Modified plant fiber plugging-while-drilling agent for drilling fluid and preparation method of plugging-while-drilling agent

A technology of plant fiber and plugging while drilling, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of high cost, complicated production of plugging agent while drilling, poor plugging effect, etc., and achieve low cost , Small change in dynamic shear force, small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

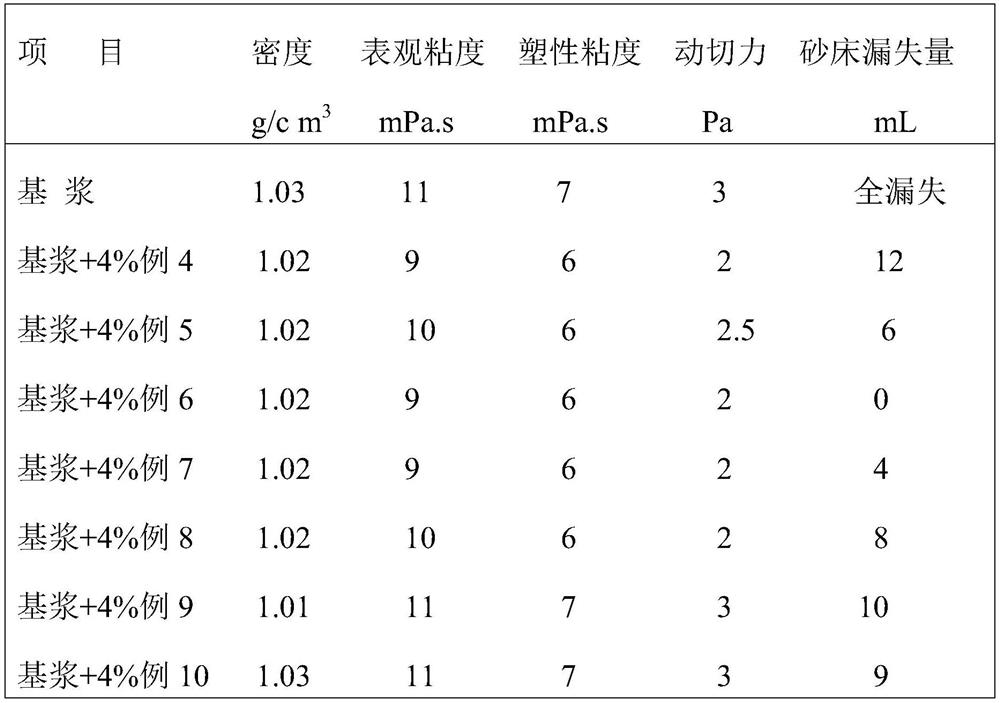

Examples

Embodiment 1

[0029] Weigh 95g of water, add 5g of hydrolyzed polyacrylonitrile ammonium salt, stir at 20°C-60°C to fully dissolve the ammonium salt, adjust the pH value to less than 6 with 10% hydrochloric acid, and continue stirring for 20 minutes to obtain a viscous liquid for use .

Embodiment 2

[0031] Install a heating mantle, a stirrer and a condenser in a 500m three-necked bottle, add 300mL of water and 5g of sodium hydroxide into the there-necked bottle, and put 30g of acrylic waste silk into the three-necked bottle after chopping.

[0032] Gradually heat up to 90°C-100°C while stirring, and open the condenser to reflux at the same time. When the acrylic fiber is completely dissolved and forms a white or yellow viscous liquid, measure its apparent viscosity. When the apparent viscosity is less than 15mPa.s, Stop responding.

[0033] Cool the reaction solution below 60°C, adjust the pH value to less than 6 with 10% hydrochloric acid, add 5.0g aluminum trichloride hexahydrate (ALCL 3 ·6H 2 (0), stirring makes aluminum chloride dissolve and forms viscous liquid, continues to stir 20 minutes, must stand-by viscous liquid.

Embodiment 3

[0035] According to embodiment 2, before adjusting pH, add 10g bentonite, after pH value is adjusted to be less than 6, add 5.0g aluminum trichloride hexahydrate (ALCL 3 ·6H 2 O), must stand-by viscous liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com