Patents

Literature

69results about How to "Constant reaction temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thin films and methods of making them using cyclohexasilane

InactiveUS20120024223A1Constant reaction temperatureHigh reaction temperaturePolycrystalline material growthSemiconductor/solid-state device manufacturingProduction rateSemiconductor

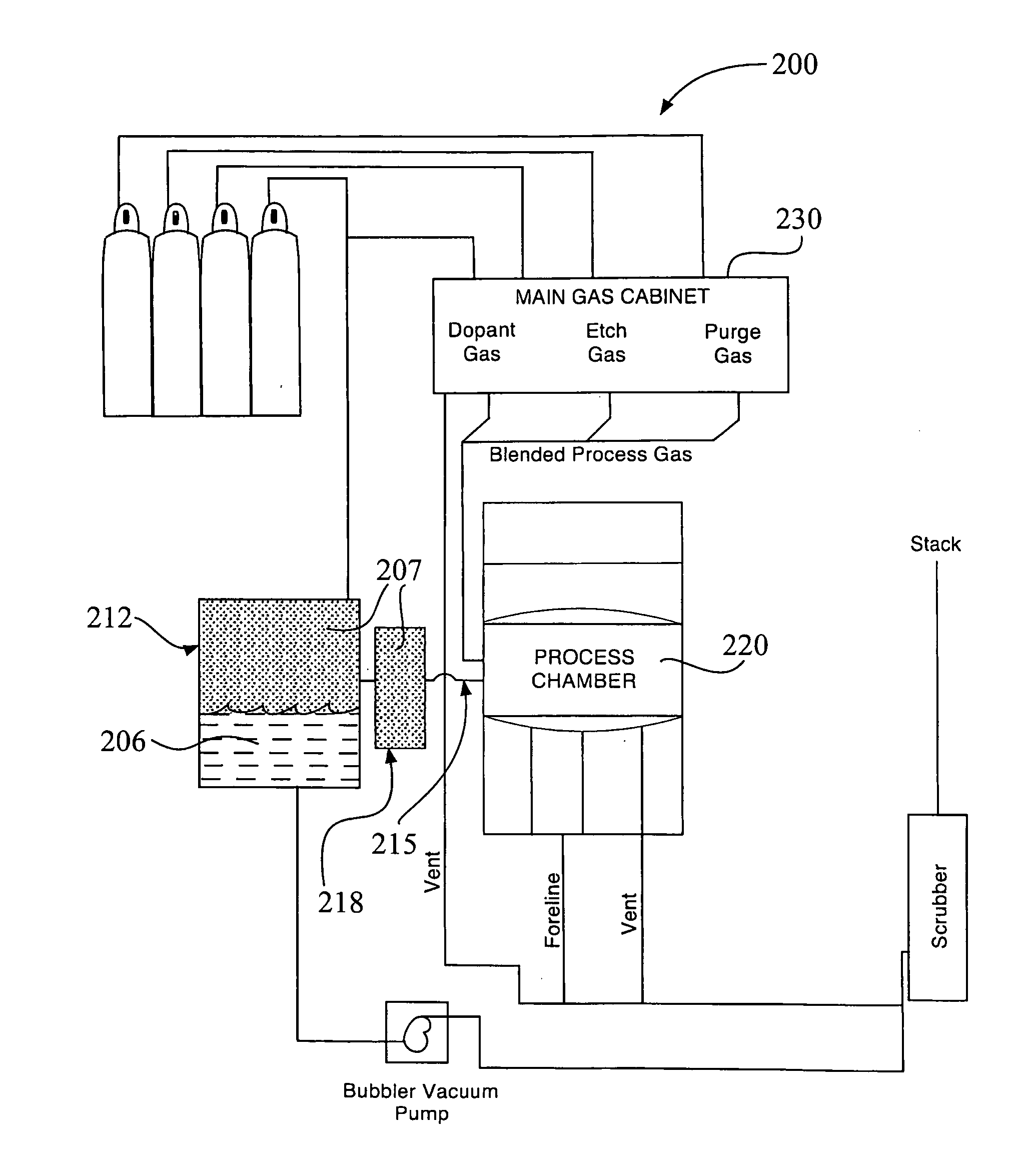

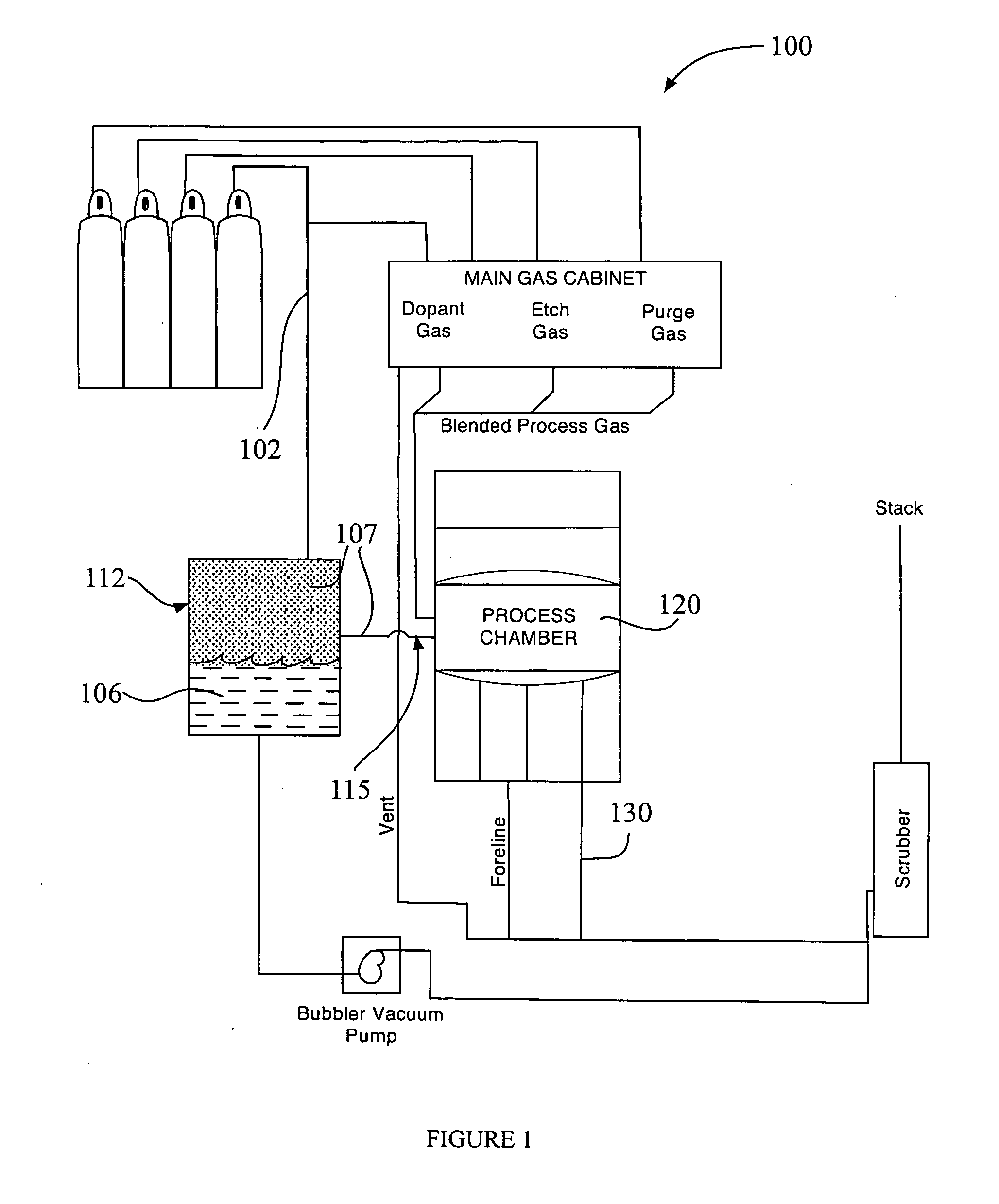

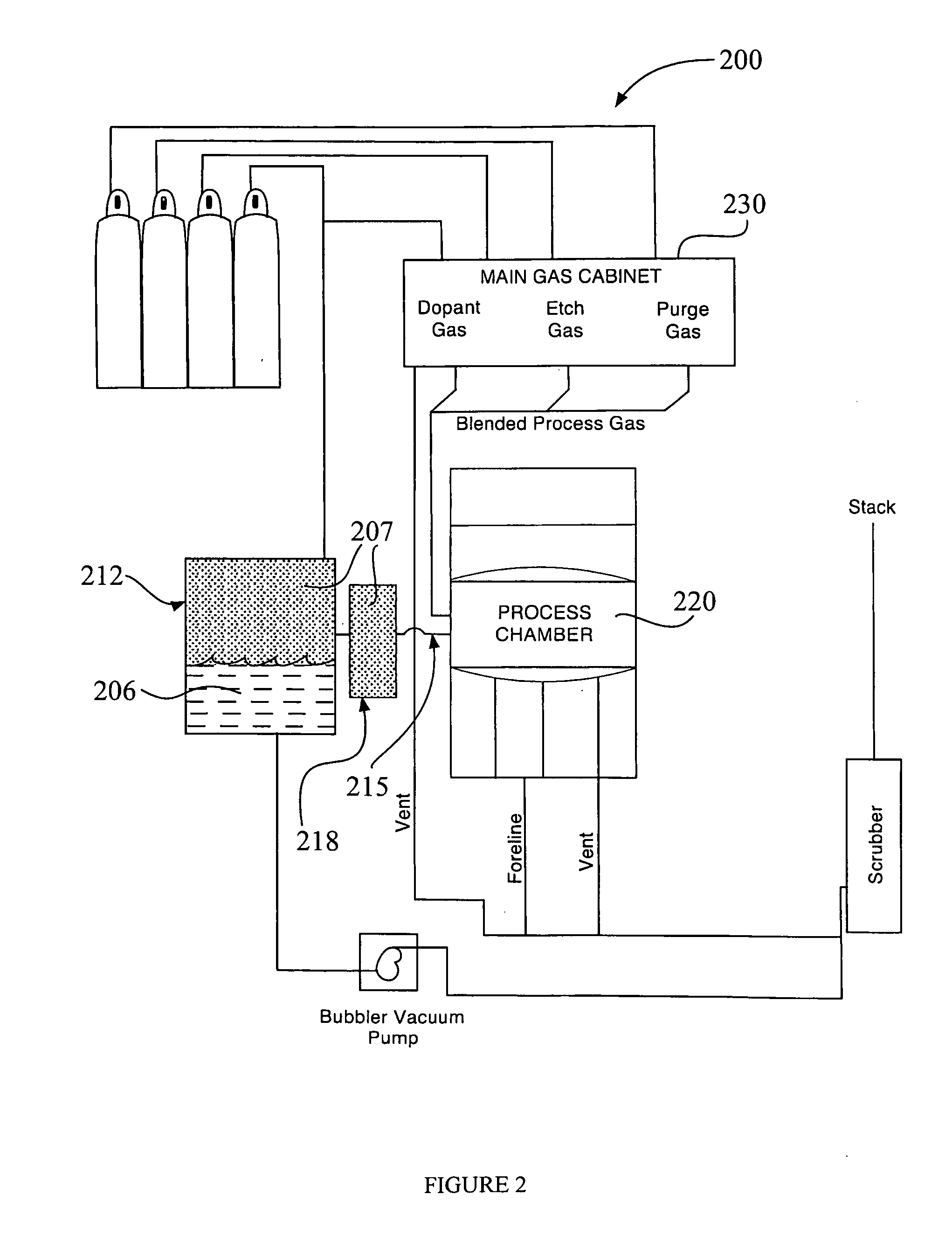

Cyclohexasilane is used in chemical vapor deposition methods to deposit epitaxial silicon-containing films over substrates. Such methods are useful in semiconductor manufacturing to provide a variety of advantages, including uniform deposition over heterogeneous surfaces, high deposition rates, and higher manufacturing productivity. Furthermore, the crystalline Si may be in situ doped to contain relatively high levels of substitutional carbon by carrying out the deposition at a relatively high flow rate using cyclohexasilane as a silicon source and a carbon-containing gas such as dodecalmethylcyclohexasilane or tetramethyldisilane under modified CVD conditions.

Owner:MATHESON TRI GAS

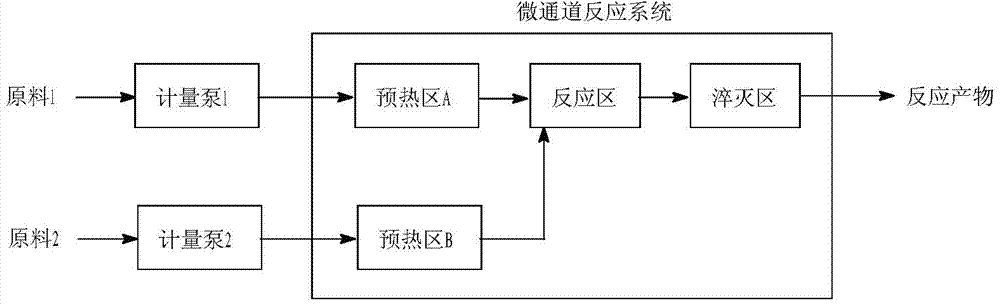

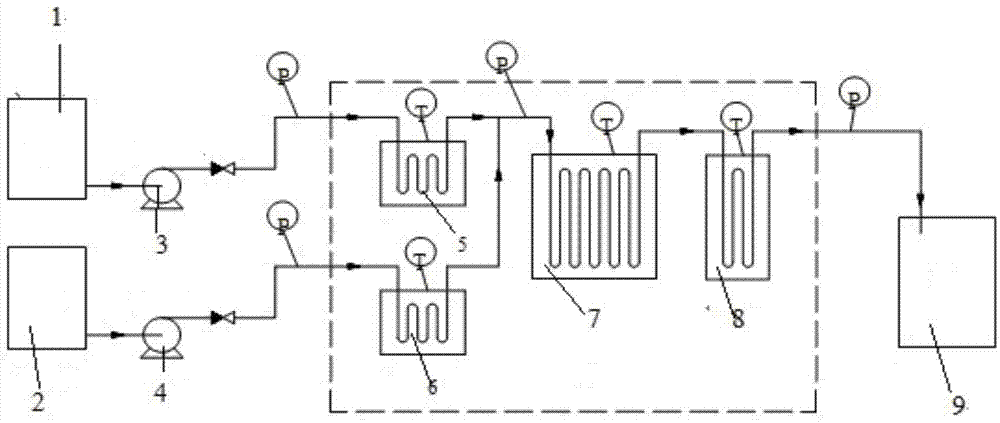

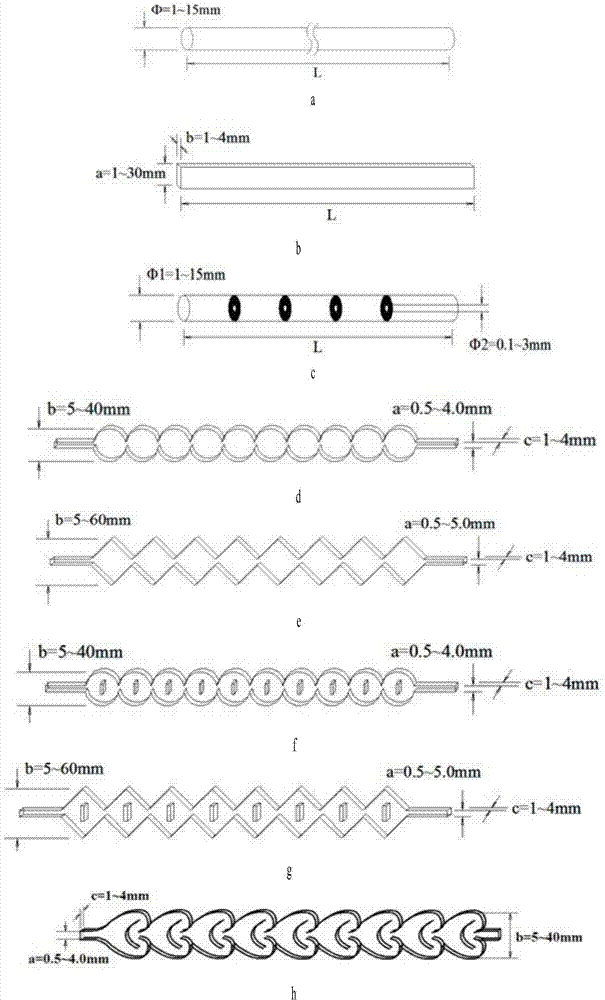

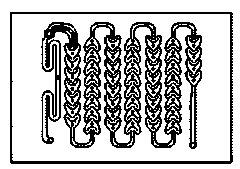

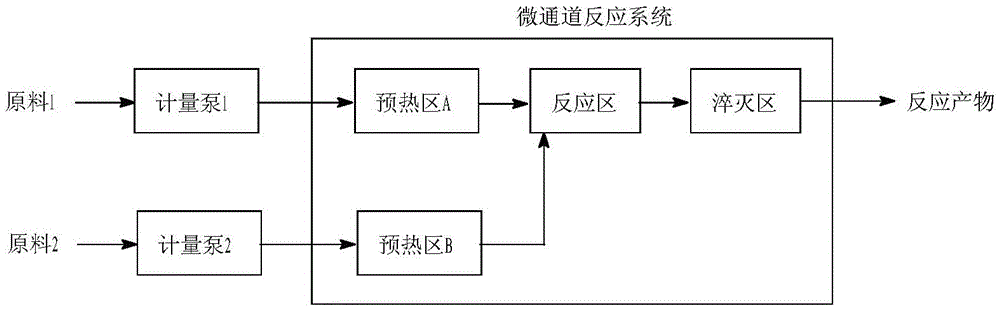

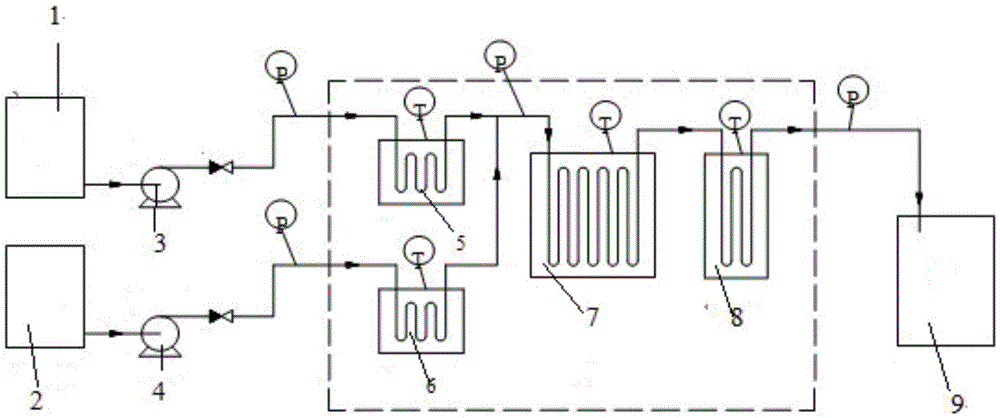

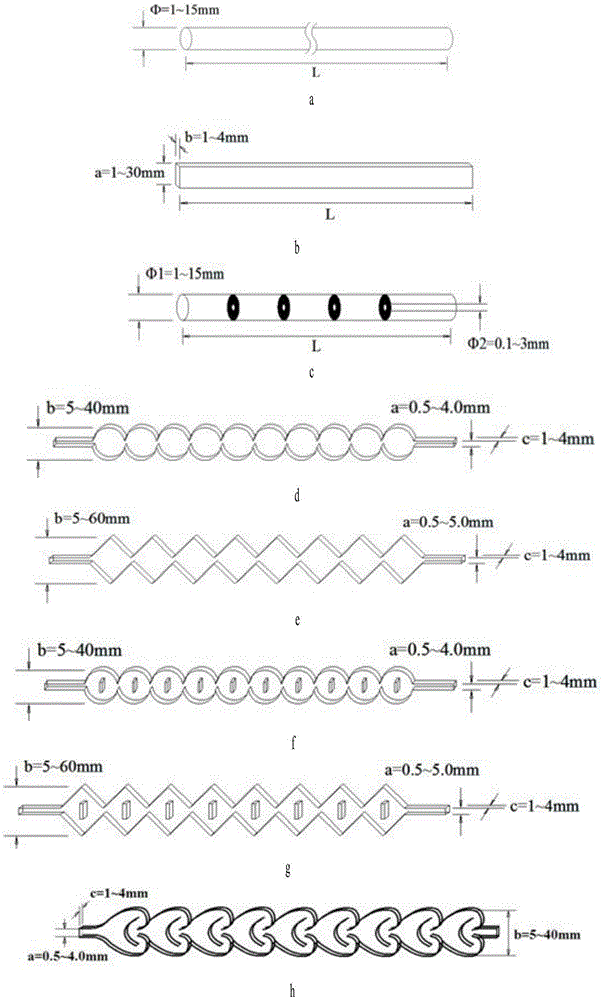

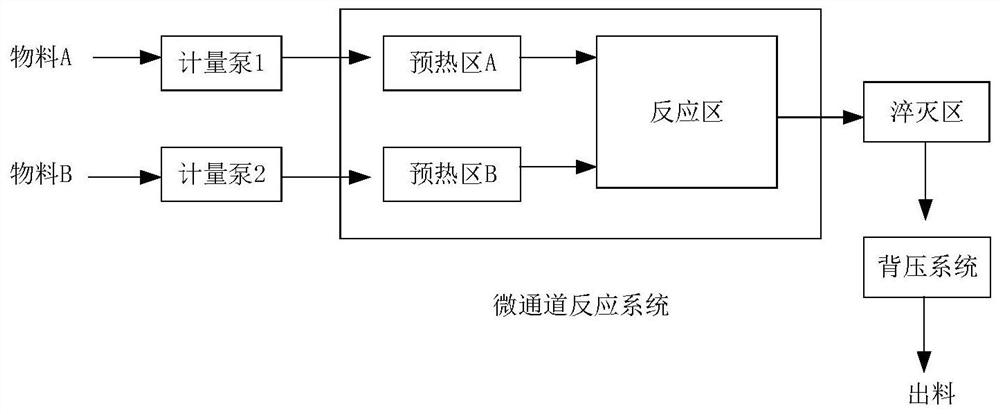

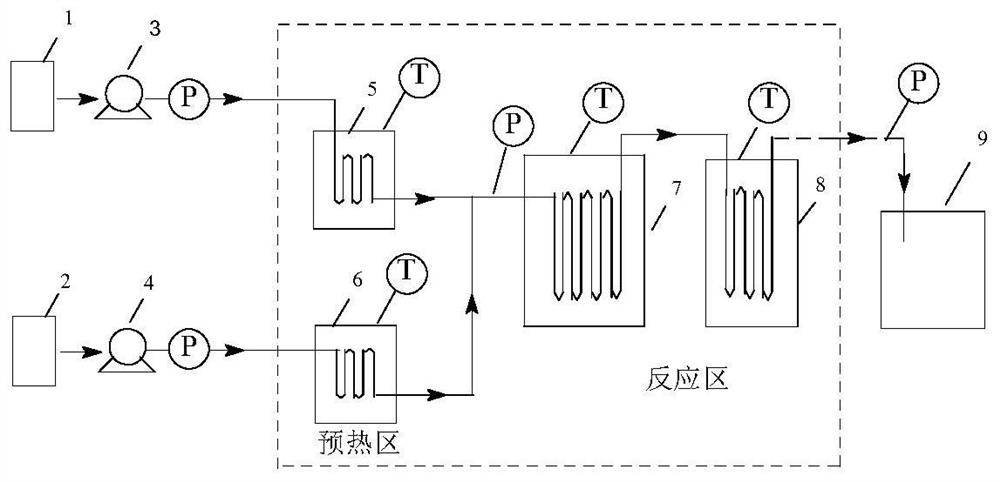

Method for undergoing chlorobenzene nitration reaction by using micro-channel reactor

ActiveCN102432471APrevent leakageAvoid dangerNitro compound preparationTemperature controlChlorobenzene

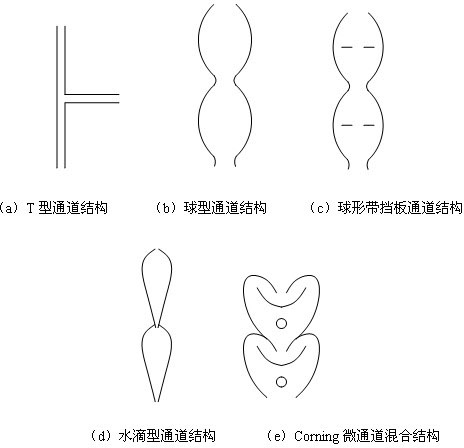

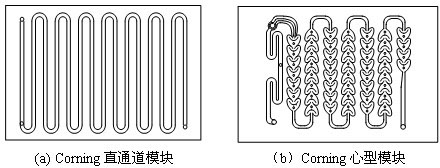

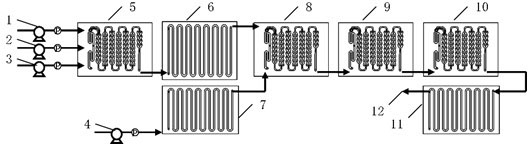

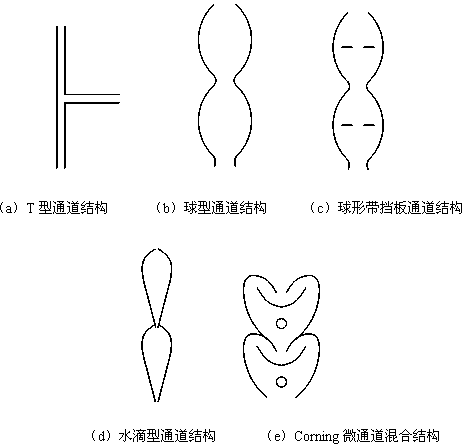

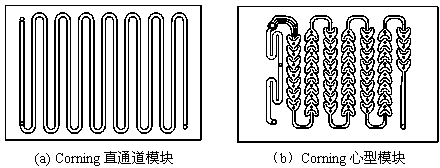

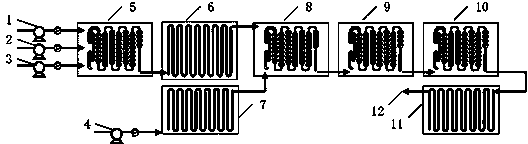

The invention relates to a method for undergoing a chlorobenzene nitration reaction by using a micro-channel reactor, belonging to the technical field of application of organic synthesis. In the method, nitric acid, sulfuric acid, water and chlorobenzene are taken as initial reaction raw materials, and processes such as mixed acid preparation, mixed acid and chlorobenzene preheating, mixed acid and chlorobenzene reacting and the like are completed in a micro-channel reactor system. In the reaction, nitro-sulfuric mixed acid is taken as a nitrating agent, the effective concentration of sulfuric acid in the mixed acid is 50-90 percent, the molar ratio of the nitric acid to the sulfuric acid in the mixed acid is 1:1-1:10, the molar ratio of the chlorobenzene to the nitric acid is 1:1.0-1:2.0, the reaction temperature is 50-100 DEG C, and the reaction time is 30-120 seconds. The chlorobenzene transformation ratio is up to 97 percent, the selectivity of nitrochlorobenzene serving as a product is over 96.5 percent, and the ratio of ortho-para nitrochlorobenzene is over 0.6. A strengthened mixed micro-channel reactor adopted in the invention is particularly suitable for undergoing a continuous nitration reaction, and has the characteristics of stable temperature control and safe process.

Owner:CHANGZHOU UNIV

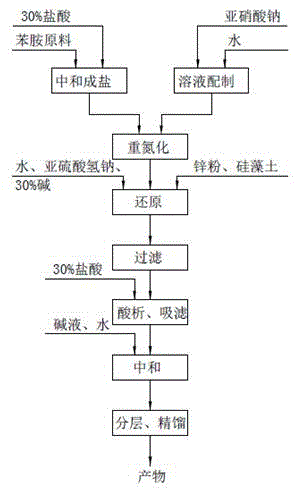

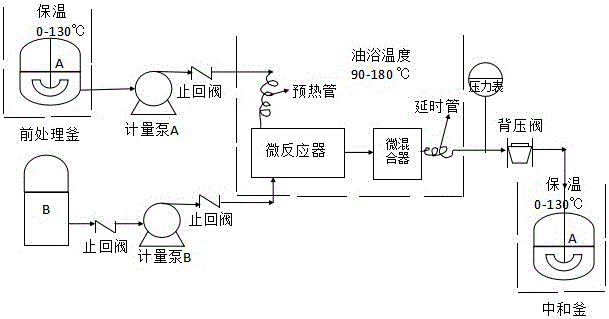

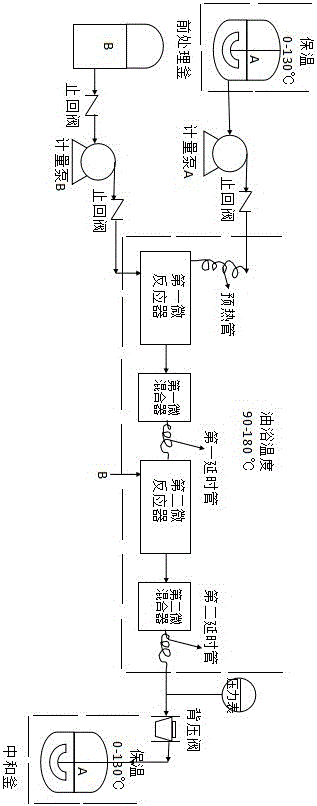

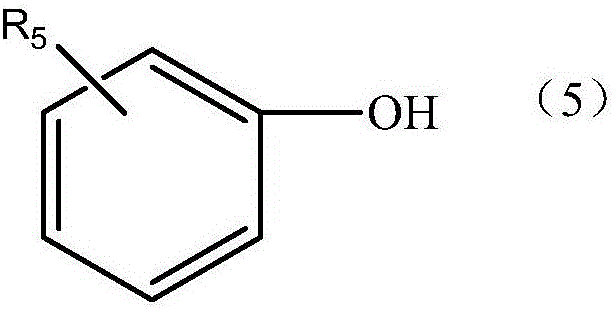

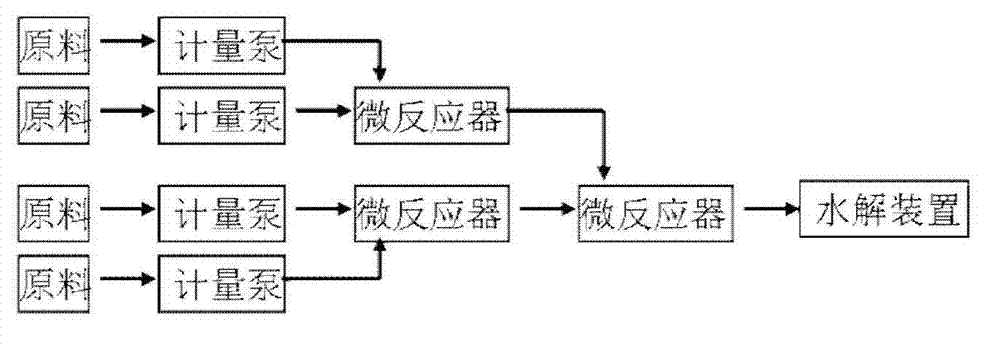

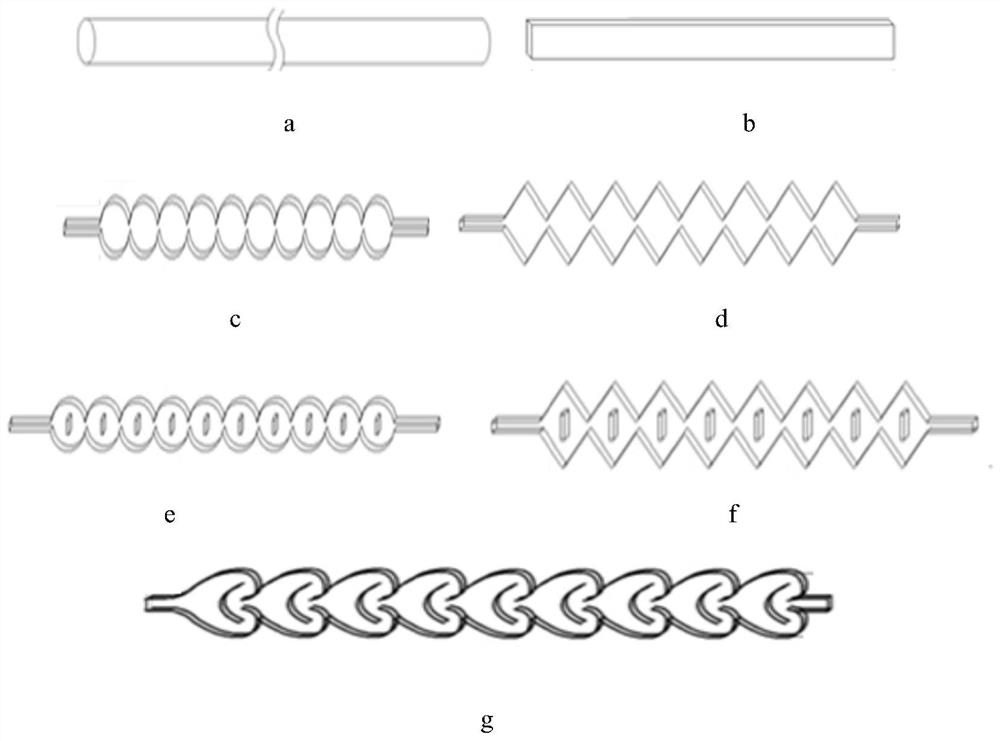

Method for preparing hydrazinobenzene in continuous micro-channel reactor

InactiveCN106316879AHigh mixing mass transfer effectImprove thermal conductivityHydrazine preparationToxic gasContinuous flow

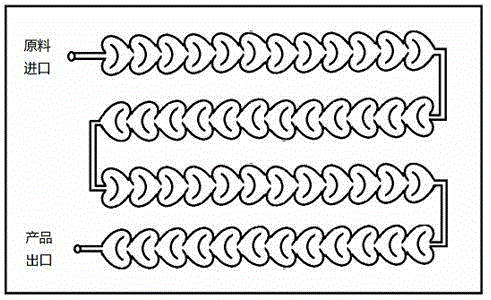

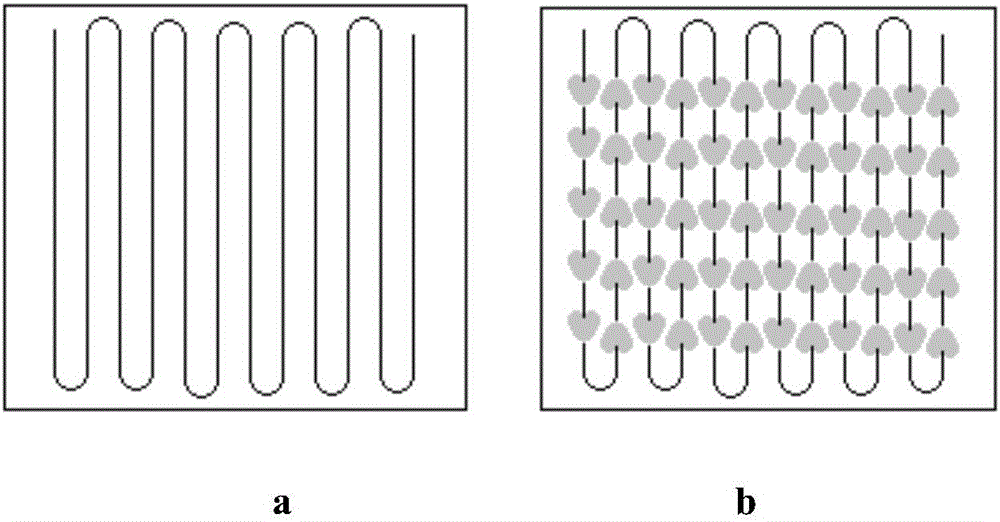

The invention relates to a method for preparing highly pure hydrazinobenzene by using continuous flow micro-channel reactor. The method concretely comprises the following steps: preparing aniline hydrochloride from hydrochloric acid and aniline, respectively pumping the aniline hydrochloride and a sodium nitrite solution into the micro-channel reactor by two metering pumps to obtain a diazo salt solution, reducing the obtained reaction solution, carrying out acid separation on the reduced solution, filtering the obtained solution, neutralizing the filtered solution, and distilling the neutralized solution to obtain the highly pure hydrazinobenzene. The diazotization process is a strong exothermic reaction, and the generated diazo salt easily decomposes after standing at a high temperature for a long time, and generates toxic gases which pollute environment and even blast. The mixing effect of the heart-shaped micro-channel reactor is far better than the mass transfer effect generated by stirring, so the aniline conversion rate can reach 99%, the mixing mass transfer effect is good, and heat conduction is fast to avoid local overheating phenomenon; and the reaction can be carried out at constant temperature conditions, so the temperature runaway blast danger of general reactors is eliminated, and the safety is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

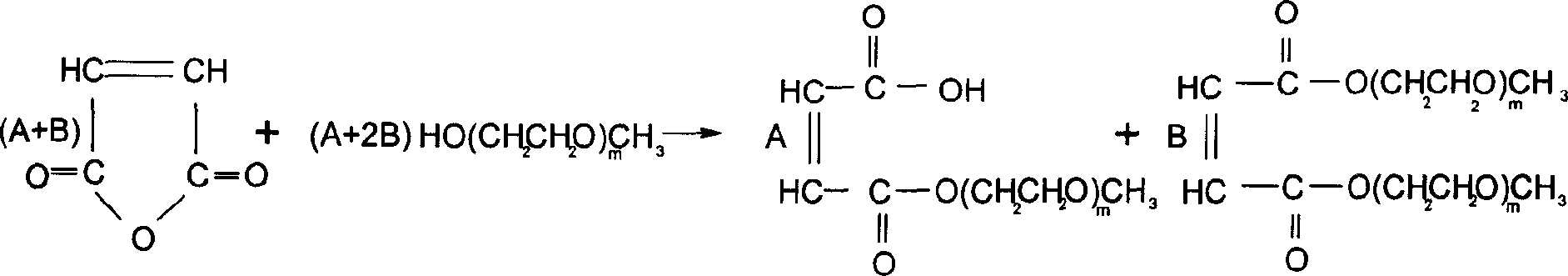

Method for producing alkoxylate through microchannel reactor

The invention relates to a method for producing alkoxylate through a microchannel reactor, and discloses a method for continuously performing alkoxylation reaction in a microreactor. According to the invention, initiator potassium alcoholate in which low molecules (the low molecules herein are mainly water and methanol) are removed and epoxide enter a microreactor, a delay line and a mixer in a liquid-phase form to perform liquid-liquid reaction, the purpose of sufficient mass transfer and heat transfer is achieved, and the liquid-liquid reaction is realized by increasing the pressure of the reaction system and adding a counterbalance valve. Compared with the alkoxylation reaction in the prior art, the method can effectively solve the heat transfer problem of such reaction, realizes fast and uniform mixing and constant reaction temperature, avoids the temperature runaway phenomenon and reduces the side reaction; the process is continuous flow reaction, and the reaction time is shortened to a few minutes, thus obviously improving the reaction efficiency and production efficiency; and the microreactor hardly has scale-up effect and is high in safety performance, thus being suitable for industrial production.

Owner:YANGZHOU SPED CHEM

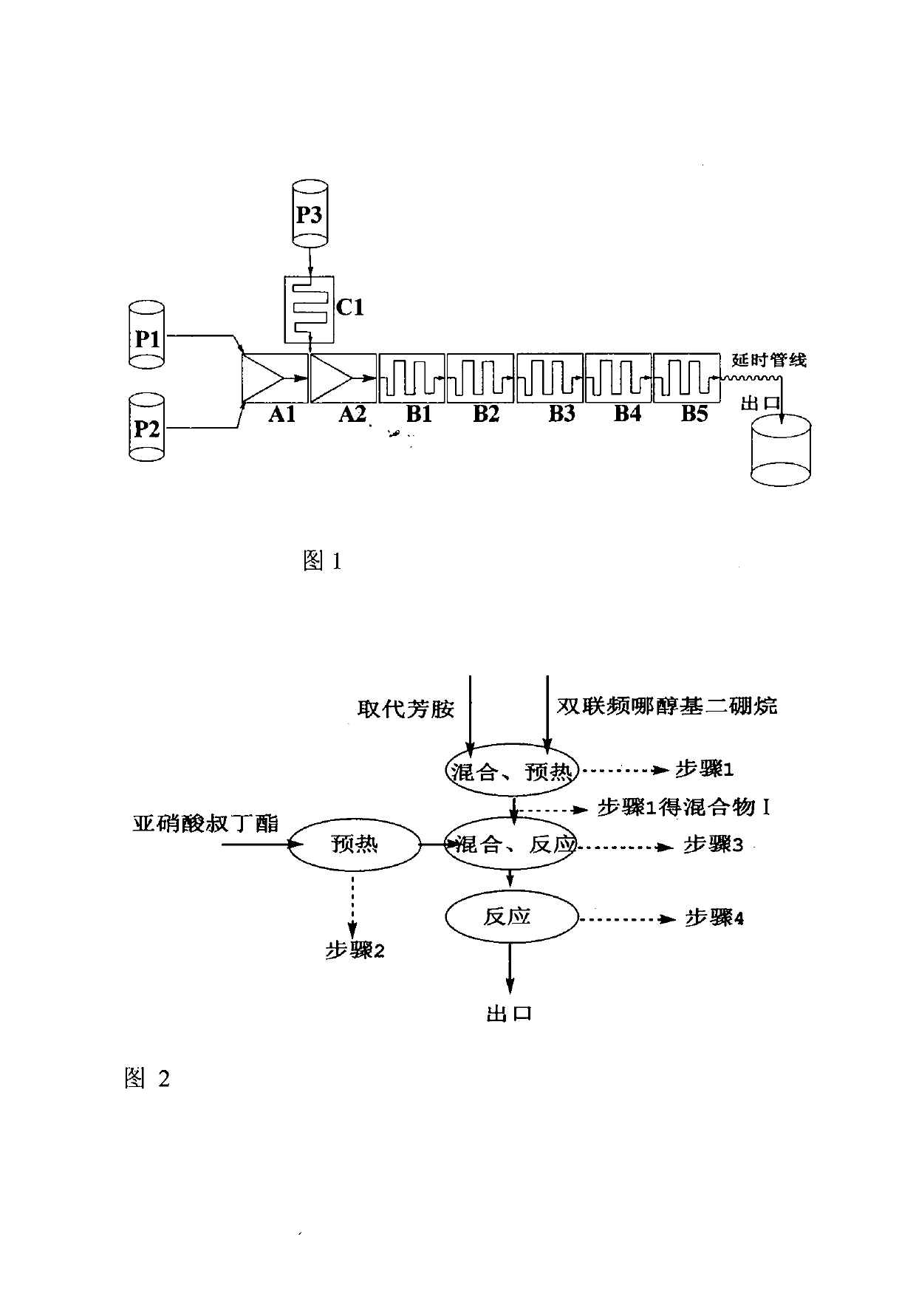

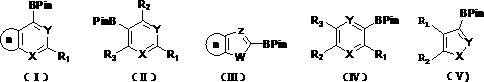

Method for continuously synthesizing arylboronic acid ester by utilizing microreactor

InactiveCN103275112ADegree of reductionShort reaction timeGroup 3/13 element organic compoundsOrganic synthesisN-butyl nitrite

The invention relates to a method for continuously synthesizing arylboronic acid ester by utilizing a microreactor, which belongs to the technical field of green organic synthesis application. The method comprises the following steps of: preheating substituted arylamine, tert-butyl nitrite, bisdiborane in a continuous-flow micro-channel reactor system by using substituted arylamine, acetonitrile, tert-butyl nitrite and bisdiborane as starting materials; and mixing the substituted arylamine with the bisdiborane and then reacting the obtained mixture with the tert-butyl nitrite, wherein in the reaction, the molar ratio of the substituted arylamine to the bisdiborane is (1:0.5)-(1:1.25), the molar ratio of the substituted arylamine to isoamyl nitrite is (1:1.1)-(1:1.5), the reaction temperature is 60 DEG C-120 DEG C, the reaction time is 50 seconds-3600 seconds, and the effective conversion ratio of the substituted arylamine is 50%-90%. The continuous-flow microreactor, which is capable of strengthening the mixing effect, the mass transfer effect and the heat transfer effect, is especially suitable for carrying out homogeneous reaction of the method. Moreover, the method has the characteristics of stable temperature control, safe process and less waste material.

Owner:JINAN SHAOYUAN MEDICAL TECH

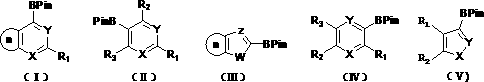

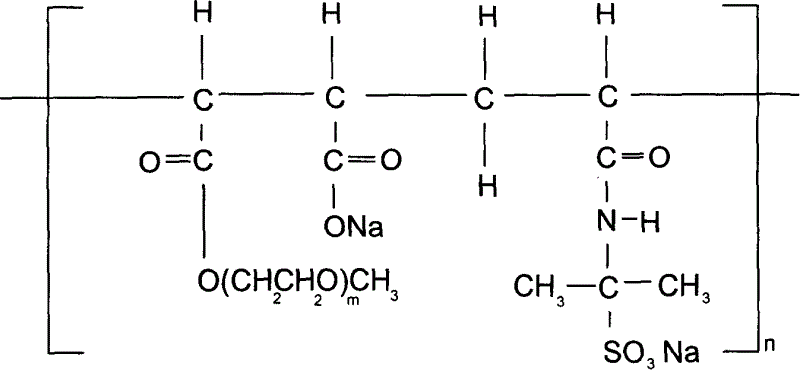

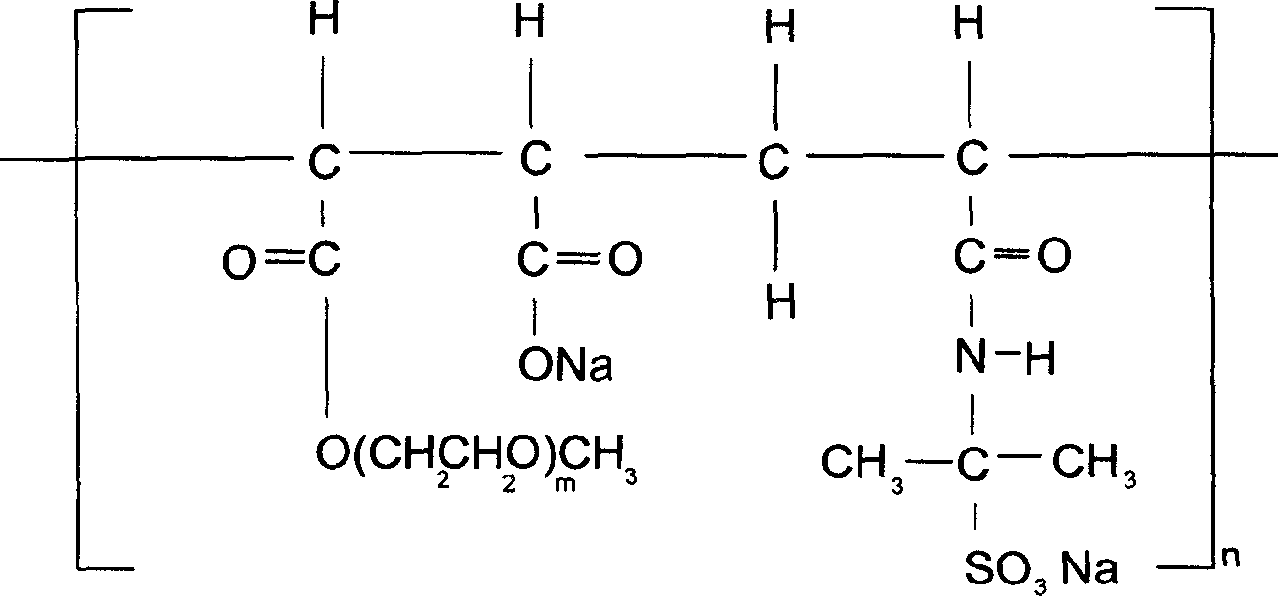

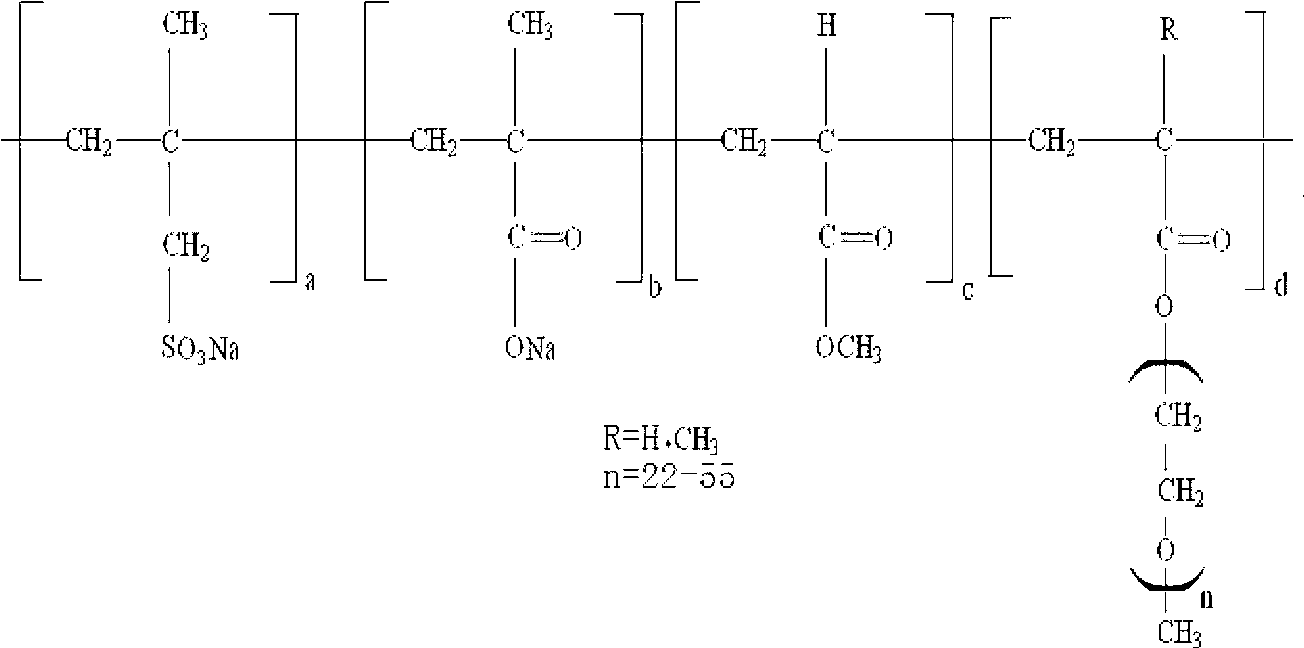

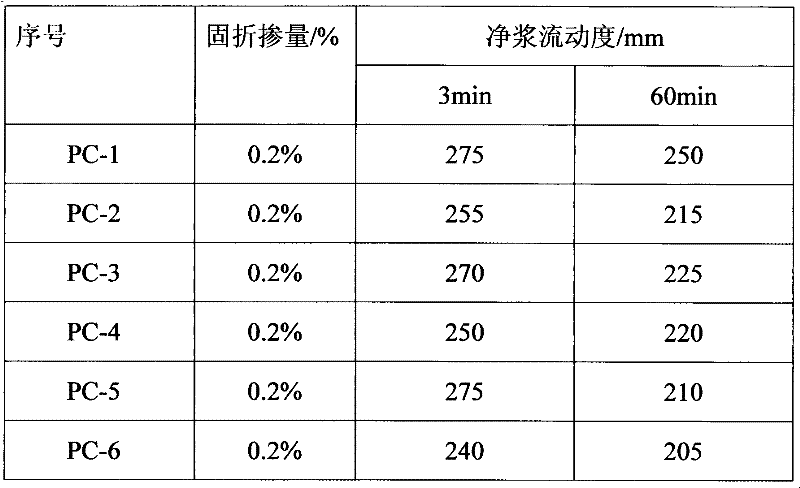

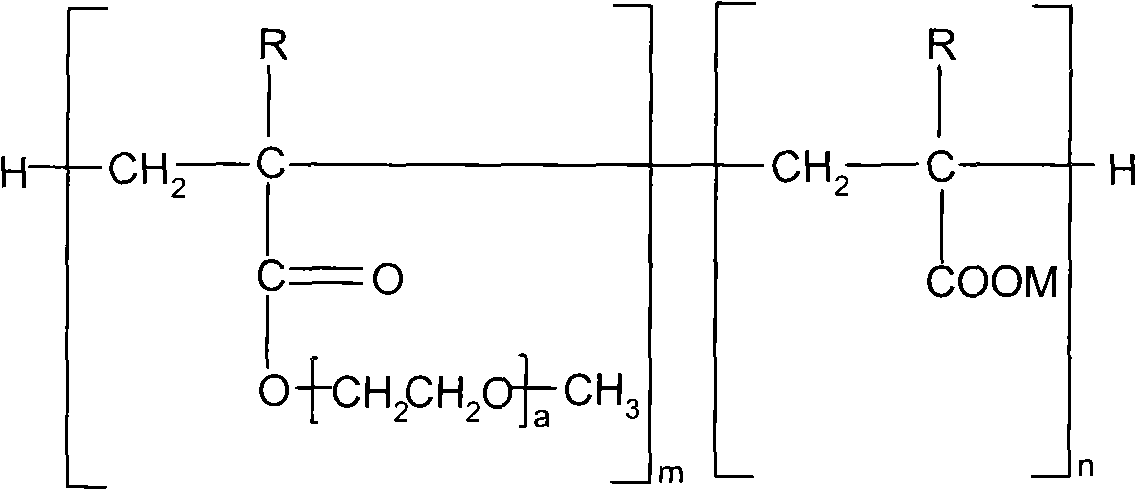

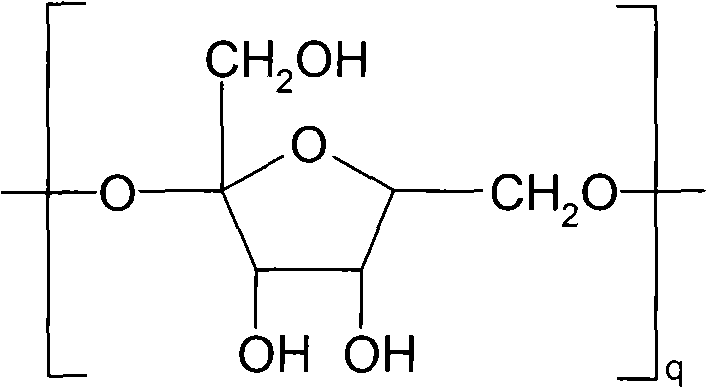

Concrete water reducing agent of polyacrylic acid and its synthesis process

InactiveCN1636921AConstant reaction temperatureThe feeding procedure is simpleDouble bondHigh performance concrete

The concrete water reducing agent of polyacrylic acid is prepared through esterification between polyglycol and acrylic acid to obtain esterified product, and the copolymerization of the esterified product with acrylic acid, 2-acrylamide-2-methyl propenyl sodium sulfonate and other sulfonate with unsaturated double bond. The concrete water reducing agent has weight average molecular weight of 20000-60000, concrete water reducing rate over 35 %, concrete compression strength raised by 100-300 % in 3 days, 40-80 % in 28 days and 30-50 % in 90 days, no loss in 2-hr slump of concrete, raised concrete placeability, etc. and is suitable for matching with flyash, slag and other active admixture to prepare high performance concrete.

Owner:WUHAN UNIV OF SCI & TECH

Maleic acid anhydride series concrete water-reducing agent and preparation process thereof

InactiveCN1792960AThe feeding procedure is simpleReaction conditions are easy to controlMaleic anhydrideMaterials science

A maleic anhydride series water-reducing agent for concrete is prepared through reaction between methoxy polyethanediol and maleic anhydride to generate monomethoxy polyethanediol maleate, and copolymerizing on 2-acrylamide-2-sodium methylpropyl sulfonate. Its advantages are high water-reducing effect, low content of alkali, and high flowability and low slump of concrete.

Owner:WUHAN UNIV OF TECH

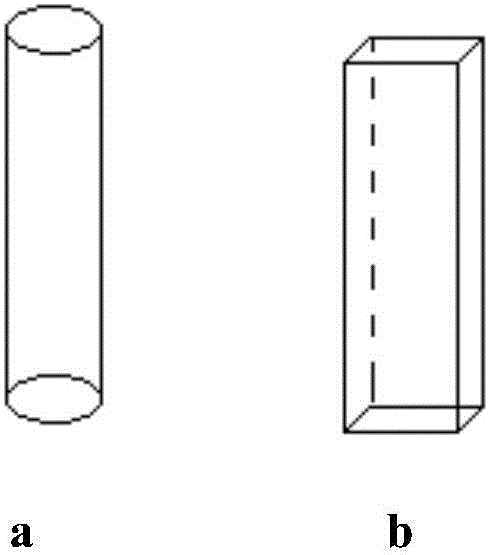

Continuous reaction technological method for preparing epsilon-caprolactone, and microchannel reaction equipment

InactiveCN103539770AShort reaction timeImprove reaction efficiencyOrganic chemistryChemical/physical/physico-chemical microreactorsCyclohexanoneAcetic anhydride

The invention relates to a continuous reaction technological method for preparing epsilon-caprolactone, and microchannel reaction equipment, belonging to the technical field of organic synthesis. The method takes cyclohexanone as initial reaction raw material and peracetic acid generated in the reaction of hydrogen peroxide and acetic anhydride as an oxidizing agent, and the processes such as peroxy acid preparation, cyclohexanone oxidation and the like are continuously completed in a microchannel reactor system. The continuous reaction technological method effectively controls the temperature in the reaction process, is high in safety, does not need an additional solvent, catalyst and stabilizing agent, is beneficial to separation and purification of caprolactone, and enables the high-yield continuous production of the epsilon-caprolactone to be possible; the microchannel reaction equipment provided by the invention highly meets the requirements of the reaction technology. The conversion rate of the cyclohexanone reaches 50-95%, and the selectivity of the epsilon-caprolactone is 80-100%.

Owner:CHANGZHOU UNIV

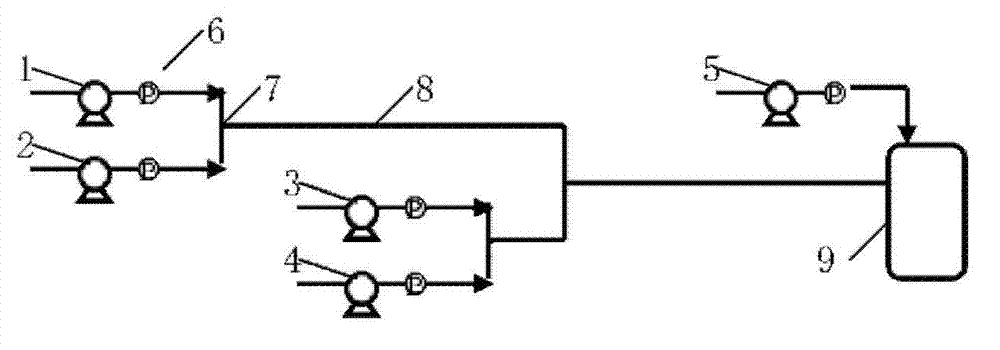

Method for synthesizing nitryl chloroaniline compound by using micro-channel reactor

InactiveCN103113235AShort reaction timeHigh selectivityOrganic compound preparationAmino compound preparationOrganic synthesisNitration

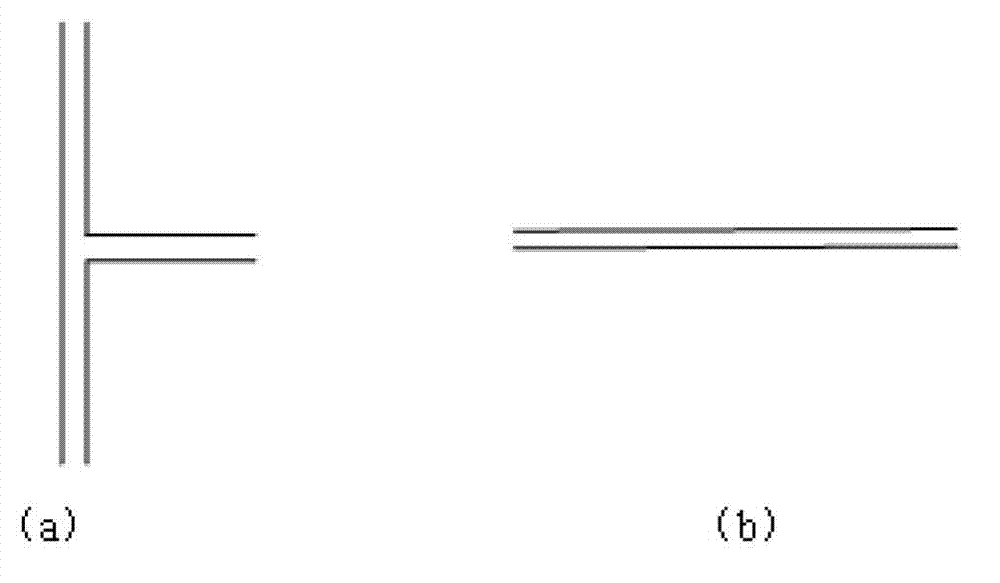

The invention relates to a method for synthesizing nitryl chloroaniline compound by using a micro-channel reactor, and belongs to the technical field of organic synthesis application. In the method, chloroaniline, acylating agent, nitric acid and sulfuric acid are used as original reaction raw materials, the processes of chloroaniline acylation, mixture acid confection, acylated chloroaniline nitration, and the like are carried out in the micro-channel reactor system, and a hydrolysis reaction process is finished out of the micro-channel device by using a normal reactor. In the reaction, acyl chloride, acid anhydride and glacial acetic acid are used as the acylating agent, and nitric acid and sulfuric acid mixture acid is used as the nitrating agent, the chloroaniline acylation transformation rate can reach 100%, and the mass content of the nitryl chloroaniline reaches higher than 92%. The micro-channel reactor used in the invention is especially suitable for carrying out continuously acylation and nitration reaction, and has the characteristics of being stable in temperature control and safe in process.

Owner:CHANGZHOU UNIV

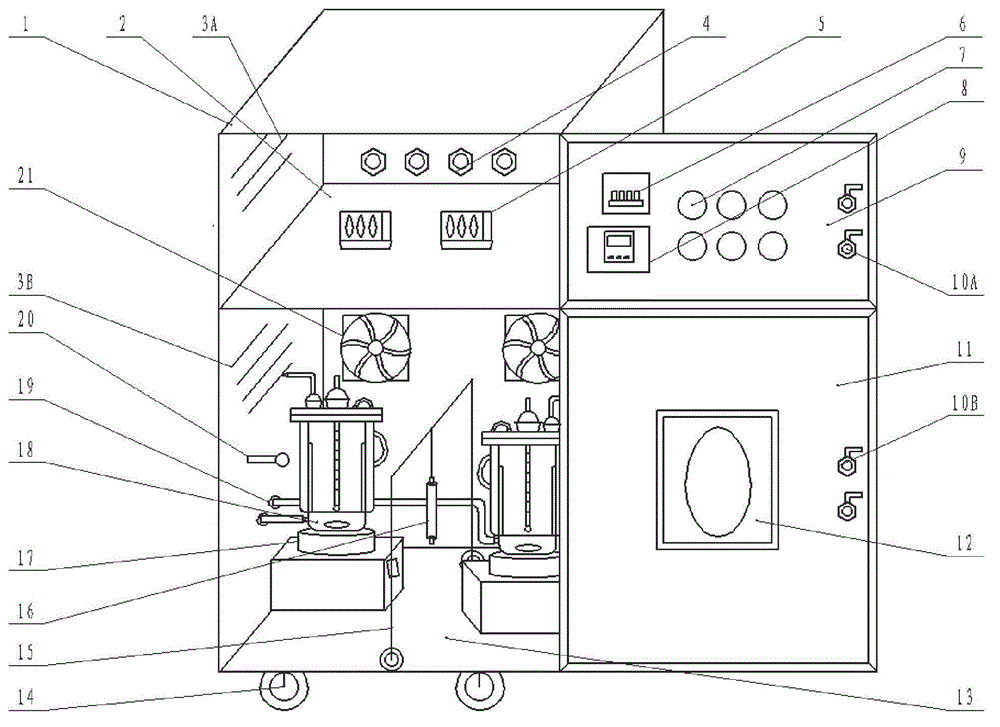

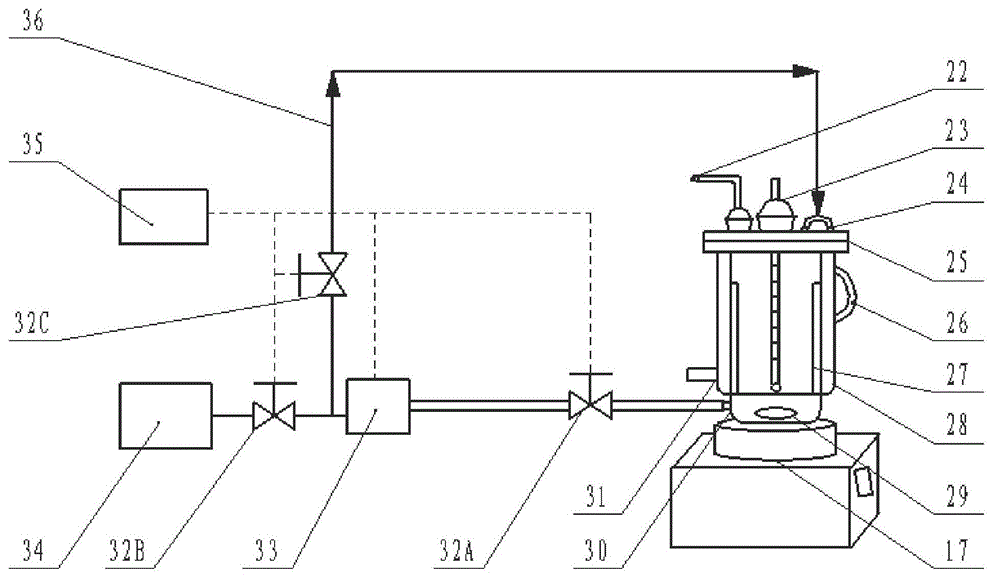

Self-controlling type outer irradiation photochemical reaction device

InactiveCN102974292AConvenience and AccuracyStrong sampling adaptabilityColor/spectral properties measurementsChemical/physical/physico-chemical stationary reactorsMagnetic stirrerLight source

The invention discloses a self-controlling type outer irradiation photochemical reaction device which comprises a box body, a reaction system and a controlling system. The box body is divided into an upper story and a lower story. The upper box body is provided with the controlling system which is composed of a power supply protection switch, ballast, a relay and a microcomputer controller. The lower box body is provided with the reaction system which comprises a quartz reactor, a magnetic stirring device and a light source unit. The self-controlling type outer irradiation photochemical reaction device further comprises a sampling system which comprises a trace metering pump, a component accumulator, a computer time switch and a magnetic valve. When the self-controlling type outer irradiation photochemical reaction device is used, the sampling system inputs reaction liquid to the quartz reactor. The reaction system is controlled by the controlling system to start or stop. The quartz reactor is adequately mixed and reacted under the action of the magnetic stirring device and the light source. The self-controlling type outer irradiation photochemical reaction device has the advantages of being capable of regularly booting and shutdown, automatically adjusting power and intensity of light, automatically and quantificationally sampling, enabling the reaction liquid to adequately and evenly mix and react. The temperature is controllable and the reaction is stayed at an even temperature.

Owner:GUANGXI UNIV

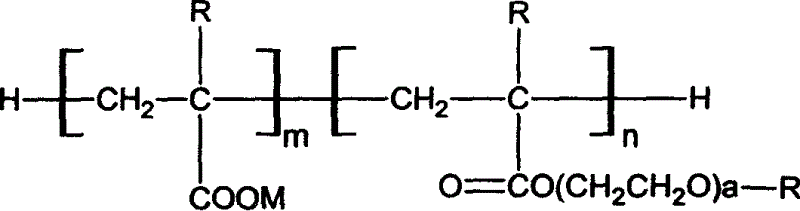

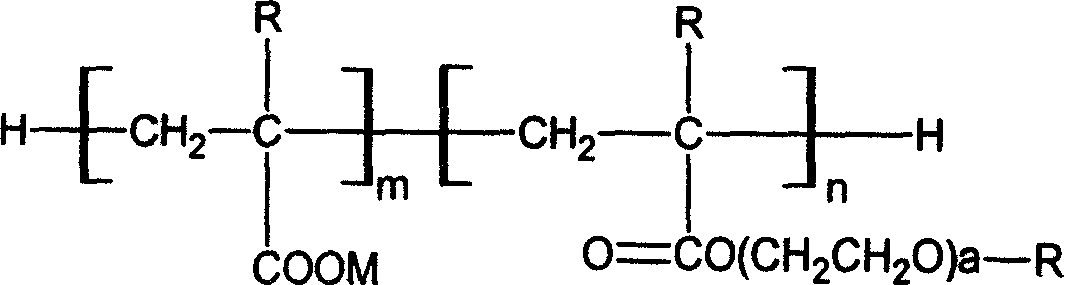

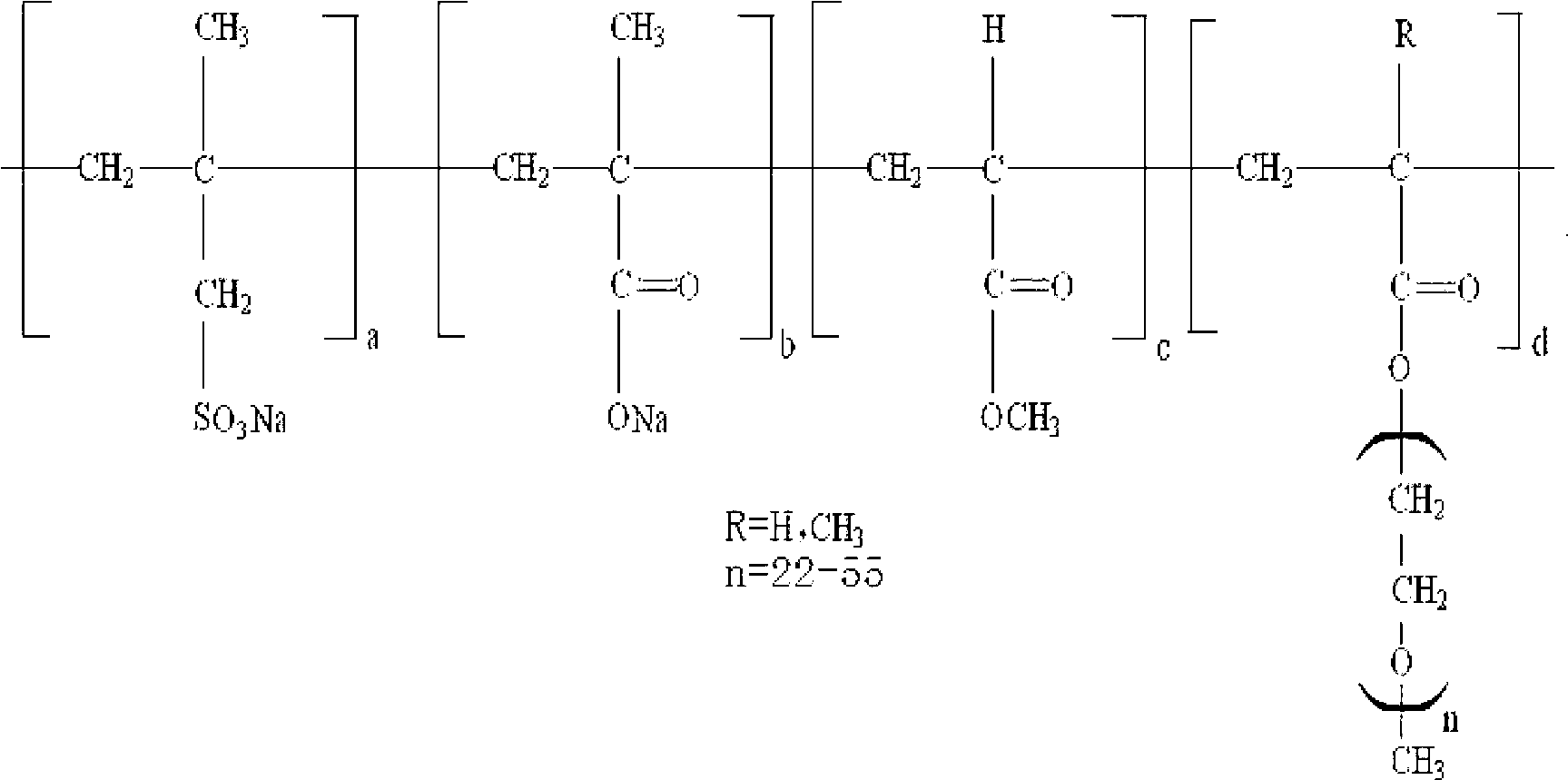

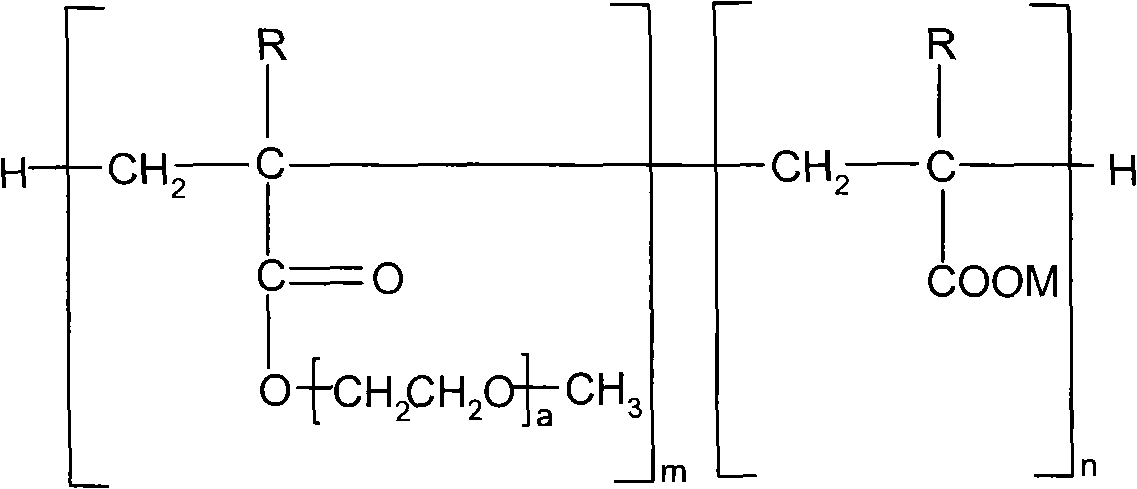

Universal polycarboxylic acid water reducing agent and preparation method thereof

ActiveCN102992682AConstant reaction temperatureThe feeding procedure is simpleSide chainMethyl group

The invention relates to a universal polycarboxylic acid water reducing agent and a preparation method thereof. The universal polycarboxylic acid water reducing agent is of a liquid state and has the solid content of 40%. The universal polycarboxylic acid water reducing agent is the water reducing agent which is prepared from monomers such as allyl polyether, and maleic anhydride, (meth)acrylic acid or itaconic acid, methyl acrylate and sodium methallyl sulfonate through polymerization under the effects of a molecular weight chain initiator and a chain transfer agent and neutralization; and the water reducing agent contains carboxyl, sulfonic group and an allyl polyether side chain. The universal polycarboxylic acid water reducing agent disclosed by the invention is low in alkali content, high in water-reducing rate, labor-saving in concrete operation, simple in production process, easy in reaction condition control and free of environmental pollution; the cement mixture has high mobility and slump keeping property, and good peaceability; and the universal polycarboxylic acid water reducing agent disclosed by the invention can be used as an important component of high-performance concrete, and can be widely applied to stirred and cast-in-place concrete and ready-mixed concrete for various industrial and civil buildings.

Owner:YUEYANG ORIENTAL YUHONG WATERPROOF TECH +1

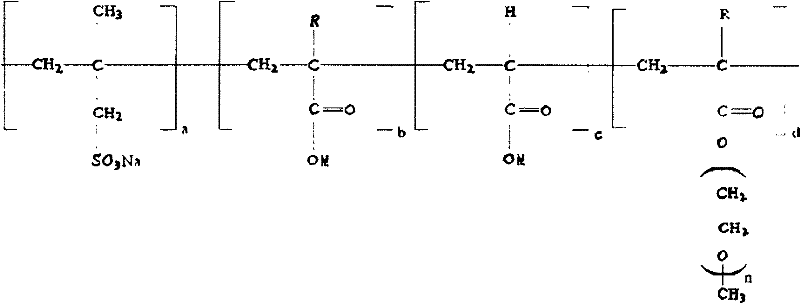

Method for synthesizing universal polycarboxylic water reducer

The invention relates to universal polycarboxylic water reducer and preparation method thereof. The universal polycarboxylic water reducer is in liquid state, and the solid content of the universal polycarboxylic water reducer is 40%. The universal polycarboxylic water reducer containing carboxyl, sulfonyl and polyoxyethylene side chains is prepared by aggregation of modified polyoxyethylene ether or polyoxypropylene ether with (methyl) acrylic acid or itaconic acid, sodium methylallyl sulfonate and the like under the action of chain initiator and chain transfer agent. The universal polycarboxylic water reducer prepared by the method is low in alkali content and high in water reducing rate. When the universal polycarboxylic water reducer is added into concrete by the cementing material weight ratio of 0.25-10%, operation of the concrete is laborsaving, and cement mixture has high liquidity, falling protection capacity and workability. The universal polycarboxylic water reducer and the preparation method thereof are simple in process, easy to control and free of environment pollution. The polycarboxylic water reducer which is used as an important component of high-performance concrete is widely applicable to pre-mixed and cast-in-situ concrete for various industrial and civil buildings, and especially has excellent performance in high-strength concrete.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

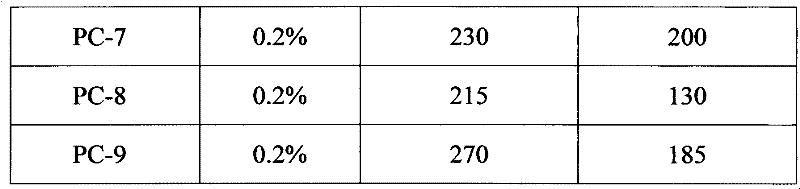

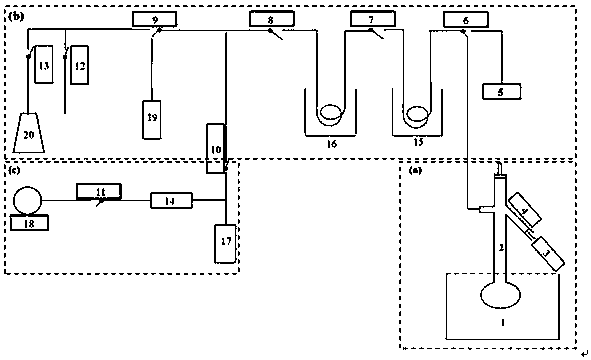

Novel sample preparation system for carbon and oxygen isotopes of carbonate and sample preparation method thereof

ActiveCN105277401AHigh degree of automationGuaranteed normal injectionPreparing sample for investigationWater bathsAutosampler

The invention provides a novel sample preparation system for carbon and oxygen isotopes of carbonate and a sample preparation method thereof. The sample preparation system comprises an original sample reaction device, a finished sample extraction device and a system vacuum degree controlling device, wherein the original sample reaction device is connected with an autoinjection device. The sample preparation system employs the autoinjection device, so the automation degree of the sample preparation system is increased, and it is guaranteed that all the saturated phosphoric acid solution enters the bottom of a reaction tube and participates in a reaction; a touch button type vacuum valve is used to replace a conventional turn button type vacuum valve, so service life is prolonged, simplicity of usage of devices is improved, and operation time is shortened in preparation; and a constant temperature water-bath is added, vacuum-pumping and reaction can be completed in the devices in the same time, so a transfer step between vacuum-pumping and sample reaction is reduced. Moreover, the invention provides the sample preparation method of the novel sample preparation system. According to the invention, accuracy and the automation degree in preparation of a test sample are effectively improved, and standardized operational process is formed.

Owner:CHINA PETROLEUM & CHEM CORP +1

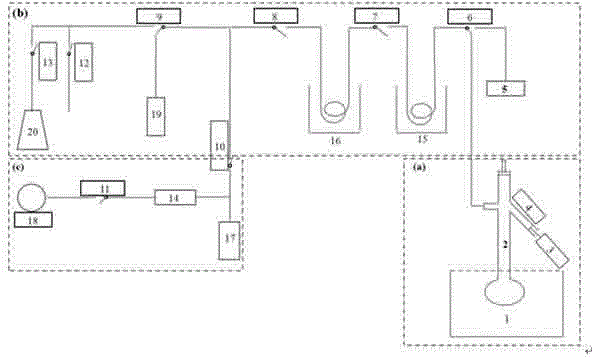

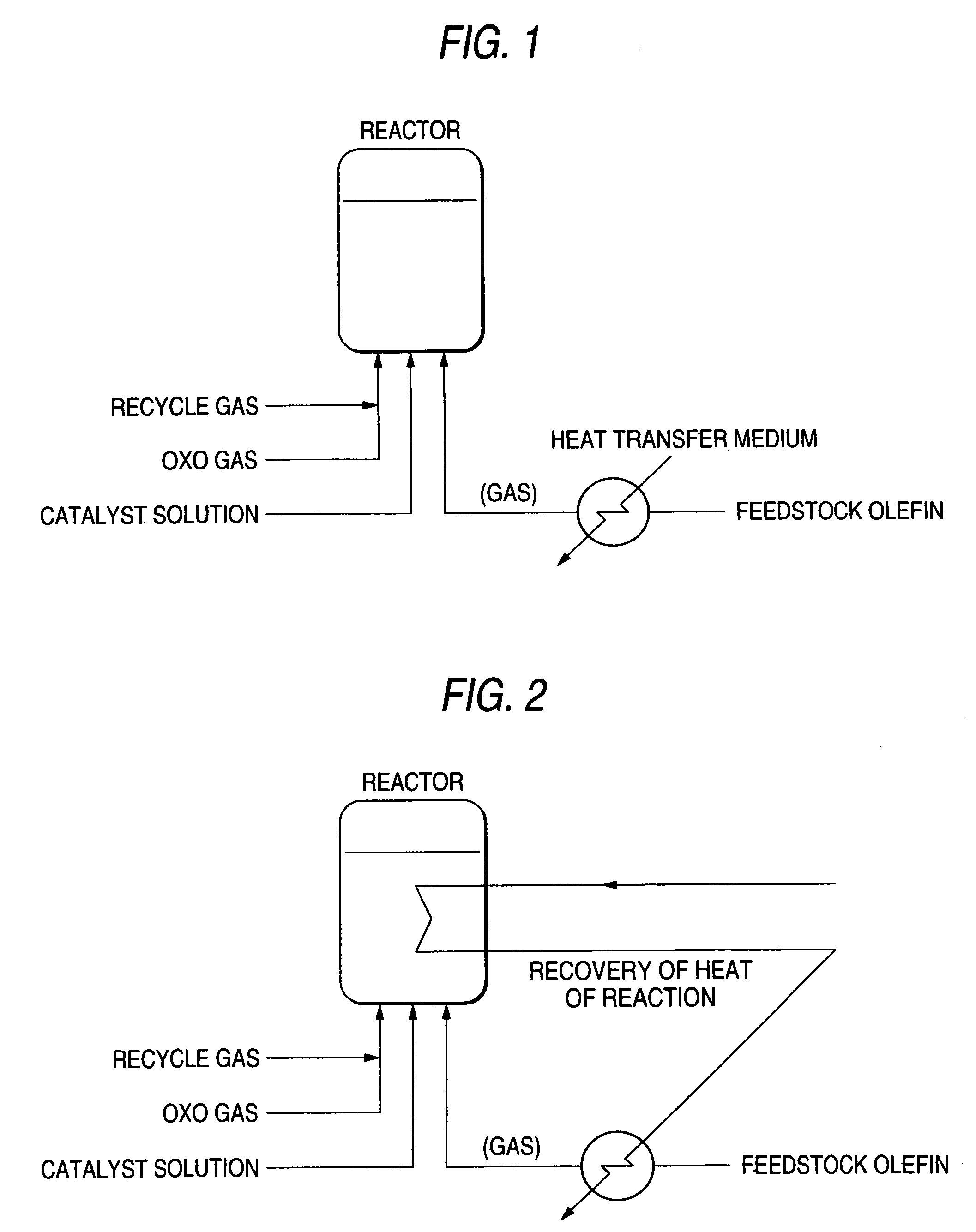

Process for producing aldehyde

ActiveUS7420092B2Constant reaction temperatureAvoid poor resultsOrganic compound preparationOrganic chemistry methodsHydrogenAlkene

A process by which a hydroformylation reaction can be efficiently conducted without lowering the yield of an aldehyde in the reaction is provided. A process for producing an aldehyde which includes subjecting an olefin to a hydroformylation reaction with carbon monoxide and hydrogen in the presence of a catalyst, characterized in that the olefin is fed as a gas to a reactor. In feeding the olefin as a gas to the reactor, it is preferred to gasify the olefin with the heat of the hydroformylation reaction.

Owner:MITSUBISHI CHEM CORP

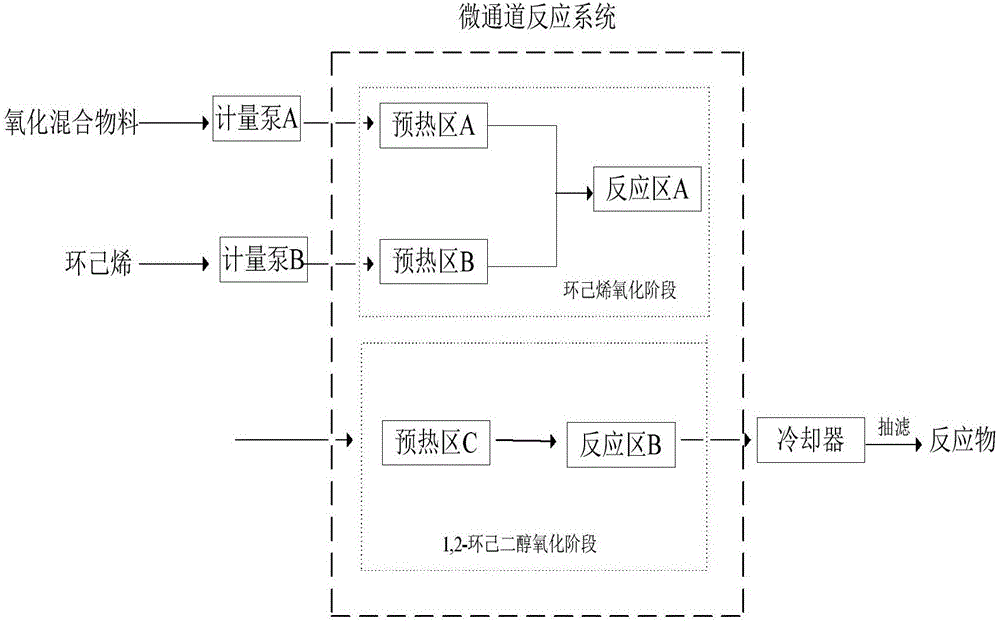

A method of continuously synthesizing hexanedioic acid through a microchannel reactor

ActiveCN106380375AAchieve serializationShort reaction timePreparation by oxidation reactionsOrganic compound preparationOrganic synthesisCyclohexene

A method of continuously synthesizing hexanedioic acid through a microchannel reactor is disclosed and belongs to the technical field of organic synthesis processes. The method includes fully mixing hydrogen peroxide and a tungsten-containing catalyst, and pumping the mixture and cyclohexene which are two material streams into the microchannel reactor to continuously produce the hexanedioic acid, wherein a process of cyclohexene oxidation to prepare the hexanedioic acid is performed in two stages, namely a stage of oxidizing the cyclohexene into 1,2-cyclohexanediol and a stage of oxidizing the 1,2-cyclohexanediol into the hexanedioic acid. The method utilizes high mass transfer and heat transfer efficiencies of the microchannel reactor to effectively enhance the mass transfer speed between the two-phase materials, to stabilize the reaction temperature and to greatly improve experiment safety and operability. The reaction system is free of solvents, phase transfer catalysts and acid auxiliaries, thus reducing the production cost and facilitating separation and purification of the hexanedioic acid. The method allows efficient continuous production of the hexanedioic acid to be possible. The conversion ratio of the cyclohexene is 100%, and selectivity of the hexanedioic acid is 95.4%.

Owner:CHANGZHOU UNIV

Preparation method of ultra-low hydration heat polycarboxylate-based water reducing agent

InactiveCN101284717AHigh compressive strengthImprove appearance qualityPolymer scienceThermal insulation

The invention relates to a method for preparing an ultra-low hydration-heat polycarboxylate-based water reducing agent. Methacrylic acid and Monomer methylacrylic acid polyethylene glycol single armor ether ester (MAAMPEA) water solution, initiator and modifier solution are simultaneously and slowly added into the solvent water drop by drop within 6 to 7 hours at the temperature of 80 DEG C to 90 DEG C, then the solvent water is subjected to thermal insulation for 4 to 5 hours at 90 DEG C to 95 DEG C and is naturally cooled down to the room temperature, and finally NaOH is used to adjust the pH value to 7 to 8, thereby obtaining the ultra-low hydration-heat polycarboxylate-based water reducing agent. The reaction conditions are easily controlled, no organic solvent is used during the polymerization process, and the process is simple with no industrial pollution. The concrete prepared by adopting the ultra-low hydration-heat polycarboxylate-based water reducing agent has the advantages as follows: when the mixing amount of the water reducing agent with the concentration being 25 wt percent is 1.0% of the concrete weight, the water reducing ratio can reach 30 percent, the 3d compressive strength of the concrete can be improved by more than 60 percent, the 28d compressive strength can be improved by more than 50 percent, and the 90d compressive strength can be improved by 30 percent.

Owner:WUHAN UNIV OF TECH

Method for preparing o-nitro anisole by using micro-channel reaction apparatus

InactiveCN105503610APrecise control of reaction conditionsEasy to operateOrganic chemistryOrganic compound preparationO-NitroanisoleReaction rate

The present invention provides a new method for preparing o-nitro anisole by using a micro-channel reactor, particularly application of a micro-channel reactor with an enhanced mass transfer unit structure to carry out a continuous flow o-nitro chloro benzene etherification reaction. According to the present invention, the mass transfer and the heat transfer can be completed dependent on the kinetic energy of the fluid without the mechanical stirring process under the reactor operation condition higher than the normal temperature, the space time reaction rate of the micro-channel reactor can be substantially improved, the temperature fluctuation and the concentration fluctuation during the reaction process can be avoided, the phenomena such as temperature runaway and overheating do not exist, and the reaction process is safe.

Owner:CHINA PETROLEUM & CHEM CORP +1

A continuous reaction process method and microchannel reaction equipment for preparing ε-caprolactone

InactiveCN103539770BShort reaction timeImprove reaction efficiencyOrganic chemistryChemical/physical/physico-chemical microreactorsCyclohexanoneAcetic anhydride

Owner:CHANGZHOU UNIV

Preparation method of DOPO vinylidene bridged derivative, flame retardant and flame-retardant polymer material

ActiveCN110885344AEvaporation absorbs less energyAct as a water-carrying agentGroup 5/15 element organic compoundsPolymer chemistryPerylene derivatives

The invention discloses a preparation method of a DOPO vinylidene bridged derivative, a flame retardant and a flame-retardant polymer material. The method is characterized in that a DOPO compound reacts with cyclic carbonate in a reaction system containing the DOPO compound and cyclic carbonate to obtain the DOPO vinylidene bridged derivative. The method can be used for efficiently, simply and conveniently preparing the DOPO vinylidene bridged derivative with low energy consumption. The invention also provides the flame retardant containing the product prepared by the method and the flame-retardant polymer material containing the product prepared by the method.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for undergoing chlorobenzene nitration reaction by using micro-channel reactor

ActiveCN102432471BHigh selectivityShort reaction timeNitro compound preparationTemperature controlChlorobenzene

The invention relates to a method for undergoing a chlorobenzene nitration reaction by using a micro-channel reactor, belonging to the technical field of application of organic synthesis. In the method, nitric acid, sulfuric acid, water and chlorobenzene are taken as initial reaction raw materials, and processes such as mixed acid preparation, mixed acid and chlorobenzene preheating, mixed acid and chlorobenzene reacting and the like are completed in a micro-channel reactor system. In the reaction, nitro-sulfuric mixed acid is taken as a nitrating agent, the effective concentration of sulfuric acid in the mixed acid is 50-90 percent, the molar ratio of the nitric acid to the sulfuric acid in the mixed acid is 1:1-1:10, the molar ratio of the chlorobenzene to the nitric acid is 1:1.0-1:2.0, the reaction temperature is 50-100 DEG C, and the reaction time is 30-120 seconds. The chlorobenzene transformation ratio is up to 97 percent, the selectivity of nitrochlorobenzene serving as a product is over 96.5 percent, and the ratio of ortho-para nitrochlorobenzene is over 0.6. A strengthened mixed micro-channel reactor adopted in the invention is particularly suitable for undergoing a continuous nitration reaction, and has the characteristics of stable temperature control and safe process.

Owner:CHANGZHOU UNIV

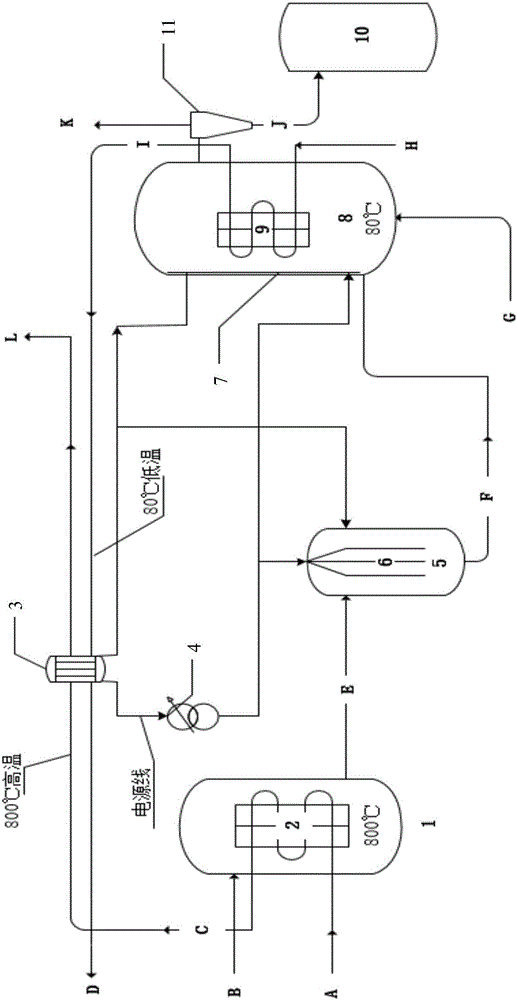

Device and method for removing CO2 from flue gas in power plant by using fly ash

ActiveCN106474912ARealize resource utilizationLow costGas treatmentDispersed particle separationCold airFluidized bed

The invention discloses a device for removing CO2 from flue gas in a power plant by using fly ash. The device comprises an activation reactor, a charging device, a fluidized bed, a cyclone separator and a waste material bin, wherein the output end of the activation reactor is connected with the charging device; the output end of the charging device is connected with the fluidized bed; the output end of the fluidized bed is connected with the cyclone separator; and the output end of the cyclone separator is connected with the waste material bin. The invention also discloses a method for removing the CO2 from the flue gas in the power plant by using the fly ash. The method comprises the following steps: conveying the fly ash into the activation reactor and carrying out activation treatment, then carrying out conveying into the charging device and carrying out charging treatment, then carrying out conveying into the fluidized bed so as to remove the CO2 in the flue gas, and finally carrying out conveying into the waste material bin. According to the invention, the device organically combines with a coal-fired power generating system; the flue gas and cold air in the coal-fired power plant can be utilized to provide a heat source and a cold source for the device; meanwhile, needed electric energy is provided for the device through a thermoelectric power generation technology; thus, an optimization scheme capable of reducing cost and energy consumption is realized.

Owner:NANJING NORMAL UNIVERSITY

Preparing method for sodium alginate wound application with thrombin

ActiveCN107412842AIncrease contact areaReduce sensitization ratePharmaceutical delivery mechanismAbsorbent padsAnti adhesiveChemistry

The invention relates to the field of medical care, in particular to a preparing method for sodium alginate wound application with thrombin. The preparing method comprises the following steps that an ethanol aqueous solution of the thrombin is configured, then sodium alginate long beam fiber is put into a reaction tank of the thrombin ethanol aqueous solution for constant temperature soaking, sodium alginate short fiber is prepared through drying and cutting after soaking, the short fiber is curled, non-woven fabrics are prepared through non-woven processes such as opening and scutching, carding, lapping and needling and cut into application cores of needed sizes, the application cores, silicone hydrogel membranes with holes, a polyurethane film adhesive tape and an anti-adhesive layer are composited through an application machine, and finally, a finished product of the sodium alginate wound application with the thrombin can be prepared. According to the composite application prepared through the preparing method, activity of the thrombin can be maintained to the utmost extent, the excellent hemostatic and absorption performance is achieved, meanwhile, adhesion of the application and wound can be prevented, a moist healing environment is provided for the surface of the wound, and wound healing is prompted.

Owner:GUANGDONG TAIBAO MEDICAL SCI TECH

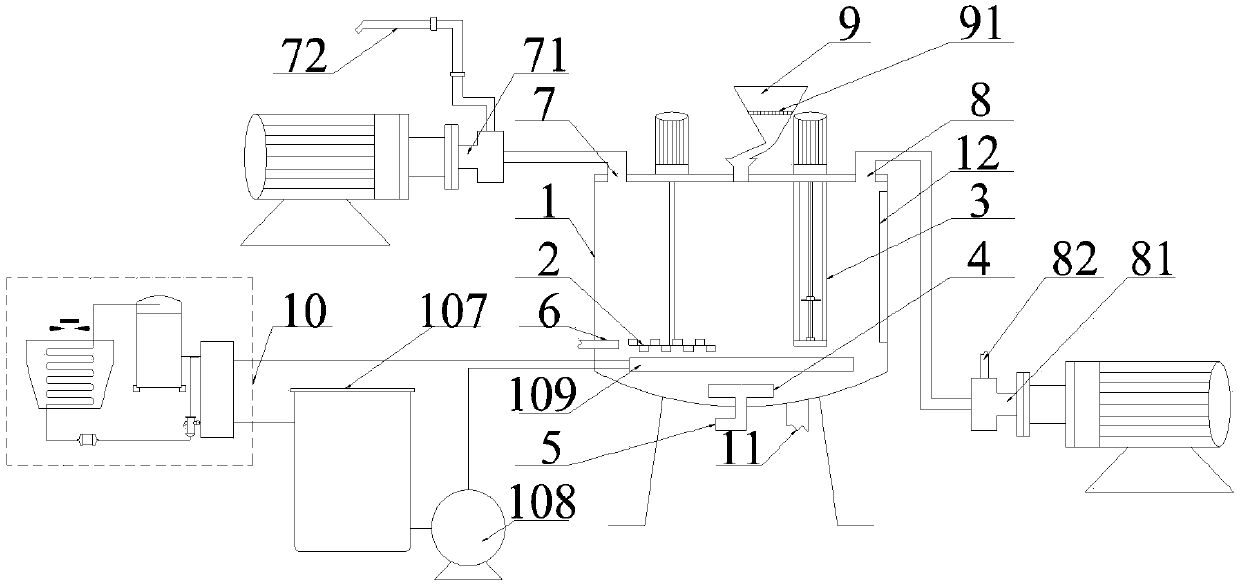

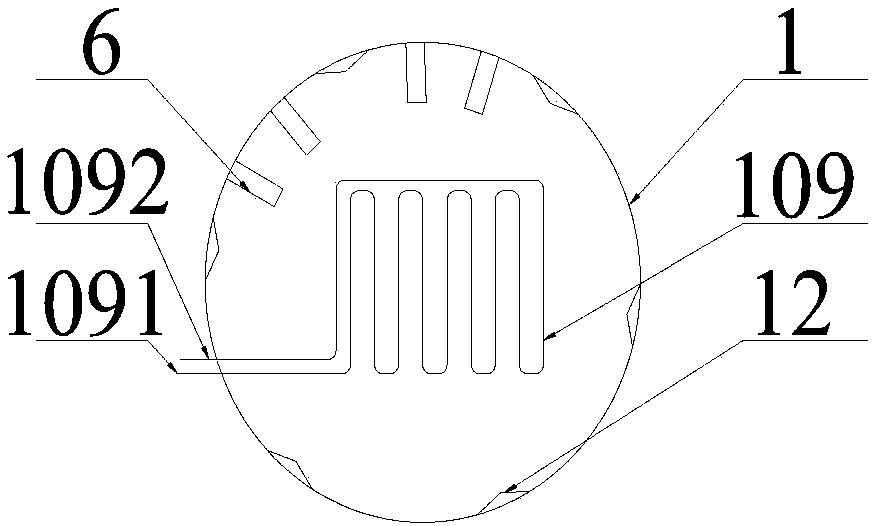

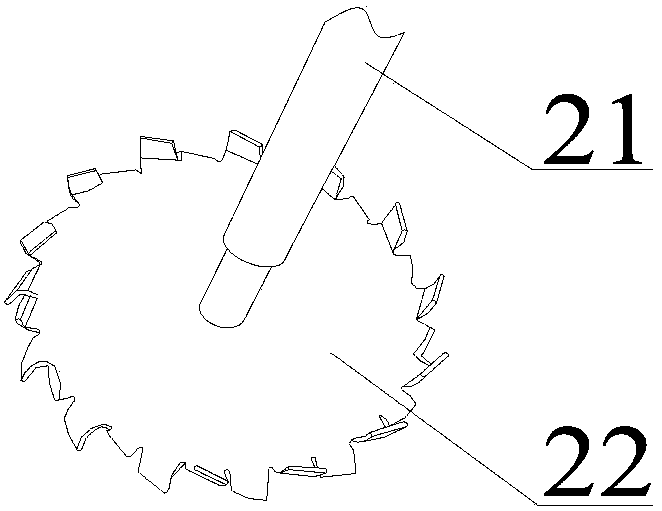

Stirring device for dissolved paste of chlorophyll and with temperature controlling function

InactiveCN108043264AStir wellImprove cleanlinessTransportation and packagingRotary stirring mixersTemperature controlReaction temperature

The invention especially relates to a stirring device for dissolved paste of chlorophyll and with a temperature controlling function, belonging to the field of stirring devices. The stirring device comprises a stirring tank, and a stirrer and an emulsification head arranged in the stirring tank, wherein the top of the stirring tank is provided with a powder feed inlet, a liquid feed inlet and a solid feed hopper; the sidewall of the stirring tank is provided with a plurality of flow-disturbing ribs and heating pipes; a cooling pipe is arranged in the stirring tank and connected with a coolingsystem; and the cooling system comprises a liquid coolant cooling unit, a liquid coolant case and a water pump. With such a manner, raw materials are fully stirred through arrangement of the stirrer and the emulsification head in the stirring tank; raw materials of different forms can be added via a powder suction pipe, the solid feed hopper and the liquid feed inlet; a feeding pump is used for sucking powder and liquid raw materials, so a production site is maintained clean; the heating pipes and the cooling pipe are arranged in the stirring tank to guarantee constant reaction temperatures; and the flow-disturbing ribs are arranged on the sidewall of the stirring tank to prevent dead stirring angles during stirring of a solution, so production efficiency and product quality are improved.

Owner:WEIFANG HANXING CHLOROPHYLL

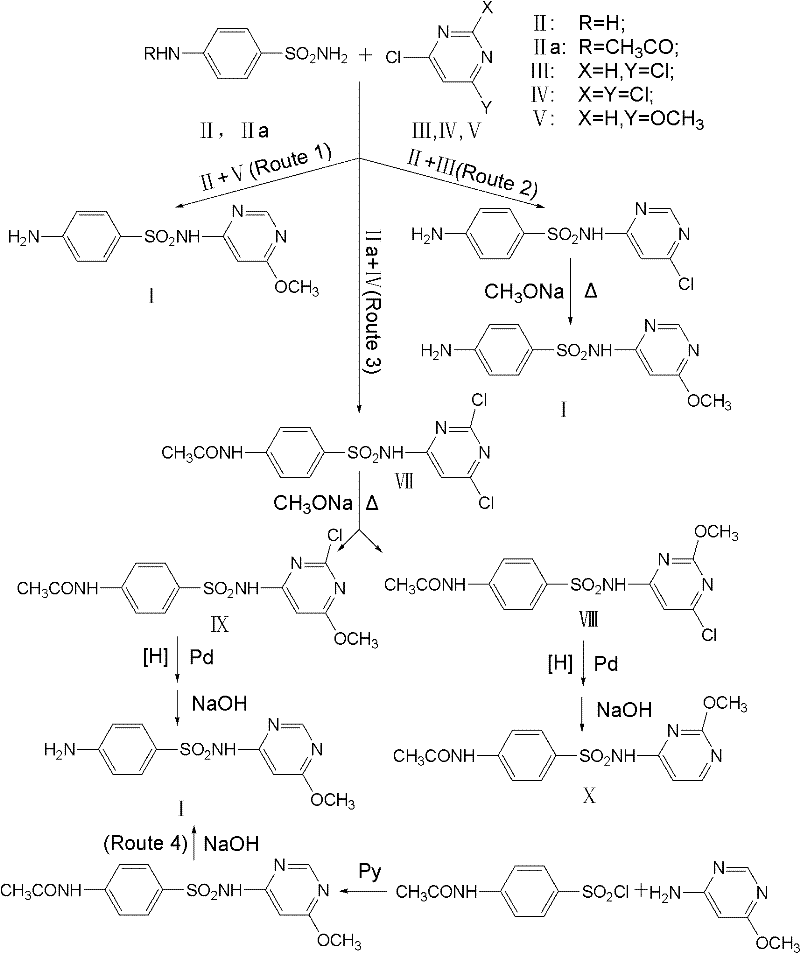

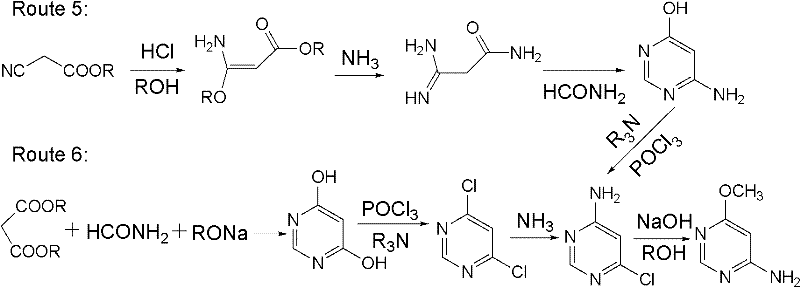

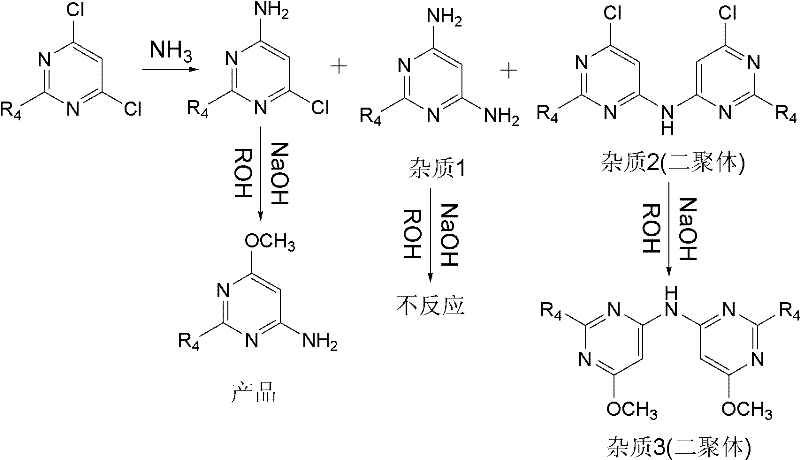

Preparation method for 4-amino-6-alkoxyl pyrimidine compounds

ActiveCN102516182AMeet production requirementsThe reaction temperature is easy to controlOrganic chemistryAlcoholAminolysis

The invention discloses a preparation method for 4-amino-6-alkoxyl pyrimidine compounds, wherein 4,6-dichloropyrimidine compounds wide, easy to get and low in price are used in the method. The method comprises the following steps of: obtaining 4,6-dichloropyrimidine compounds via atmospheric-pressure ammonolysis or aminolysis; mixing the 4,6-dichloropyrimidine compounds with alcohol compounds and an alkaline catalyst, and then perform reflux reaction; and treating the reaction solution to obtain the 4-amino-6-alkoxyl pyrimidine compounds. The preparation method disclosed by the invention has the advantages of being green and environment-friendly, simple and convenient in operation, low in cost, high in yield, low in the content of impurities and suitable for industrialized production.

Owner:浜田智子

Method for continuously preparing 3, 5-dinitrobenzoic acid by using micro-channel reactor

ActiveCN112679358AShort reaction timeShort preparation cycleChemical/physical/physico-chemical processesNitro compound preparationBenzoic acidPtru catalyst

The invention discloses a method for continuously preparing 3, 5-dinitrobenzoic acid by using a micro-channel reactor, and belongs to the technical field of organic synthesis processes. According to the method, benzoic acid and concentrated nitric acid are used as raw materials, fuming sulfuric acid is used as a solvent, trifluorosulfonic acid ketone is used as a catalyst, and the preparation process of 3, 5-dinitrobenzoic acid is continuously completed in a micro-channel reactor system. After the raw materials are introduced into the micro-channel reactor through a metering pump, the 3, 5-dinitrobenzoic acid product is obtained through preheating, mixed reaction and separation, the method can strictly control the temperature and the retention time in the reaction process, accurately control the reaction temperature to prevent temperature runaway, and improve the safety of a reaction device; and due to the strong mass transfer effect of the micro-channel reactor, the mass transfer effect among the raw materials in the reaction system is enhanced, and the reaction efficiency and the yield of 3, 5-dinitrobenzoic acid are greatly improved.

Owner:CHANGZHOU UNIV

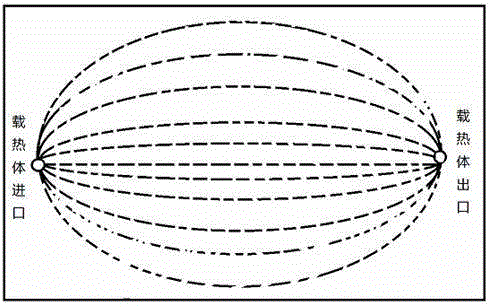

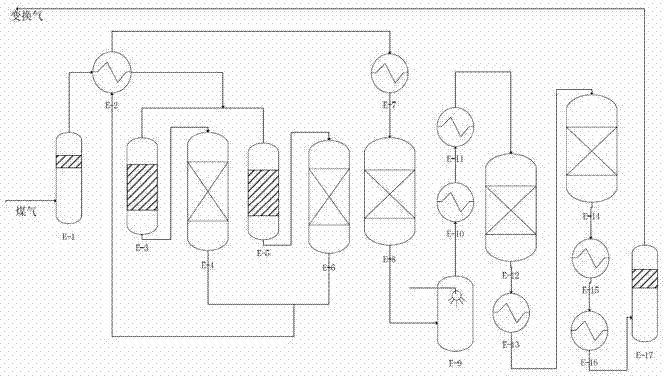

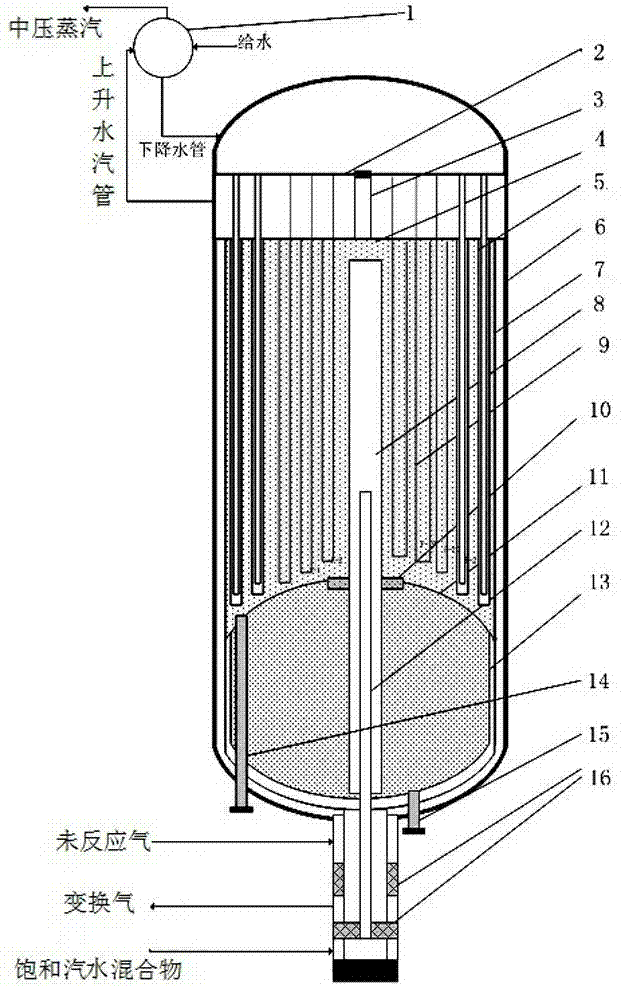

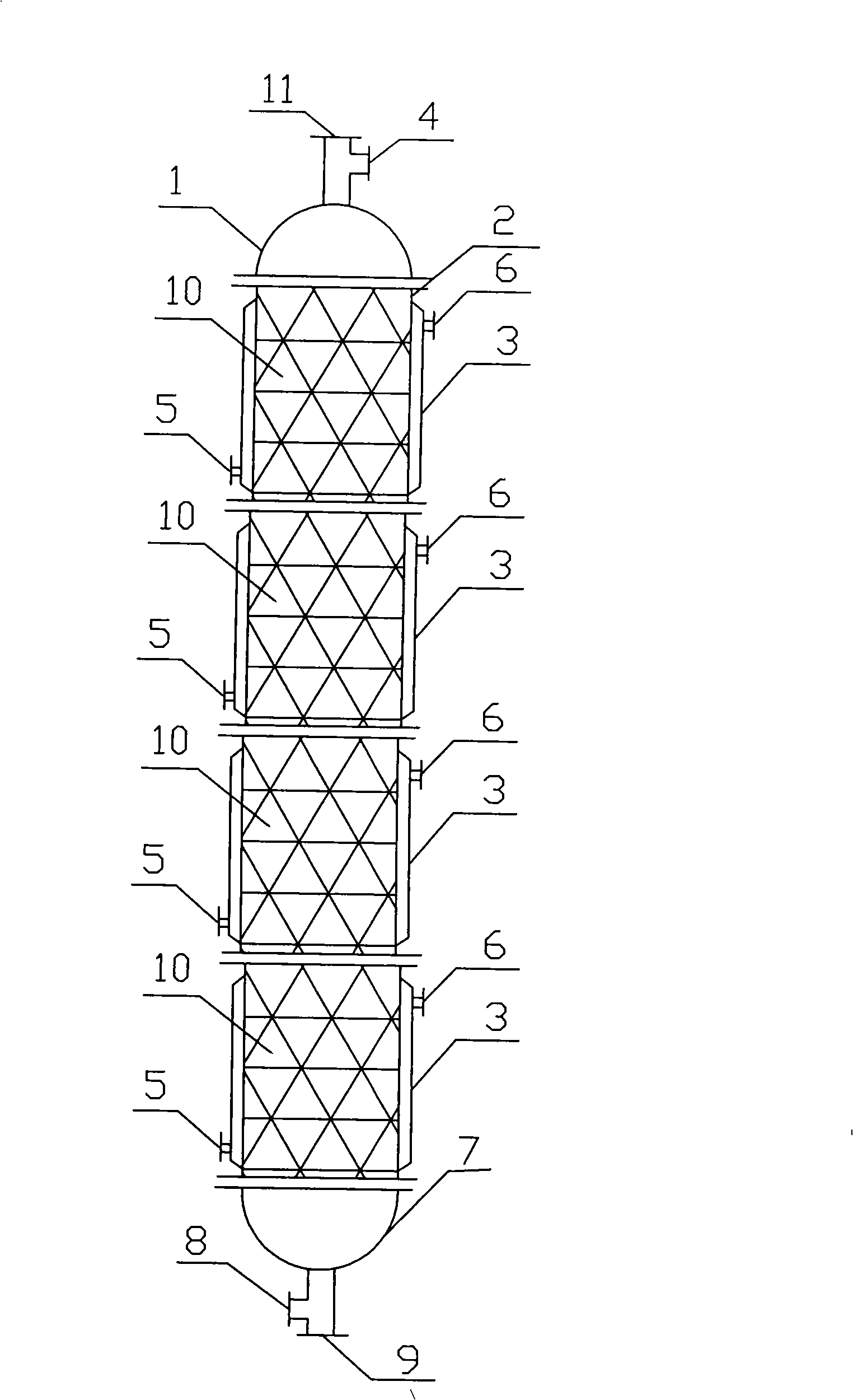

High-CO high-conversion-rate isothermal shift reactor

ActiveCN103435006BStable temperatureReduce the temperatureHydrogenEnergy inputNuclear engineeringSpray nozzle

An isothermal carbon monoxide (CO) shift reactor having high CO conversion and the process technology comprises the outside pressure vessel; the catalyst unit; tipper and lower tube sheets welded with water tubes and bottom tee joints; the said outside pressure vessel has seal heads at the upper and lower ends; the said vessel has a water chamber and a steam chamber at the upper section. The catalyst unit comprises the upper catalyst bed with water tubes. There is a central pipe that is located in the said vessel, of which the upper end is located in the upper catalyst bed while the lower end is located in the lower catalyst bed; the said bottom tee joint has an inlet for feed gas, outlet for reacted shift gas and inlet for steam-water mixture; the said central pipe is installed with spray nozzle for steam-water mixture; the said reactor is applicable for process technologies for feed and effluent gas having different CO contents. Low temperature, high CO feed content, high shift conversion and low system pressure drop are direct results of this disclosure.

Owner:HUNAN ANCHUN ADVANCED TECH

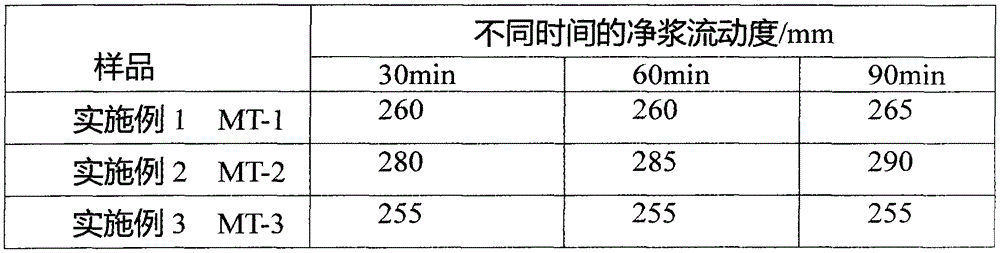

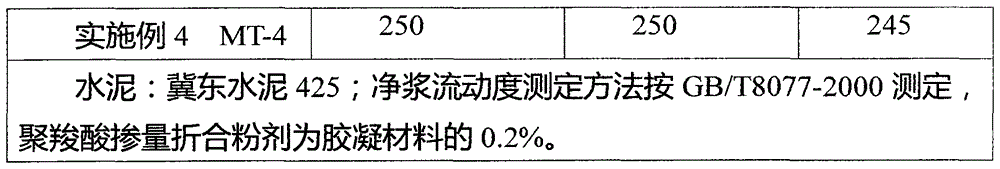

High-performance polycarboxylate superplasticizer and preparation method thereof

The invention discloses a high-performance polycarboxylate superplasticizer and a preparation method thereof. The high-performance polycarboxylate superplasticizer is prepared from, by weight, 350 parts of polycarboxylate superplasticizer macromonomers, 370-500 parts of deionized water, 40-55 parts of acrylic acid, a chain transfer agent and an initiator water solution, wherein addition quantity of the chain transfer agent is 0.01-1% of the total weight of methyl alkenyl polyethenoxy ether and acrylic acid, and concentration of the initiator water solution is 2-10%, and addition quantity of the initiator water solution is 0.01-3% of the total weight of methyl alkenyl polyethenoxy ether and acrylic acid. The high-performance polycarboxylate superplasticizer has advantages that reasonable process, low preparation cost and excellent service performances are achieved, and when mixing amount converted powder is 0.2-0.4% of a concrete cementing material, water reducing rate can reach 28%, 3d compressive strength is increased by 80-100%, and setting time is shortened evidently; high concrete workability, freeness of large bubbles, high concrete appearance quality, low alkali content, freeness of chloride ions and rebar corrosion and excellent anti-freeze and anti-carbonization performances are realized.

Owner:北京麦凯特科技有限公司

Process for preparing bromoundecanoic acid by tower type addition of undecylenic acid

InactiveCN101289379AConstant reaction temperatureLess side effectsOrganic compound preparationCarboxylic compound preparationSide effectHydrogen

The invention relates to an engineering plastic process for producing nylon-11 by caster oil, and particularly relates to a method of a tower-typed addition production of 11-bromoundecanoic acid by an undecylenic acid, which belongs to the process flow and solves the problems of interval operations, enormous settings, large engineering investment and bad economical benefits in the addition technology for processing an undecylenic acid bromine in the prior art. The undecylenic acid and toluene liquid are mixed into undecylenic acid toluene liquid according to the quality proportion of 1:3-4, which is sprayed into the tower from the tower top; meanwhile, hydrobromic gas is sent from the tower bottom continuously; the mol proportion of the undecylenic acid and the bromide hydrogen is 1:1-1.5, and the 11-bromoundecanoic acid is produced in the condition that the reaction temperature is controlled between 20 to 30 DEG C by the continuous reverse touching. The engineering plastic process has the advantages of constant reaction temperature, small side effect, steady quality of products, continuous operability, large potential of engineering enlargement, relatively and evidently small volume of a device, good investment benefits, simple structure and easy processing and manufacturing.

Owner:山西宏远科技股份有限公司

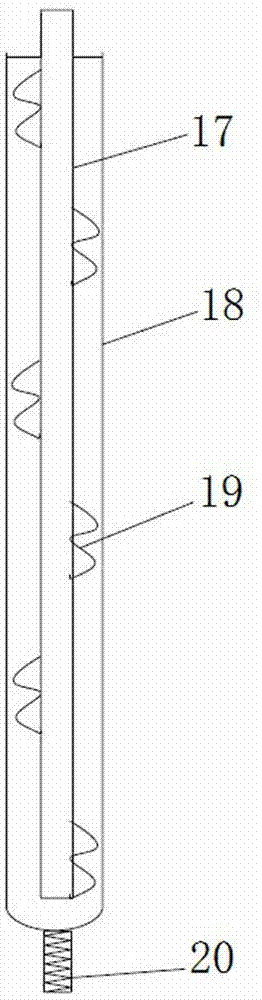

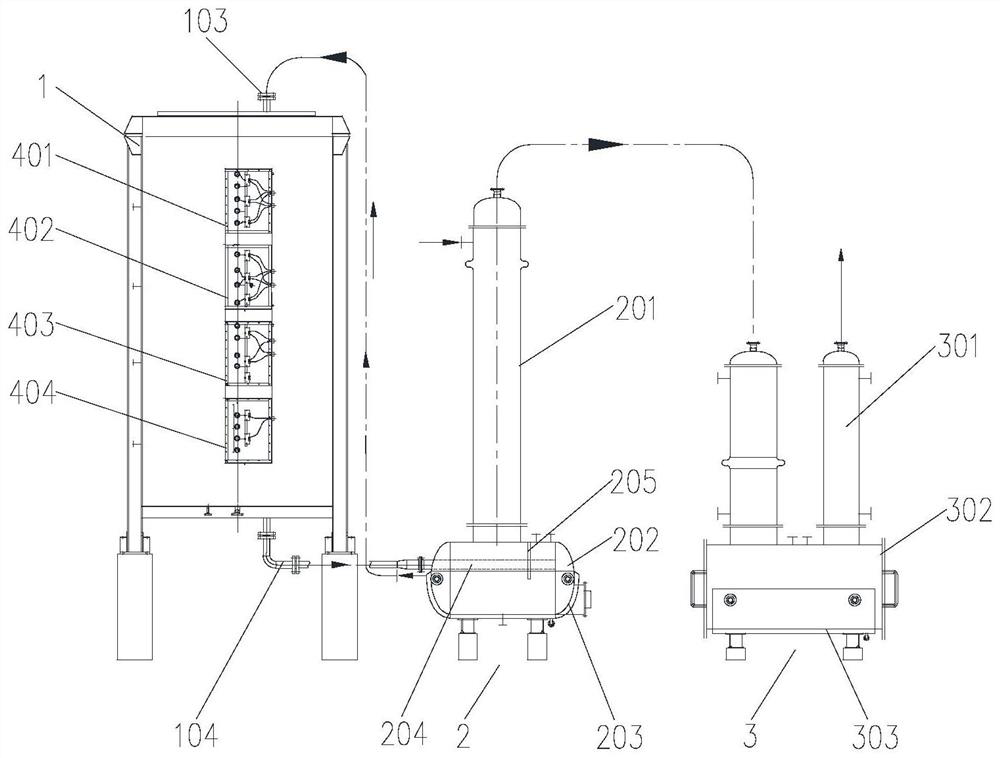

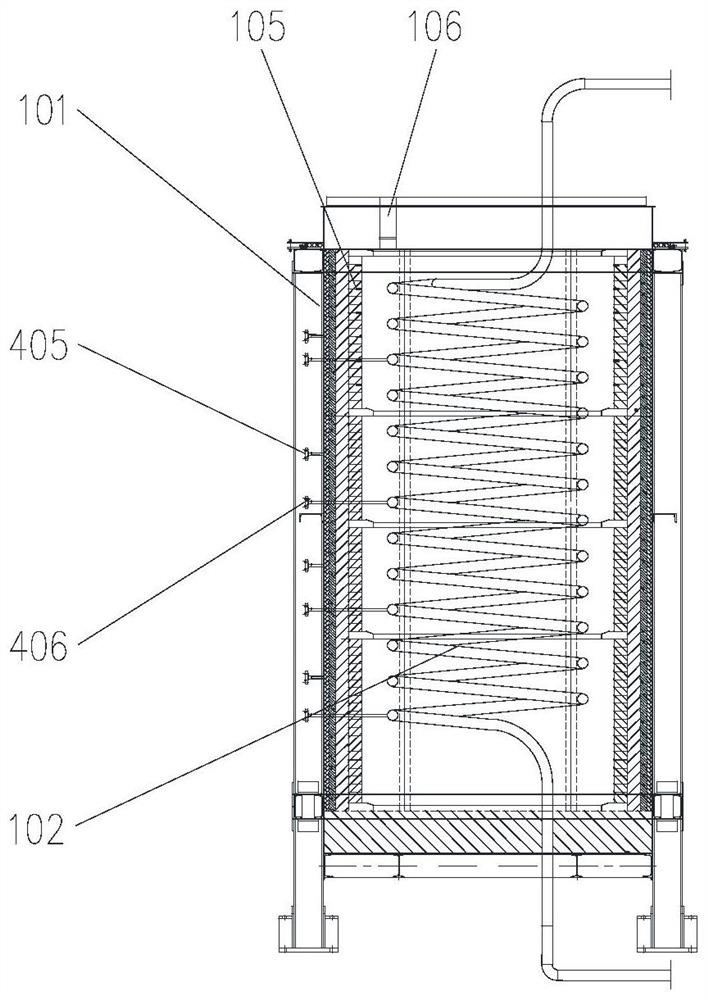

Novel anti-coking VDF cracking furnace system and using method thereof

ActiveCN113976046AEvenly heatedLess side effectsPreparation by hydrogen halide split-offFurnace safety devicesProcess engineeringThermal recovery

The invention discloses a novel anti-coking VDF cracking furnace system which comprises a cracking furnace, a waste heat recoverer and a quench cooler, wherein the cracking furnace is internally provided with a spiral furnace tube and partition heating devices from top to bottom; the waste heat recoverer comprises a first shell-and-tube heat exchanger and a first horizontal tank body, a first jacket is arranged outside the first horizontal tank body, a discharge port of the cracking furnace is communicated with the first horizontal tank body, a discharge port of the first horizontal tank body is communicated with a tube pass feed port of the first shell-and-tube heat exchanger, a cold material is introduced into a shell pass of the first shell-and-tube heat exchanger, a shell pass discharge port of the first shell-and-tube heat exchanger is communicated with a feed port of the first jacket, and a discharge port of the first jacket is communicated with a feed port of the cracking furnace; and the waste heat recoverer is connected with a feed port of the quench cooler, and a discharge port of the quench cooler is connected to a product collection process. The cracking furnace system can reduce coking in the cracking furnace tube and the heat exchanger pipeline, prolongs the cleaning period of the cracking furnace tube and the heat exchanger, preheats cold materials through the waste heat recoverer, and reduces energy consumption.

Owner:JIANGSU GELAN ENVIRONMENTAL TECH CO LTD

A new type of carbonate carbon and oxygen isotope sample preparation system and sample preparation method

ActiveCN105277401BHigh degree of automationGuaranteed normal injectionPreparing sample for investigationWater bathsAutosampler

The invention provides a novel sample preparation system for carbon and oxygen isotopes of carbonate and a sample preparation method thereof. The sample preparation system comprises an original sample reaction device, a finished sample extraction device and a system vacuum degree controlling device, wherein the original sample reaction device is connected with an autoinjection device. The sample preparation system employs the autoinjection device, so the automation degree of the sample preparation system is increased, and it is guaranteed that all the saturated phosphoric acid solution enters the bottom of a reaction tube and participates in a reaction; a touch button type vacuum valve is used to replace a conventional turn button type vacuum valve, so service life is prolonged, simplicity of usage of devices is improved, and operation time is shortened in preparation; and a constant temperature water-bath is added, vacuum-pumping and reaction can be completed in the devices in the same time, so a transfer step between vacuum-pumping and sample reaction is reduced. Moreover, the invention provides the sample preparation method of the novel sample preparation system. According to the invention, accuracy and the automation degree in preparation of a test sample are effectively improved, and standardized operational process is formed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com