Method for synthesizing epoxy soybean oil base polyol under heterogenous catalysis system

An oil-based polyol and heterogeneous catalysis technology, which is applied in chemical instruments and methods, preparation of organic compounds, molecular sieve catalysts, etc., can solve the problems of non-recyclable catalysts, environmental pollution of equipment, complicated operation process, etc., and achieve simplification Post-treatment process, ensuring purity, and improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 20g of epoxidized soybean oil, 0.1g of HY molecular sieve and 20g of anhydrous methanol into an autoclave equipped with stirring and a volume of 100ml, heat up to 60°C, react for 20h, and discharge the material to obtain a milky white liquid. Analyze the product test.

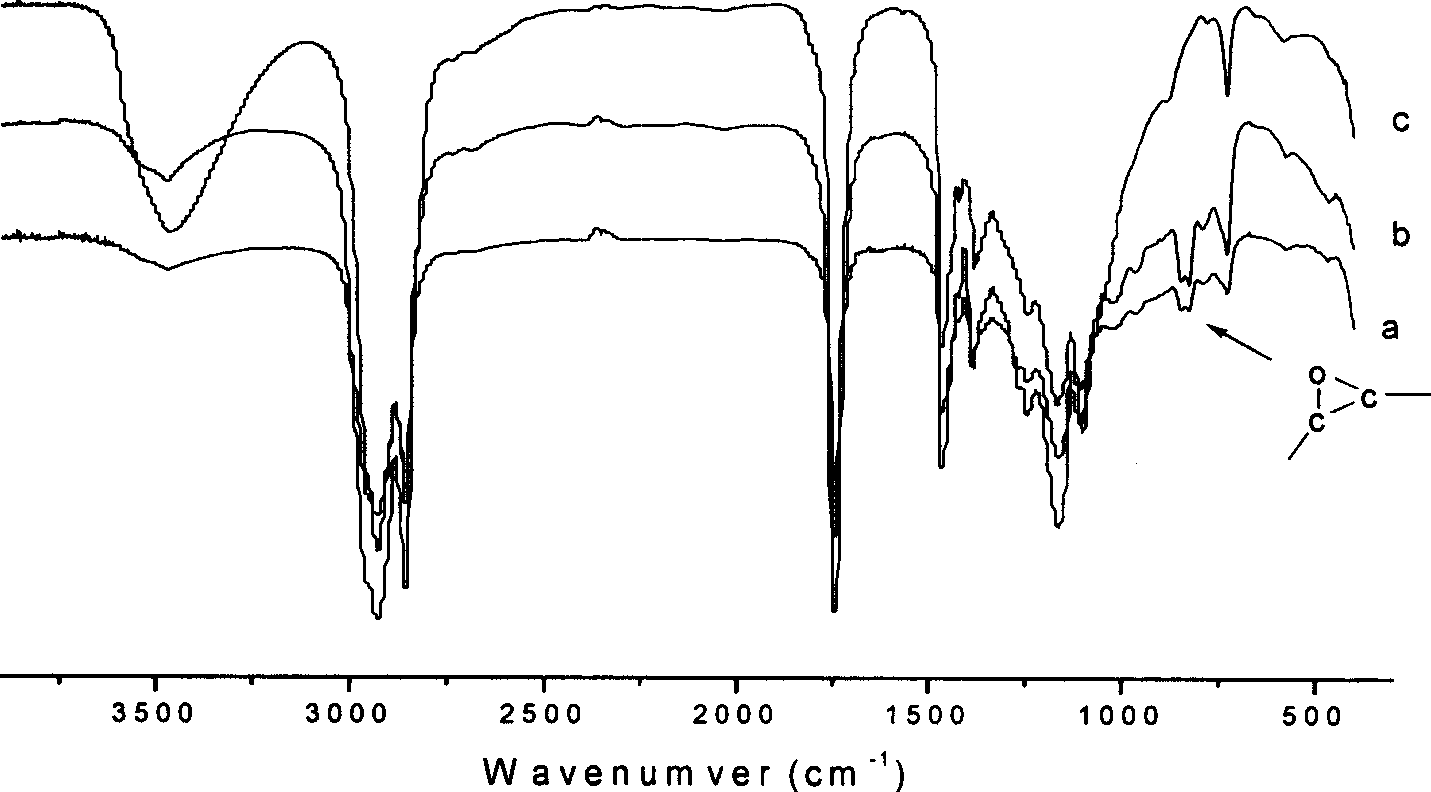

[0023] The epoxy value of epoxidized soybean oil is 0.376, and the epoxy value of the product measured after the reaction is 0.0167. The product is analyzed by infrared spectroscopy, as can be seen from the figure that the product is at 3400cm -1 The characteristic absorption peak of hydroxyl group appears on the left and right, 840cm -1 and 820cm -1 The characteristic peak of the epoxy group at the place disappears, thus confirming that the product is a vegetable oil polyol.

Embodiment 2

[0025] Add 20g of epoxidized soybean oil, 0.5g of LiY molecular sieve and 30g of anhydrous methanol into an autoclave equipped with agitation and a volume of 100ml, heat up to 80°C, react for 15h and discharge to obtain milky white liquid, analyze the product test. The epoxy value of epoxidized soybean oil is 0.376, and the epoxy value of the product measured after the reaction is 0.0036.

Embodiment 3

[0027] Add 20g of epoxidized soybean oil, 1.0g of KY molecular sieve and 40g of anhydrous methanol into an autoclave equipped with stirring and a volume of 100ml, heat up to 100°C, react for 10h, and discharge the material to obtain a milky white liquid. Analyze the product test. The epoxy value of epoxidized soybean oil is 0.376, and the epoxy value of the product measured after the reaction is 0.0045.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com