Novel anti-coking VDF cracking furnace system and using method thereof

A cracking furnace and anti-coking technology, which is applied to chemical instruments and methods, furnaces, vertical furnaces, etc., can solve problems such as increased operating costs, easy coking, and reduced production efficiency, and achieves no grid harmonic pollution and waste heat recovery rate High, conversion-increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

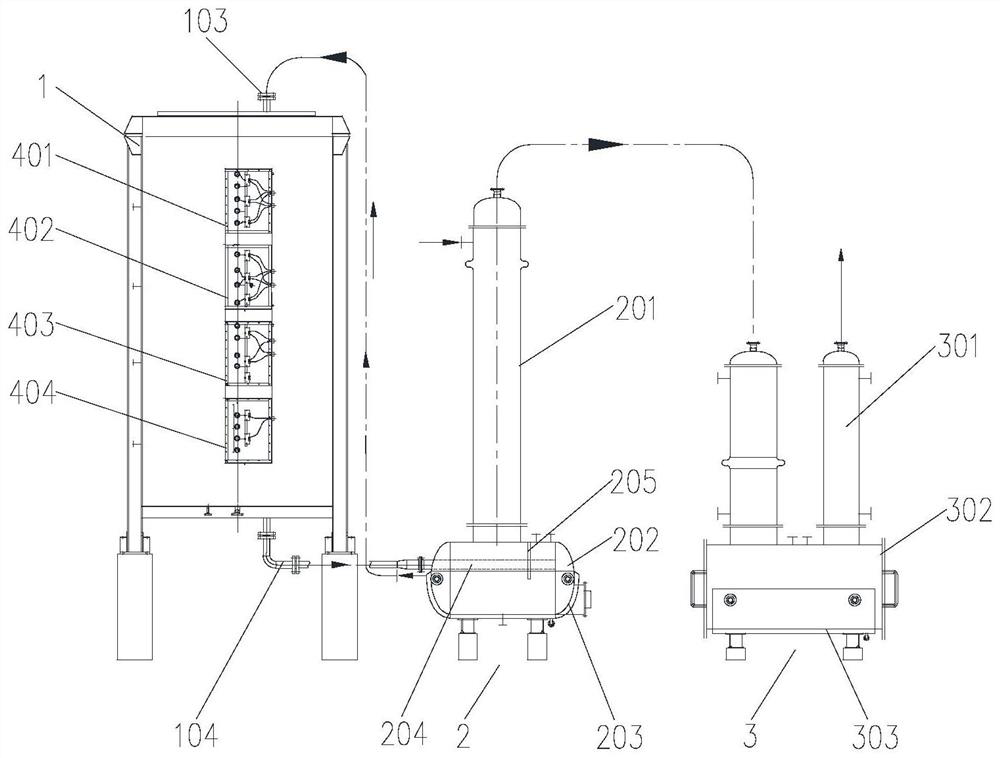

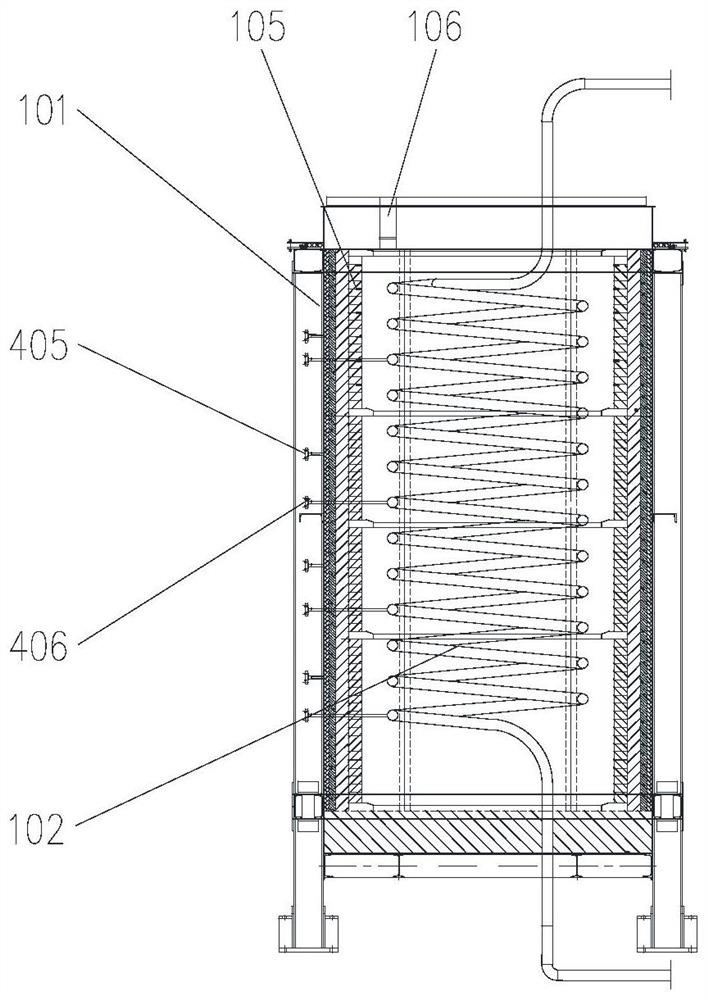

[0040] refer to figure 1 and figure 2 , a new anti-coking VDF cracking furnace system provided in this embodiment includes a cracking furnace 1, a waste heat recovery device 2 and a quencher 3. First, the material is passed into the cracking furnace 1 and heated in the cracking furnace 1 to carry out the cracking reaction Then the reaction product after the reaction is completed is discharged from the cracking furnace 1 and enters the waste heat recovery device 2, and heat exchange is carried out in the waste heat recovery device 2, and the waste heat of the reaction product is used to preheat the material, so that it can enter before the cracking furnace 1 Reaching a certain temperature can reduce the energy consumption of the cracking furnace; then the cooled reaction product enters the quencher 3, and the circulating cooling water is used as the cooling medium in the quencher 3 to further cool down the reaction product, and then discharge it to the collection process.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com