Patents

Literature

54results about How to "Reduce pump pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

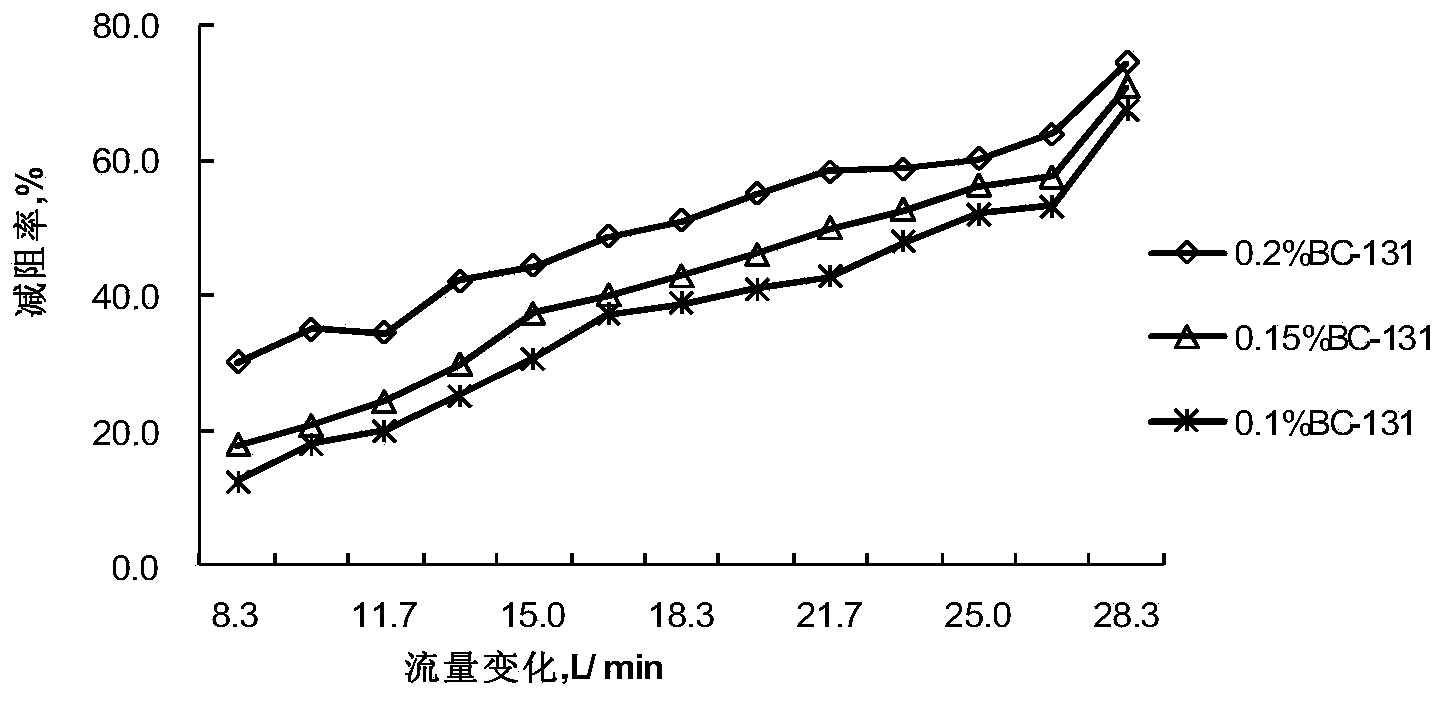

Acid liquor friction reducer and preparation method thereof

InactiveCN103820099AHigh resistance reduction rateImprove temperature resistanceDrilling compositionMeth-Pump pressure

The invention discloses an acid liquor friction reducer and a preparation method thereof. According to the invention, the preparation method comprises the following steps: weighing monomer 2-acrylamide-2-methylpro panesulfonic acid; placing into a beaker; adding deionized water for dissolution; adding caustic soda flakes to adjust to the pH value of the system to be 8-10; adding monomer acrylamide and long-chain cation monomer; mixing under the condition of supplying an inert gas; adjusting the water bath temperature to be the initiation reaction temperature and adding an initiator; reacting to obtain transparent gelatin blocks; manually cutting the transparent gelatin blocks; drying, smashing, and screening with 100 mesh to obtain powdered acid liquor friction reducer. According to the invention, the synthesis method is simple, the raw materials are easy to obtain, and the cost is lowered; the acid liquor friction reducer prepared by the invention has a friction reducing rate as high as 65%, the pump pressure is reduced, the pipe line loss is reduced, and the service life of equipment is prolonged; the acid liquor friction reducer is good in temperature tolerance and compatibility, and has a certain speed reducing effect.

Owner:CHENGDU BAICHUN PETROLEUM TECH

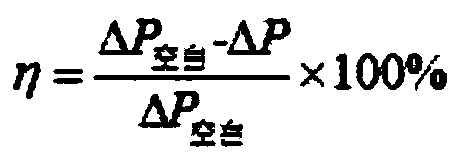

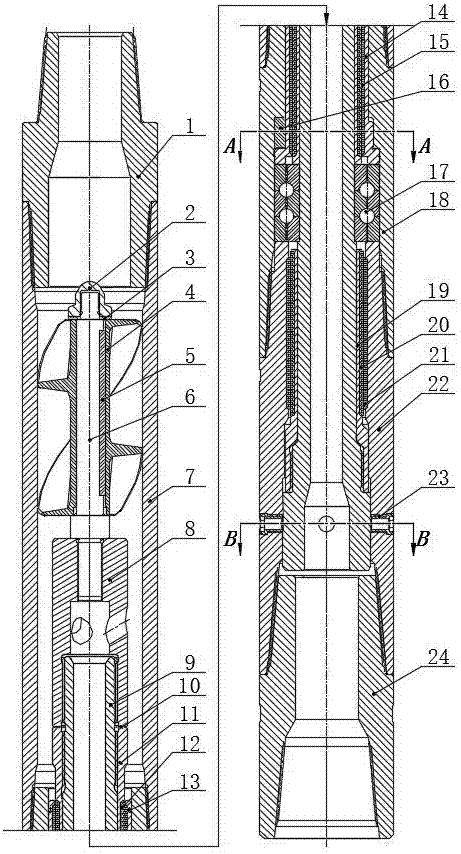

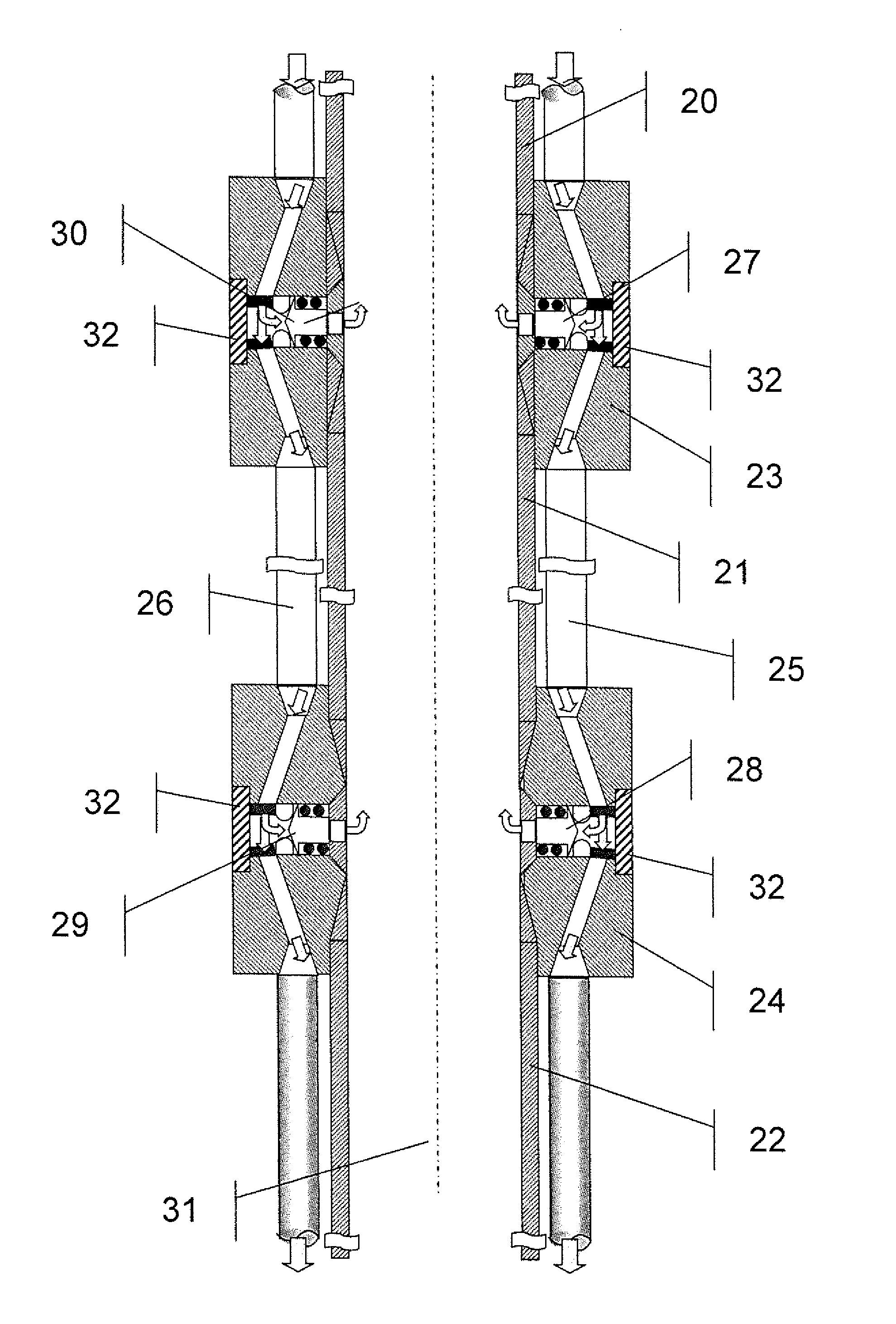

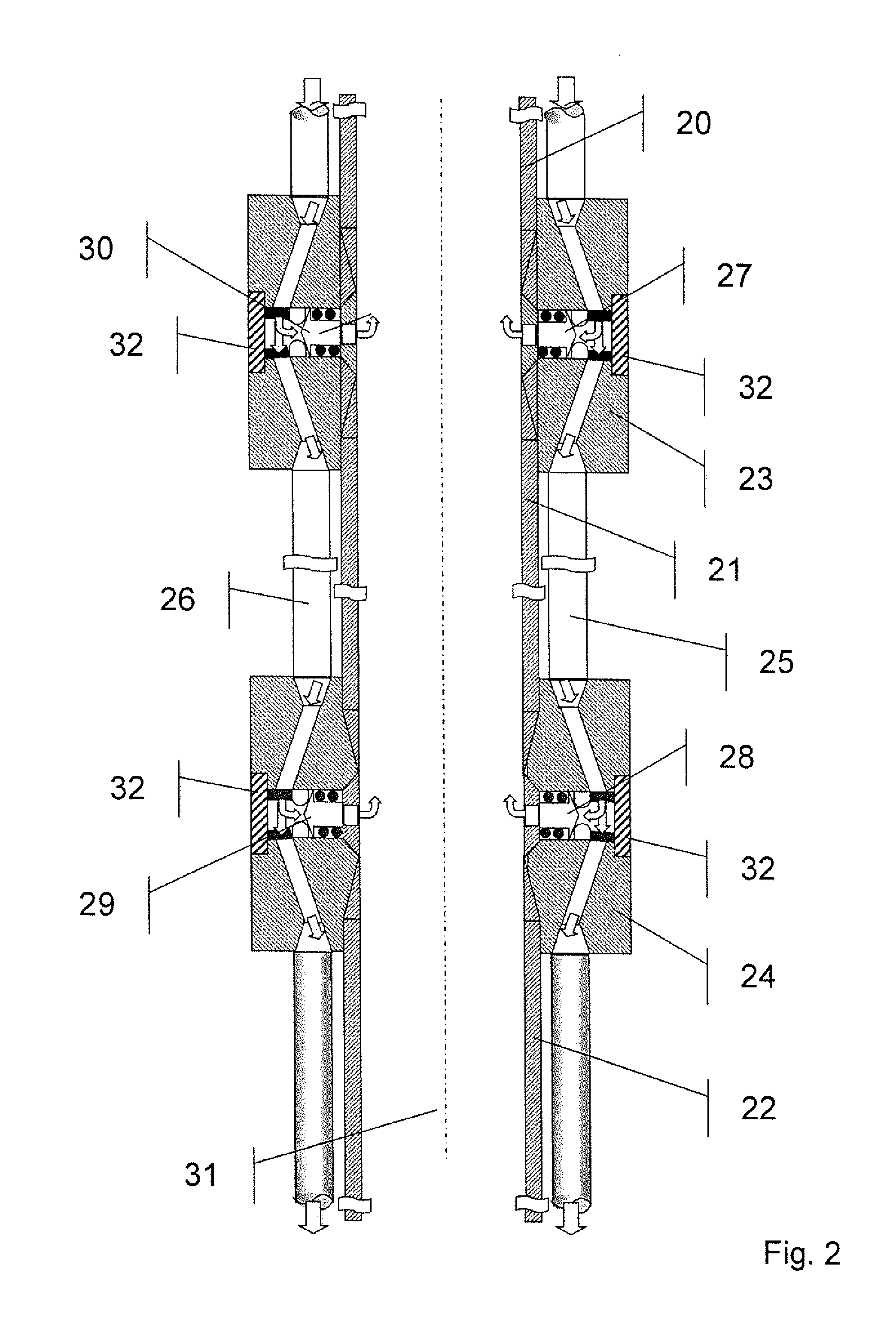

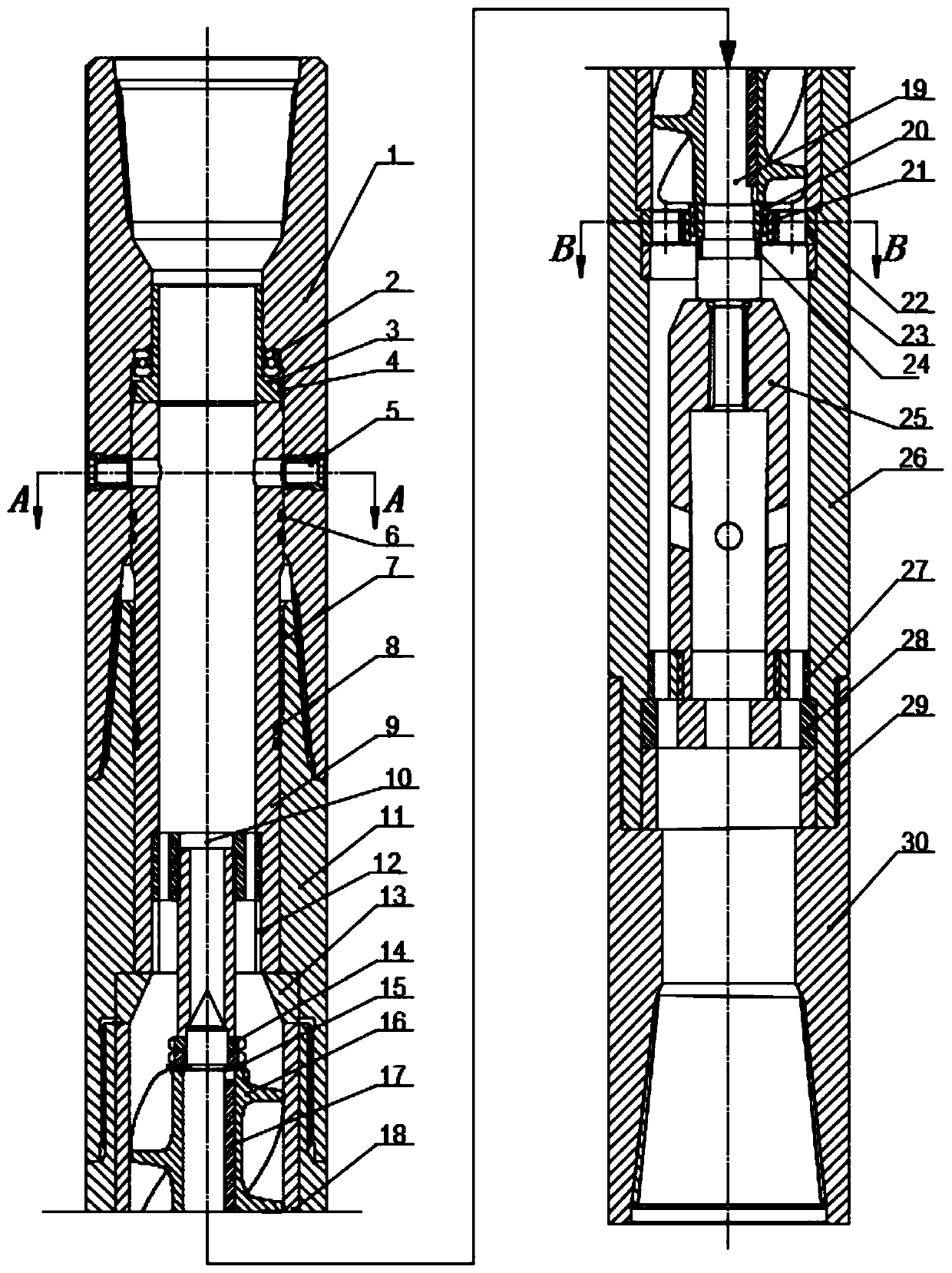

Screw type negative pressure pulsed hydroscillator

ActiveCN107165577AImprove rock-carrying abilityHelp transportVibration devicesVibration drillingDrive shaftSpray nozzle

The invention discloses a hydroscillator which is used in petroleum drilling and other fields and has a cuttings discharging function. According to the technical scheme, an upper connector, a stator casing, a universal shaft casing, a bearing supporting sub and a lower connector are sequentially in threaded connection; a power assembly comprises the upper connector, a rotor compressing cap, a screw rotor, a rubber stator and the stator casing; the screw rotor, a universal shaft and a transmission shaft are sequentially in threaded connection; a valve assembly comprises a flow passing transmission shaft, a cam system, a spray nozzle, a spring system and the lower connector, the flow passing transmission shaft and a cam bushing are in threaded connection, a cam is fixed on the cam bushing through screws, and a valve element is matched with the lower connector through a key groove; the cam system converts rotation motion of a screw motor into axial motion of the valve element, and opening and closing of a valve are realized. With the adoption of the hydroscillator, friction resistance between a drilling tool at the lower part of a horizontal well or a large-displacement well and the well wall can be reduced effectively, the cuttings bringing capacity of a drilling fluid can be improved, the drilling efficiency is improved, and downhole accidents such as sticking can be avoided.

Owner:SHANDONG WANGCHAOTIANRUN MACHINERY MFG CO LTD

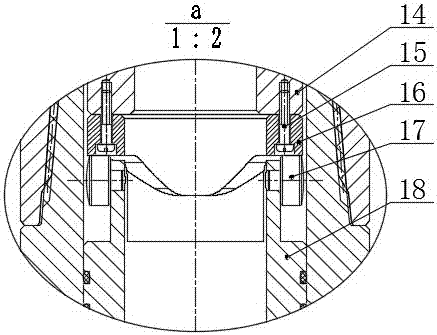

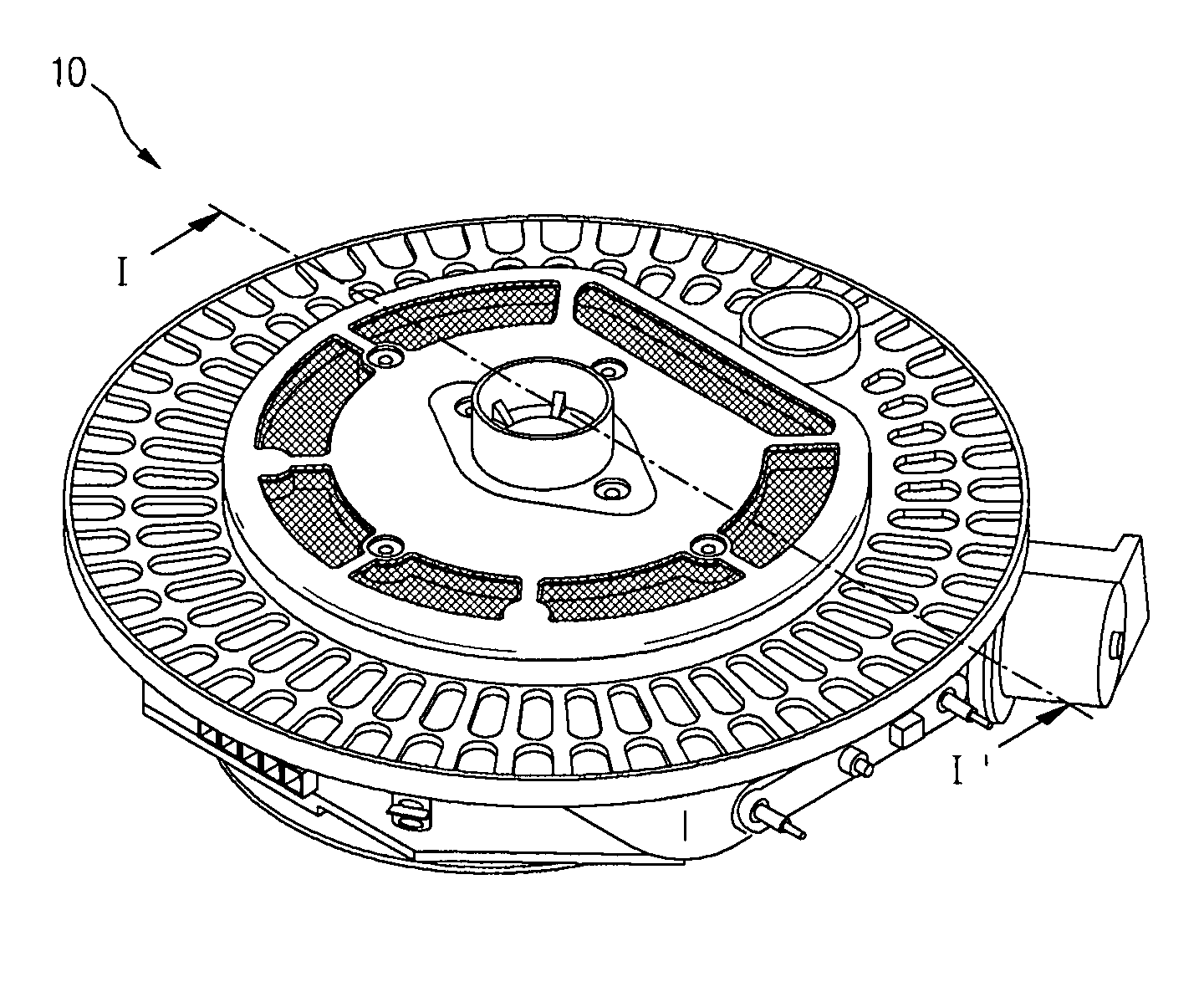

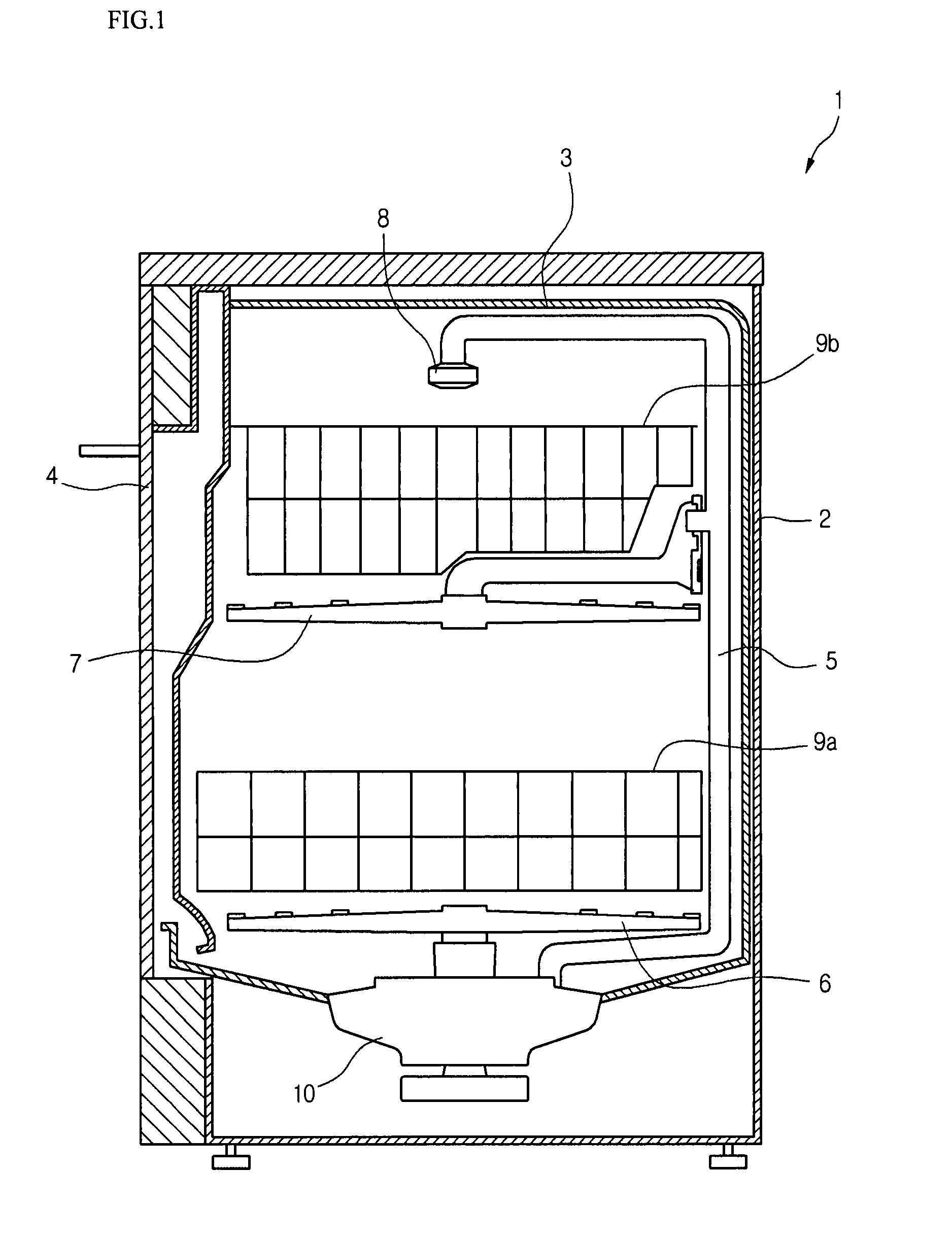

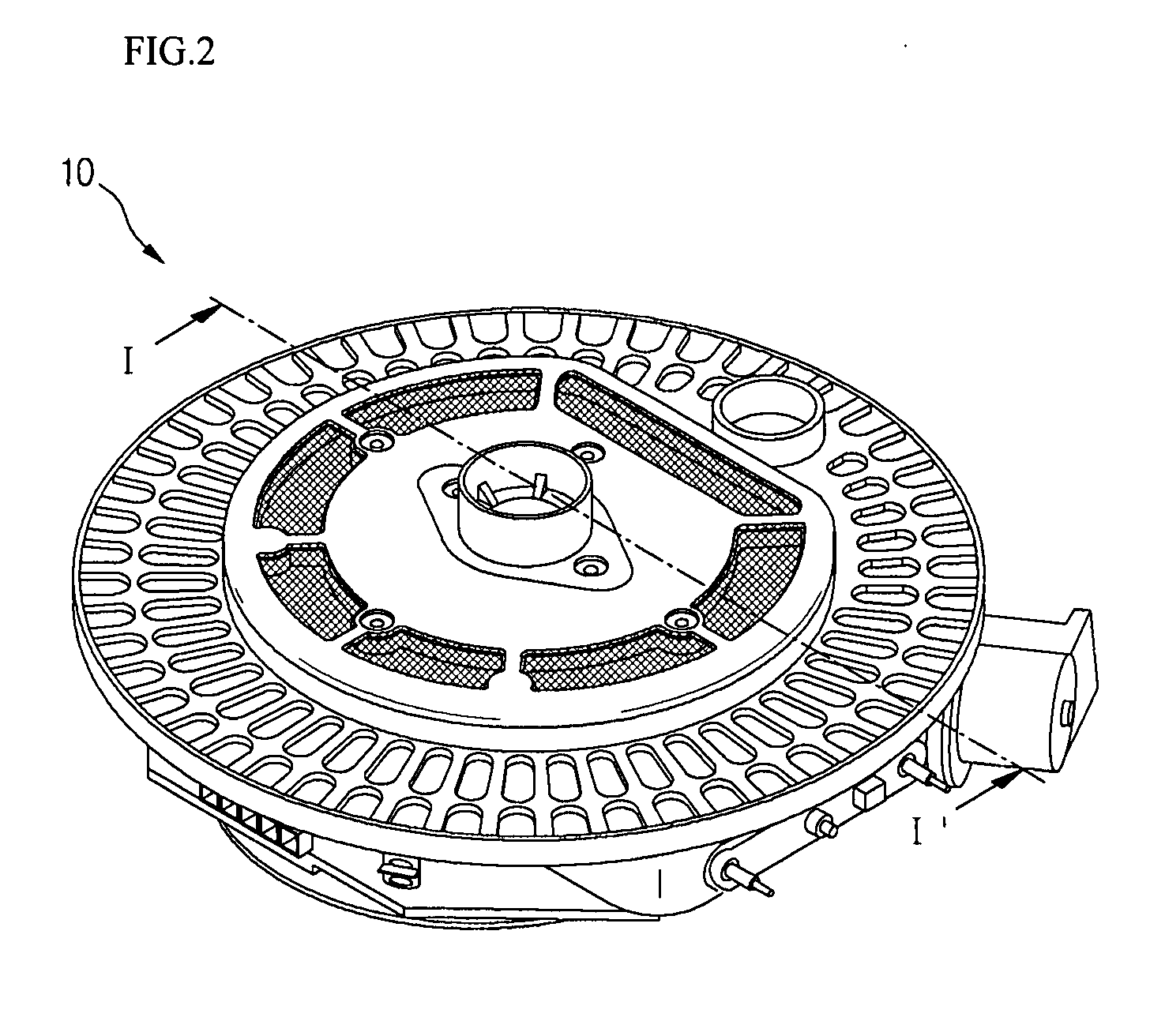

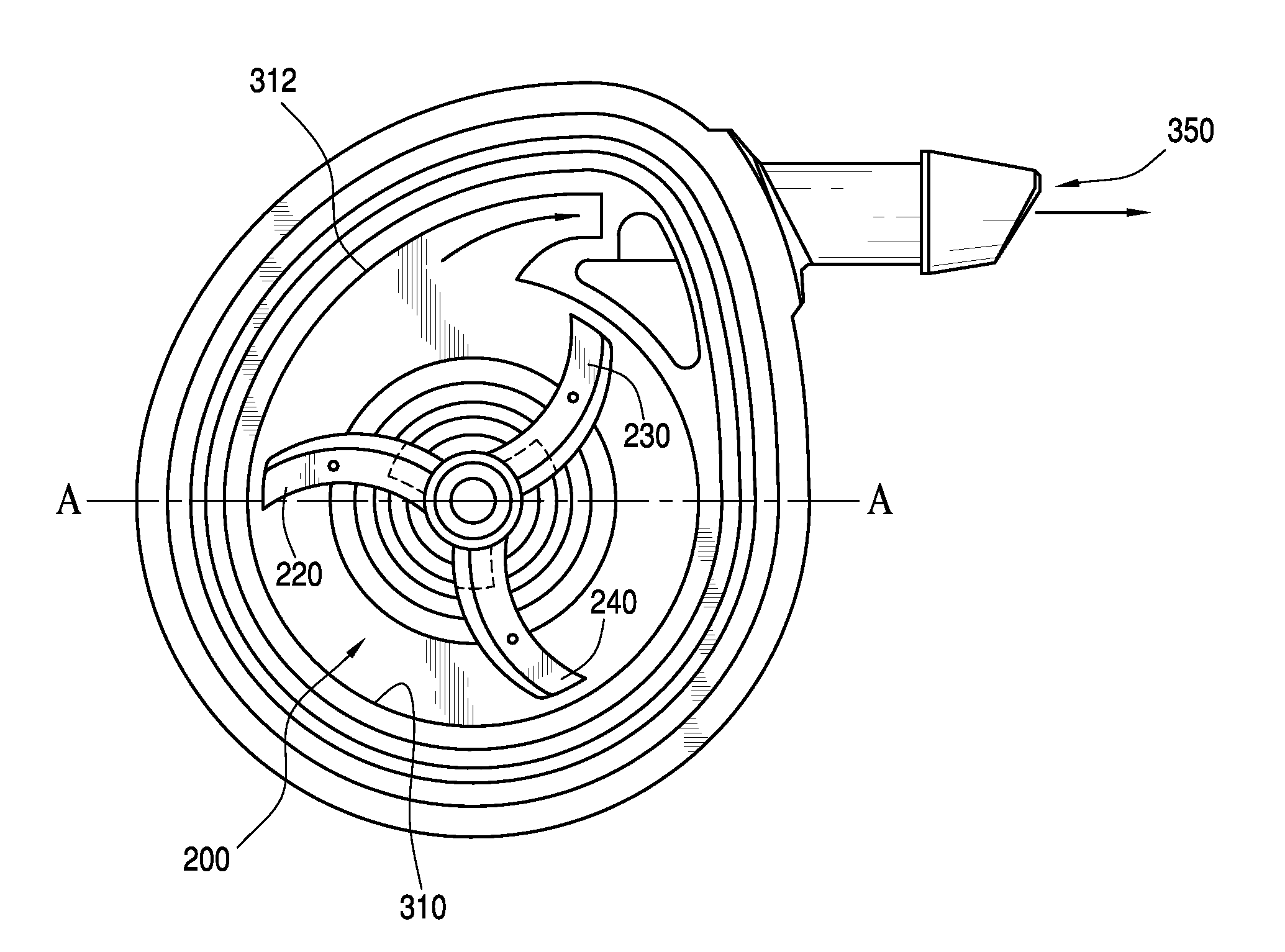

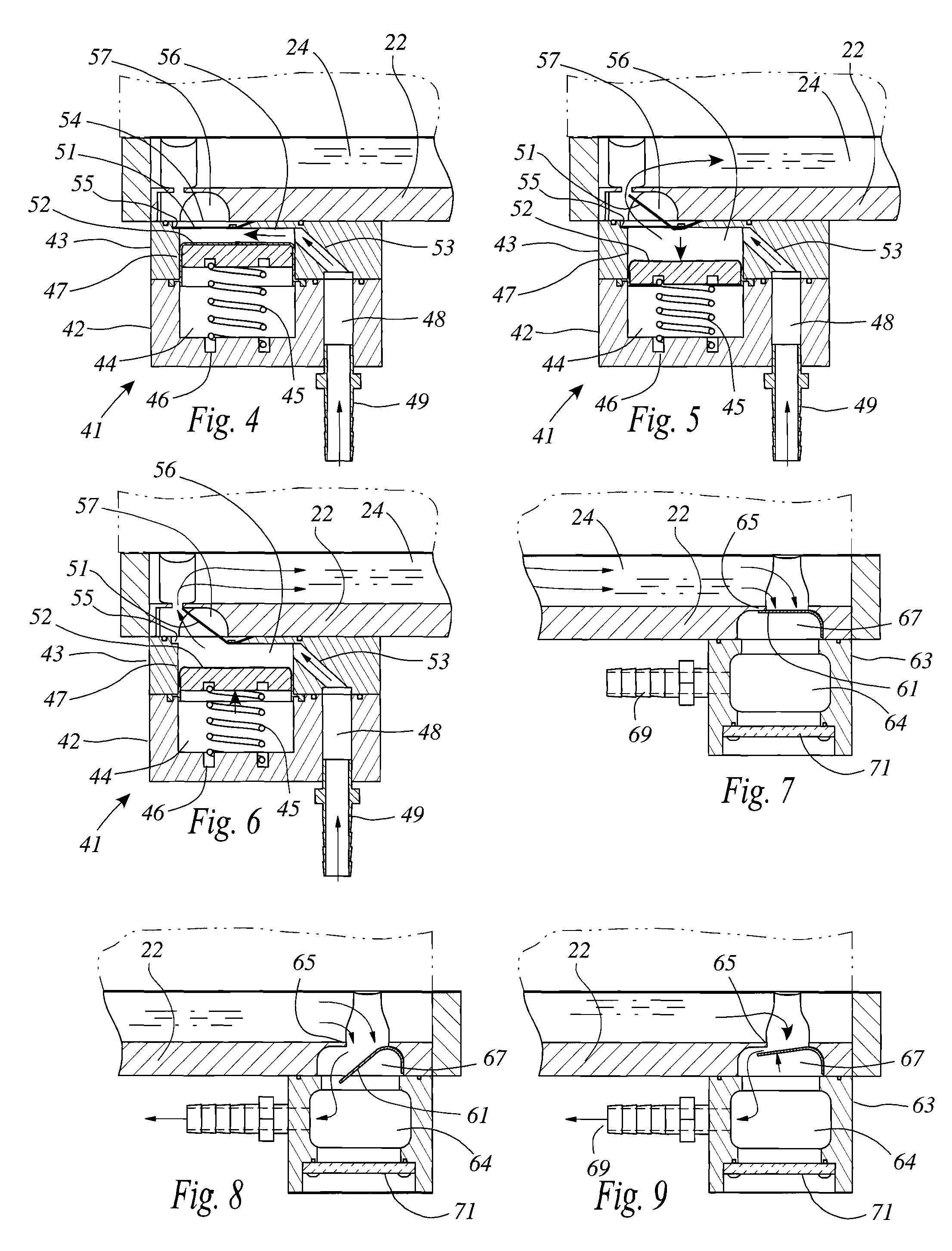

Sump for dishwasher

InactiveUS20080072934A1Simplify the assembly processReduce pump pressureTableware washing/rinsing machine detailsCleaning using liquidsEngineeringSump

A sump for a dishwasher includes a sump case for storing washing fluid, a washing pump assembly including a flow guide to pump out the washing fluid, and a filtering assembly including a flow guide to accumulate foreign particles contained in the washing fluid during the circulation of the washing fluid. The sump includes a sump cover to cover an opening of the sump case, and a self-cleaning assembly for filtering out the foreign particles directed to the flow guide. The flow guide, the sump cover and the self-cleaning assembly are thermally bonded to form a single unit.

Owner:LG ELECTRONICS INC

Polyacrylamide slurry for fracturing fluids

ActiveUS20170313930A1Promote hydrationEnhances inversionFluid removalDrilling compositionFracturing fluidSuspending Agents

The present disclosure relates to fracturing fluids that use friction reducers. The composition of the present disclosure is a slurry comprising a water-soluble polymer suspended in an oil-based vehicle with the aid of a suspension agent and a surfactant. Specifically, the water-soluble polymer is polyacrylamide and the oil-based vehicle is petroleum distillate. The surfactant is an ethoxylated nonionic emulsifier. The surfactant can be a fatty chain EO / PO (ethylene oxide propylene oxide) and / or oxylated propoxy copolymer. The suspension aid is any variation of diblock copolymers based on styrene and ethylene / propylene. The composition may also contain a dispersant such as organophilic clay or a synthetic alternative as the suspension agent.

Owner:PFP IND LLC

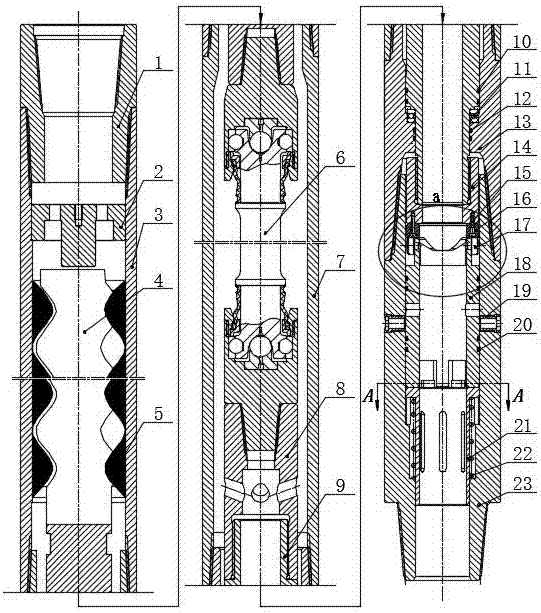

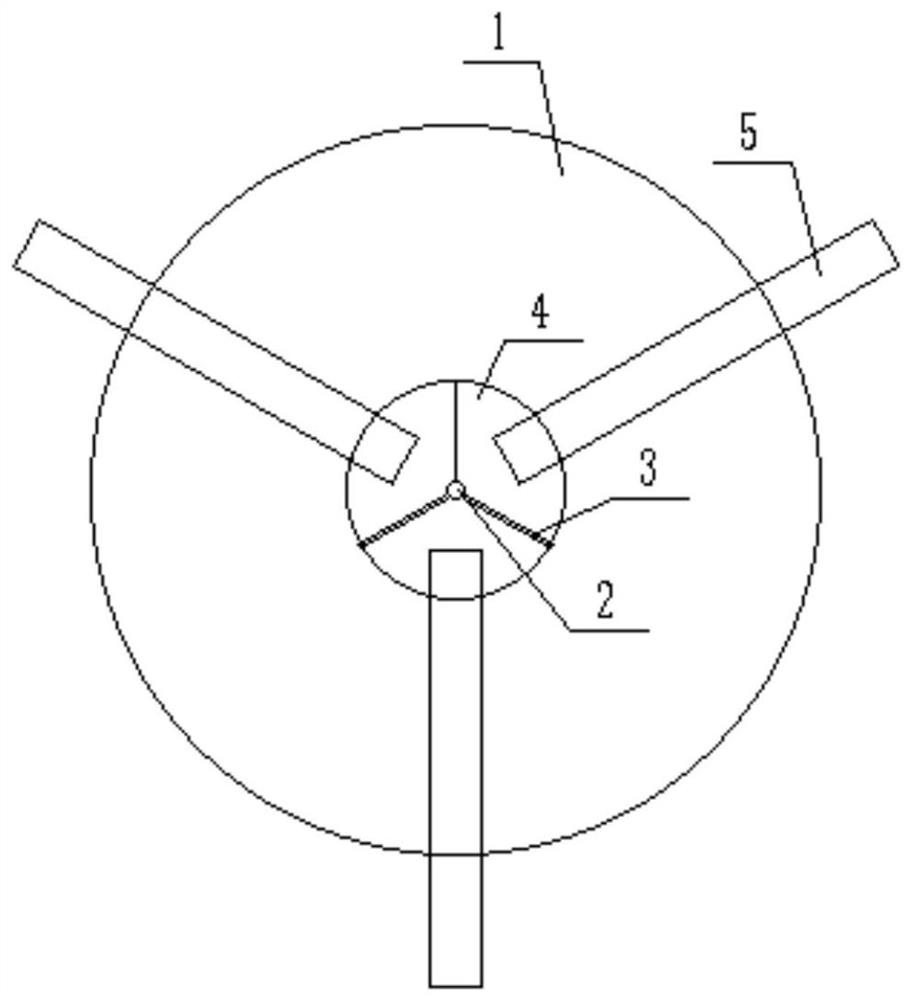

Negative pressure pulse oscillator

InactiveCN107420061AReduce consumptionImprove rock-carrying abilityVibration devicesVibration drillingImpellerEngineering

The invention discloses an oscillator which is used in the field of petroleum drilling and is capable of promoting cutting bringing of drilling fluid. According to the technical scheme, an upper connector, an impeller shell, a bearing shell, a nozzle shell and a lower connector are in threaded connection in sequence; an impeller and an impeller mandrel are positioned through a flat key and a locking cap; the impeller mandrel, a water cap and a valve core tube are in threaded connection in sequence; torque generated by the impeller impacted by drilling fluid is conducted to the valve core tube through the impeller mandrel and the water cap, and then the valve core tube is driven to rotate. A radial through hole is formed in the nozzle shell, fluid inside the tube is communicated and cut off from the outside when the valve core tube is rotated, pressure fluctuation of the fluid inside a tube column is achieved through internal and external pressure differences of the tube column, and a drilling column is vibrated. By adopting the oscillator, the friction resistance of a drill rig at the lower part of a horizontal well or a large displacement well to a well wall is effectively reduced, the cutting carrying property of the drilling fluid is improved, the drilling efficiency is improved, and under-well accidents such as drilling blocking can be avoided.

Owner:SOUTHWEST PETROLEUM UNIV

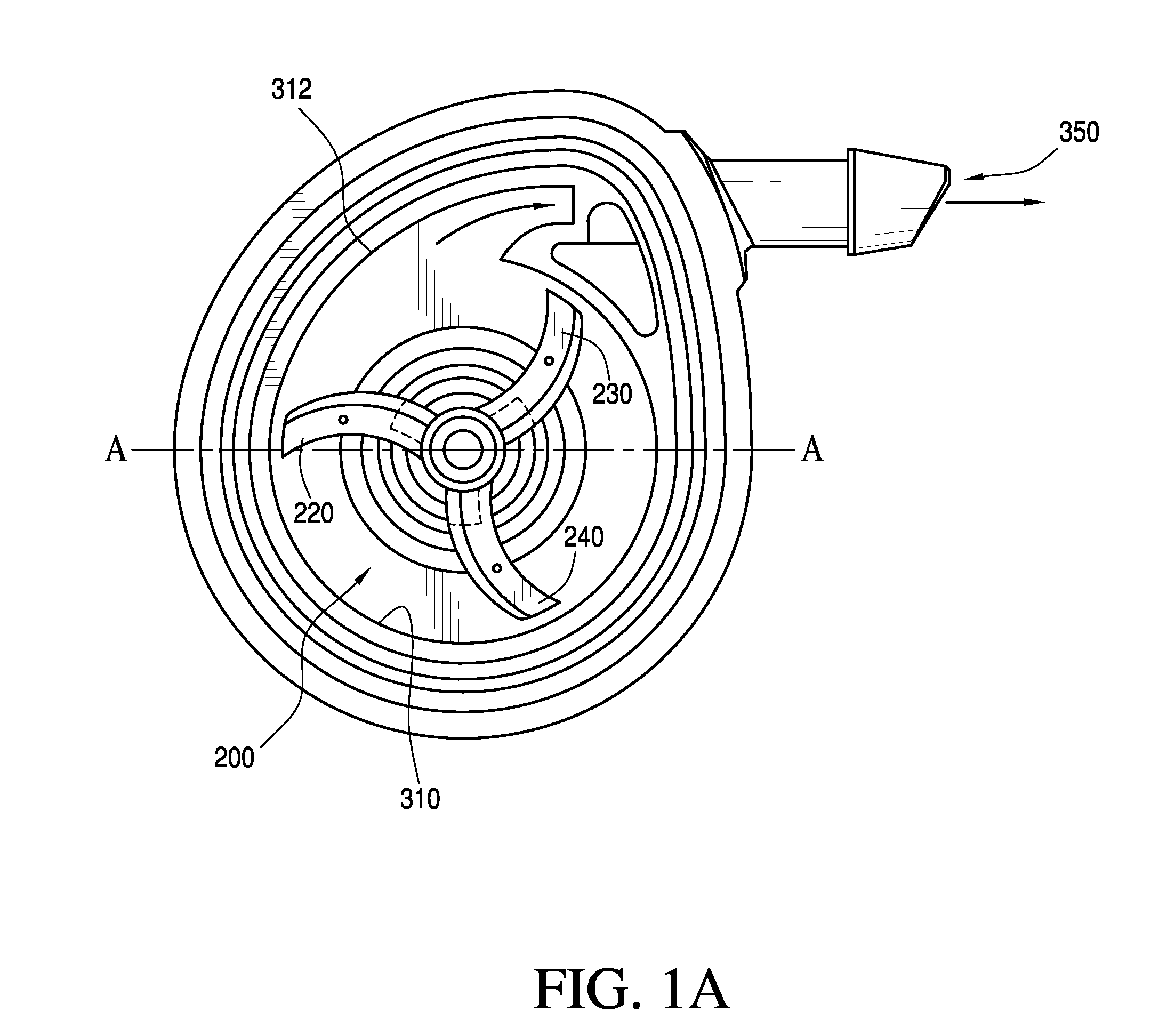

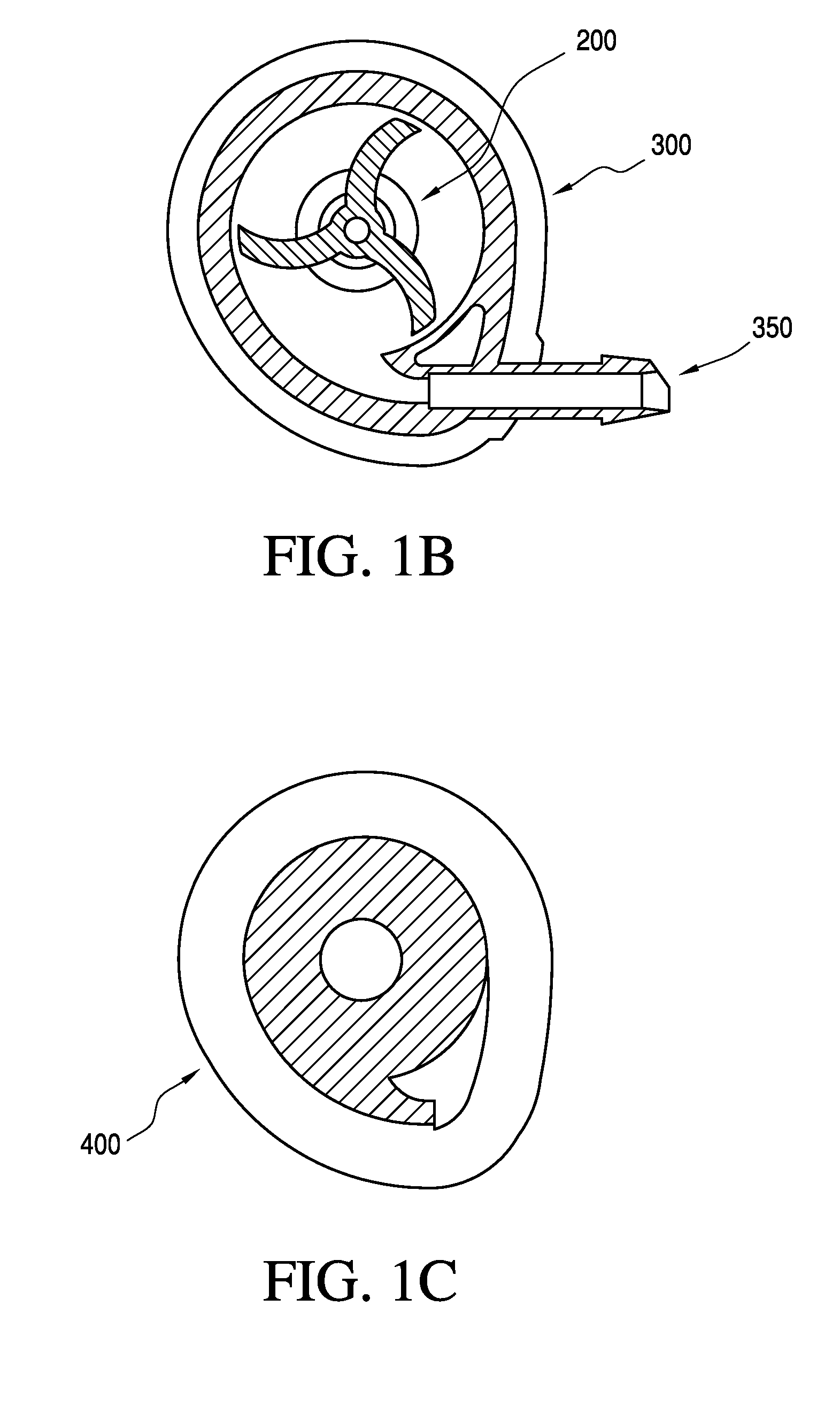

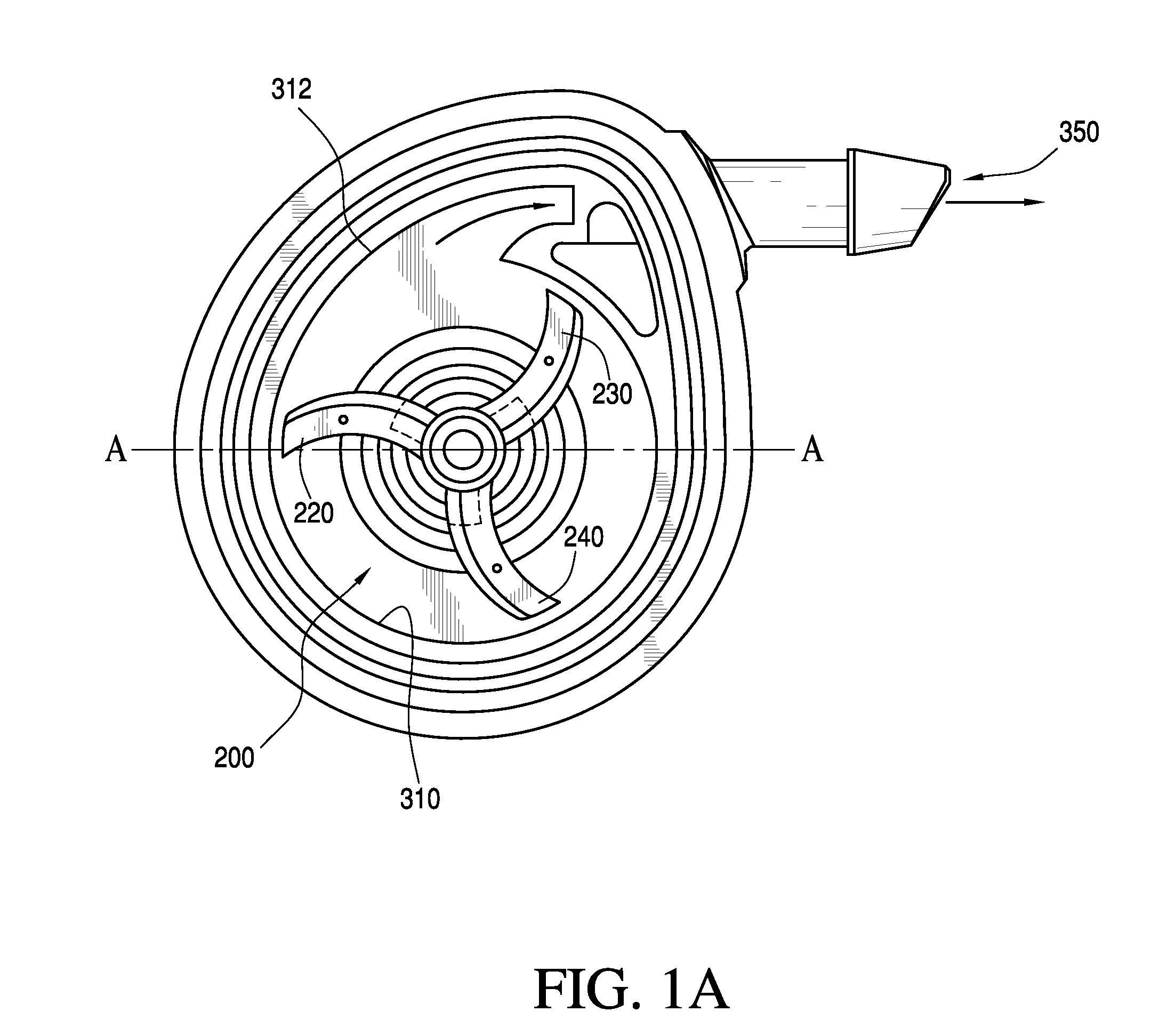

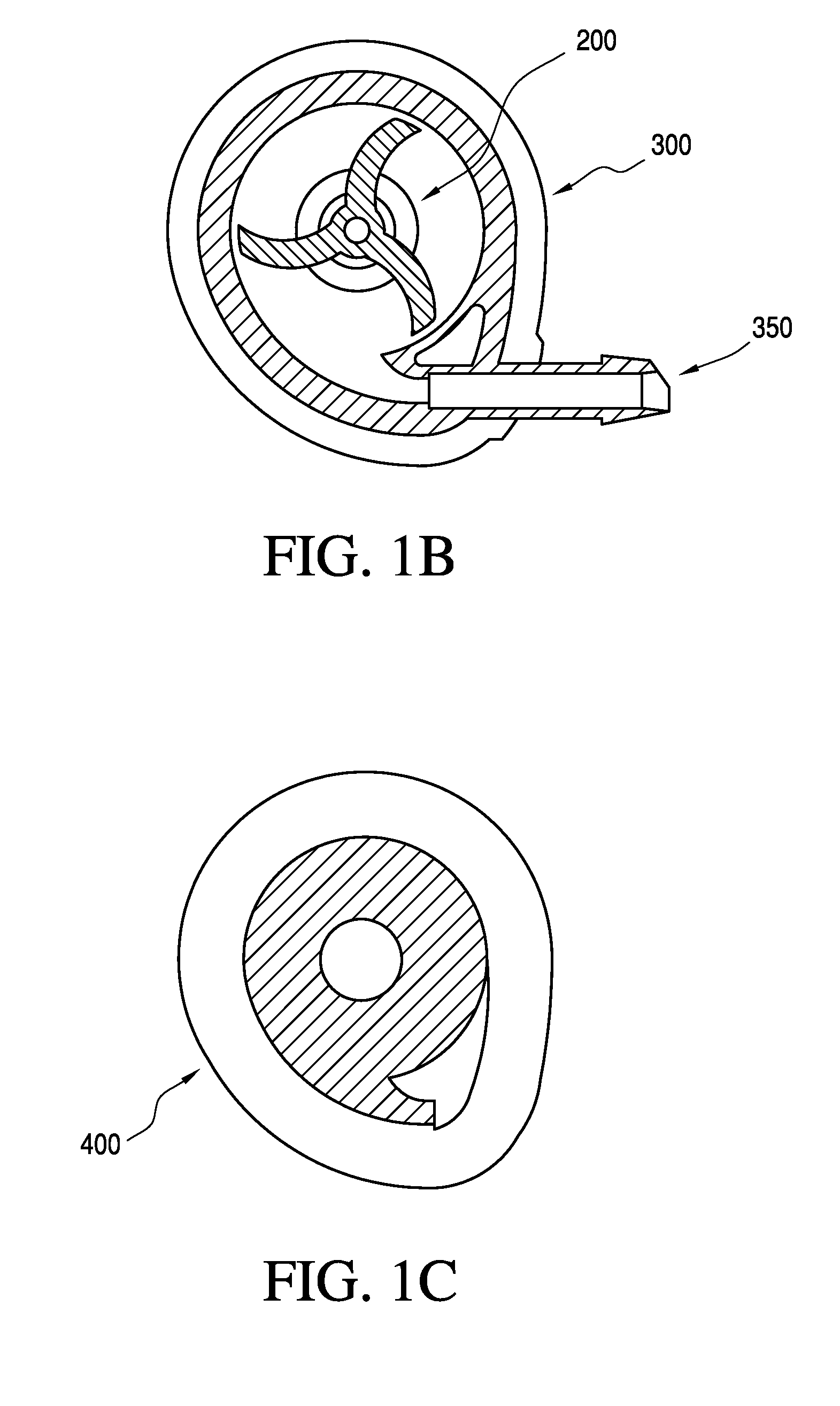

Washer pump

ActiveUS8348606B2Improved Pressure-flow rate (P-Q) curveReduce pump pressurePropellersPump componentsImpellerPump chamber

An enhanced pump assembly includes an impeller and volute casing designed to provide high operating pressures (“P”) and flow rates (“Q”) with low energy usage. The impeller has a central shaft carrying radially projecting curved primary vanes, and each primary vane also has a twist in the radial direction. Secondary impeller vanes define triangular connecting fillet-like wall segments connecting each primary vane to the impeller shaft. The casing of the pump has a slight spiral deviation so that the pump chamber's radial sidewall flares away from the swept area of the impeller's vanes to define a fluid outlet that contributes to higher P-Q performance, especially when pumping colder fluids.

Owner:DLHBOWLES INC

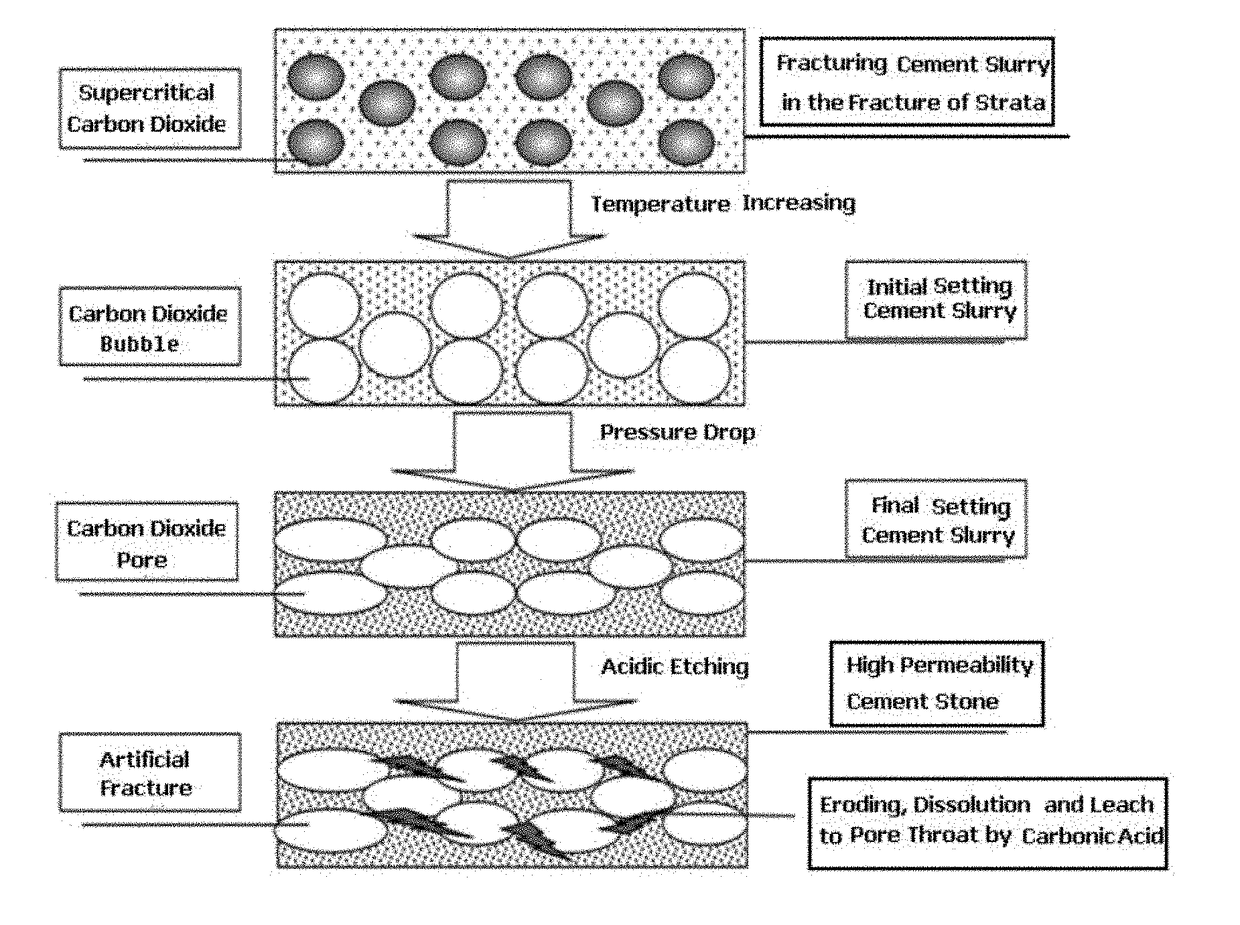

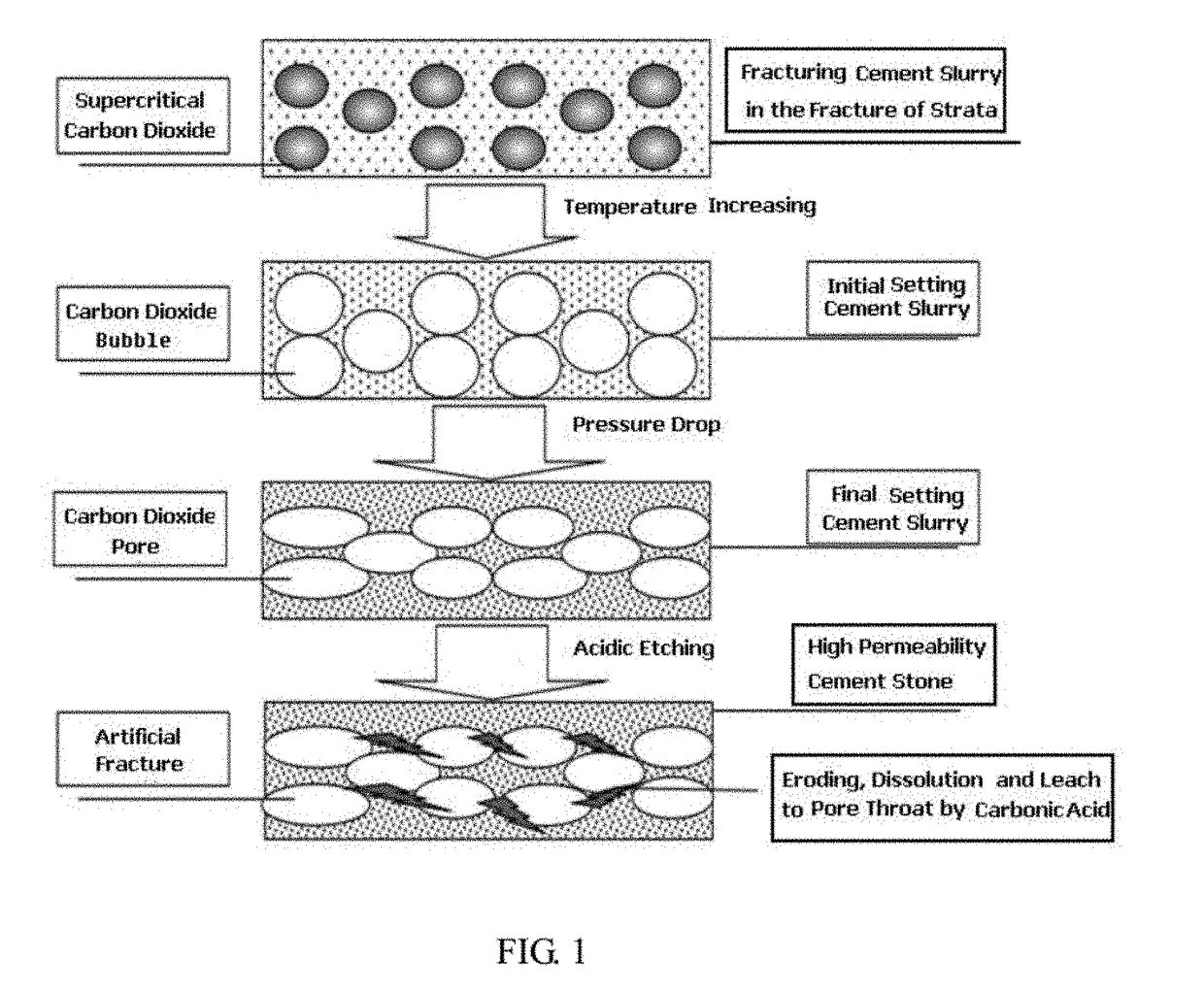

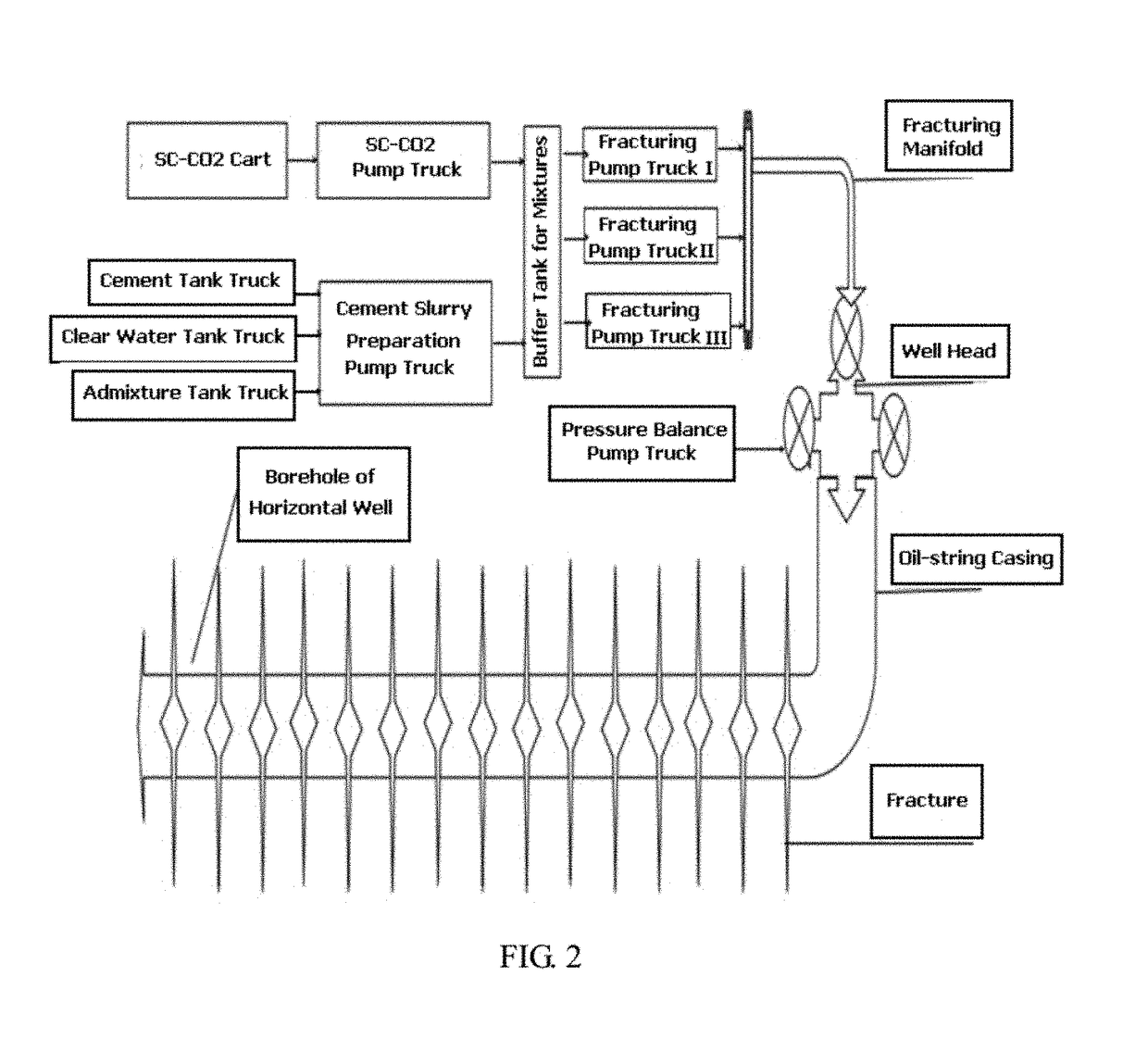

Permeable cement stone fracturing exploitation method for non-conventional oil and gas layer

ActiveUS20180238157A1High Effective PermeabilityStimulated is largeConstructionsOther gas emission reduction technologiesTight oilFracturing fluid

Disclosed is a permeable cement stone fracturing exploitation method for non-conventional oil and gas layer such as tight oil and gas, shale gas, coal-bed gas, combustible ice and so on. The method comprises the following complementary processes and embodiments: transporting, storing and pumping process for supercritical carbon dioxide; transporting, storing, preparing and pumping process for fracturing cement slurry; process for mixing the supercritical carbon dioxide and the cement slurry; process of fracturing the supercritical carbon dioxide and the cement slurry on ground; process of forming a permeable cement stone under the ground; and so on. The present invention provides a method for non-conventional oil and gas layer fracturing exploitation without using conventional fracturing proppant and fracturing fluid, having advantages of no flow-back fluid, less water, less material, less equipment, smaller area of well site, lower cost, better stimulation effect, environmental protection, and wide application.

Owner:SICHUAN XINGZHI ZHIHUI INTPROP OPERATION CO LTD +1

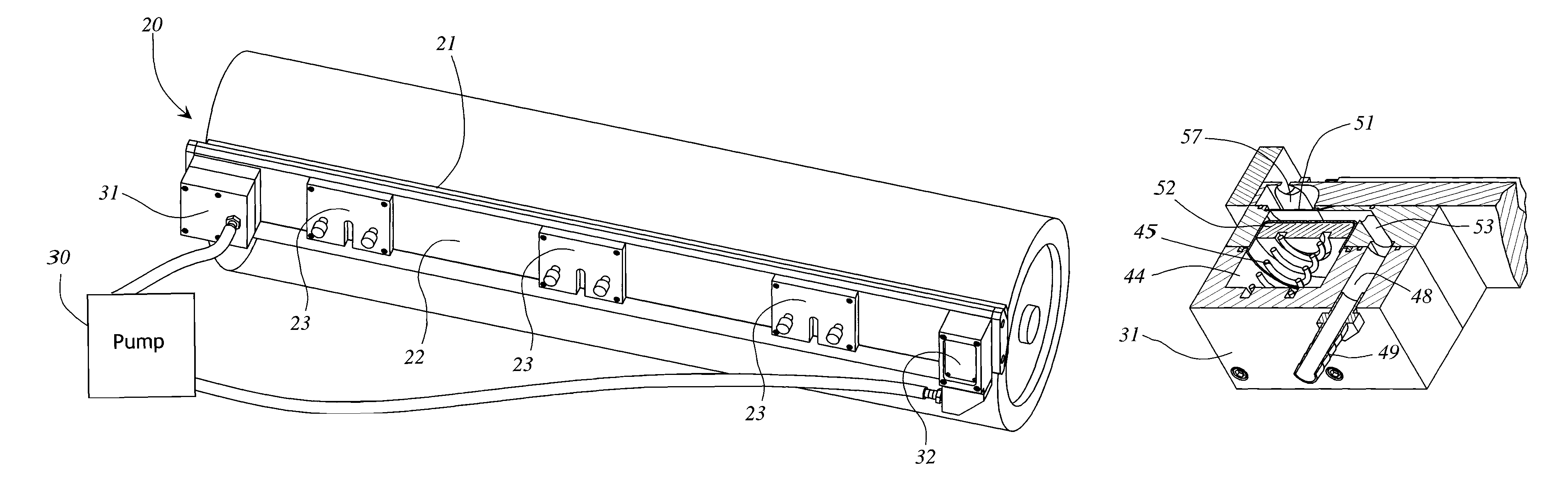

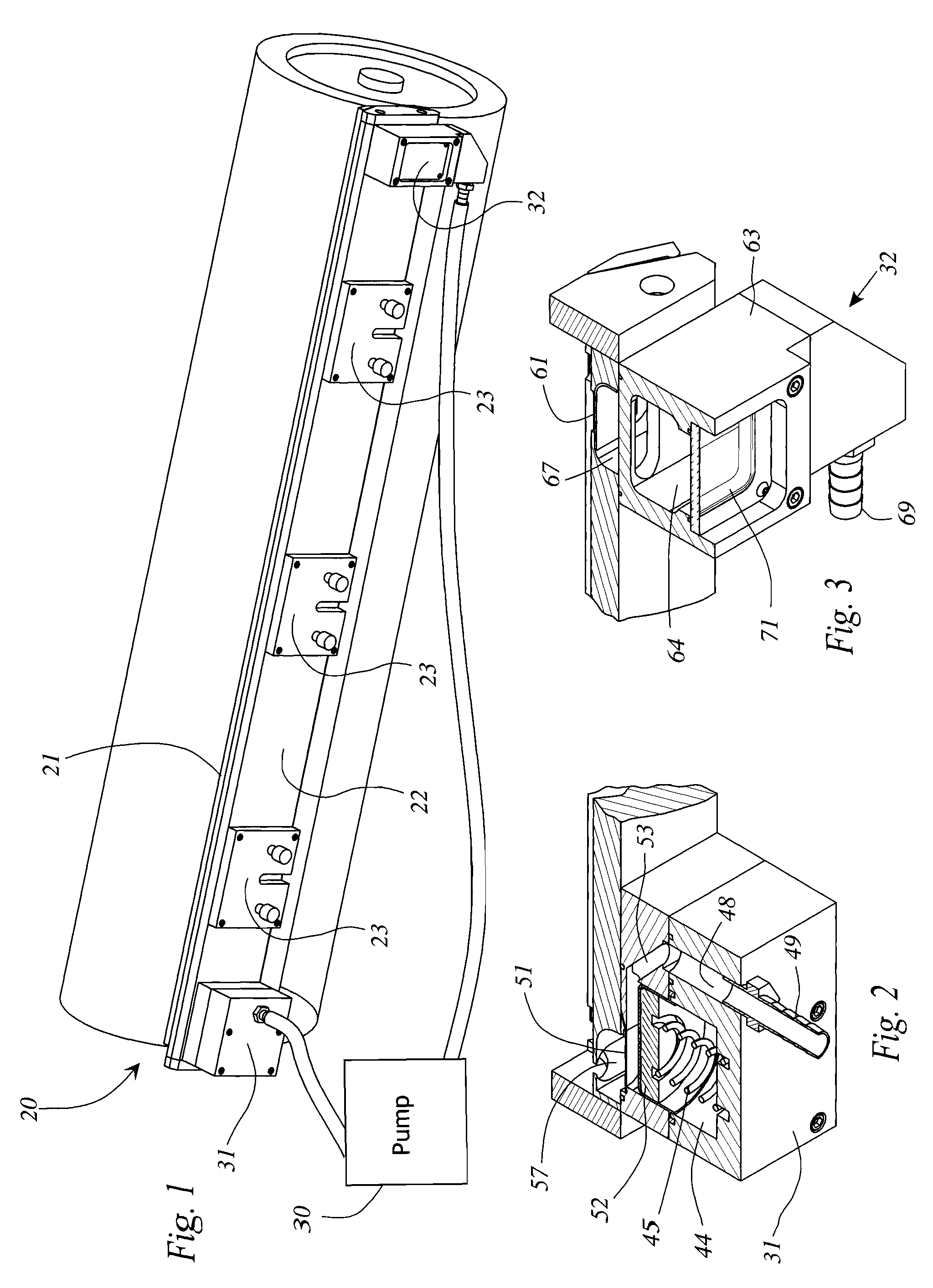

Stabilized high flow doctor blade head for transfer roller

InactiveUS20140060426A1High velocity flowReduce fluid pressureLiquid surface applicatorsCoatingsEngineeringPiston

A doctor blade head for coating a transfer roller includes a semi-cylindrical cavity to enable streamline fluid flow therethrough, and check plates at the inlet and outlet openings for permitting unidirectional flow into the inlet opening from said pump and out of the outlet opening toward the pump. An hydraulic accumulator acts as a fluid pressure and fluid velocity balancing device, and includes a rolling diaphragm piston moving in a cylinder that is connected to the inlet fluid path, with a spring impinging on the piston to absorb pressure surges and compensate pressure dropoffs.

Owner:HARRIS & BRUNO MACHINE

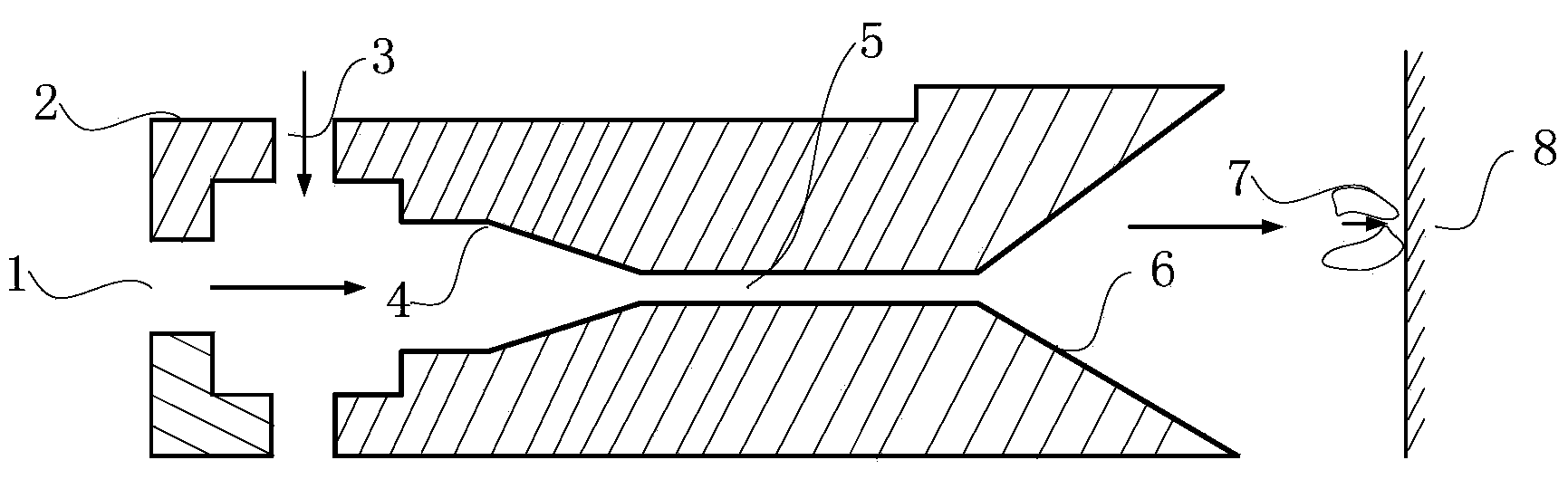

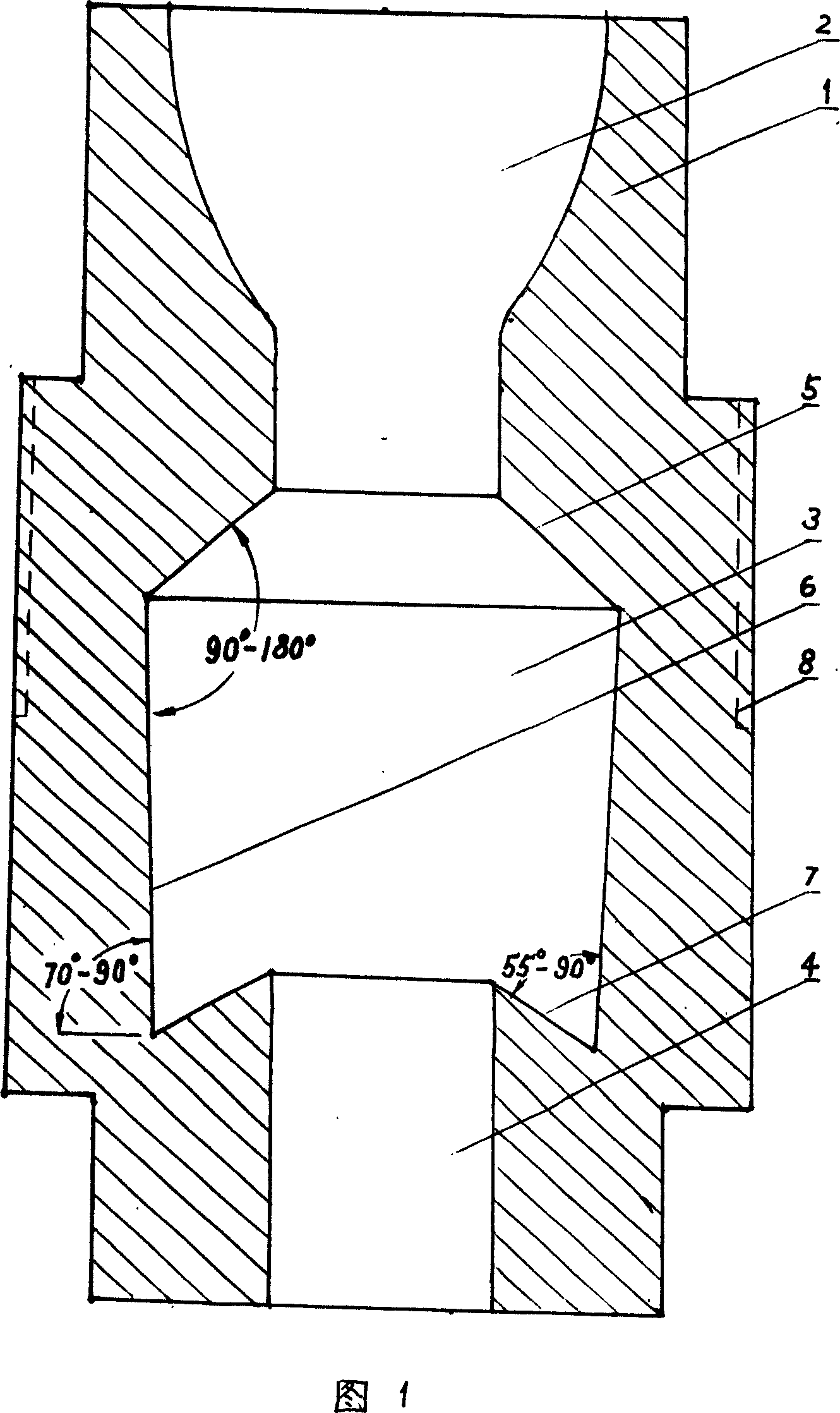

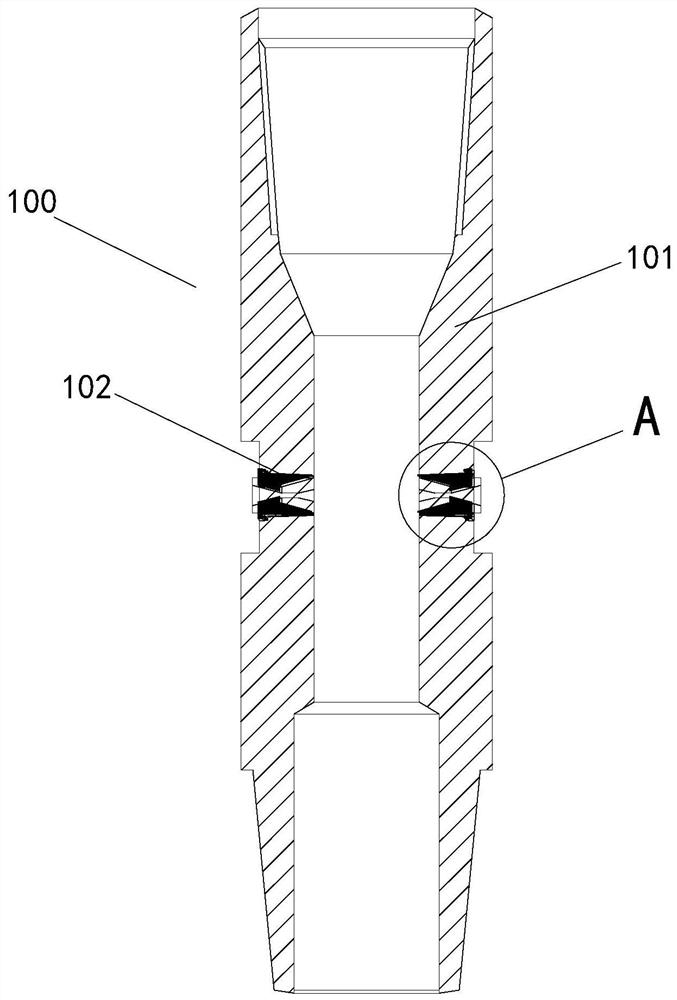

Structure for cleaning cavitation device by utilizing hyperventilation cavitating jet

InactiveCN104384122AReduce pump pressureReduce energy consumptionCleaning using liquidsHyperventilationSpray nozzle

The invention provides a structure for cleaning a cavitation device by utilizing hyperventilation cavitating jet. The cavitation device comprises a cavitation device wall surface, wherein a cavitation device chamber is formed in the inner part of the cavitation device wall surface, the cavitation device chamber comprises a cavitation device inner part contraction section, a cavitation device inner part advection section and a cavitation device inner part diffusion section which are sequentially communicated, the end part of the cavitation device inner part diffusion section is positioned at one end of the cavitation device wall surface, a cavitation device spray nozzle inlet is formed in the other end of the cavitation device wall surface, the cavitation device spray nozzle inlet is connected with a pump, a ventilation inlet is formed in the cavitation device wall surface between the cavitation device spray nozzle inlet and the cavitation device inner part contraction section, and the ventilation inlet is communicated with the cavitation device spray nozzle inlet and the cavitation device inner part contraction section. According to the cavitation device provided by the invention, the number of gas nucleus in water can be effectively increased, the collapsing and perishing number of cavitation bubbles can be increased, high pressure which is obtained through collapsing and perishing of the cavitation bubbles is used for cleaning, the pumping pressure needed for cleaning can be effectively reduced, and the energy consumption can be reduced.

Owner:HARBIN ENG UNIV

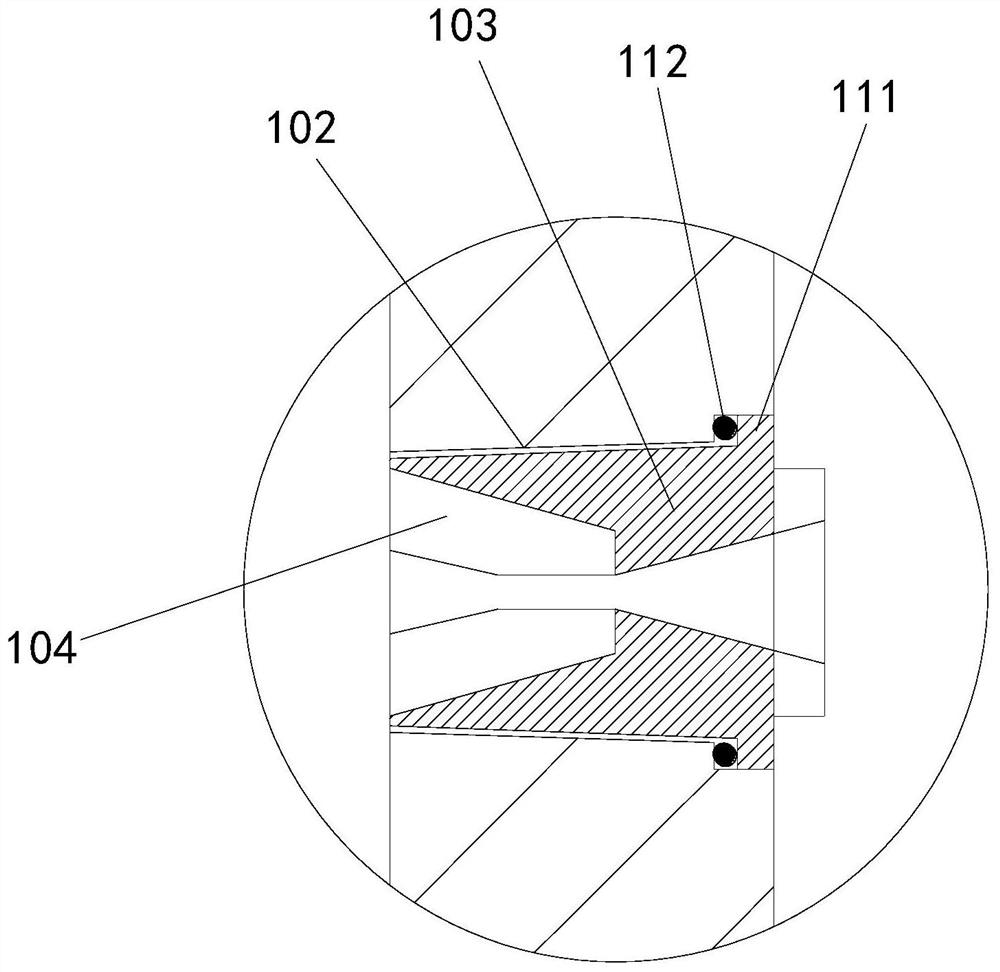

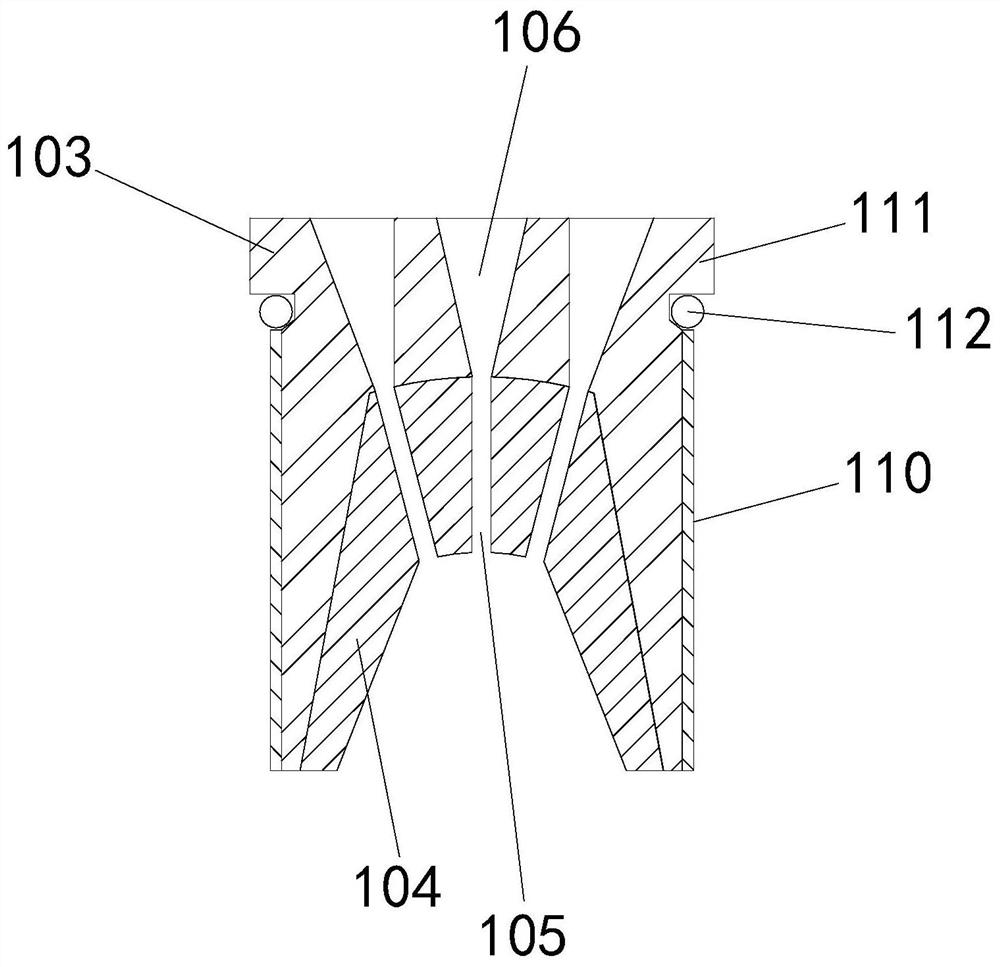

Cavitation jet cleaning cavitator

The invention discloses a cavitation jet cleaning cavitator. The cavitation jet cleaning cavitator comprises a pump and a shell, wherein a cavitation channel is arranged in the shell, and the pump iscommunicated with the inlet of the cavitation channel; the cavitation channel comprises a plurality of Venturi tube cavities which are sequentially connected in series, wherein the inlet section of the first grade of Venturi tube cavity is communicated with the inlet of the cavitation channel, the throat section of the final stage of Venturi tube cavity is communicated with the outlet of the cavitation channel, and a diffusion section is also arranged between the throat section of the final stage of Venturi tube cavity and the outlet of the cavitation channel; and an axial flow turbine is mounted at the inlet section of the first grade of Venturi tube cavity, and blades of the axial flow turbine are provided with through holes penetrating through the blades. The cavitation effect is enhanced by utilizing multiple stages of Venturi tube cavities and the through holes in the blades, and the water flow is accelerated by the axial flow turbine so as to ensure that cavitation bubbles arriveat a cleaning region in time; cleaning is performed through the energy generated when the cavitation bubbles collapse, so that the cavitation efficiency is improved; and the pumping pressure requiredby cleaning can be effectively reduced, and the energy consumption can be reduced.

Owner:ZHEJIANG SCI-TECH UNIV

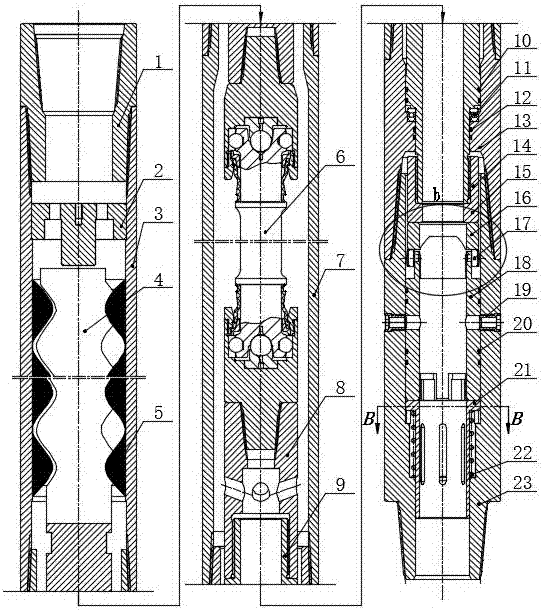

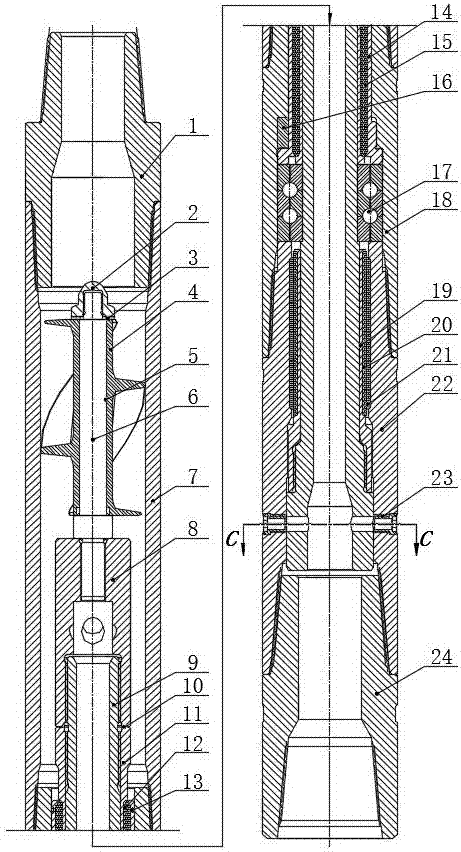

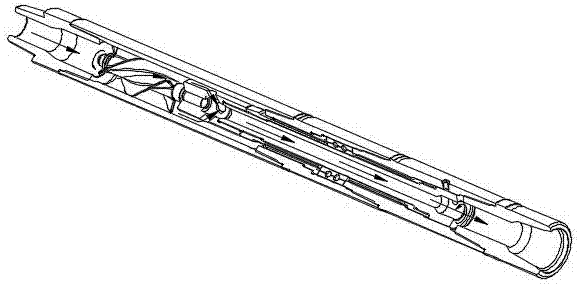

Tectonic coal large-diameter well completion bidirectional reciprocating type drilling three-level reaming drilling tool and hole-drilling method

ActiveCN108071344AReach out to achieveThe locking position is reachedDrill bitsDrilling machines and methodsThree levelTectonics

The invention relates to a tectonic coal large-diameter well completion bidirectional reciprocating type drilling three-level reaming drilling tool which is suitable for underground coal mine. A one-level reaming and a two-level reaming are completed with a plunger drill bit, a three-level reaming is completed with a cutter wing, and the activation of the reaming is adopted with a hydraulic control mode; springs are used for converting a fixed pressure value of the reaming pumping pressure to a pressure range with an appropriate range, and the operability of controlling the reaming pressure can be improved; and a three-level reaming recycling assembly drilling tool inner pipe is composed of an upper section and a lower section which are connected and sealed through an inner pipe connectingseal ring, and the down-moving of a cutter wing blocking mechanism and the cutter-out of the cutter wing can be completed step by step. The drilling reaming with a horizontal well, a vertical well, aslant well and the other modes can be achieved at the tectonic coal and other softer formation, a three-level reciprocating type reaming operation of one of hole segments can be completed according to engineering requirements, and the requirements of the tectonic coal coal-bed gas exploitation and the other engineering activities can be met.

Owner:CHINA UNIV OF MINING & TECH

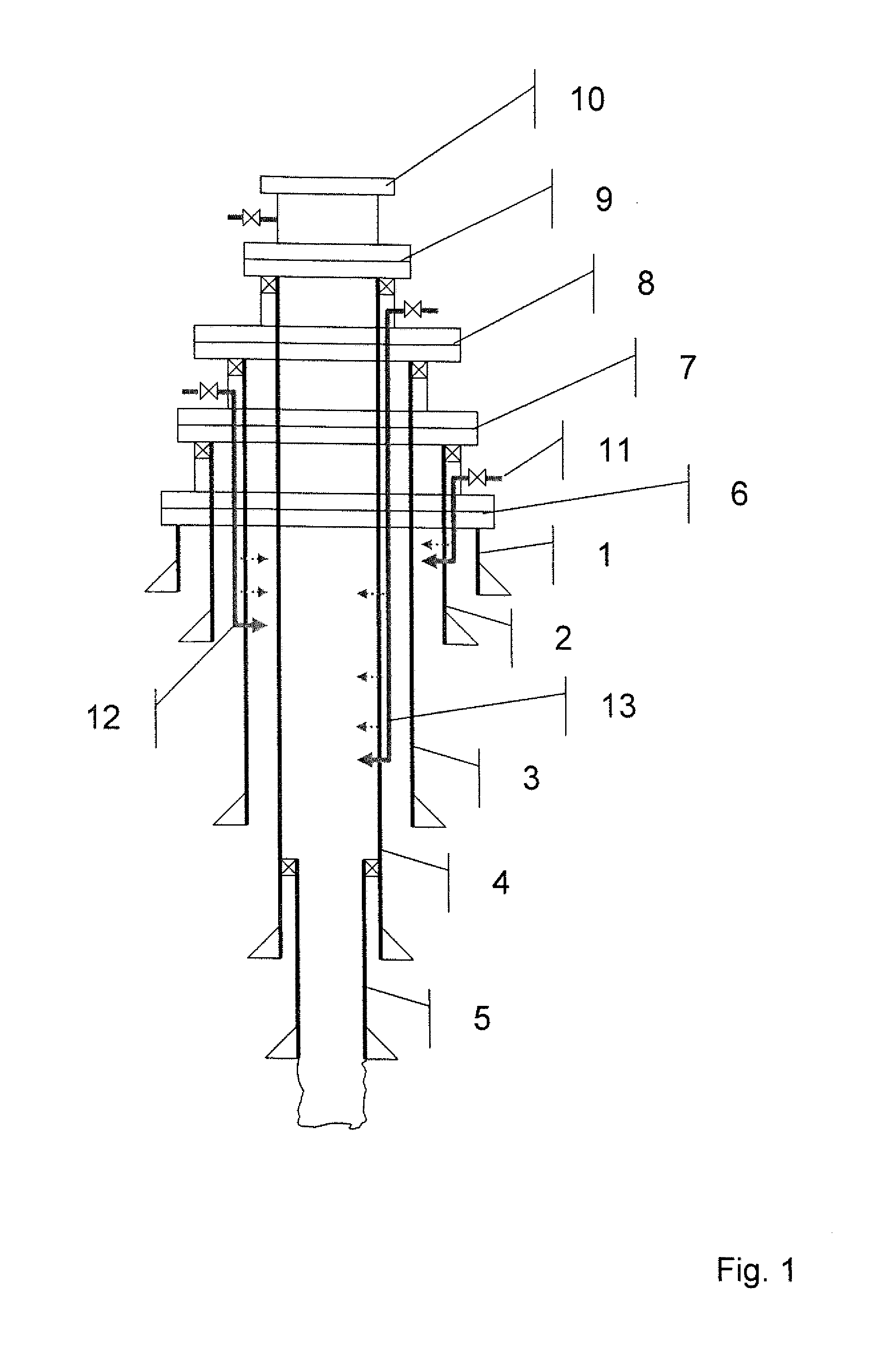

Apparatus for a pipe string of a geological drill hole, pipe string, method for operating a geological drilling gear and method for producing a pipe string for a geological drill hole

InactiveUS20120024603A1Damage formationAdvanced technologyDrilling rodsFluid removalDrill holeEngineering

The invention relates to an apparatus for a pipe string of a geological drill hole, with a pipe string element and a fluid supply line which is arranged outside the pipe string element, extends along the pipe string element and is connected to a fluid injection device on the pipe string element, by means of which a fluid supplied through the fluid supply line can be introduced into an inner space of the pipe string element. The invention furthermore relates to a pipe string of a geological drill hole, in particular of a geothermal drill hole, a method for operating a geological drilling machine and a method for producing a pipe string for a geological drill hole.

Owner:GEOFORSCHUNGSZENT POTSDAM A CORP OF GERMANY

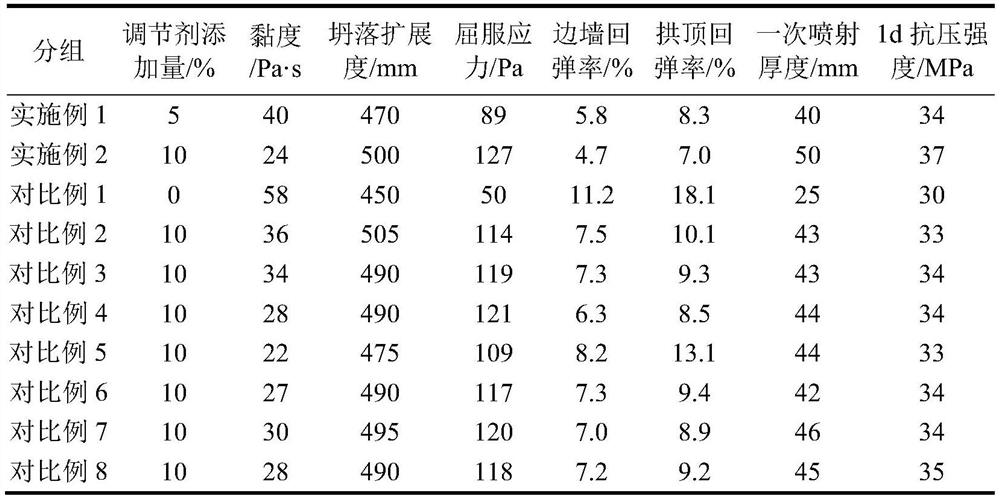

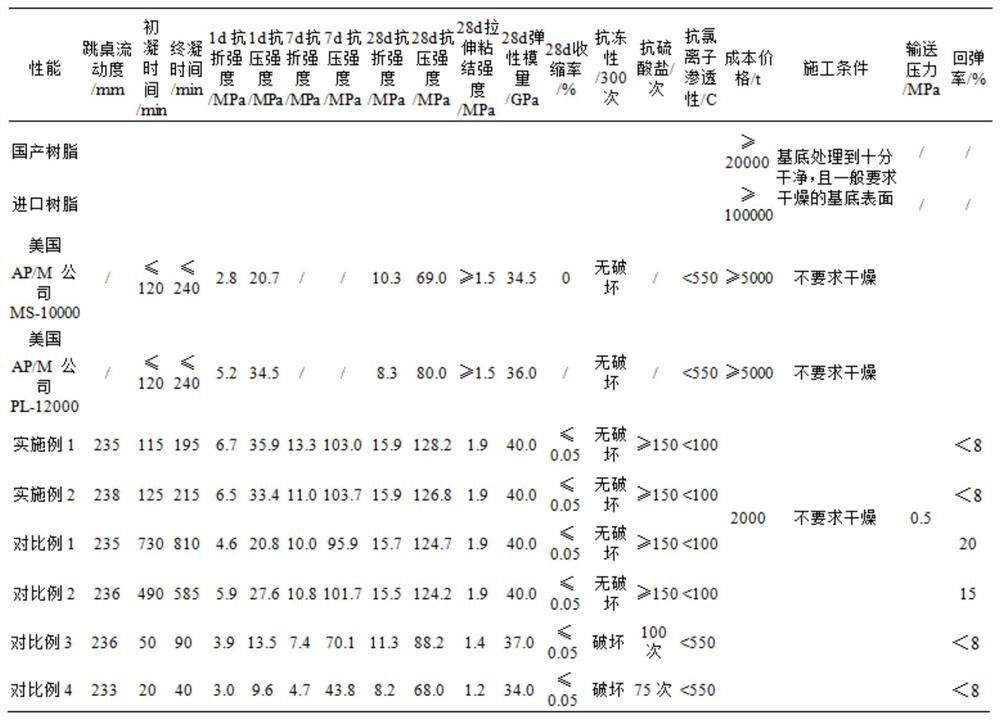

Wet-process sprayed ultra-high performance concrete rheological property regulator and using method thereof

The invention discloses a wet spraying ultra-high performance concrete rheological property regulator and a using method thereof. After the wet-process sprayed ultra-high-performance concrete rheological property regulator is used, the concrete rheological property is improved; the viscosity of the ultra-high performance concrete is reduced through the viscosity reducing component; the pumping pressure in the spraying process is reduced; the yield stress of the ultra-high performance concrete is improved through the anti-sagging component; the early strength component is combined to synergistically improve the bonding performance of the material after spraying, and the sprayability and early strength of the sprayed ultra-high performance concrete are effectively improved, so that the rebound rate is reduced, the one-time spraying thickness is improved, the compactness is improved, and the continuous wet spraying construction of the ultra-high performance concrete is realized.

Owner:CCCC SECOND HARBOR ENG +3

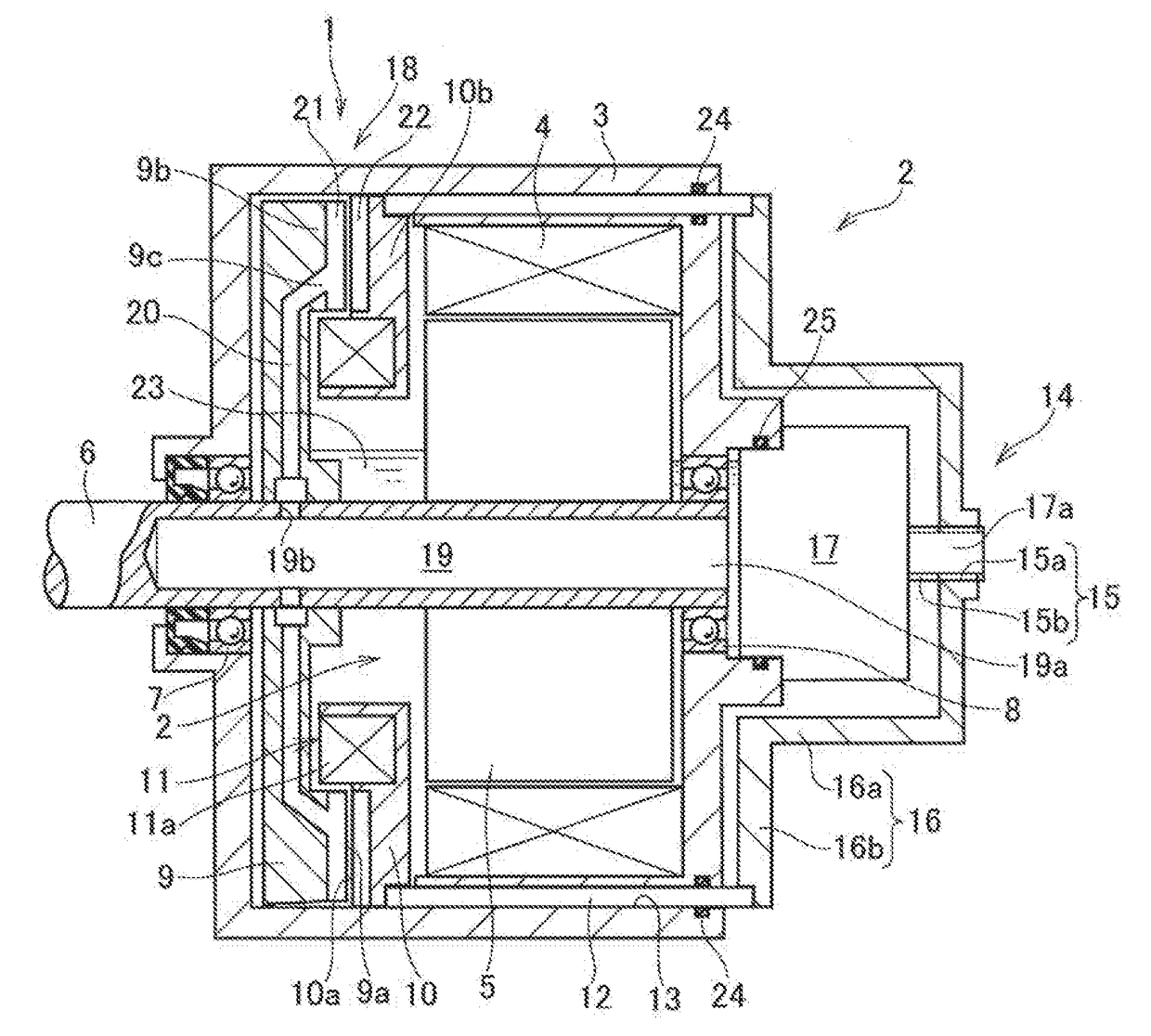

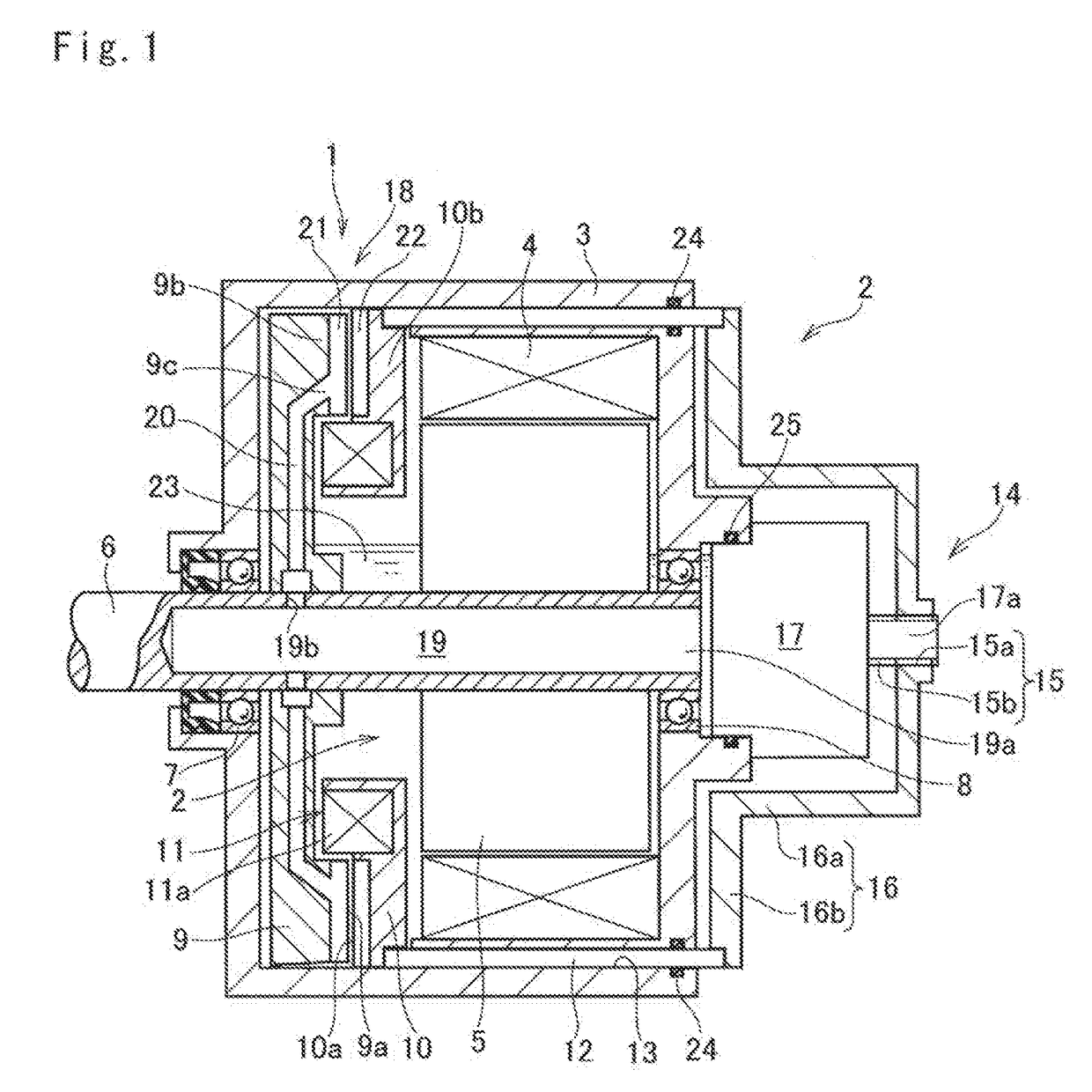

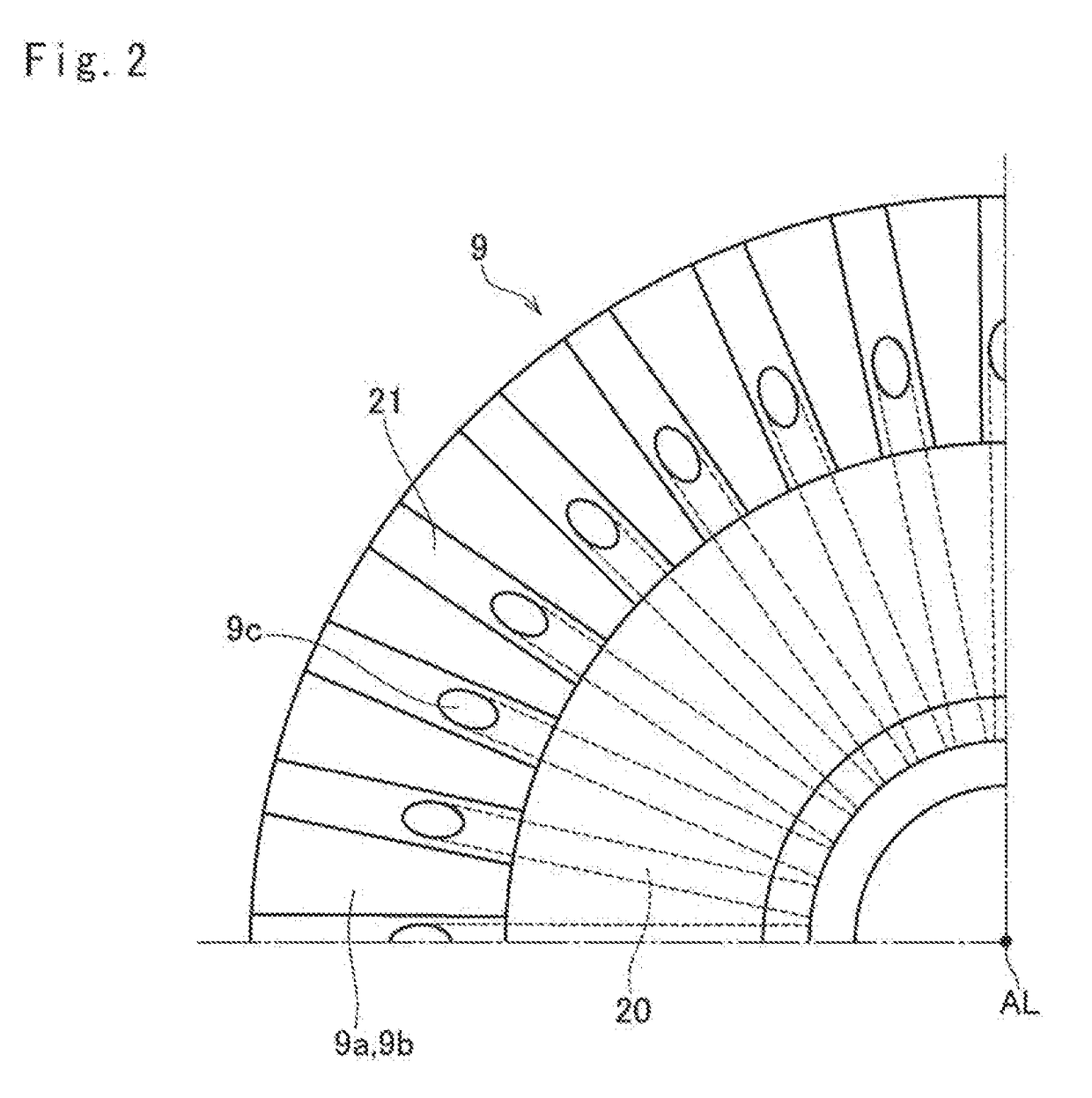

Brake device

InactiveUS20170248185A1Cool and lubricate efficientlyReduce friction lossMechanically actuated brakesBrake actuating mechanismsFriction lossStator

A brake device that can be cooled effectively while reducing a friction loss of a rotary member is provided. In the brake device, a second friction face formed on a brake stator is brought into contact to a first friction face formed on a brake rotor to stop rotation of a rotary shaft, and coolant is held in a casing. The brake device comprises a first cooling groove formed on the brake rotor to allow the coolant to flow over the first friction face, and a second cooling groove formed on the brake stator to allow the coolant to flow over the second friction face.

Owner:TOYOTA JIDOSHA KK +1

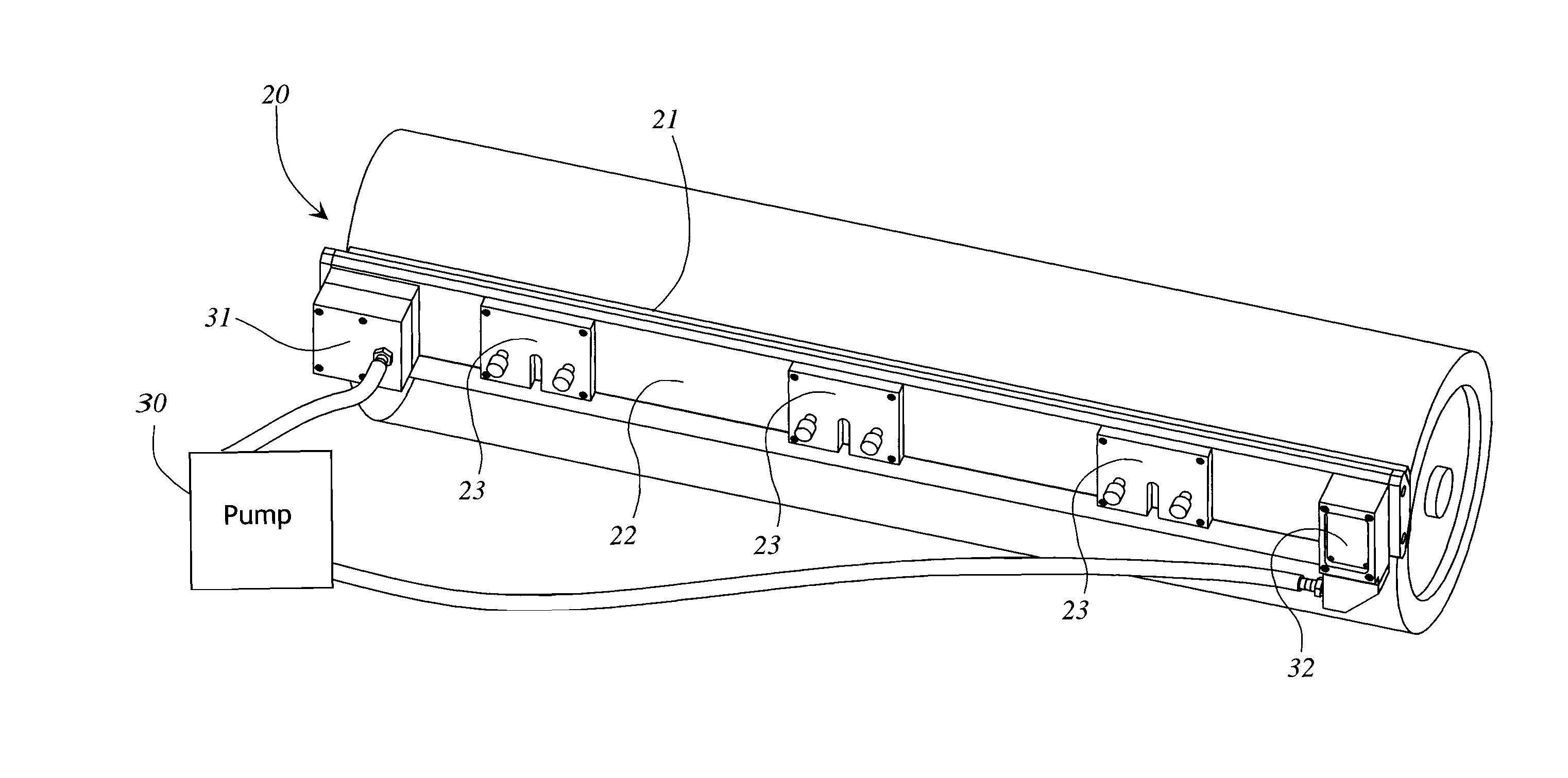

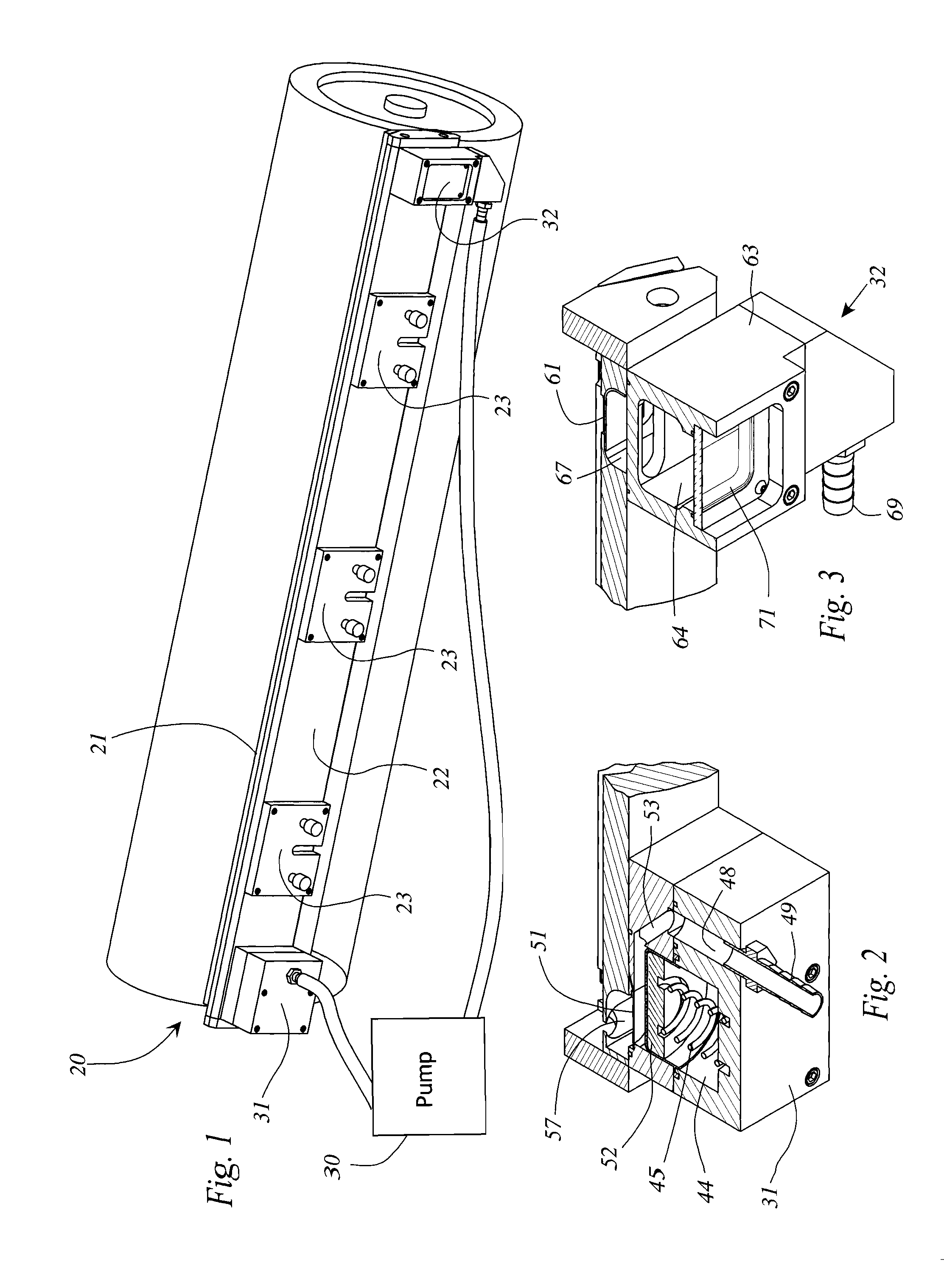

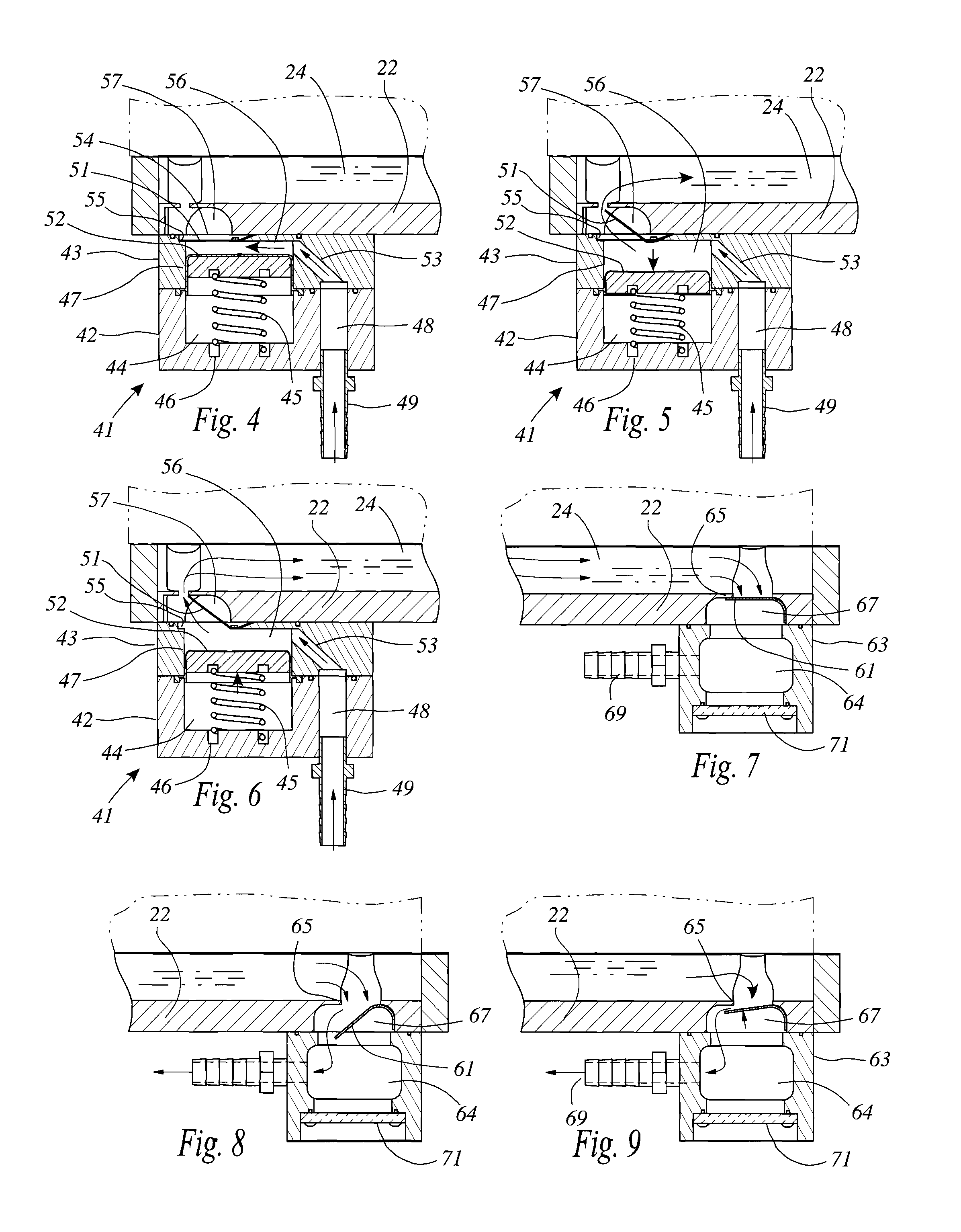

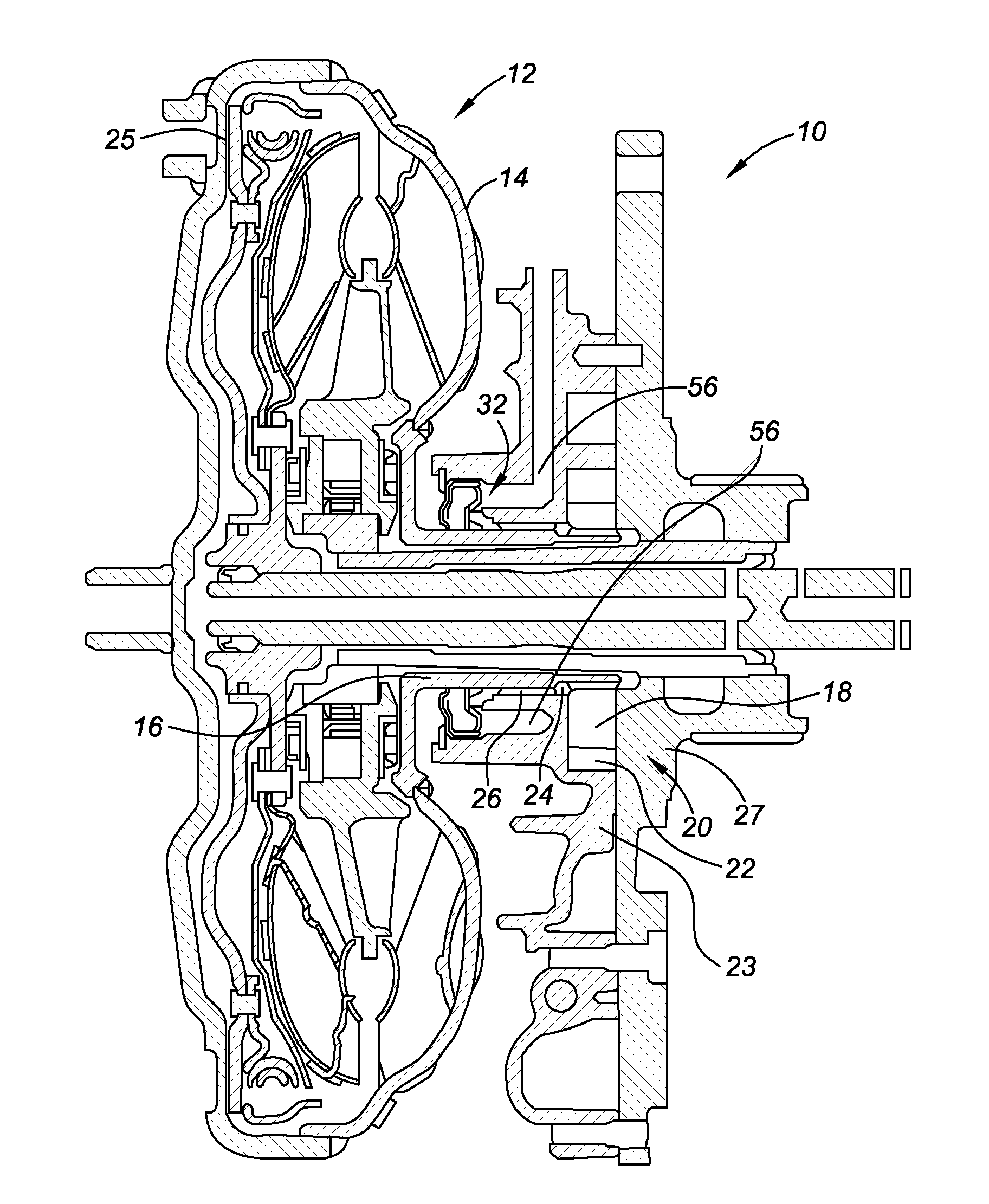

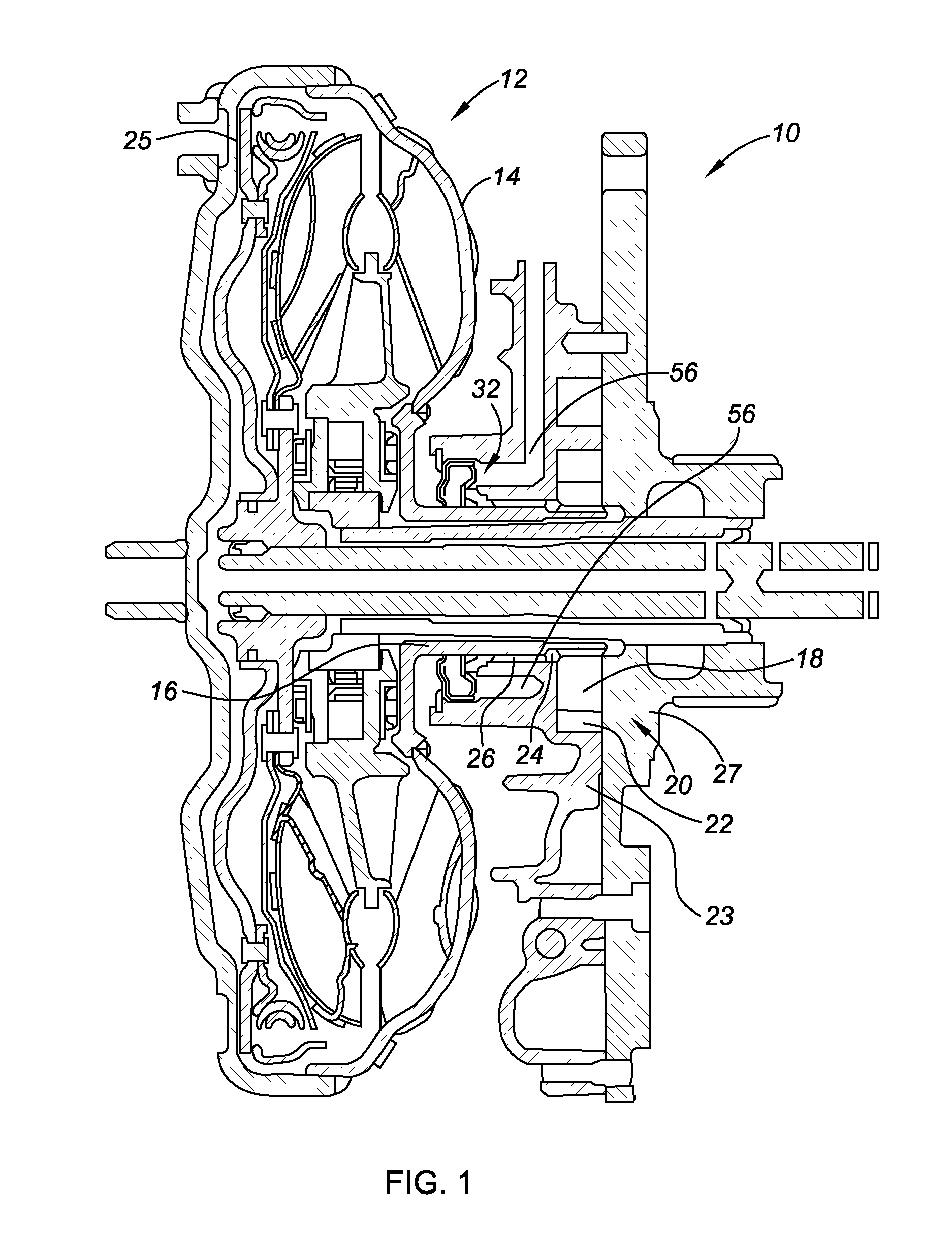

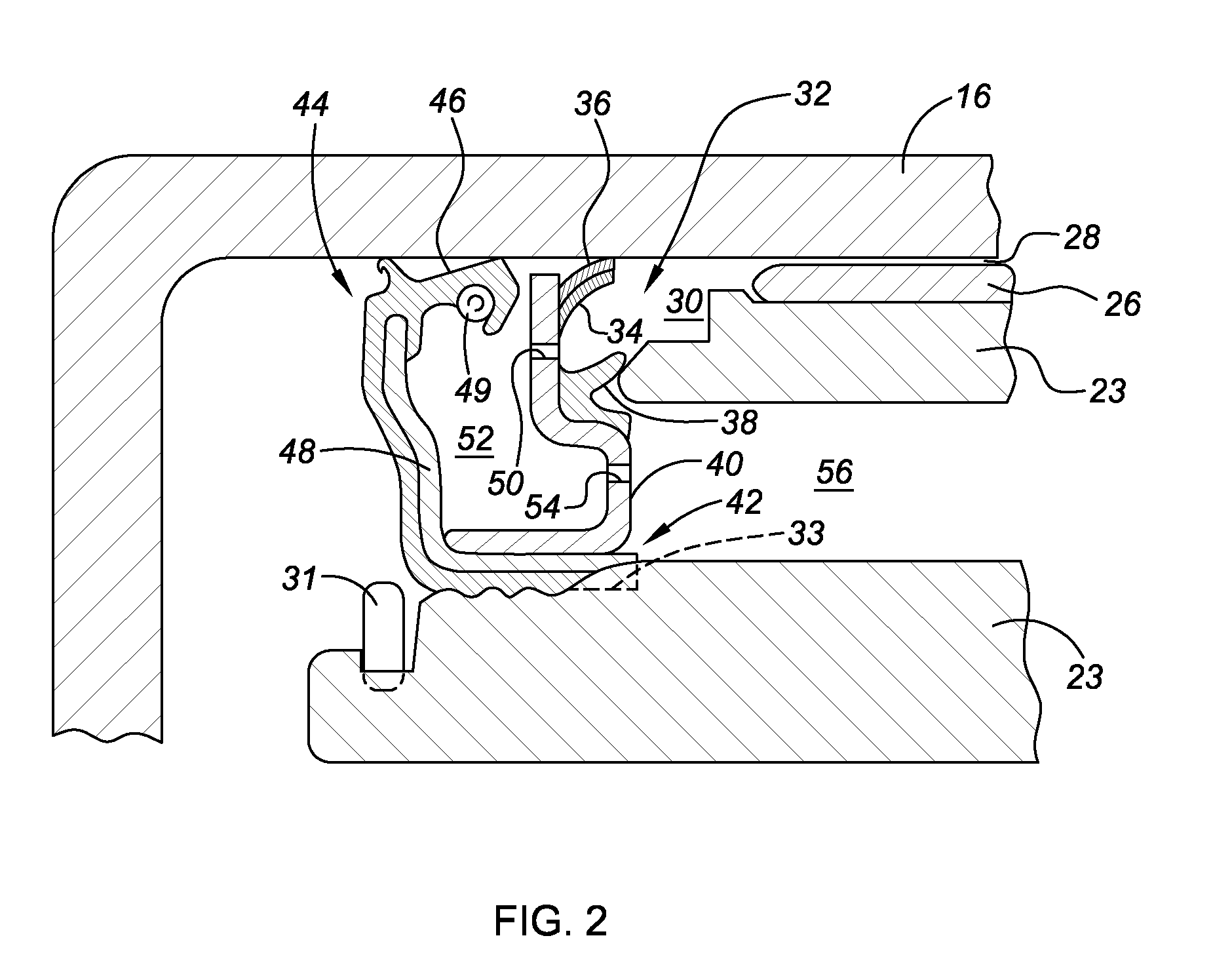

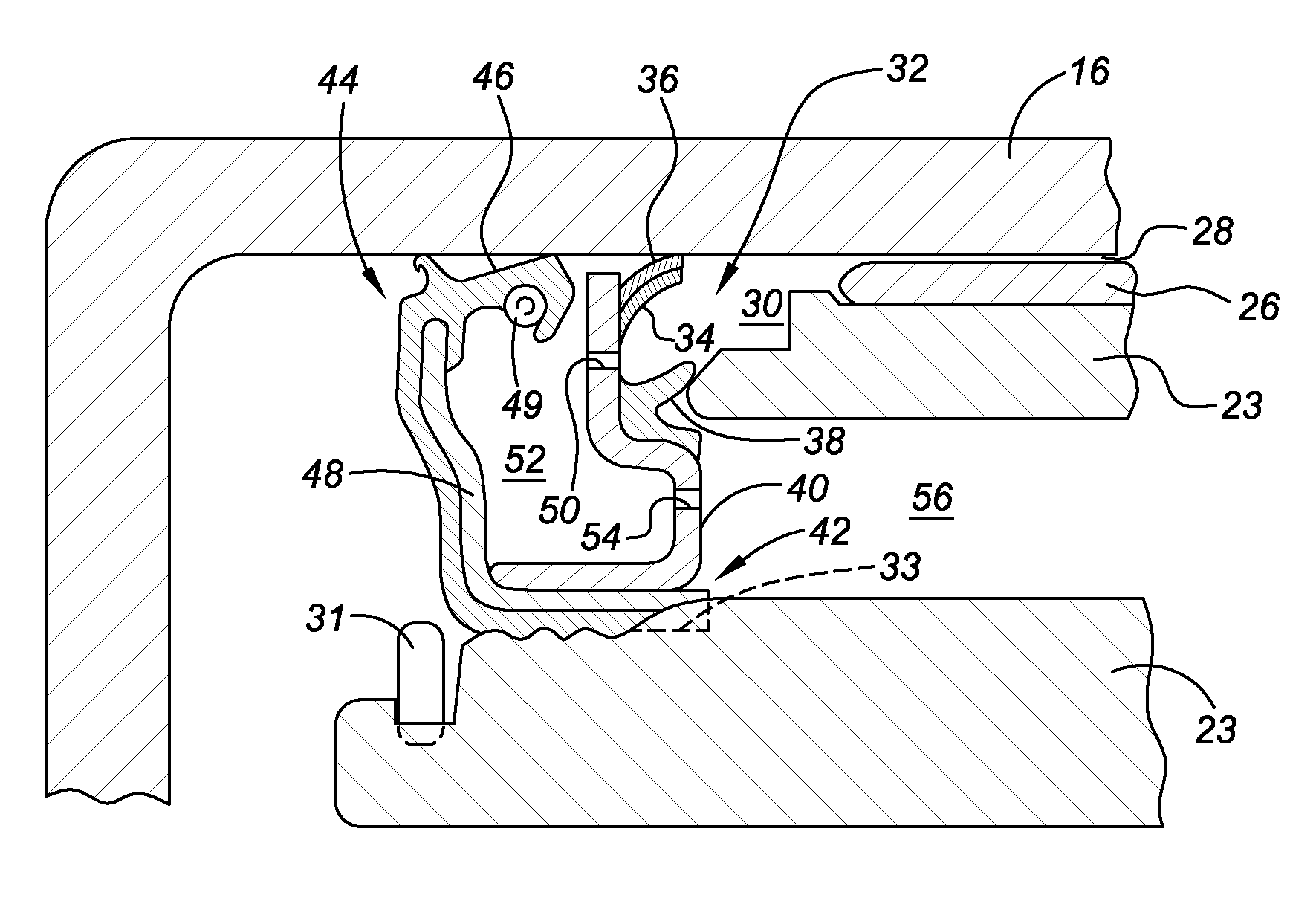

Seal assembly for reducing fluid loss from transmission pump

ActiveUS20080289926A1Reduce lossesReduce pump pressureEngine sealsRotary clutchesContact layerEngineering

An improved seal assembly is provided that minimizes loss of transmission pump pressure by controlling fluid flow past a torque converter hub bushing to meet bushing lubrication requirements without unnecessarily diminishing pump pressure and while also minimizing frictional losses. The seal assembly includes a rigid carrier adapted to fit between a pump body member and the torque converter hub. An elastomeric lip extends from the rigid carrier. A contact layer is connected to the elastomeric lip and configured to sealingly contact the torque converter hub. The contact layer is integral with and harder than the elastomeric lip, therefore minimizing frictional losses.

Owner:GM GLOBAL TECH OPERATIONS LLC

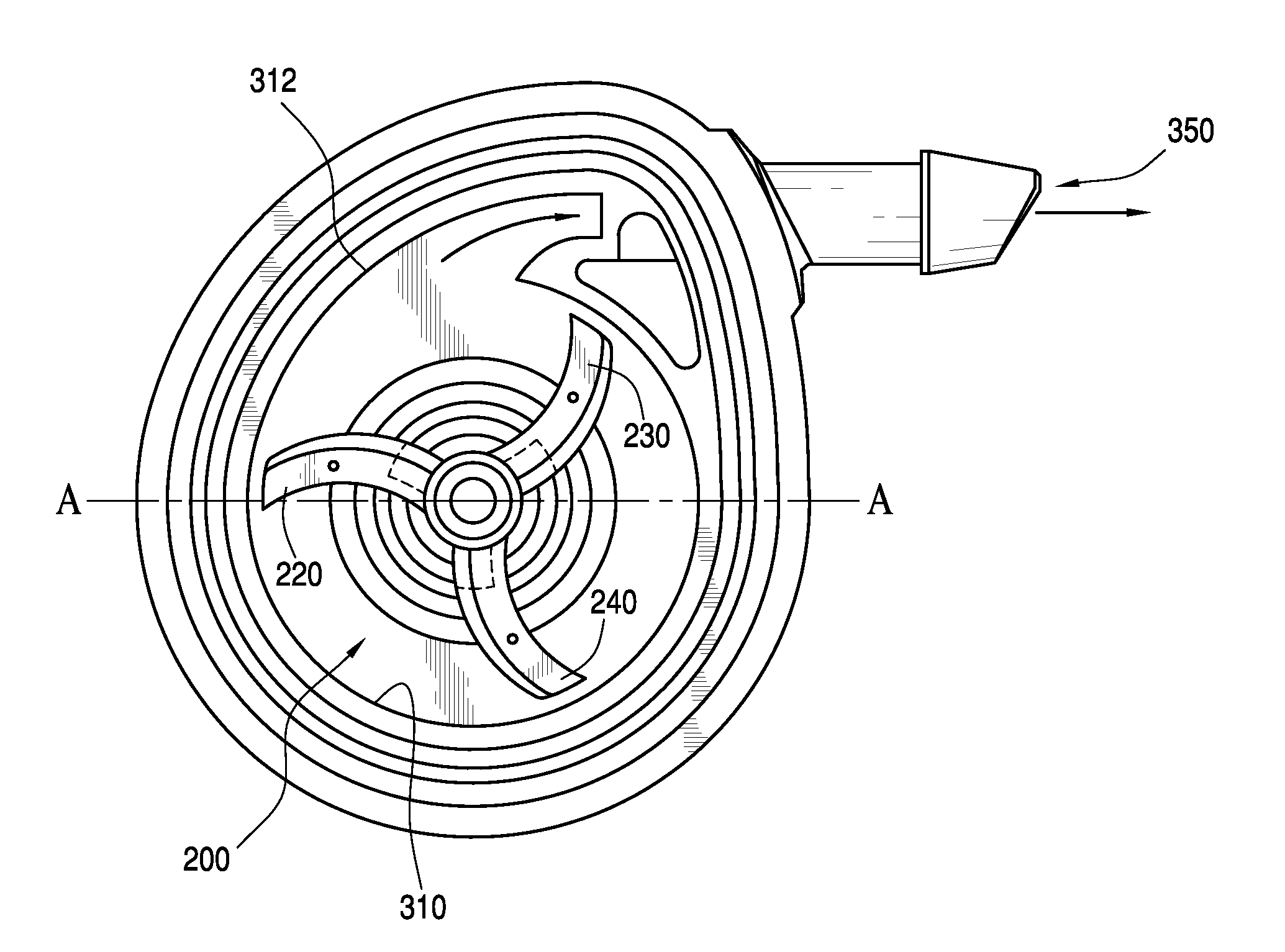

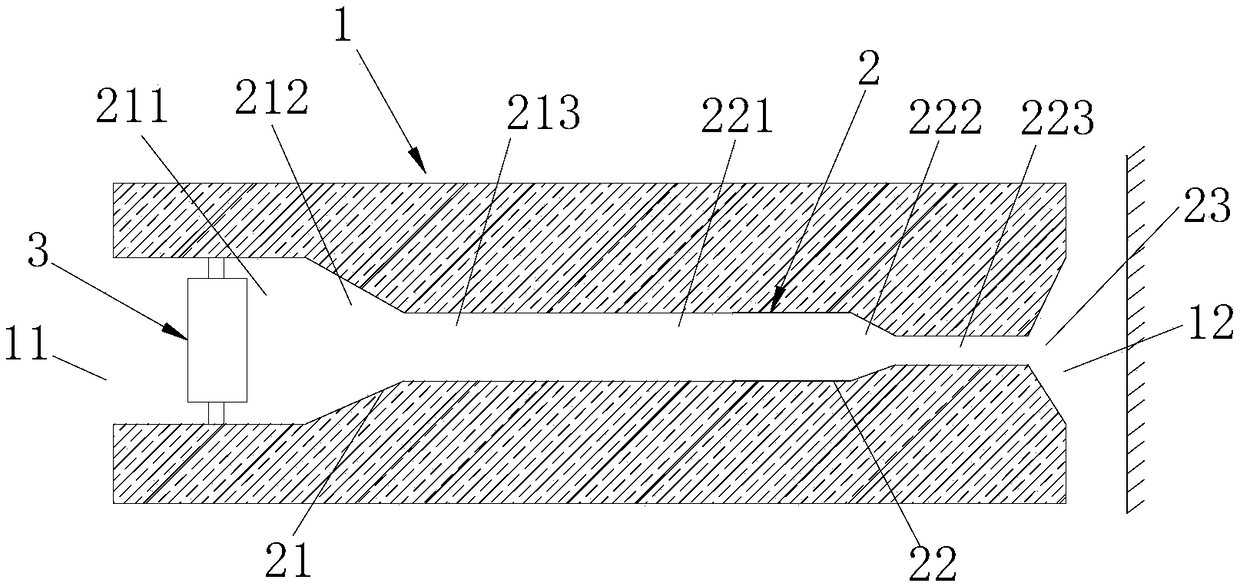

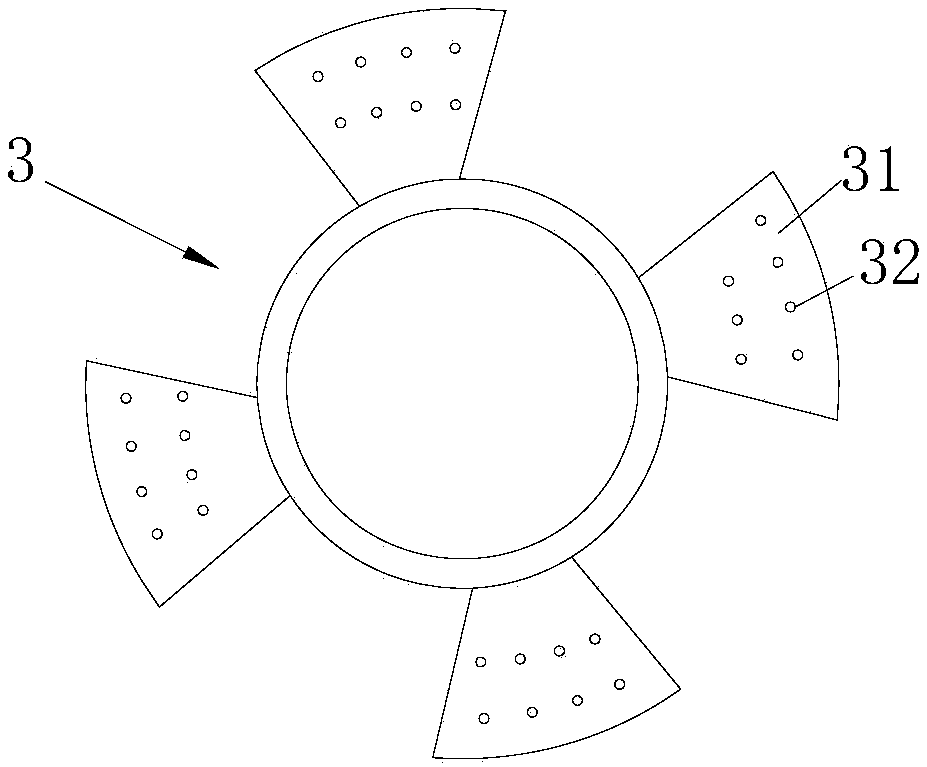

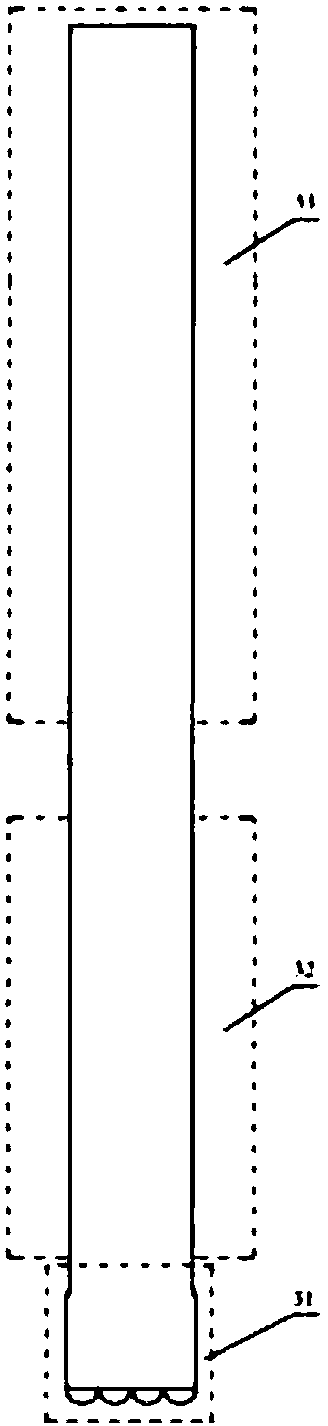

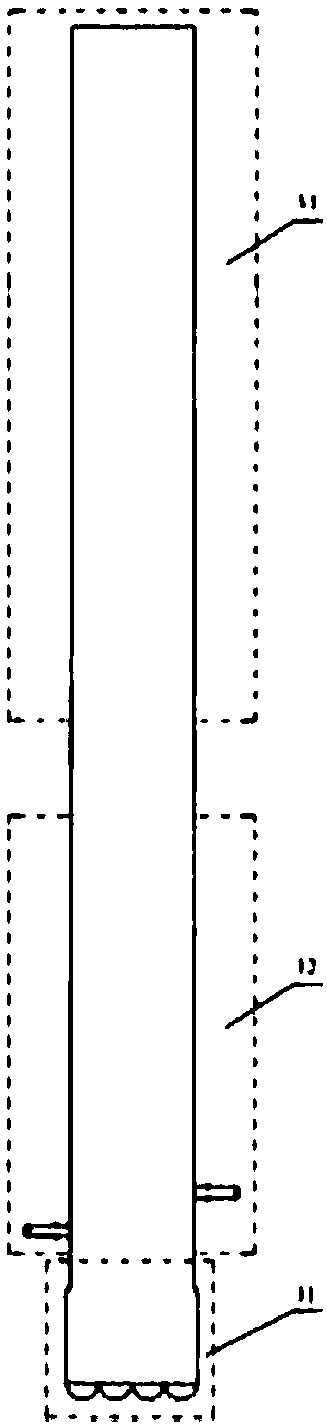

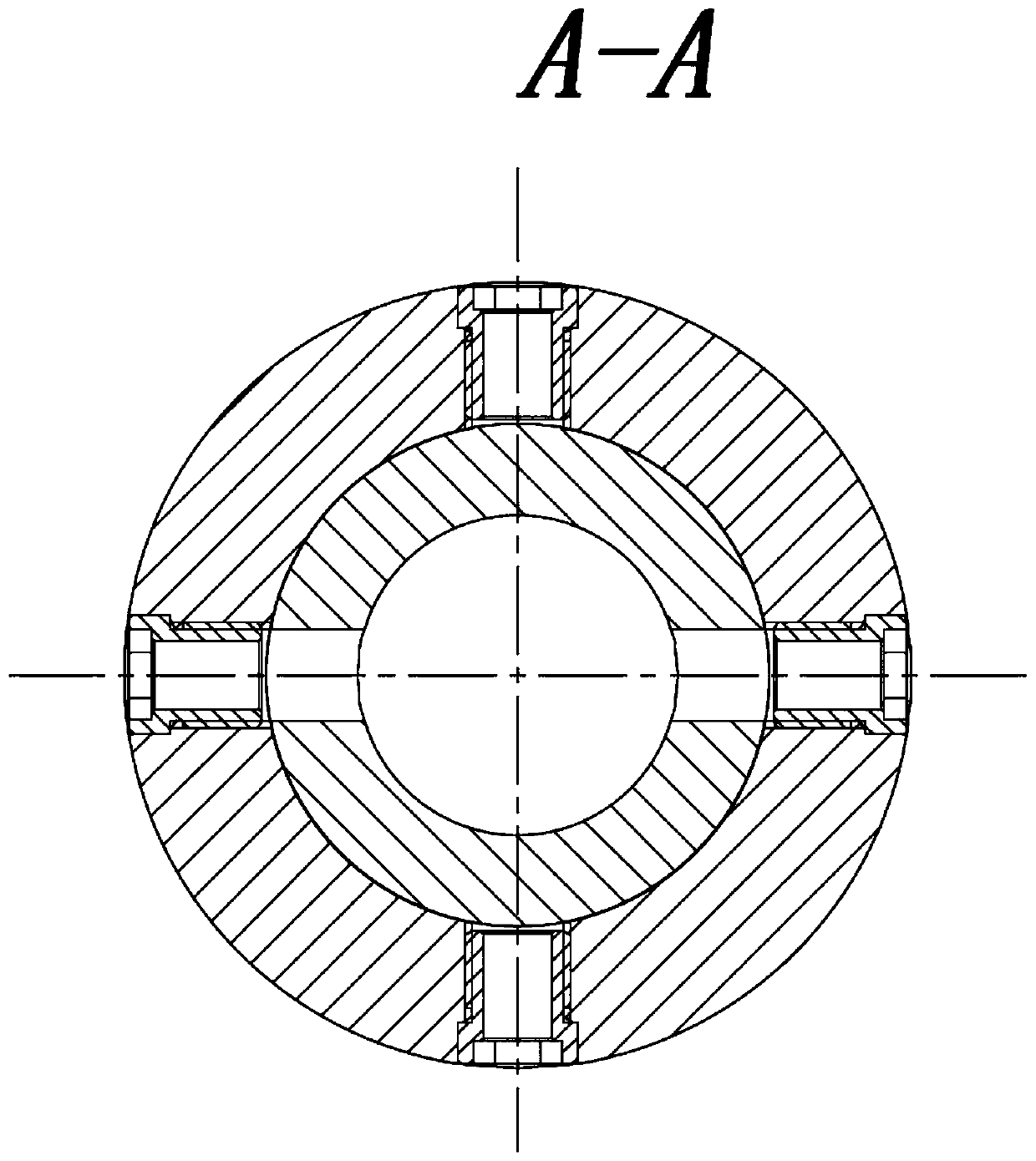

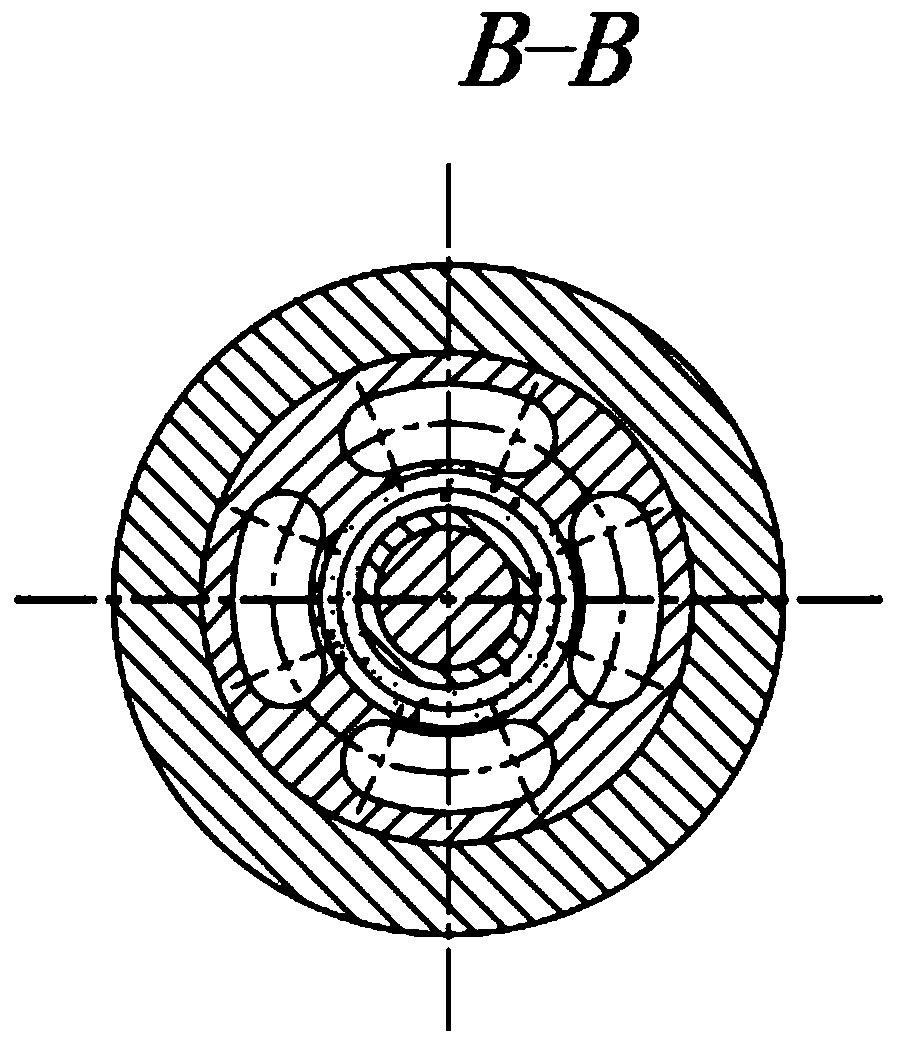

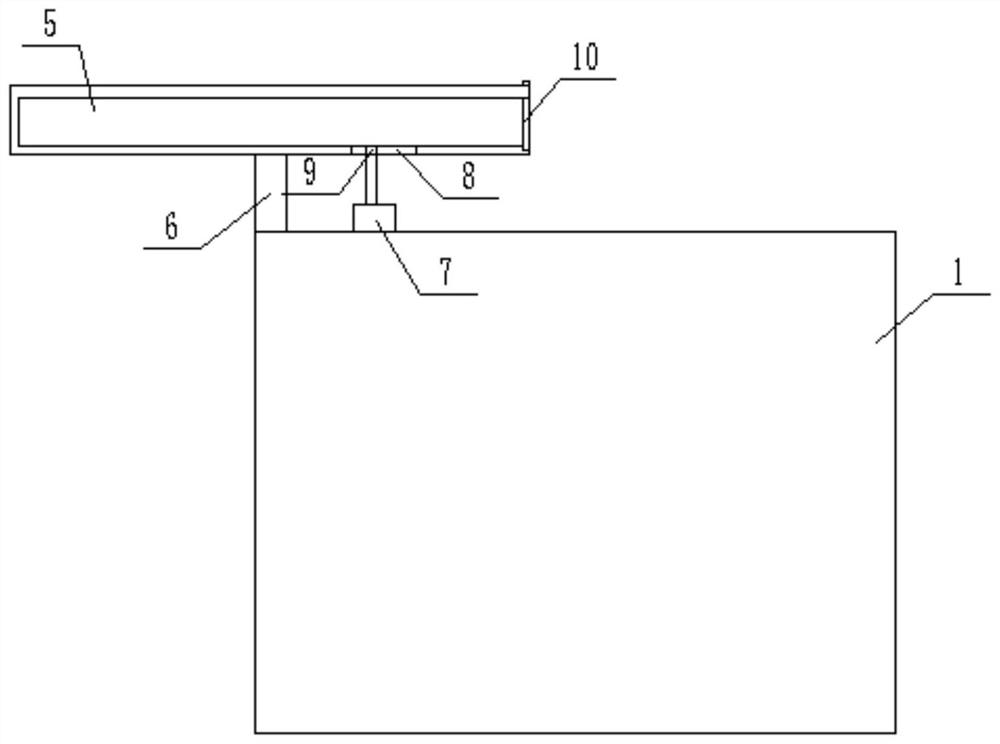

Impeller type multi-pulse water power oscillator

InactiveCN109707313AIncrease drilling speedReduce pump pressureVibration devicesVibration drillingImpellerCarrying capacity

The invention discloses a water power oscillator. The water power oscillator is used in the fields of petroleum drilling and the like and has the function of chip removal promotion. According to the technical scheme, an upper joint, an upper shell body, a lower shell body and a lower joint are sequentially connected through threads; an impeller is matched with an impeller shaft through flat keys,thus circumferential positioning of the impeller is achieved, axial positioning of the impeller is achieved through stairs and a locknut, and the stairs and the locknut are arranged on the impeller shaft; an impeller spindle, a transmission short section and a valve core are sequentially connected through threads; four through-holes are formed in the transmission short section in the radial direction, the four through-holes are spaced with each other at 90 degrees, and the lower end of the transmission short section is connected with a moving valve plate through threads; two radial through-holes are formed in the upper end of the valve core and are spaced with each other at 180 degrees; two through-holes are formed in the middle part of the upper joint and are spaced with each other at 180degrees, and after parts are assembled, the through-holes of the upper joint and the through-holes of the valve core are located at the same plane in the radial direction. According to the impeller type multi-pulse water power oscillator, axial vibration can be generated, frictional resistance between lower drilling tools of a horizontal well and a large-displacement well and the wall of the wells is effectively decreased, rock-carrying capacity of a drilling fluid can be improved, the drilling efficiency is improved, and meanwhile, downhole accidents such as sticking and clamping can be avoided.

Owner:SOUTHWEST PETROLEUM UNIV

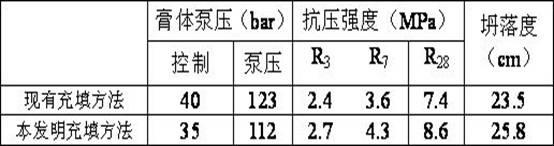

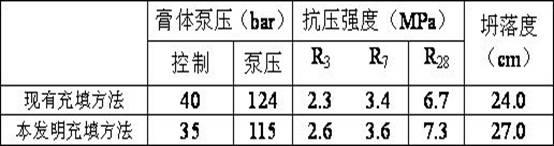

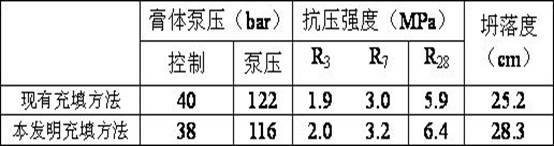

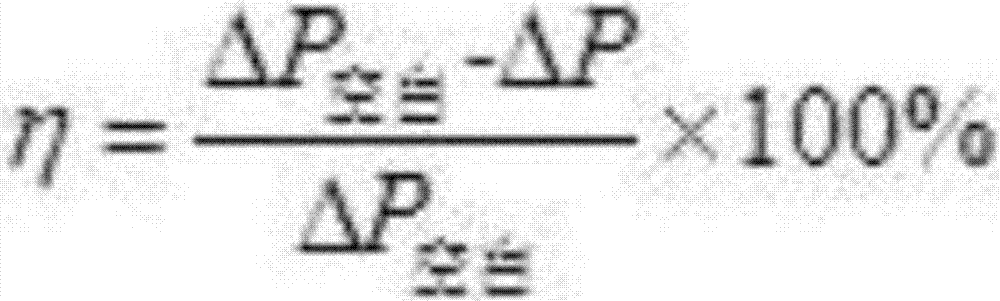

Filling method for reducing onway resistance losses of paste-like slurry

The invention provides a filling method for reducing onway resistance losses of paste-like slurry. In the method, a container connected with a motor-driven flow pump is arranged above an agitator bath of a paste-like filling system; an existing method is used to prepare the paste-like slurry and the paste-like slurry is delivered to the container; a water reducing agent is added to the container to obtain mixed paste-like filling slurry; the mixed paste-like filling slurry is delivered to the agitator bath and stirred evenly, wherein the temperature and the humidity in the agitator bath are controlled to be 28-30 DEG C and 75-85% respectively, thus full tailing paste-like slurry can be prepared; and the paste-like filling system transmits the full tailing paste-like slurry to a stope so as to fill the filling. The filling method is utilized to improve the fluidity of the paste-like slurry, reduce the paste-like pump voltage, enhance the compression strength and the slump, realize the remote transmission of the paste-like slurry, be beneficial to extending the paste-like filling system to a deep mining system and improve the strengths of the fillers at different ages especially the early age, and the filling method is a new way and method for broadening the deep mining field by using the paste-like filling technology in China.

Owner:JINCHUAN GROUP LIMITED

Drag-reduction agent for carbon dioxide dry-process fracturing and application thereof

ActiveCN108864387AReduce surface pump pressureReduce stressDrilling compositionChemistryDrag reducing agent

The invention provides a drag-reduction agent for carbon dioxide dry-process fracturing and application thereof. The drag-reduction agent mainly comprises a fluorinated acrylate-styrene-sulfonated styrene block copolymer prepared by carrying out polymerization reaction on a fluorinated acrylate polymer, sulfonated styrene and styrene, wherein the mass ratio of the fluorinated acrylate polymer to the sulfonated styrene to the styrene is (55 to 65) to (20 to 30) to (10 to 20). The drag-reduction agent has relatively good compatibility with carbon dioxide; the drag-reduction agent is dissolved into a carbon dioxide fracturing solution and the friction resistance in a fracturing process can be reduced, so that the ground pump pressure is reduced and the pressure bearing capability of a pipeline is reduced, and furthermore, carbon dioxide dry-process fracturing engineering is safer and the pipeline can meet working requirements better; the speed of injecting liquid-state carbon dioxide is improved, and the carbon dioxide dry-process fracturing can be used in deeper reservoir stratums with more extreme conditions; the drag-reduction effect still can be kept under the more extreme conditions; the drag-reduction effect can reach 30 percent to 40 percent in carbon dioxide work.

Owner:BEIJING NIUHE RUICHEN ENERGY TECH CO LTD

High-density fracturing fluid and preparation method thereof

InactiveCN106566518AAdjustable densityReduce pump pressureFluid removalDrilling compositionCross-linkHigh density

The invention provides a high-density fracturing fluid and a preparation method thereof. The high-density fracturing fluid comprises the following raw materials: 100 parts by weight of water, 20 to 80 parts by weight of an organic salt weighting agent, 0.5 to 2.0 parts by weight of a drag-reducing lubricating agent, 0.1 to 0.5 part by weight of a thickening agent, 0.1 to 0.6 part by weight of a cross-linking agent, 0.1 to 0.3 part by weight of a pH regulator and 0.01 to 0.1 part by weight of a gel breaker. The preparation method of the high-density fracturing fluid comprises the steps of adding the thickening agent into water, and circularly stirring the materials; adding the organic salt weighting agent under circular stirring; adding the drag-reducing lubricating agent and the pH regulator under circular stirring to regulate the pH value to be 10 to 12; and adding the cross-linking agent and the gel breaker through a cross-linking pump, so as to obtain the high-density fracturing fluid. According to the high-density fracturing fluid, requirements on construction equipment and tools can be reduced, construction safety is improved, and the success rate of construction is increased.

Owner:PETROCHINA CO LTD

Acid liquid drag reducer and preparation method thereof

InactiveCN107501470AHigh resistance reduction rateImprove temperature resistancePipeline systemsWater bathsSynthesis methods

The invention discloses an acid liquid drag reducer and a preparation method thereof. The preparation method comprises the following steps: weighing 2-acrylamido-2-methylpropane sulfonic acid monomers in a beaker; adding water for dissolution, and adjusting the system pH value to be 8-10; adding acrylamide monomers and long chain cation monomers; performing stirring under the condition that an inert gas is pumped therein; adjusting the bath temperature to be an initiation reaction temperature, after that, adding an initiator, and enabling a reaction to prepare a transparent gum block; at last, manually cutting the transparent gum block into pieces; performing drying and crushing; and performing screening by use of a 100-mesh screen to prepare the powdery acid liquid drag reducer. The synthetic method is simple, the raw materials are easily accessible, and the cost is lowered; the prepared acid liquid drag reducer has the drag reduction rate up to 65%, pumping pressure and pipeline loss are reduced, and the equipment service life is prolonged; and the acid liquid drag reducer is good in temperature resistance and compatibility, and meanwhile, has a certain retarding effect.

Owner:如皋市玉辉助剂厂

Preset fracture hydraulic fatigue fracturing design method

InactiveCN110954419AReduce pump pressureReduce construction difficulty and safety risksMaterial strength using repeated/pulsating forcesStandard samplesFracture propagation

The invention discloses a preset fracture hydraulic fatigue fracturing design method which comprises the following steps of manufacturing a rock-like material standard sample, and performing a mechanical parameter test by utilizing the sample to obtain the mechanical parameters of a rock-like material; making a sample containing a through fracture, and performing a periodic cyclic load tension andcompression failure test by using the sample to obtain a stress-strain curve, a strain frequency curve and the material parameters in a Paris formula; utilizing a finite element software to establisha rock-like material finite element model, presetting fractures and fracture sizes in the finite element model, and substituting the test results into the finite element model; loading in a circulating pressure form, obtaining the fracture propagation of the rock-like material, and determining the combination form of the amplitude and the frequency parameter of the optimal circulating water pressure load.

Owner:SHANDONG UNIV

A drag reducing agent for carbon dioxide dry fracturing and its application

ActiveCN108864387BEconomic development effectReduce stressDrilling compositionLiquid statePolystyrene

The invention provides a drag-reduction agent for carbon dioxide dry-process fracturing and application thereof. The drag-reduction agent mainly comprises a fluorinated acrylate-styrene-sulfonated styrene block copolymer prepared by carrying out polymerization reaction on a fluorinated acrylate polymer, sulfonated styrene and styrene, wherein the mass ratio of the fluorinated acrylate polymer to the sulfonated styrene to the styrene is (55 to 65) to (20 to 30) to (10 to 20). The drag-reduction agent has relatively good compatibility with carbon dioxide; the drag-reduction agent is dissolved into a carbon dioxide fracturing solution and the friction resistance in a fracturing process can be reduced, so that the ground pump pressure is reduced and the pressure bearing capability of a pipeline is reduced, and furthermore, carbon dioxide dry-process fracturing engineering is safer and the pipeline can meet working requirements better; the speed of injecting liquid-state carbon dioxide is improved, and the carbon dioxide dry-process fracturing can be used in deeper reservoir stratums with more extreme conditions; the drag-reduction effect still can be kept under the more extreme conditions; the drag-reduction effect can reach 30 percent to 40 percent in carbon dioxide work.

Owner:BEIJING NIUHE RUICHEN ENERGY TECH CO LTD

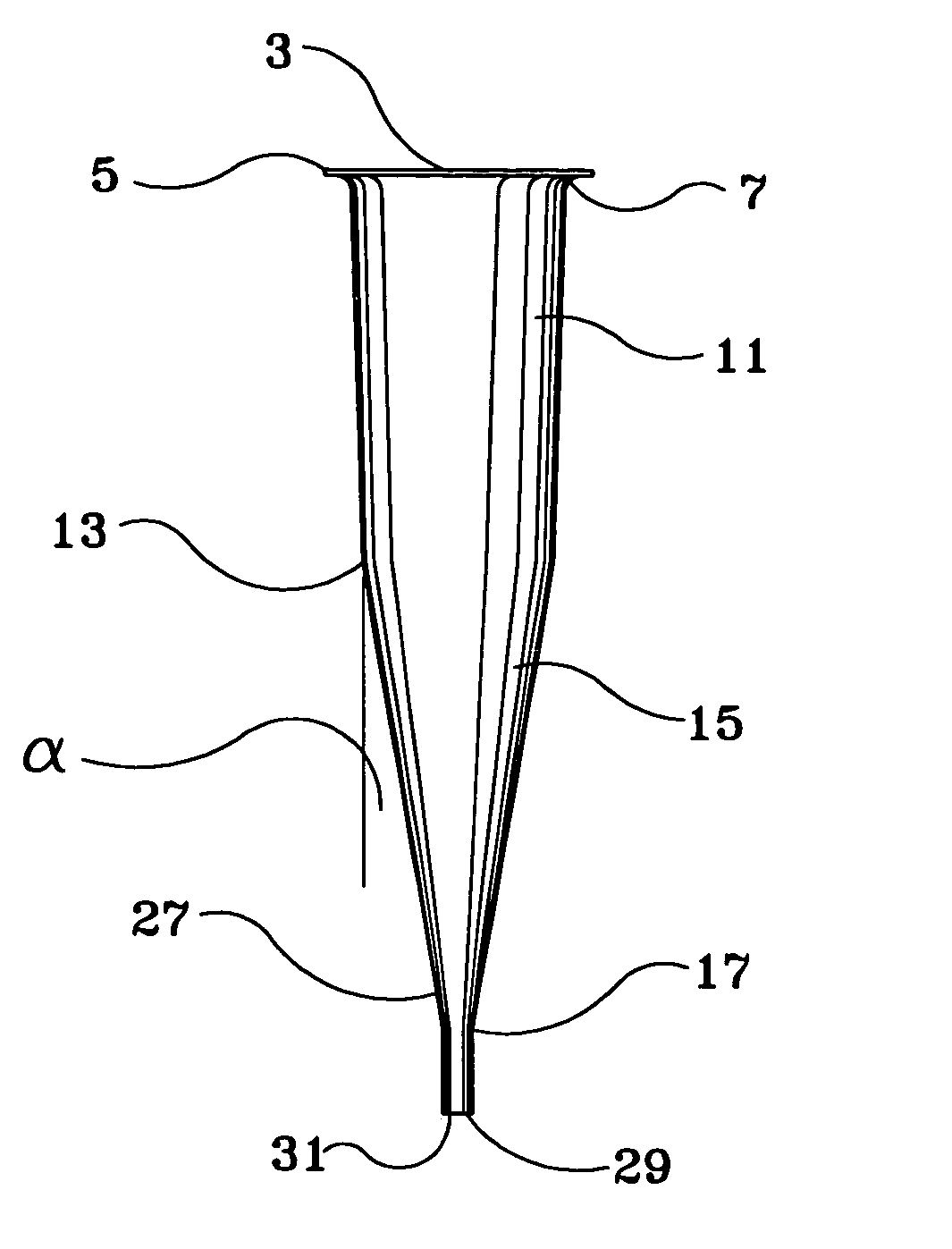

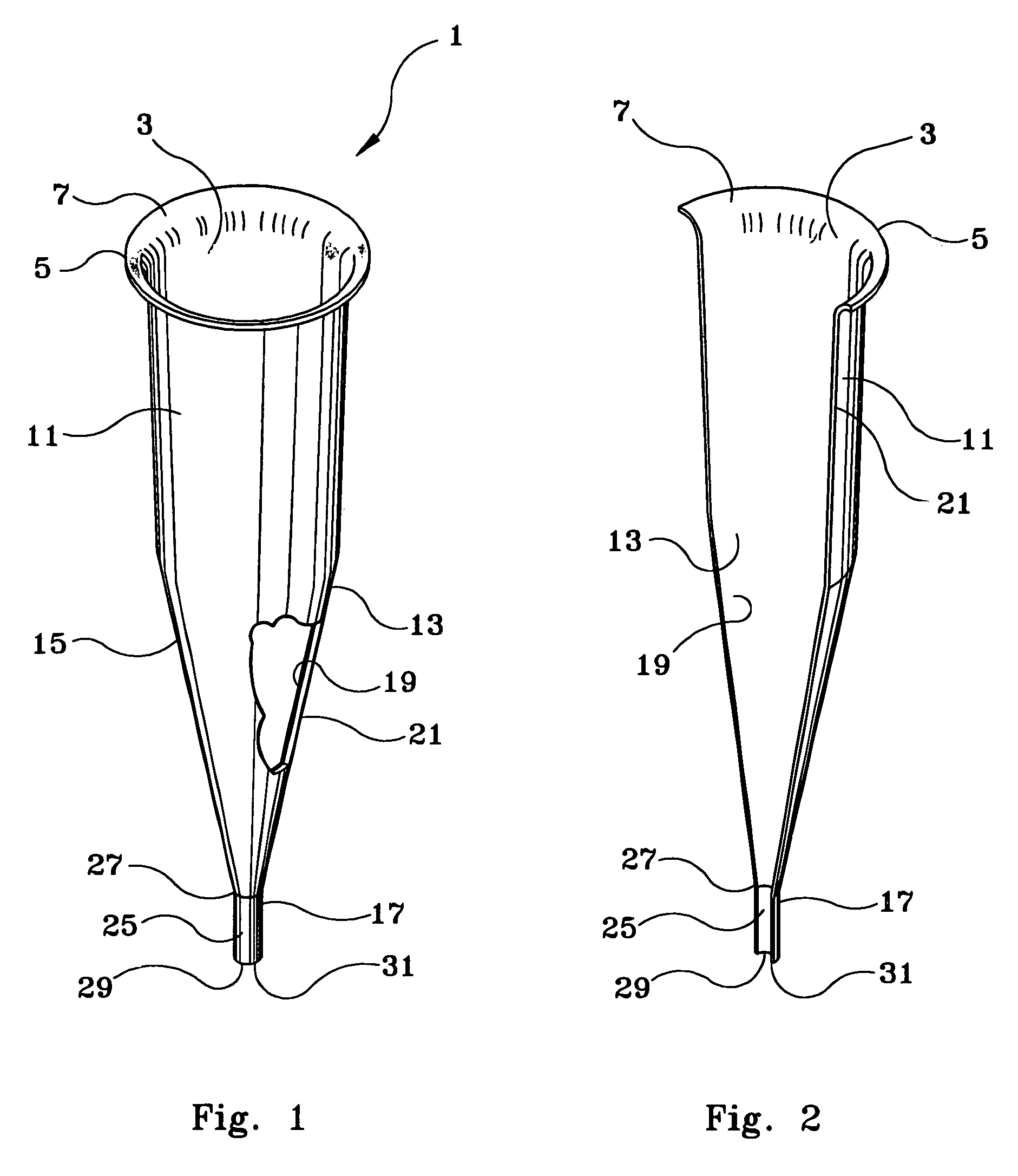

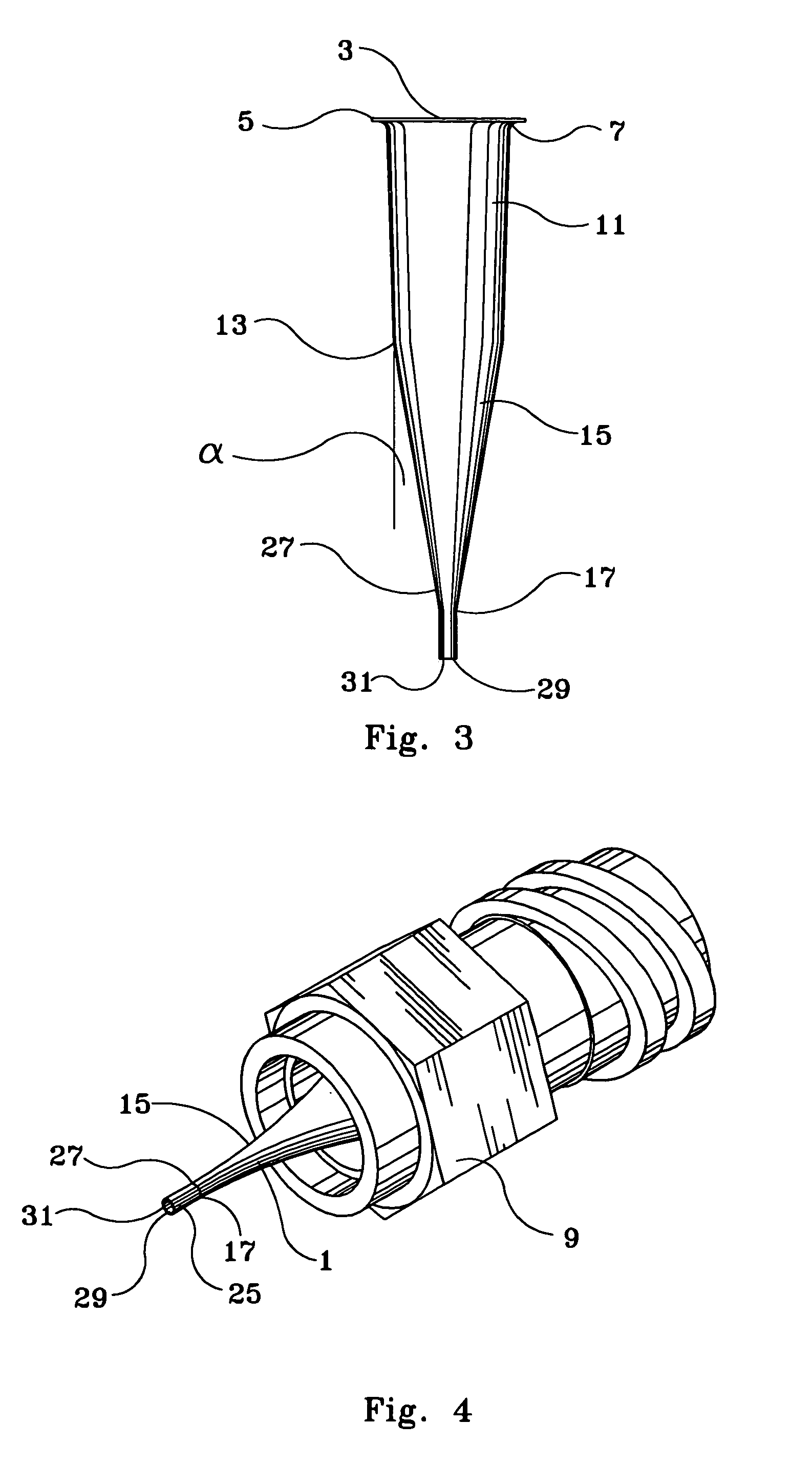

Deep drawn nozzle for precision liquid dispensing

InactiveUS8210455B2Easy and accurate applicationLow viscosityLiquid surface applicatorsMetal-working apparatusViscous liquidEngineering

A nozzle for delivering a measured quantity of viscous liquid including a flared opening defined by a horizontal perimeter and a flare wall extending inward from the perimeter, a cylindrically-shaped barrel wall extending from the flare wall downward to a break point defined by a circle parallel to the flare opening and spaced-apart therefrom, a cone-shaped wall extending downward from the circular break point and inward therefrom to a circular exit opening, and a small-diameter exit tube extending from the circular exit opening to a circular exit aperture.

Owner:VERRILLI BRIAN +1

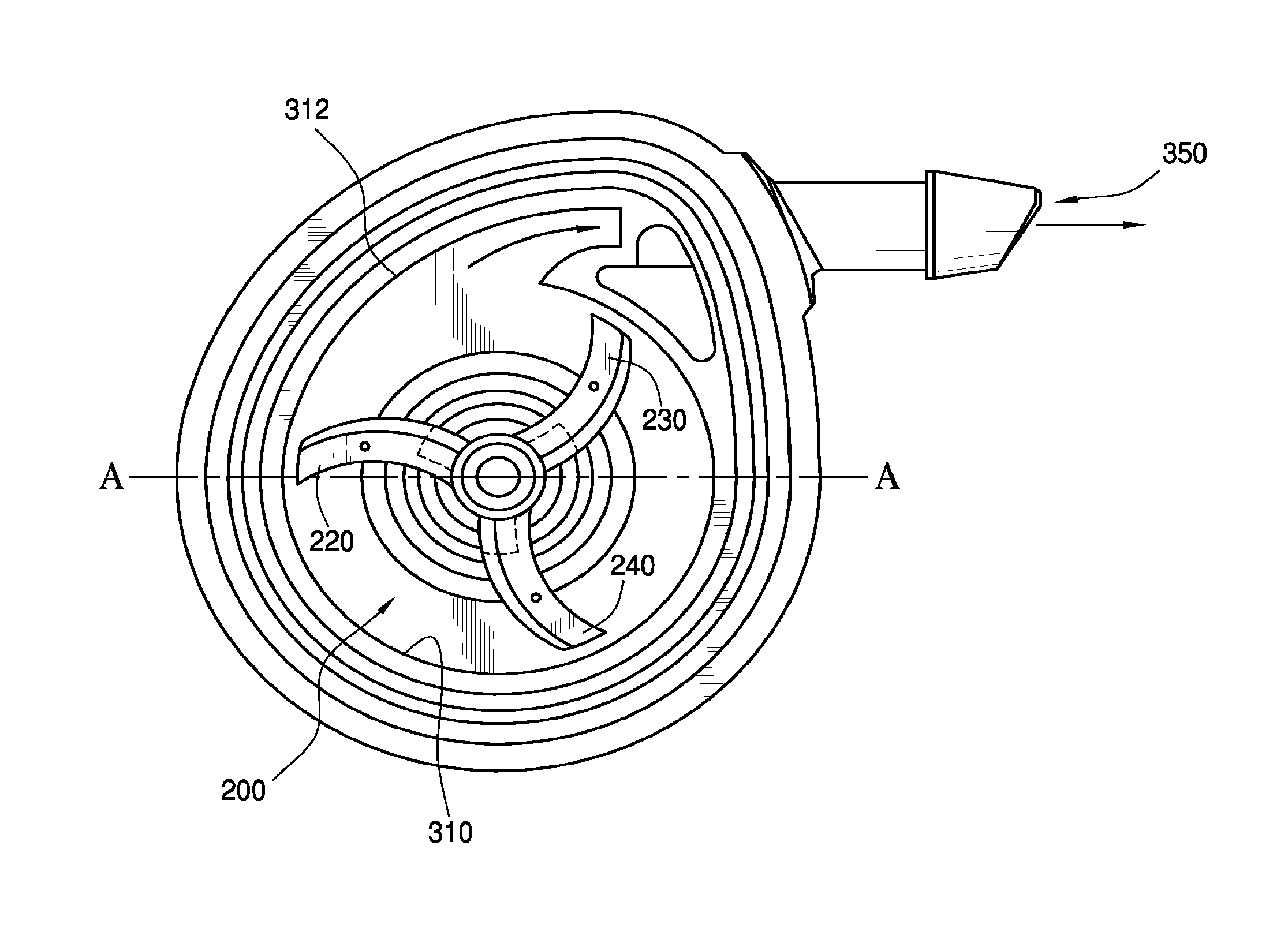

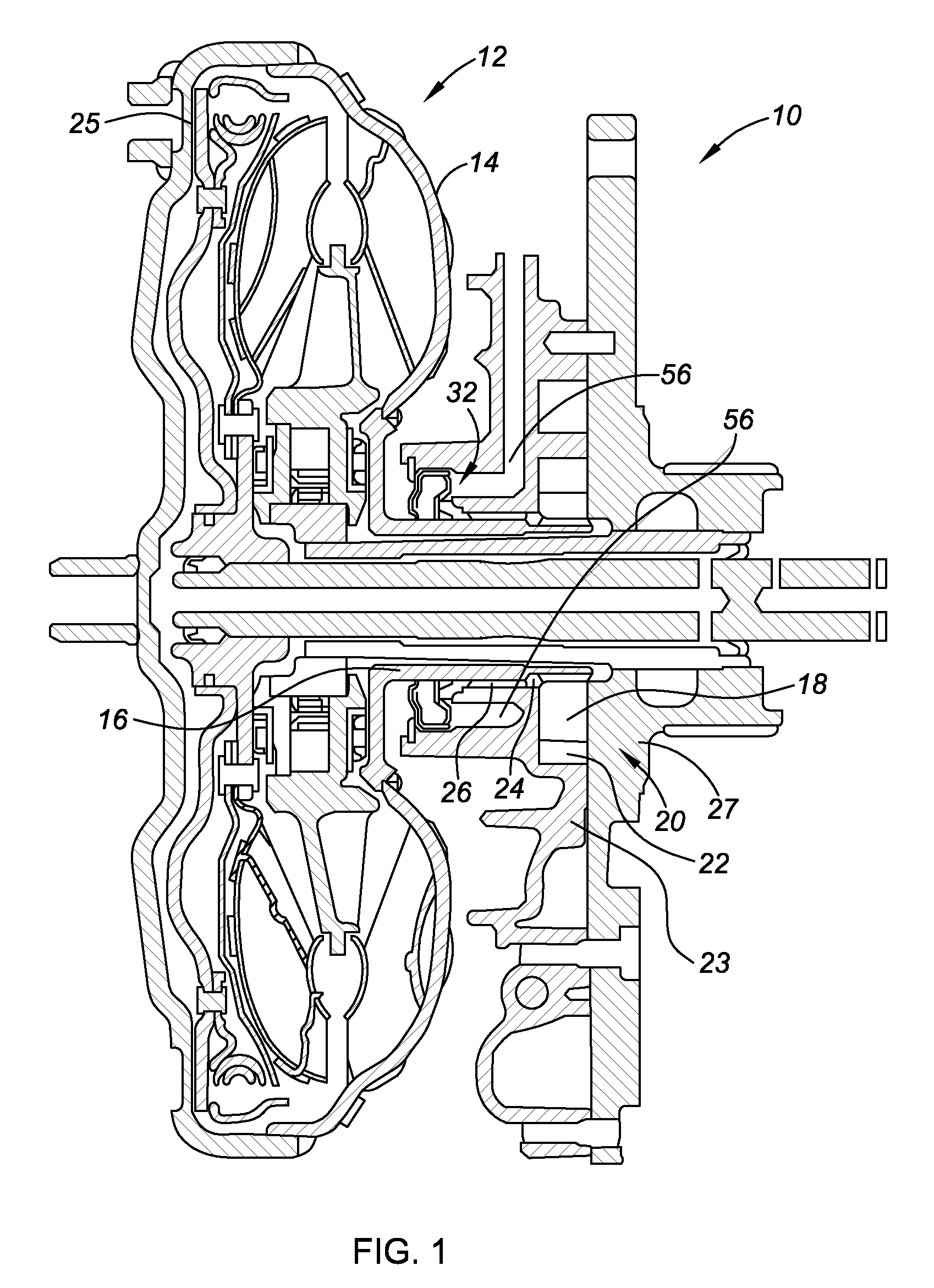

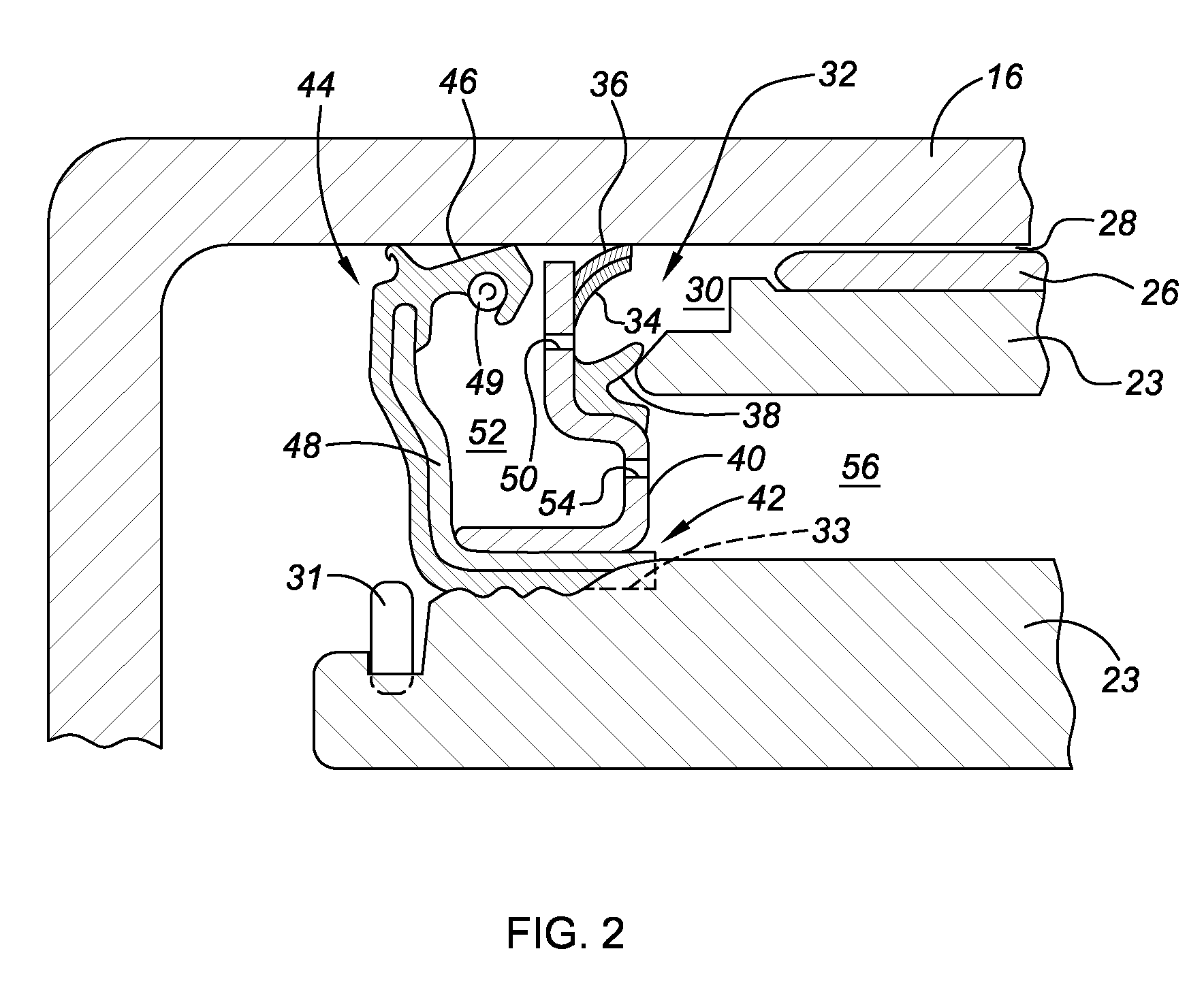

Washer pump

ActiveUS20130045095A1Improved Pressure-flow rate (P-Q) curveReduce pump pressurePump componentsStatorsImpellerTransition point

An improved automotive pump assembly includes a volute pumping chamber configured to operably contain a rotatable impeller which, when driven, draws fluid into a fluid inlet and pumps the fluid to and through a fluid outlet. The volute chamber has an exterior sidewall with a constant internal first radius over a first sidewall portion and transitions to a second sidewall portion of increasing radius. The chamber's second sidewall portion defines a first end at a sidewall transition point tangent to the constant radius sidewall segment to define a second end which is tangent to the volute chamber's fluid outlet with a second radius that is greater than the first radius.

Owner:DLHBOWLES INC

Self-excitation resonant pulse device

InactiveCN101000124AReduce constructionReduce wax depositionPipeline systemsResonant cavitySelf excited

The invention is a self-excited resonant pulse device, belonging to the pulsating sprayer technical field, for providing a self-excited resonant pulse device able to automatically increase in-pipe pressure in transportation. And its technical solution comprises casing, inlet, resonant cavity and outlet, where the inlet is a round hole big up and small down and located in the upper section in the casing; the outlet is located in the lower section in the casing; the resonant cavity is located in the middle section in the casing and the upper section of the resonant cavity is a conical hole with inside diameters small up and big down, and the peripheral wall of the conical hole forms an upper reflecting surface; the middle section of the resonant cavity is a round cavity and the peripheral wall of the middle section of the resonant cavity forms a middle reflecting surface; a cone is formed between the top end surface of the outlet and the bottom end edge of the middle reflecting surface and the surface of the cone forms a lower reflecting surface. And it is mainly applied to liquid or gas pipeline transportation. And it can also be used for well drilling, hydraulic drive and cleaning.

Owner:宋家英 +1

Cement-based composite material for trenchless centrifugal spraying repair of pipeline and preparation method of material

ActiveCN113307587ALow plastic viscosityHigh yield stressSolid waste managementUltimate tensile strengthMechanical engineering

The invention discloses a cement-based composite material for trenchless centrifugal spraying repair of a pipeline. The cement-based composite material is prepared from the following components in parts by weight: 900 to 940 parts of cement, 140 to 160 parts of viscosity reducer, 370 to 390 parts of thickener, 1500 to 1600 parts of sand, 0.5 to 2 parts of thixotropic agent, 60 to 100 parts of setting-adjusting early strength agent, 6 to 12 parts of fiber, 30 to 40 parts of water reducing agent and 260 to 280 parts of mixing water. The invention further discloses a preparation method of the cement-based composite material for pipeline trenchless centrifugal spraying repair. According to the invention, the sprayability and early strength of the high-performance cement-based composite material can be effectively improved, so that the rebound rate is reduced, the one-time spraying thickness is increased, the compactness is improved, and continuous centrifugal spraying construction of the high-performance cement-based composite material is realized.

Owner:CHANGJIANG INT HYDRO ENG CO LTD

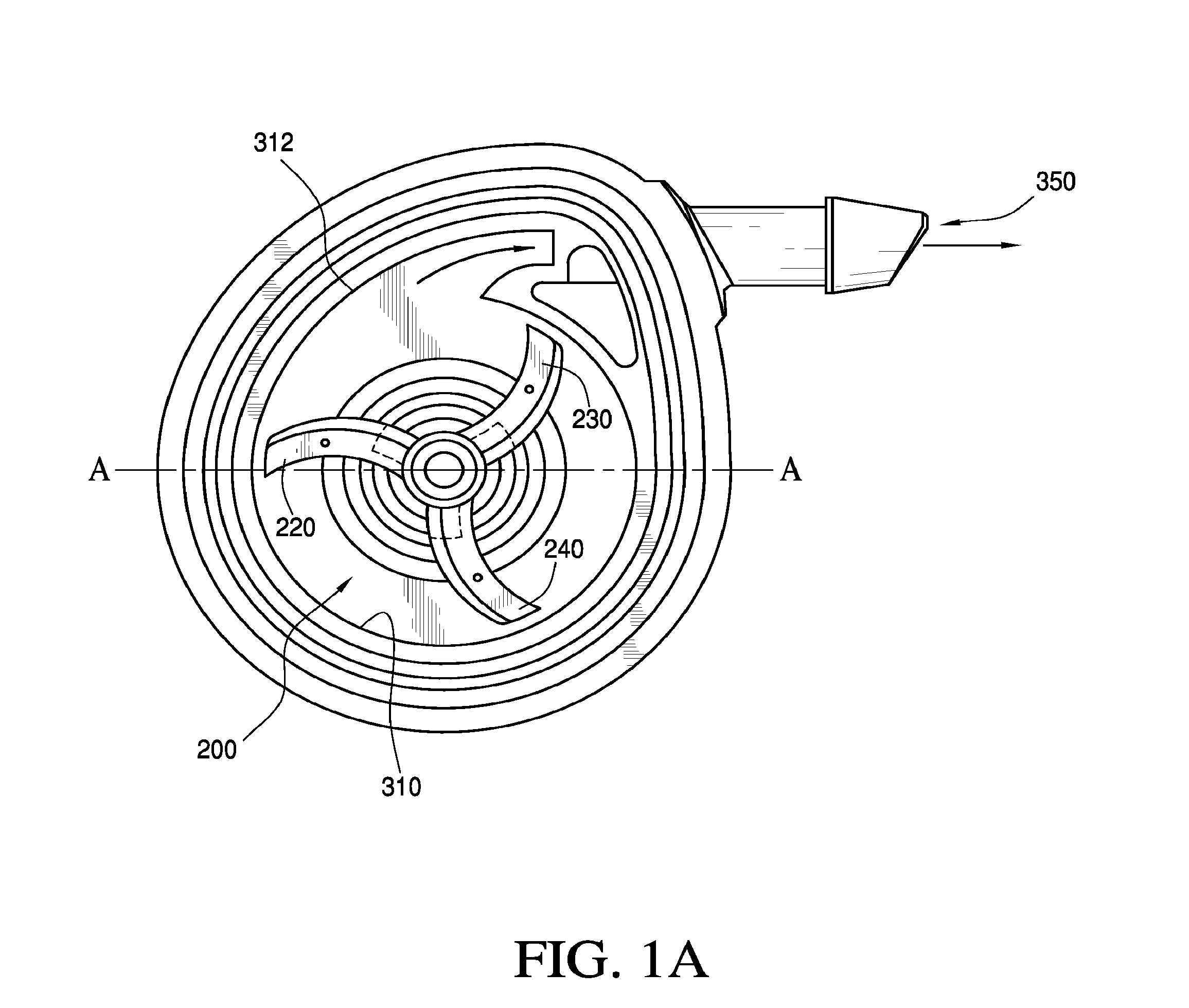

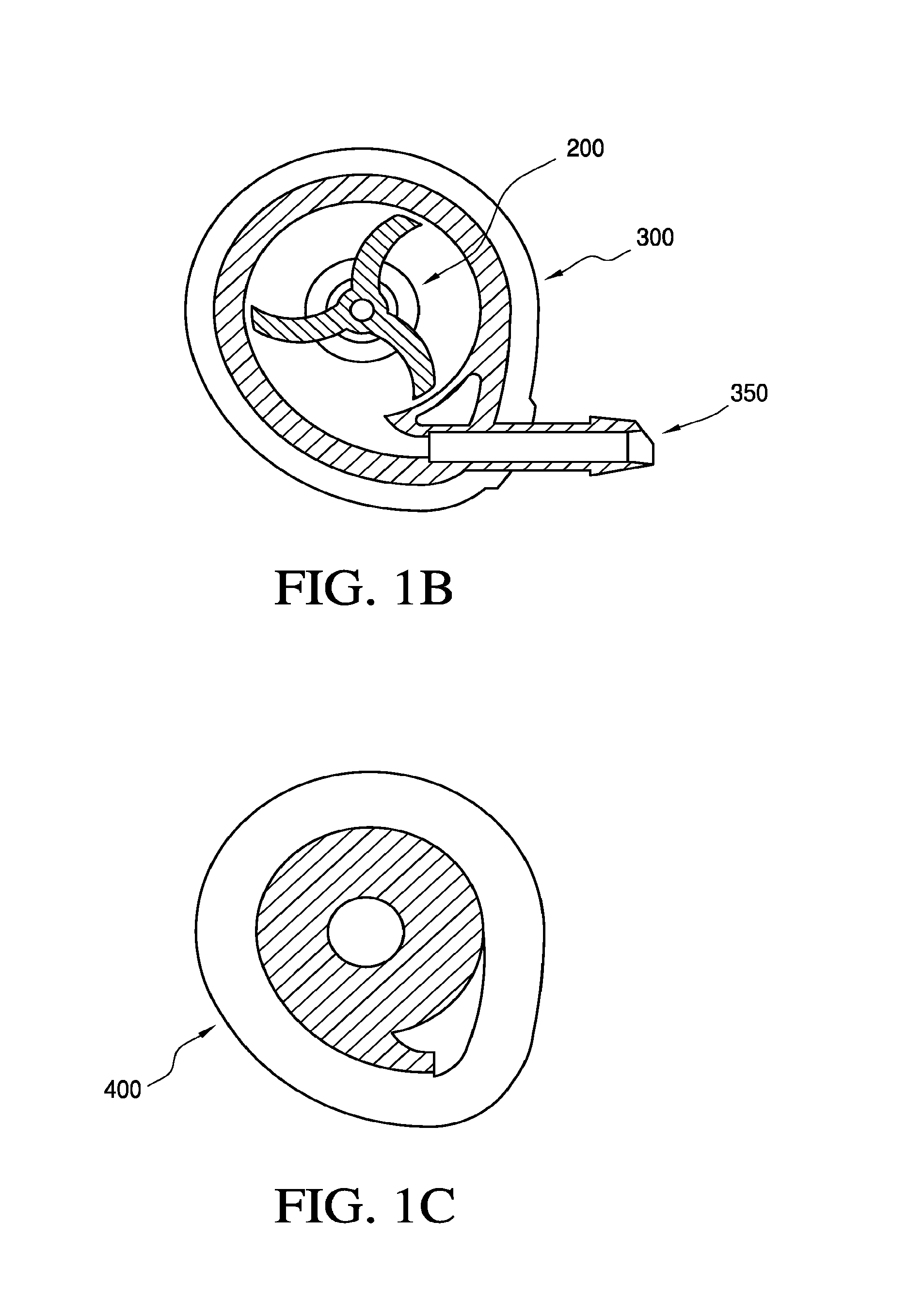

Washer pump

ActiveUS20090324434A1Enhanced P-Q performanceIncreasing impeller clearancePropellersPump componentsImpellerPump chamber

An enhanced pump assembly includes an impeller and volute casing designed to provide high operating pressures (“P”) and flow rates (“Q”) with low energy usage. The impeller has a central shaft carrying radially projecting curved primary vanes, and each primary vane also has a twist in the radial direction. Secondary impeller vanes define triangular connecting fillet-like wall segments connecting each primary vane to the impeller shaft. The casing of the pump has a slight spiral deviation so that the pump chamber's radial sidewall flares away from the swept area of the impeller's vanes to define a fluid outlet that contributes to higher P-Q performance, especially when pumping colder fluids.

Owner:DLHBOWLES INC

Stabilized high flow doctor blade head for transfer roller

InactiveUS9044776B2Strong flow abilityReduce fluid pressureLiquid surface applicatorsPaper/cardboardPistonHydraulic accumulator

A doctor blade head for coating a transfer roller includes a semi-cylindrical cavity to enable streamline fluid flow therethrough, and check plates at the inlet and outlet openings for permitting unidirectional flow into the inlet opening from said pump and out of the outlet opening toward the pump. An hydraulic accumulator acts as a fluid pressure and fluid velocity balancing device, and includes a rolling diaphragm piston moving in a cylinder that is connected to the inlet fluid path, with a spring impinging on the piston to absorb pressure surges and compensate pressure dropoffs.

Owner:HARRIS & BRUNO MACHINE

Hydraulic radial surface cutting ejector, cutting assembly and cutting method

PendingCN112814632AImprove permeabilityImprove diversion capacityFluid removalEngineeringRadial surface

The invention discloses a hydraulic radial surface cutting ejector, a cutting assembly and a cutting method. The hydraulic radial surface cutting ejector comprises a body, at least one ejection hole formed in the axial side wall of the body, a nozzle and an outer sheath, wherein the nozzle and the outer sheath are arranged in the ejection hole; and the outer sheath is arranged outside the nozzle in a sleeving mode and fixedly connected with the ejection hole. The nozzle is provided with at least three ejection holes in different ejection directions. When the hydraulic radial surface cutting ejector is used for cutting, the nozzle is provided with the at least three ejection holes in different ejection directions, hydraulic radial surface cutting is adopted, a fan-shaped hole channel is formed, cracks develop along the minimum principal stress under the action of ground stress, and therefore the stratum permeability is improved, and the purposes of increasing the yield and injection are achieved.

Owner:GUANGZHOU MARINE GEOLOGICAL SURVEY

Seal assembly for reducing fluid loss from transmission pump

ActiveUS7827786B2Reduce lossesReduce pump pressureEngine sealsRotary clutchesContact layerEngineering

An improved seal assembly is provided that minimizes loss of transmission pump pressure by controlling fluid flow past a torque converter hub bushing to meet bushing lubrication requirements without unnecessarily diminishing pump pressure and while also minimizing frictional losses. The seal assembly includes a rigid carrier adapted to fit between a pump body member and the torque converter hub. An elastomeric lip extends from the rigid carrier. A contact layer is connected to the elastomeric lip and configured to sealingly contact the torque converter hub. The contact layer is integral with and harder than the elastomeric lip, therefore minimizing frictional losses.

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com