Modification machine, modification cooling system and modification process

A modification and modifying agent technology, which is applied in the direction of heat transfer modification, mixers, mixer accessories, etc., can solve the problems of open flames, high local temperature, and low heated area, and achieve high efficiency and high activity speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings.

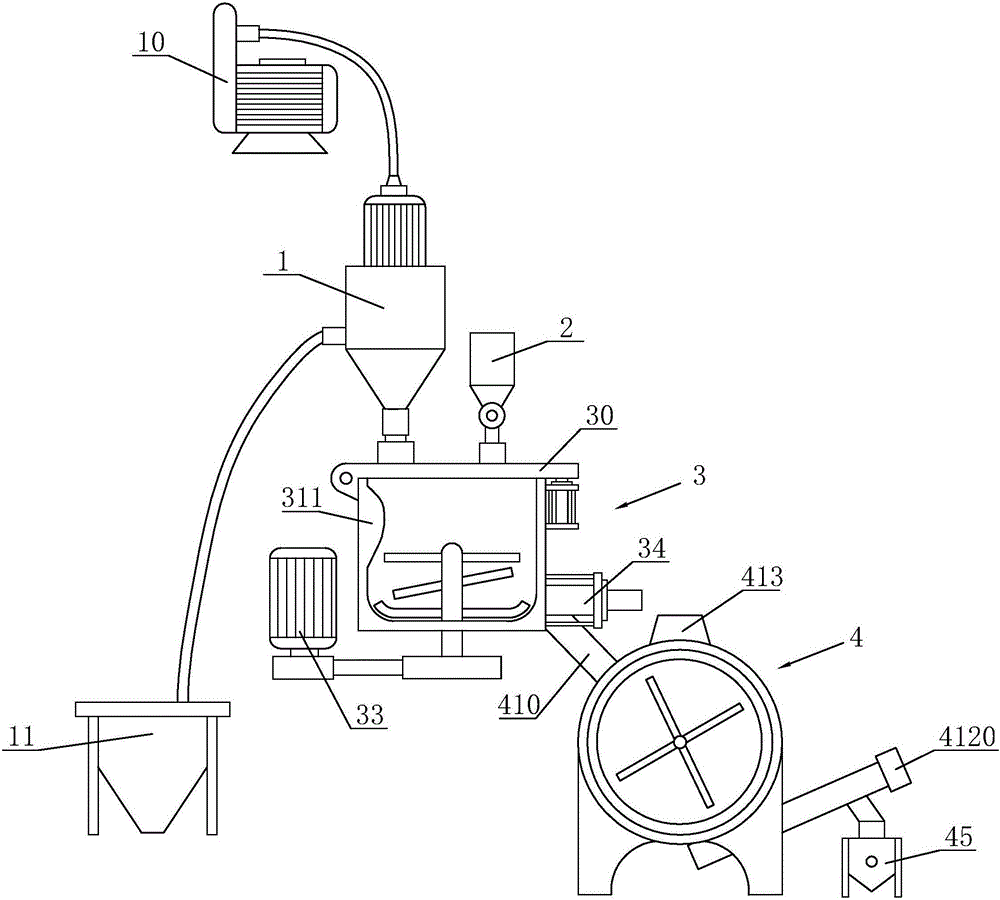

[0047] Such as figure 1 As shown, a modified cooling system includes a hopper 11, a vacuum feeder 1, an automatic metering feeder 2, a cooling machine 4 and the above-mentioned modification machine 3;

[0048] The vacuum feeder 1 is connected with a negative pressure fan 10, and there is a negative pressure between the vacuum feeder 1 and the hopper 11 to allow the material to enter the pipeline of the vacuum feeder 1, and the outlet of the vacuum feeder 1 is connected to the modification machine 3 The material inlet is 300.

[0049] The automatic metering feeder 2 is provided with a cavity for containing modifier, and the outlet of the automatic metering feeder 2 is connected to the modifier inlet 301 of the modifier 3 .

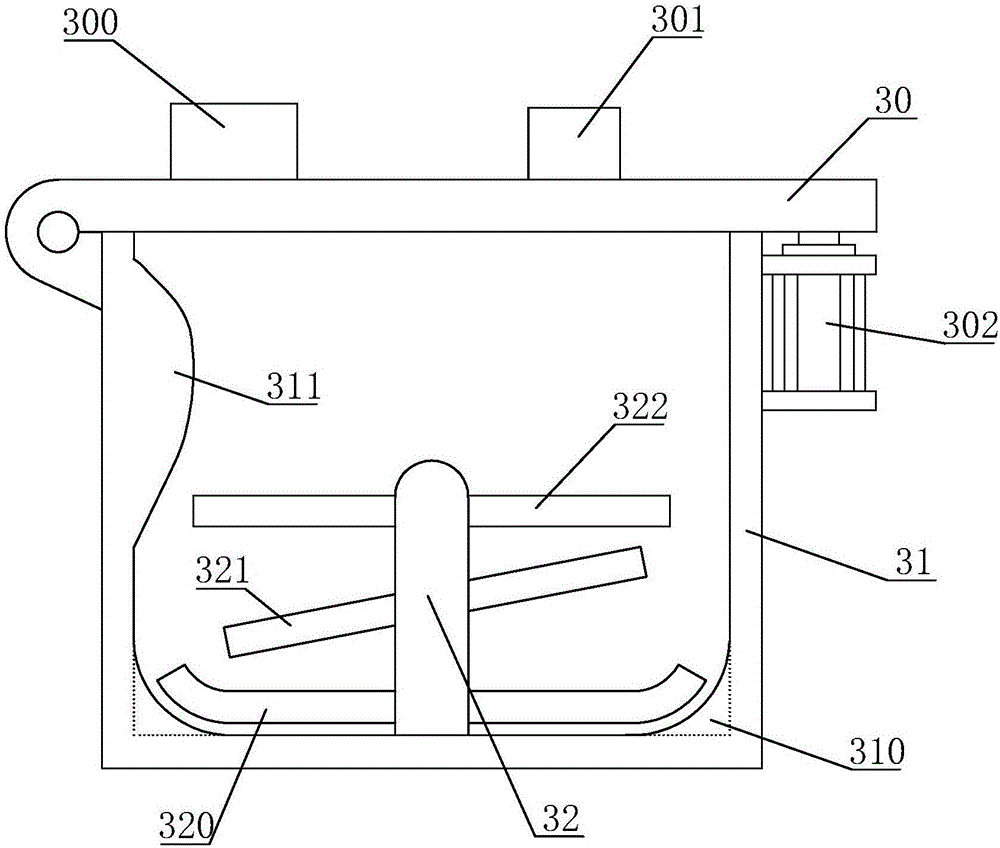

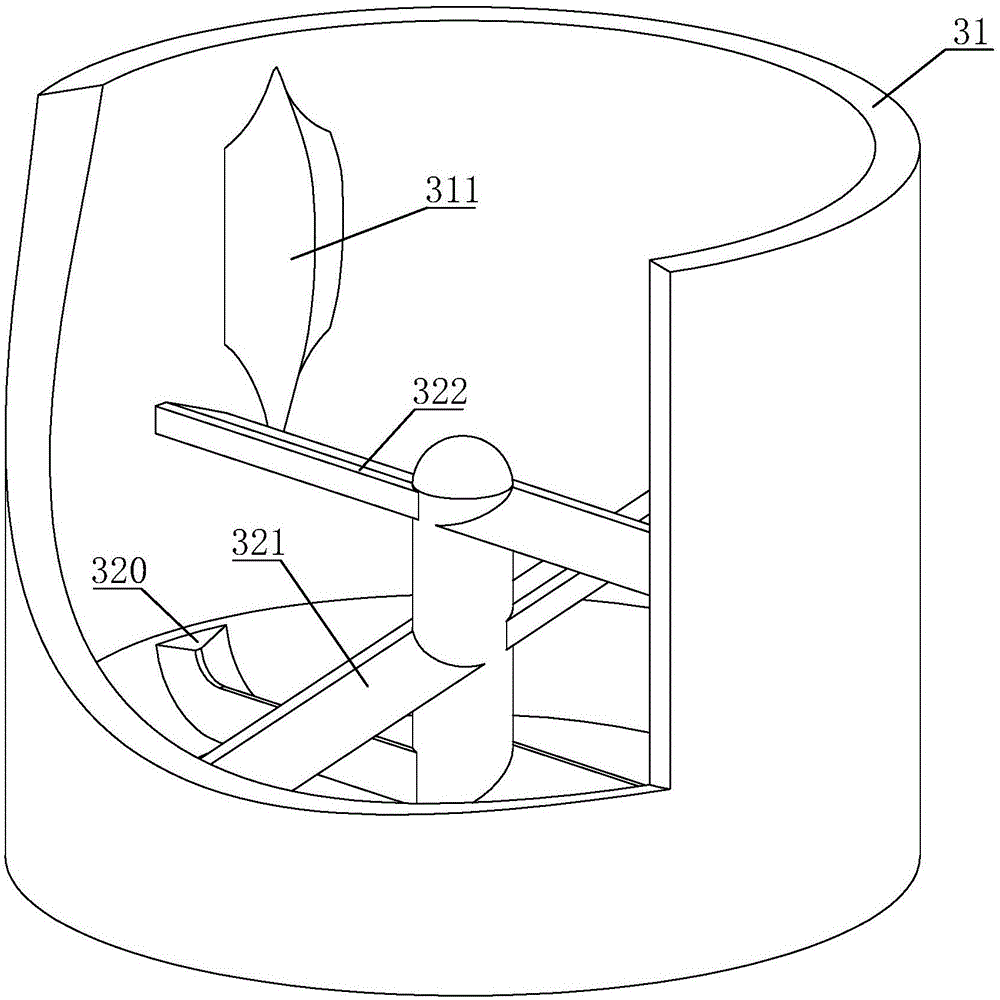

[0050] Such as Figure 2 to Figure 4 As shown, the reformer includes a cylinder body 31 and a cover 30, the cover 30 is provided with a material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com