Concrete water reducing agent of polyacrylic acid and its synthesis process

A concrete water-reducing agent and a polyacrylic acid-based technology, which are applied in the field of polyacrylic-based high-efficiency water-reducing agent and synthesis technology, can solve the problems of complex production process of water-reducing agent and high equipment requirements, and achieve good appearance quality and anti-segregation performance. Good, no bleeding line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

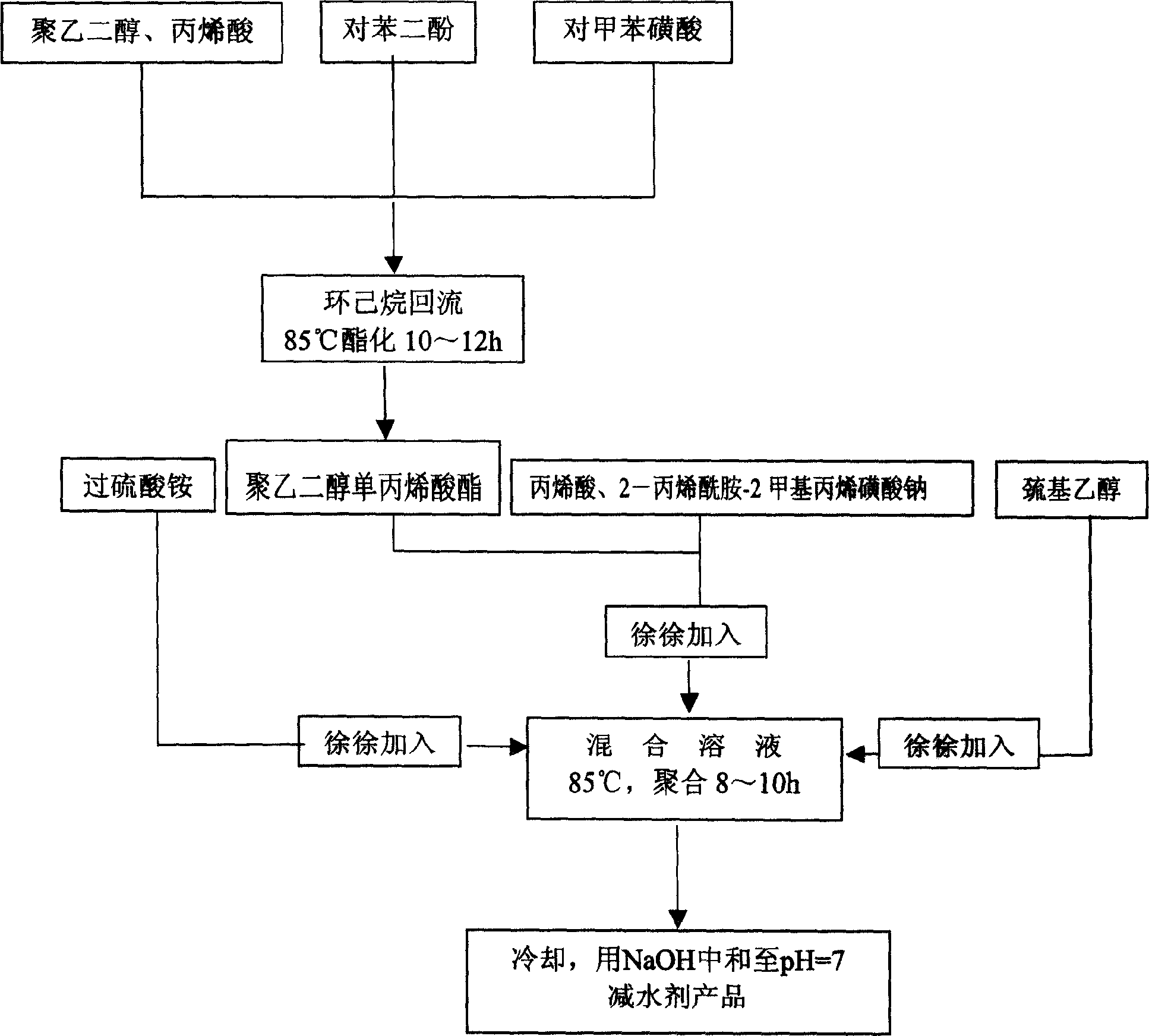

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1: Get the best matching ratio

[0052] Put 40.00 g of polyethylene glycol with a molecular weight of 400, 8.4 g of acrylic acid, 0.25 g of hydroquinone, 1.5 g of p-toluenesulfonic acid and 200 g of cyclohexane into a reaction vessel, stir at a temperature of 60° C. After diphenol and p-toluenesulfonic acid are completely dissolved, then keep the temperature at 80-90°C for 8 hours, then filter, vacuumize and remove cyclohexane to obtain polyethylene glycol monoacrylate; add 54.41g of water into a three-necked flask and The temperature is controlled at 85±5°C, and then 46.80g of the esterification product of the first step, 14g of acrylic acid and 9.16g of sodium 2-acrylamide-2-methylpropene sulfonate are added, and 54.41g of water is added to dissolve and mix until dripped. Dissolve 1.19 g of ammonium persulfate and 1.62 g of mercaptoethanol in 54.41 g, and add the three to the three-necked flask at a controlled rate dropwise, so that the drops are completed ...

Embodiment 2

[0054] Put 40.00g of polyethylene glycol with a molecular weight of 400, 10.5g of acrylic acid, 0.26g of hydroquinone, 2.65g of p-toluenesulfonic acid and 210g of cyclohexane into a reaction vessel, stir at a temperature of 60°C, and wait for p-toluenesulfonic acid to After diphenol and p-toluenesulfonic acid are completely dissolved, then keep the temperature at 80-90°C for 8 hours, then filter, vacuumize and remove cyclohexane to obtain polyethylene glycol monoacrylate; add 55.84 g of water into a three-necked flask and Control the temperature at 85±5°C, then add 46.80g of the first step esterification product, 14g of acrylic acid and 10.99g of sodium 2-acrylamide-2-methylpropene sulfonate, add 55.84g of water to dissolve and mix until dripping, then add water Dissolve 1.19 g of ammonium persulfate and 1.62 g of mercaptoethanol in 55.84 g, and add the three to the three-necked flask at a controlled rate dropwise, so that the drops are completed within 2 ± 0.5 hours, and the r...

Embodiment 3

[0056] Put 40.00g of polyethylene glycol with a molecular weight of 400, 8.4g of acrylic acid, 0.25g of hydroquinone, 1.51g of p-toluenesulfonic acid and 200g of cyclohexane into a reaction vessel, stir at a temperature of 60°C, and wait for p-toluenesulfonic acid to After the diphenol and p-toluenesulfonic acid are completely dissolved, then keep the temperature at 110-115°C and react for 8±0.5 hours, then filter, vacuumize and remove cyclohexane to obtain polyethylene glycol monomethacrylate; add 60.92g of water There is a three-necked flask and the temperature is controlled at 85±5°C, then add 46.80g of the esterification product of the first step, 22.36g of acrylic acid and 9.16g of sodium 2-acrylamide-2-methylpropenesulfonate, and add 60.92g of water to dissolve them Mix, dissolve 1.19 g of ammonium persulfate and 1.62 g of mercaptoethanol in 60.92 g of water, and add the three to the three-necked flask at a controlled rate dropwise, so that the drops are completed within ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com