Patents

Literature

39results about How to "Reduced pumping resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

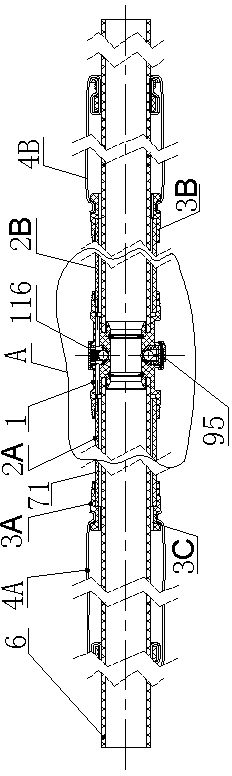

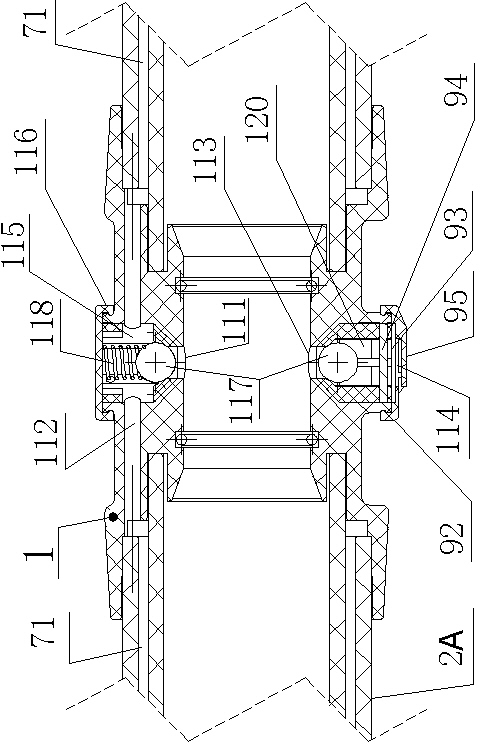

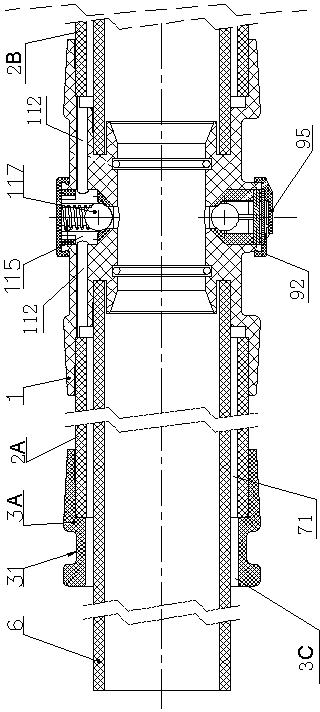

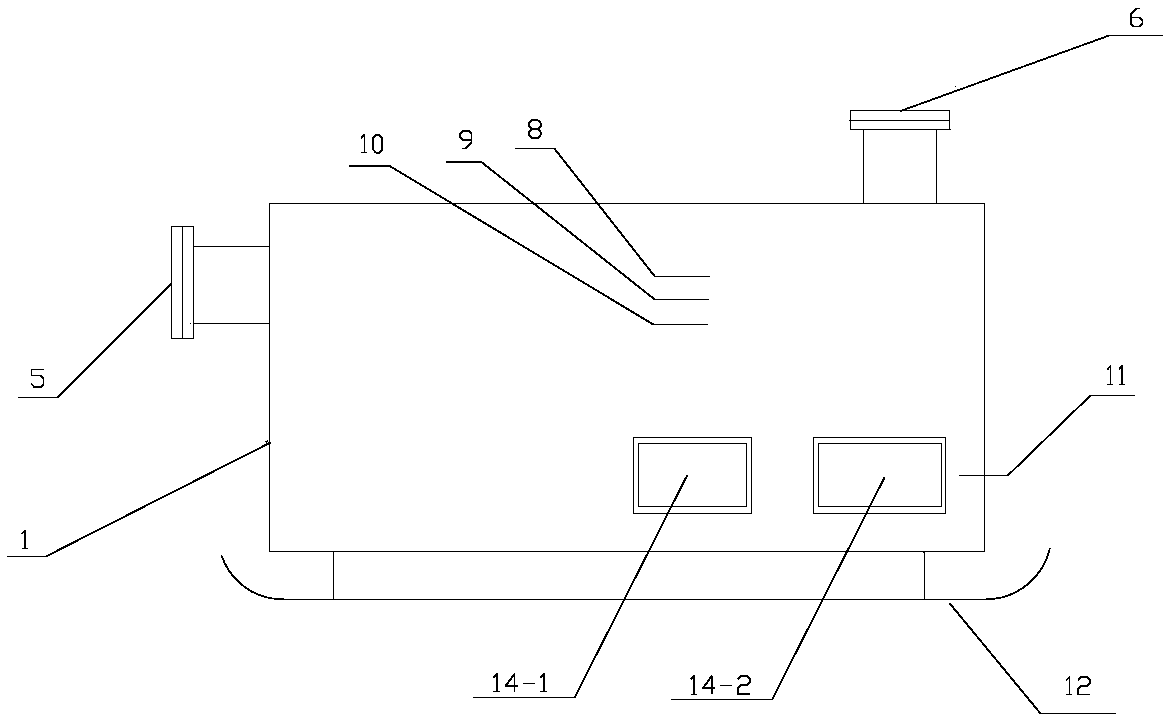

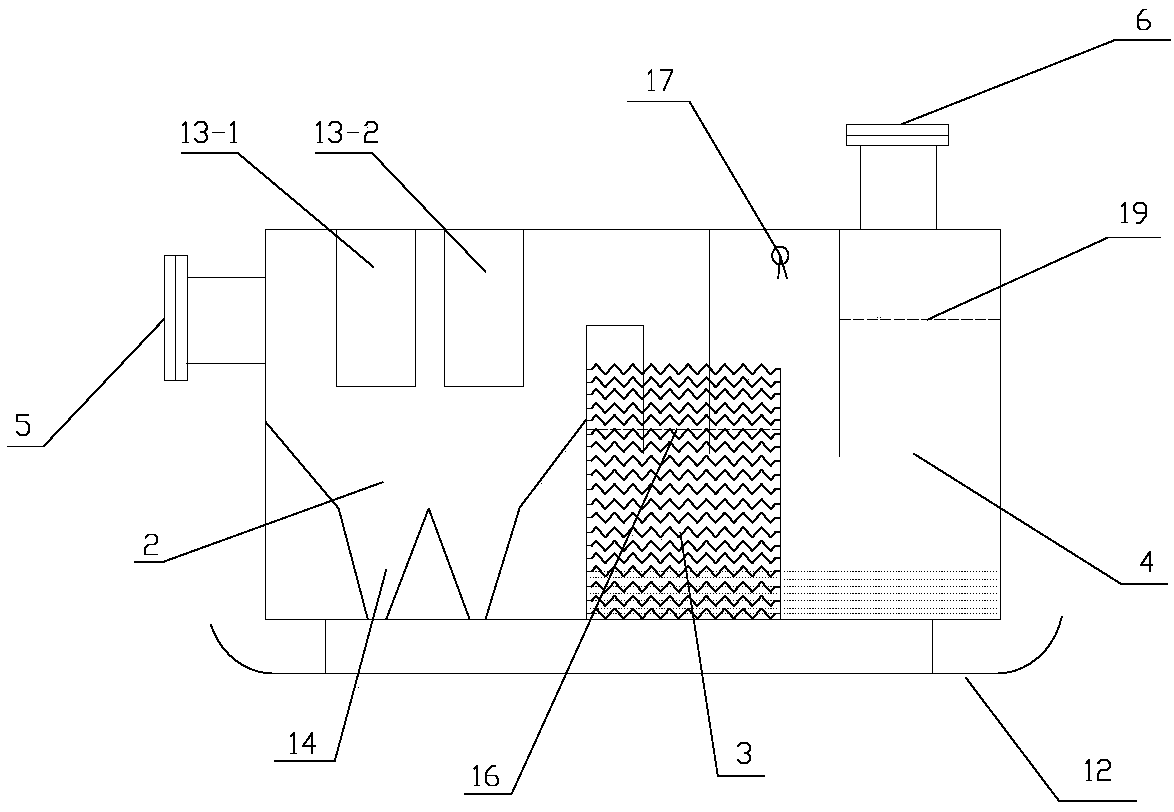

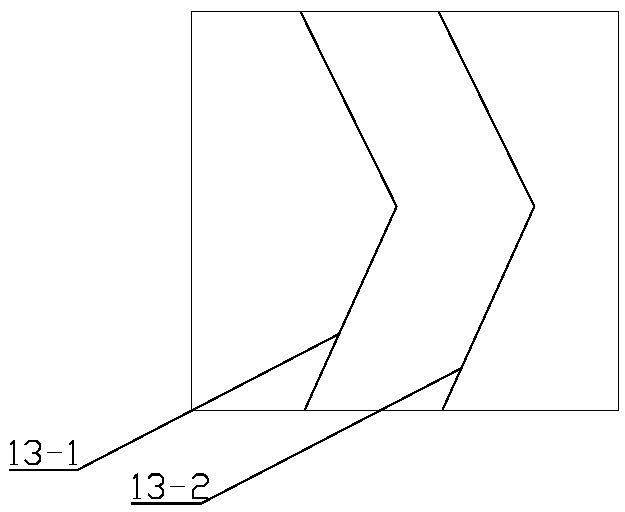

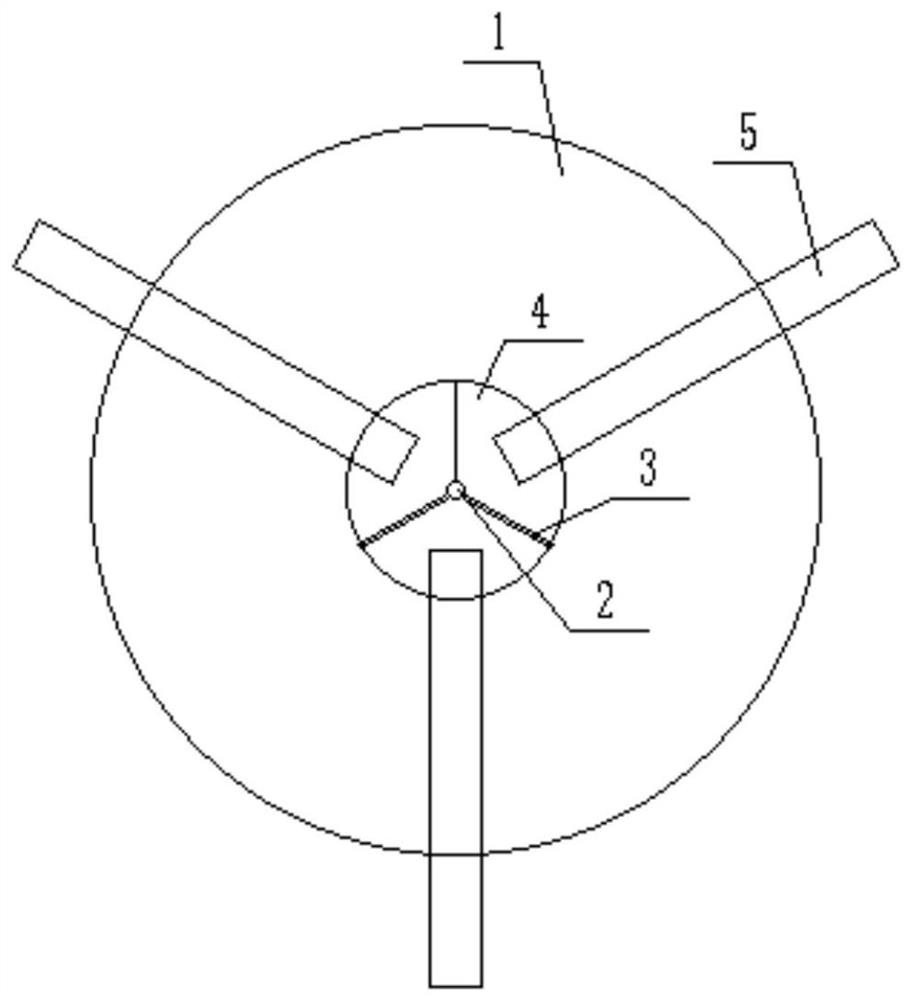

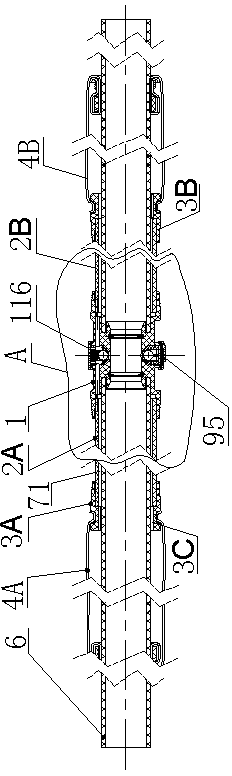

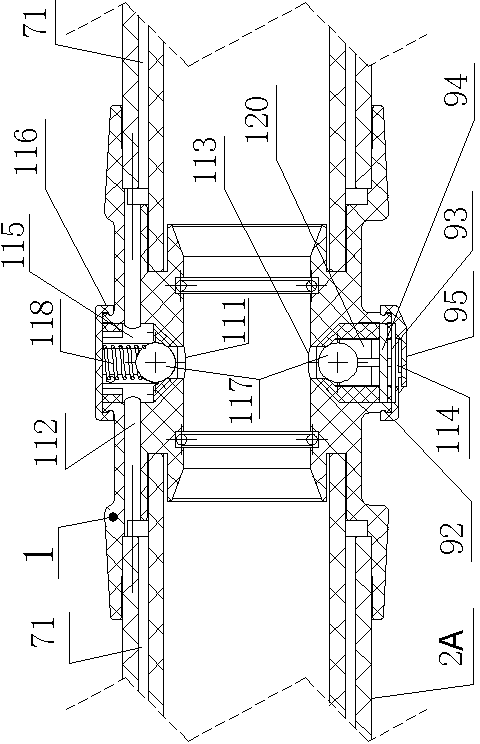

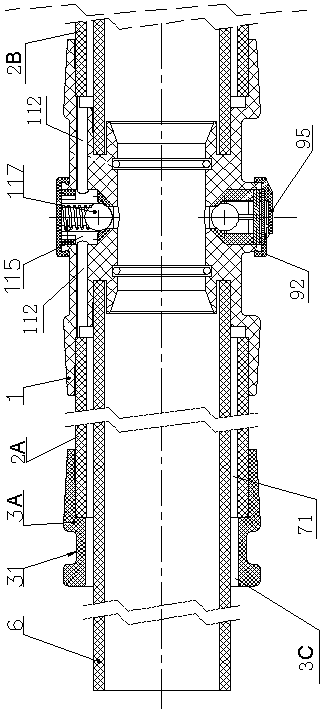

Gas extraction center divided-flow type grouting and hole sealing device and hole sealing method

InactiveCN102200024AReduced pumping resistanceQuality improvementGas removalSealing/packingEngineeringSlurry

The invention discloses a gas extraction center divided-flow type grouting and hole sealing device which comprises an extraction pipe, a grouting plug, a left bag and a right bag, wherein the extraction pipe penetrates through the left bag and the right bag, a multifunctional valve is arranged in the extraction pipe, and the left side and the right side of the multifunctional valve are respectively connected with a left flow division pipe and a right flow division pipe; the left flow division pipe and the right flow division pipe are both sheathed on the extraction pipe, and the inner diameter of the left flow division pipe and that of the right flow division pipe are both greater than that of the extraction pipe so as to form a slurry passage among the left flow division pipe, the right flow division pipe and the extraction pipe; and a grouting insertion pipe is inserted into the extraction pipe. Through the gas extraction center divided-flow type grouting and hole sealing device, more effective grouting and hole sealing of drilling holes in the hole sealing section can be realized, and the generation and the propagation of leakage cracks around the drilling holes can be better prevented. The invention also provides a hole sealing method by using the gas extraction center divided-flow type grouting and hole sealing device. Through the method, high stress regions are produced around the drilling holes in the hole sealing section, the permeability of coal around the drilling holes in the hole sealing section is reduced, and the purpose of effectively grouting and sealing the drilling holes in the hole sealing section is realized.

Owner:HENAN POLYTECHNIC UNIV

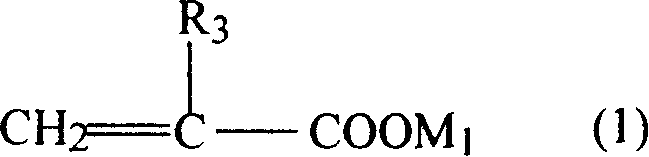

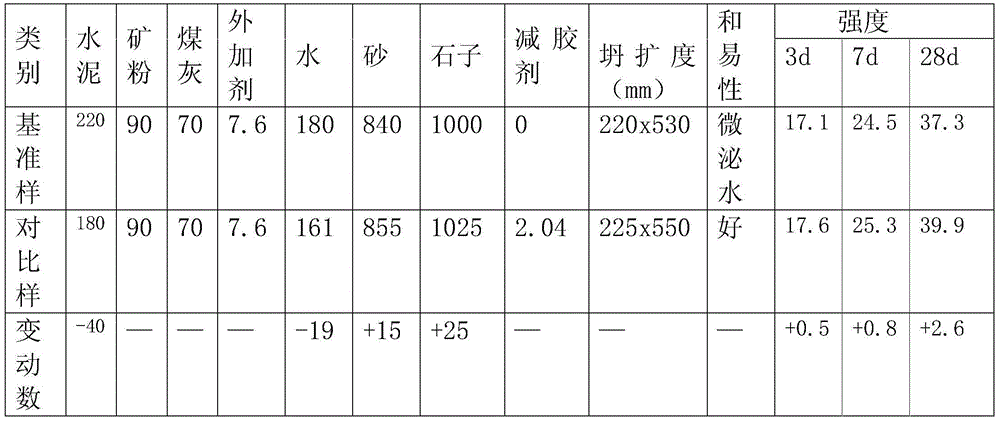

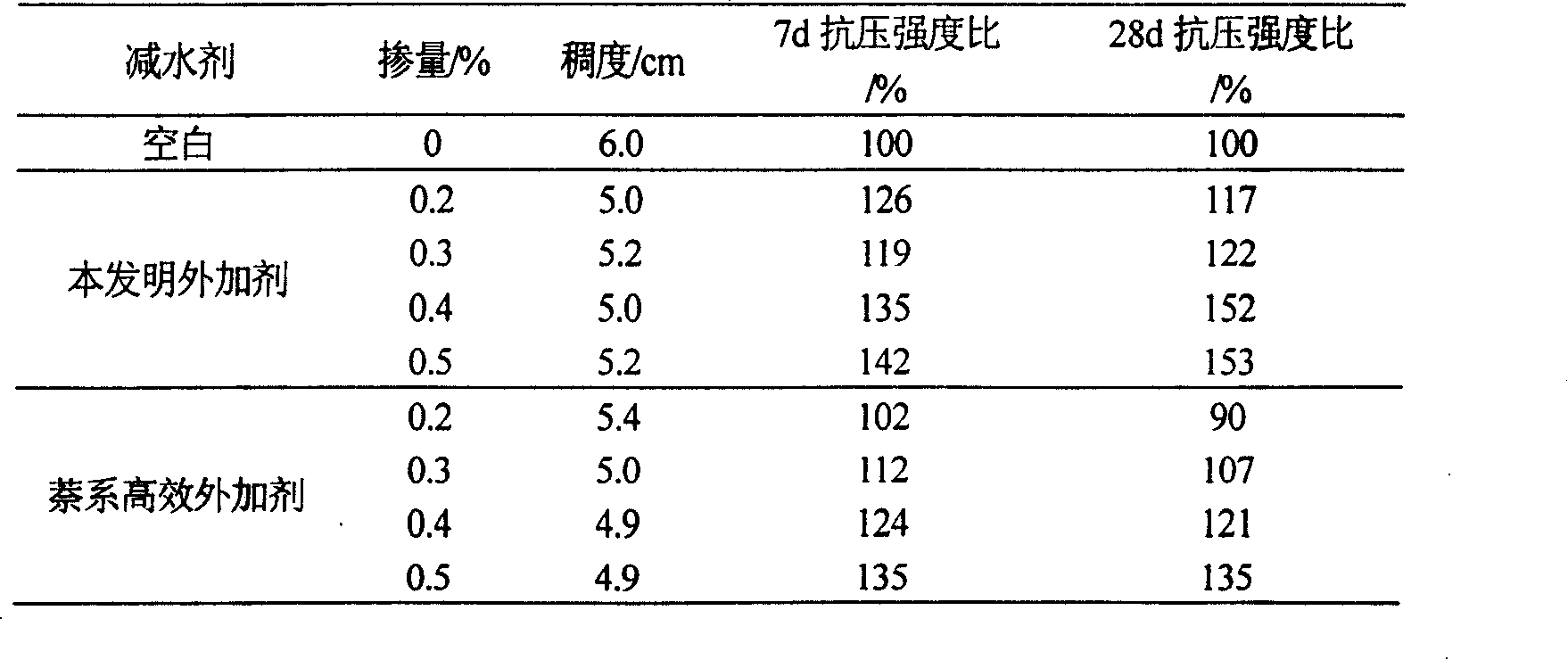

Multifunctional carboxylic-acid comb-shape graft copolymer concrete superplasticizer

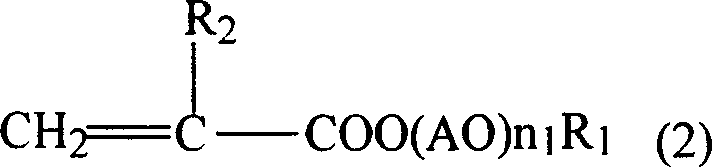

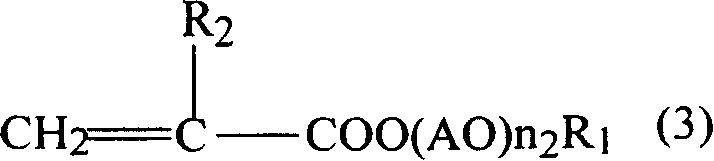

The multifunctional super concrete plasticizing agent of carboxylic acid comb grafting copolymer is prepared through the water free radical copolymerization of the following monomers: monomer A with the general expression I in 10-40 wt%, monomer B with the general expression II in 30-70 wt%, monomer C with the general expression III in 10-50 wt%, monomer D with the general expression IV in 3-15 wt%, monomer F with the general expression VI in 0-15 wt%, and reactive defoaming agent E in 0.2-2 wt% of the sum of foregoing five kinds of monomer. The present invention can reduce the shrinkage of concrete, and has good adaptability on cement and admixture material, good dispersivity and slump maintaining performance, high weeping resistance and resolution resistance, small pumping drag, product yield near 100 % and no waste produced in the production process.

Owner:JIANGSU SOBUTE NEW MATERIALS

Concrete synergist and preparation method for same

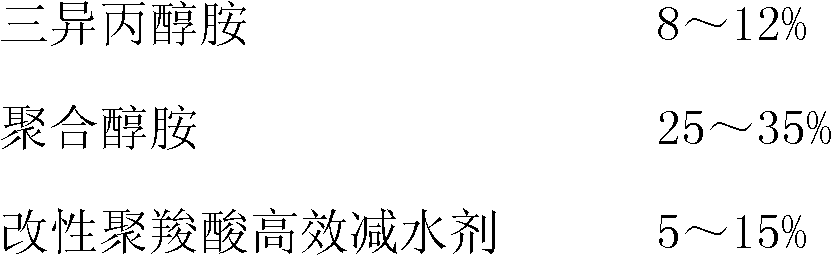

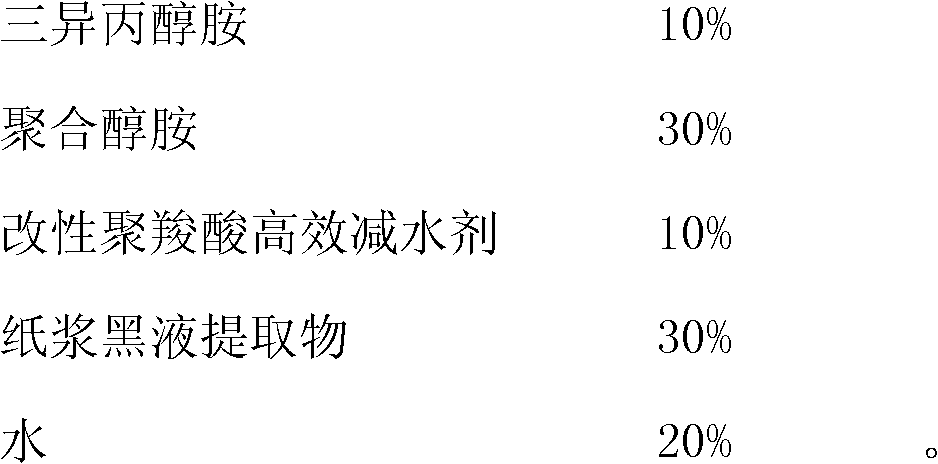

The invention relates to concrete synergist. Components of the concrete synergist, mixed by weight, include 8%-12% of triisopropanolamine, 25%-35% of polymeric alkylol amine, 5%-15% of modified polycarboxylic acid water reducer, 25%-35% of black liquor extractive and water. The concrete synergist, which is prepared by means of scientific proportioning and mixing of all components, is non-poisonous, free of abnormal odor, green and healthy. When concrete added with the concrete synergist is compared with traditional concrete, a concrete grade is increased on the premise of the same consumption, and 10%-15% of cement consumption is reduced on the premise of the same grade, so that pumping resistance is small during conveyance, workability of the concrete is improved, the concrete is resistant to bleeding, concrete cracks are decreased, all components of the concrete are more disperse, and the concrete is integrally uniform after hardening.

Owner:TIANJIN DAR TECH

Polymer repairing mortar and preparation method thereof

The invention discloses a polymer repairing mortar. The polymer repairing mortar comprises 400-500 parts of cement, 500-600 parts of quartz sand, 1-5 parts of a high-molecular polymer, 5-15 parts of a polymer, 1-5 parts of silicon micropowder and 0.1-0.3 parts of wood fiber, wherein the high-molecular polymer is cellulose ether, and the polymer is re-dispersible latex powder. The purpose of the invention is to provide the polymer repairing mortar with the characteristic of long service life and no cracking, and a preparation method thereof.

Owner:浙江泰正建材有限公司

Dry-mixed mortar prepared from industrial solid waste

The invention provides dry-mixed mortar prepared from industrial solid waste. The dry-mixed mortar is characterized by being prepared from materials in parts by weight as follows: 100 parts of cement, 300-400 parts of river sand, 50-100 parts of steel slag, 0-50 parts of iron mine tailings, 0-50 parts of glass powder, 1-2 parts of an interface reinforcing agent, 1-2 parts of an exciting agent, 0.1-0.5 parts of a water retaining agent, 1-2 parts of a water reducing agent and 0.1-0.3 parts of reinforcing fibers. According to the dry-mixed mortar, the industrial solid waste is fully utilized as aggregate to replace natural river sand, environmental protection is facilitated, resource recycling is realized, and meanwhile, performance such as the freezing resistance, the permeability resistance and the like of the dry-mixed mortar is improved through addition of the industrial solid waste.

Owner:四川震强建筑材料有限责任公司

Improved Venetian plaster and application thereof

The invention relates to improved Venetian plaster and the application thereof. The improved Venetian plaster comprises the following components in parts by weight: 20-50 parts of sulphoaluminate cement, 20-35 parts of Portland cement, 0.2-1 part of water reducer, 1.5-4 parts of silica fume, 1-4 parts of slag powder, 1-3 parts of coal ash, 0.1-1 part of thickener, 1-4 parts of redispersible powder, 20-35 parts of silica sand powder, 0-5 parts of organic color paste and 0-5 parts of inorganic color powder, wherein the ratios of the slag powder and coal ash to the total weight are both greater than or equal to 2%. The improved Venetian plaster disclosed by the invention has good water resistance, oil resistance and weather fastness, is safe, environment-friendly, durable, elegant and luxury, has unique artistic decoration effect, can replace traditional coating and tiles, and can be applied to inner wall decoration of buildings.

Owner:湖南交泰建材有限公司

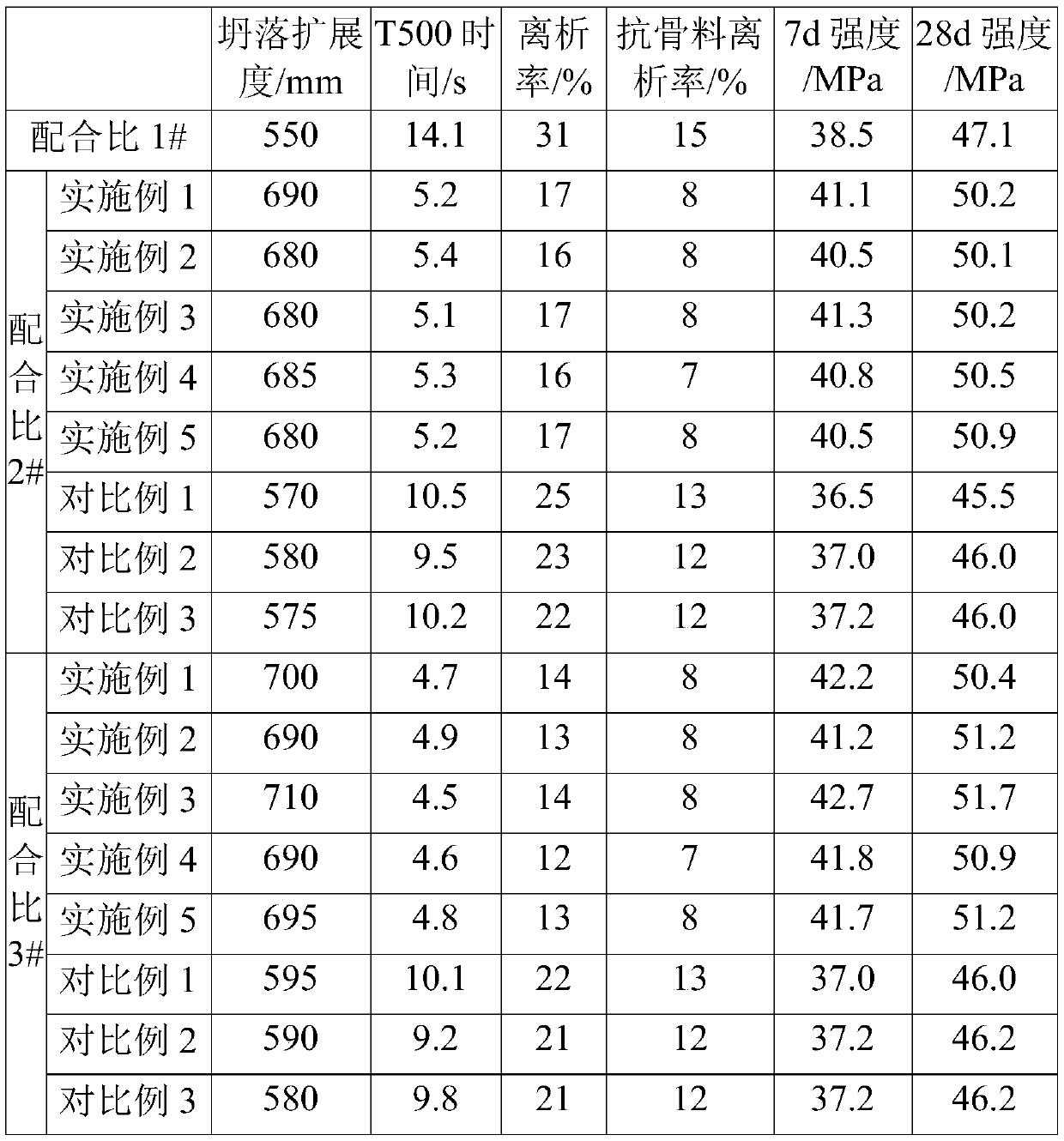

C60 pumping concrete and preparation method thereof

The invention discloses C60 pumping concrete and a preparation method thereof. According to the technical scheme, the C60 pumping concrete is characterized by being prepared from the following components in parts by weight: 400 to 420 parts of cement, 130 to 150 parts of an admixture, 690 to 710 parts of a fine aggregate, 960 to 980 parts of a coarse aggregate, 8 to 10 parts of an admixture and 160 to 170 parts of water, wherein the fine aggregate is formed by mixing river sand and machine-made sand in a weight ratio of 3:7, the fineness modulus of the river sand is 0.9-1.1, and the fineness modulus of the machine-made sand is 2.8-2.9; the coarse aggregate is formed by mixing large pebbles and small pebbles in a weight ratio of 6.5:3.5, the particle size of the large pebbles is 10-20 mm, the mud content of the large pebbles is smaller than 0.5%, the particle size of the small pebbles is 5-10 mm, and the mud content of the small pebbles is smaller than 0.6%. The pumping concrete has theadvantages of being high in compressive strength, good in workability and high in pumping height.

Owner:重庆华西易通建设股份有限公司

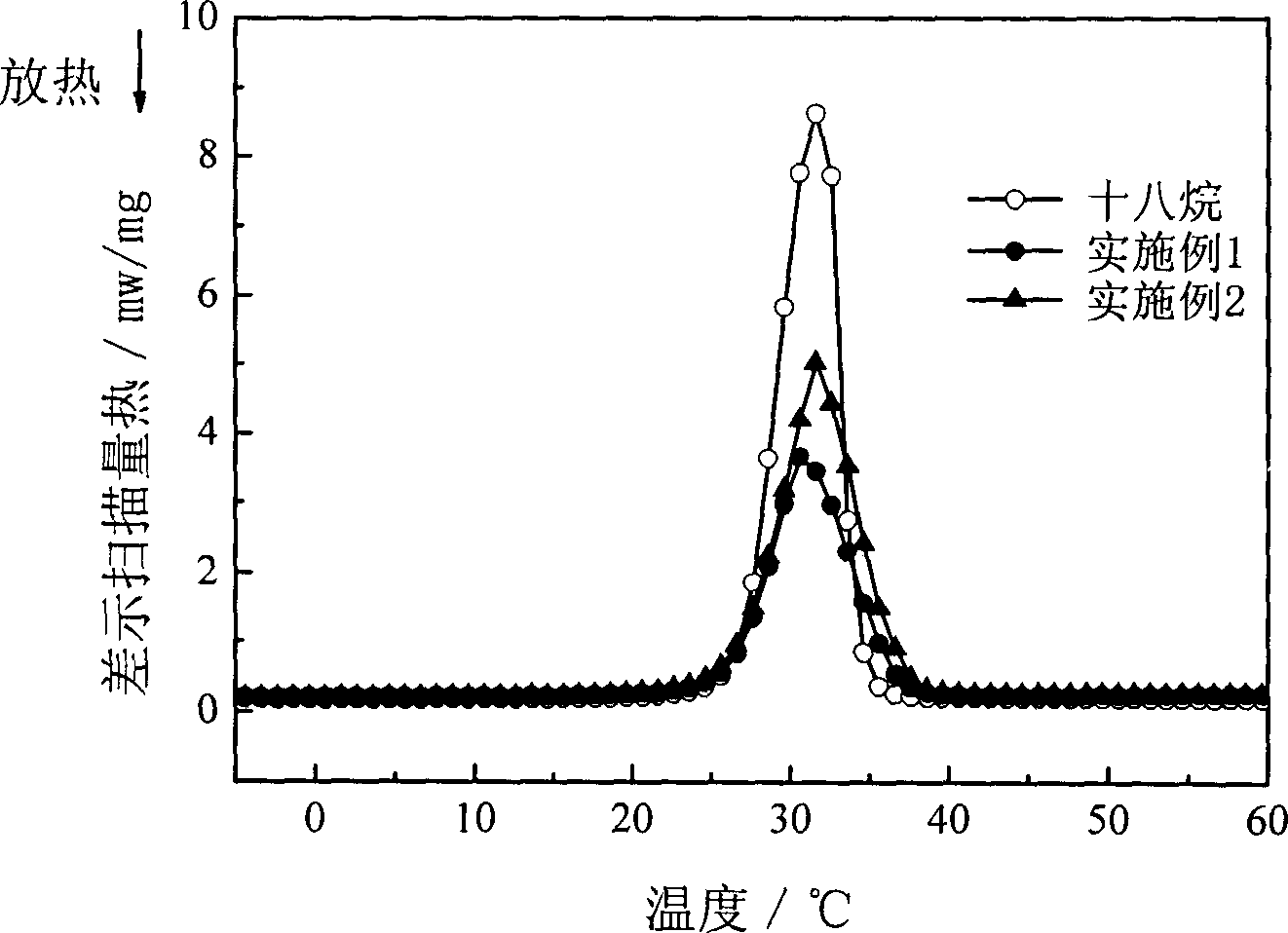

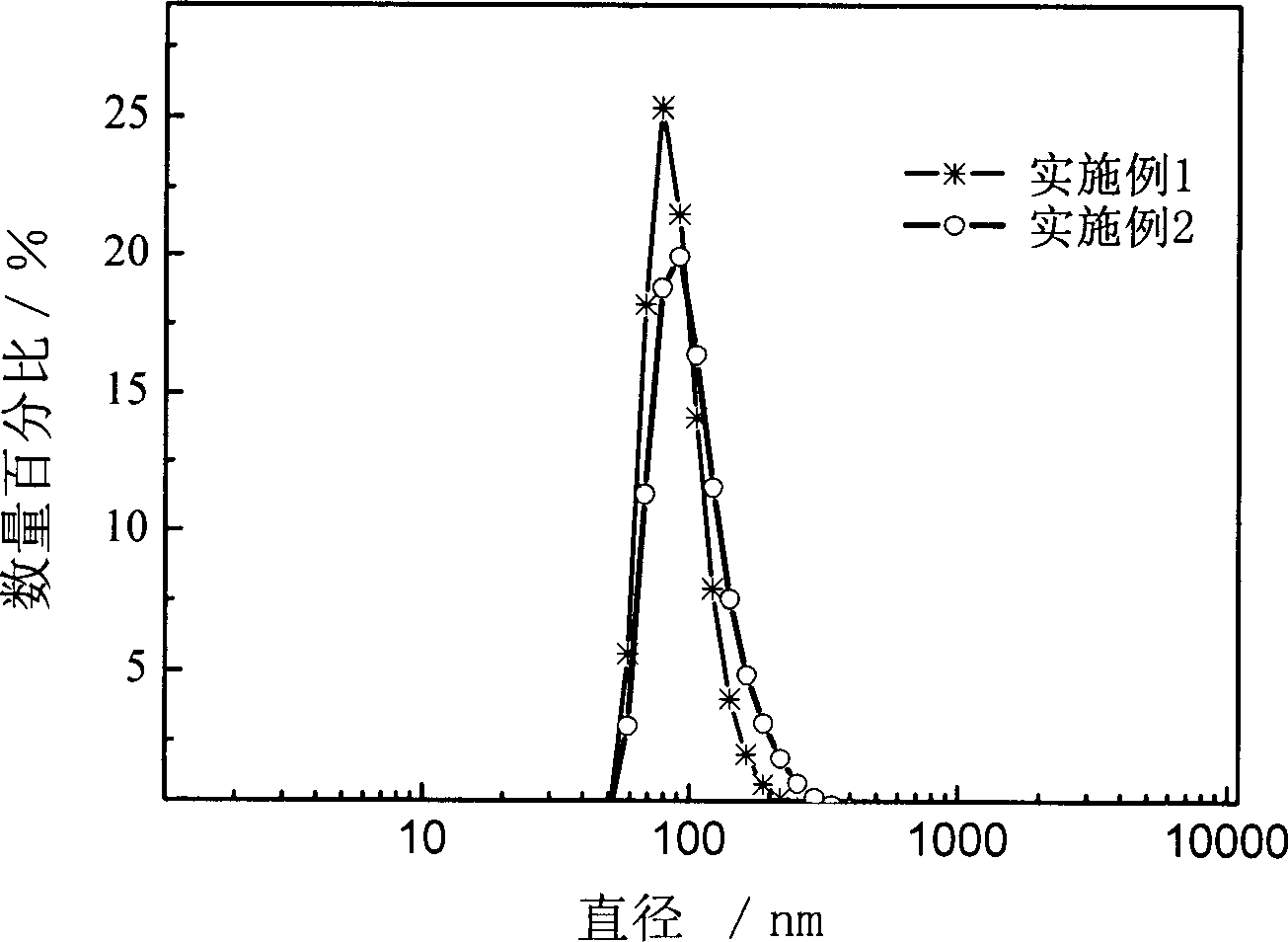

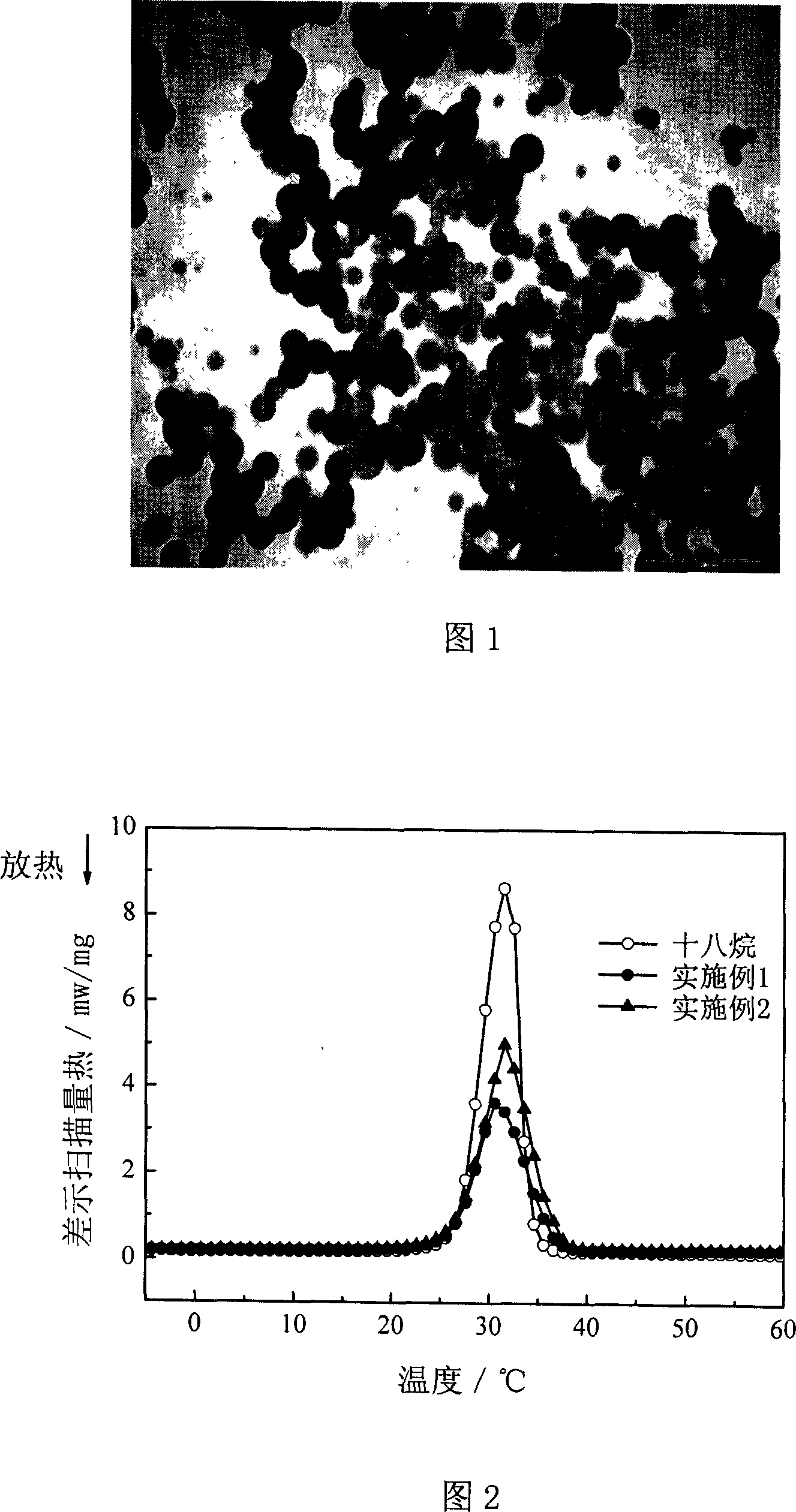

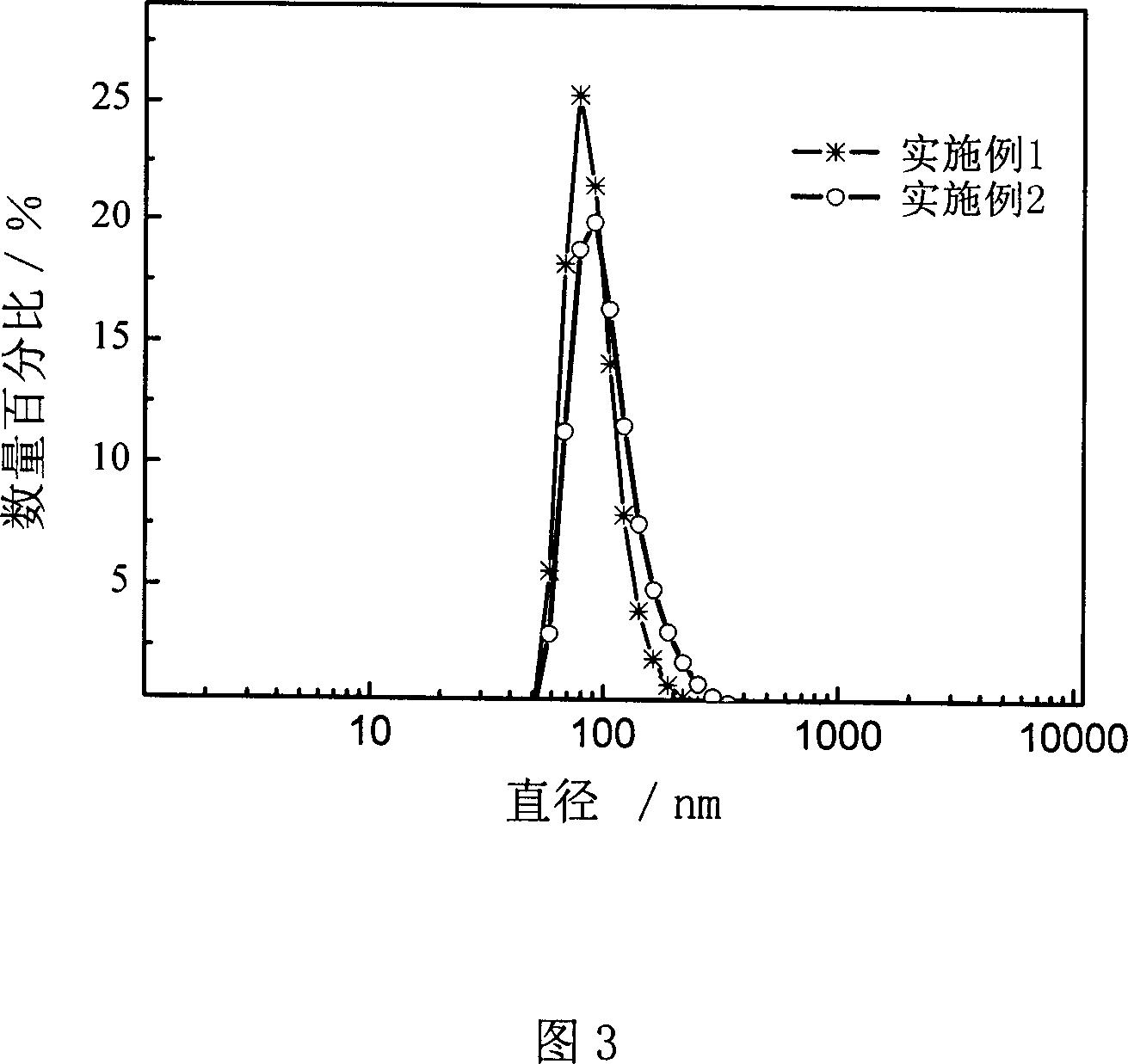

Process for preparing nano capsule phase change material emulsion

InactiveCN1900209ASmall particle sizeUniform dispersionHeat-exchange elementsAlkanePhase change enthalpy

The process of preparing nanometer capsule phase change material emulsion includes adding the oil phase liquid compounded with olefin monomer, hydrophilic monomer, alkane, initiator and n-lauryl mercaptan into the mixed liquid of emulsifier and deionized water via stirring and ultrasonic dispersing to obtain micro emulsion, introducing nitrogen to the micro emulsion system to eliminate oxygen via stirring, reflux condensing, heating to 65 deg.c and constant temperature polymerization reaction for 5 hr, and cooling naturally to room temperature to obtain the nanometer capsule phase change material emulsion. Thus prepared nanometer capsule phase change material emulsion has nanometer size, stable performance, great phase change enthalpy and wide application in latent heat functional hot fluid, heat accumulating and temperature regulating fabric, energy saving building wall and other fields.

Owner:SOUTH CHINA UNIV OF TECH

High-temperature annular protection sealing liquid for water injection well

ActiveCN103289661AReasonable designSimple preparation processDrilling compositionPotassium ferricyanidePhenol

The invention discloses a high-temperature annular protection sealing liquid for a water injection well. A base fluid is prepared from the following compositions in percentage by weight: 3.5-10% of gelatinizing agent, 0.5-3% of crosslinking agent A, 0.3-1.0% of crosslinking agent B, 0.006-0.015% of initiator, 0.001-0.006% of modifier, and the balance of water, wherein the gelatinizing agent is acrylamide, the crosslinking agent A is formaldehyde, the crosslinking agent B is phenol, the initiator is azodiisobutyronitrile, and the modifier is potassium ferricyanide. The sealing liquid is prepared by the step of crosslinking the base fluid at 70-90DEG C for 4-8 hours or at 100-130DEG C for 1.5-3 hours. According to the high-temperature annular protection sealing liquid for the water injection well, the manufacture and usage cost is low, the construction is safe and reliable, the annular protection effect for the water injection well is obvious, and the oilfield exploitation production cost can be greatly lowered.

Owner:中国石油化工股份有限公司华东油气分公司泰州采油厂

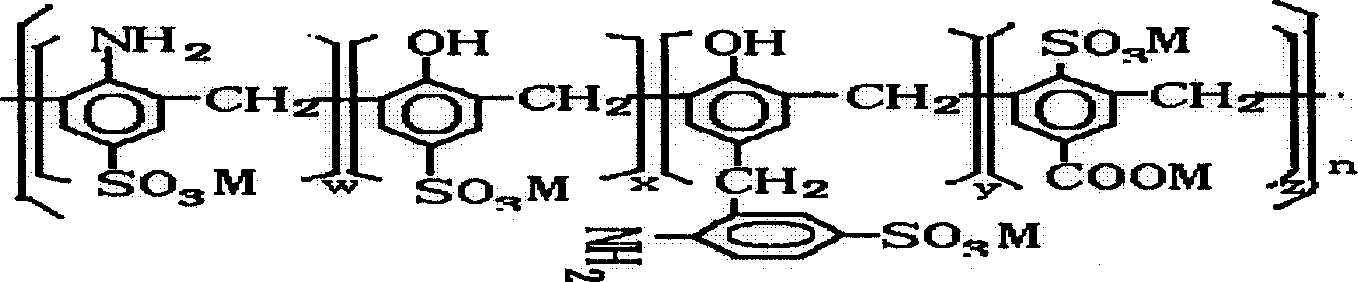

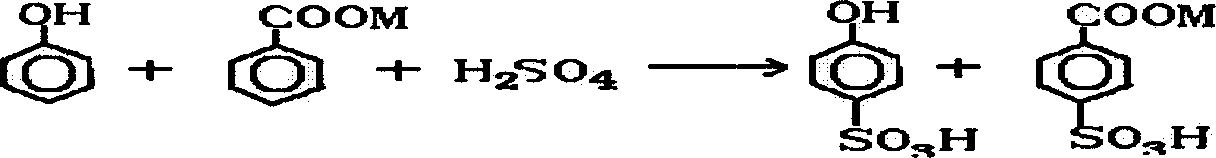

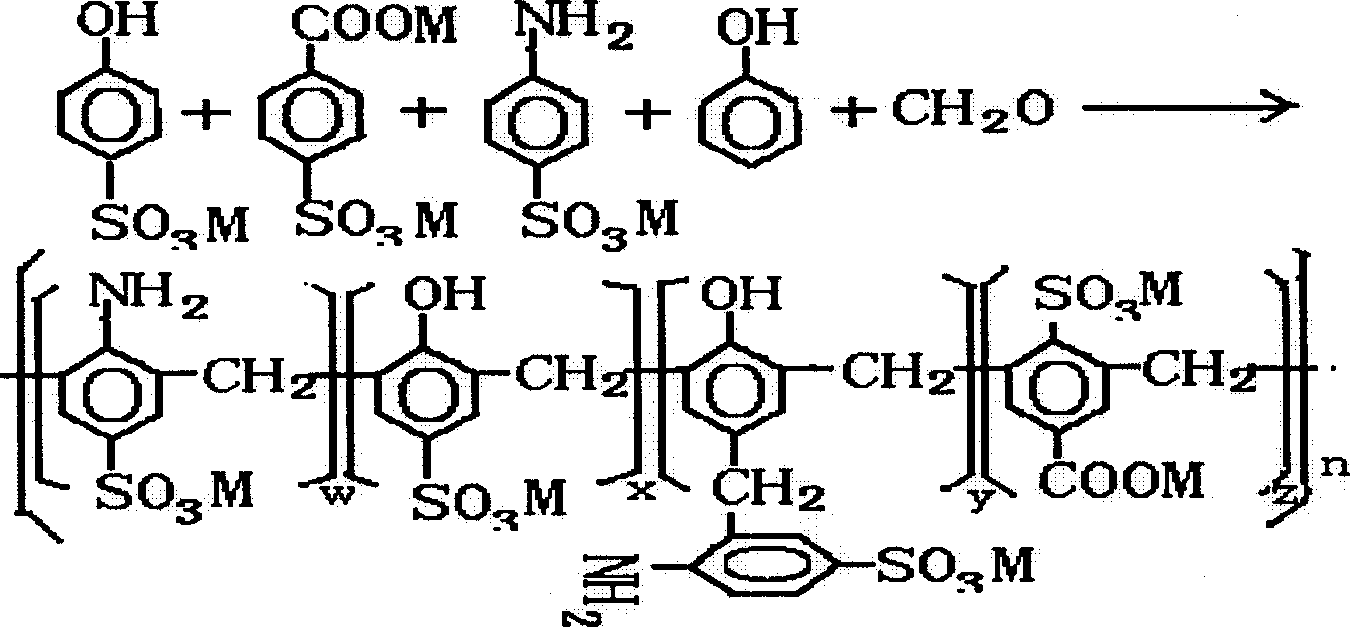

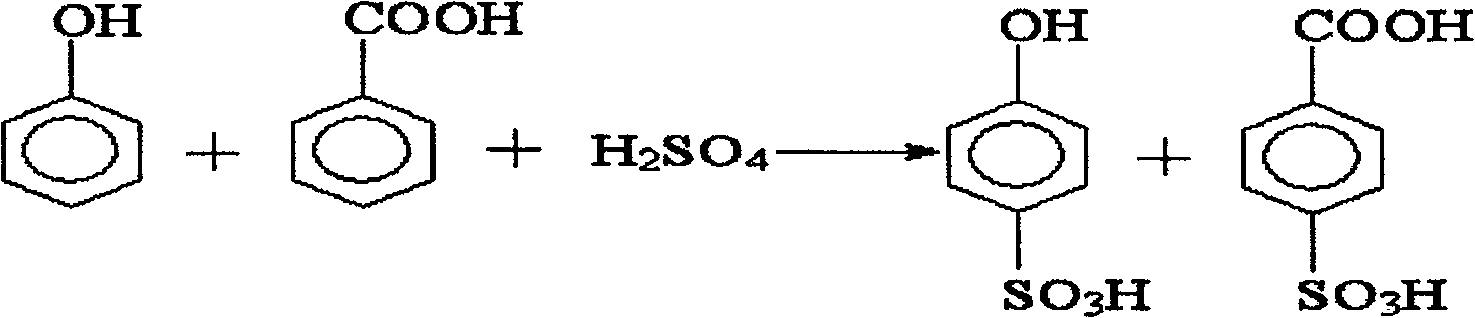

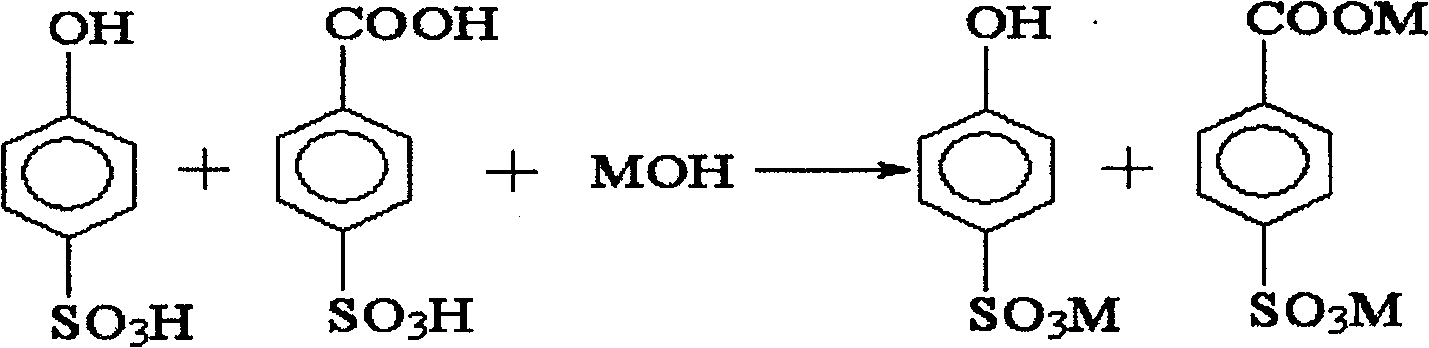

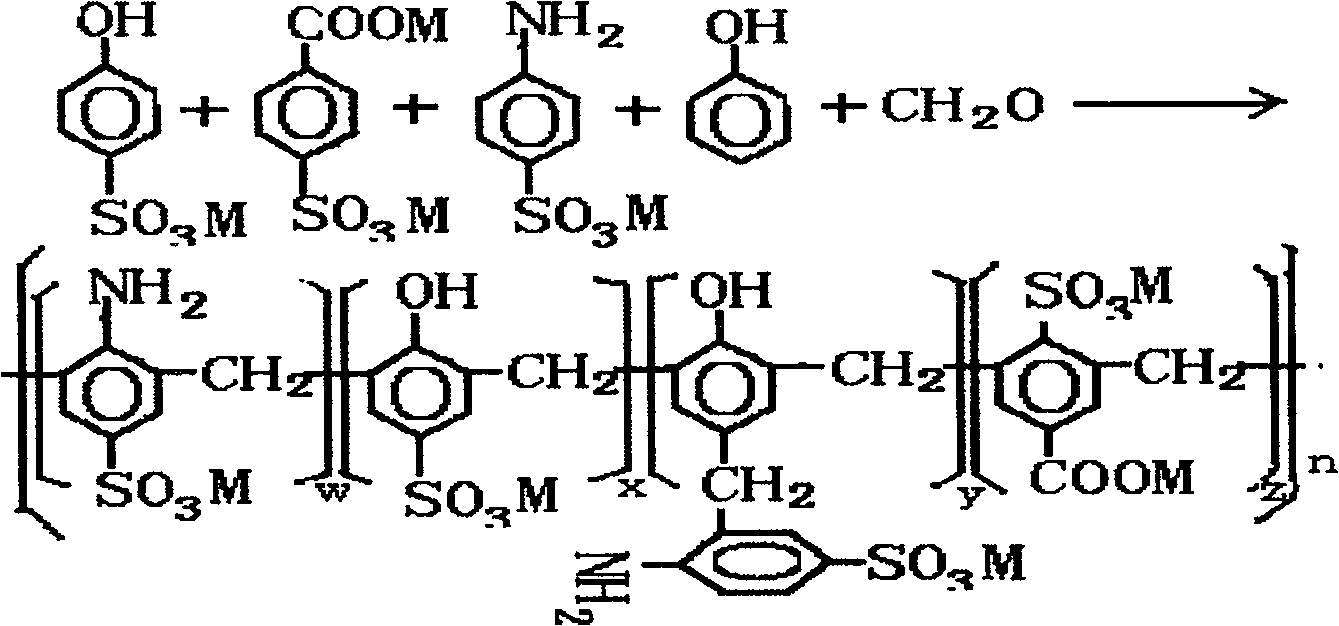

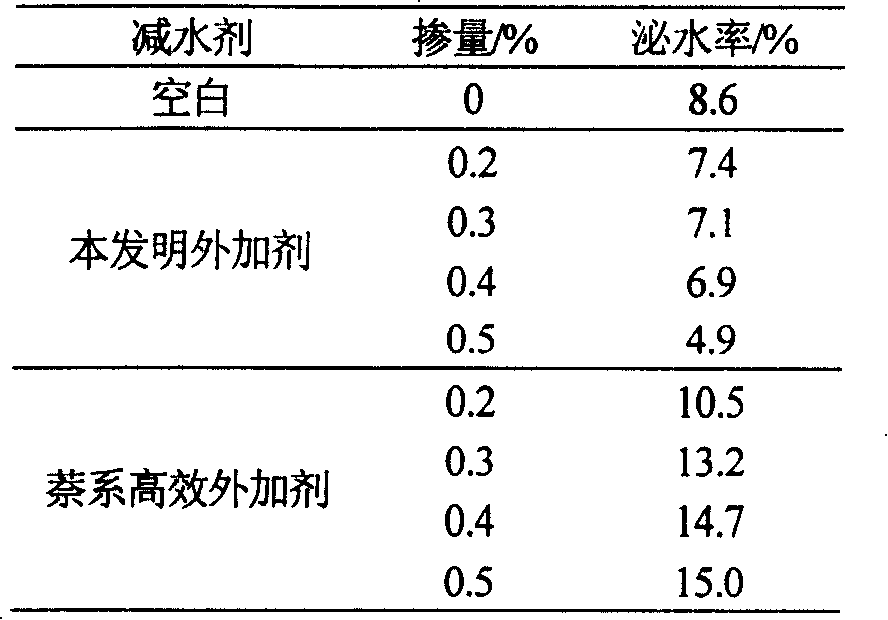

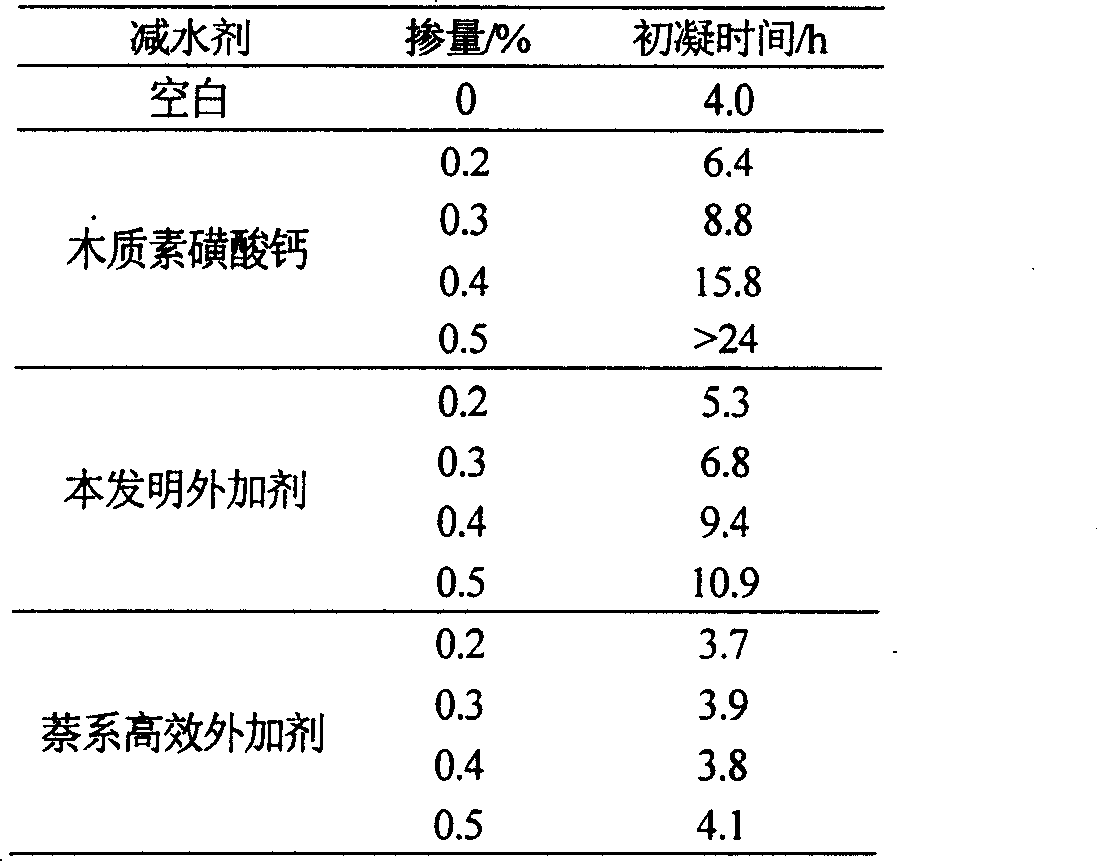

Concrete superplasticizer in amino carboxyl classes, and synthetic method

InactiveCN101003424ALow costHigh water reduction rateWaste water treatment from textile industryBenzoic acidSuperplasticizer

This invention discloses a high-efficiency amino-carboxylic water reducer for concrete. The water reducer has such advantages as low cost, high water-reducing rate, and good adaptability to cement. This invention also discloses the method for synthesizing the water reducer, and its application. The method comprises: performing sulfonation reaction on concentrated H2SO4, benzoic acid and phenol, neutralizing with NaOH to obtain sulfonation product, and performing condensation polymerization for 6 plus and minus 0.5 h. When the addition amount is 0.35-0.6 wt. % of cement, the water reducer can exhibit a water-reducing rate of 20-35%.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Process for preparing nano capsule phase change material emulsion

InactiveCN1900209BSmall particle sizeUniform dispersionHeat-exchange elementsHydrophilic monomerAlkane

The process of preparing nanometer capsule phase change material emulsion includes adding the oil phase liquid compounded with olefin monomer, hydrophilic monomer, alkane, initiator and n-lauryl mercaptan into the mixed liquid of emulsifier and deionized water via stirring and ultrasonic dispersing to obtain micro emulsion, introducing nitrogen to the micro emulsion system to eliminate oxygen viastirring, reflux condensing, heating to 65 deg.c and constant temperature polymerization reaction for 5 hr, and cooling naturally to room temperature to obtain the nanometer capsule phase change material emulsion. Thus prepared nanometer capsule phase change material emulsion has nanometer size, stable performance, great phase change enthalpy and wide application in latent heat functional hot fluid, heat accumulating and temperature regulating fabric, energy saving building wall and other fields.

Owner:SOUTH CHINA UNIV OF TECH

Special binder for unfired refractory brick masonry of inside liner of rotary kiln

The invention discloses a special binder for unfired refractory brick masonry of an inside liner of a rotary kiln. The special binder comprises the following raw materials in parts by weight: (1) 1-5 parts of fluorite of 0.8-1mm, (2) 10-25 parts of floating bead of 0.425-0.633mm, (3) 10-15 parts of sub-white fused alumina of 0.8-1mm, (4) 4-6.5 parts of mullite of 0.088mm, (5) 25-30 parts of clay powder of 0.425-0.633mm, and (6) 15-18 parts of silica fume of 0.85-1mm. A preparation method comprises the following steps of: 1) preparing the raw materials of the special binder for unfired refractory brick masonry into the required specifications respectively to obtain a prepared material; and 2) sufficiently mixing the prepared material obtained by the step 1), and packing to obtain the special binder for unfired refractory brick masonry. The special binder disclosed by the invention has the beneficial effects of strong caking property, high anti-peeling strength, oxidation resistance, erosion resistance and good wear resistance, is convenient to construct, and reduces the labor intensity of workers and the construction conditions.

Owner:登封市宏发煤矿机械厂

Multi-stage totally-enclosed mining drilling and dust removal device

The invention relates to a multi-stage totally-enclosed mining drilling and dust removal device, which comprises a box body, a gravity dust removal chamber, a water bath dust removal chamber and a spray dust removal chamber. In the coal mine drilling process, the generated dust-containing gas enters a gravity settling chamber through an air inlet, and larger granular dust is firstly removed, and discharged from a slag discharge hopper at the bottom under the action of the gravity and a baffle plate. And then the gas sequentially enters the water bath dust removal chamber and the spray dust removal chamber to realize the separation of gas and dust, and the discharge of water vapor is reduced through a gas-water separator at an air outlet. The clean gas in the gas-water separator enters an extraction pipeline, dust particles are deposited at the bottom of the container, and the dust particles are collected and discharged from a slag digging port. The multi-stage totally-enclosed mining drilling and dust removal device can effectively reduce the dust content of the construction roadway and avoid dust blocking the extraction pipeline, and has the advantages of low cost, easy operationand convenient movement.

Owner:ANHUI UNIV OF SCI & TECH

A kind of glue reducer for concrete and preparation method thereof

The invention relates to the technical field of researches of glue reducing agents for concrete and particularly relates to a glue reducing agent for the concrete and a preparation method of the glue reducing agent. The glue reducing agent is composed of the following formula components: 25-45% of mixed alcohol amine, 5-20% of mixed alcohol, 5-15% of a melamine efficient water reducing agent, 2-5% of a catalyst and the balance of water. The glue reducing agent has the very strong dispersity and the strong chelating effect; the glue reducing agent is used in the concrete and 10-20% of main raw materials of the concrete can be reduced; the concrete workability is improved; the bleeding is reduced and the pumping resistance is reduced, so that the concrete is dense and the concrete durability is improved; the problems that more air bubbles are formed in the concrete and cannot be treated, and the strength fluctuation of the concrete is great after similar products are added and great air bleeding is caused can be overcome; the glue reducing agent for the concrete is suitable for popularization and application.

Owner:JIANGSU YOURUI TECH

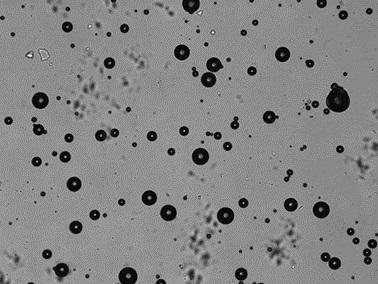

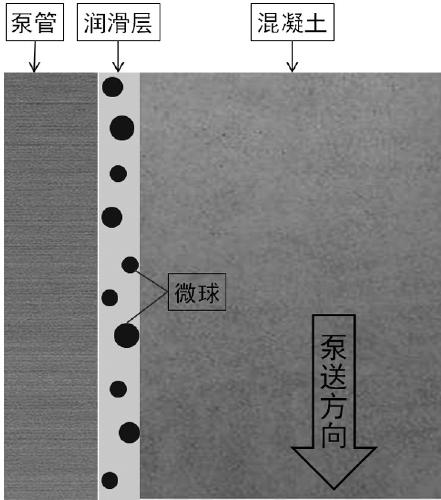

Novel lubricant for concrete pumping pipelines

InactiveCN109777570AGive full play to the drag reduction effectReduce dosageLubricant compositionCelluloseMicrosphere

The invention relates to a novel lubricant for concrete pumping pipelines. The novel lubricant comprises the following component in weight percentage: 4-8% of polyacrylamide, 2-6% of cellulose ether,30-50% of a dissolving promoter and 36-60% of drag-reduction microspheres; wherein the drag-resistance microspheres adopt inorganic microspheres with high strength and smooth surfaces, thereby obviously reducing the frictional resistance between concrete and pipelines. The novel lubricant for the concrete pumping pipelines provided by the invention has the advantages of being low in cost, rapid indissolution, green and environmental-friendly, easy to apply in field construction, capable of significantly reducing concrete pumping resistance, and the like.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

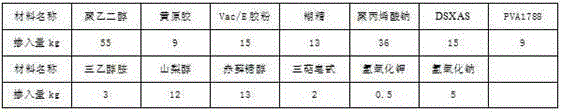

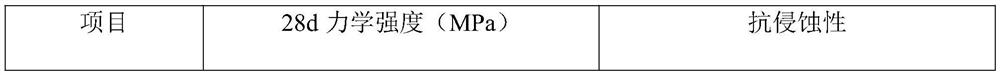

Cement-based composite material for trenchless centrifugal spraying repair of pipeline and preparation method of material

ActiveCN113307587ALow plastic viscosityHigh yield stressSolid waste managementUltimate tensile strengthMechanical engineering

The invention discloses a cement-based composite material for trenchless centrifugal spraying repair of a pipeline. The cement-based composite material is prepared from the following components in parts by weight: 900 to 940 parts of cement, 140 to 160 parts of viscosity reducer, 370 to 390 parts of thickener, 1500 to 1600 parts of sand, 0.5 to 2 parts of thixotropic agent, 60 to 100 parts of setting-adjusting early strength agent, 6 to 12 parts of fiber, 30 to 40 parts of water reducing agent and 260 to 280 parts of mixing water. The invention further discloses a preparation method of the cement-based composite material for pipeline trenchless centrifugal spraying repair. According to the invention, the sprayability and early strength of the high-performance cement-based composite material can be effectively improved, so that the rebound rate is reduced, the one-time spraying thickness is increased, the compactness is improved, and continuous centrifugal spraying construction of the high-performance cement-based composite material is realized.

Owner:CHANGJIANG INT HYDRO ENG CO LTD

Viscosity-reducing agent for vibration-free concrete and preparation and use methods thereof

The invention relates to the technical field of concrete admixtures, and specifically discloses a viscosity-reducing agent for vibration-free concrete and preparation and use methods thereof. The viscosity-reducing agent includes, by weight, 10-30% of silica fume, 5-30% of ultra-fine slag powder, 5-20% of glass powder, 10-50% of microbead fly ash particles, 0.1-0.5% of an alcohol amine compound, 0.1-1% of a defoamer, 0.1-0.5% of an air entraining agent and 1-10% of an inorganic activator. The prepared viscosity-reducing agent can reduce viscosity of concrete, increase fluidity, enhance construction operability, and effectively increase strength of concrete.

Owner:河北铁园科技发展有限公司

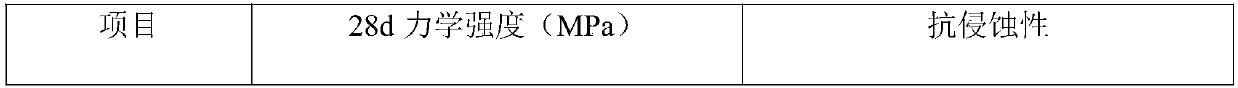

Toughening and corrosion-resistant concrete additive

The invention discloses a toughening and corrosion-resistant concrete additive. The toughening and corrosion-resistant concrete additive is characterized by being prepared from, by mass, 30-40% of mineral powder, 30-40% of silicon micropowder, 6-12% of polypropylene fiber, 6-12% of modified furan resin, 0.1-0.2% of a silane coupling agent, 0.1-0.2% of p-toluenesulfonic acid and 4-8% of sodium sulfate. The toughening and corrosion-resistant concrete additive has the advantages that through the synergistic action of the silicon micropowder, the polypropylene fiber and the furan resin, the toughness and corrosion resistance of concrete can be significantly improved, the raw materials are easy to obtain, the preparation process is simple, the construction is simple and convenient, the incorporation of thermosetting resin can reduce the dosage of a gel material, and the construction cost is reduced.

Owner:武汉市浩盛特种建材有限责任公司

Concrete superplasticizer in amino carboxyl classes, and synthetic method

InactiveCN100560530CLow costHigh water reduction rateWaste water treatment from textile industryBenzoic acidSuperplasticizer

The invention discloses an ammonia carboxyl high-efficiency water reducer for concrete. The ammonia carboxyl high efficiency water reducer for concrete has low cost, high water reducing rate and good adaptability to cement. The invention also discloses the method and application of synthesizing the high-efficiency water reducer of ammonia carboxyl concrete. Firstly, concentrated sulfuric acid, benzoic acid and phenol are used as reaction raw materials to carry out sulfonation reaction, and then neutralized with sodium hydroxide to obtain a sulfonated product. Then the mass ratio of polycondensation reaction is 65-80:25-40; the polycondensation reaction time is 6±0.5h. When the amount of the ammonia carboxyl new concrete high-efficiency water-reducing agent converted into solid is 0.35-0.6% of the cement weight, the water-reducing rate is 20%-35%. The sulfamate high-efficiency water reducer of the invention has low cost, high water reducing rate, good adaptability to cement and easy industrial production.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Preparation method of water-resistant anti-seismic gypsum-based self-leveling material

The invention provides a preparation method of a water-resistant anti-seismic gypsum-based self-leveling material. The preparation method comprises the following steps: mixing and stirring 100-120 parts by weight of anhydrous phosphogypsum, 10-15 parts by weight of silica fume, 20-30 parts by weight of modified ultrafine steel slag and 1-5 parts by weight of straw powder nano crystals for 10-20 minutes to obtain a solid mixture A; step 2, taking 0.1-0.5 part by weight of a defoaming agent, 0.4-0.8 part by weight of a water reducing agent, 0.2-0.6 part by weight of a water retaining agent, 6-8parts by weight of a composite excitant and 70 parts by weight of water, stirring for 10-20 minutes, and uniformly mixing to obtain a liquid mixture B; and step 3, mixing and stirring the solid mixture A and the liquid mixture B obtained in the step 1 and the step 2 for 5-10 minutes to obtain the anti-seismic gypsum-based self-leveling material. According to the method, the gypsum-based self-leveling material prepared by a specific construction process has good flowability, stability, high strength and high shock resistance.

Owner:HUBEI UNIV OF TECH

Lignins metro shield grouting additive and its preparation method

The present invention relates to one kind of lignin admixture for subway shield grouting and its preparation process. The lignin admixture is prepared with modified lignin sulfonate proposed in patent ZL98116516.8 in 1000 weight portions, cross-linking agent in 20-200 weight portions, air entraining agent in 1-50 weight portions, inorganic salt reinforcer in 100-500 weight portions and water soluble polymer in 10-50 weight portions as material, and through condensation and physical re-compounding. The product of the present invention is used in subway shield grouting, has excellent water reducing reinforcing and stabilizing effect and makes the grout possess intermediate condensation time and less pumping resistance.

Owner:SOUTH CHINA UNIV OF TECH

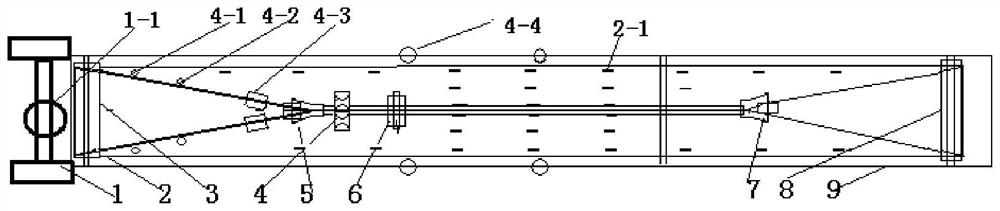

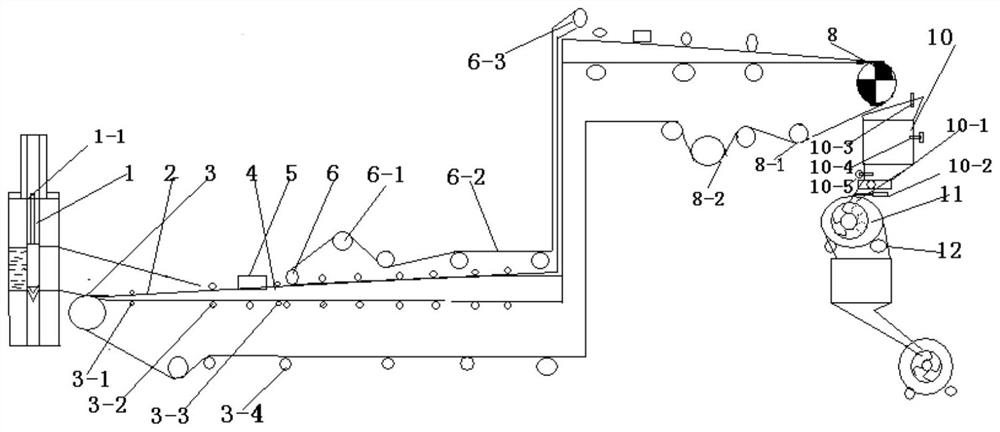

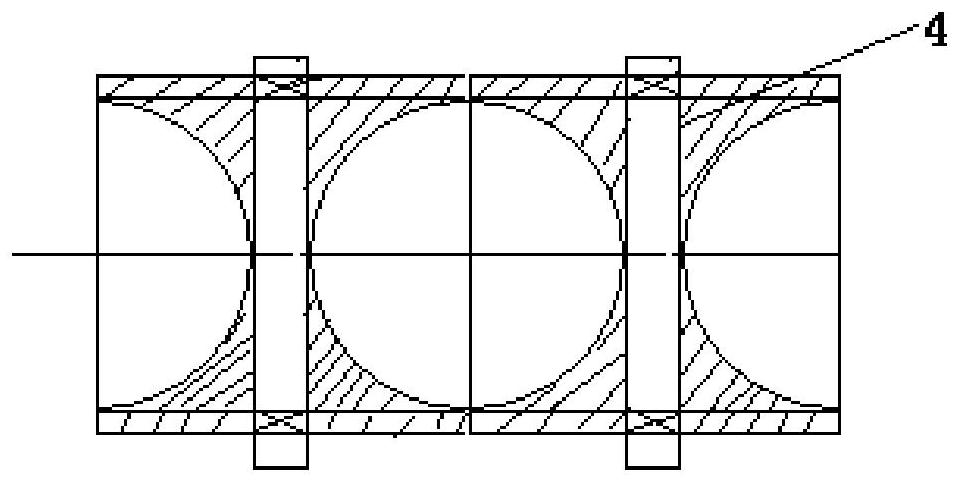

Magnetic suspension soft-sealing tubular belt conveyor manufacturing process method and water delivery power generation device

PendingCN113719399AReduce pumping resistanceImprove water delivery efficiencyFinal product manufactureHydro energy generationWater pipeDistributed power generation

The invention relates to a magnetic suspension soft-sealing tubular belt conveyor manufacturing process method and a water delivery power generation device, and belongs to the field of tubular belt liquid conveying. A system can convey water from a low position to a steel structure frame body water tank or a reservoir at a high position of a high mountain for afforestation of barren mountains in a long distance without limitation, can convey solid materials such as superfine powder and the like, can also achieve multi-stage multi-unit water storage power generation by utilizing the fall, is an upgrading and updating product of a multi-stage pumping station, can be in butt joint with various pressure-resistant water pipes for installation and use, thoroughly changes the traditional process of complex water pumping engineering, large investment and high cost of the traditional multi-stage pumping station, and provides an effective way for large-area rapid afforestation of the barren mountains and distributed power generation. The construction speed is high, the occupied area is small, the requirement on a water source is not strict, compared with traditional water pumping and water storage power generation, the efficiency is improved by 2-4 times, the investment is reduced by more than 30%, ecology is not destroyed, and the system is clean, environmentally friendly, low in cost, high in efficiency and good in benefit.

Owner:崔爱萍

Gas extraction center divided-flow type grouting and hole sealing device and hole sealing method

InactiveCN102200024BReduced pumping resistanceQuality improvementGas removalSealing/packingEngineeringSlurry

The invention discloses a gas extraction center divided-flow type grouting and hole sealing device which comprises an extraction pipe, a grouting plug, a left bag and a right bag, wherein the extraction pipe penetrates through the left bag and the right bag, a multifunctional valve is arranged in the extraction pipe, and the left side and the right side of the multifunctional valve are respectively connected with a left flow division pipe and a right flow division pipe; the left flow division pipe and the right flow division pipe are both sheathed on the extraction pipe, and the inner diameter of the left flow division pipe and that of the right flow division pipe are both greater than that of the extraction pipe so as to form a slurry passage among the left flow division pipe, the right flow division pipe and the extraction pipe; and a grouting insertion pipe is inserted into the extraction pipe. Through the gas extraction center divided-flow type grouting and hole sealing device, more effective grouting and hole sealing of drilling holes in the hole sealing section can be realized, and the generation and the propagation of leakage cracks around the drilling holes can be better prevented. The invention also provides a hole sealing method by using the gas extraction center divided-flow type grouting and hole sealing device. Through the method, high stress regions are produced around the drilling holes in the hole sealing section, the permeability of coal around the drilling holes in the hole sealing section is reduced, and the purpose of effectively grouting and sealing the drilling holes in the hole sealing section is realized.

Owner:HENAN POLYTECHNIC UNIV

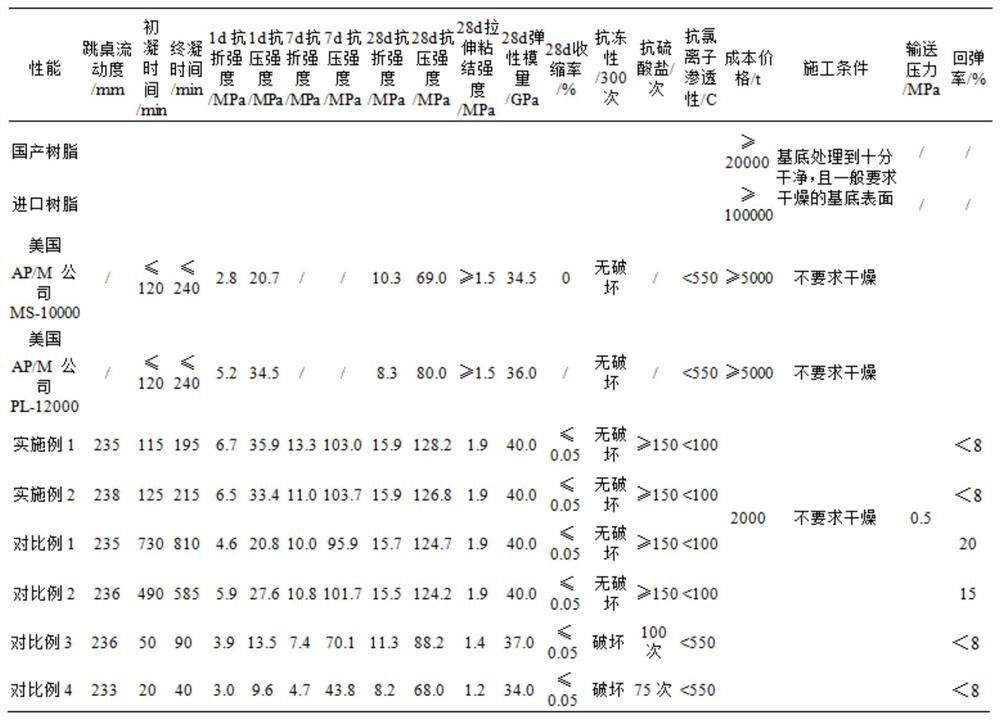

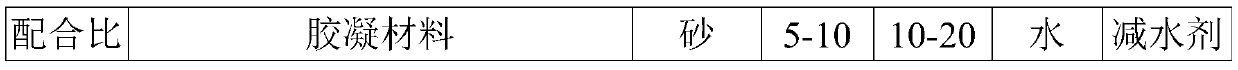

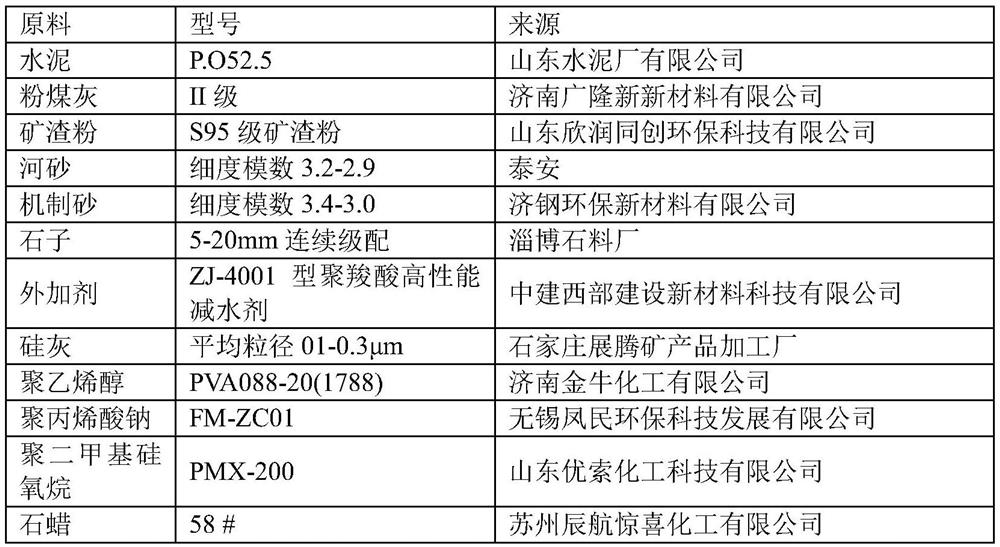

A kind of super high-rise jacking self-compacting concrete and its construction technology

ActiveCN113929401BIncrease rationalityImprove homogeneityBuilding material handlingCrack resistanceSlag

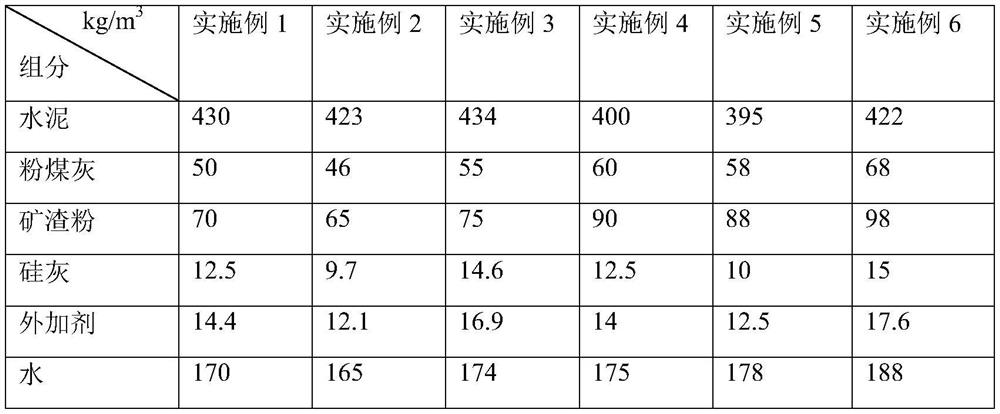

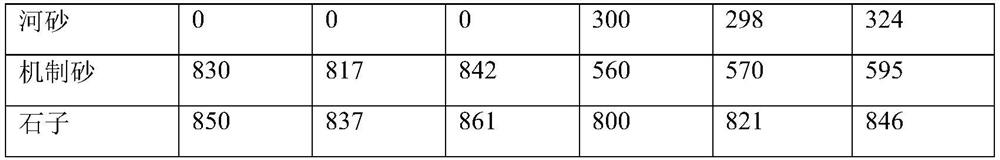

The present application relates to the field of building materials, and specifically discloses a super high-rise self-compacting concrete and a construction process thereof. The super high-rise jacking self-compacting concrete includes the following components in parts by weight: 395-434 parts of cement, 46-68 parts of fly ash, 65-98 parts of slag powder, 9.7-15 parts of silica fume, 12.1-17.6 parts of admixture, 165-188 parts of water, 0-324 parts of river sand, 570-842 parts of machine-made sand, and 821-861 parts of stones; the content of stone powder in the machine-made sand is ≤12%; the construction process is: S1, preparing concrete, S2, Concrete transportation and pumping, S3, curing. The super high-rise jacking self-compacting concrete of the present application has the advantages of good workability, good homogeneity, little loss over 3 hours, high crack resistance, high impermeability and strong carbonization resistance.

Owner:SHANDONG JIANZE CONCRETE

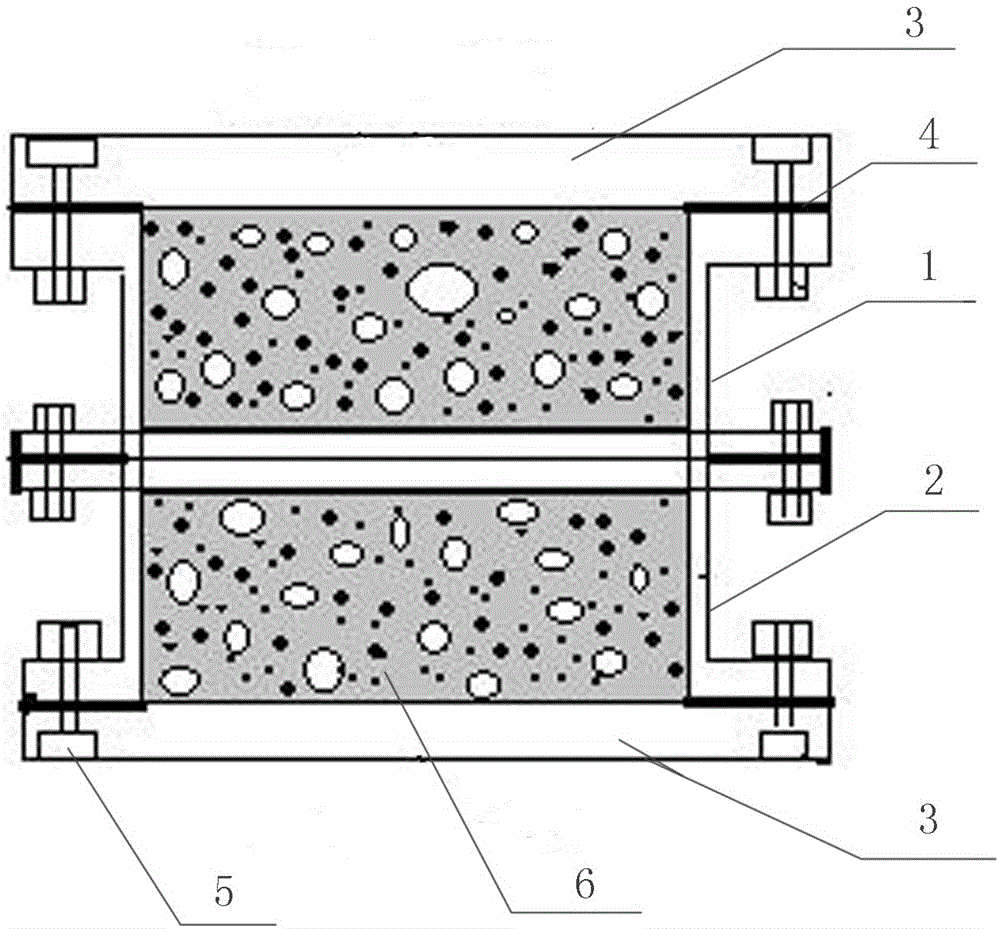

Ceramsite floating restraining and resistance reducing agent and method for reducing floating degree of ceramsite in pumped ceramsite concrete

The invention provides a ceramsite floating restraining and resistance reducing agent and a method for reducing the floating degree of ceramsite in pumped ceramsite concrete. A method for detecting the ceramsite floating index for representing the floating degree of the ceramsite is provided, a reverse vibrating treatment measure and a reverse secondary hitting method are adopted, operation is easy and fast, and the result reliability is high. According to the ceramsite floating restraining and resistance reducing agent and the method applying the ceramsite floating restraining and resistance reducing agent to reducing the floating degree of the ceramsite in the pumped ceramsite concrete, pumping resistance can be effectively lowered, the pumping and lubricating effect can be improved, the pumping speed can be increased, pumping pressure can be lowered, and the percent of the slump of the ceramsite concrete doped with the ceramsite floating restraining and resistance reducing agent to the slump of ceramsite concrete without being doped with the ceramsite floating restraining and resistance reducing agent is not lower than 90%.

Owner:济南四建(集团)有限责任公司

An Improved Venetian Plaster and Its Application

ActiveCN104609807BImprove waterproof performanceGood oil resistanceSolid waste managementAluminateWeather resistance

The invention relates to improved Venetian plaster and the application thereof. The improved Venetian plaster comprises the following components in parts by weight: 20-50 parts of sulphoaluminate cement, 20-35 parts of Portland cement, 0.2-1 part of water reducer, 1.5-4 parts of silica fume, 1-4 parts of slag powder, 1-3 parts of coal ash, 0.1-1 part of thickener, 1-4 parts of redispersible powder, 20-35 parts of silica sand powder, 0-5 parts of organic color paste and 0-5 parts of inorganic color powder, wherein the ratios of the slag powder and coal ash to the total weight are both greater than or equal to 2%. The improved Venetian plaster disclosed by the invention has good water resistance, oil resistance and weather fastness, is safe, environment-friendly, durable, elegant and luxury, has unique artistic decoration effect, can replace traditional coating and tiles, and can be applied to inner wall decoration of buildings.

Owner:湖南交泰建材有限公司

A toughening and corrosion-resistant concrete additive

Owner:武汉市浩盛特种建材有限责任公司

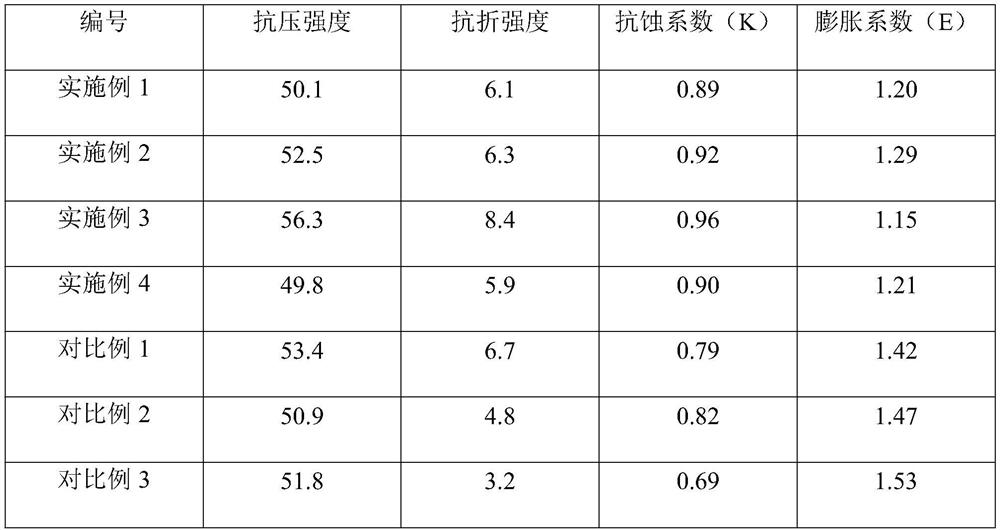

Switch type air entraining agent applicable to wet spraying concrete

The invention discloses a switch type air entraining agent applicable to wet spraying concrete. The switch type air entraining agent consists of an ingredient A and an ingredient B, wherein through being metered in parts by mass, the ingredient A is a mixture of 30 to 50 parts of sapindoside powder, 5 to 15 parts of K12 surfactant (sodium dodecyl sulfate) powder and 8 to 12 parts of polyacrylamide powder; the ingredient B is a mixture of 18 to 27 parts of annular polydimethylsiloxane and 5 to 15 parts of hexadecyltrimethylammonium chloride powder; according to a mass ratio being (0.05 to 1):100, the ingredient A and the concrete are added into concrete slurry in the stirring process; according to a mass ratio being (0.015 to 0.03):100, the ingredient B and the concrete are carried and injected into the concrete slurry by compressed air in an air ring position of a spray gun connected with a concrete spraying pipe. The switch type air entraining agent has the advantages that good pumpable performance and sprayed coating performance are realized; the manufacturing cost and the use cost are low; green and environment-friendly effects are achieved; the use is safe; good market promotion values are realized.

Owner:SHANDONG UNIV OF SCI & TECH

A kind of reinforced pumping agent for concrete

The invention discloses a reinforcing pumping admixture for concrete. A preparation method of the reinforcing pumping admixture comprises the following steps of firstly preparing a rheological agent,wherein the rheological agent is prepared from the following raw materials in parts by weight: 20 to 30 parts of magnesium aluminum silicate, 5 to 10 parts of bentonite, 3 to 5 parts of dihydroxyl polydimethylsiloxane, 2 to 5 parts of maleic anhydride, 1 to 2 parts of tetramethyldivinyldisilazane and 20 to 30 parts of durene. The uniformity of slurry of the concrete which is provided by the invention and into which the reinforcing pumping admixture is added is enabled to subsequently become good; the viscosity is decreased; the flow speed of pulp becomes quick; the suspension property of an aggregate in the concrete is enhanced; the bottom deposition phenomenon cannot occur within a longer time; the pulp is enabled to more uniformly enwrap the aggregate and the rheological agent in the reinforcing pumping admixture is used for ameliorating the flowability of the pulp.

Owner:佛山市南海区沥建混凝土有限公司

A kind of C60 pumping concrete and preparation method thereof

The invention discloses a C60 pumping concrete and a preparation method thereof. The key point of the technical solution is a C60 pumping concrete, which comprises the following components in parts by weight: 400-420 parts of cement, 130-150 parts of admixture 690-710 parts of fine aggregate, 960-980 parts of coarse aggregate, 8-10 parts of admixture and 160-170 parts of water; the fine aggregate is mixed with river sand and machine-made sand in a weight ratio of 3:7 The fineness modulus of the river sand is 0.9-1.1, and the fineness modulus of the machine-made sand is 2.8-2.9; the coarse aggregate is mixed with pebbles and pebbles with a weight ratio of 6.5:3.5 The particle size of large pebbles is 10-20mm, and the mud content is <0.5%; the particle size of small pebbles is 5-10mm, and the mud content is <0.6%. The pumping concrete in the invention has the advantages of high compressive strength, good workability and high pumping height.

Owner:重庆华西易通建设股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com