Preparation method of nano-silver particles

A technology of nano-silver particles and silver nitrate, which is applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc. The effect of reducing process equipment and energy costs, reducing raw material and process costs, and simplifying post-treatment processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

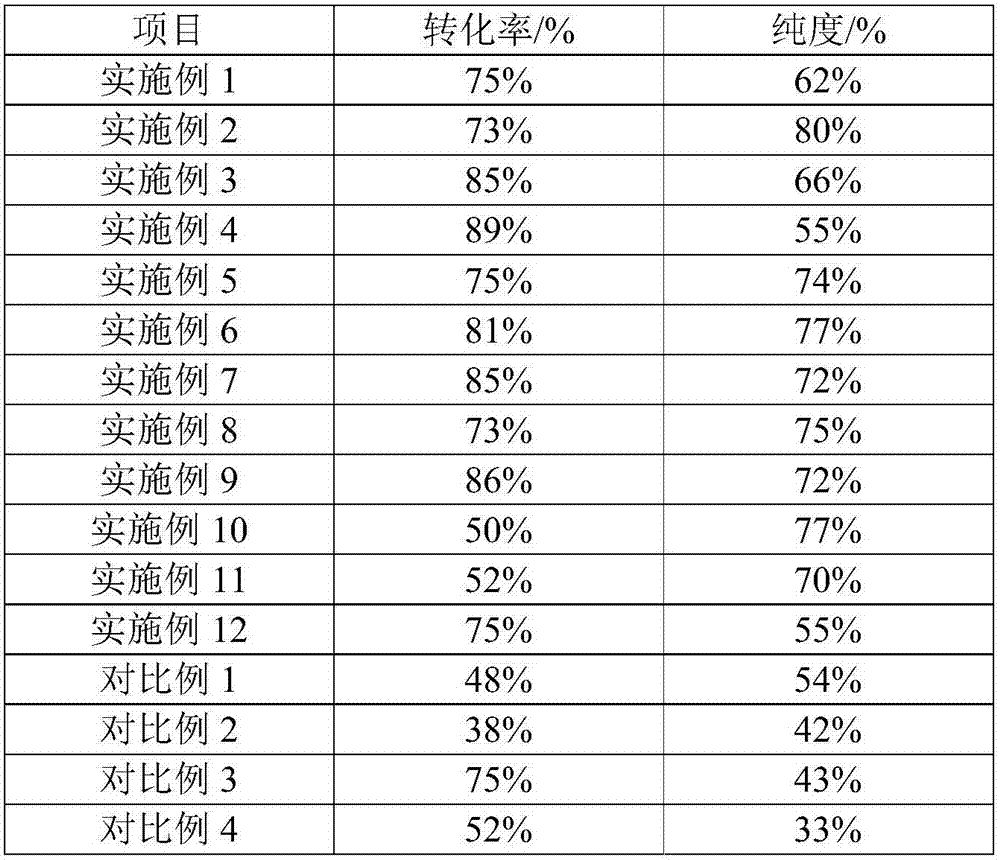

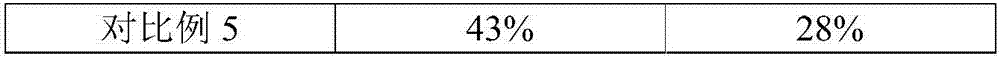

Examples

Embodiment 1

[0035] A preparation method of nano-silver particles, said method comprising the following steps:

[0036](1) Disperse 1.4g of silver nitrate in 30mL of ethylene glycol to obtain a silver nitrate dispersion, and disperse 1.1g of PVPK15 in 30mL of ethylene glycol to obtain a polyvinylpyrrolidone dispersion;

[0037] (2) Mix the silver nitrate dispersion obtained in step (1) with the polyvinylpyrrolidone dispersion, react at 120° C. for 1 h under stirring at 400 r / min, centrifuge, wash, and dry to obtain silver nanoparticles.

Embodiment 2

[0039] A preparation method of nano-silver particles, said method comprising the following steps:

[0040] (1) Disperse 2.5g of silver nitrate in 30mL of ethylene glycol to obtain a silver nitrate dispersion, and disperse 1.8g of PVPK30 in 30mL of ethylene glycol to obtain a polyvinylpyrrolidone dispersion;

[0041] (2) Mix the silver nitrate dispersion obtained in step (1) with the polyvinylpyrrolidone dispersion, react at 135° C. for 2.5 h under stirring at 550 r / min, centrifuge, wash, and dry to obtain silver nanoparticles.

Embodiment 3

[0043] A preparation method of nano-silver particles, said method comprising the following steps:

[0044] (1) Disperse 3.5g of silver nitrate in 30mL of glycerol to obtain a silver nitrate dispersion, and disperse 3g of PVPK40 in 30mL of glycerol to obtain a polyvinylpyrrolidone dispersion;

[0045] (2) Mix the silver nitrate dispersion obtained in step (1) with the polyvinylpyrrolidone dispersion, react at 145° C. for 4.5 h under stirring at 750 r / min, centrifuge, wash, and dry to obtain silver nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com