Method for synthesizing low molecular weight phenylethylene / maleic anhydride alternate copolymer

A technology of alternating copolymer and maleic anhydride, applied in the field of preparing low molecular weight styrene/maleic anhydride alternating copolymer by precipitation polymerization, can solve the problems of unfavorable environmental protection, irritating odor of copolymer, affecting the performance of copolymer, etc. Achieve the effect of avoiding influence and simple post-processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Material preparation: monomer MAH 1.7658g, St 1.6892g, the molar ratio of the two is 1:0.90; initiator AIBN 0.1831g; solvent mixture of isoamyl acetate 9mL and cyclohexane 36mL; molecular weight regulator AMS 0.2132g .

[0028] Synthesis of copolymer: put MAH, AIBN and solvent in a four-neck flask equipped with a stirring device and nitrogen gas, stir at room temperature for 15 minutes, heat for 15 minutes in a constant temperature water bath at 80°C, and then drop them at a constant speed within 1 hour The mixture of St and AMS, after the dropwise addition, continue to stir and react for 1h to obtain a dispersion system of styrene / maleic anhydride alternating copolymer, centrifuge the dispersion and dry to obtain a white powder of styrene / maleic anhydride alternating copolymer .

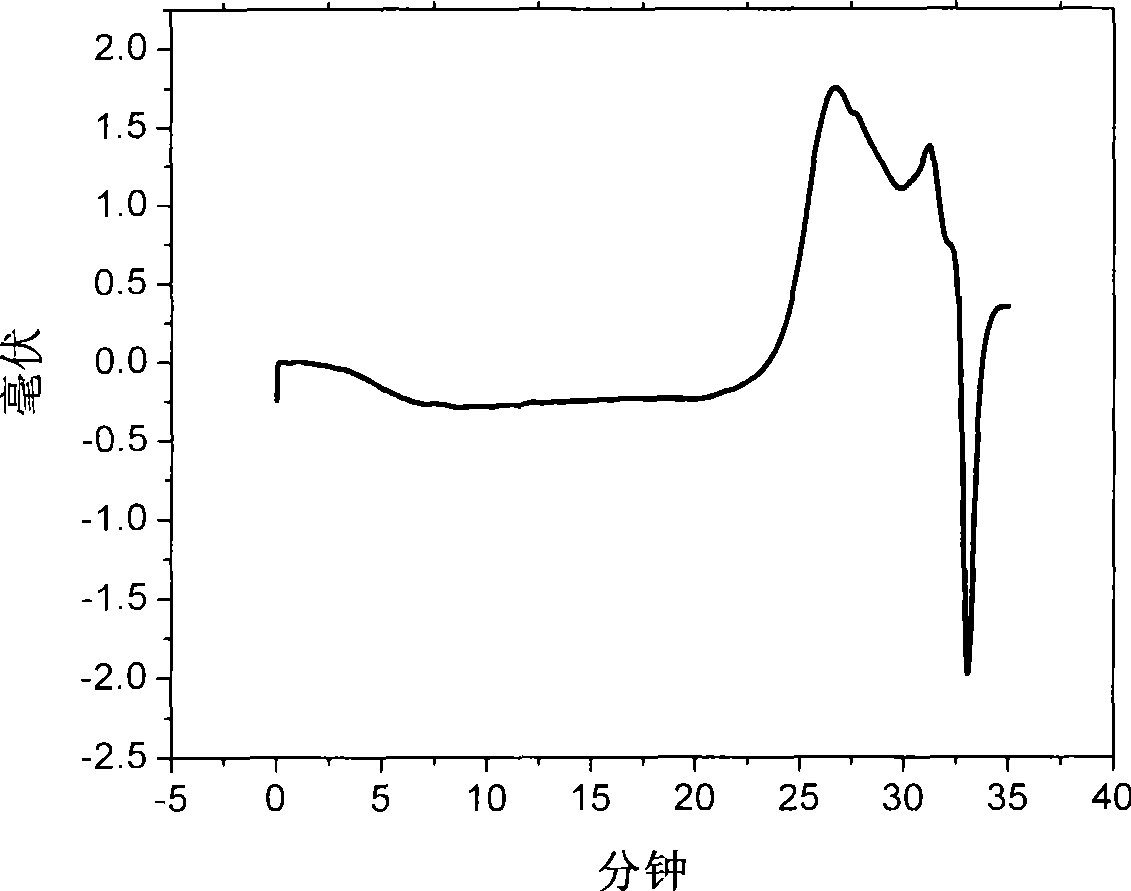

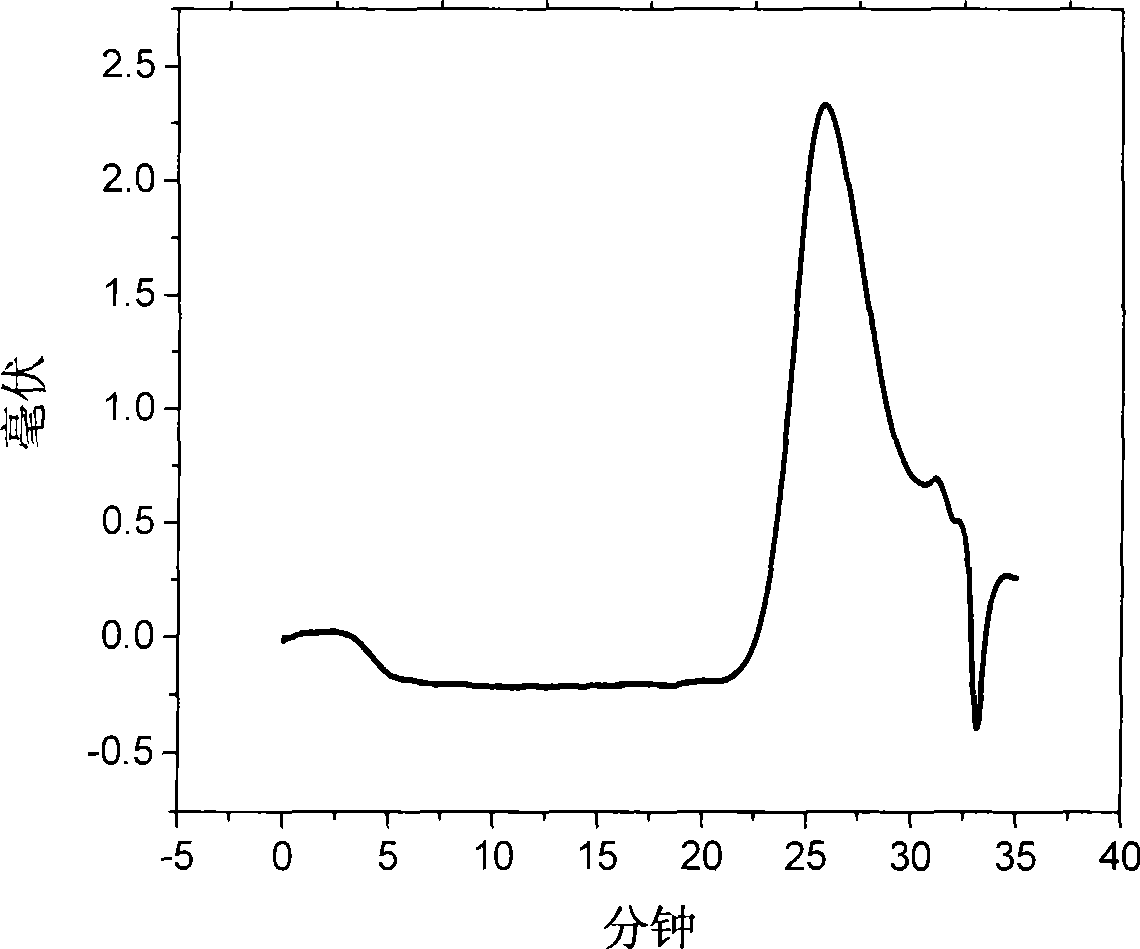

[0029] Polymerization yield (C p ), the number average molecular weight (Mn) of the copolymer and its distribution (PDI) results are shown in Table 1, and the GPC spectrogram of the copolym...

Embodiment 2

[0031] Material preparation: monomer MAH 0.4420g, St 0.557g, the molar ratio of the two is 1:0.90; initiator AIBN 0.0459g; solvent is a mixture of 9mL butyl acetate and 36mL cyclohexane; molecular weight modifier AMS 0.0542g .

[0032] Synthesis of copolymers: put MAH, AIBN and solvent in a four-neck flask with a stirring device and nitrogen gas, stir at room temperature for 15 minutes, heat for 15 minutes in a constant temperature water bath at 80°C, and then drop them at a constant speed within 0.5 hours Complete the mixture of St and AMS, continue to stir and react for 8 hours after the dropwise addition, and obtain the dispersion system of styrene / maleic anhydride alternating copolymer, centrifuge and dry the dispersion system to obtain the white color of styrene / maleic anhydride alternating copolymer powder.

[0033] Polymerization yield (C p ), the number-average molecular weight (Mn) of the copolymer and its distribution (PDI) results are shown in Table 1.

Embodiment 3

[0035] Preparation of materials: monomer MAH 1.3245g, St 1.2685g, the molar ratio of the two is 1:0.96; initiator AIBN 0.1360g; solvent mixture of isoamyl acetate 36mL and n-hexane 9mL; molecular weight regulator VAC 0.1175g.

[0036] Synthesis of copolymer: put MAH, AIBN and solvent in a four-neck flask with a stirring device and nitrogen gas, stir at room temperature for 15 minutes, heat in a constant temperature water bath at 60°C for 15 minutes, and then drop them at a constant speed within 1 hour The mixture of St and VAC, after the dropwise addition, continue to stir and react for 6 hours to obtain a dispersion system of styrene / maleic anhydride alternating copolymer, centrifuge the dispersion system and dry to obtain a white powder of styrene / maleic anhydride alternating copolymer .

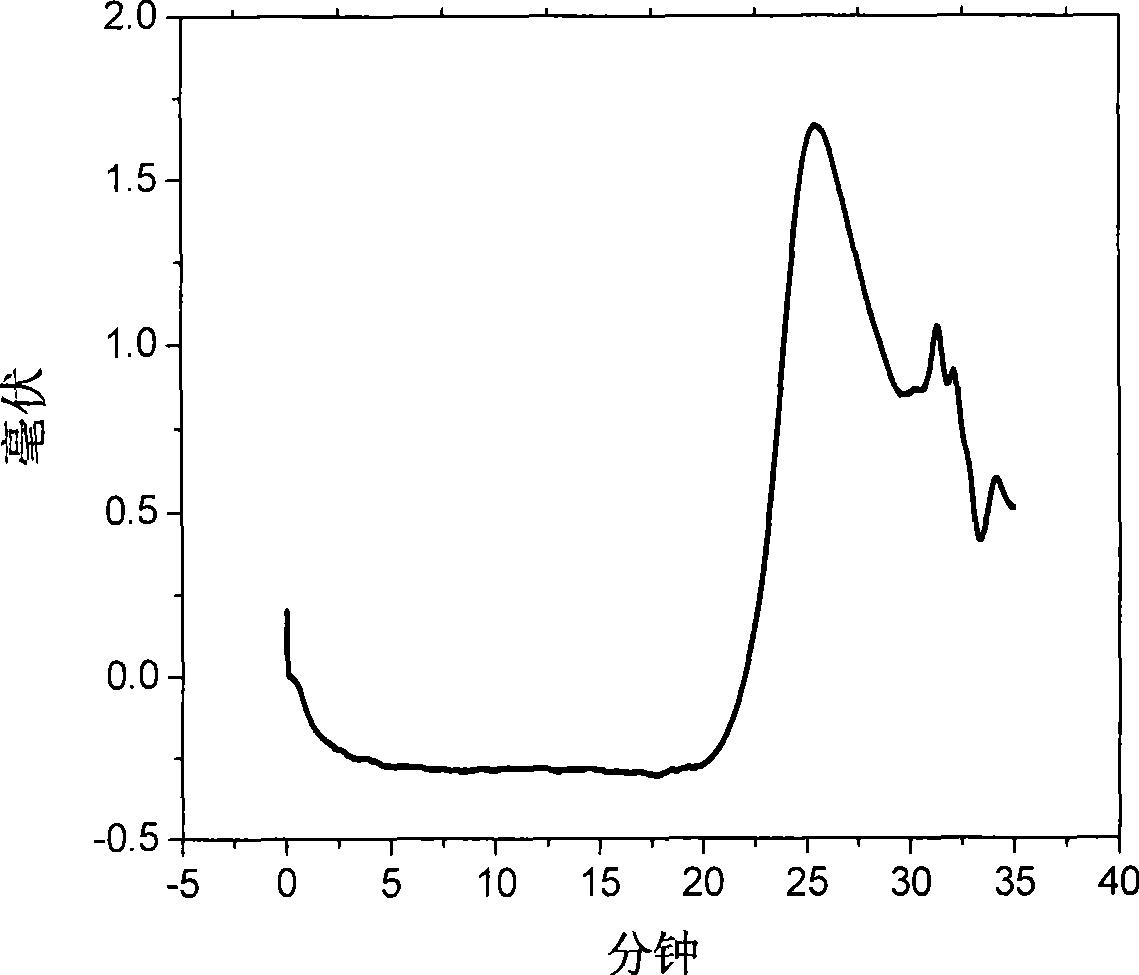

[0037] Polymerization yield (C p ), the number average molecular weight (Mn) of the copolymer and its distribution (PDI) results are shown in Table 1, and the GPC spectrogram of the copol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com