Apparatus for a pipe string of a geological drill hole, pipe string, method for operating a geological drilling gear and method for producing a pipe string for a geological drill hole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]The invention is explained in more detail below using preferred exemplary embodiments with reference to figures of a drawing. Here:

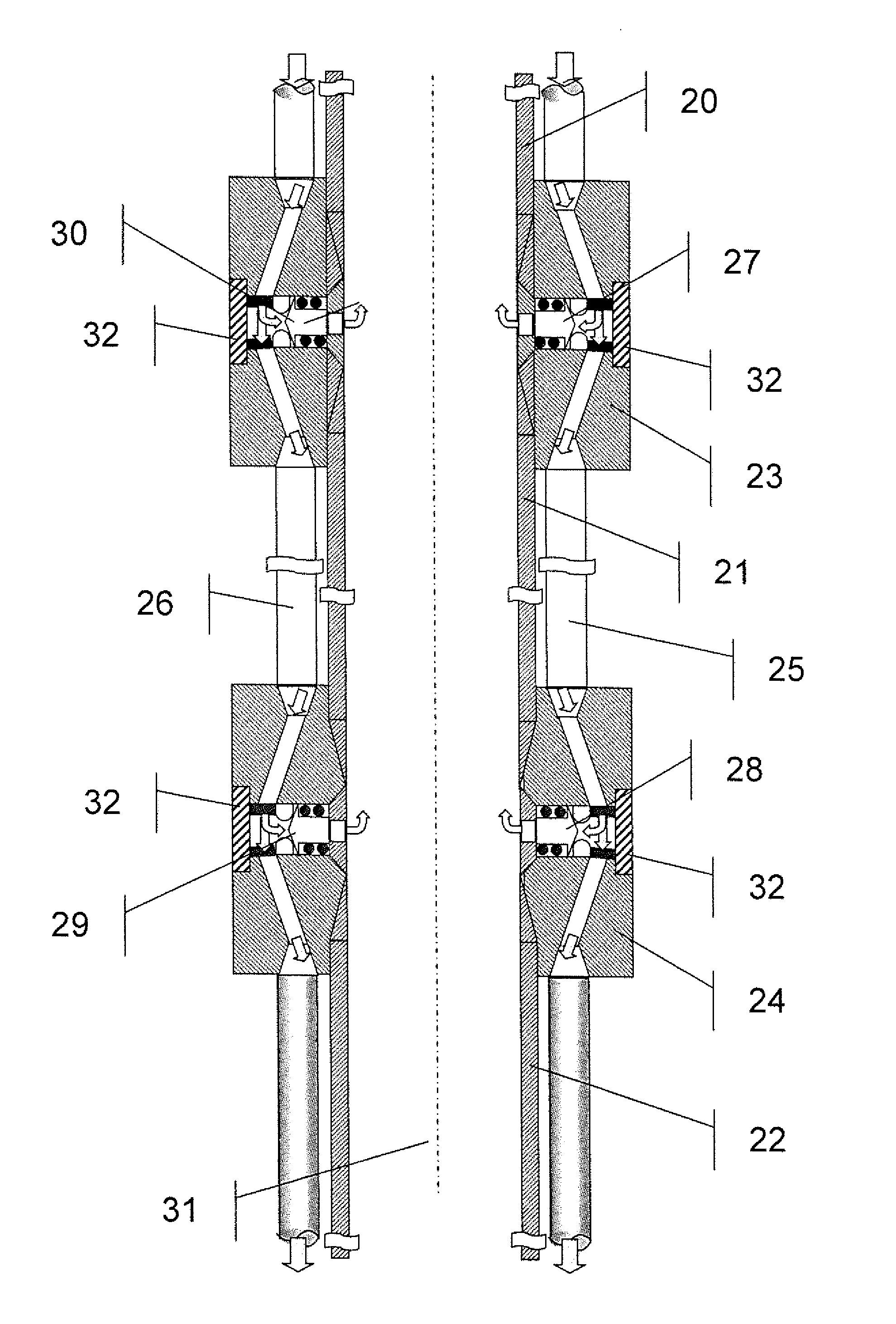

[0032]FIG. 1 shows a schematic diagram of a pipe string design with a plurality of pipe strings of a geological drill hole,

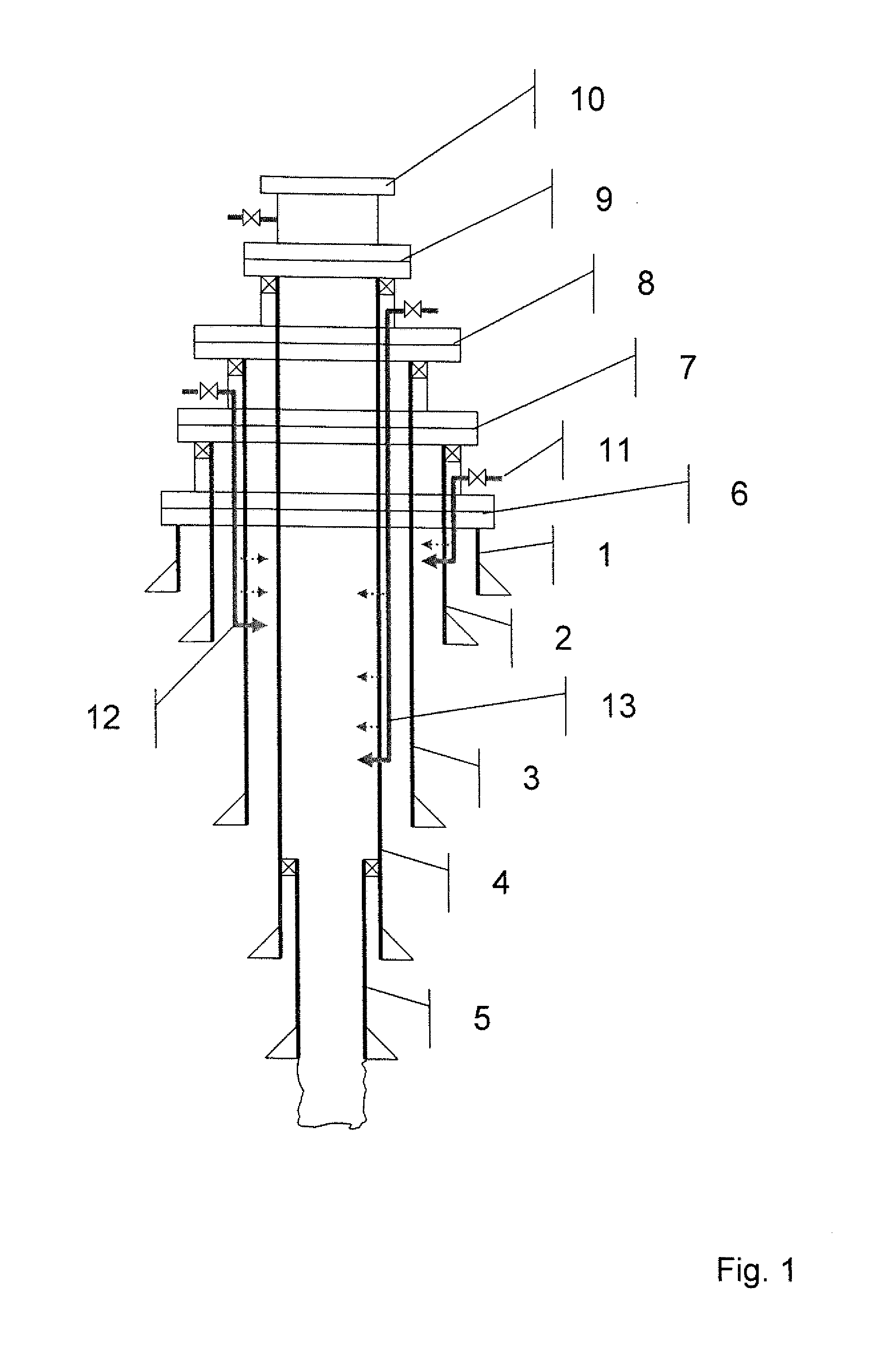

[0033]FIG. 2 shows a schematic diagram of an arrangement with three pipe string elements which are connected with connecting bushings, and

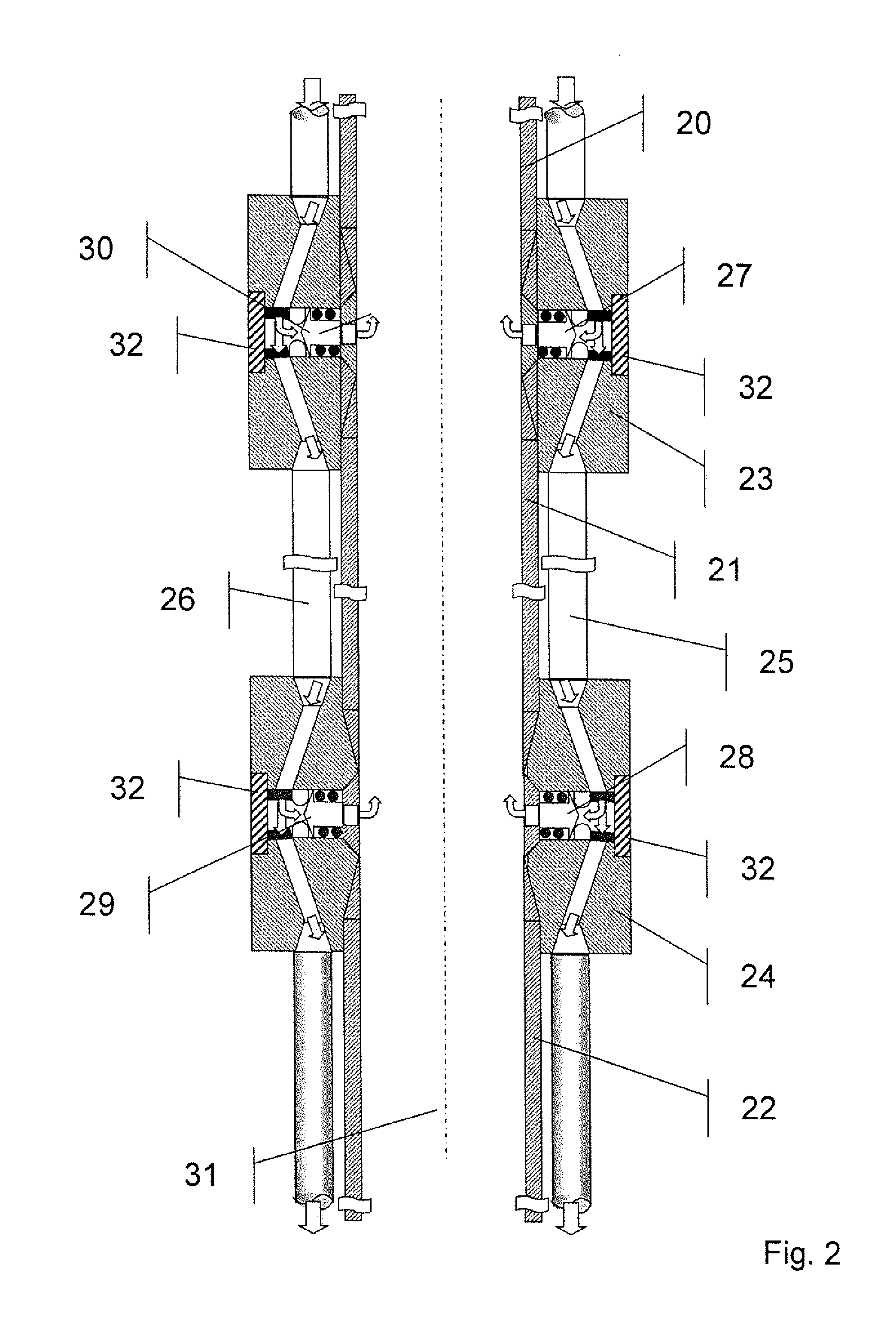

[0034]FIG. 3 shows a schematic diagram of an arrangement with three pipe strings of a geological drill hole, which are cemented in.

[0035]FIG. 1 shows a schematic diagram of a pipe string design of a geological drill hole. There is a plurality of pipe strings 1, . . . , 5, which are each cemented in, shown with different diameters. The pipe strings 1, . . . , 5 are terminated at the top with the aid of associated flanges 6, . . . , 10. Three pipe strings 2, 3, 4 are provided on the outside with a respective fluid supply line 11, 12, 13 via which a fluid, in particular a gas, can be fed into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com