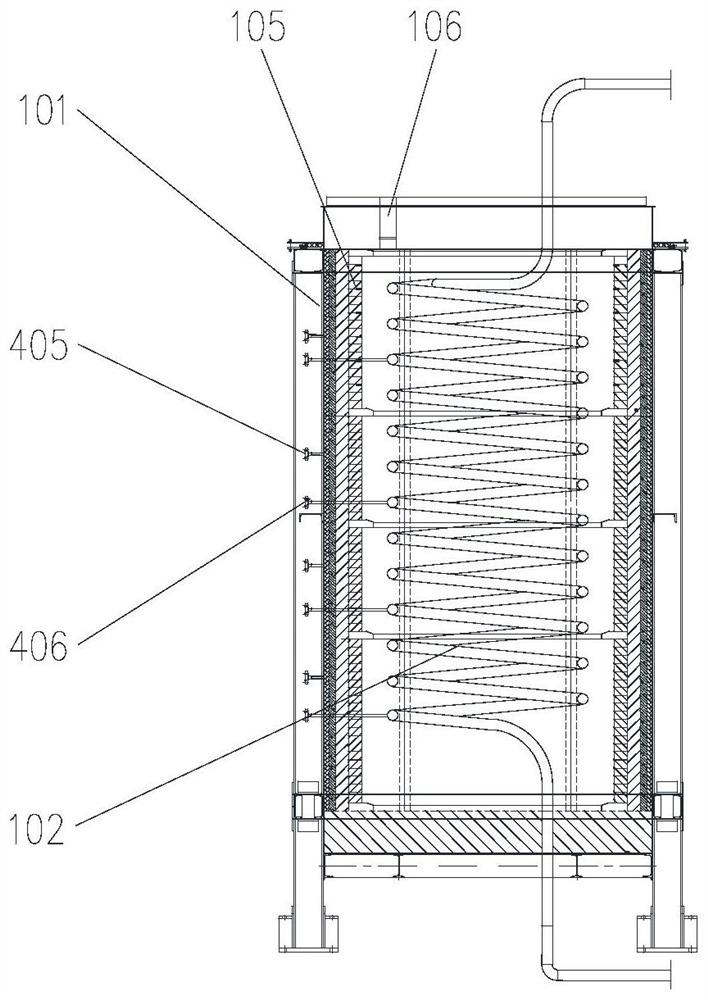

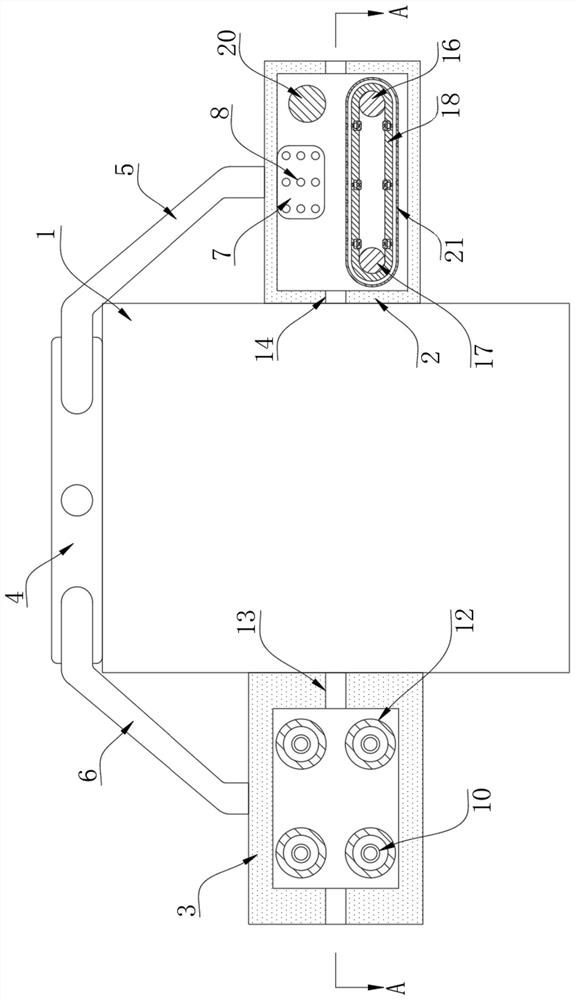

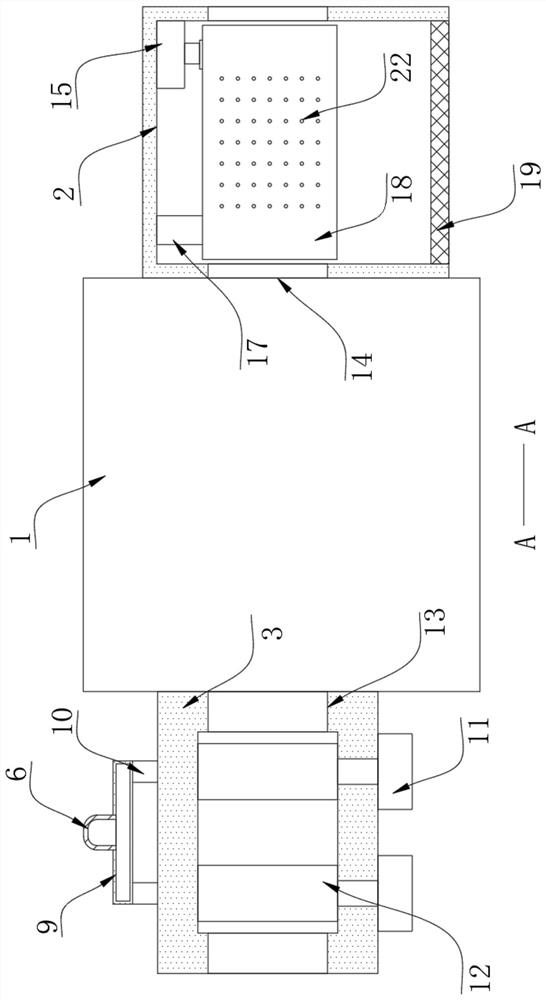

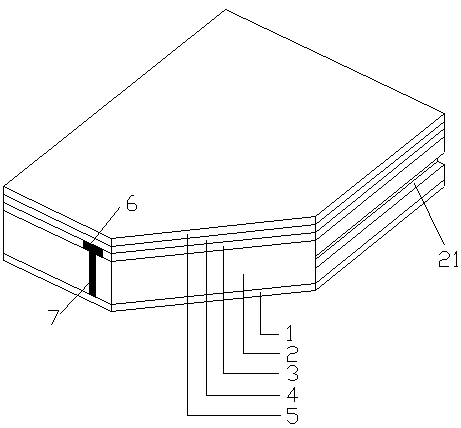

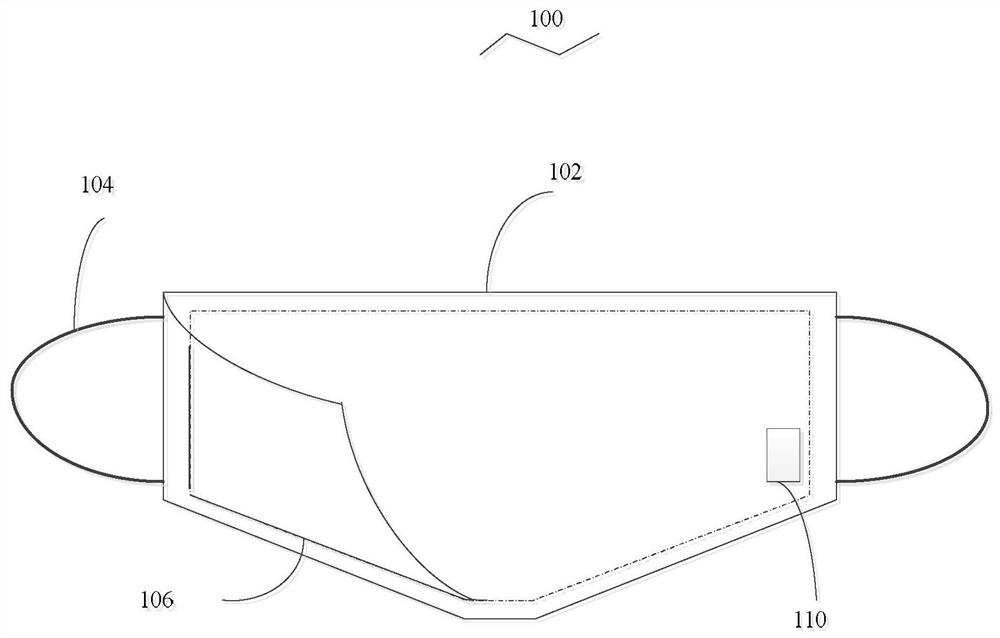

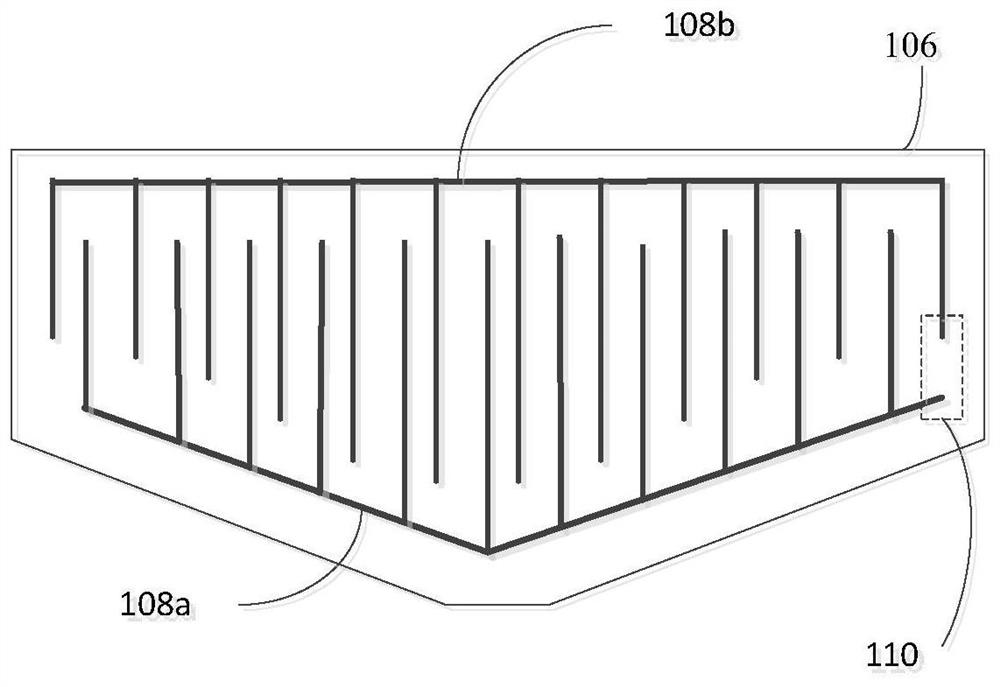

A server heat dissipation system is provided, comprising a liquid cooling server cabinet comprising a cabinet body and multiple liquid cooling servers provided inside the cabinet body, wherein it is provided with a liquid cooling device to perform direct liquid cooling to the liquid cooling servers, and with an auxiliary heat dissipation device to perform auxiliary heat dissipation to the liquid cooling servers. The present invention provides high density cooling, high heat exchange efficiency, no local overheating, small space occupied, high reliability, low noise, and long life.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

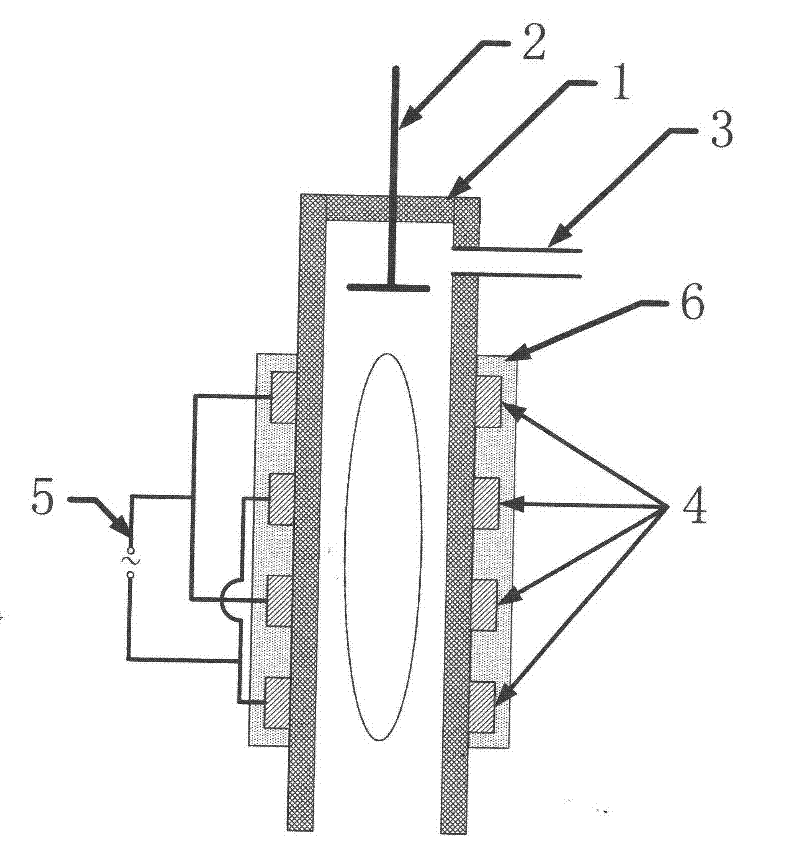

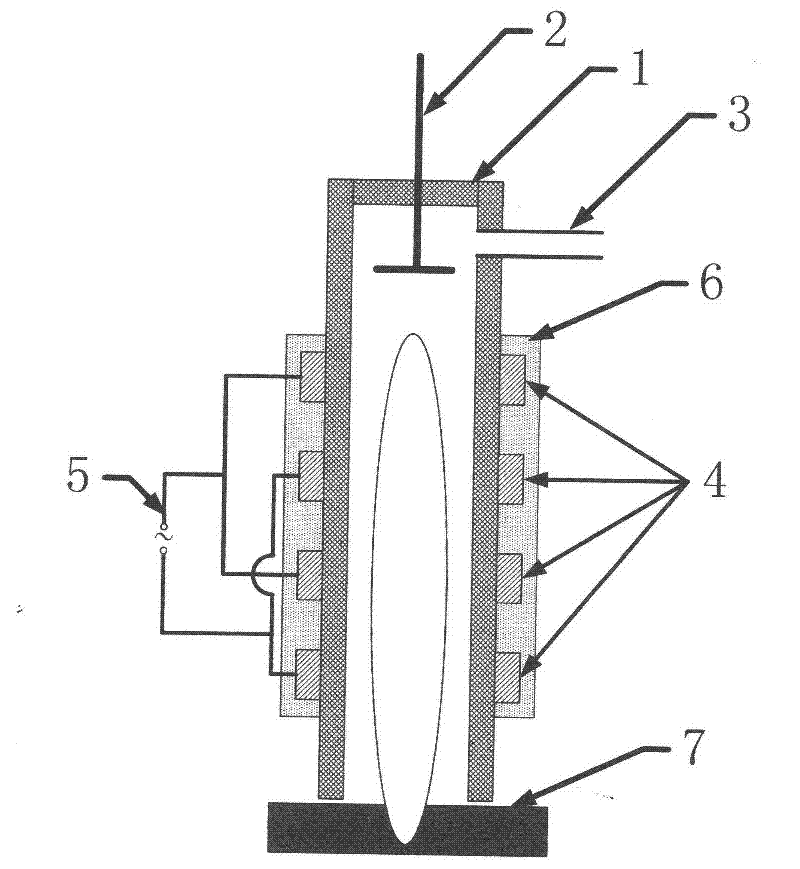

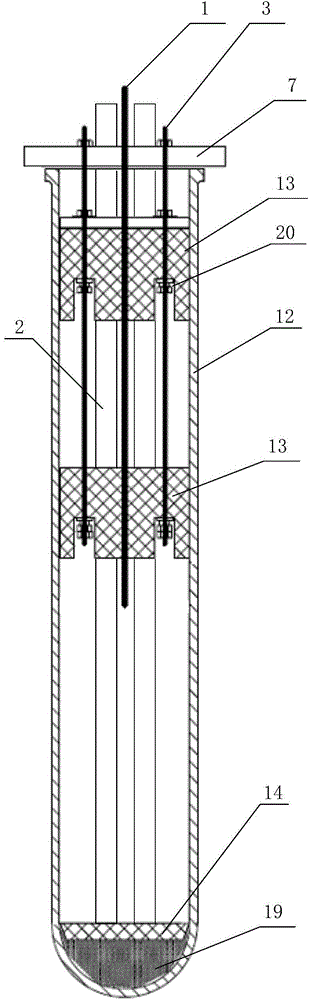

Ring dielectric barrier discharge ionization device

InactiveCN102522310AAvoid pollutionAvoid partial dischargeIon sources/gunsPlasma techniqueMaterials preparationAtmospheric pressure

The invention relates to an ionization device, in particular to a ring dielectric barrier discharge ionization device, which comprises an insulating medium cavity, discharge electrodes, a repeller electrode, an insulating medium and a power supply, wherein one end of the insulating medium cavity is open, and the other end of the insulating medium cavity is closed; a gas inlet is formed in a sidewall close to the closed end of the insulating medium cavity; the discharge electrodes are ring electrodes which form a group, closely surround the periphery of the middle part of the insulating medium cavity, and are clad by the insulating medium; the repeller electrode is a circular metal plate, and is arranged in the closed end of the insulating medium cavity and positioned above the discharge electrodes; and the power supply supplies power to the discharge electrodes. The ring dielectric barrier discharge ionization device has the characteristics of discharge stability, no electrode pollution, oxidation resistance, low power consumption, long service life, wide working air pressure range and the like, and can be widely applied in the fields of mass spectrometric ionization sources, plasma treatment, material preparation and the like.

Owner:KUSN HEXIN MASS PECTRUM TECH

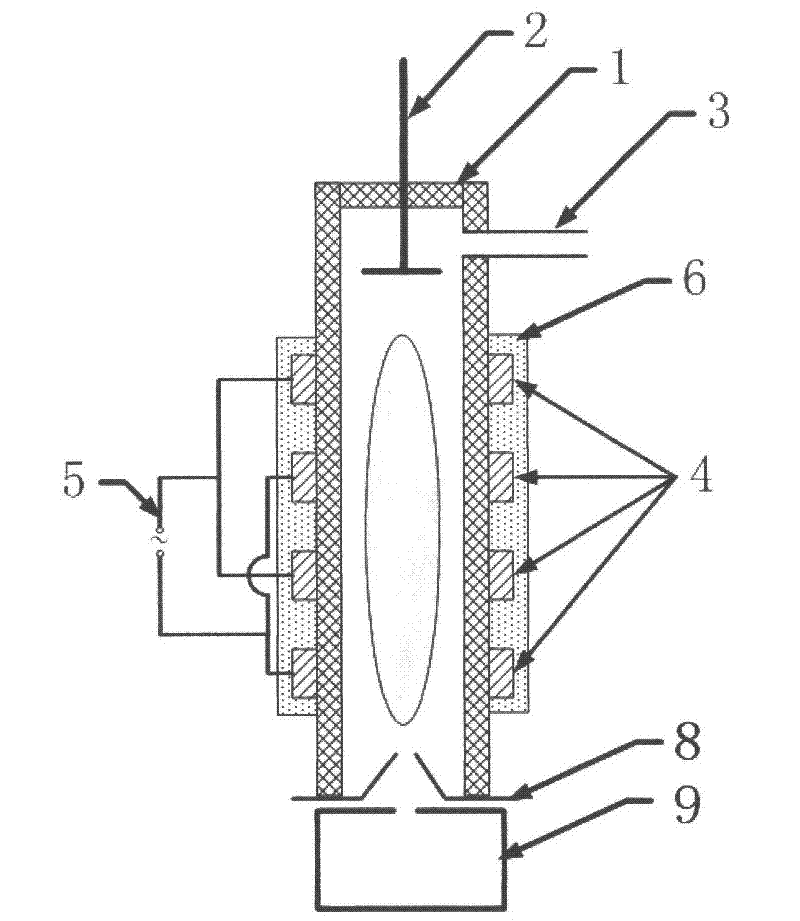

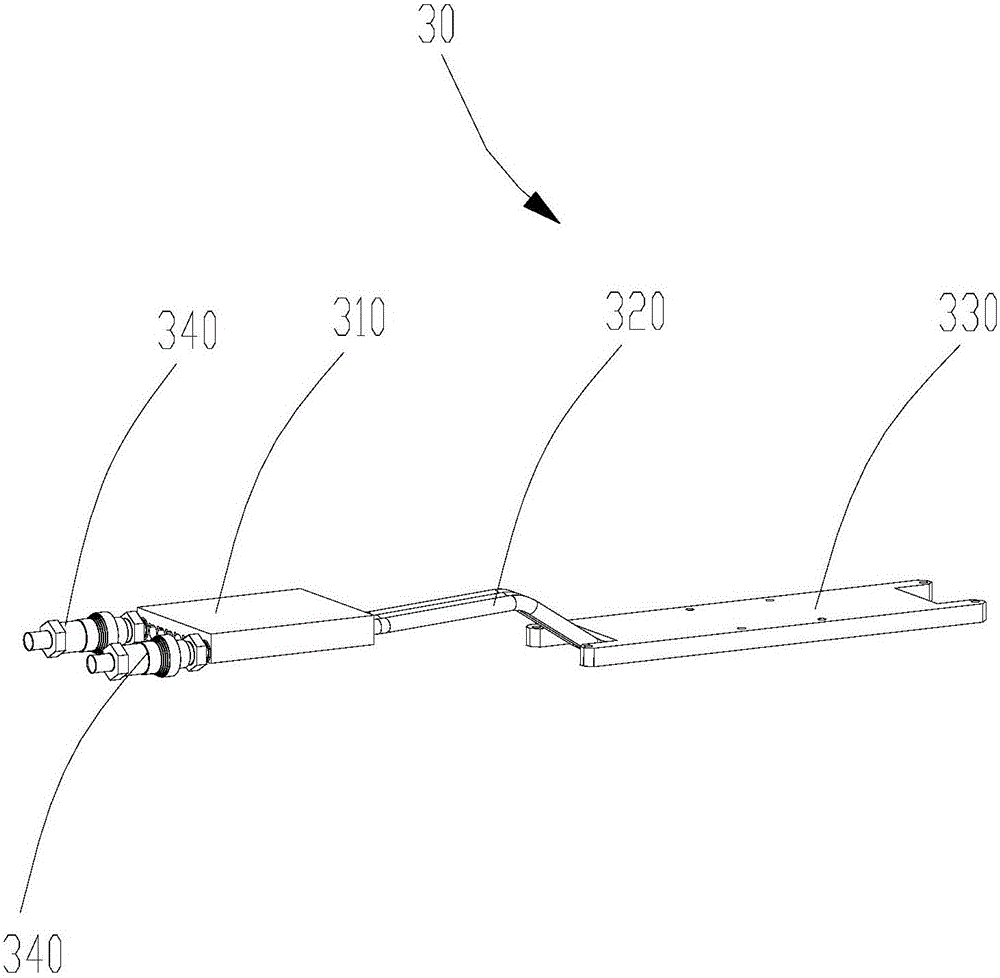

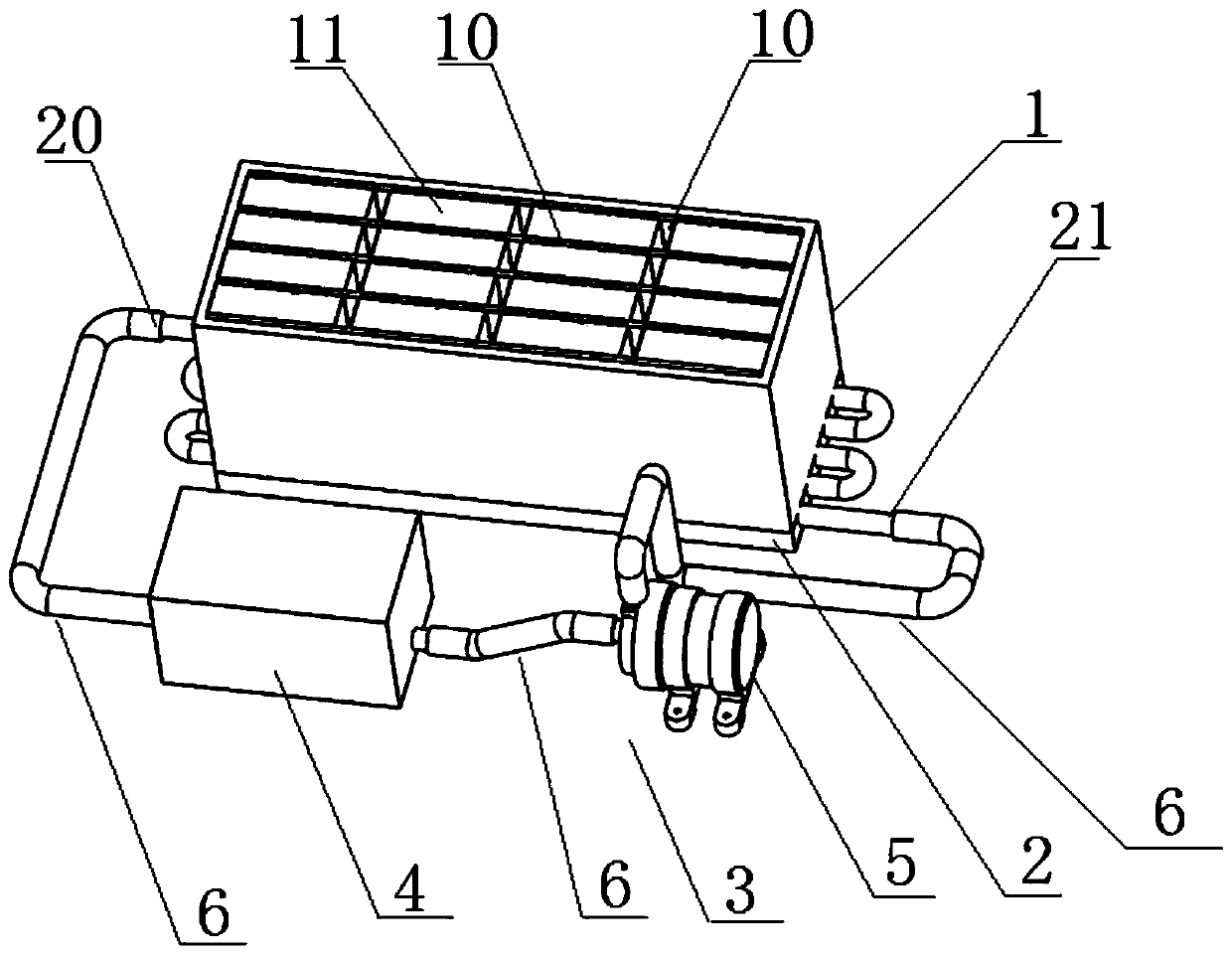

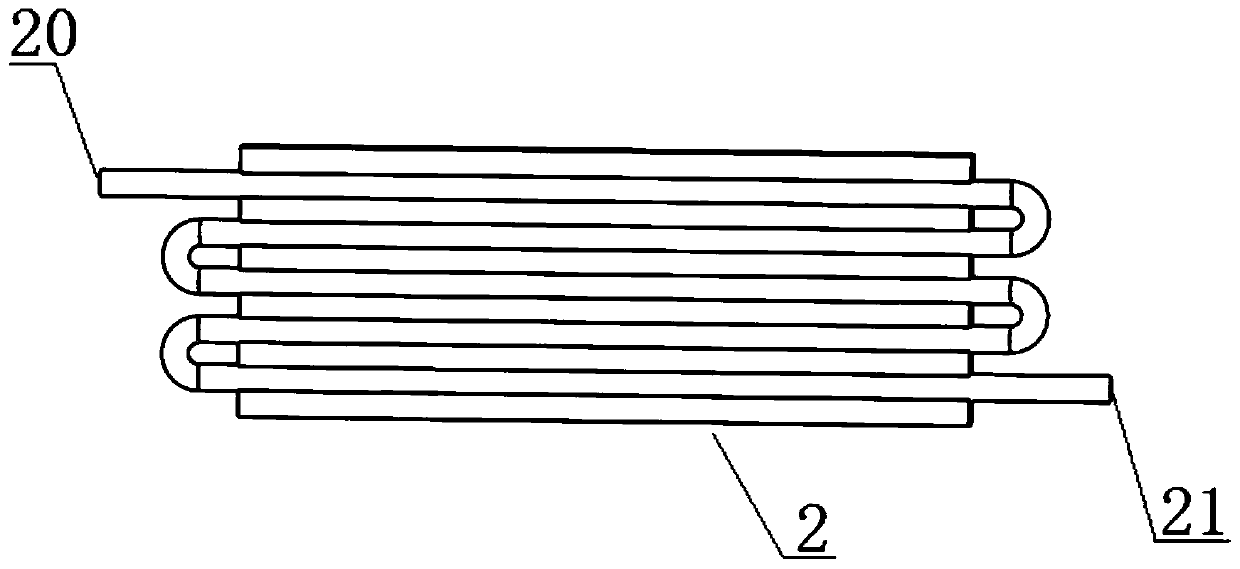

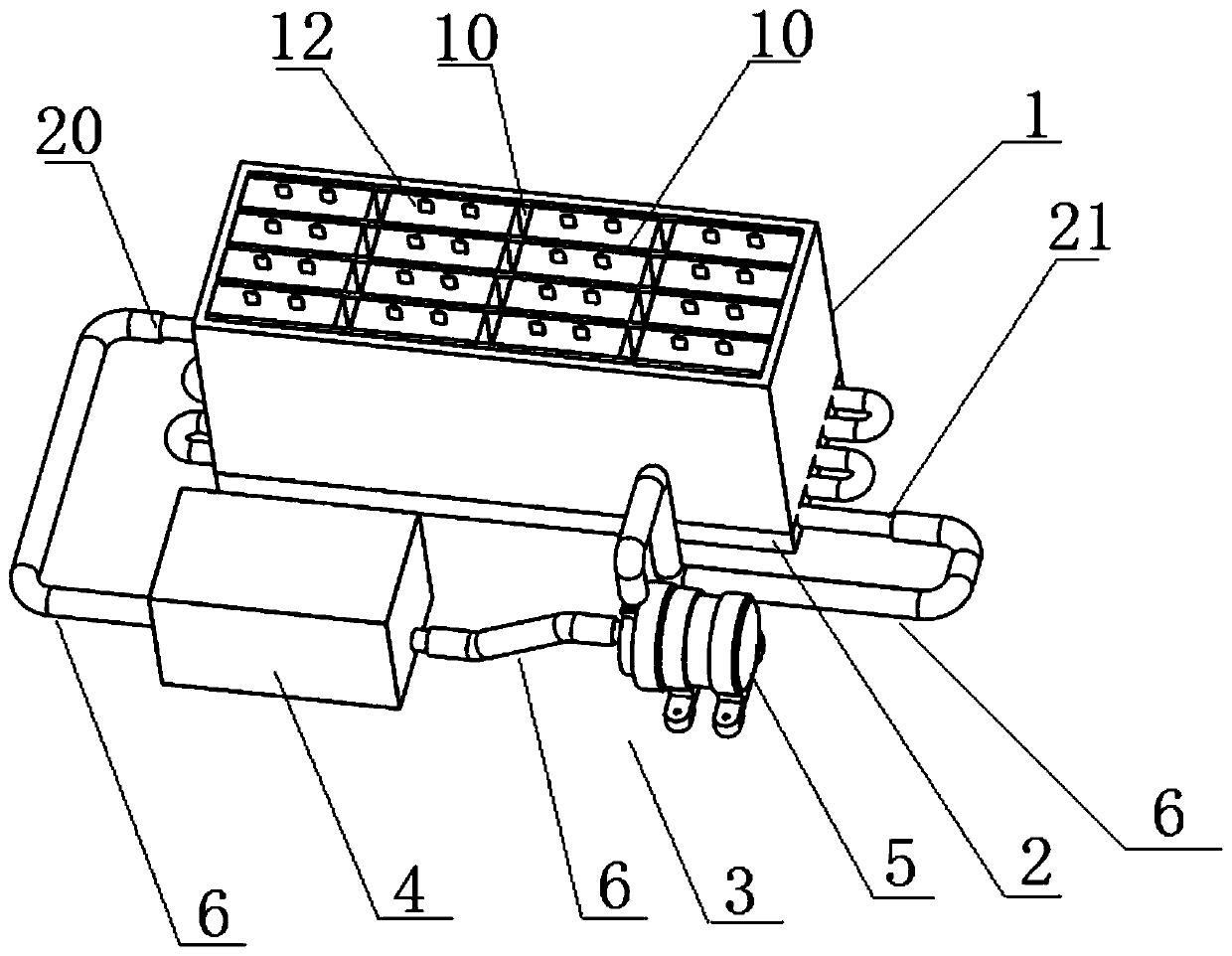

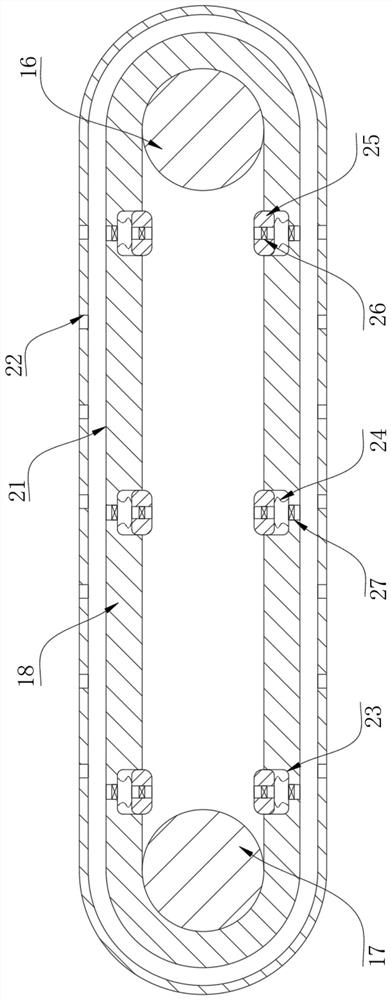

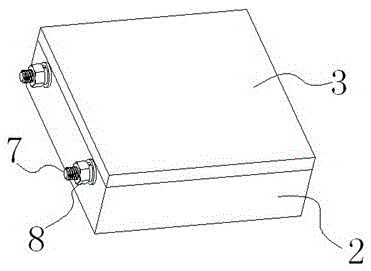

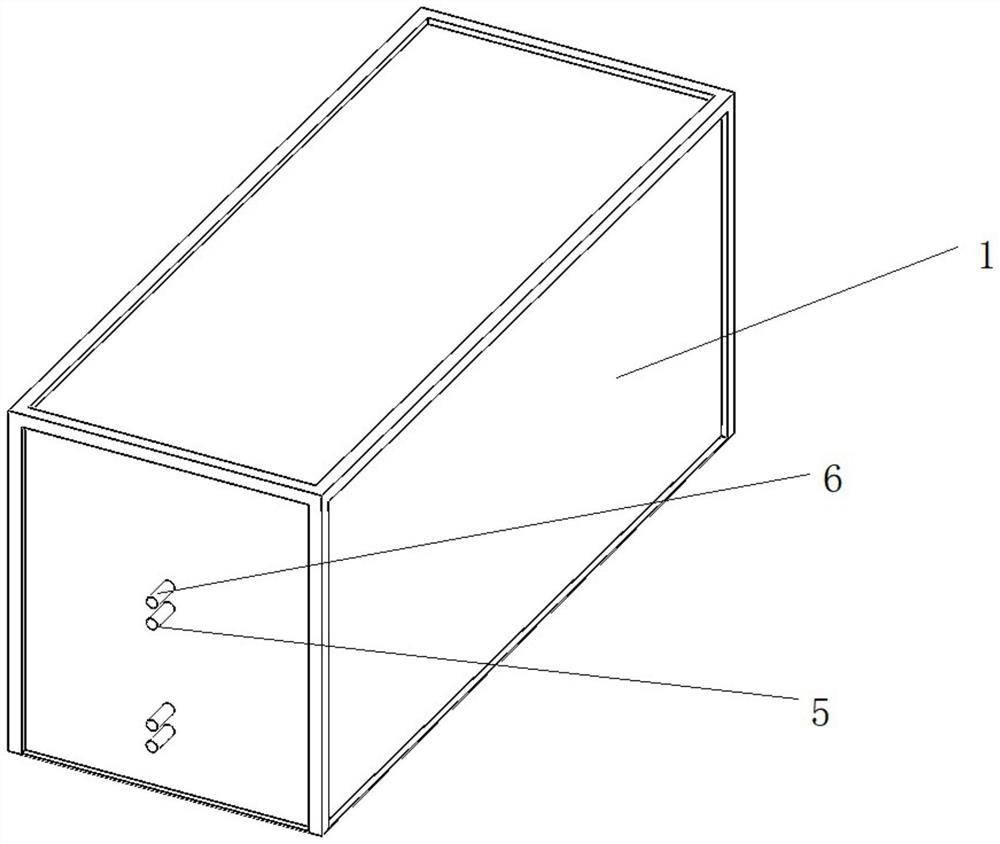

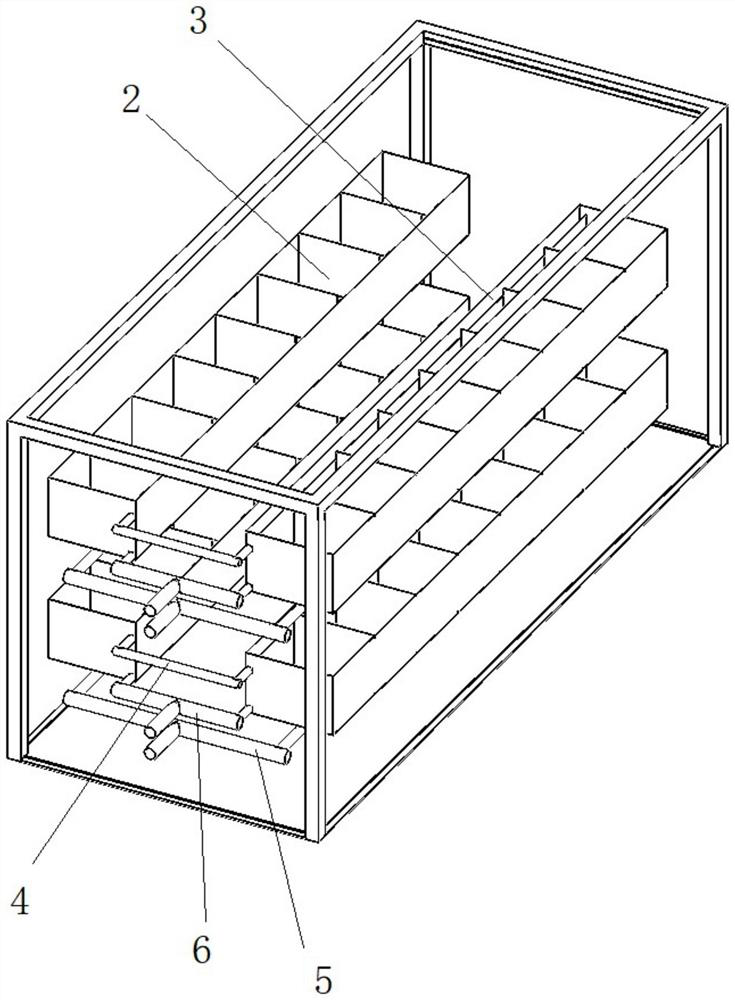

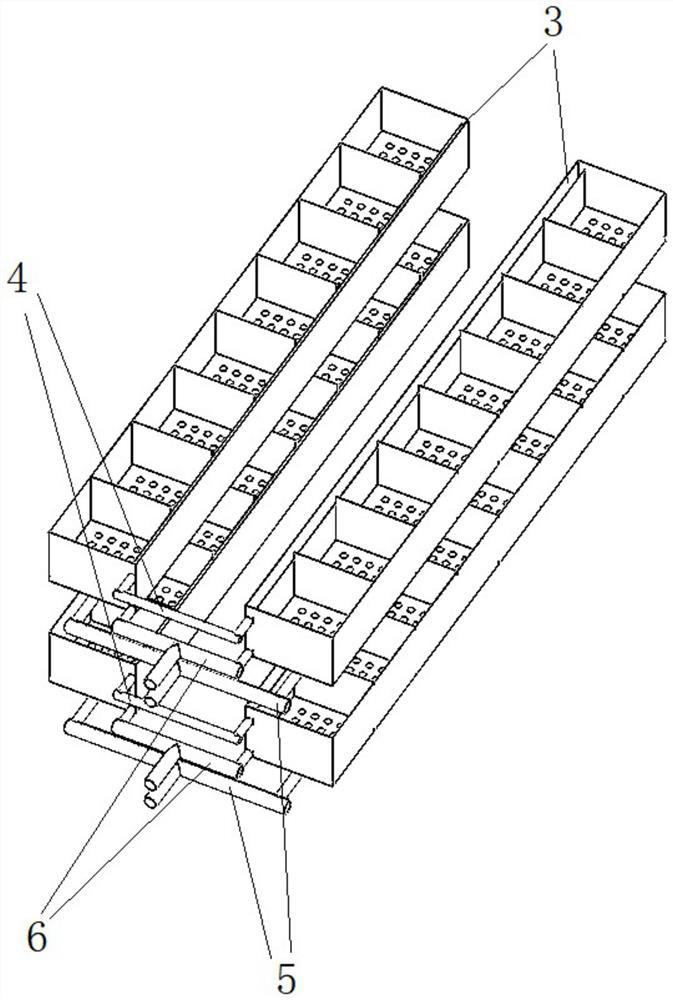

Server cabinet with liquid cooling system

ActiveCN105704989AReduce risk of damageSimplify piping layoutCooling/ventilation/heating modificationsEngineeringLiquid cooling system

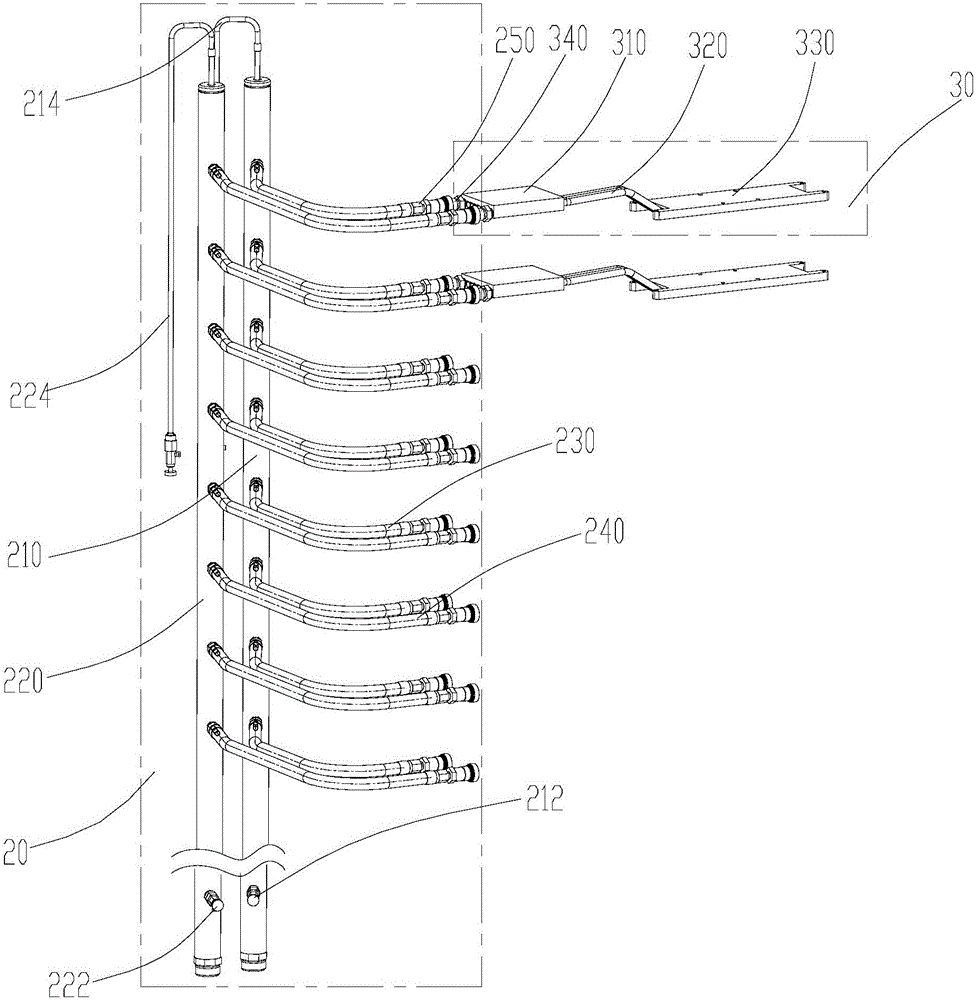

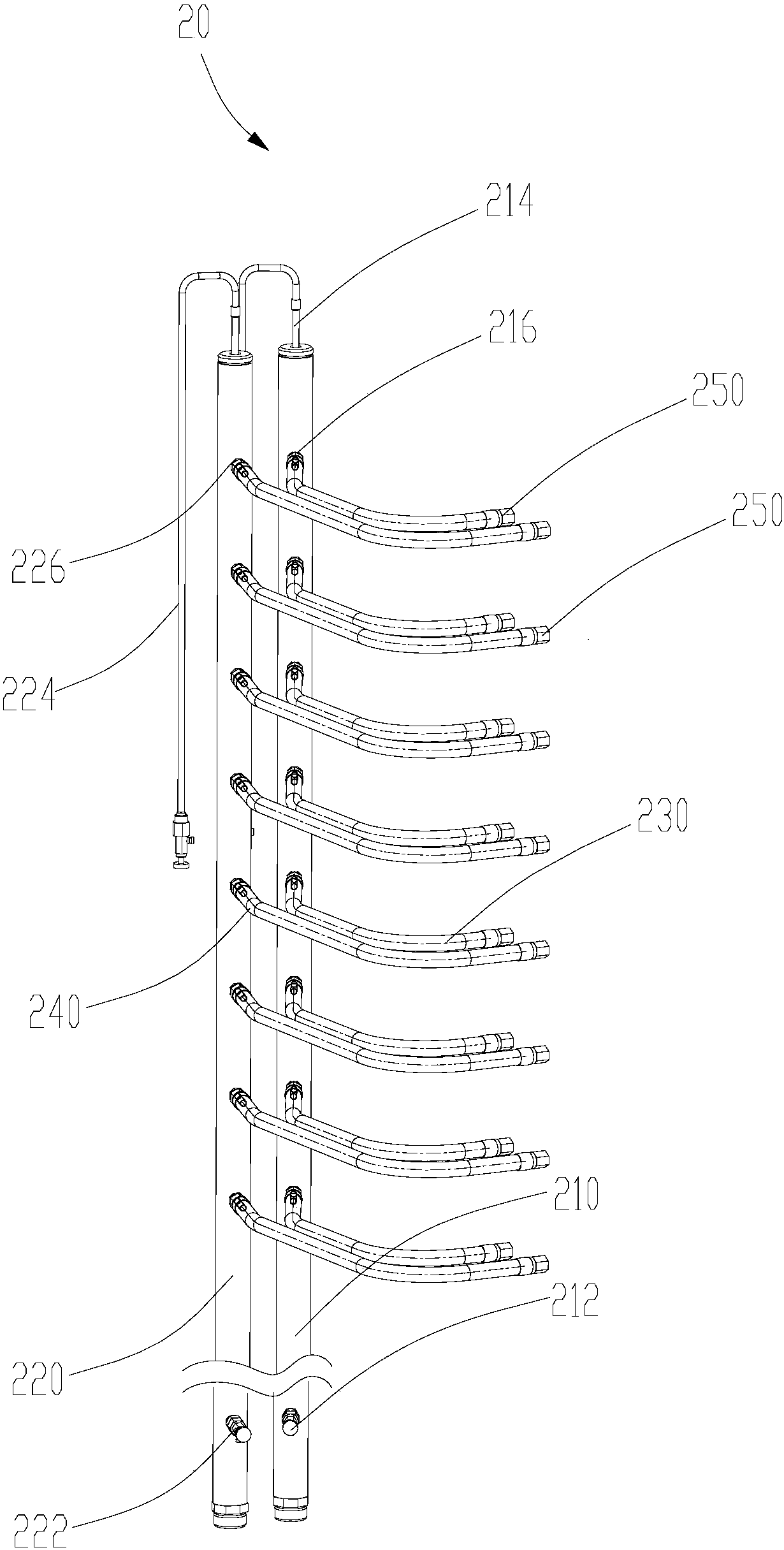

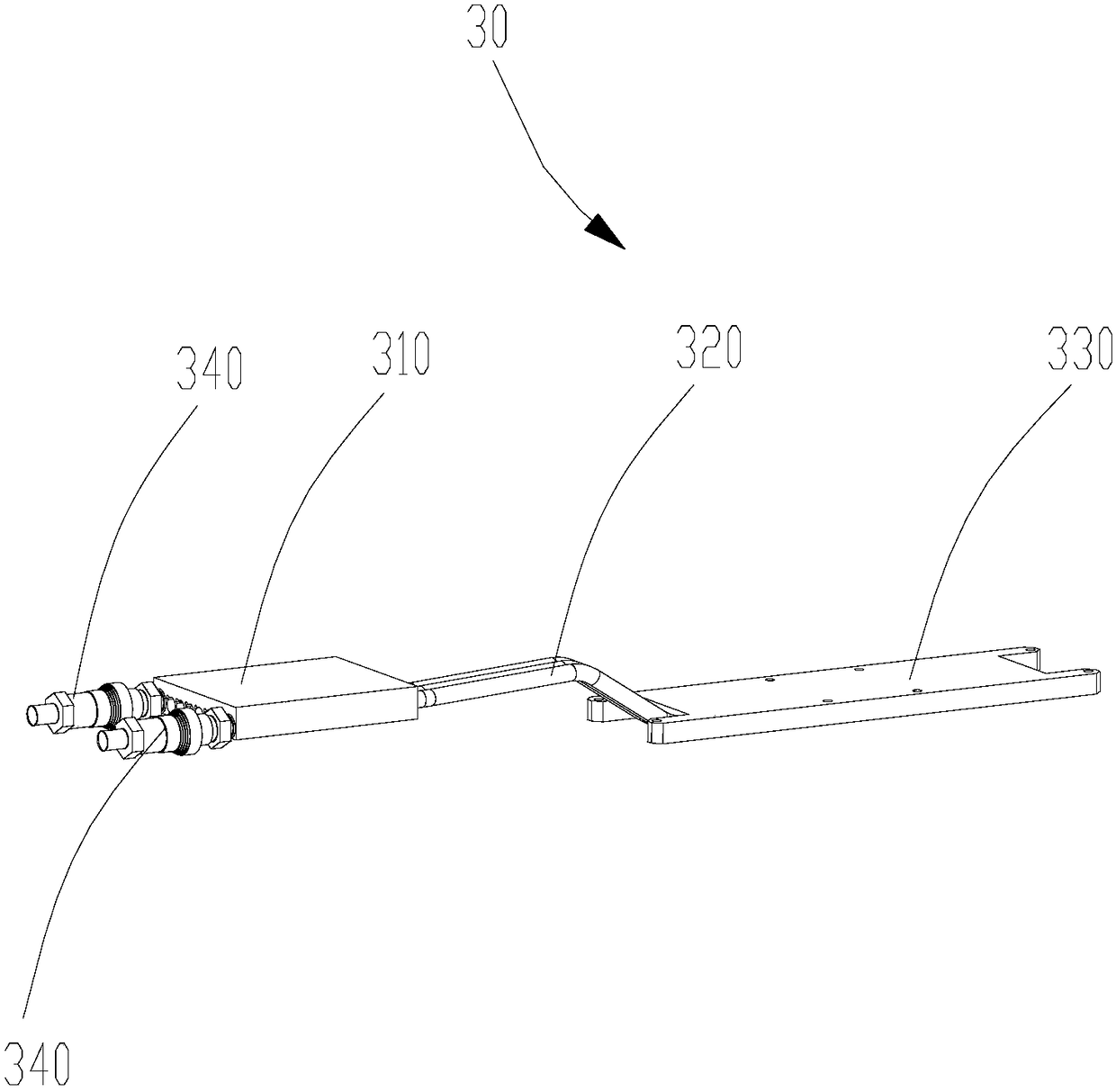

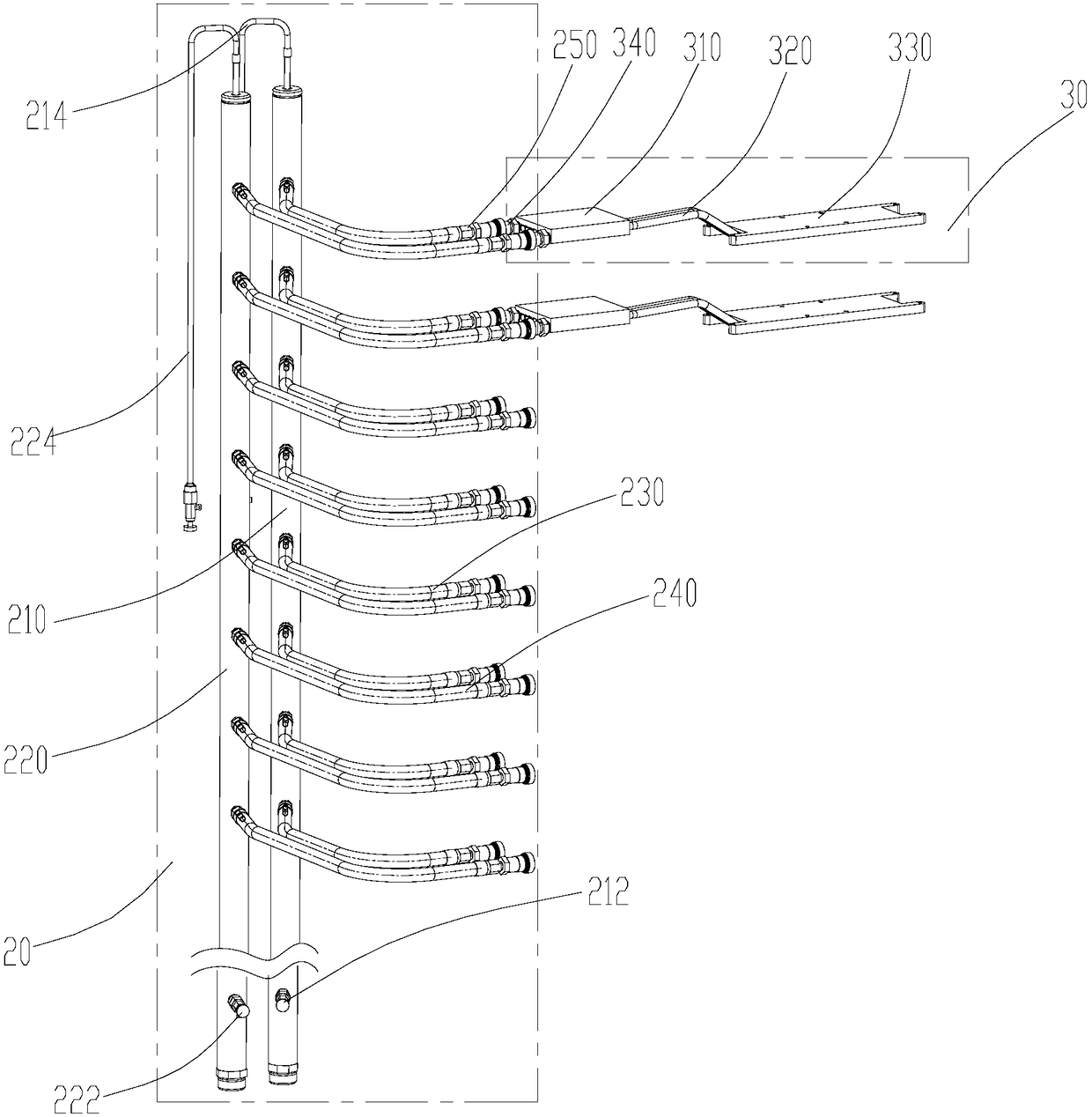

The invention relates to a server cabinet with a liquid cooling system. The server cabinet comprises a cabinet body, a liquid cooling distribution unit and a heat pipe heat-conducting unit, wherein the liquid cooling distribution unit comprises a liquid inlet pipe, a liquid outlet pipe, a liquid supply pipe and a liquid return pipe; the heat pipe heat-conducting unit comprises a liquid cooling module, a heat pipe and a heat-absorbing module; one end of the liquid supply pipe is connected with the liquid inlet pipe; the other end of the liquid supply pipe is connected with a liquid inlet of the liquid cooling module; one end of the liquid return pipe is connected with the liquid outlet pipe; the other end of the liquid return pipe is connected with a liquid outlet of the liquid cooling module; one end of the liquid return pipe is connected with the liquid outlet pipe; the other end of the liquid return pipe is connected with the liquid outlet of the liquid cooling module; one end of the heat pipe is connected with the liquid cooling module; the other end of the heat pipe is connected with the heat absorbing module; and the heat absorbing module is in contact with a server heat source of the cabinet body. Due to application of the heat pipe, a cooling liquid is prevented from entering a server; the risk that the server is damaged due to leakage of the cooling liquid is reduced; the server cabinet is simple in layout, and convenient to maintain and install; and the server can be flexibly added and reduced.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

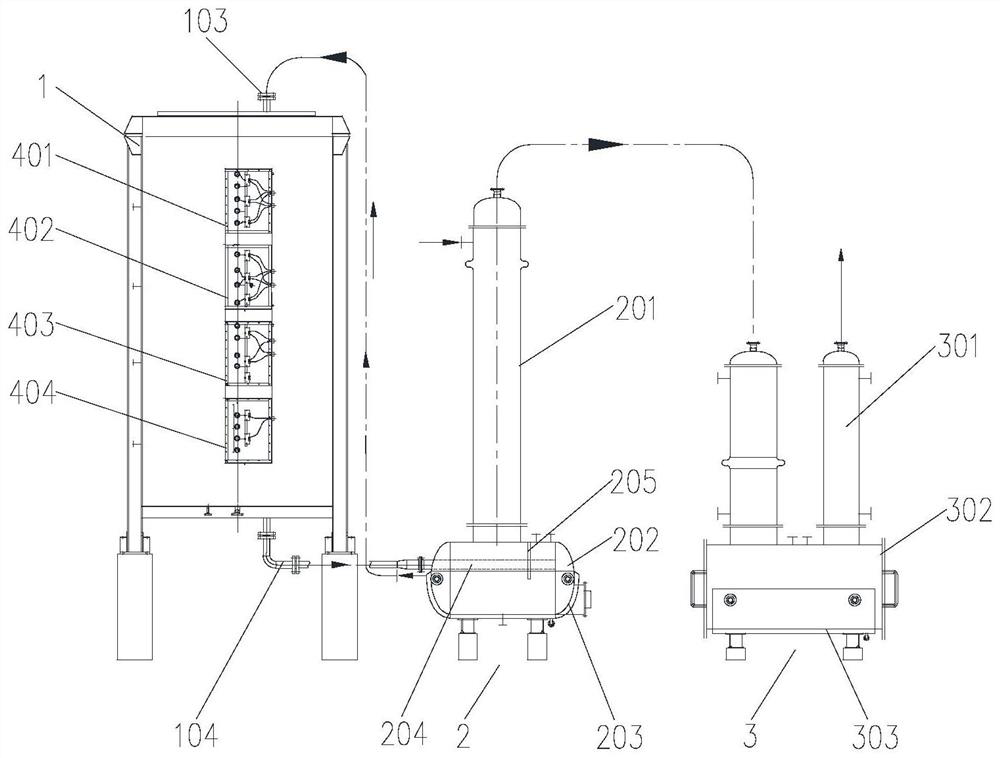

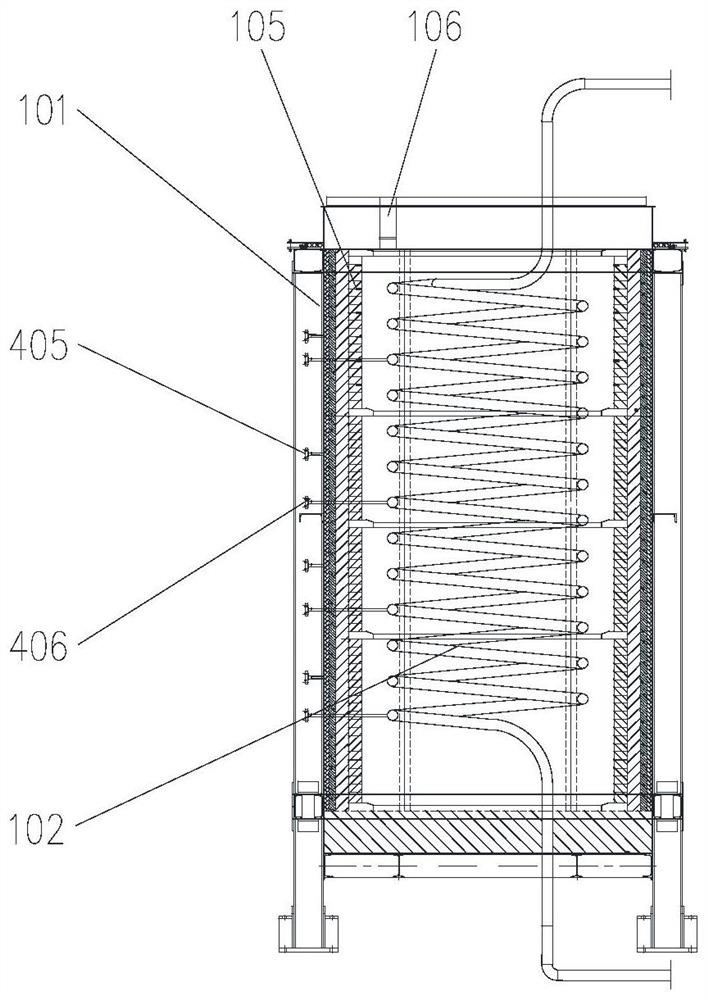

Method for preparing tetrapropylammonium bromide and horizontal autoclave

InactiveCN101148411AImproved fluid flow performanceGood solid phase dispersionAmino preparation from aminesSolid phasesFilter cake

The present invention discloses process of preparing ammonium tetrapropyl bromide and the horizontal reaction kettle therefor. Through reaction of liquid 1-bromopropane and liquid n-tripropyl amine in a horizontal reaction kettle to obtain solid ammonium tetrapropyl bromide, filtering after reaction, washing the filter cake with organic solvent and drying, ammonium tetrapropyl bromide product with Na+ ion content lower than 0.1 ppm is prepared. Adopting horizontal reaction kettle for preparing ammonium tetrapropyl bromide has operation convenience, easy dispersion of both liquid phase and solid phase, favor to heat transfer, low energy consumption, improved reaction procedure, high yield and high product quality.

Owner:EAST CHINA UNIV OF SCI & TECH

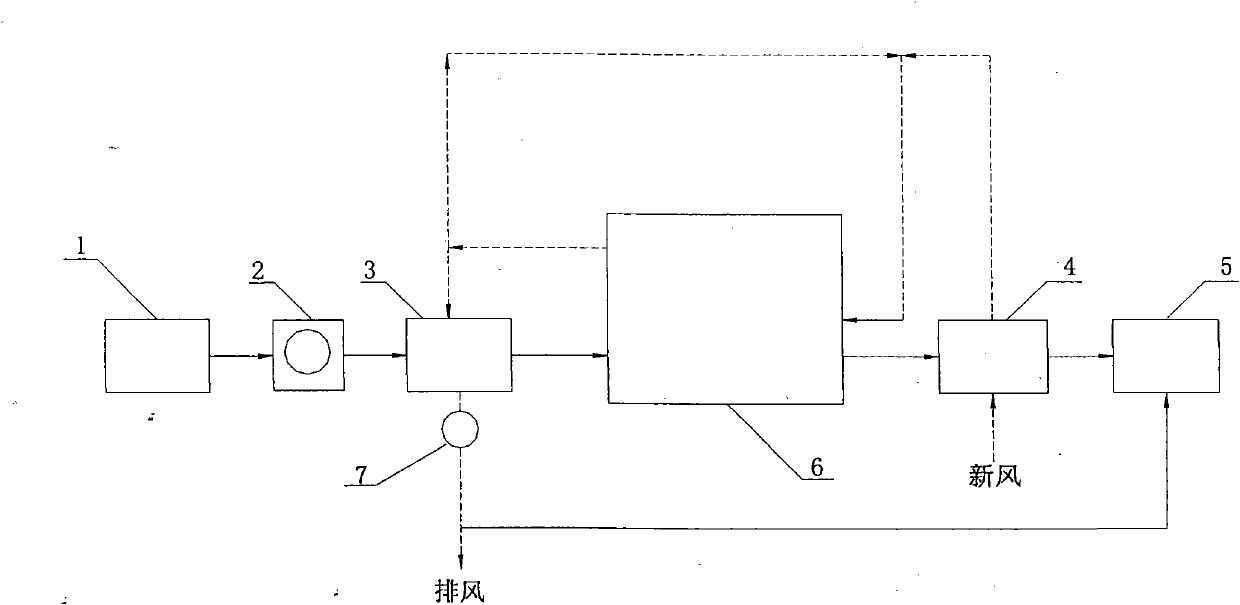

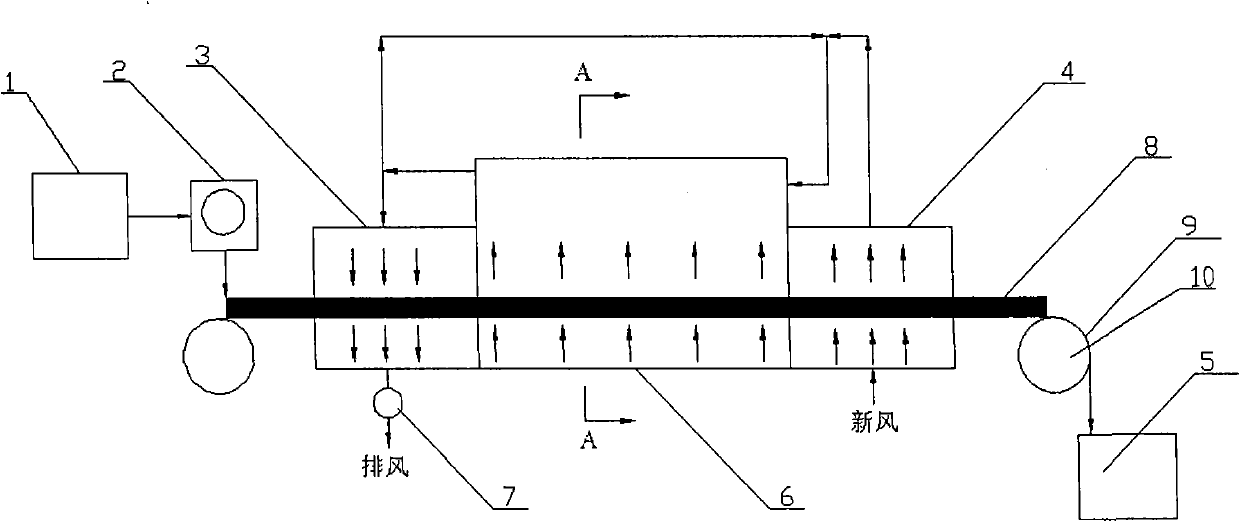

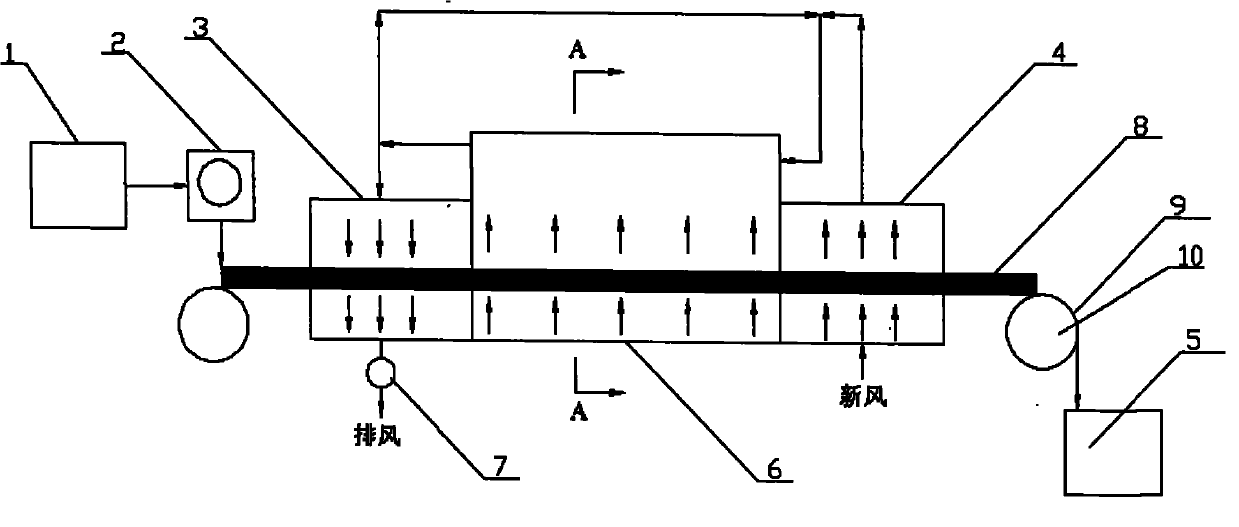

Belt-conveying drying system and method for realizing dehydration upgrading of lignite by using solar energy

InactiveCN101907383AGood energy saving and emission reduction effectEmission reductionDrying solid materials with heatDrying gas arrangementsFresh airCooling chamber

The invention relates to the field of coal high-efficiency utilization and aims to provide a belt-conveying drying system and a belt-conveying drying method for realizing the dehydration upgrading of lignite by using solar energy. The system comprises a feed preheating chamber, a dryer and a discharged material cooling chamber, which are connected in turn by a belt-conveying equipment, wherein the dryer is divided by a vertical partition into an air preheating chamber and a drying chamber, through holes are formed on the partition, and the air preheating chamber is provided with an air inlet, a drying chamber and an air outlet; and the discharged material cooling chamber is provided with a fresh air inlet, the air outlet of the discharged material cooling chamber is connected with the air inlet of the air preheating chamber by an air duct, the air outlet of the drying chamber is connected with the air inlet of the feed preheating chamber and the air inlet of the air preheating chamber by air ducts at the same time, and the air outlet of the feed preheating chamber is connected to a coal powder separation system. The system and the method have the advantages that: the energy-conservation and emission-reduction effect is obvious; the drying process is simple; the initial investment is small; the operation cost is low; the normal energy consumption is low; the pollutant emission is small; and the management and use of the whole device can be accepted by a user more easily.

Owner:ZHEJIANG UNIV

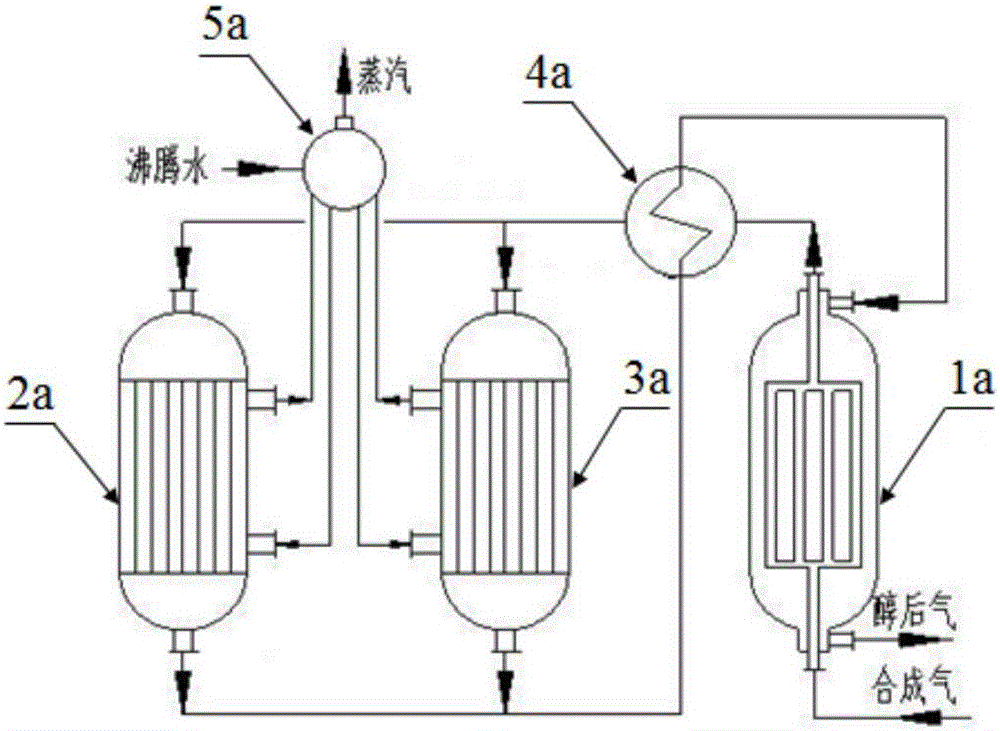

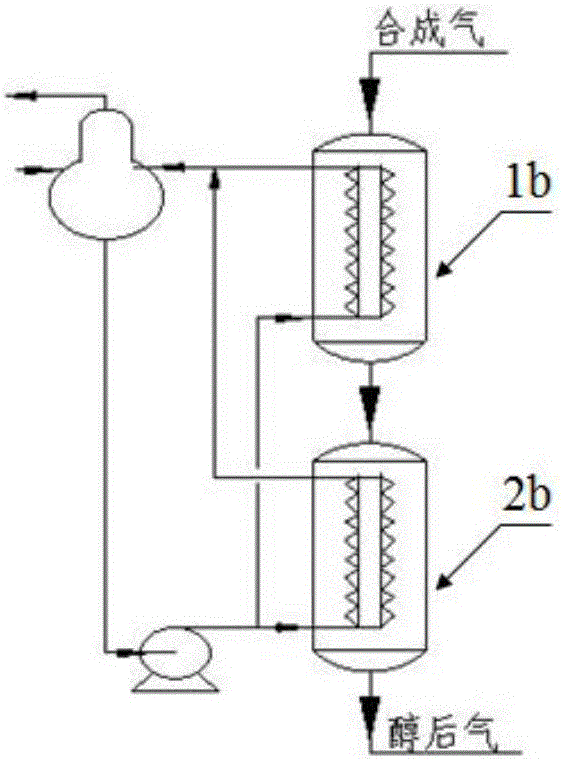

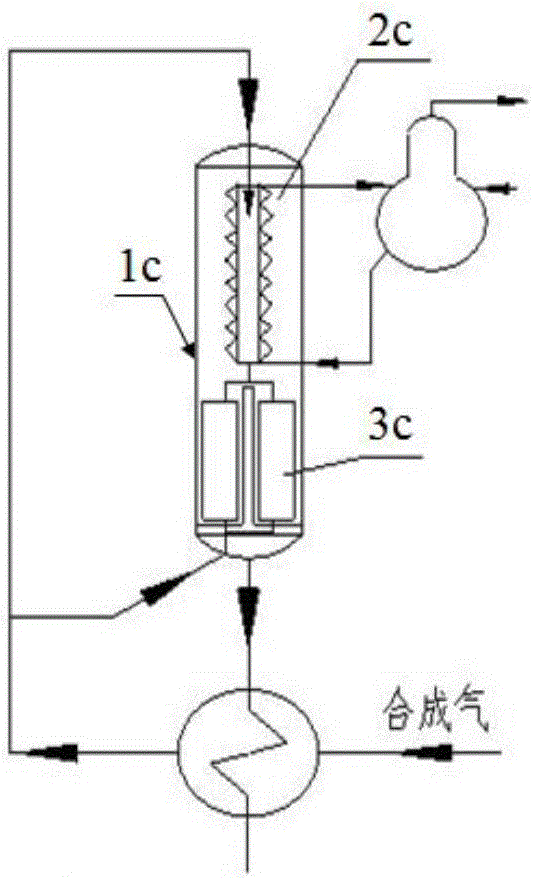

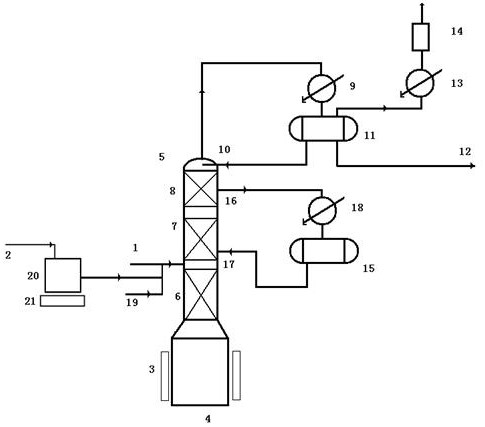

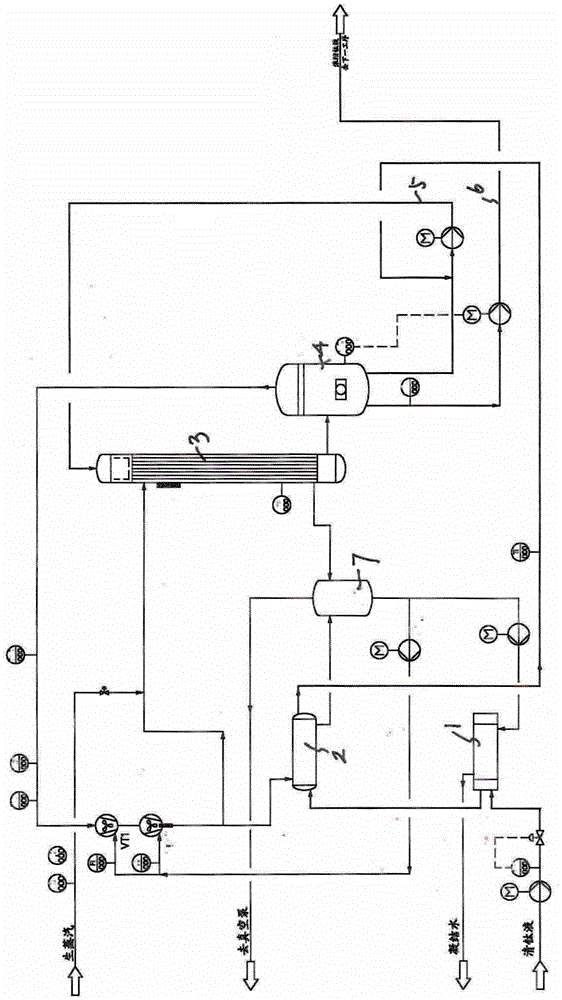

Energy-saving inter-section high low temperature gradient alcohol-division two-stage alcohol generation method and energy-saving inter-section high low temperature gradient alcohol-division two-stage alcohol generation device

ActiveCN105753646AReduce CO concentrationGuaranteed conversion rateOrganic compound preparationHydroxy compound preparationSyngasAlcohol

The invention discloses an inter-section high low temperature gradient alcohol-division two-stage alcohol generation method which comprises the following steps: respectively reheating fresh synthesis gas and recycle gas, mixing the fresh synthesis gas with the recycle gas, introducing the mixed gas into a first reactor, and enabling part of carbon oxides to react to obtain methyl alcohol; cooling a mixture containing synthesis gas and methyl alcohol steam output from the first reactor, guiding the mixture to flow to a first methyl alcohol separator, separating out methyl alcohol, pressurizing the separated gas, preheating, then introducing into a second reactor, and enabling part of carbon oxides to react to obtain methyl alcohol; cooling a mixture containing synthesis gas and methyl alcohol steam output from the second reactor, guiding the mixture to flow to a second methyl alcohol separator, separating out methyl alcohol, preheating the separated gas which separately serves as the recycle gas and fresh synthesis gas, mixing the recycle gas and the fresh synthesis gas, and feeding the mixture into the first reactor so as to perform next round of circulating preparation of methyl alcohol. The invention further discloses an inter-section high low temperature gradient alcohol-division two-stage alcohol generation device. The method is relatively high in single-pass alcohol net value and relatively small in circulation ratio, achieves a ton-alcohol steam yield as high as 1.2-1.3 ton, and is high in energy heat recovery amount.

Owner:NANJING GOODCHINA CHEM TECH

Server rack heat sink system with combination of liquid cooling device and auxiliary heat sink device

ActiveUS10356949B2Improve cooling efficiencyGood effectModifications using liquid coolingSingle machine energy consumption reductionLow noiseHigh density

A server heat dissipation system is provided, comprising a liquid cooling server cabinet comprising a cabinet body and multiple liquid cooling servers provided inside the cabinet body, wherein it is provided with a liquid cooling device to perform direct liquid cooling to the liquid cooling servers, and with an auxiliary heat dissipation device to perform auxiliary heat dissipation to the liquid cooling servers. The present invention provides high density cooling, high heat exchange efficiency, no local overheating, small space occupied, high reliability, low noise, and long life.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

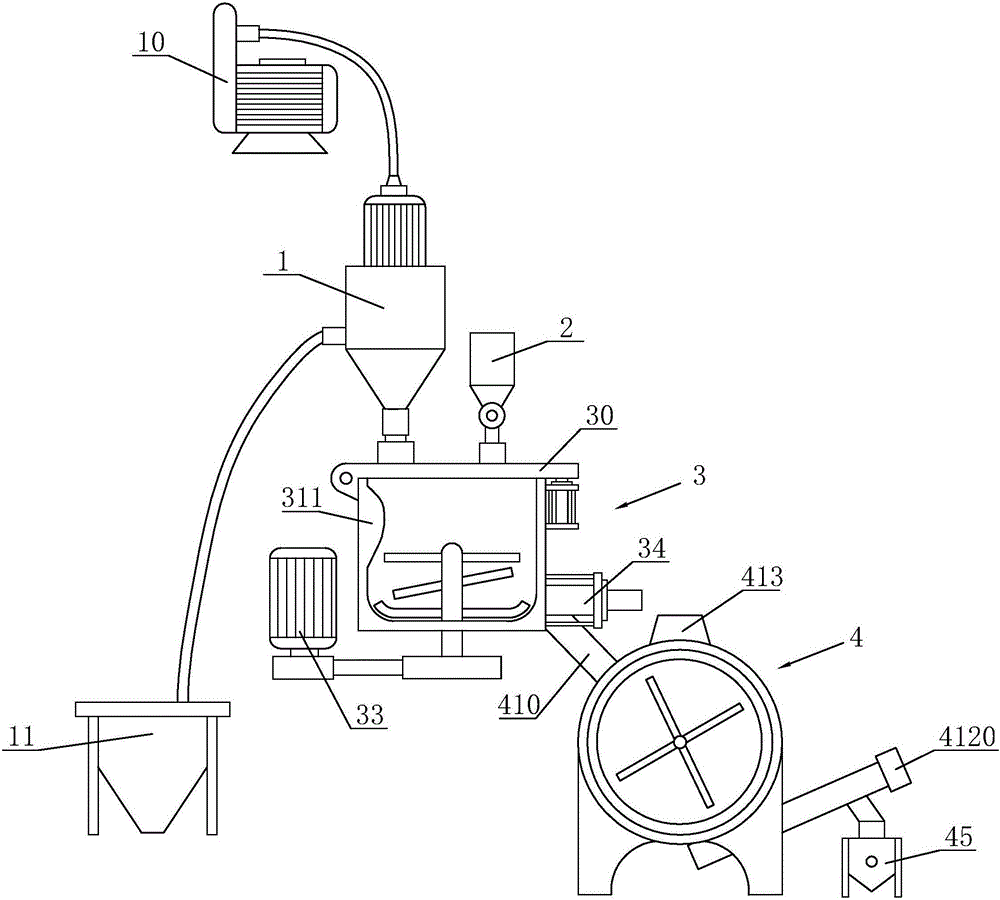

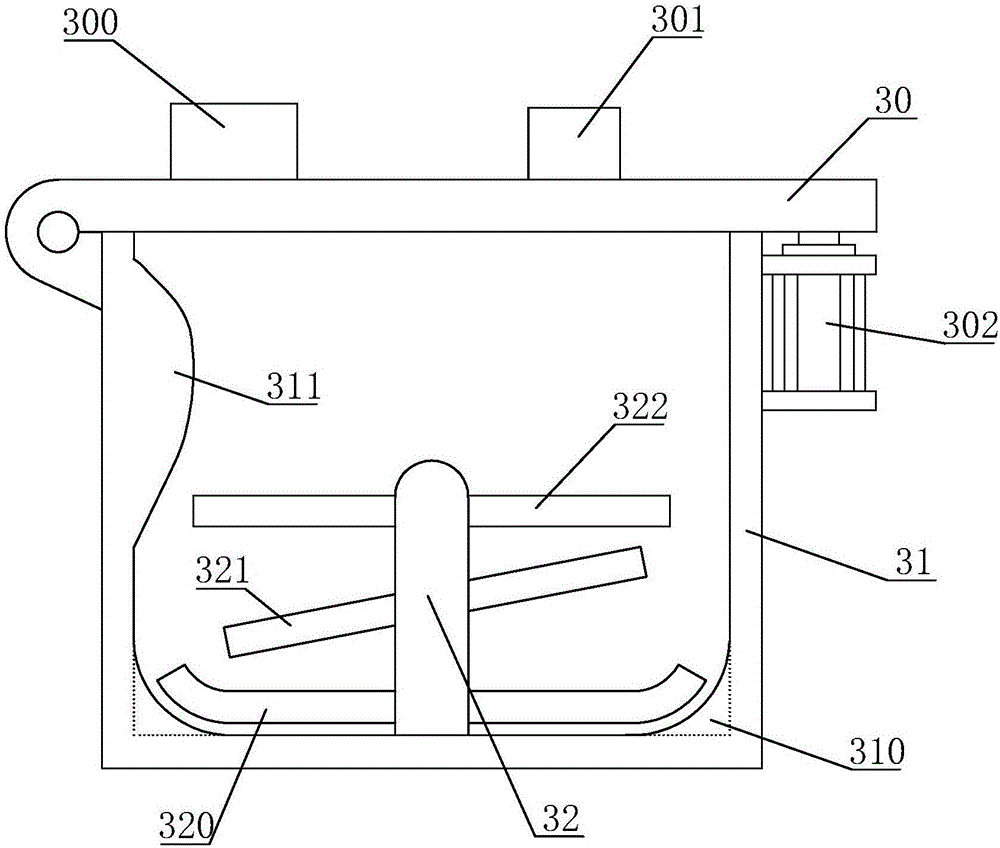

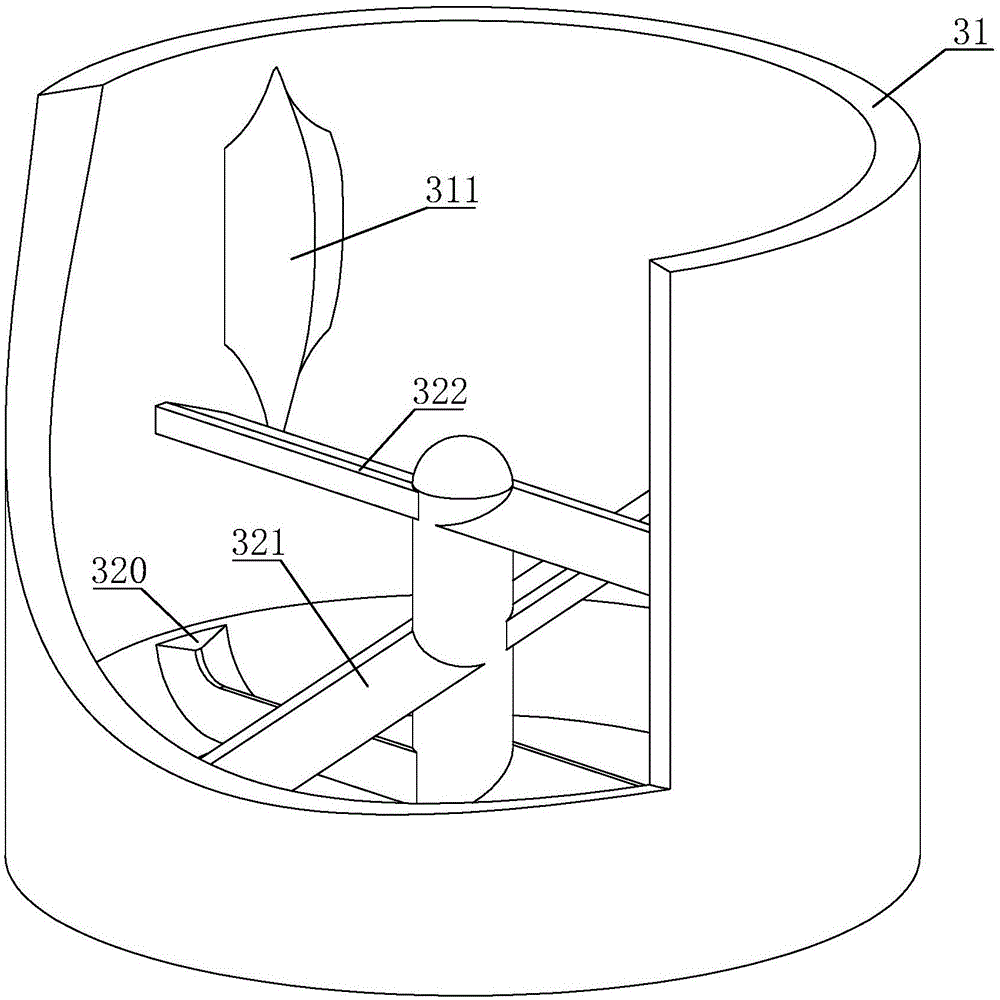

Modification machine, modification cooling system and modification process

PendingCN106823923AAvoid burning and heatingNo problems with open flamesRotary stirring mixersTransportation and packagingEngineeringFrequency modulation

The invention discloses a modification cooling system which comprises a hopper, a vacuum loading machine, an automatic metering feeder, a cooler and a modification machine. The vacuum loading machine is connected with the modification machine, the automatic metering feeder is connected with the modification machine, the cooler is positioned below the modification machine, the modification machine comprises a barrel and a sealing cover, a modifier inlet is arranged on the sealing cover, a stirring blade is arranged in the barrel, and a frequency modulation motor is arranged outside the barrel; the stirring blade comprises a raising blade which is positioned on the surface of the bottom of the barrel, a raising structure for enabling materials at the bottom of the barrel to rotate along with the raising blade to be raised along the wall of the barrel is arranged in the barrel, and the raising structure is positioned at a junction of the bottom of the barrel and the inner wall of the barrel; the stirring blade further comprises a friction blade for enabling material particles to collide to generate heat. The blades in the modification machine are utilized to enable the materials to mutually collide at high frequency for friction to generate heat, increasing of adhesion rate of the modifier on the material particles is facilitated effectively, speed of a modification process is increased, and product quality is improved.

Owner:JINHUA XINSHENG ZEOLITE DEV

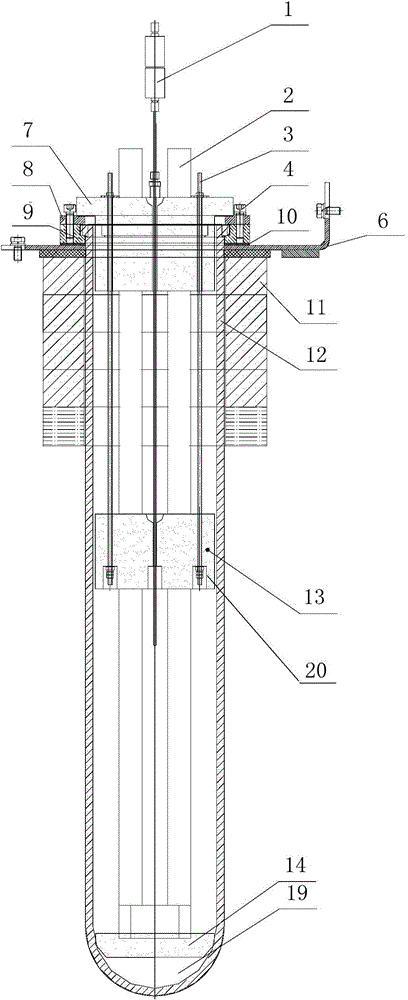

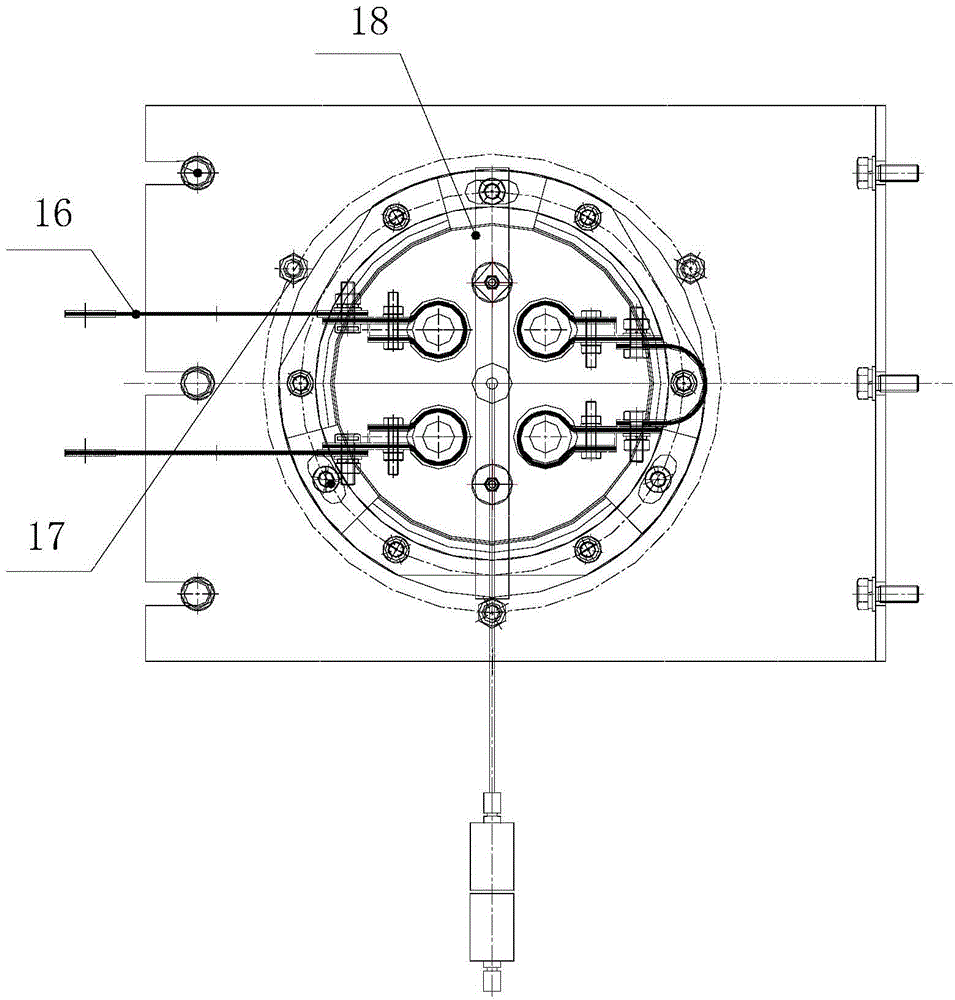

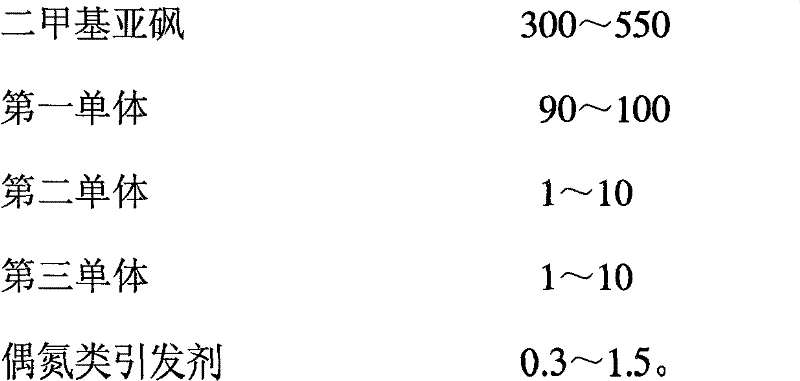

Preparation method and polymerization equipment of acrylonitrile base carbon fiber spinning solution

ActiveCN101768239AImprove the mixing effectIncrease the length/diameter ratioFibre chemical featuresPolymer scienceSurface layer

The invention discloses a preparation method and polymerization equipment of acrylonitrile base carbon fiber spinning solution. The preparation method is characterized in that solution polymerization is carried out in the polymerization equipment; the polymerization equipment comprises a reaction kettle and a reactive extruder; and the reaction kettle and the reactive extruder are connected with each other and are respectively provided with a temperature regulating device. The invention has the following benefits: the reaction kettle is connected with the reactive extruder; the screw extrusion structure of the reactive extruder can introduce the reaction media and the chemical reaction in the process of extrusion and has the functions of the synthesis reactors besides the function of mixing materials of the traditional extruders; the reactive extruder can further process high viscosity materials and continuously and quickly generate new and thin material surface layers, thus increasing the surface volume ratio of the materials; and the reaction media are uniformly distributed in the materials and the degree of reaction is improved.

Owner:KINGFA SCI & TECH CO LTD +1

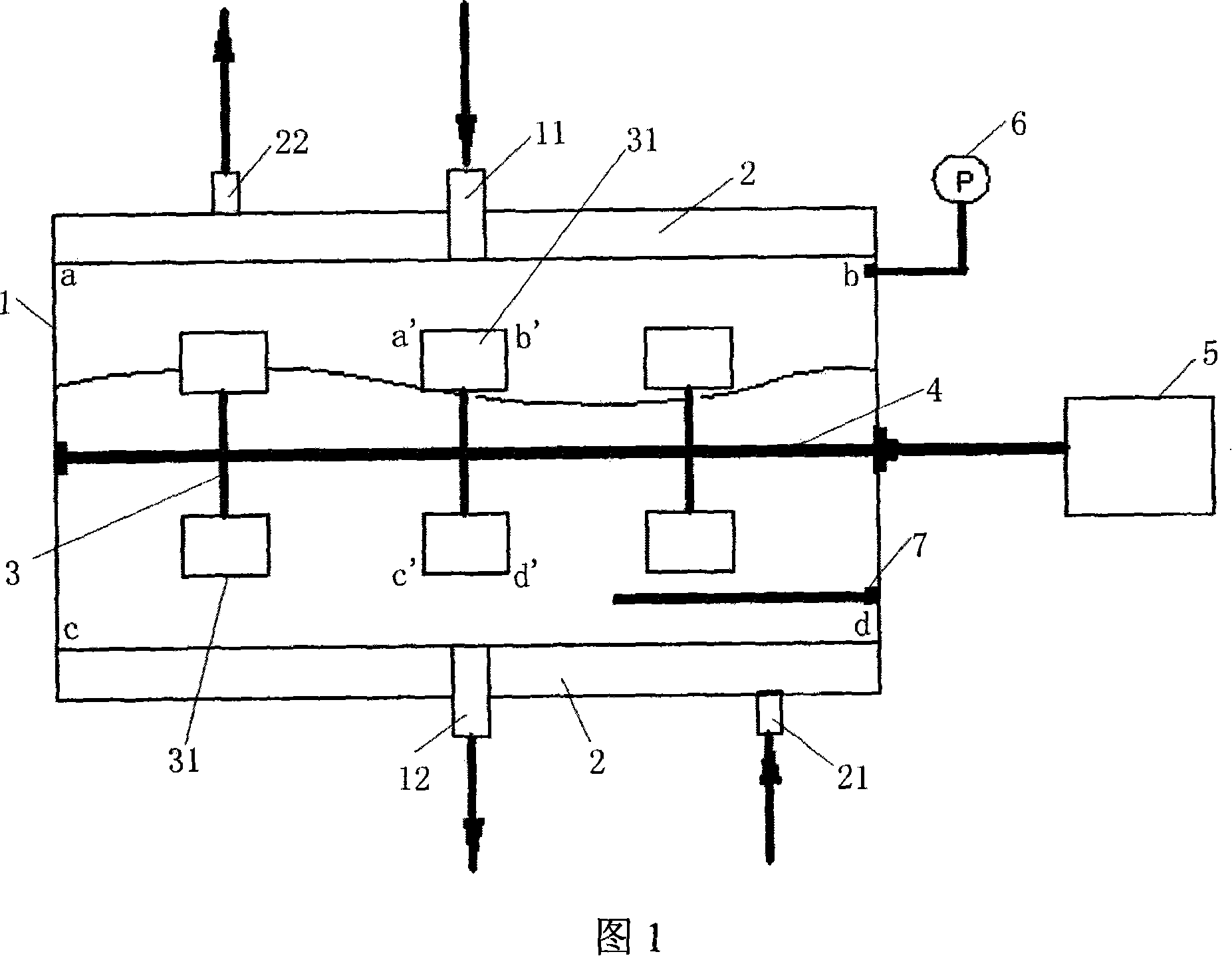

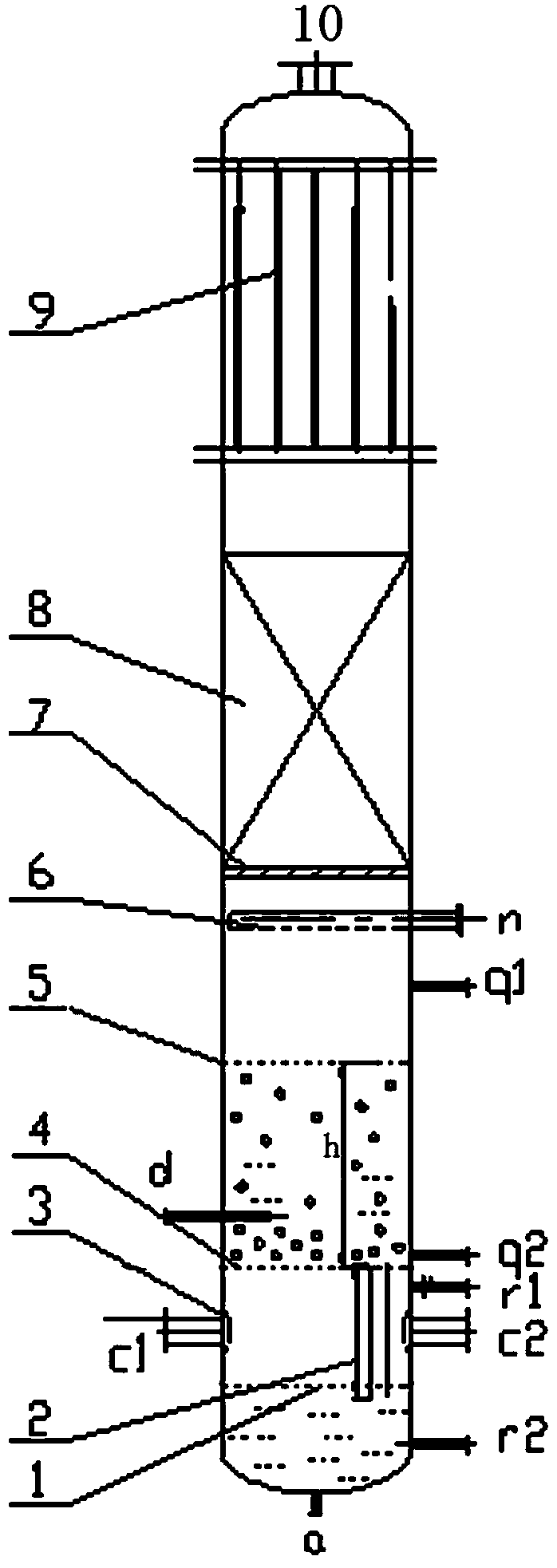

Reaction rectification reactor

ActiveCN103706309AUniform air intakeReduce volatilityLiquid-gas reaction processesFractional distillationGas phaseSolvent

The invention discloses a reaction rectification reactor. The reaction rectification reactor comprises a reaction section, a rectification section and a reflux condensation part from bottom to top, wherein a liquid outlet, a gas inlet and a gas distribution plate are arranged on the reaction section from bottom to top; a downspout and the gas distribution plate are arranged in the reactor; the upper end of the downspout is fixed on the gas distribution plate; a liquid inlet is formed in the reactor side wall between the reaction section and the rectification section; holes are evenly formed in the gas distribution plate. Compared with the prior art, the reaction rectification reactor has the beneficial effects that (1) a gas feeding manner of a gas phase is even, the amplitude of fluctuation of a reaction liquid level is small, the liquid level is easily controlled, and the problems of difficult connection between a large-diameter gas inlet pipeline and a gas distributor and processing difficulty of the gas distributor are avoided; (2), one part of reaction heat can be removed by gas carrying a gasified solvent, the temperature is controlled to be stable, and the problems of overheating locally and removing the reaction heat difficultly are avoided; (3), the rectification section and a condenser are capable of better separating certain components which are difficulty separated.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

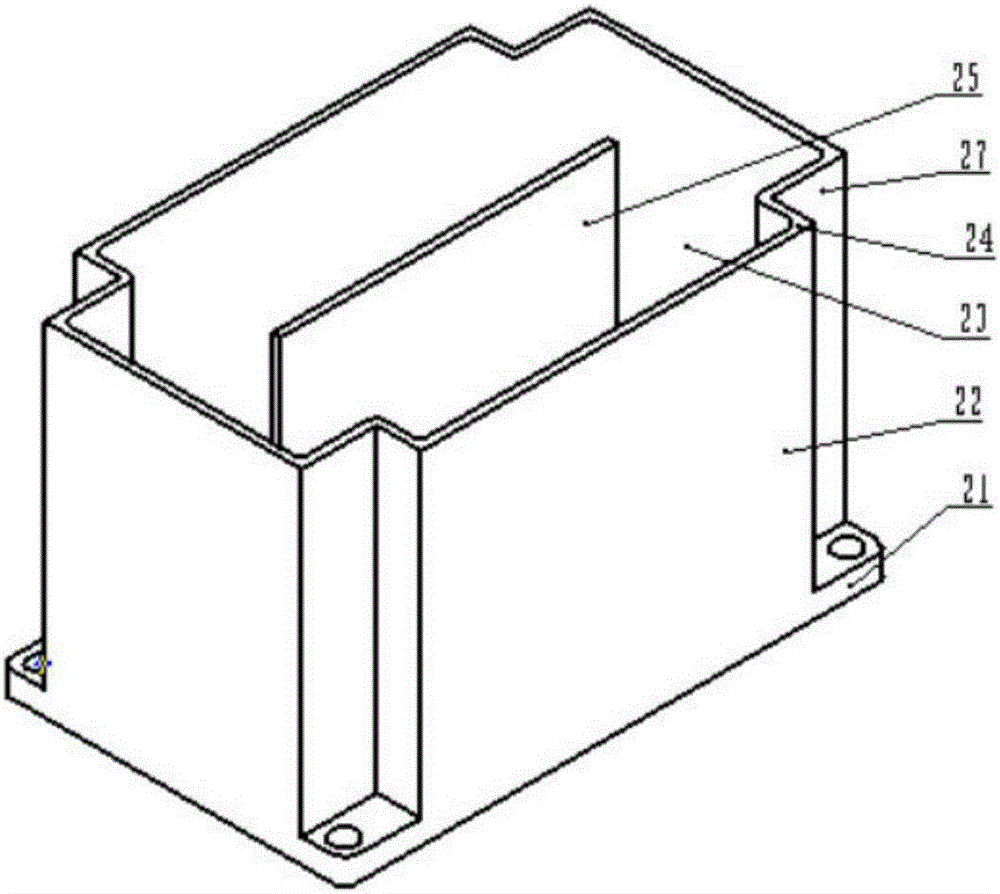

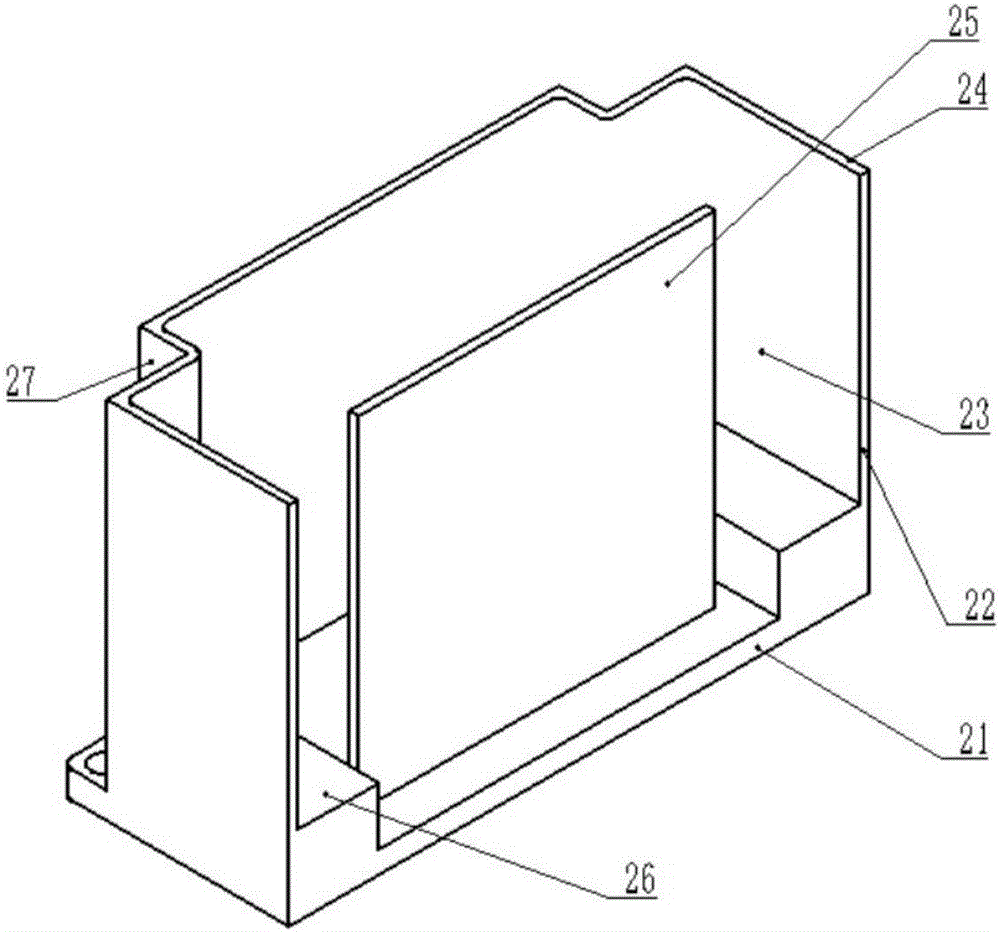

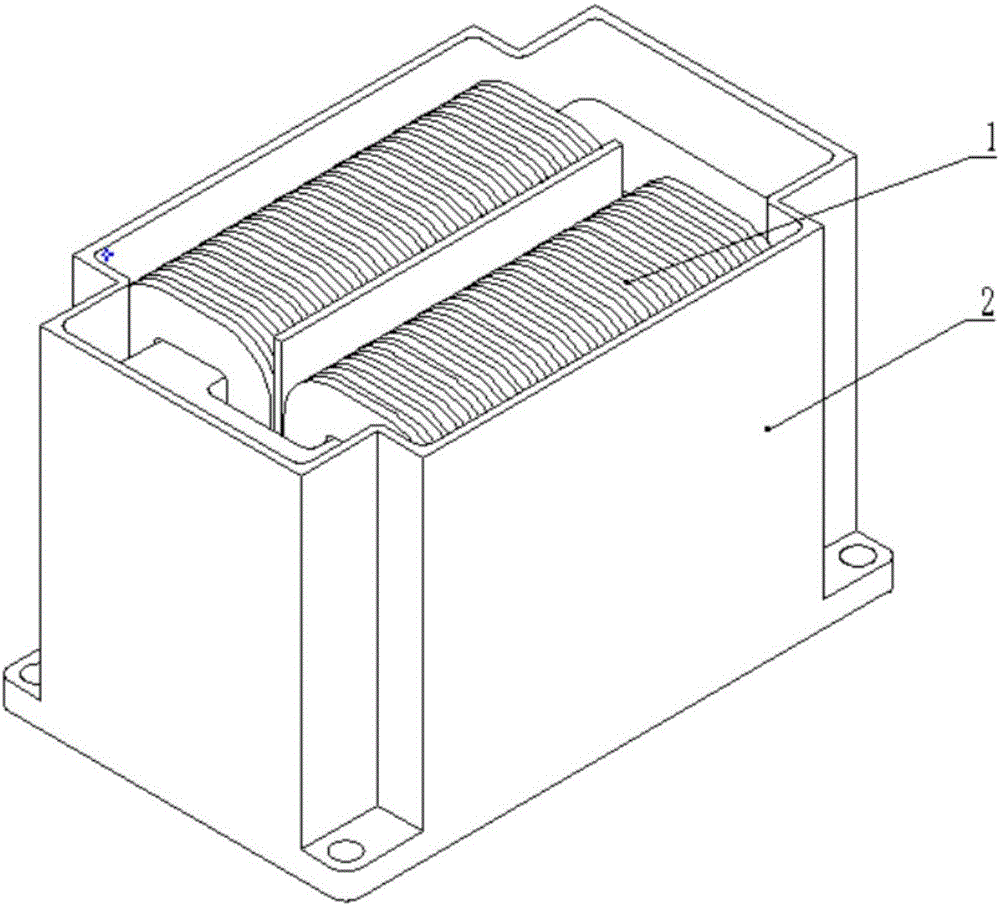

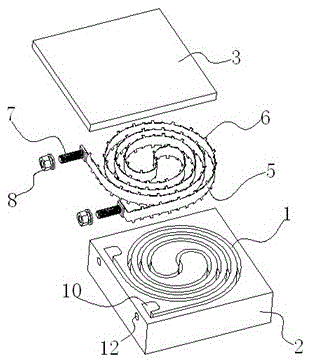

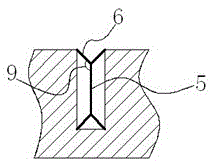

High-frequency inductor with embedded radiator

ActiveCN106571209ASmall temperature differenceNo local overheatingTransformers/inductances coolingFixed transformersInductor windingsHeat conducting

The invention relates to an inductor, especially relates to a high-frequency inductor with an embedded radiator, and belongs to the technical field of inductor structure design, wherein the inductor is used in a power electronic high-frequency filter system. The invention aims at solving problems that a conventional natural cooling inductor is low in radiation frequency, is large in size, is high in cost, is poor in radiation uniformity, and is liable to cause local overheating between phases. The high-frequency inductor mainly comprises an inductor and a radiator. The radiator is a cavity formed through the enclosing of a bottom plate and surrounding plates. An opening is disposed in a direction opposite to the bottom plate, and the inductor is embedded into the cavity of the radiator through the opening. The radiator also comprises a tongue plate which extends from the bottom plate to a cover plate. The tongue plate is inserted between the phases of an inductor winding, and heat-conducting silica gel is disposed between a gap between the inductor and the cavity. The inductor is used in the structural design of a power electronic high-frequency inductor, can improve the heat-dissipation efficiency, and avoid the local overheating.

Owner:SHENZHEN YINLI ELECTRIC APPLIANCES MFG

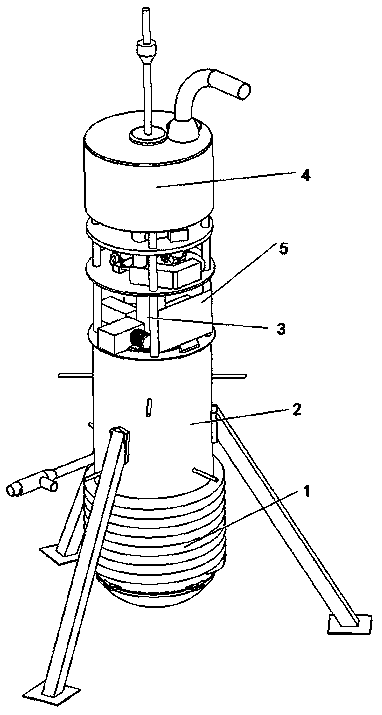

Multilevel eddy current electromagnetic ultrafine dust flue gas treatment device for cracking reaction of methyl alcohol

ActiveCN108837639AWide range of usesAccurate measurementUsing liquid separation agentAlcoholHydrogen

The invention relates to a multilevel eddy current electromagnetic ultrafine dust flue gas treatment device for the cracking reaction of methyl alcohol, and belongs to the technical field of the cracking reaction of methyl alcohol. The multilevel eddy current electromagnetic ultrafine dust flue gas treatment device comprises a high-speed spiral tube pretreatment system, a spraying and impurity removing system, a central impurity removing system, a double dust removal system and a support pillar III, the spraying and impurity removing system is fixedly arranged at the top end of the support pillar III, the high-speed spiral tube pretreatment system is fixedly wound on the outer wall of the bottom part of the spraying and impurity removing system, the central impurity removing system is fixedly arranged on the center of the inner part of the spraying and impurity removing system, the double dust removal system is fixedly arranged at the upper part of the spraying and impurity removing system, and the high-speed spiral tube pretreatment system, the spraying and impurity removing system, the central impurity removing system, and the double dust removal system are sequentially communicated. The multilevel eddy current electromagnetic ultrafine dust flue gas treatment device effectively removes the extra small suspension particle, the purity and the dryness of the prepared hydrogen are greatly increased, and the injury of the human body and the environment pollution caused by the ultrafine dust, the nano-particle and the organic gas are reduced.

Owner:KUNMING UNIV OF SCI & TECH

A kind of method of producing cyclopentene by dicyclopentadiene

ActiveCN108069814BHeating evenlyNo local overheatingChemical industryCatalystsCyclopentenePtru catalyst

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP +1

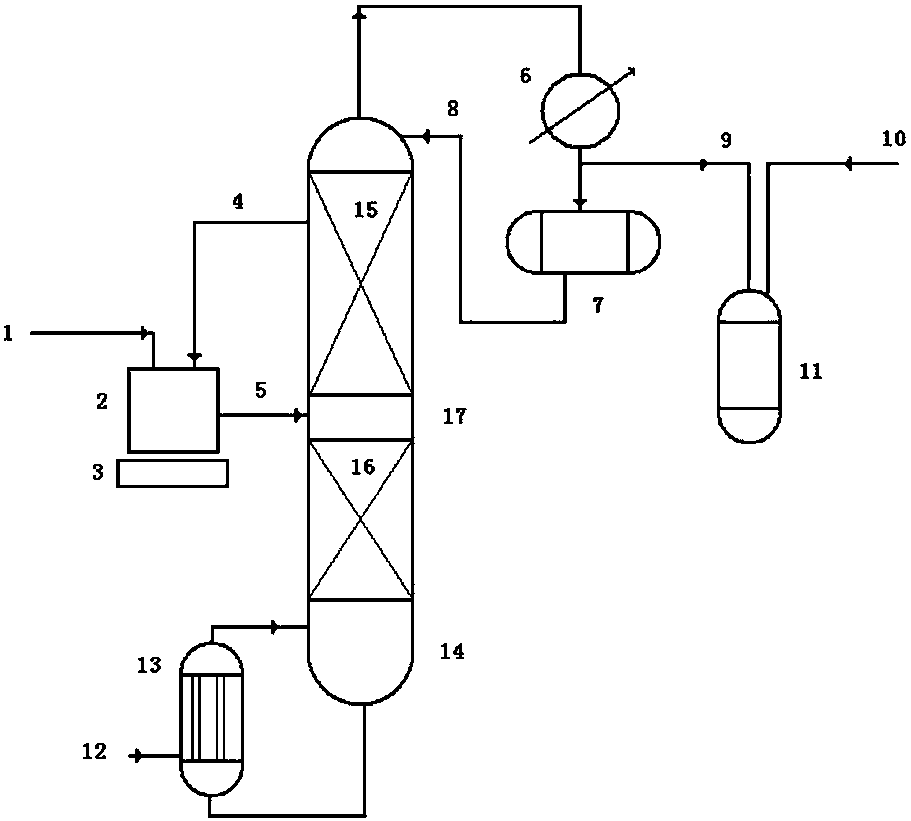

Method for preparing high-purity cyclopentadiene from dicyclopentadiene

ActiveCN108069813AHeating evenlyNo local overheatingDistillation purification/separationHydrocarbon by depolymerisationGas phaseDecomposition

The invention discloses a method for preparing high-purity cyclopentadiene from dicyclopentadiene. Dicyclopentadiene and circulating distillate oil light components enter a heater to be heated, partially decomposed and fed into a feeding section; a decomposition product and vaporized distillate oil light components flow upwards, cyclopentadiene is extracted from the top of a rectifying column andcooled, a part of cyclopentadiene is taken as a product, and the other part of cyclopentadiene as reflux returns to the top of the column; the distillate oil light components are extracted from the lateral line of the rectifying section and circularly return to the heater; undecomposed dicyclopentadiene flows into a stripping section from top to bottom, is mixed and contacted with distillate oil gas-phase components evaporating from the column bottom and is heated and gradually decomposed into cyclopentadiene. According to the method, a heating medium and the heated materials are subjected todirect contact, mixing, mass transfer and heat transfer, the problem of coking due to non-uniform heating is solved, and the higher yield of the target product can be realized.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP +1

Novel anti-coking VDF cracking furnace system and using method thereof

ActiveCN113976046AEvenly heatedLess side effectsPreparation by hydrogen halide split-offFurnace safety devicesProcess engineeringThermal recovery

The invention discloses a novel anti-coking VDF cracking furnace system which comprises a cracking furnace, a waste heat recoverer and a quench cooler, wherein the cracking furnace is internally provided with a spiral furnace tube and partition heating devices from top to bottom; the waste heat recoverer comprises a first shell-and-tube heat exchanger and a first horizontal tank body, a first jacket is arranged outside the first horizontal tank body, a discharge port of the cracking furnace is communicated with the first horizontal tank body, a discharge port of the first horizontal tank body is communicated with a tube pass feed port of the first shell-and-tube heat exchanger, a cold material is introduced into a shell pass of the first shell-and-tube heat exchanger, a shell pass discharge port of the first shell-and-tube heat exchanger is communicated with a feed port of the first jacket, and a discharge port of the first jacket is communicated with a feed port of the cracking furnace; and the waste heat recoverer is connected with a feed port of the quench cooler, and a discharge port of the quench cooler is connected to a product collection process. The cracking furnace system can reduce coking in the cracking furnace tube and the heat exchanger pipeline, prolongs the cleaning period of the cracking furnace tube and the heat exchanger, preheats cold materials through the waste heat recoverer, and reduces energy consumption.

Owner:JIANGSU GELAN ENVIRONMENTAL TECH CO LTD

Water-cooling backboard heat dissipating device and control method thereof

PendingCN108323096AImprove cooling efficiencySimple and reasonable airflow organizationCooling/ventilation/heating modificationsEngineeringRecuperator

The invention discloses a water-cooling backboard heat dissipating device which comprises a water-cooling backboard. A circulation loop is formed by a cooling water unit, a water pump and the water-cooling backboard through a pipeline. The water-cooling backboard comprises a heat exchanger and an air-cooling device on one side of the heat exchanger. After cooling water of the cooling water unit istransferred from a heat exchanger water inlet pipe to the heat exchanger for heat exchange, and the cooling water returns to the cooling water unit by a heat exchanger water outlet pipe. A bypass pipe is arranged between the heat exchanger water inlet pipe and the heat exchanger water outlet pipe, and a flow regulating device is arranged between the heat exchanger water inlet pipe and the bypasspipe. The invention also a control method of the above water-cooling backboard heat dissipating device. Compared with the prior art, the hot air blown by a server is directly recirculated and used after being cooled by the backboard, under the intelligent control of a PLC, the accurate cooling for a hot object can be realized, the efficiency is high, and the energy consumption is low. The specialdesign of an air duct is not needed, air flows directly from the back of the server to the front side, the airflow organization is simple and reasonable, the design and installation are simple, and the energy saving effect of airflow transportation is more remarkable.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

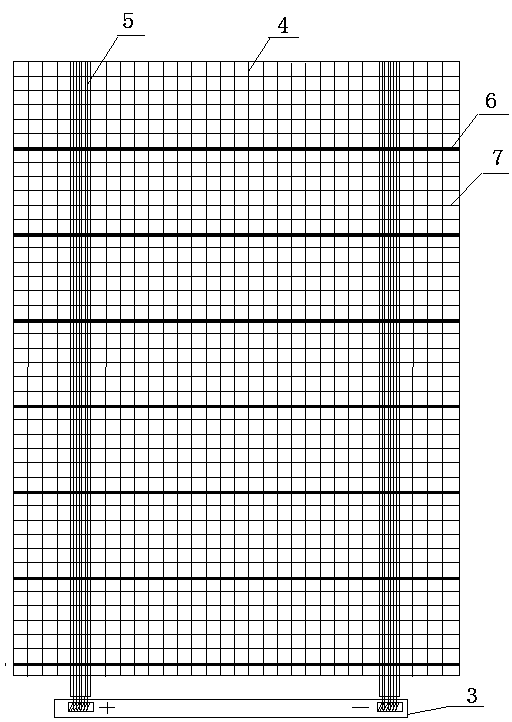

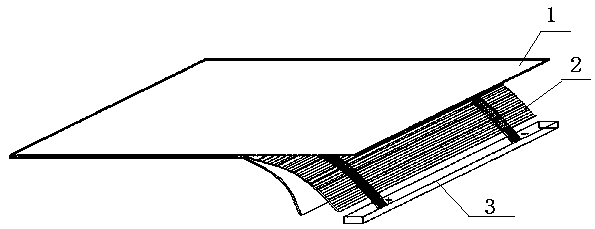

Woven graphene filament electric heating cloth

InactiveCN110621091AGood physical and mechanical propertiesEvenly heatedOhmic-resistance electrodesOhmic-resistance waterproof/air-tight sealsEngineeringGraphene

The invention relates to woven graphene filament electric heating cloth. The woven graphene filament electric heating cloth comprises two insulating layers and heating cloth located between the insulating layers. The heating cloth is of a woven structure formed by interweaving warp yarns and weft yarns, the warp yarns are warp filament yarns and conductive fiber yarns, and the weft yarns are graphene filament yarns and weft filament yarns; a plurality of conductive fiber warp yarns are respectively woven at two sides of the breadth of the heating cloth, and the other warp yarns are warp filament yarns; the plurality of conductive fiber warp yarns at two sides form conductive bands at two sides, the weft filament yarns and the graphene filament yarns are arranged at intervals, and the graphene filament yarns are in contact with and electrically connected with the conductive bands at two sides. According to the invention, the graphene filaments and the common filaments are combined and woven together, so the whole electric heating cloth can have better mechanical and physical properties of bending resistance or bending resistance than existing metal wire electric heating cloth, the conductive fiber warp and the graphene filaments in the electric heating cloth form a plurality of parallel circuits, the graphene filaments are evenly arranged in the weft direction, and therefore, the electric heating cloth is even in heating and free of local overheating in the working process.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Heating pipe and installation method thereof

InactiveCN104390470AAvoid damageNo local overheatingElectric heating for furnacesContact protectionHeat pipe

The invention discloses a heating pipe which comprises a protection pipe, a heating element and a fireproof supporting block on the inner bottom surface of the protection pipe, wherein the fireproof supporting block is arranged between the heating element and the protection pipe. According to the invention, by adding the fireproof supporting block inside the protection pipe of the heating pipe to isolate the heating element from the pipe wall of the protection pipe, the heating element is prevented from being in direct contact with the pipe wall of the protection pipe and the condition of local overheating cannot occur to the pipe wall, which is very sensitive to temperature variation, of the protection pipe, so that the service life of the pipe wall of the protection pipe is prolonged, the consumable quantity of the protection pipe is reduced and economy of the integral device is promoted. In addition, the invention also provides a heating pipe installation method. The method can avoid damage to the heating pipe and prolong the service life of the heating pipe.

Owner:SOUTHWEST ALUMINUM GRP

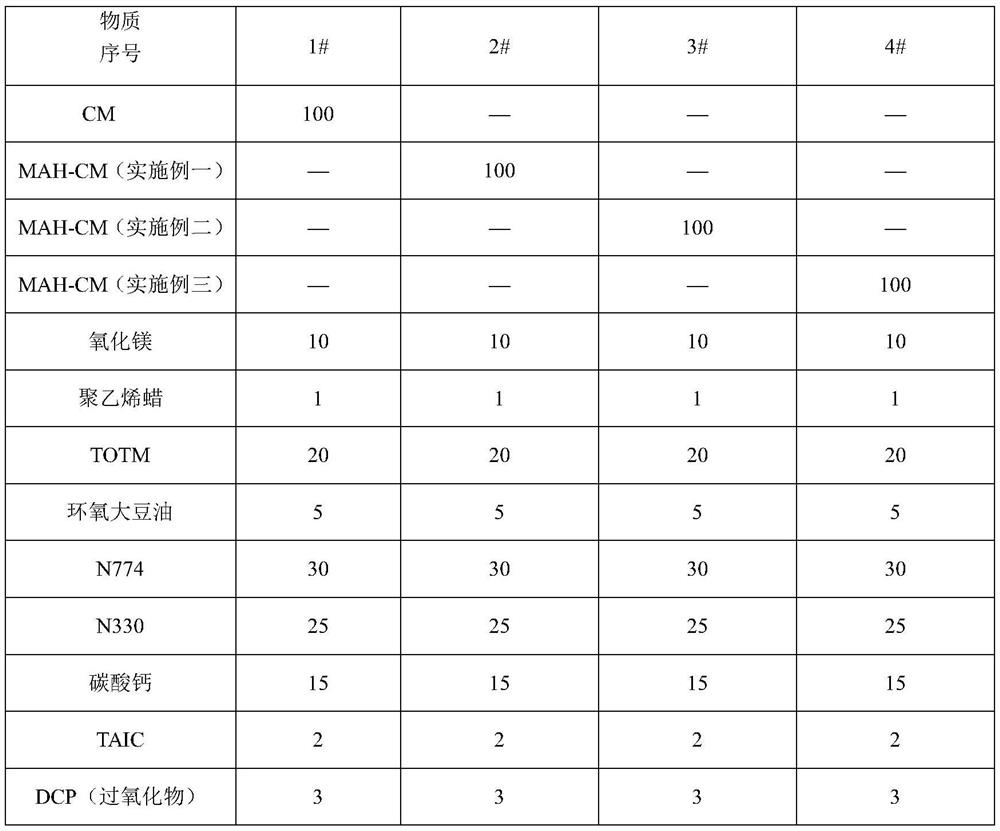

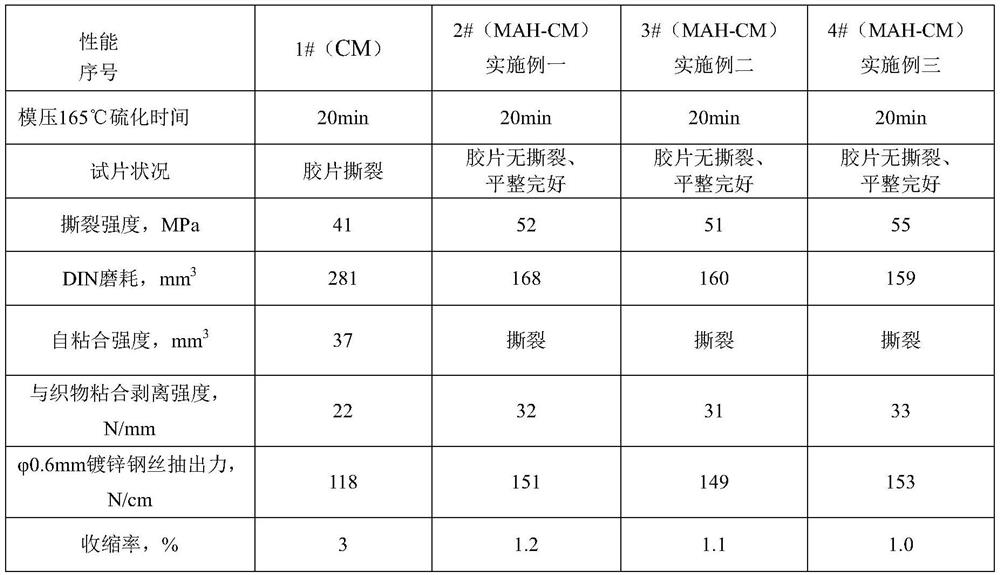

Continuous reaction production method of maleic anhydride grafted chlorinated polyethylene copolymer rubber

The invention discloses a continuous reaction production method of maleic anhydride grafted chlorinated polyethylene copolymer rubber, and belongs to the field of chlorinated polyethylene rubber preparation. The method comprises the following steps: uniformly mixing chlorinated polyethylene rubber powder, an acid acceptor, a stabilizer and an antioxidant; respectively dissolving maleic anhydride and an initiator with certain mass in acetone; then respectively pouring chlorinated polyethylene rubber powder, the acid acceptor, the stabilizer, the antioxidant mixture and an acetone solution of the maleic anhydride and the initiator into a charging barrel of a reactor, and metering and injecting into a co-rotating twin-screw continuous reactor with a special screw combination; metering and injecting a chain terminator at the tail end of the co-rotating twin-screw continuous reactor, and obtaining maleic anhydride grafted chlorinated polyethylene copolymer rubber granules after the graftingreaction is finished. 1-8% by weight of maleic anhydride branched chain is grafted on a macromolecular chain so that the hot tearing strength, wear resistance, self-adhesion and adhesion performancewith a reinforced fabric or a steel wire of a rubber product produced by maleic anhydride grafted chlorinated polyethylene copolymer rubber are obviously improved, and the problem that the shrinkage rate of a traditional chlorinated polyethylene product is relatively large is solved.

Owner:潍坊硕邑化学有限公司

Server cabinet with liquid cooling system

ActiveCN105704989BReduce risk of damageSimplify piping layoutCooling/ventilation/heating modificationsHeat conductingLiquid cooling system

The invention relates to a server cabinet with a liquid cooling system. The server cabinet comprises a cabinet body, a liquid cooling distribution unit and a heat pipe heat-conducting unit, wherein the liquid cooling distribution unit comprises a liquid inlet pipe, a liquid outlet pipe, a liquid supply pipe and a liquid return pipe; the heat pipe heat-conducting unit comprises a liquid cooling module, a heat pipe and a heat-absorbing module; one end of the liquid supply pipe is connected with the liquid inlet pipe; the other end of the liquid supply pipe is connected with a liquid inlet of the liquid cooling module; one end of the liquid return pipe is connected with the liquid outlet pipe; the other end of the liquid return pipe is connected with a liquid outlet of the liquid cooling module; one end of the liquid return pipe is connected with the liquid outlet pipe; the other end of the liquid return pipe is connected with the liquid outlet of the liquid cooling module; one end of the heat pipe is connected with the liquid cooling module; the other end of the heat pipe is connected with the heat absorbing module; and the heat absorbing module is in contact with a server heat source of the cabinet body. Due to application of the heat pipe, a cooling liquid is prevented from entering a server; the risk that the server is damaged due to leakage of the cooling liquid is reduced; the server cabinet is simple in layout, and convenient to maintain and install; and the server can be flexibly added and reduced.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

A new anti-coking vdf cracking furnace system and its application method

ActiveCN113976046BEvenly heatedLess side effectsPreparation by hydrogen halide split-offFurnace safety devicesProcess engineeringThermal recovery

Owner:JIANGSU GELAN ENVIRONMENTAL TECH CO LTD

Battery pack heat dissipation device and battery system

InactiveCN111554999AImprove distribution efficiencyImprove cooling efficiencySecondary cellsCell component detailsThermodynamicsWater circulation

The invention provides a battery pack heat dissipation device which comprises a liquid cooling plate, a water circulation system and a box body for placing a battery pack. The liquid cooling plate isarranged at the bottom of the box body, one end of the water circulation system is connected with a water inlet of the liquid cooling plate, and the other end of the water circulation system is connected with a water outlet of the liquid cooling plate. The present invention further provides a battery system which is characterized by comprising the battery pack heat dissipation device, wherein thebattery pack is placed in the box body. According to the invention, the water circulation system is combined with the liquid cooling plate for heat dissipation, so that the efficiency of dissipating heat to the outside is greatly improved; the opening and closing of the water circulation system can be adjusted according to the use state, when the temperature of the battery pack is too high, the water circulation system is turned on, the higher the temperature is, the higher the working power of the water circulation system is, and the outward transportation and dissipation of heat are accelerated; and the liquid cooling plate is located on the box surface of the highest temperature position of the battery pack box body, so that the heat dissipation efficiency is greatly improved.

Owner:GUANGDONG UNIV OF TECH

Combined type environment-friendly package printing device

InactiveCN111619213AWill not deformImprove printing effectRotary pressesOther printing apparatusCold airThermodynamics

The invention discloses a combined type environment-friendly package printing device comprising a printing box, a discharge box and a feed box. The discharge box and the feed box are installed on thetwo sides of the printing box correspondingly. A vortex tube is fixed to the top of the sprinting box. A cold flow tube and a hot flow tube are installed on a cold air opening and a hot air opening ofthe vortex tube correspondingly. A cold spray box is fixed to the inner wall of the discharge box. The cold flow tube penetrates through the side wall of the discharge box to be communicate with theinner portion of the cold spray box. The combined type environment-friendly package printing device has the advantages that in the combined type environment-friendly package printing device, simultaneous output of hot air flow and cold air flow is achieved by arranging the vortex tube, there is no need to additionally control conveying of the cold air flow and the hot air flow; and by arranging the feed box, packaging paper can be ground by a conveying roller to be more smooth before printing, the conveying roller is heated through the hot air flow at the same time, the packaging paper can besubjected to preheating treatment before printing, and therefore the packaging paper cannot deform due to large temperature changes, and the printing effect can be effectively improved.

Owner:武汉积墨包装印刷有限公司

Heating element for floor or ceramic tile and preparation method

PendingCN108024393AAvoid defectsQuality assuranceLighting and heating apparatusElectric heating systemFiberCarbon fibers

The invention discloses a heating element for a floor or ceramic tile and a preparation method. The heating element adopts a balanced adhesive tape layer, an oriented structural particleboard, a carbon fiber chip paper layer, a woodgrained paper layer and a wear-resistant layer which are sequentially laminated, wherein the diameter of carbon fibers in the carbon fiber chip paper layer is 300nm, the carbon fibers are compounded by adopting short fibers and long fibers, and an aluminum foil electrode and a copper electrode are arranged at two ends of the carbon fiber chip paper layer and the oriented structural particleboard and are mutually connected. According to the invention, long and short fiber wood pulp and carbon fibers are sufficiently mixed and then made into carbon fiber chip paper; the paper and the oriented structural particleboard are solidified and combined in a balanced hot-pressing mode, then a balanced adhesive tape, the woodgrained paper layer and the wear-resistant adhesive tape layer are respectively covered, and the aluminum foil electrode and the copper electrode are set to obtain the heating element. The heating element and the preparation method overcome defects of the traditional heating floor or ceramic tile, the heating is uniform, and there is no local overheating. In addition, the heating element is reliable in combination with the floor or ceramic tile body, and the ground quality after the laying is ensured.

Owner:陆上驰 +1

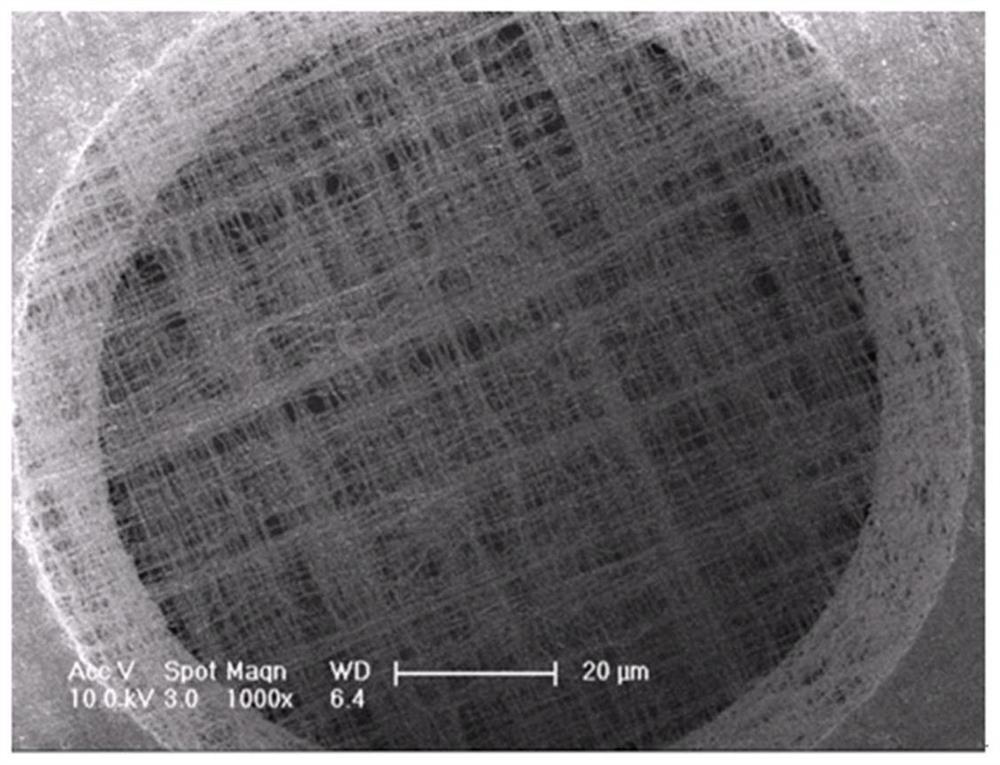

Mask with sterilization function

PendingCN114009878AImprove breathabilityPlay a filtering roleBreathing filtersBreathing masksFiberCarbon fibers

The invention provides a mask with a sterilization function. The mask comprises a mask body, a functional layer, at least two electrodes and a power supply access port, the functional layer and the at least two electrodes are arranged in the mask body, the at least two electrodes are positioned on the surface of the functional layer and are electrically connected to the power supply access port, the at least two electrodes are used for introducing current into the functional layer to increase the temperature of the functional layer, the functional layer is a carbon fiber layer, and the carbon fiber layer comprises a plurality of carbon fibers and micropores.

Owner:BEIJING FUNATE INNOVATION TECH

Concentration method and special device for sulfuric acid process titanium dioxide solution

The invention discloses a concentrating method of titaniferous solution for sulfate process titanium dioxide and a special device. The secondary steam produced in the evaporation concentration process of a clear titaniferous solution returns to an evaporation concentration system after being pressurized and heated through a mechanical steam compressor, and an evaporation system runs under -0.08MPa. The local overheating cannot be caused in the titaniferous solution concentration process, and the stability of the concentrated titaniferous solution is superior to that of the conventional single-effect concentration. The concentrating method has the characteristics that the steam consumption is greatly reduced, the energy-saving effect is obvious, and the stability of the titaniferous solution is good.

Owner:NANTONG SUNSHINE GRAPHITE EQUIP TECH

An environmentally friendly waste heat recovery device for waste gas treatment

ActiveCN111351386BImprove the efficiency of waste heat absorptionEvenly distributedRecuperative heat exchangersDispersed particle filtrationMechanical engineeringWaste gas

An environment-friendly waste heat recovery device for waste gas treatment, comprising a shell structure (1) and a closed structure (2) arranged on the shell structure (1), the environment-friendly waste heat recovery device for waste gas treatment also includes a housing The liquid collection structure (4) in the housing structure (1), the gas collection structure (5) arranged around the liquid collection structure (4), the liquid collection structure (4) includes a heat conducting frame (41 ), a number of first springs (42) housed in the heat conduction frame (41), a stirring frame (43), a heat conduction plate (44) located below the heat conduction frame (41), a heat conduction plate (44) located under the heat conduction frame (41 ) a positioning rod (45) on one side, a positioning frame (46), a second hose (47) located on the other side of the heat conducting frame (41), several sealing frames accommodated in the heat conducting frame (41) (48). The invention can effectively evenly distribute the heat in the heat conduction frame in the water, and is beneficial to ensure the heat absorption efficiency of the water in the heat conduction frame in contact with the inner wall.

Owner:HEBEI HUATONG INNOVATION TECH

A water-cooled resistor for frequency conversion cabinet and its manufacturing method

ActiveCN103680778BUniform cooling and heat dissipationImprove performanceEnvelope/housing resistor manufactureResistor mounting/supportingFrequency conversionCooling effect

The invention discloses a water-cooling resistor for a variable-frequency cabinet and a manufacturing method of the water-cooling resistor. The water-cooling resistor comprises an insulation body with a passage, an insulation cover, a resistance band and a lead end, wherein the resistance band is arranged in the passage of the insulation body, the lead end is connected with two ends of the resistance band, the insulation body is also provided with two water gaps, the resistance band comprises a resistance band body and a plurality of lugs, the resistance band body and the lugs are integrated, every two adjacent lugs on each side of the resistance band body are oppositely distributed on the resistance band body in a staggered manner, the lugs are contacted with two inner side walls of the of the passage of the insulation body, so that the resistance band body is vertically buckled onto a central axis position of the passage of the insulation body. The water-cooling resistor is good in cooling effect, simple in structure and convenient to install.

Owner:SHIDAI ELECTRIC FACTORY ZHUZHOU ELECTRIC LOCOMOTIVES INST MIN OF RAILWAYS

Extensible server container with liquid cooling system

PendingCN114710938AFlexibilityAmbient temperature has little effectEnergy efficient computingCooling/ventilation/heating modificationsThermodynamicsLiquid cooling system

The invention provides an extensible server container with a liquid cooling system, and relates to the field of servers, the extensible server container comprises an external shell, an internal cabinet and a cooling liquid distribution unit; the internal cabinet specifically comprises a plurality of cooling tanks used for placing server monomers, the bottoms of the plurality of cooling tanks are communicated and allow cooling liquid to enter, one side of each cooling tank is further provided with a hot liquid interlayer used for receiving heat-carrying liquid, and the plurality of cooling tanks share one hot liquid interlayer; the cooling liquid distribution unit specifically comprises a balance pipe, a liquid inlet pipe and a liquid discharge pipe, the liquid inlet pipe is communicated with the bottom of the cooling tank, the liquid discharge pipe is communicated with the bottom of the hot liquid interlayer, and the balance pipe is communicated with the upper part of the hot liquid interlayer, so that liquid higher than the upper liquid level in the hot liquid interlayer flows out of the hot liquid interlayer. The system is high in cooling efficiency, good in expandability, obvious in energy-saving advantage, uniform in cooling, free of local overheating and small in influence on the environment temperature.

Owner:清链科技(北京)有限公司

A kind of preparation method of acrylonitrile-based carbon fiber spinning liquid and its polymerization reaction equipment

ActiveCN101768239BImprove the mixing effectIncrease the length/diameter ratioFibre chemical featuresFiberTemperature control

The invention discloses a preparation method of acrylonitrile-based carbon fiber spinning solution and polymerization reaction equipment thereof. The preparation method of the present invention carries out solution polymerization reaction in the polymerization reaction equipment, and described polymerization reaction equipment comprises reaction kettle and reaction extruder, and reaction kettle is connected with reaction extruder, and reaction kettle and reaction extruder are respectively provided with temperature control device . In the present invention, a reaction extruder is connected to the reaction kettle, and the screw extrusion structure adopted by the reaction extruder not only has the function of mixing materials of a traditional extruder, but also can introduce a reaction medium and a chemical reaction in the extrusion process, and has the advantages of The function of the synthesis reactor, the reaction extruder is better able to handle high-viscosity materials, and can continuously and rapidly produce new, very thin material surface layers, so that the surface / volume ratio of the materials increases, and the reaction medium is evenly distributed in the materials , the degree of response increases.

Owner:KINGFA SCI & TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com