High-performance polycarboxylate superplasticizer and preparation method thereof

A technology of polycarboxylate and water reducer, which is applied in the field of high-performance polycarboxylate water reducer and its preparation, can solve the problems of long reaction cycle time, increased production cost, long production cycle, etc. Improved compressive strength and strong product adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

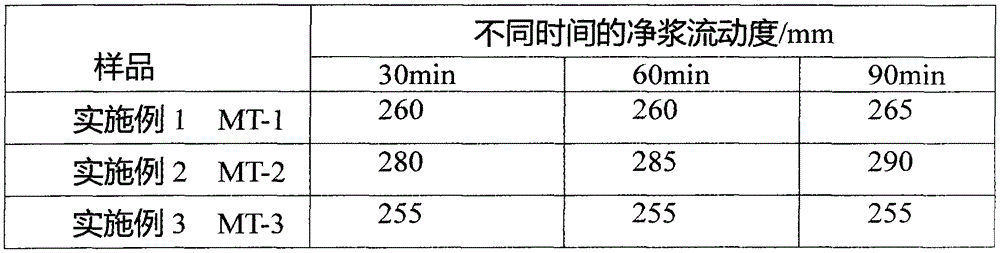

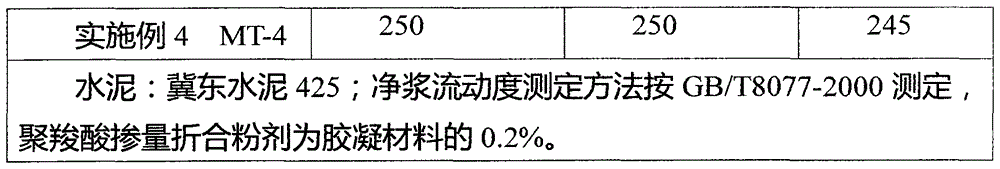

[0020] Put 350 parts of methyl alkenyl polyoxyethylene ether (molecular weight 2400) and 370 parts of deionized water into the reactor, stir and heat up, and keep stirring at a temperature of 50-60°C to completely dissolve the reactants, and then add Put 55 parts of acrylic acid and 3 parts of mercaptopropionic acid into the container at one time, and add 200 parts of 2% ammonium persulfate aqueous solution dropwise at the same time. The dropping time is 1.5 hours. The high-performance polycarboxylate water reducer of the present invention can be prepared by adjusting the pH of the solution to 5-6 with aqueous sodium hydroxide solution, marked as MT-1. The experimental data are shown in Table 1 and Table 2 of the example experimental data.

Embodiment 2

[0022] Put 350 parts of methyl alkenyl polyoxyethylene ether (molecular weight 2400) and 450 parts of deionized water into the reactor, stir and heat up, and keep stirring at a temperature of 50-60°C to completely dissolve the reactants, and then add Put 40 parts of acrylic acid and 4 parts of mercaptopropionic acid into the container at one time, and add 150 parts of 5% ammonium persulfate aqueous solution dropwise at the same time. The dropping time is 100 minutes. Sodium hydroxide aqueous solution adjusts the pH of the solution to 5-6, and the high-performance polycarboxylate water reducer of the present invention can be prepared, marked as MT-2. The experimental data are shown in Table 1 and Table 2 of the example experimental data.

Embodiment 3

[0024] Put 350 parts of methyl alkenyl polyoxyethylene ether (molecular weight 2400) and 400 parts of deionized water into the reactor, stir and heat up, and keep stirring at a temperature of 50-60°C to completely dissolve the reactants, and then add Put 45 parts of acrylic acid and 3 parts of mercaptopropionic acid into the container at one time, and add 100 parts of 8% ammonium persulfate aqueous solution dropwise at the same time. The dropping time is 80 minutes. Sodium hydroxide aqueous solution adjusts the pH of the solution to 5-6, and the high-performance polycarboxylate water reducer of the present invention can be prepared, which is marked as MT-3. The experimental data are shown in Table 1 and Table 2 of the example experimental data.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com