Maleic acid anhydride series concrete water-reducing agent and preparation process thereof

A technology of concrete water reducing agent and maleic anhydride, which is applied in the field of preparation of maleic anhydride-based concrete water reducing agent, can solve the problems of harsh reaction conditions, unfavorable industrial production, high equipment requirements, etc., and achieve no large bubbles, antifreeze The effect of improved melting ability and simple feeding procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

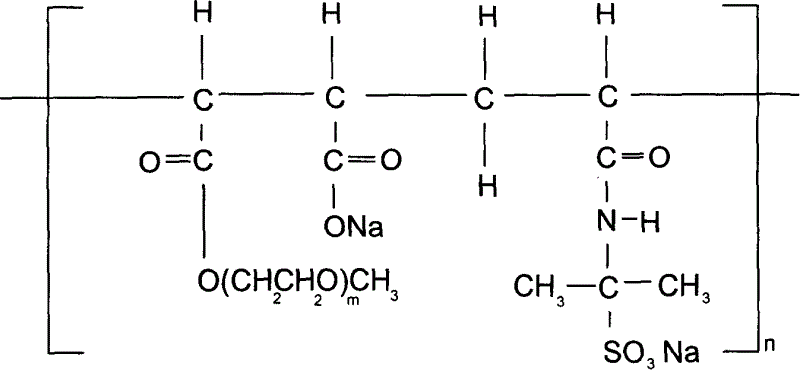

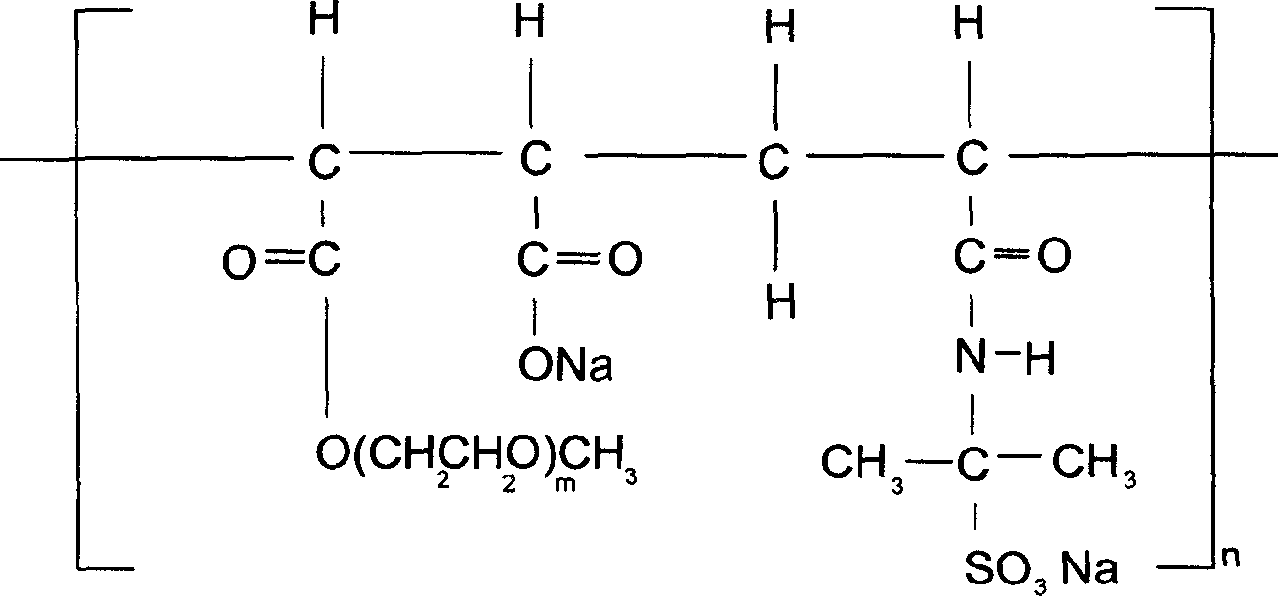

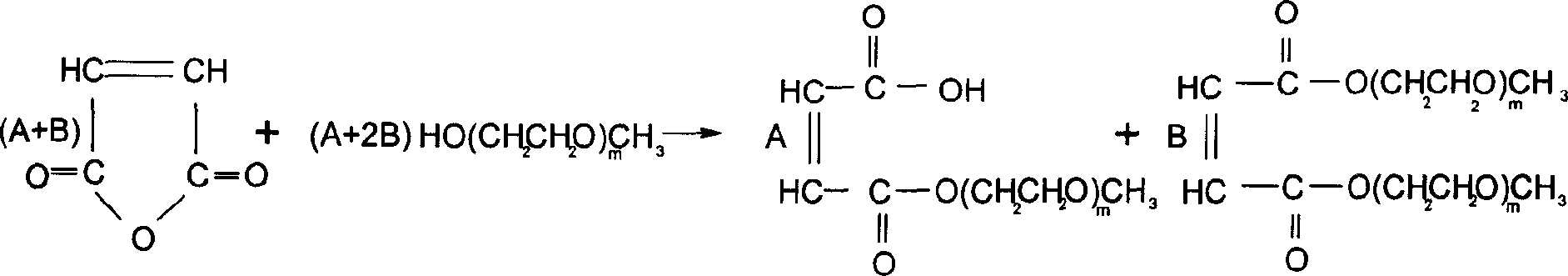

[0021] Synthesis of monomethoxypolyethylene glycol maleate and bismethoxypolyethylene glycol maleate macromers:

[0022] According to the amount of each material listed in Table 1, respectively weigh maleic anhydride, methoxypolyethylene glycol, hydroquinone, cuprous chloride, p-toluenesulfonic acid, toluene (see Table 1) and put them into a three-necked flask , stir and heat to 62.5±2.5°C, keep warm for 0.75±0.25 hours after the dissolution is complete, then slowly raise the temperature to 85±5°C, keep warm for 4.5±0.5 hours, then raise the temperature to 115±5°C, keep warm for 7±1 hours ; Cool to room temperature of 20±5°C, remove the solvent toluene, and obtain monomethoxy polyethylene glycol maleate and dimethoxy polyethylene glycol maleate macromonomer.

[0023] implement

Embodiment 8~12

[0025] Polymerization of maleic anhydride-based concrete water reducer:

[0026] According to the amount of each material listed in Table 2, take respectively monomethoxypolyethylene glycol maleate and bismethoxypolyethylene glycol maleate macromonomer, 2-acrylamide-2 methyl Propylsulfonate dissolving is mixed with the aqueous solution that mass concentration is 60%, as titration solution 1; Ammonium persulfate is taken and dissolved and is mixed with aqueous solution, as titration solution 2; Mercaptoethanol is taken and is mixed with aqueous solution, as titration solution 3 (each The amount of substances used is shown in Table 2). Put an appropriate amount of water in the three-necked flask, stir and heat, keep at 82.5±2.5°C, slowly titrate solution 1 and titrant solution 2, and start to slowly add titrant solution 3 about 0.4±0.1 hours after the polymerization reaction starts, and control the dropping speed, 3.0 After ±0.5 hours, all drops are completed; then keep warm fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com