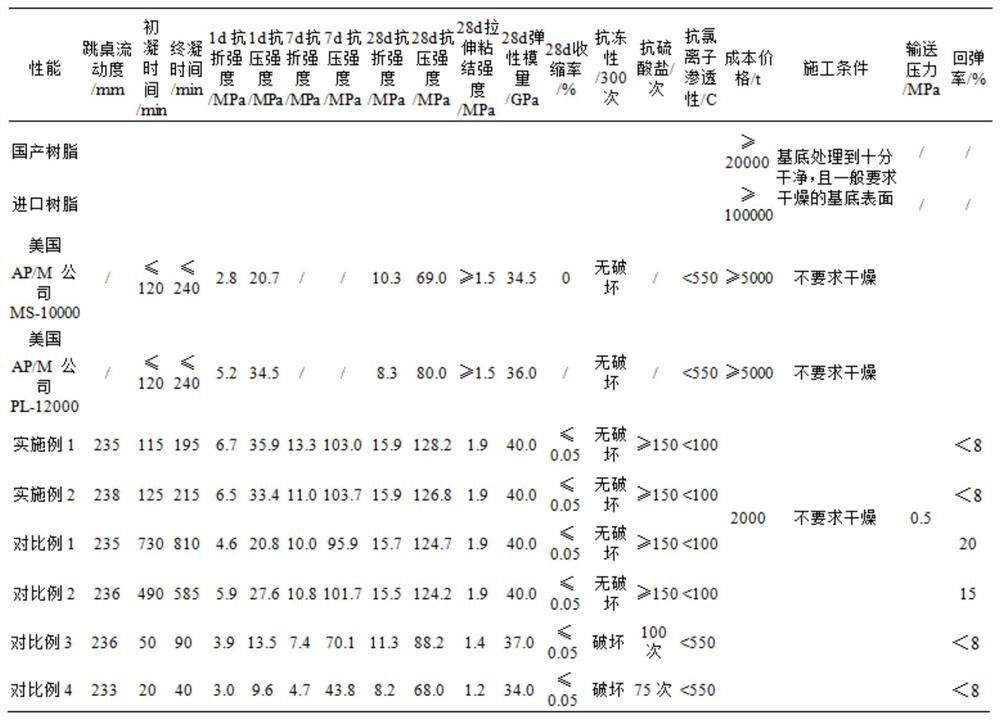

Cement-based composite material for trenchless centrifugal spraying repair of pipeline and preparation method of material

A composite material and non-excavation technology, applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of insufficient cement mortar structure strength, high construction conditions and equipment requirements, high cost, etc., and achieve improvement Good sprayability and early strength, good durability, high early strength and high late strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Cement-based composite material for pipeline non-excavation centrifugal spraying repair, including the following components by weight: 920 parts of Portland cement, 150 parts of fly ash microbeads, 380 parts of silica fume, 1550 parts of sand, hydroxyethyl methyl 1 part of cellulose ether, 80 parts of CA-50 aluminate cement, 9 parts of polypropylene fiber, 35 parts of polycarboxylate high-performance water reducer, and 270 parts of mixing water.

Embodiment 2

[0041] Cement-based composite material for pipeline non-excavation centrifugal spraying repair, including the following components by weight: 940 parts of Portland cement, 150 parts of fly ash microbeads, 380 parts of silica fume, 1550 parts of sand, hydroxyethyl methyl 1 part of cellulose ether, 60 parts of CA-50 aluminate cement, 9 parts of polypropylene fiber, 35 parts of polycarboxylate high-performance water reducer, and 270 parts of mixing water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com