High-frequency inductor with embedded radiator

A heat sink and inductor technology, which is applied in the field of inductors, can solve the problems of low heat dissipation efficiency, wire consumption, and high cost, and achieve the effects of increased heat conduction area, high heat conduction efficiency, and low inductor temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

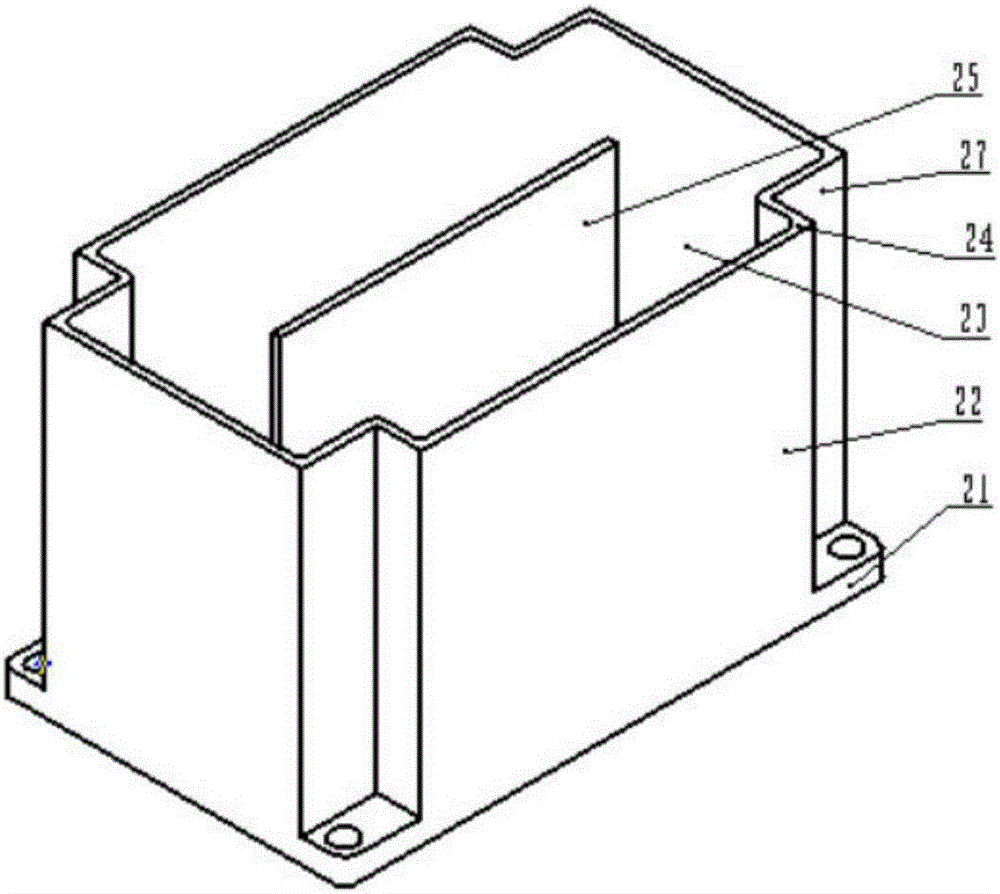

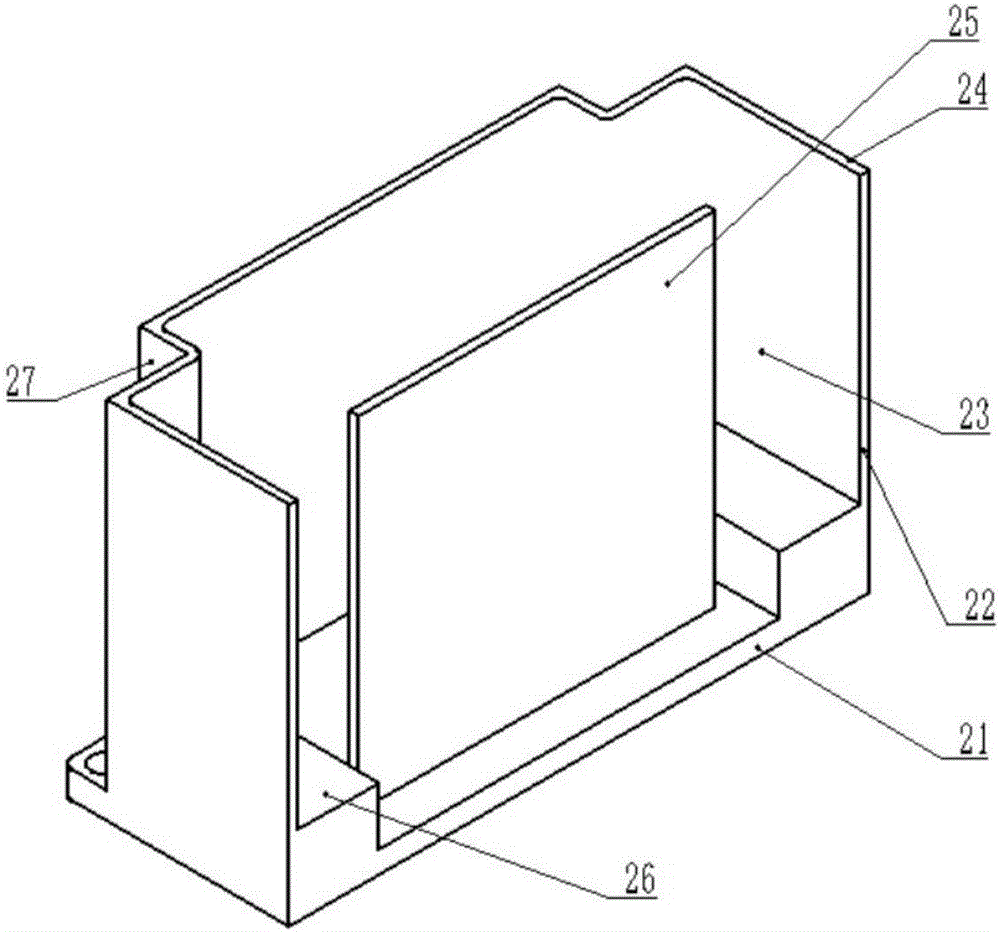

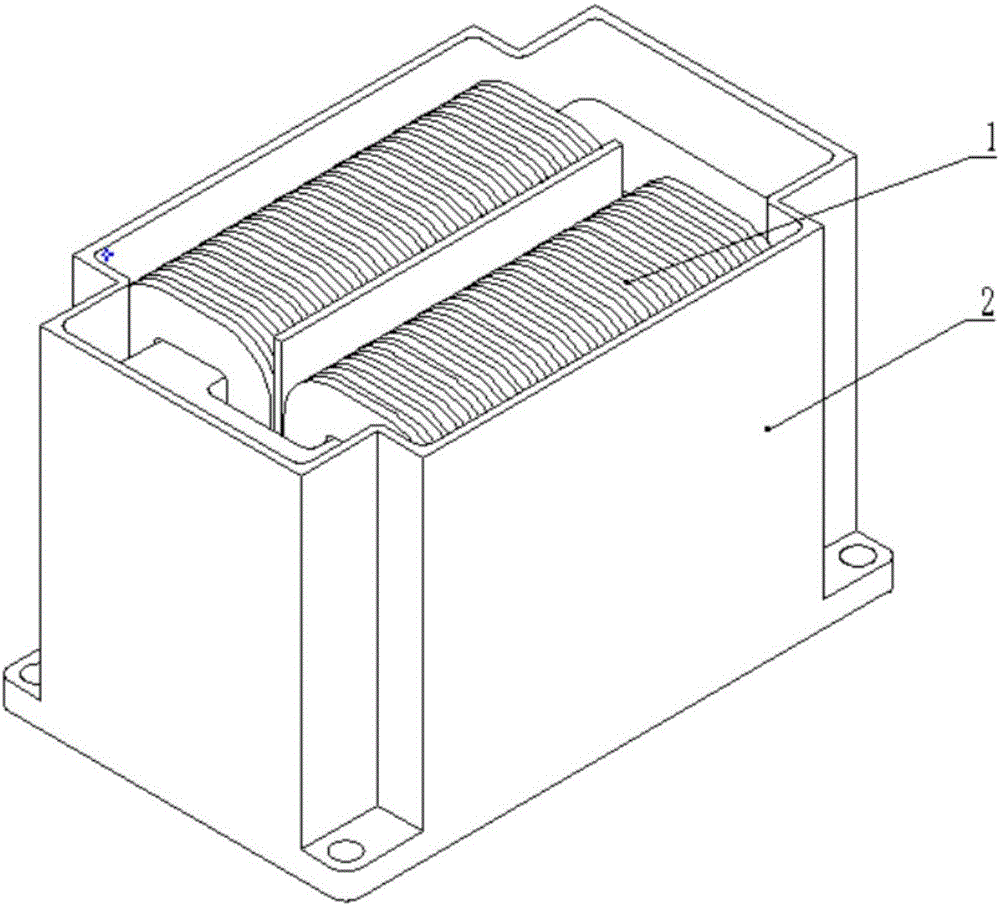

[0020] Such as Figures 1 to 3 As shown, a high-frequency inductor embedded in a radiator mainly includes an inductor 1 and a radiator 2. The radiator is made of a metal material with high thermal conductivity. The radiator is composed of a base plate 21 and surrounding plates The cavity 23 jointly surrounded by 22 has an opening 24 in the direction opposite to the bottom plate; the inductor 1 is embedded in the radiator cavity 23 through the opening 24; the radiator 2 also includes a tongue extending from the bottom plate 21 to the opening 24 Plate 25; the tongue plate 25 is inserted between phases of the inductor winding, between the rear outer surface of the inductor winding and the inner surface of the bottom plate, between the side surface of the inductor winding and the corresponding inner surfaces of the two surrounding plates 22 There is a gap between the tongue plate 25 and the inductor winding phase, and each gap is filled with heat-conducting silica gel.

[0021] F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com