Patents

Literature

175results about "Distillation corrosion inhibition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of scavenging hydrogen sulfide from hydrocarbons

InactiveUS6024866AEffective and economical processDistillation corrosion inhibitionFluid removalScavengerProduct gas

Hydrocarbons, gas mixtures of hydrocarbons, and the like containing hydrogen sulfide are brought into intimate contact with a hydrogen sulfide scavenger prepared by reacting an alkylenepolyamine with formaldehyde, whereby the amount of hydrogen sulfide in the hydrocarbon is significantly reduced.

Owner:BAKER HUGHES INC

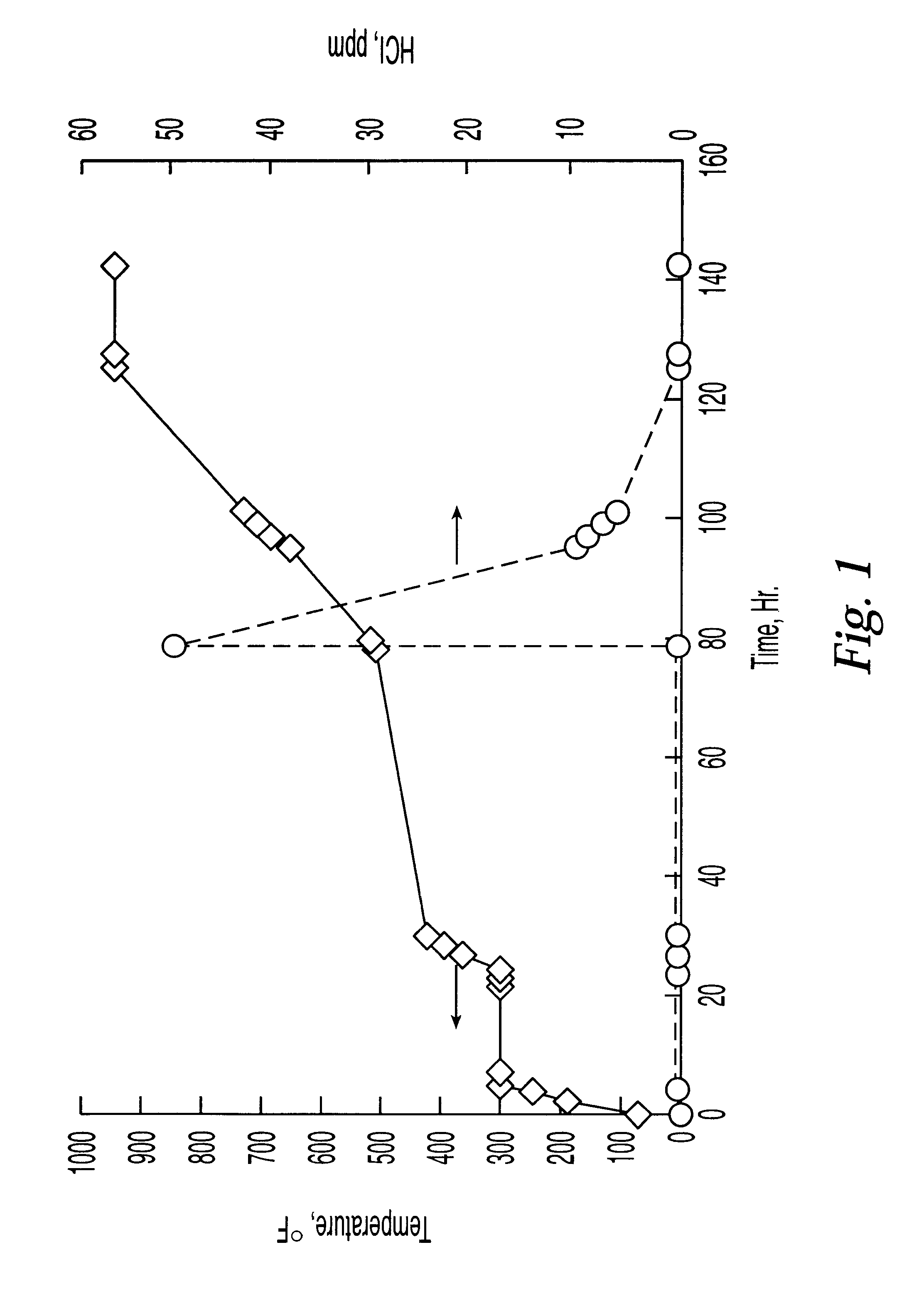

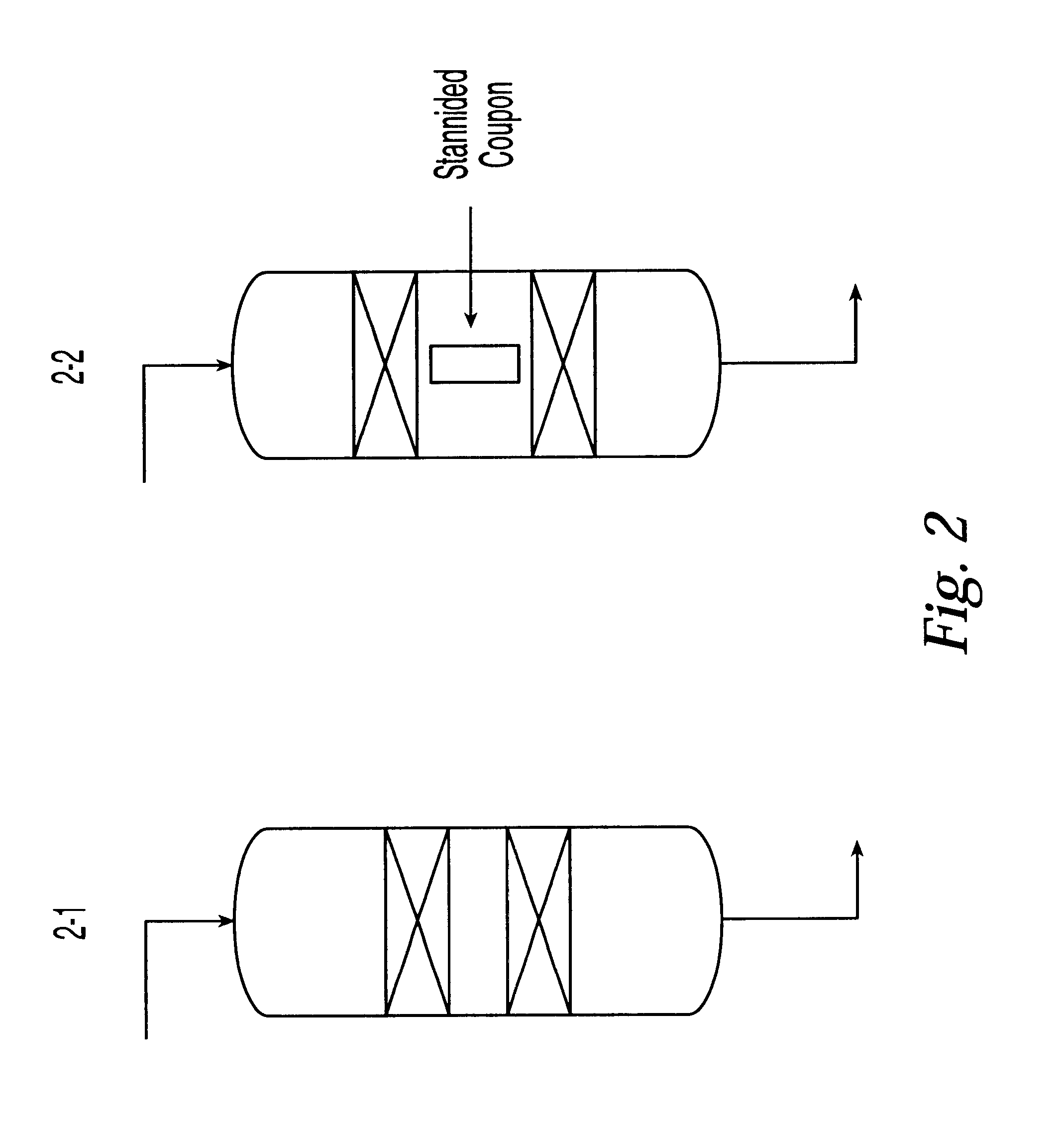

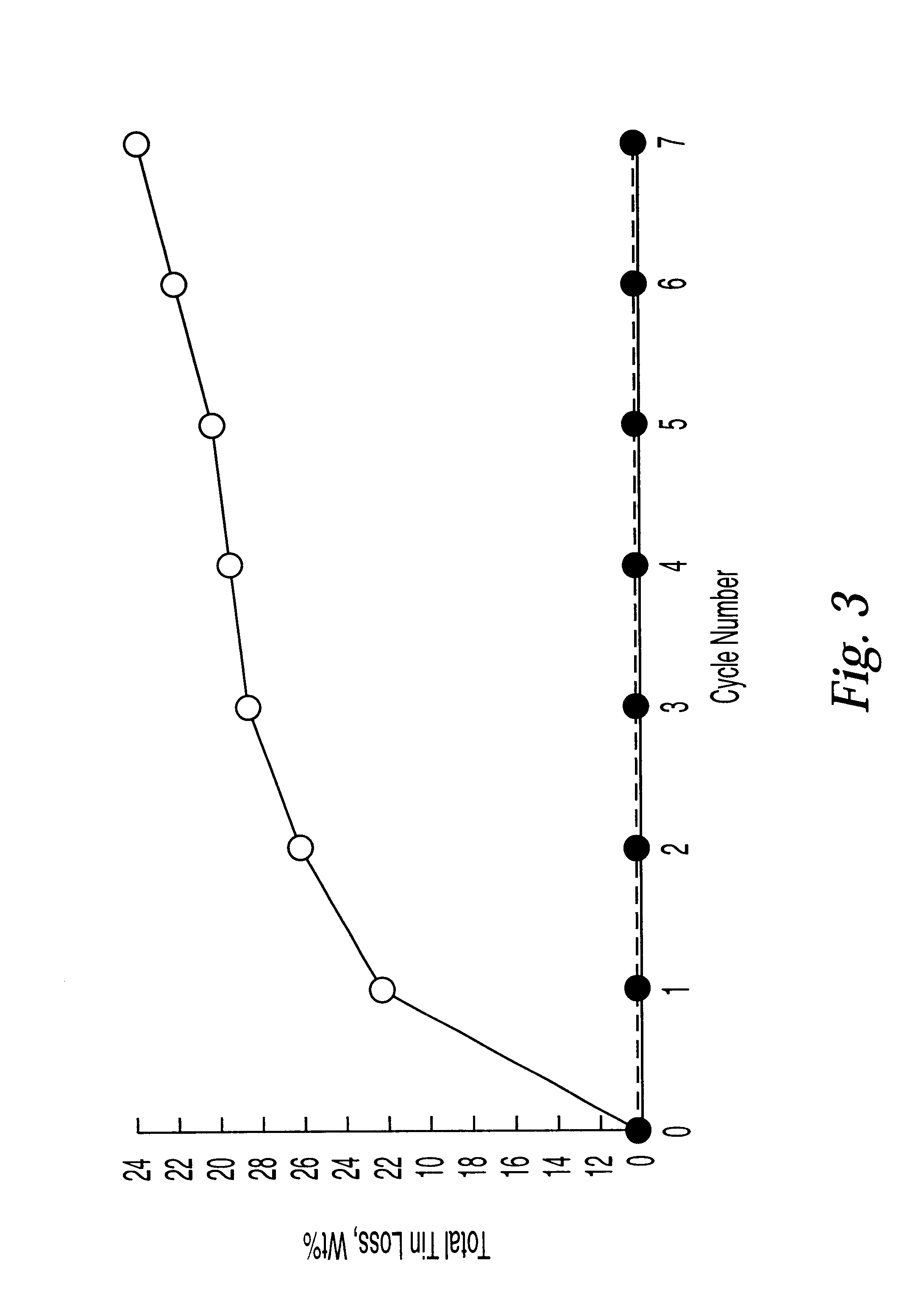

Method for removing reactive metal from a reactor system

InactiveUS6419986B1Reduce catalyst contaminationGood reproducibilityDistillation corrosion inhibitionCatalytic naphtha reformingReactor systemHalogen

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

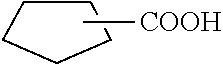

Corrosion inhibitor

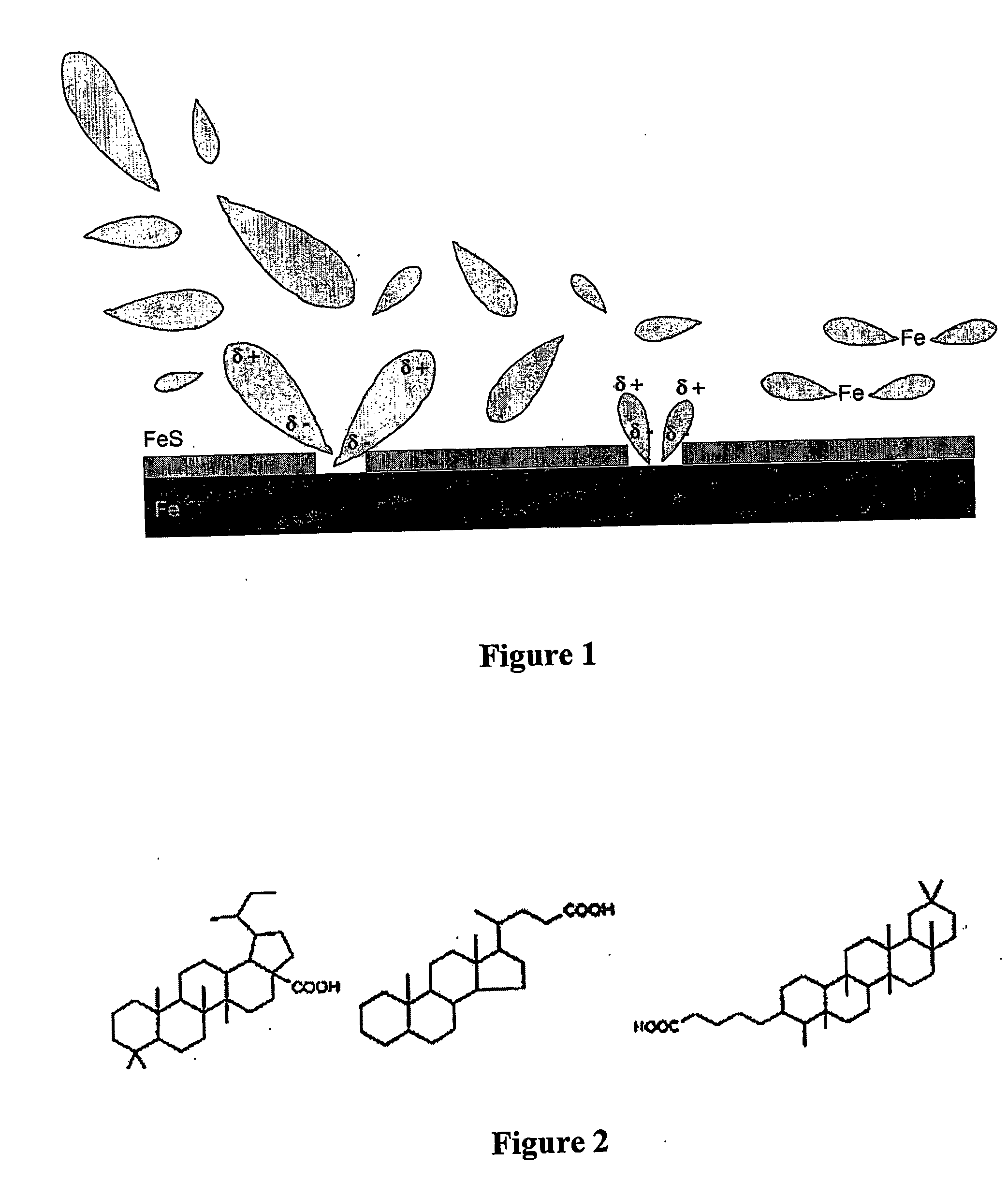

InactiveUS20070119747A1Avoid corrosionInhibiting naphthenic acid corrosionDistillation corrosion inhibitionOther chemical processesSulfur hydrideCorrosion inhibitor

A composition and method of inhibiting corrosion caused by naphthenic acid in fluids includes using a combination of a thiophosphorus compound and a hydrogen sulfide scavenging compound. The hydrogen sulfide scavenging compound significantly enhances the performance of the thiophosphorus compound and may be included at relatively low levels in the composition. The treatment may be applied to fluids including crude oils and lighter fractions thereof.

Owner:BAKER HUGHES INC

Mitigation of fouling by thermally cracked oils (LAW852)

InactiveUS6210560B1Thermal non-catalytic crackingDistillation corrosion inhibitionEngineeringResidence time

Owner:EXXON RES & ENG CO

Method of reducing hydrolysis in hydrocarbon streams

ActiveUS20030201207A1Distillation corrosion inhibitionGroup 5/15 element organic compoundsOrganic acidChloride

A method of reducing hydrolysis in a hydrocarbon stream comprising adding to a hydrocarbon stream containing a chloride compound which undergoes hydrolysis at elevated temperatures in the presence of water to form hydrochloric acid, an effective amount of a treating agent that is at least one overbased complex of a metal salt and an organic acid complexing agent, the treating agent being added to hydrocarbon stream when the stream is at a temperature below which any substantial hydrolysis of the chloride containing compound occurs.

Owner:HALLIBURTON ENERGY SERVICES INC

Multi-amine neutralizer blends

ActiveUS20050051462A1Avoid corrosionMinimizes reduces depositThermal non-catalytic crackingCatalytic crackingDistillationNuclear chemistry

Amine and amine blend compositions neutralize acid environments in distillation overheads of hydrocarbon processing facilities. The neutralizers are composed of certain combinations of amines which are relatively stronger bases and more resistant to hydrochloride salt formation. The amines, when blended together, provide greater neutralization of condensed water present without increased potential for corrosive hydrochloride salt formation.

Owner:BAKER HUGHES INC

Method for prevention of fouling in basic solution by inhibiting polymerization and solubilizing deposits using amino acids

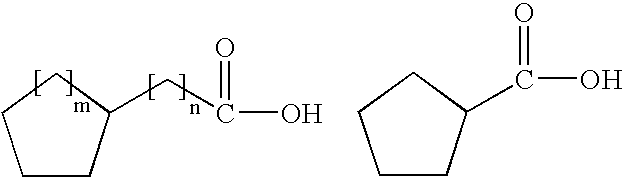

InactiveUS6986839B2Prevent scalingRemoving polymeric depositThermal non-catalytic crackingDistillation corrosion inhibitionHydrolysisCaproic Acid

A method for inhibiting and dissolving the deposits formed on caustic or alkaline scrubbers used in scrubbing acidic gases such as carbon dioxide, hydrogen sulfide, which are formed during the pyrolytic cracking of naphtha, ethane, and propane. The cracking operations produce certain oxygenated compounds such as vinyl acetate or acetaldehyde, which undergo polymerization under alkaline condition. The vinyl acetate on hydrolysis releases acetaldehyde under alkaline conditions. Amino acids such as 6 amino caproic acid and lactams such as epsilon caprolactam not only prevent but also dissolve the polymers formed by aldol condensation.

Owner:DORF KETAL CHEM (I) PTE LTD

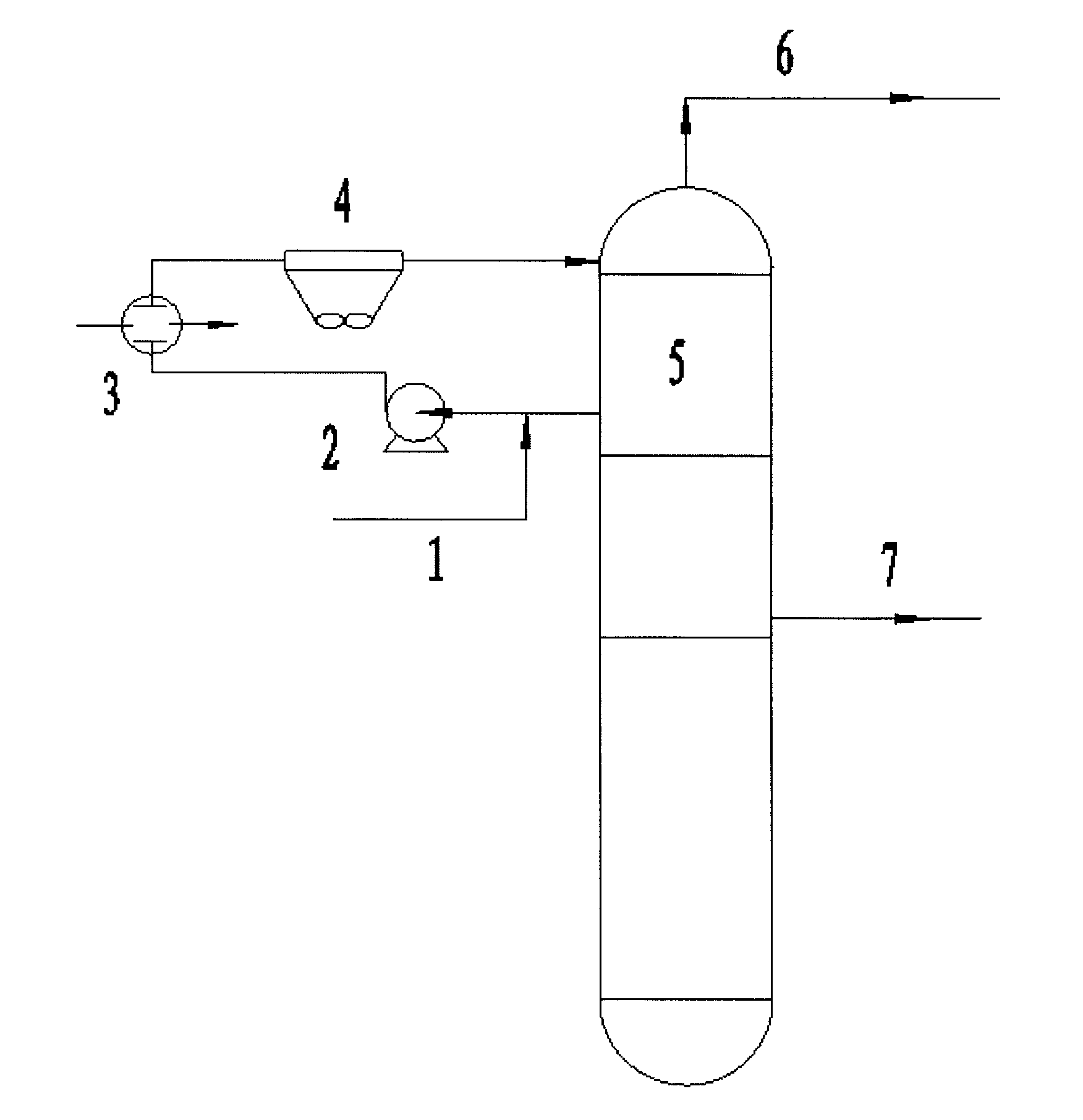

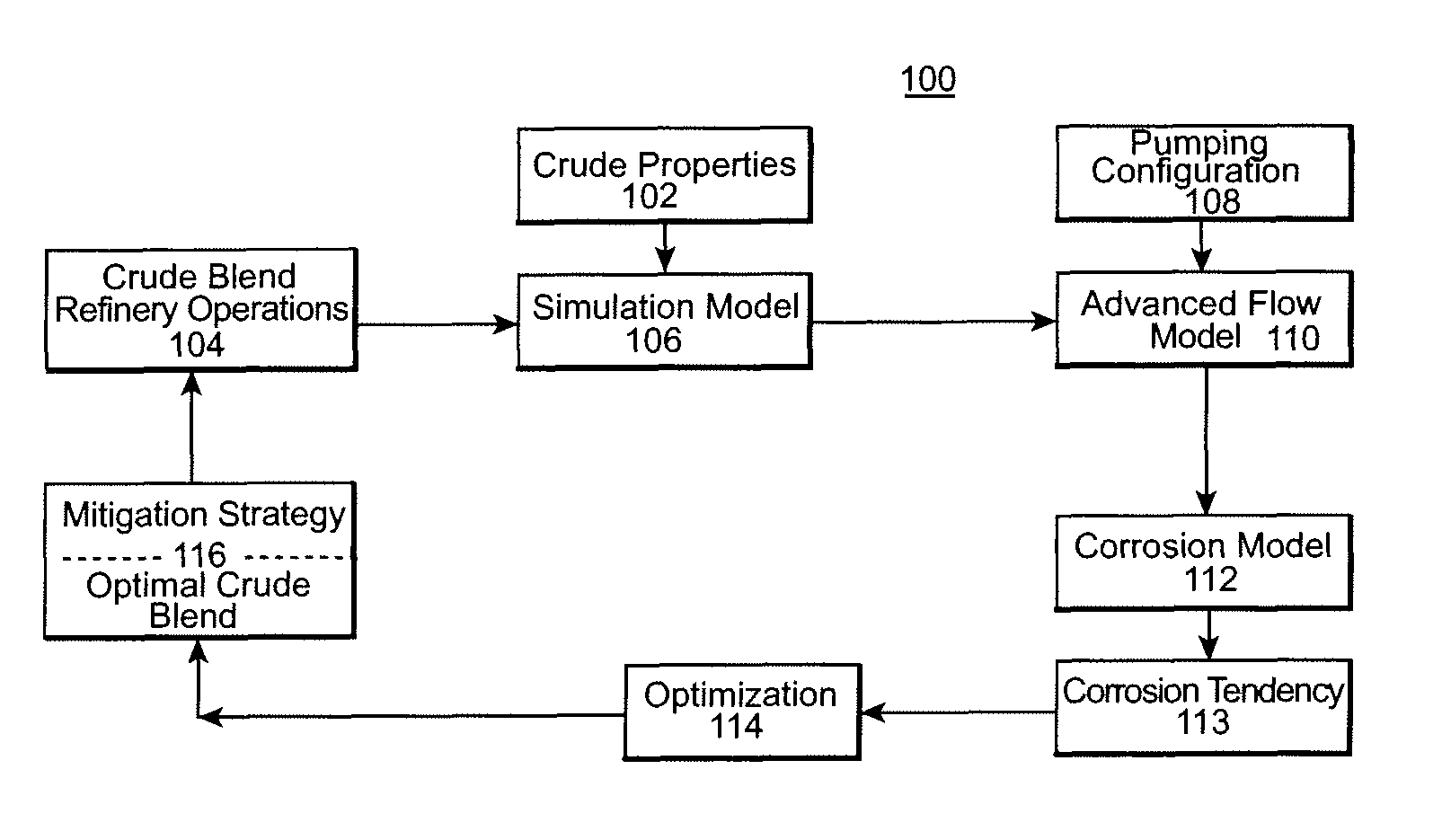

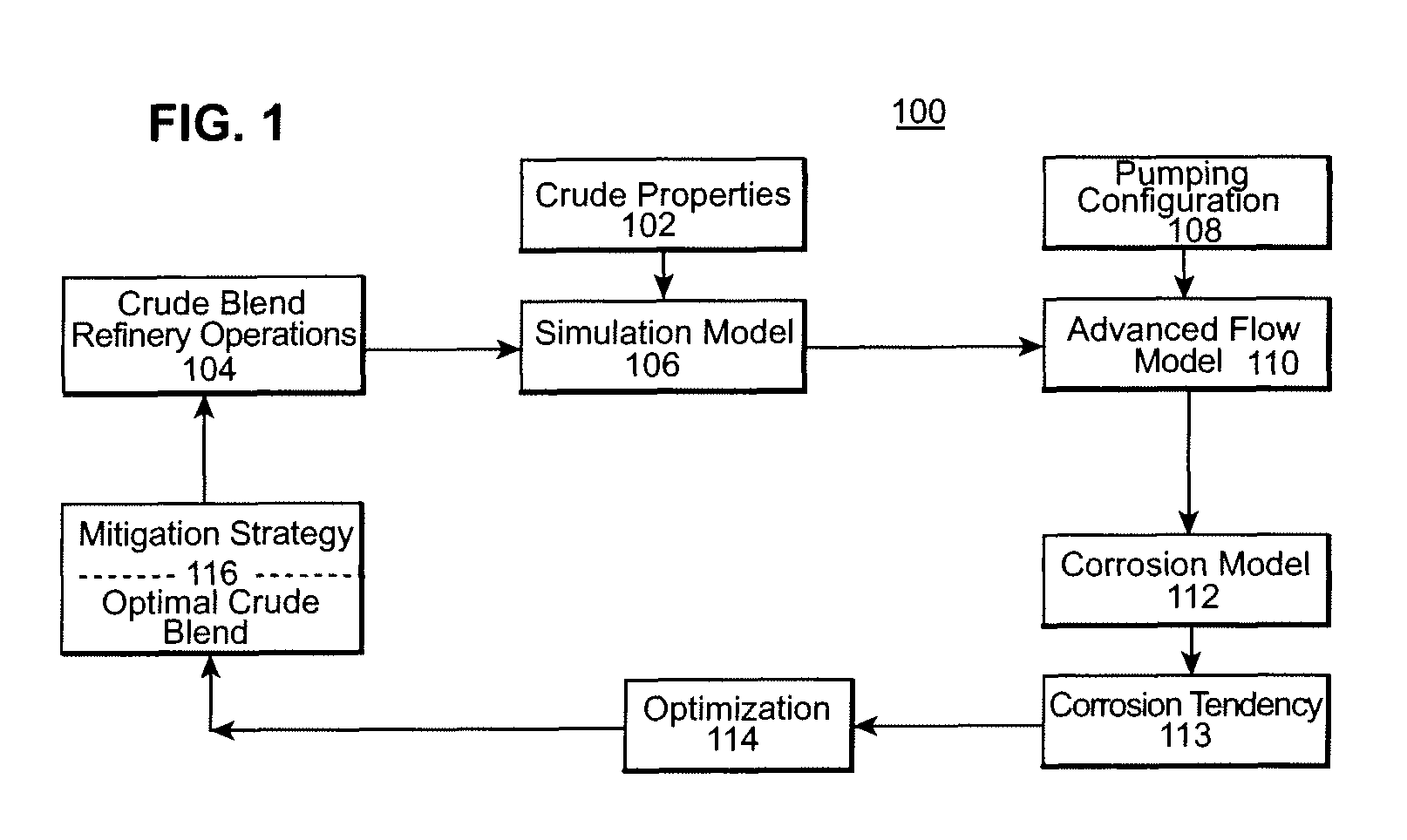

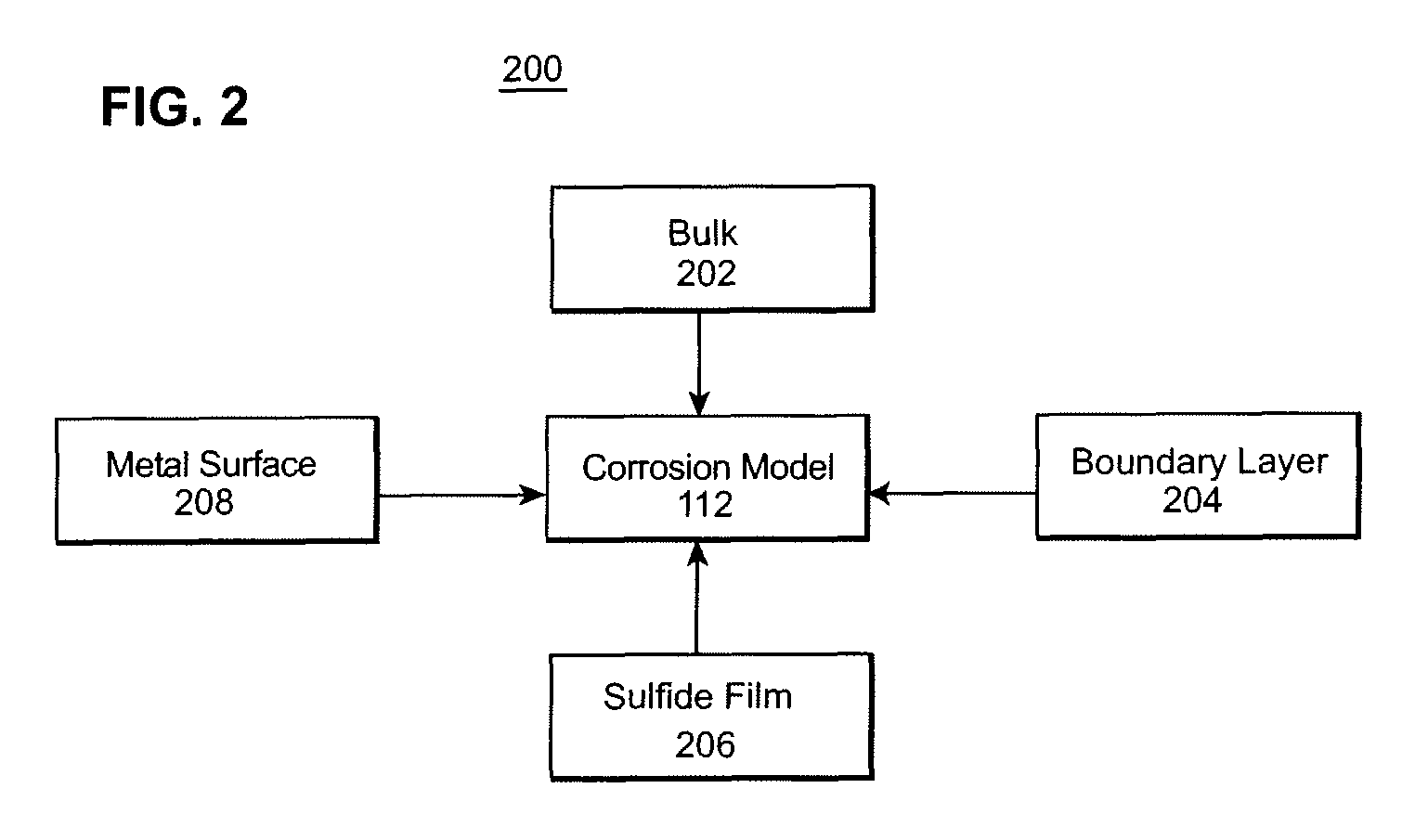

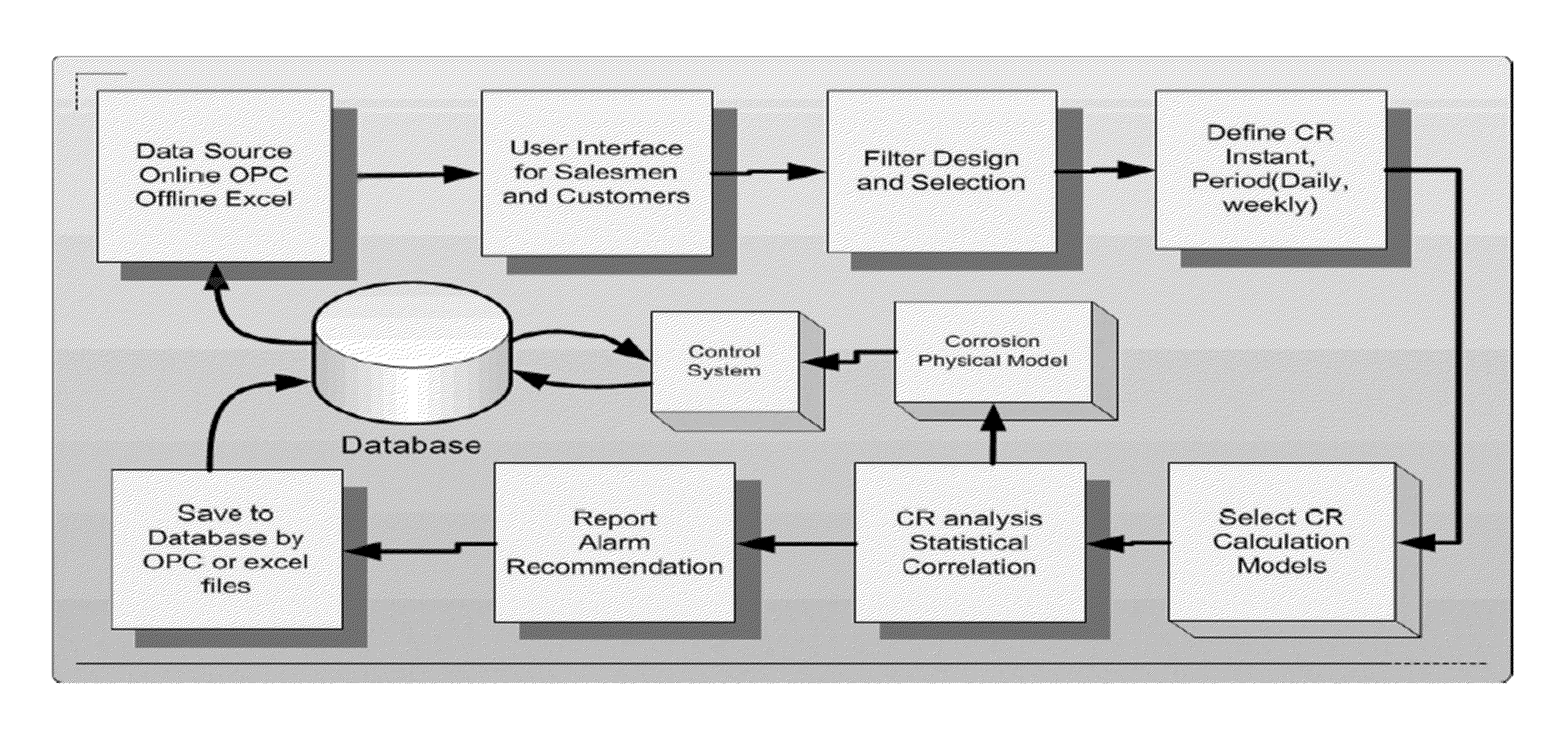

Corrosion assessment method and system

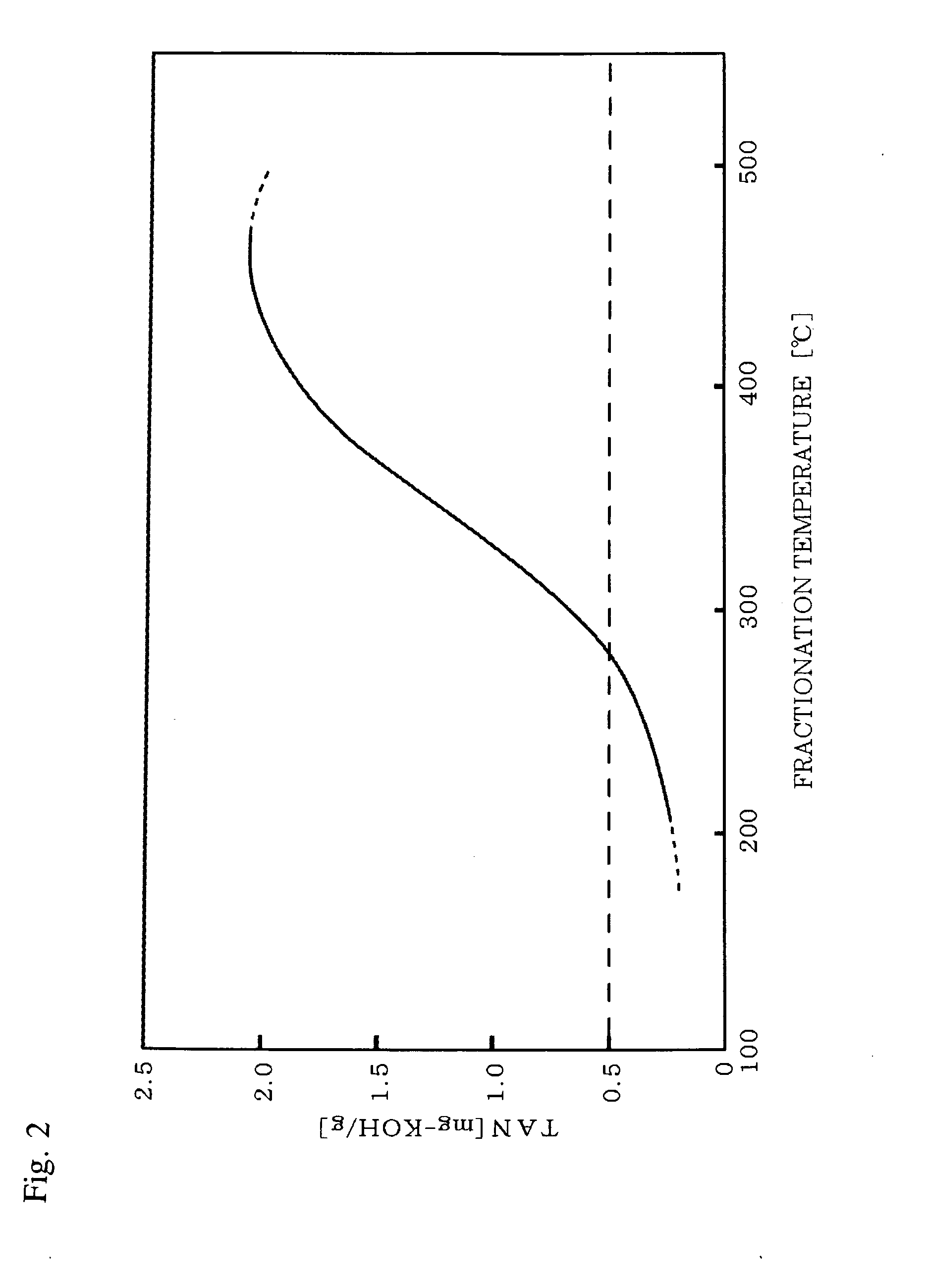

ActiveUS20080257782A1Reduce or eliminate the corrosive potentialDistillation corrosion inhibitionWeather/light/corrosion resistanceBoiling pointPetroleum

A method includes assessing corrosion in a refinery operation having a piping network. Assessing can include identifying in a petroleum sample a presence and an amount of a species determined to be potentially corrosive to corrodible equipment in a refinery. A corrosion risk presented by the presence, the amount, and the boiling point of the species is determined. And, the corrosion risk is evaluated in view of piping network information. A system for implementing the method is provided, also.

Owner:BL TECH INC

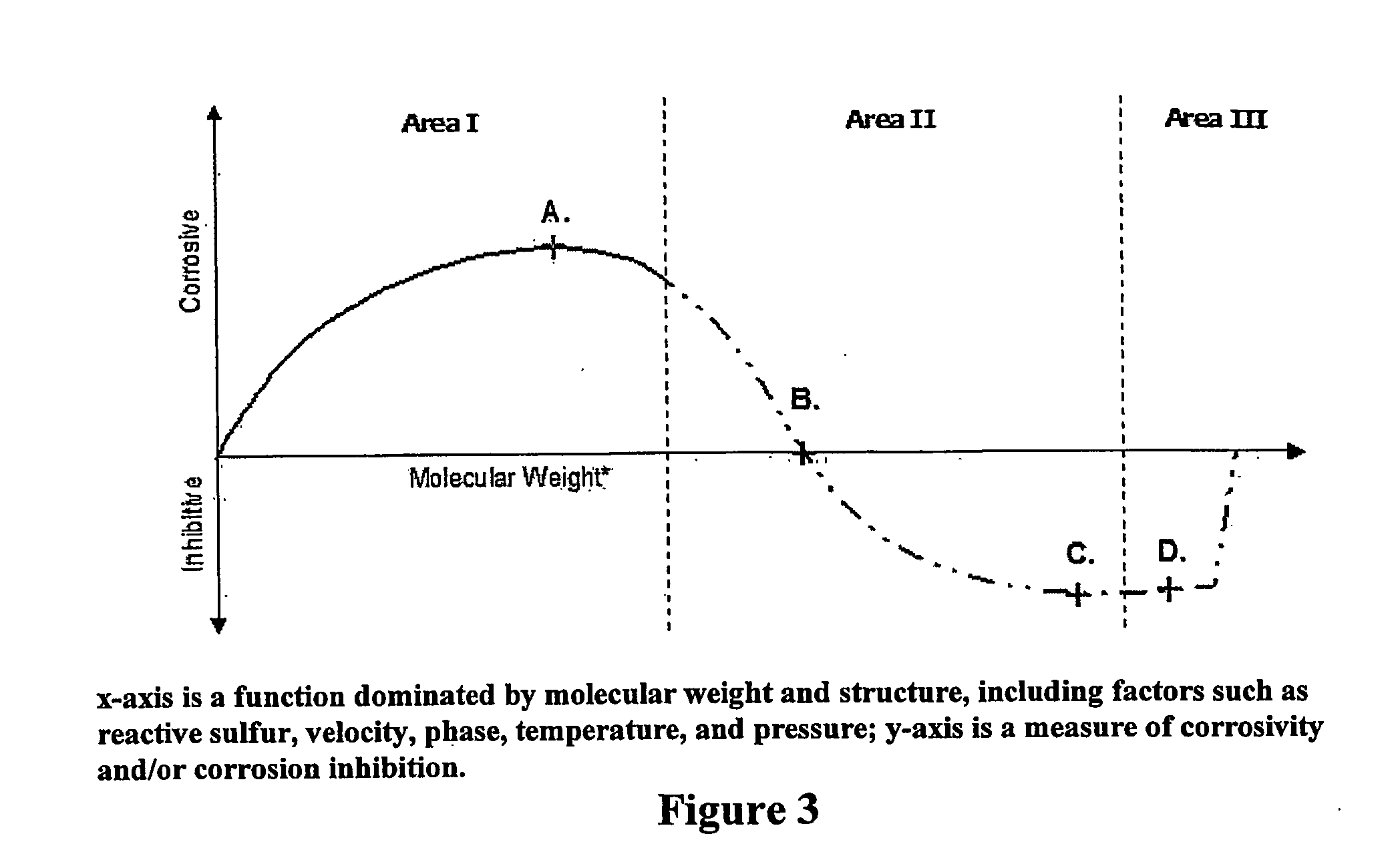

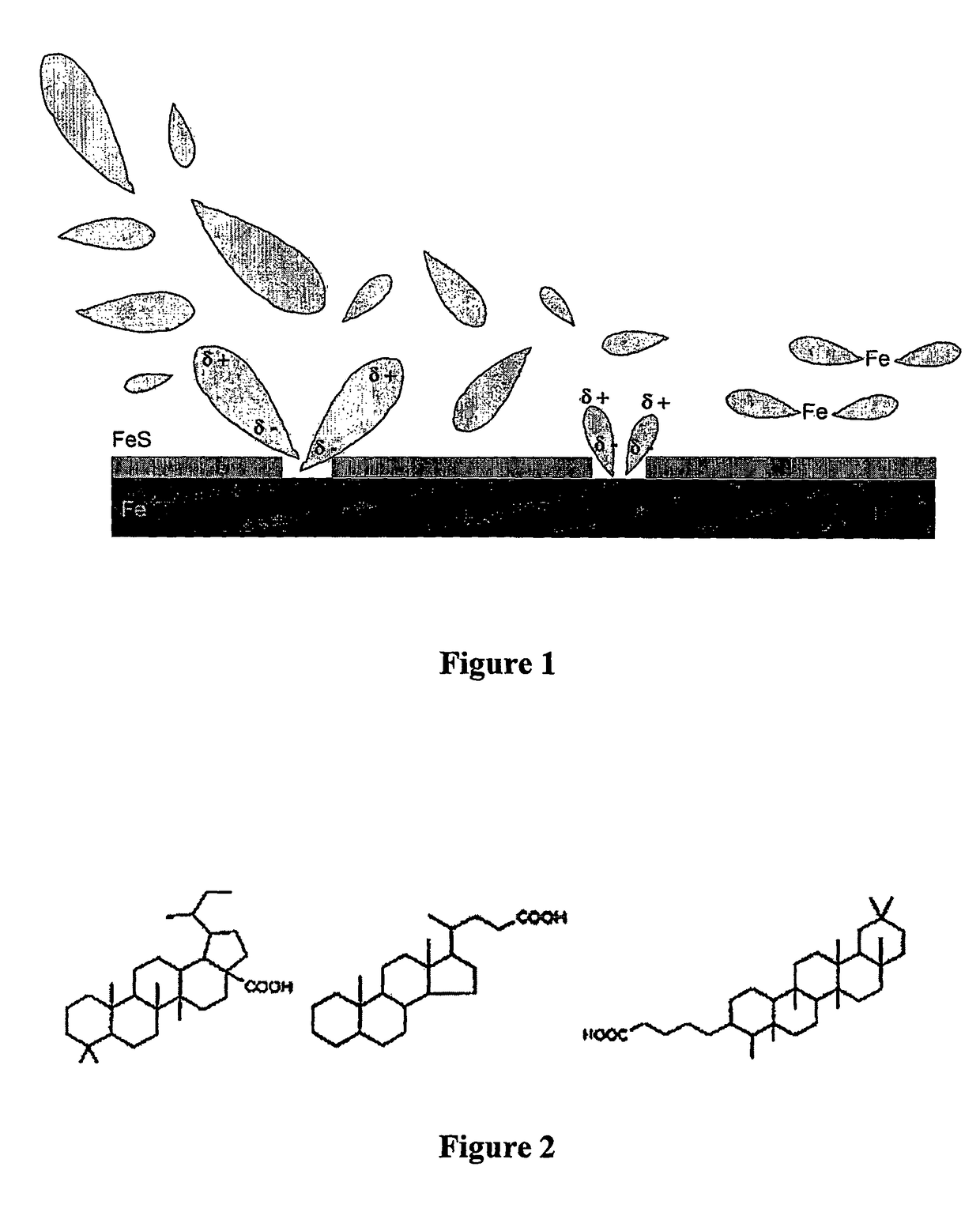

Compositions, Configurations, and Methods of Reducing Naphtenic Acid Corrosivity

InactiveUS20080164137A1Reduce naphthenic acid corrosivityReduce naphthenic acid corrosionDistillation corrosion inhibitionDistillation regulation/controlChemical compositionPhotochemistry

Naphthenic acid corrosivity of hydrocarbon feedstocks is correlated with the chemical composition of naphthenic acids, and especially with a ratio between an alpha fraction and a beta fraction of naphthenic acids. Contemplated plants, configurations, and methods are directed to reducing naphthenic acid corrosivity of hydrocarbon feedstocks by increasing the beta fraction over the alpha fraction.

Owner:FLUOR TECH CORP

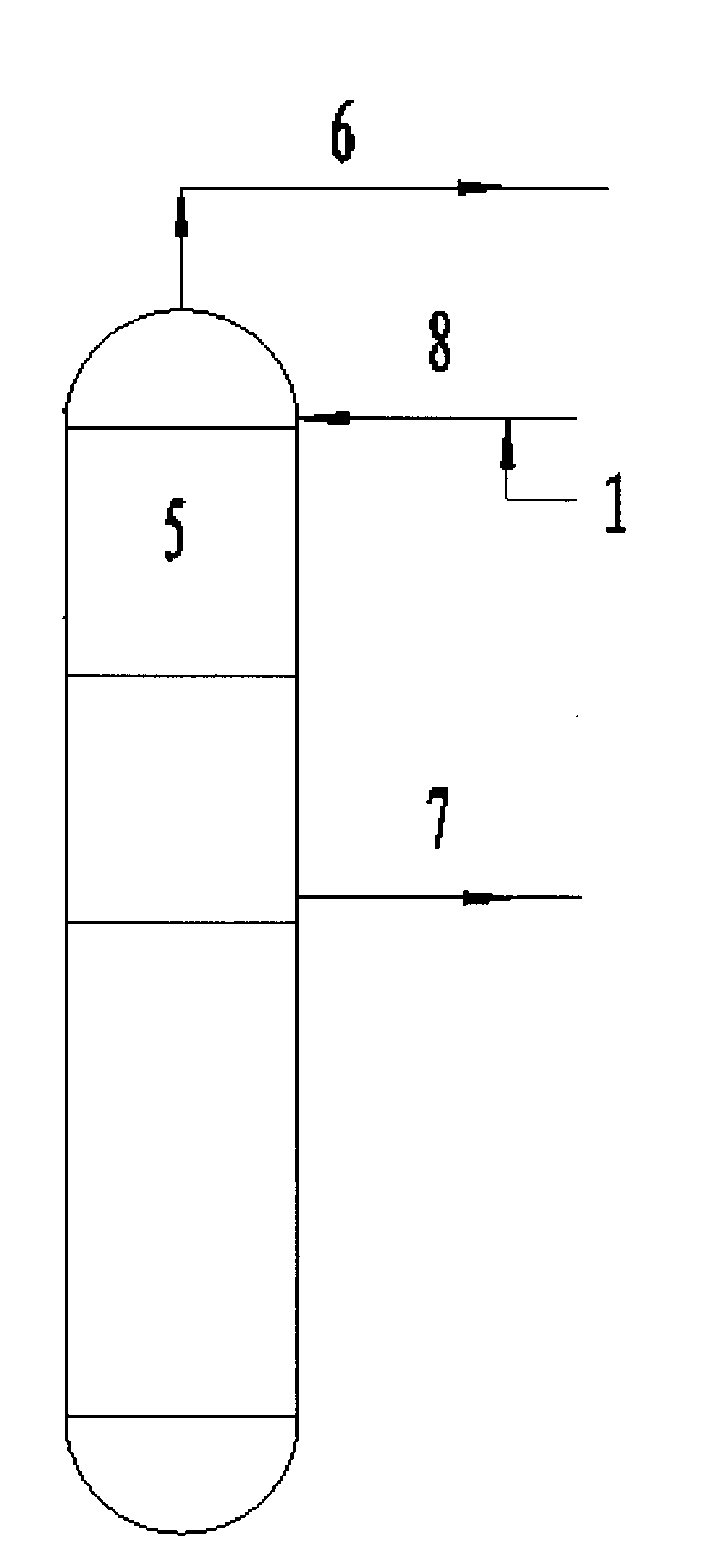

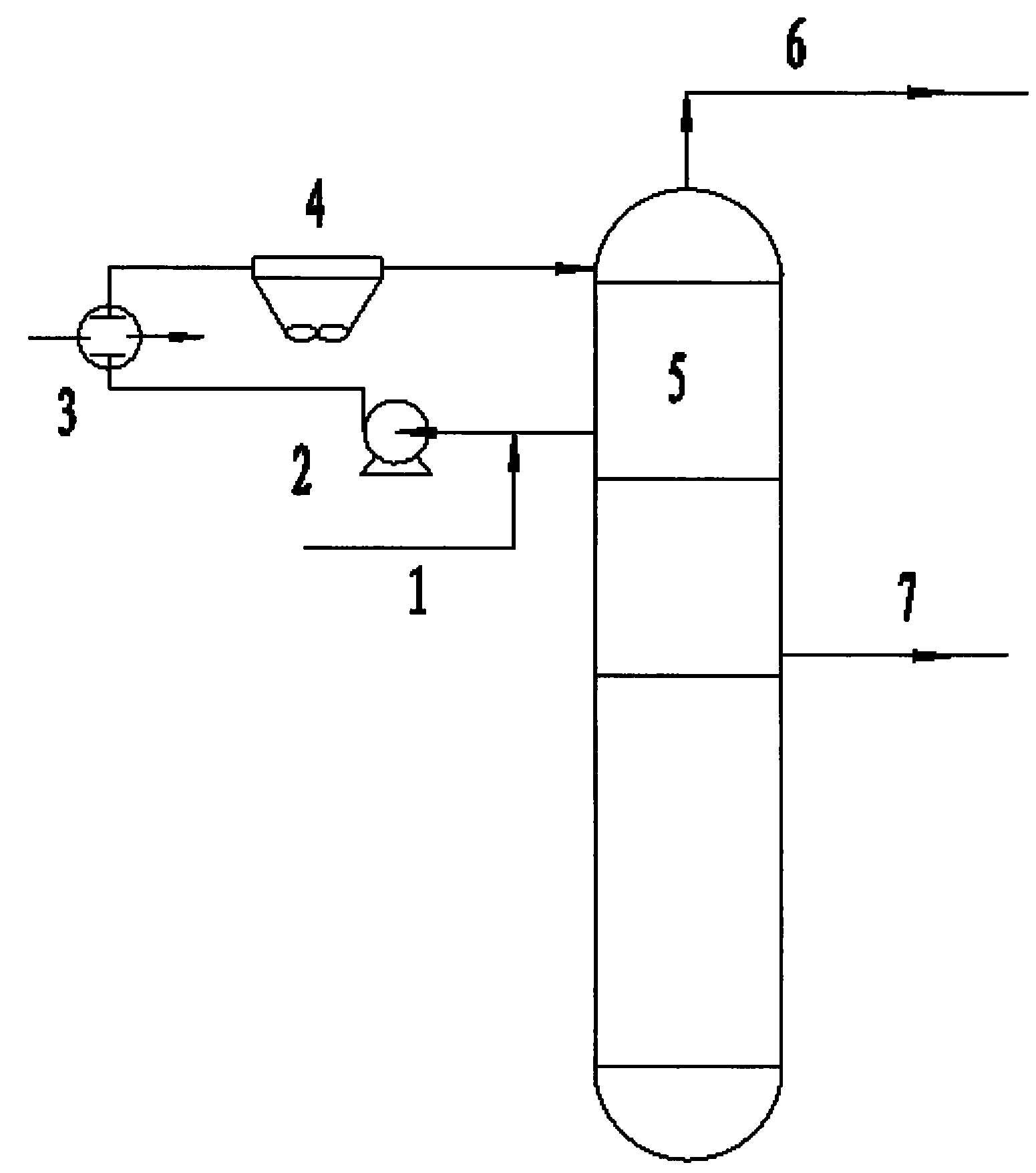

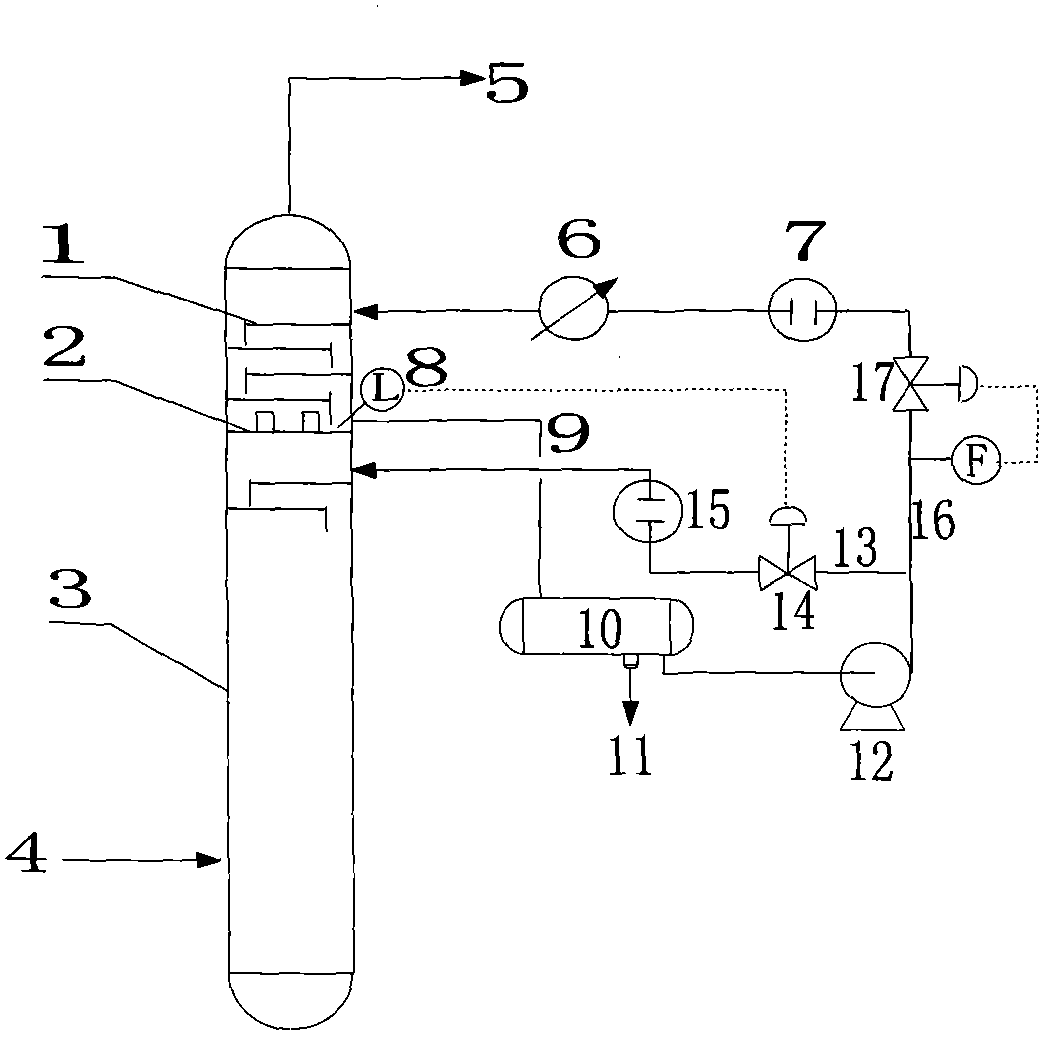

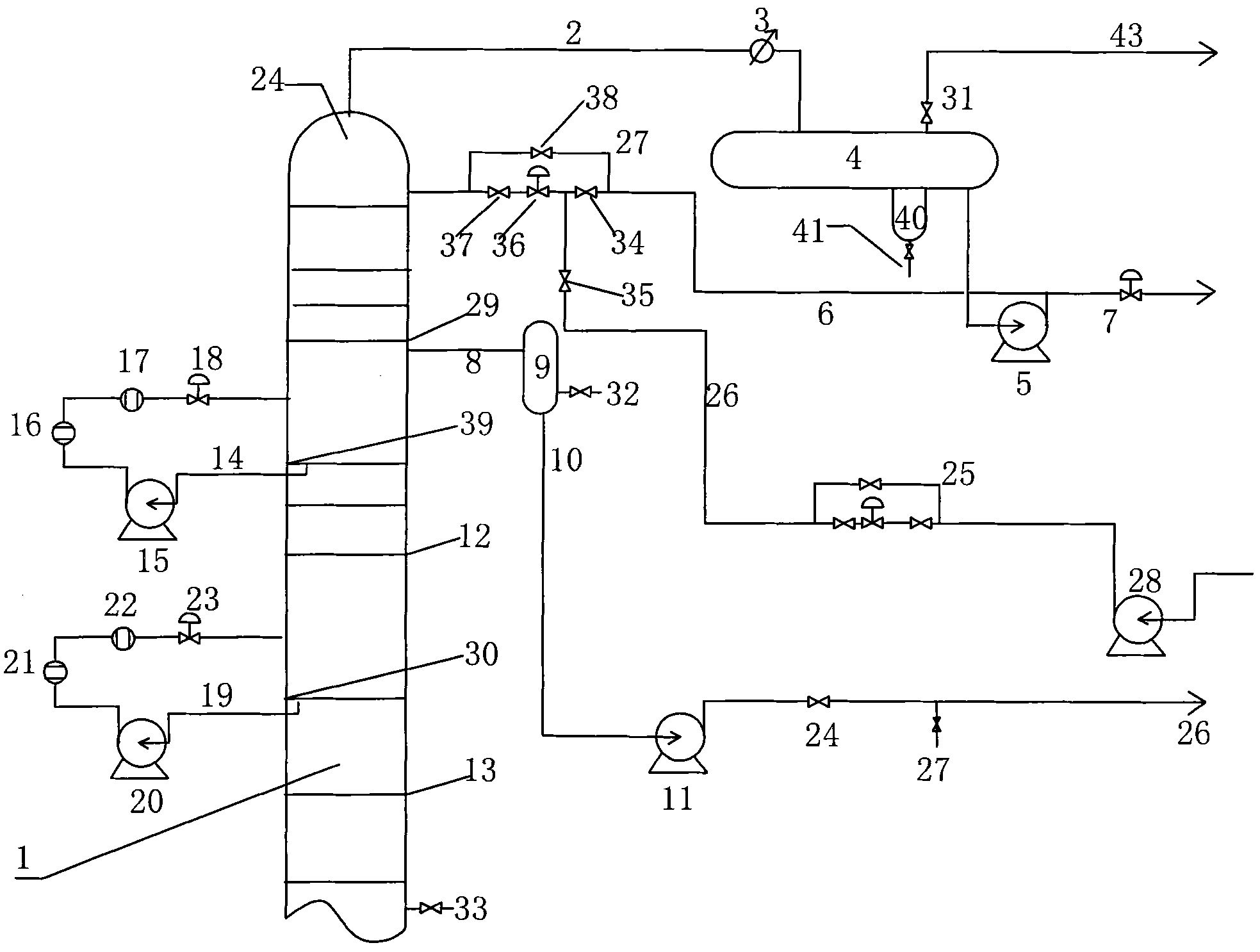

Process for treating salt deposition in fractionating tower

ActiveCN102373066AAvoid time-consuming, reduce volumeDisadvantages of Avoiding Plant DowntimeThermal non-catalytic crackingDistillation corrosion inhibitionRefluxAlcohol

The present invention discloses a process for treating salt deposition in a fractionating tower. A purpose of the present invention is to overcome disadvantages of time consuming, device shutdown or amount reducing, hidden danger of corrosion, and the like in the prior art, wherein the amount is the amount of the deposited salt. The method comprises that: a salt deposition inhibitor is consecutively added to the an oil product before the oil product enters a tower top reflux pipeline of the fractionating tower or a tower top circulating pump inlet of the fractionating tower, wherein 30-60 mg of the salt deposition inhibitor is added to per kg of the oil product in the tower top reflux pipeline of the fractionating tower or the tower top circulating pump inlet of the fractionating tower, the adding time is 30-60 hours, the salt deposition inhibitor comprises, by weight, 30-70% of an aliphatic nitrogen compound, 10-30% of alkyl alcohol and 20-40% of an organic solvent.

Owner:CHINA PETROLEUM & CHEM CORP +1

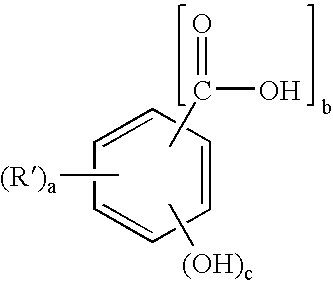

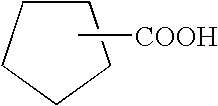

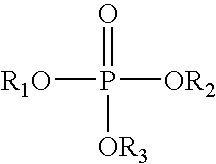

Naphthenic acid corrosion inhibition using new synergetic combination of phosphorus compounds

ActiveUS20100116718A1Low acid valueDistillation corrosion inhibitionOther chemical processesPhosphorus pentasulfidePhosphate

The present invention relates to the field of processing hydrocarbons which causes corrosion in the metal surfaces of processing units. The invention addresses the technical problem of high temperature naphthenic acid corrosion and sulphur corrosion and provides a solution to inhibit these types of corrosion. The three combination compositions are formed by three mixtures separately, with one mixture obtained by mixing compound A, which is obtained by reacting high reactive polyisobutylene (HRPIB) with phosphorous pentasulphide in presence of catalytic amount of sulphur with compound B such as trialkyl phosphate and second mixture obtained by mixing compound A with compound C such as phosphite like di-isodecyl phenyl phosphite, and third mixture obtained by mixing compound A with compound D such as a phosphonate, wherein each of these three mixtures independently provide high corrosion inhibition efficiency in case of high temperature naphthenic acid corrosion inhibition and sulphur corrosion inhibition. The invention is useful in all hydrocarbon processing units, such as, refineries, distillation columns and other petrochemical industries.

Owner:DORF KETAL CHEM (I) PTE LTD

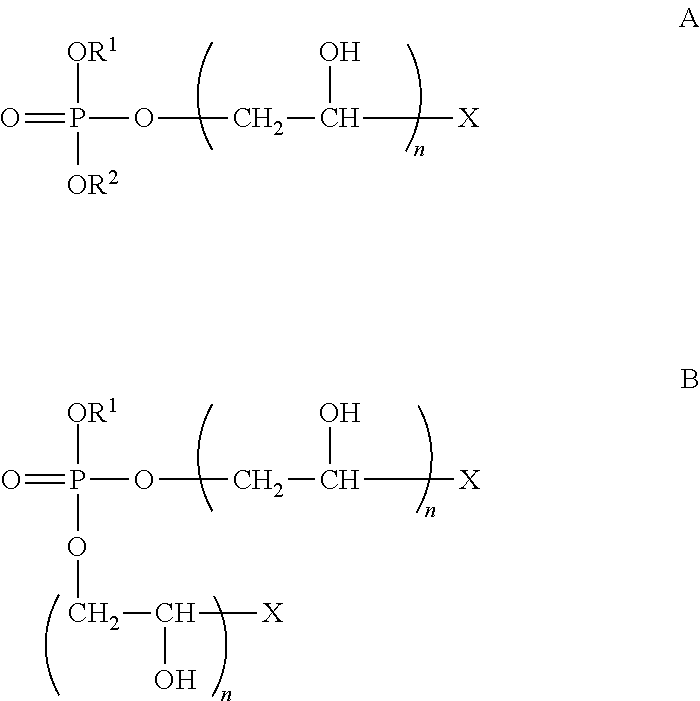

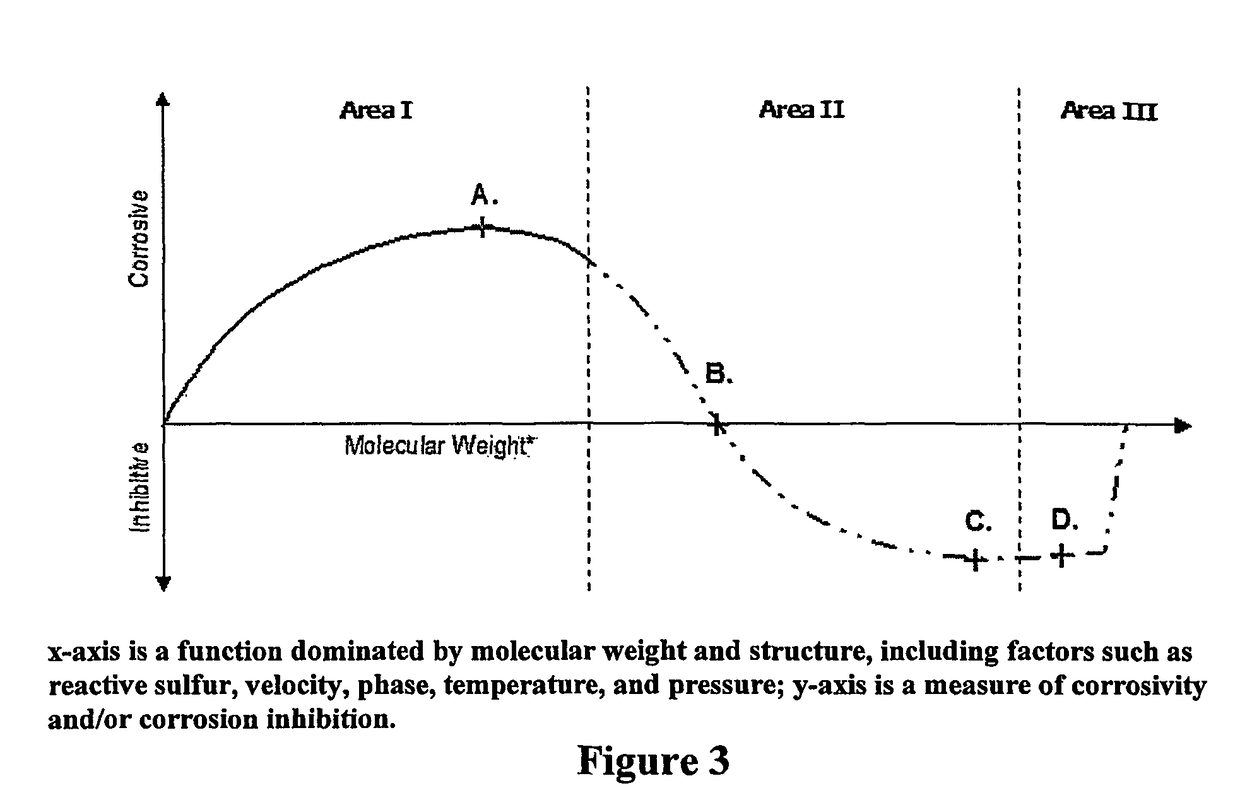

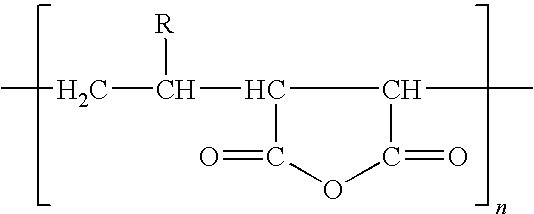

Effective novel polymeric additive for inhibiting napthenic acid corrosion and method of using the same

ActiveUS20110160405A1Reduce corrosionLow costDistillation corrosion inhibitionHydrocarbon purification/separationPhosphateAcid corrosion

The present invention relates to the field of inhibition of metal corrosion in hot acidic hydrocarbons, wherein acidity is derived from presence of naphthenic acid. More particularly, it relates to a polymeric additive for inhibiting high temperature napthenic acid corrosion, wherein said polymeric additive is polymeric phosphate ester of polyisobutylene succinate ester or oxide derivative of polymeric phosphate ester of polyisobutylene succinate ester. A polymeric phosphate ester of polyisobutylene succinate ester which is capable of acting as naphthenic acid corrosion inhibitor by inhibiting naphthenic acid corrosion in crude oil / feedstock / hydrocarbon streams containing naphthenic acid, and demonstrating higher thermal stability at elevated temperature varying from about 200° C. to about 400° C. [about 400° F. to about 750° F.] is disclosed.

Owner:DORF KETAL CHEM (I) PTE LTD

Method for preventing fractionating tower from salt deposition

InactiveCN102703114AAvoid cloggingDistillation corrosion inhibitionTreatment with plural serial refining stagesFuel tankPetrochemical

The invention discloses a method for preventing a fractionating tower from salt deposition, which belongs to the technical field of petrochemical industry and is used for solving the salt deposition problem on the upper part of a fractionating tower. The upper part of the fractionating tower is provided with appliances such as a separating member tower board, a filler or an oil collection tank. According to the method, the oil collection tank and a dewatering apparatus are arranged on the lower part of the water-containing section separating member of the upper part of the fractionating tower in order to drain the liquid-phase water out of the tower, thereby thoroughly solving the salt deposition problem on the upper part of the fractionating tower.

Owner:李小燕

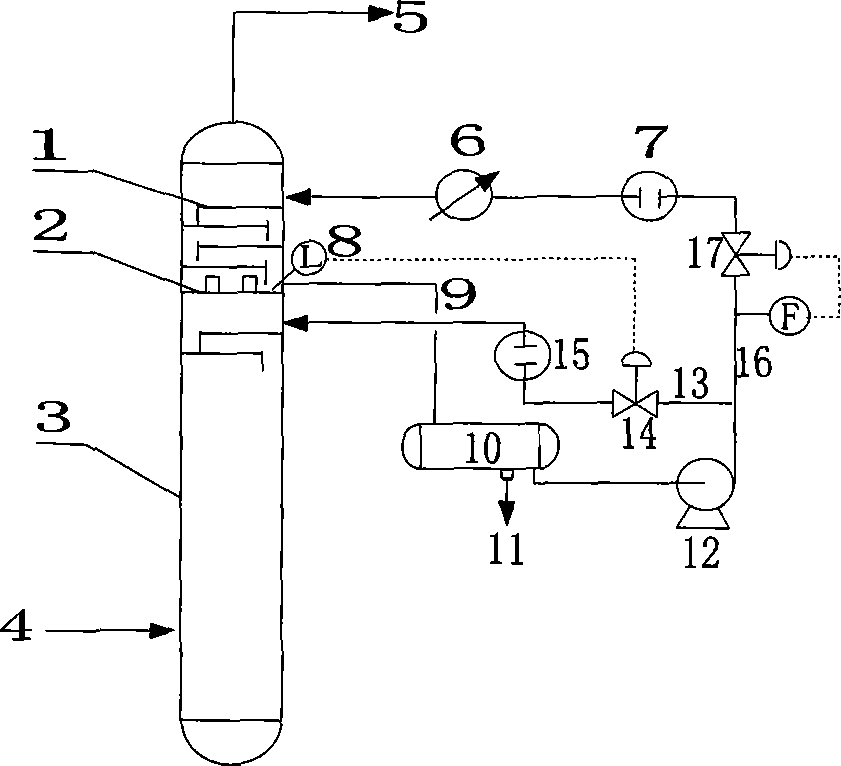

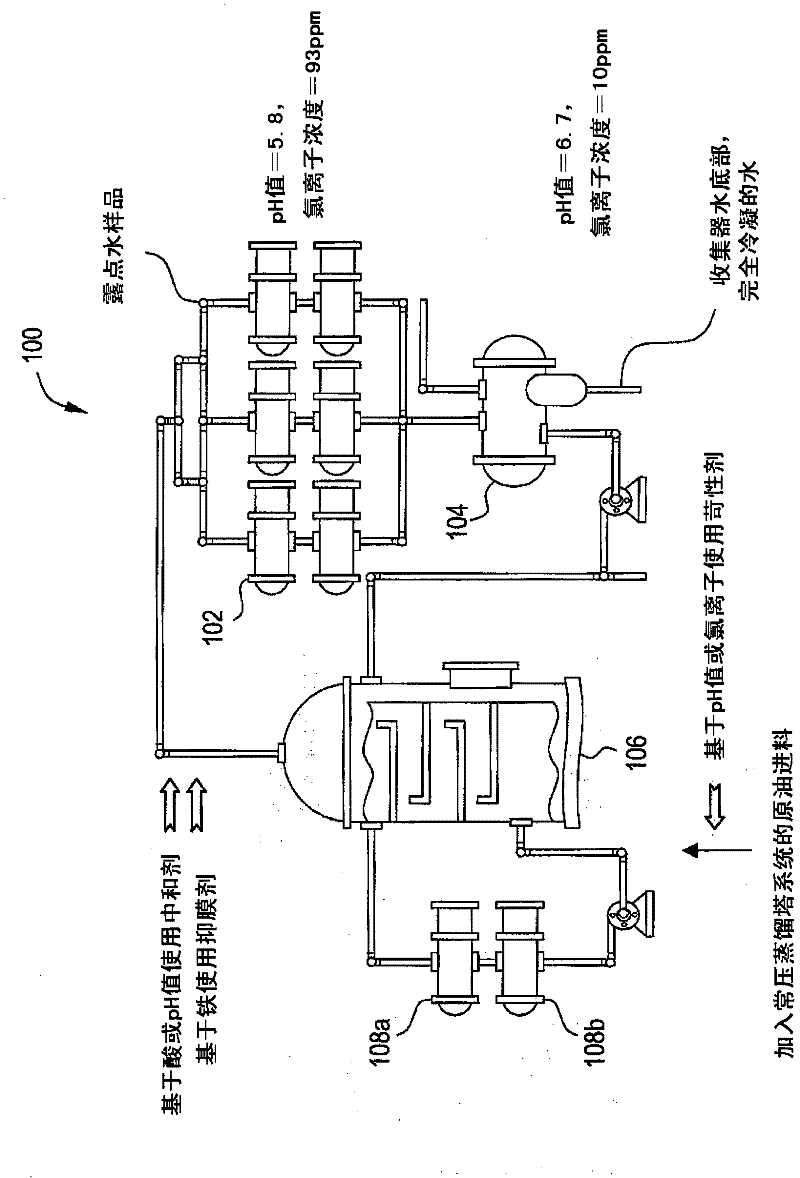

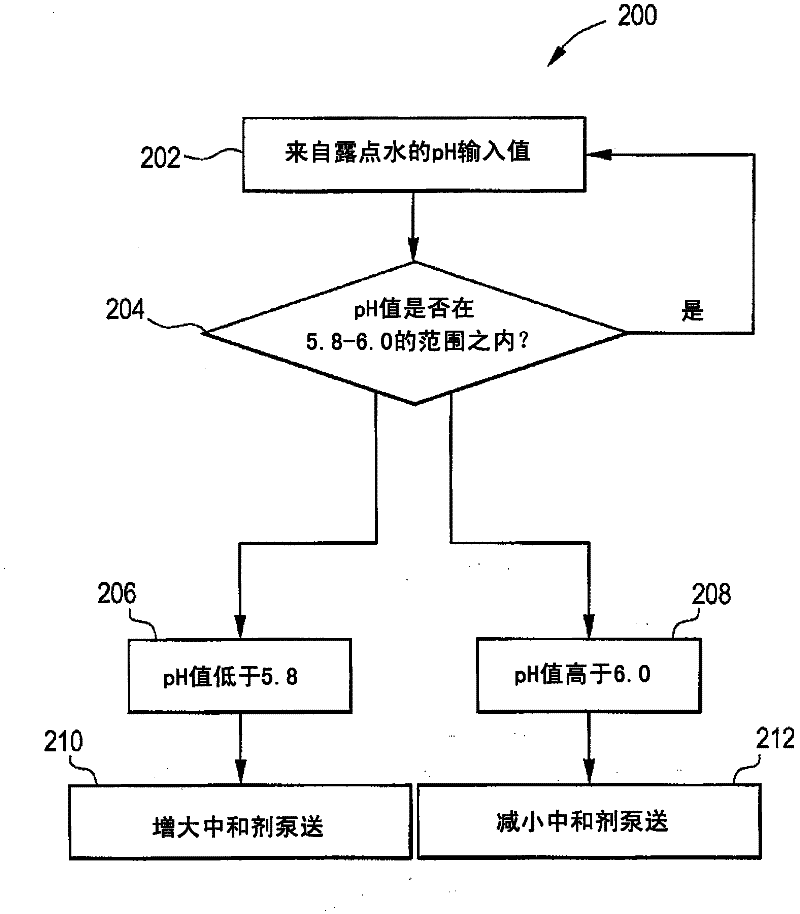

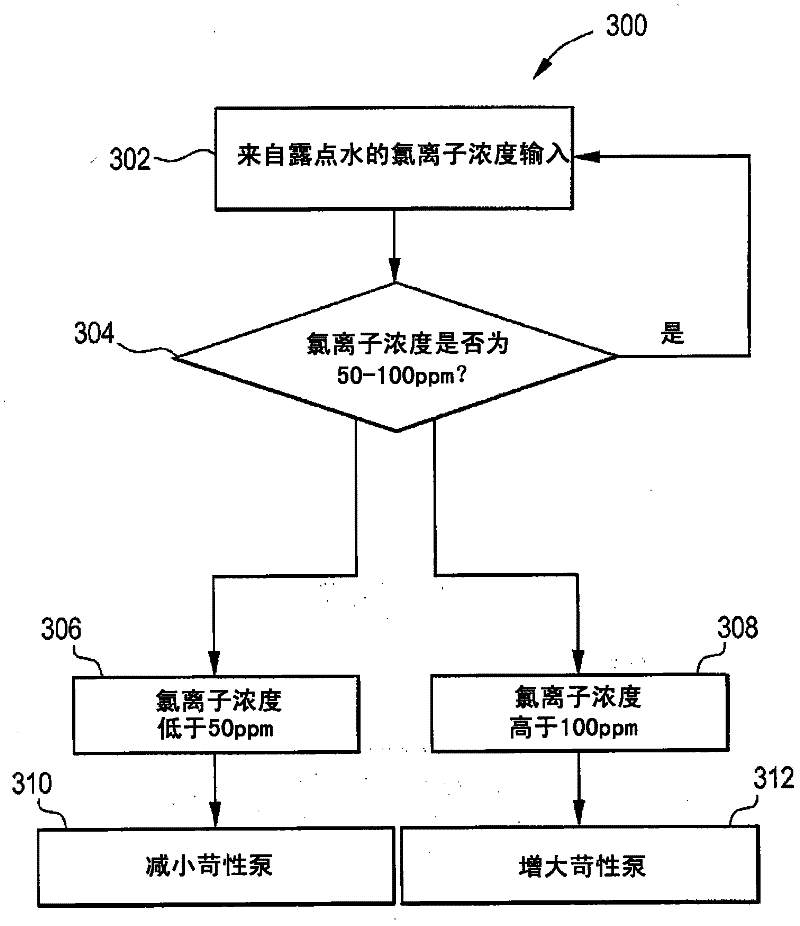

Method of reducing corrosion in a crude unit

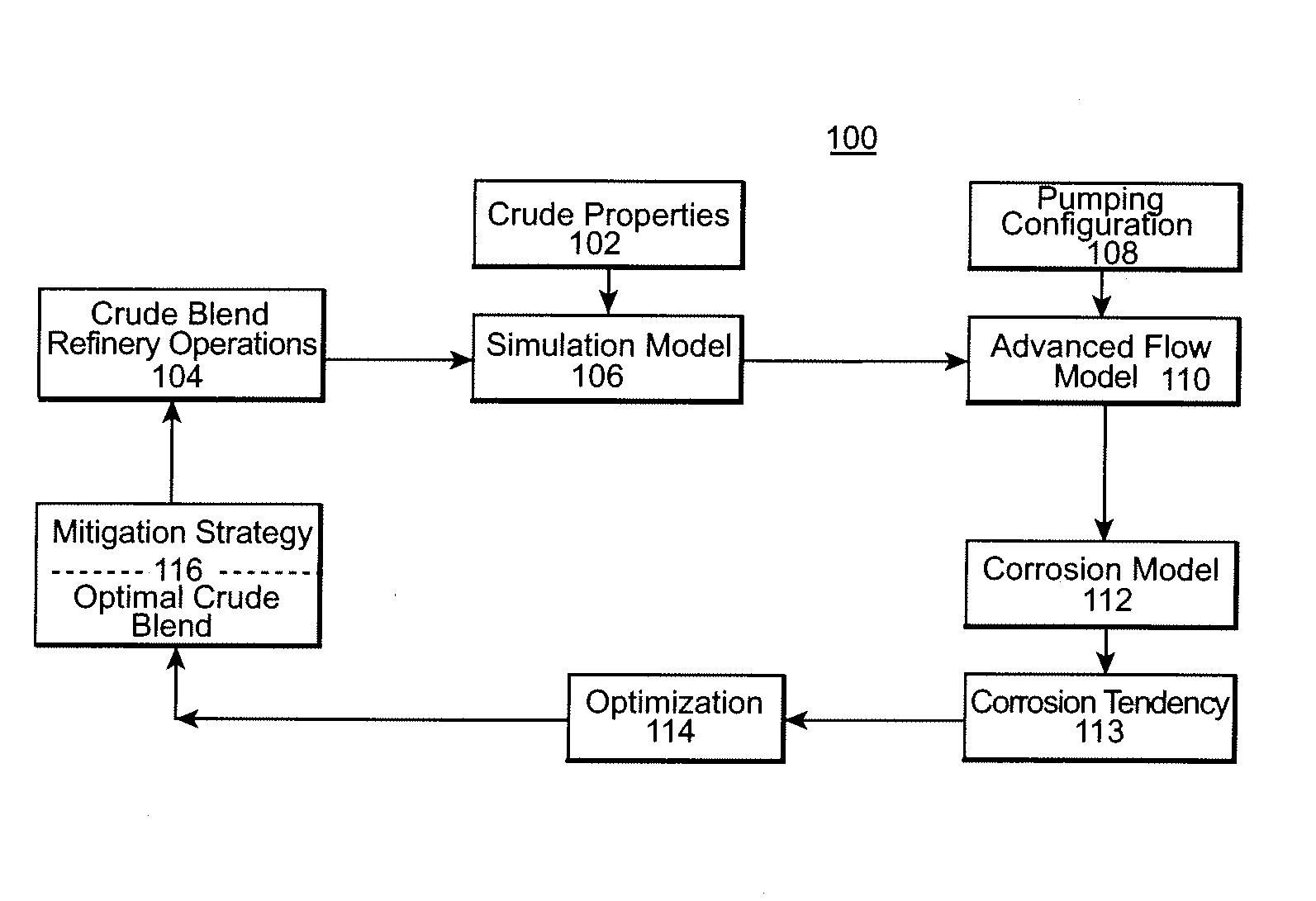

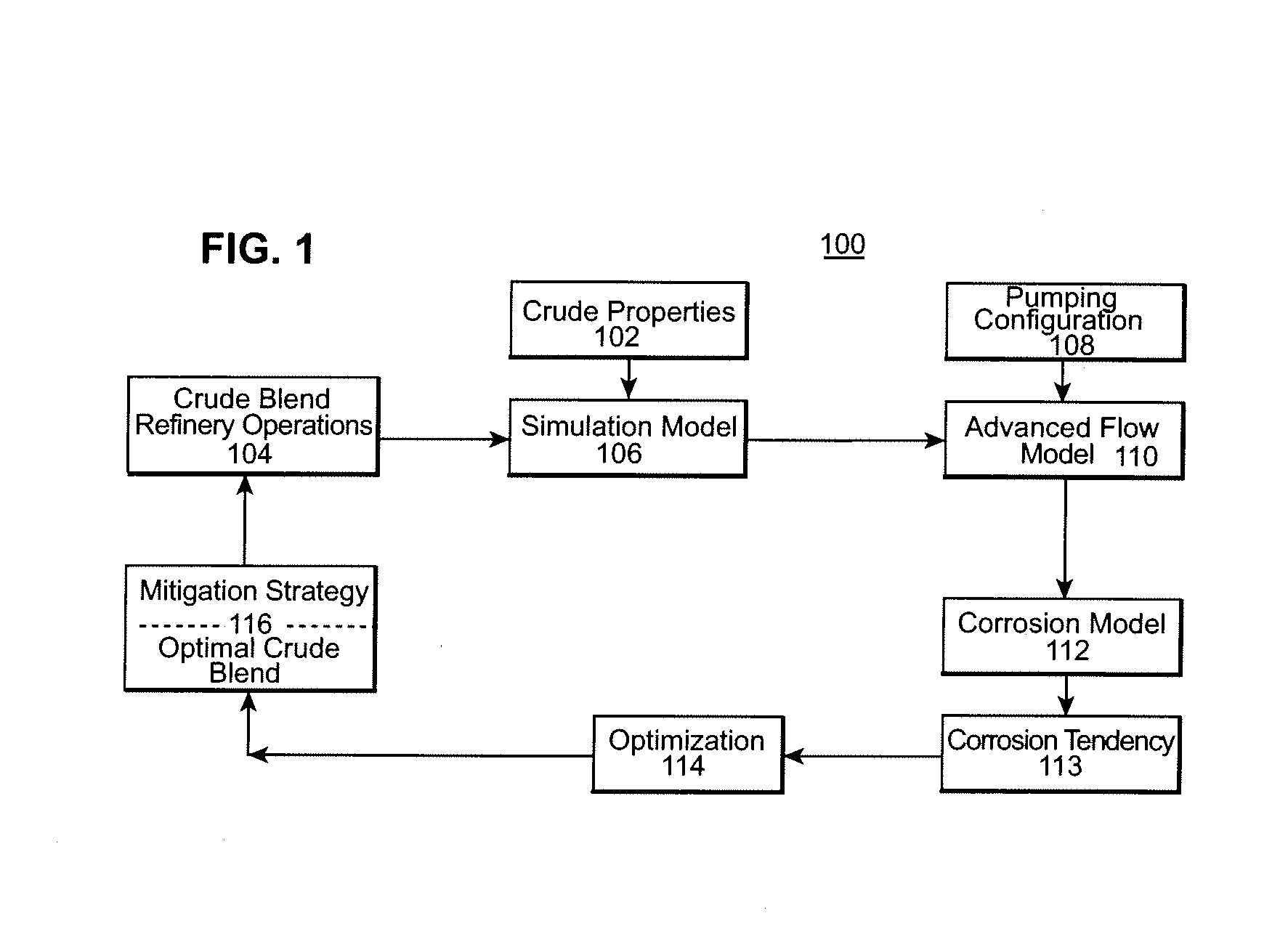

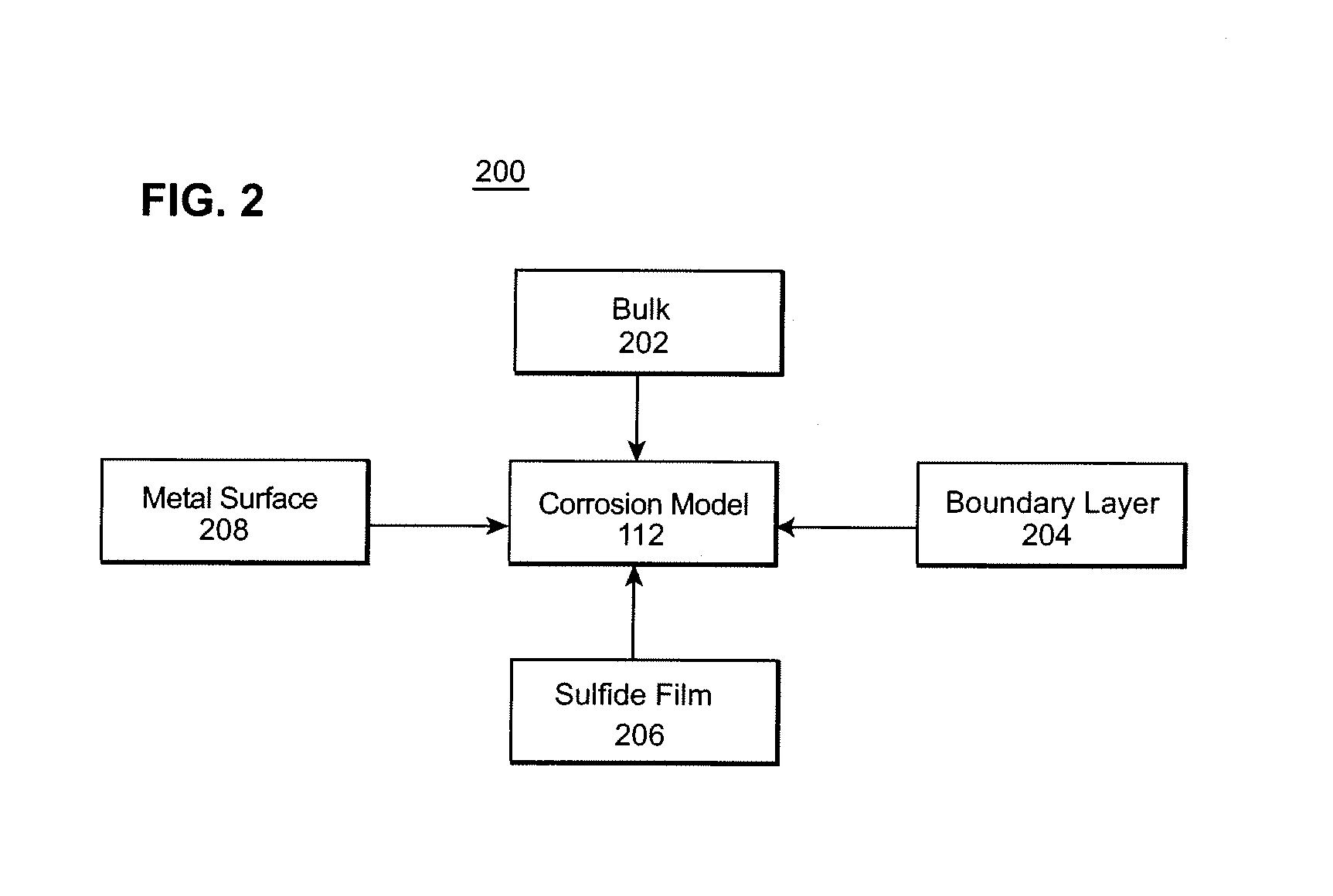

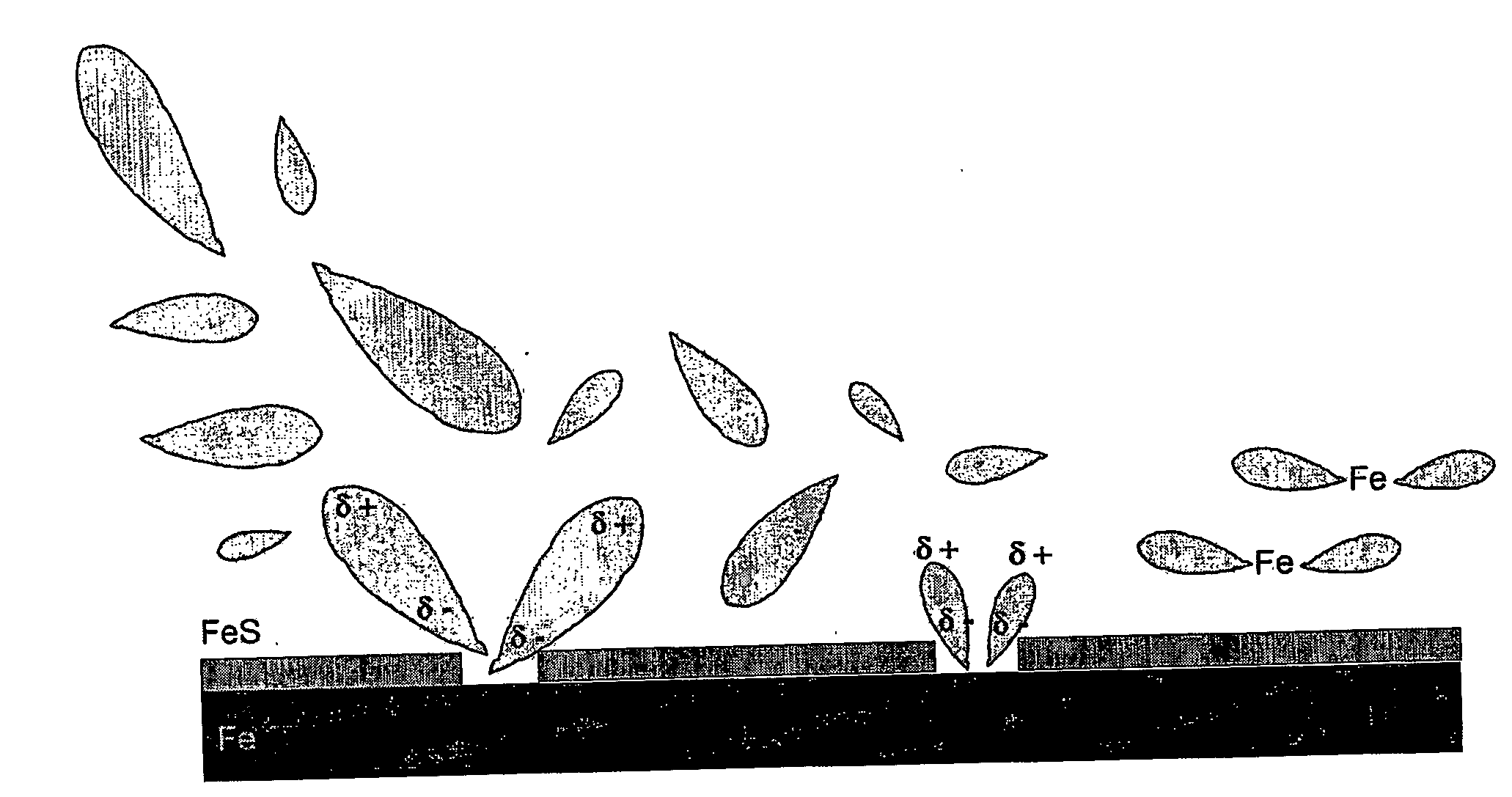

ActiveCN102203219AReduce processing stepsReduce corrosionData processing applicationsDistillation corrosion inhibitionProcess engineeringProtection system

A method of optimizing system parameters in a crude unit to reduce corrosion and corrosion byproduct deposition in the crude unit is disclosed and claimed. The method includes measuring or predicting properties associated with the system parameters and using an automated controller to analyze the properties to cause adjustments in the chemical program to optimize the system parameters. Adjusting the system parameters effectively controls corrosion in the crude unit by reducing the corrosiveness of a fluid in the process stream and / or by protecting the system from a potentially corrosive substance. System parameter sensing probes are arranged at one or more locations in the process stream to allow accurate monitoring of the system parameters in the crude unit.

Owner:NALCO CO

Compositions, configurations, and methods of reducing naphtenic acid corrosivity

InactiveUS8118994B2Reduce naphthenic acid corrosivityReduce naphthenic acid corrosionDistillation corrosion inhibitionDistillation regulation/controlChemical compositionPhotochemistry

Naphthenic acid corrosivity of hydrocarbon feedstocks is correlated with the chemical composition of naphthenic acids, and especially with a ratio between an alpha fraction and a beta fraction of naphthenic acids. Contemplated plants, configurations, and methods are directed to reducing naphthenic acid corrosivity of hydrocarbon feedstocks by increasing the beta fraction over the alpha fraction.

Owner:FLUOR TECH CORP

Corrosion assessment method and system

ActiveUS7818156B2Reduce or eliminate the corrosive potentialDistillation corrosion inhibitionAnalogue computers for chemical processesBoiling pointPetroleum

A method includes assessing corrosion in a refinery operation having a piping network. Assessing can include identifying in a petroleum sample a presence and an amount of a species determined to be potentially corrosive to corrodible equipment in a refinery. A corrosion risk presented by the presence, the amount, and the boiling point of the species is determined. And, the corrosion risk is evaluated in view of piping network information. A system for implementing the method is provided, also.

Owner:BL TECH INC

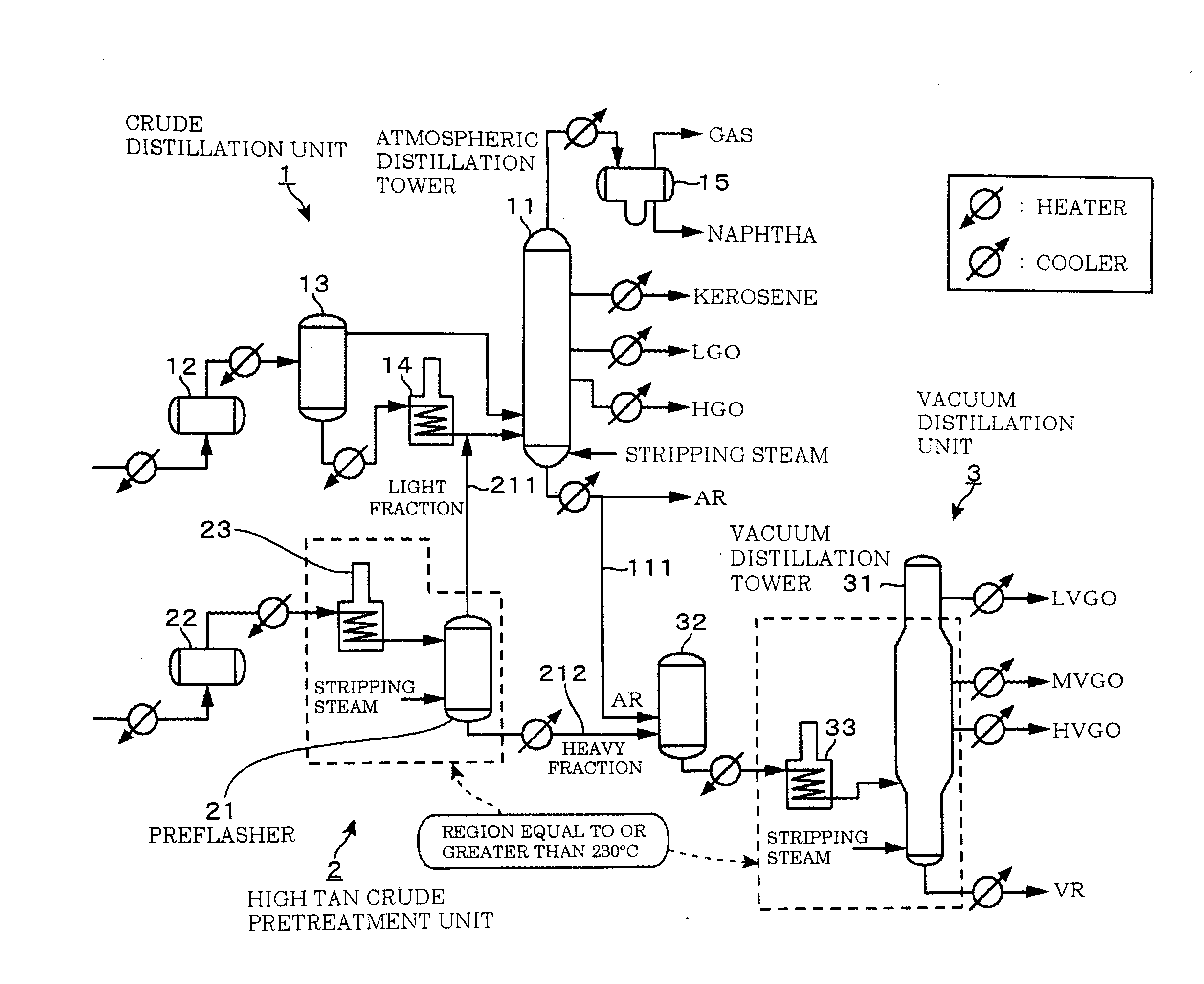

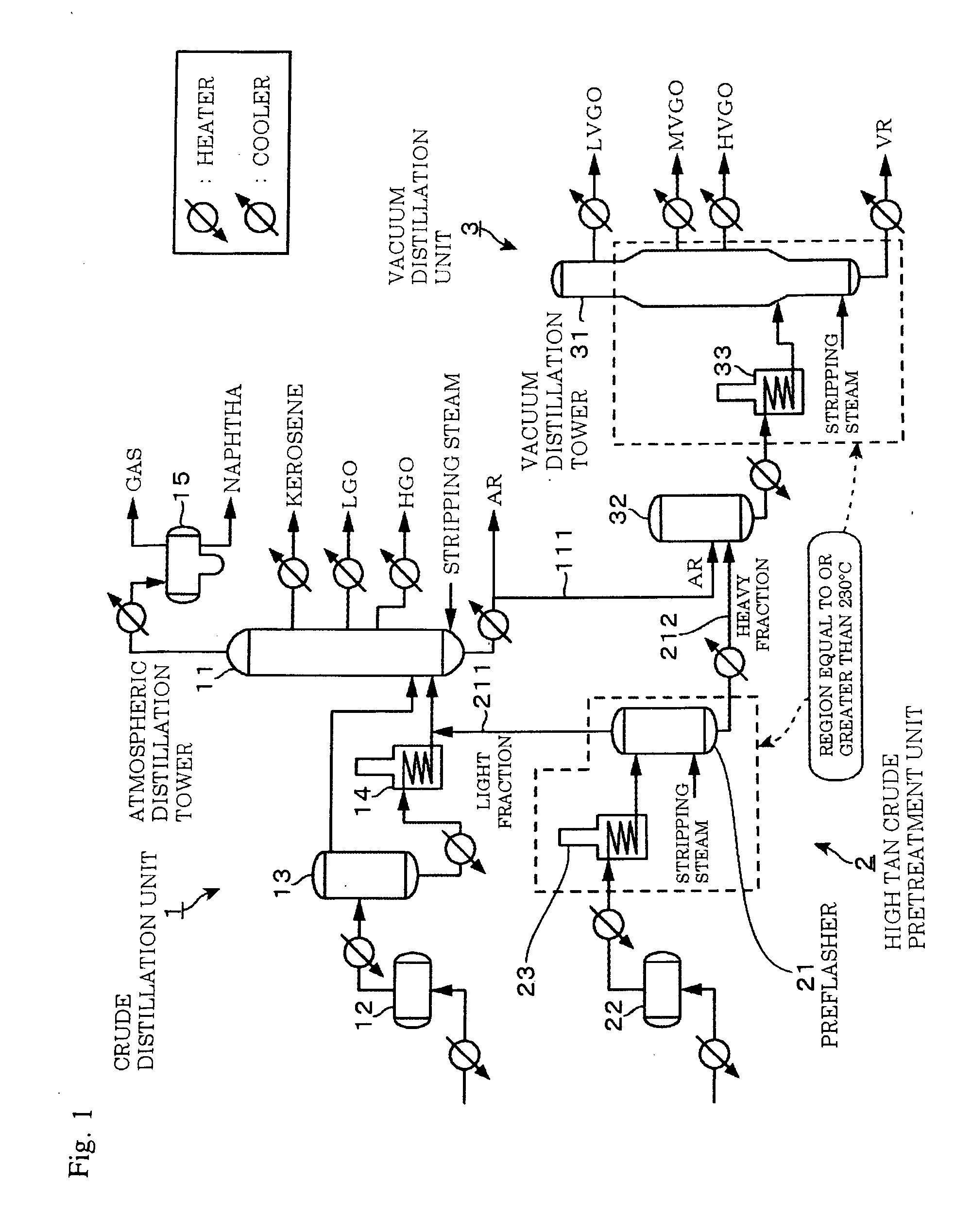

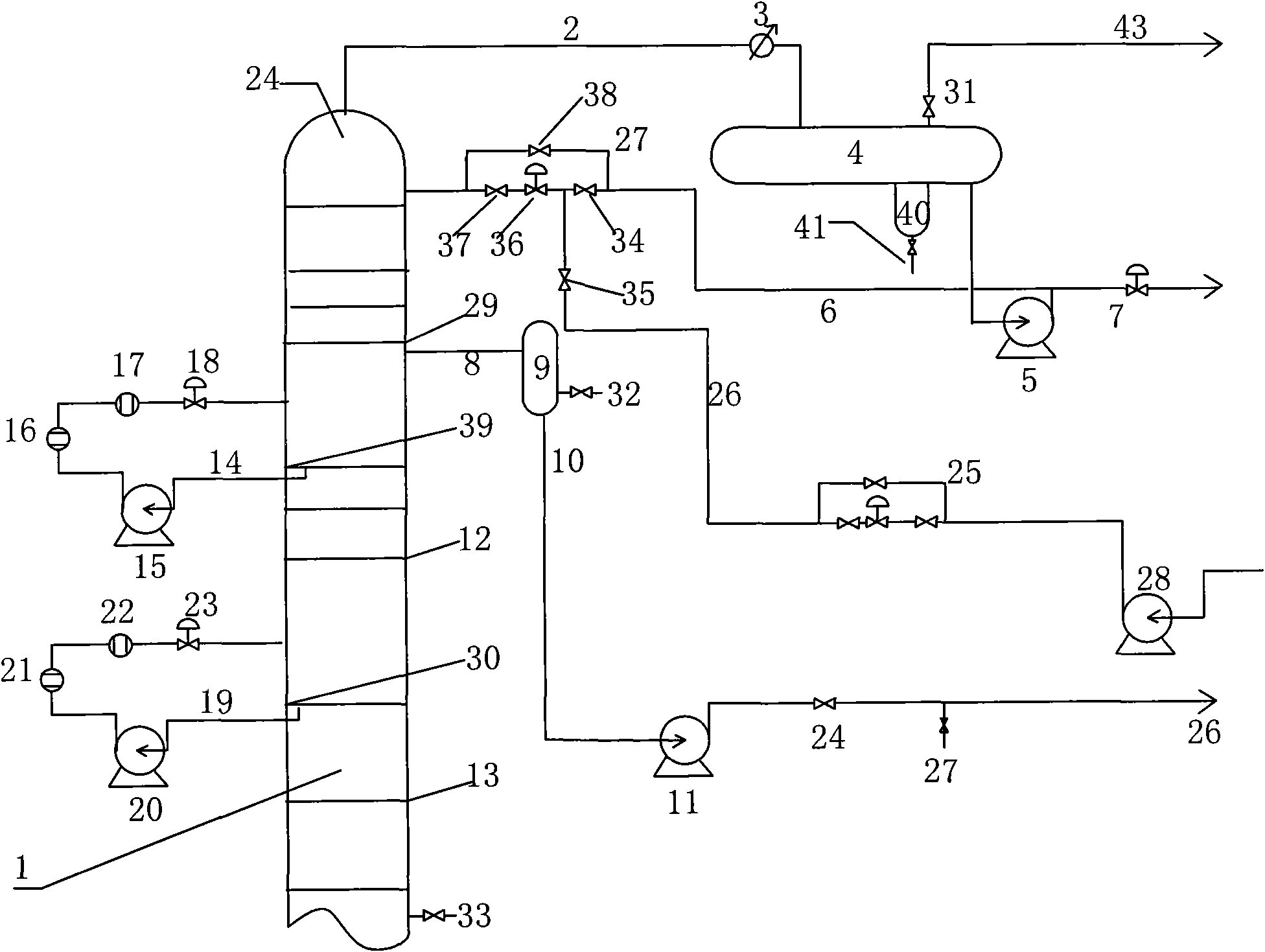

Crude treatment system

InactiveUS20110168523A1Wide choiceDistillation corrosion inhibitionRefining by heating/coolingDistillationTower

[Task] To provide a crude treatment system capable of treating crude containing a comparatively large content of a corrosive material.[Means for Resolution] A primary distillation tower 11 fractionates first crude into a target fraction. A secondary distillation tower 21 which fractionates second crude having a corrosive material content greater than that of the first crude into a light fraction of which the content of the corrosive material is an amount not causing corrosion in the primary distillation tower 11 and a heavy fraction as the remainder thereof. Also, a light fraction supply line supplies the light fraction from the secondary distillation tower 21 to the primary distillation tower 11 so as to treat the light fraction in the primary distillation tower 11. Here, the secondary distillation tower 21 and the supply line for supplying second crude to the secondary distillation tower 21 are made from a material having corrosion resistance with respect to the corrosive material under circumstances in which the secondary distillation tower 21 and the supply line contact with the second crude and the heavy fraction.

Owner:JGC CORP

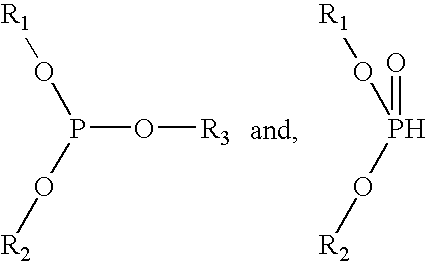

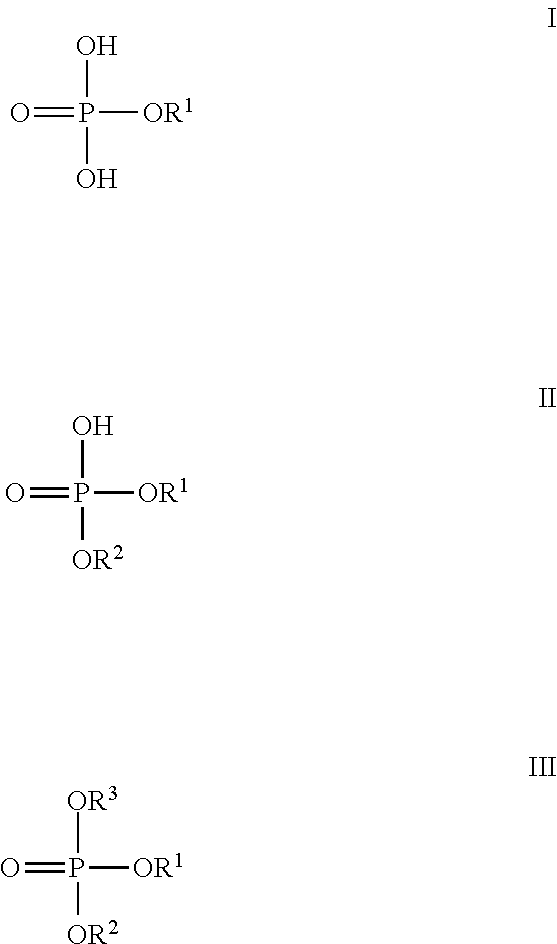

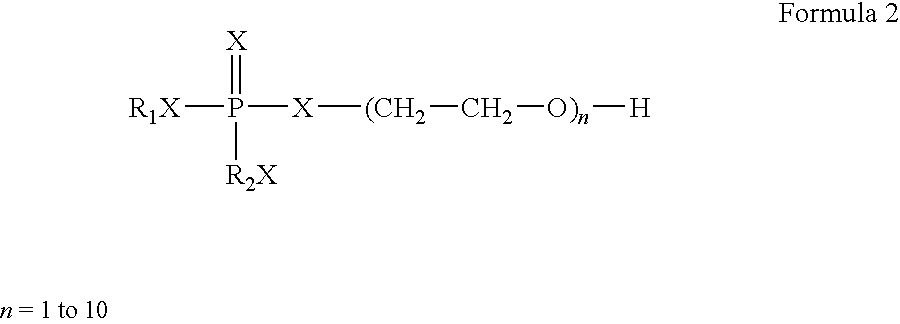

Novel additive for naphthenic acid corrosion inhibition and method of using the same

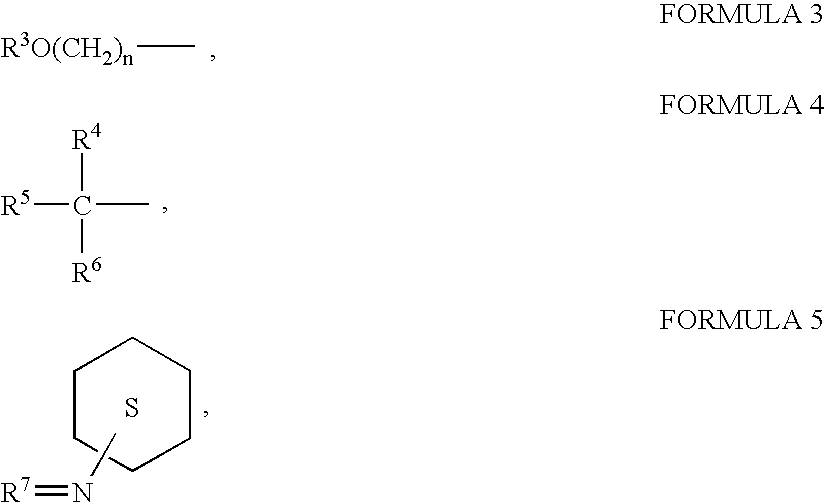

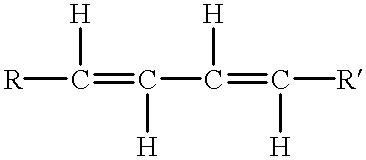

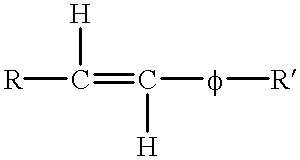

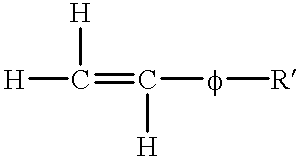

ActiveUS20100264064A1Low acid valueDistillation corrosion inhibitionOther chemical processesPhosphorus pentasulfideDistillation

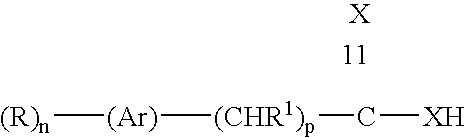

The present invention relates to the field of processing hydrocarbons which causes corrosion in the metal surfaces of processing units. The invention addresses the technical problem of high temperature naphthenic acid corrosion and sulphur corrosion and provides a solution to inhibit these types of corrosion. The three combination compositions are formed by two mixtures separately, with one mixture obtained by mixing compound A, which is obtained by reacting high reactive polyisobutylene (HRPIB) with phosphorous pentasulphide in presence of catalytic amount of sulphur with compound B which is thiophosphorous compound such as phosphorous thioacid ester of Formula (1) and second mixture obtained by mixing compound A with compound C of Formula (2) which is obtained by reacting compound B with ethylene oxide, wherein each of these two mixtures independently provide high corrosion inhibition efficiency in case of high temperature naphthenic acid corrosion inhibition and sulphur corrosion inhibition. The invention is useful in all hydrocarbon processing units, such as, refineries, distillation columns and other petrochemical industries.

Owner:DORF KETAL CHEM (I) PTE LTD

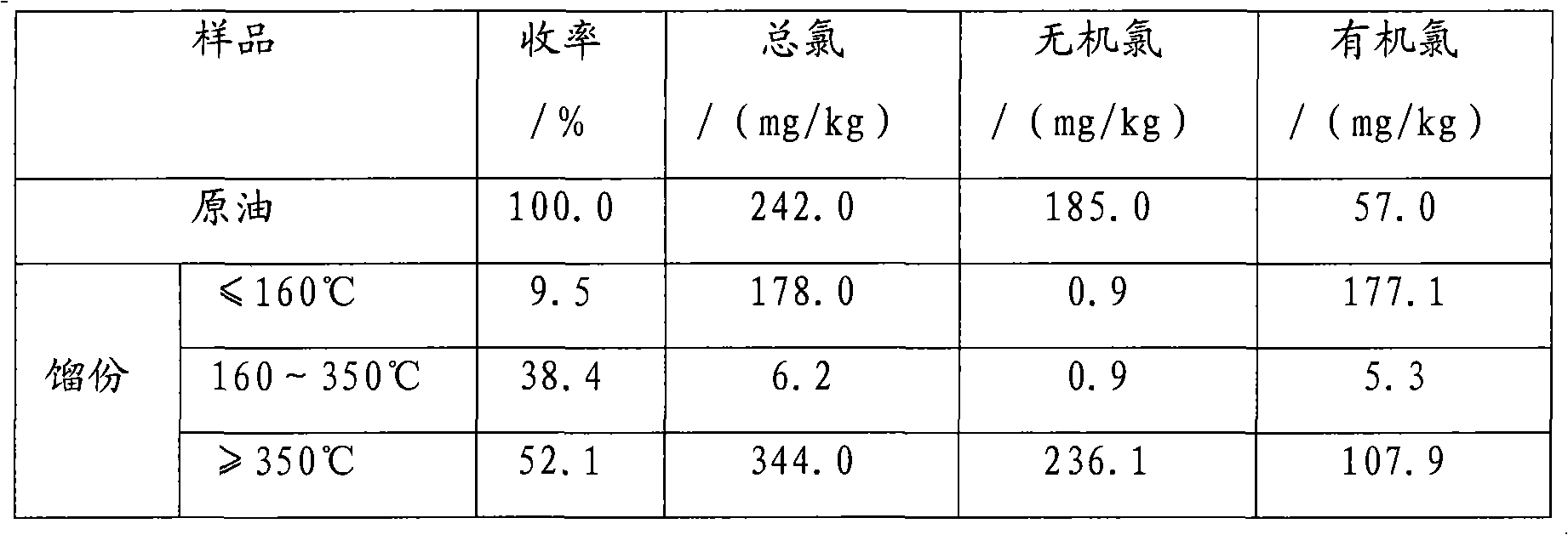

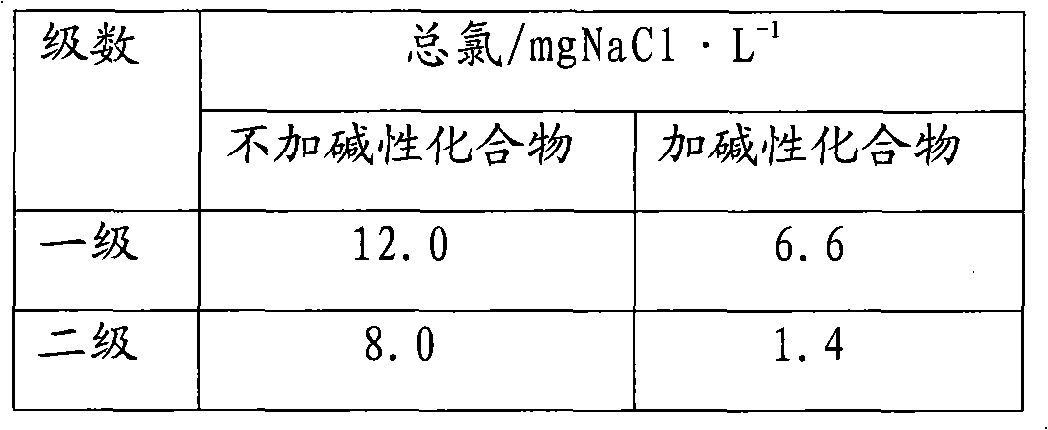

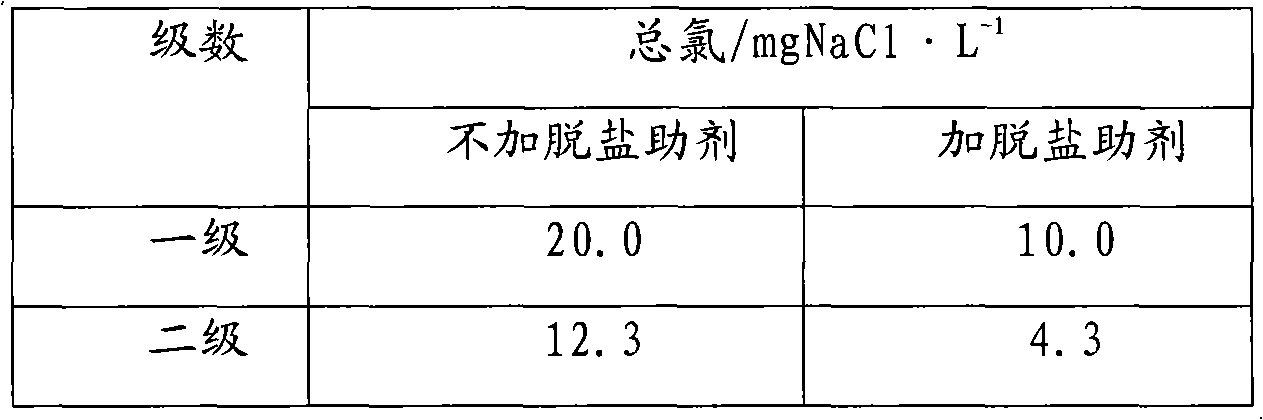

Method for lightening salt deposition of catalytic fractionating tower

ActiveCN102433155AHigh salt contentDesalination mitigationDistillation corrosion inhibitionTreatment with plural serial stages onlyInorganic saltsOrganic chloride compound

The invention relates to a method for lightening the salt deposition of a catalytic fractionating tower, wherein residual oil is pre-treated by an electro-desalting technique before entering in a catalytic cracking device; an alkaline compound is added during the electro-desalting process; and the alkaline compound is water-soluble organic amine and / or inorganic alkali. Utilizing the method disclosed by the invention, inorganic salts and organic chlorides in residual oil can be efficiently removed before the residual oil enters in a catalytic cracking device, thereby lighting the salt deposition of a catalytic fractionating tower.

Owner:CHINA PETROLEUM & CHEM CORP +1

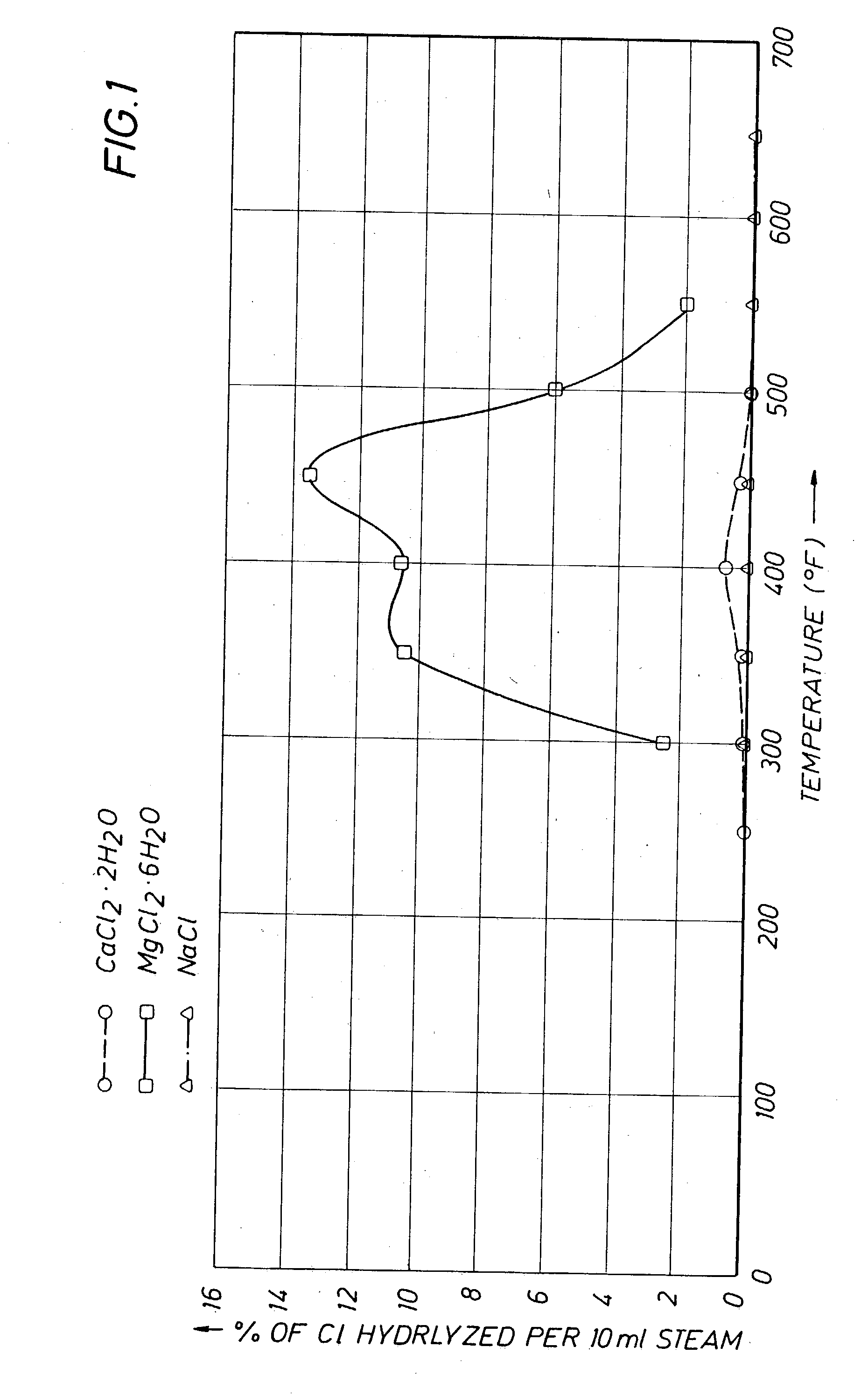

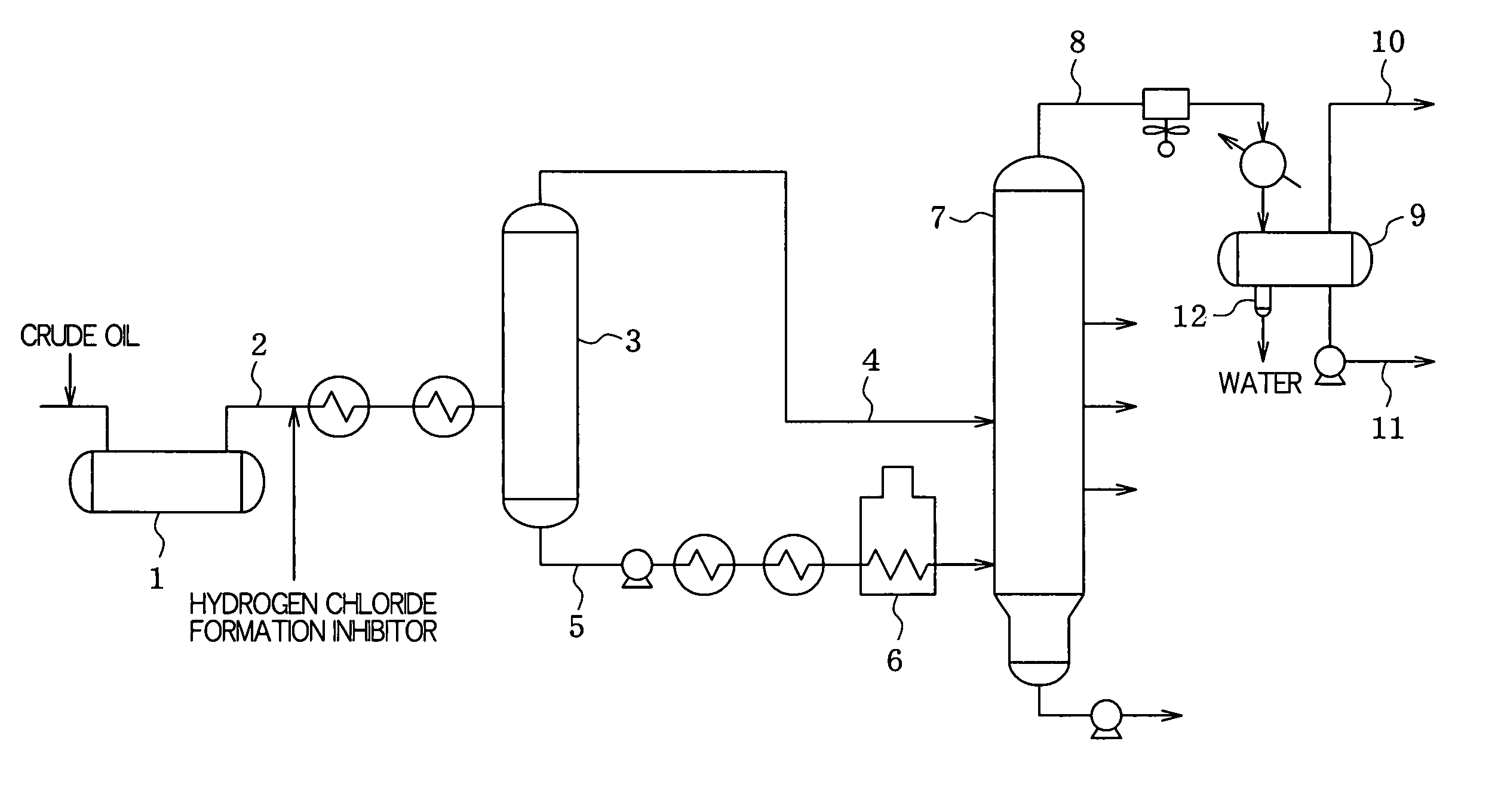

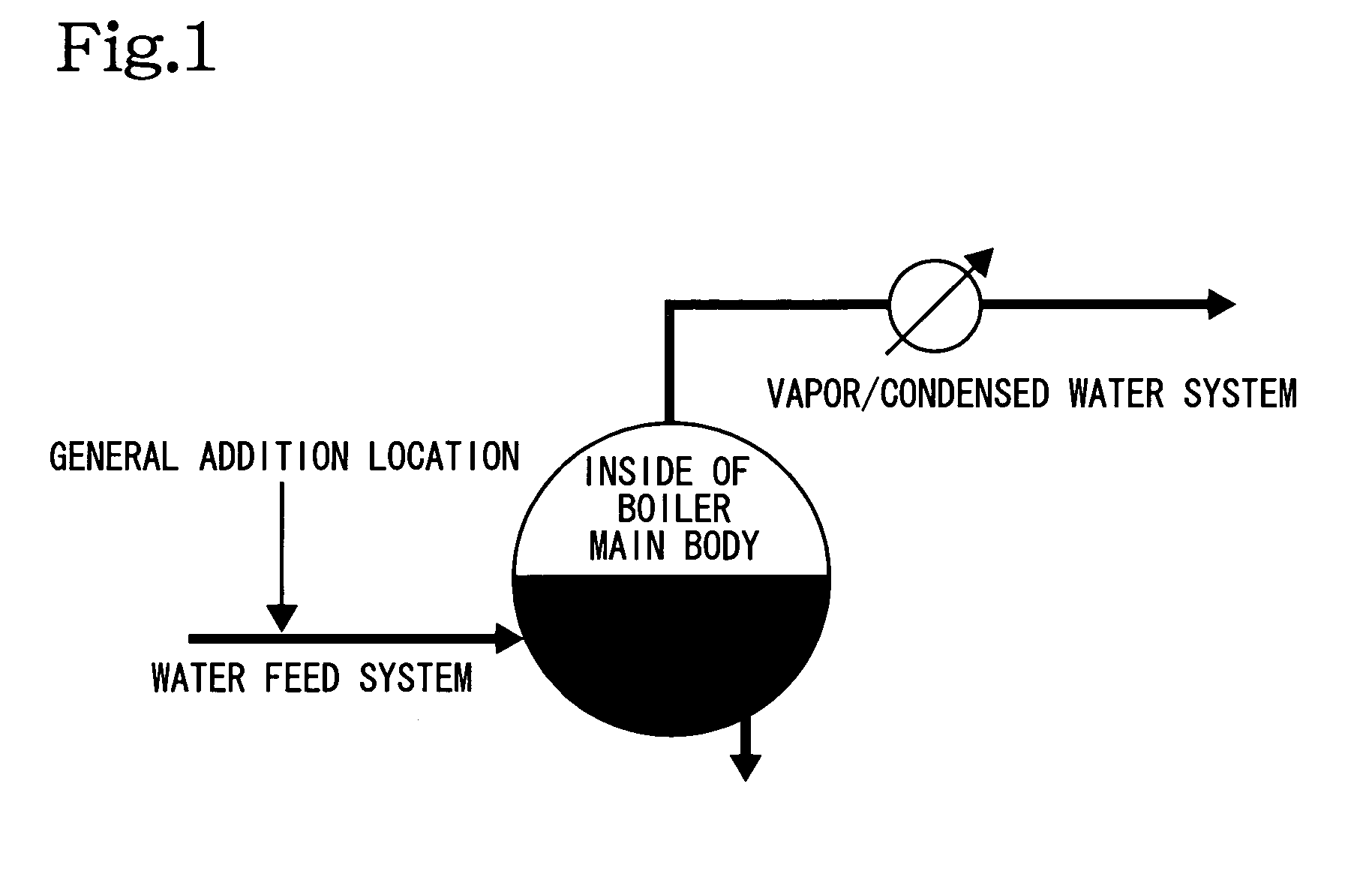

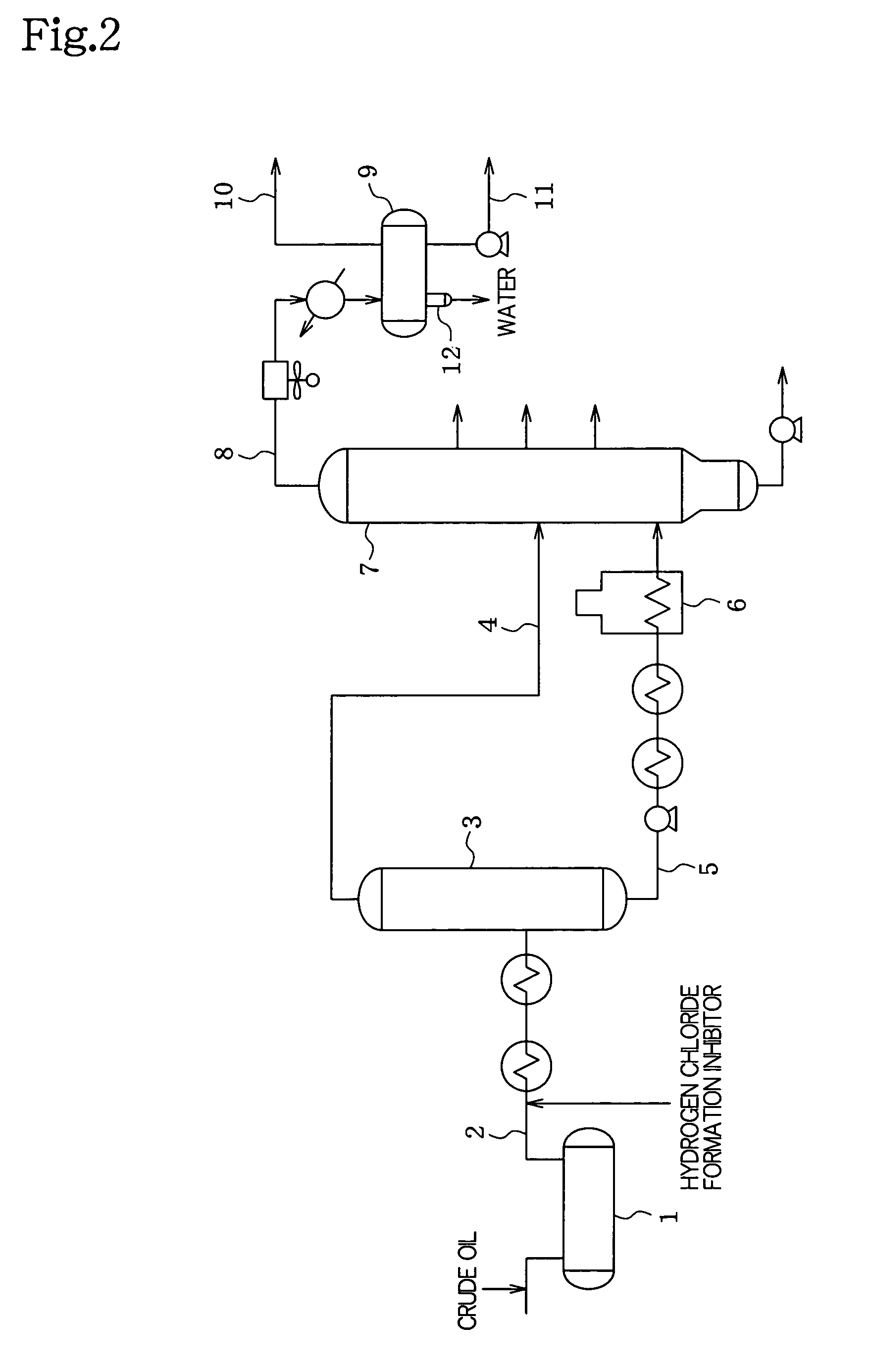

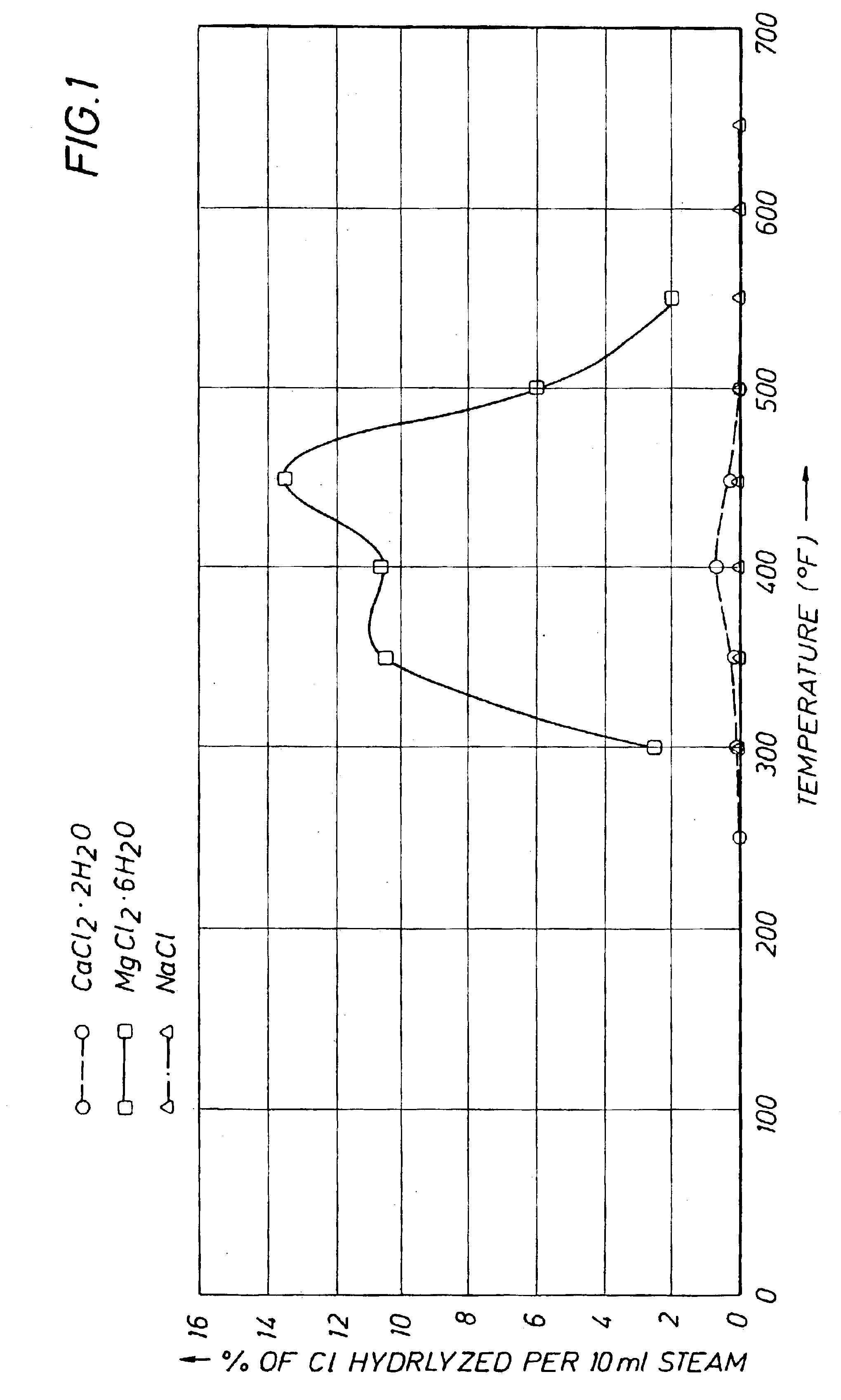

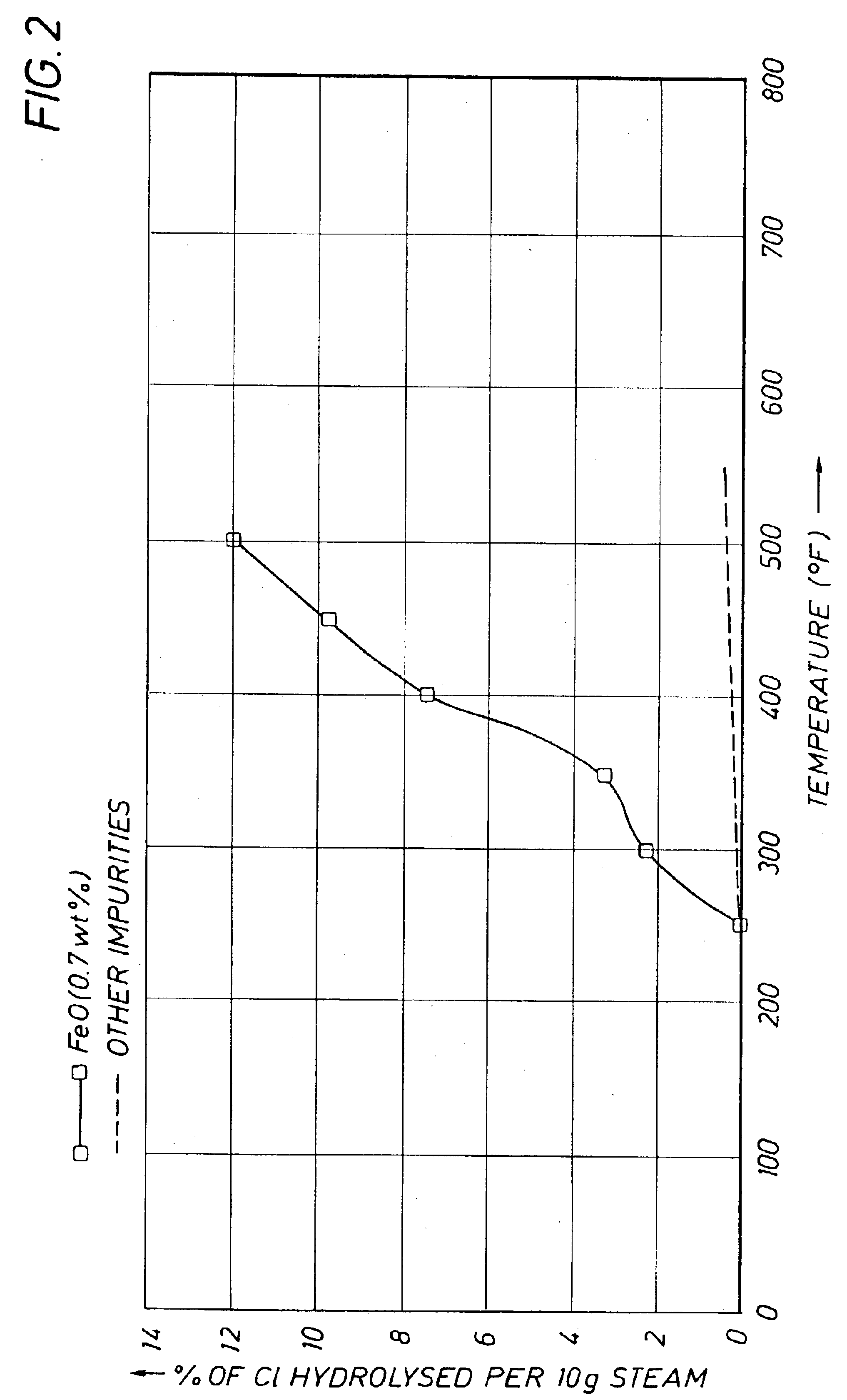

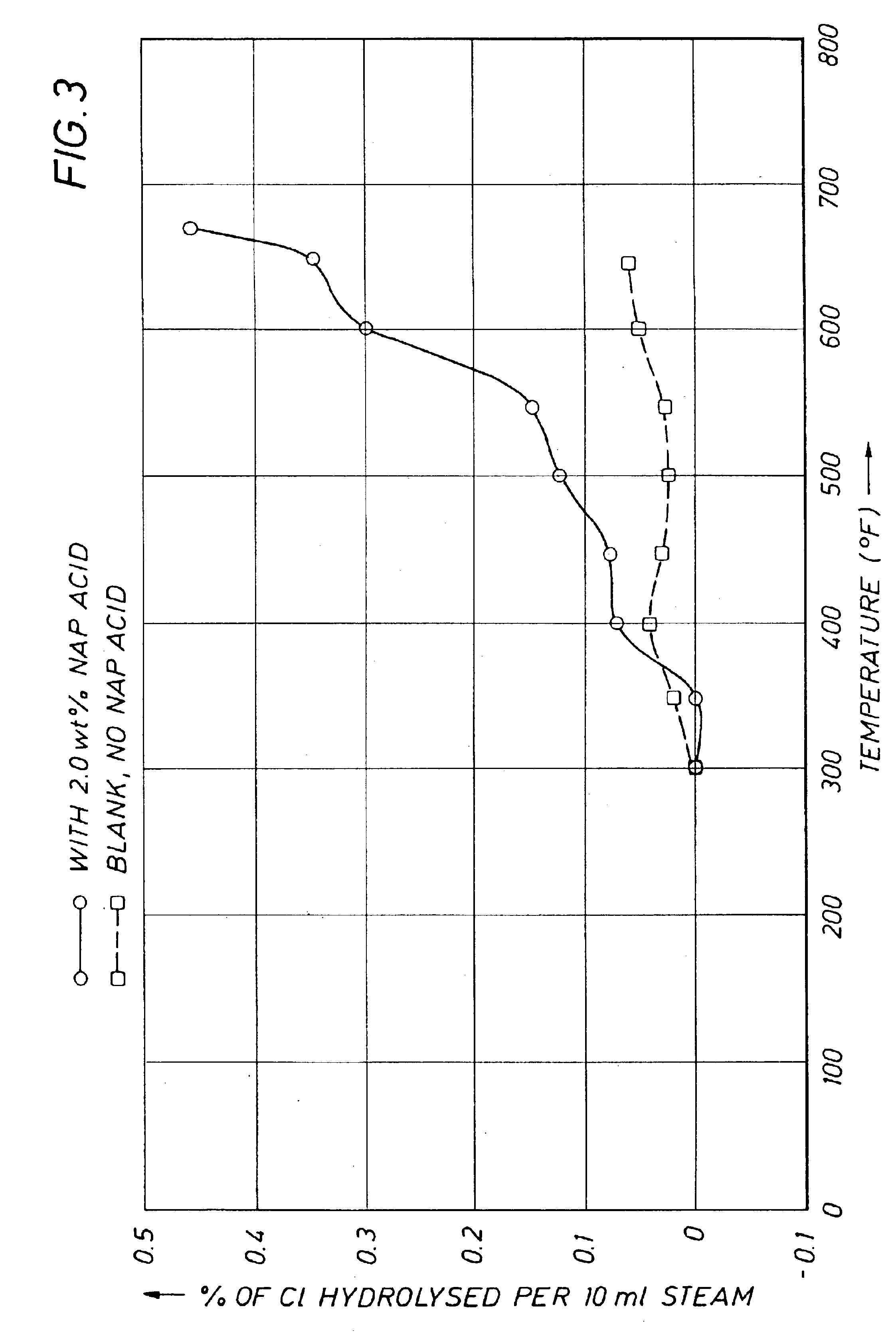

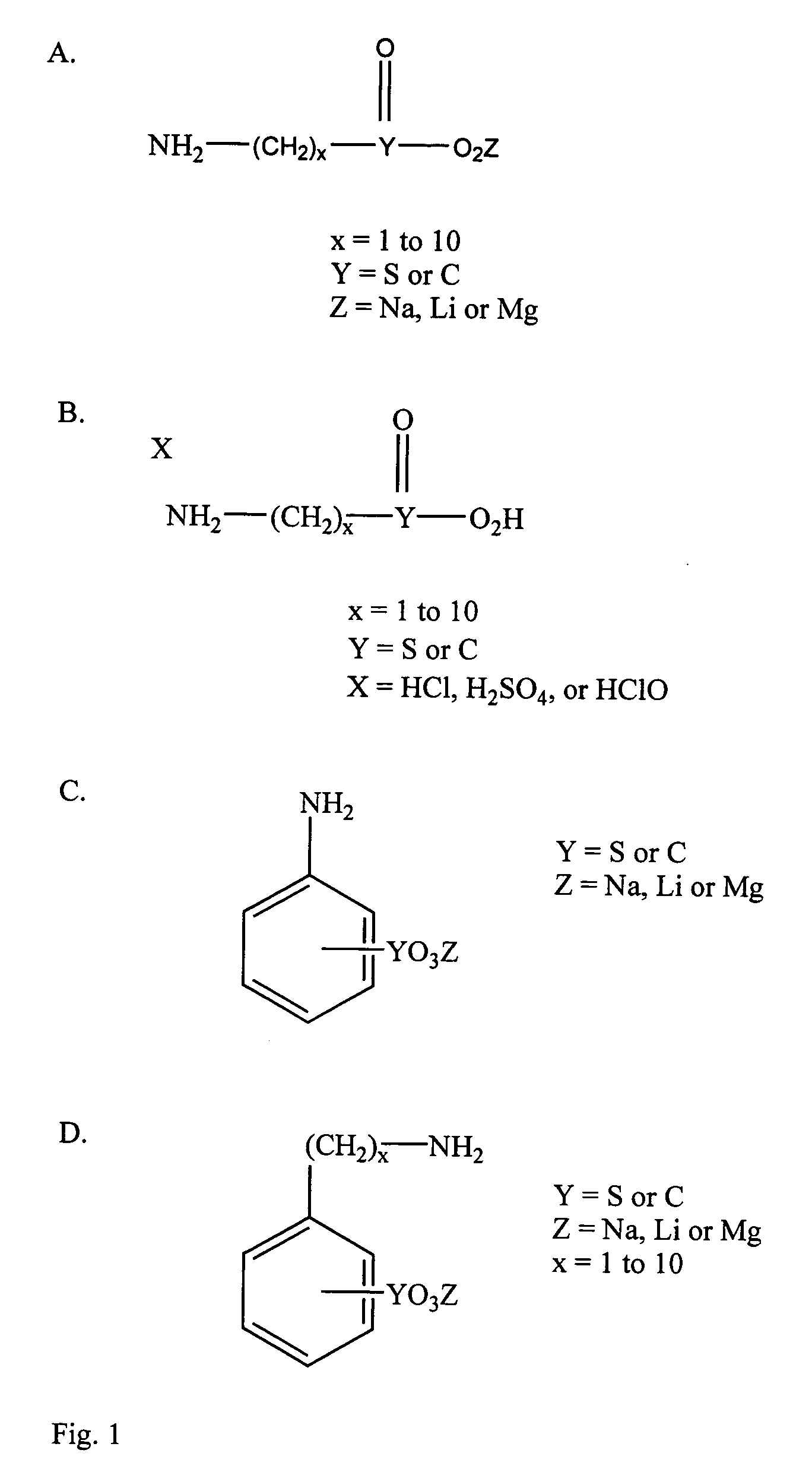

Metal corrosion inhibitor and hydrogen chloride formation inhibitor in a crude oil atmospheric distillation unit

ActiveUS8177962B2Reduce riskInhibition formationDistillation corrosion inhibitionOther chemical processesAmmonium compoundsDistillation

The quaternary ammonium compound described by general formula 1 below(wherein R1, R2 and R3 are the same or different hydrocarbon radicals with 1 to 4 carbon atoms, and n is an integer between 1 and 10) is used as a metal corrosion inhibitor. With this metal corrosion inhibitor, it is possible even with the addition of small quantities to adequately prevent corrosion of metal in a steam generating unit or petroleum refining or petrochemical process unit.Moreover, (β-hydroxyethyl)trimethylammonium hydroxide is used as a hydrogen chloride formation inhibitor for a crude oil atmospheric distillation unit. With this hydrogen chloride formation inhibitor, it is possible to prevent the formation of hydrogen chloride itself in a crude oil atmospheric distillation unit without having any adverse effect on the catalyst.

Owner:KURITA WATER INDUSTRIES LTD

Method of reducing hydrolysis in hydrocarbon streams

InactiveUS6902662B2Distillation corrosion inhibitionGroup 5/15 element organic compoundsOrganic acidChloride

A method of reducing hydrolysis in a hydrocarbon stream comprising adding to a hydrocarbon stream containing a chloride compound which undergoes hydrolysis at elevated temperatures in the presence of water to form hydrochloric acid, an effective amount of a treating agent that is at least one overbased complex of a metal salt and an organic acid complexing agent, the treating agent being added to hydrocarbon stream when the stream is at a temperature below which any substantial hydrolysis of the chloride containing compound occurs.

Owner:HALLIBURTON ENERGY SERVICES INC

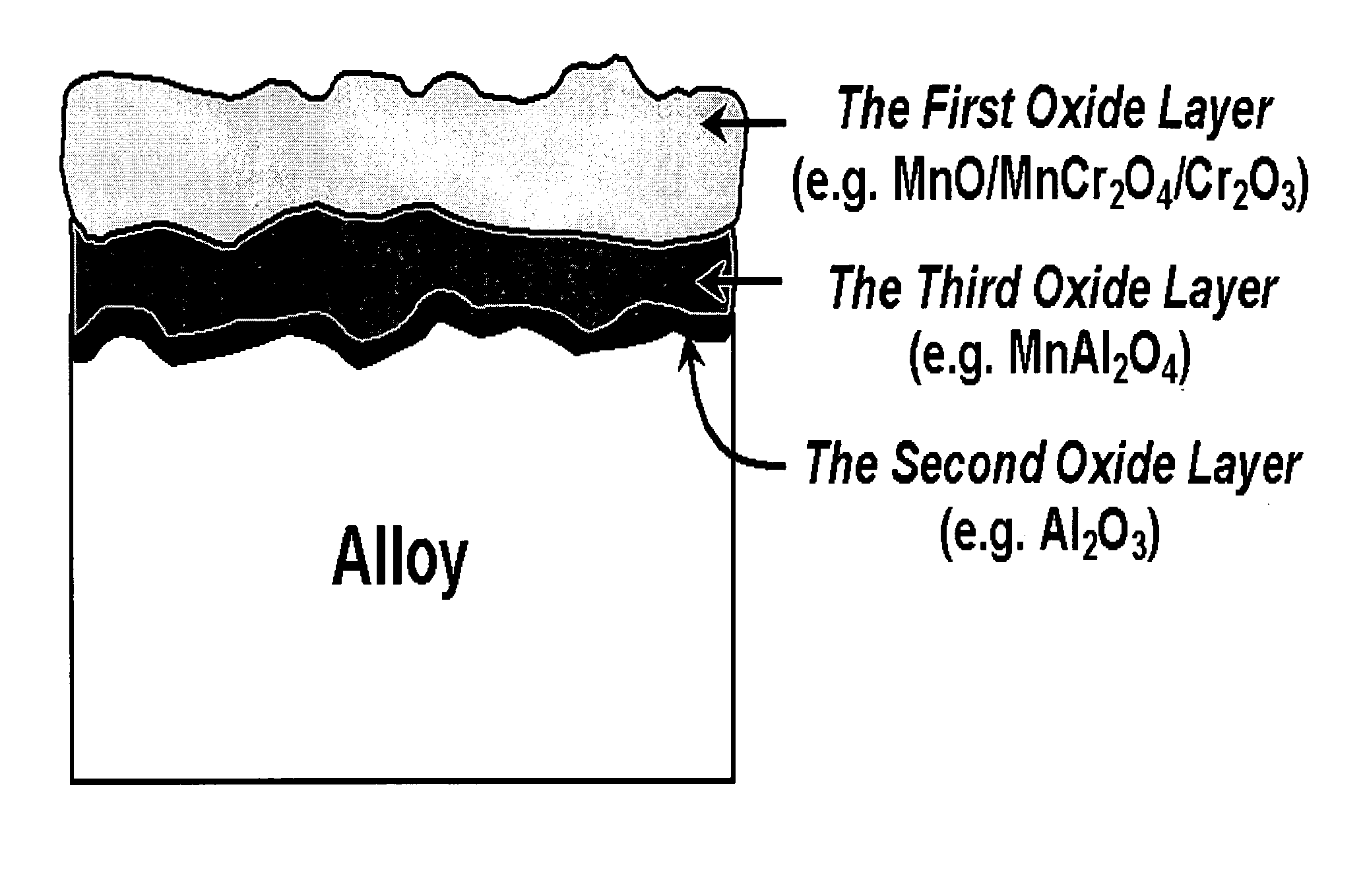

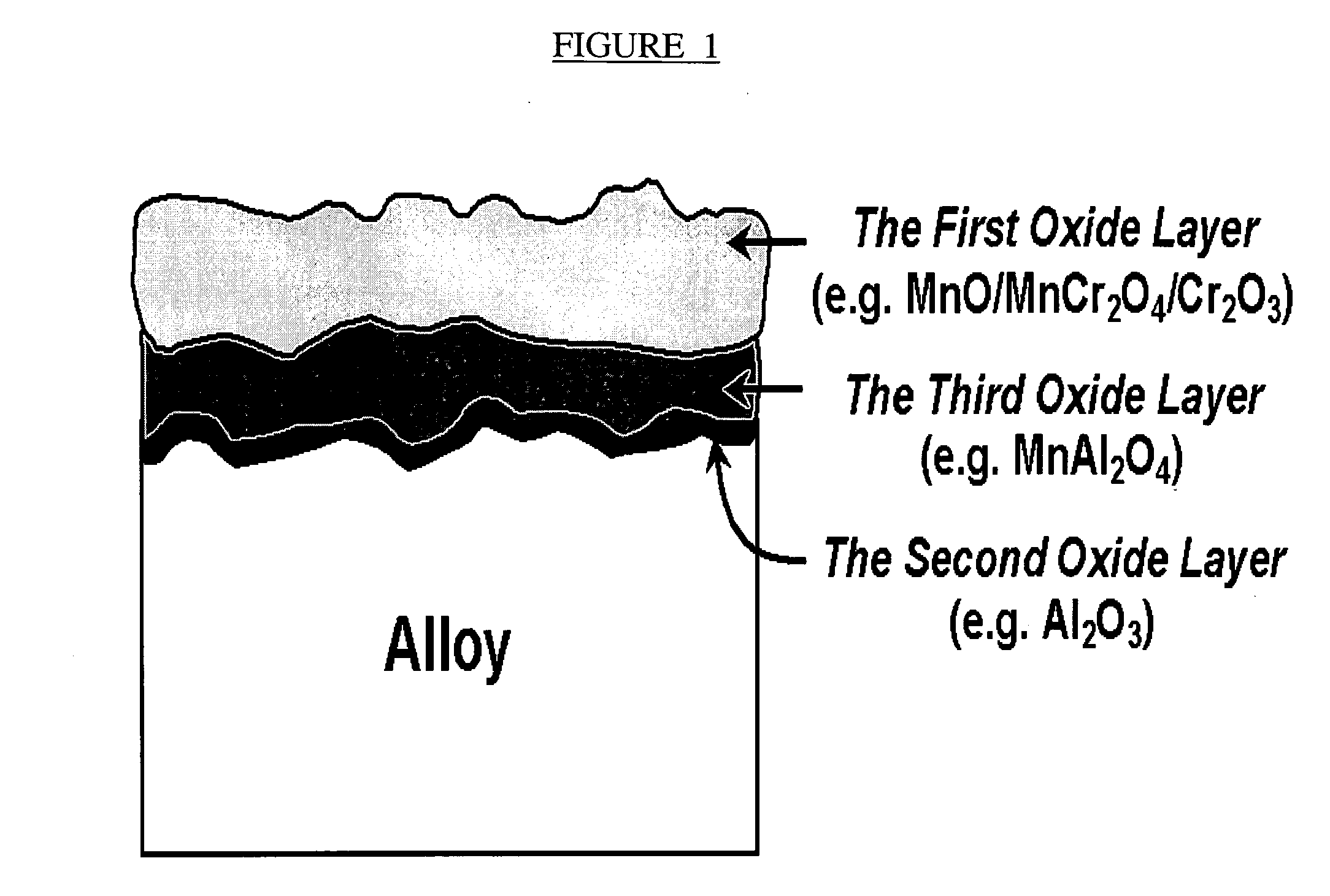

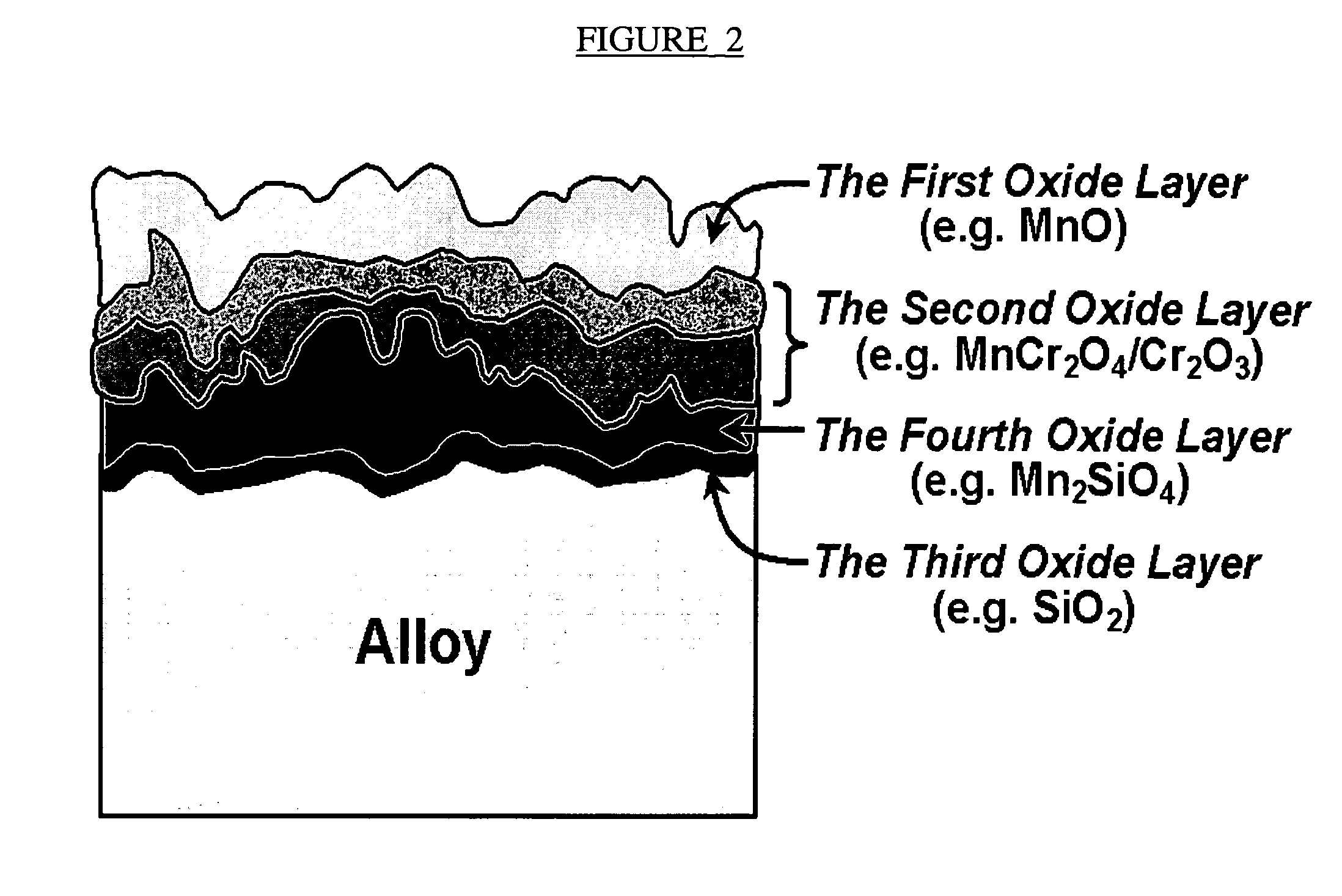

High performance alloys with improved metal dusting corrosion resistance

InactiveUS20060257675A1Molten spray coatingDistillation corrosion inhibitionReactor systemMetal dusting

Alloy compositions which are resistant to metal dusting corrosion are provided by the present invention. Also provided are methods for preventing metal dusting on metal surfaces exposed to carbon supersaturated environments. The alloy compositions include an alloy (PQR), and a multi-layer oxide film on the surface of the alloy (PQR). The alloy (PQR) includes a metal (P) selected from the group consisting of Fe, Ni, Co, and mixtures thereof, an alloying metal (Q) comprising Cr, Mn, and either Al, Si, or Al / Si, and an alloying element (R). When the alloying metal (Q) includes Al, the multi-layer oxide film on the surface of the alloy includes at least three oxide layers. When the alloying metal (Q) includes Si, the multi-layer oxide film on the surface of the alloy (PQR) includes at least four oxide layers. When the alloying metal (Q) includes Al and Si, the multi-layer oxide film on the surface of the alloy (PQR) includes at least three oxide layers. The multi-layer oxide film is formed in situ during use of the alloy composition in a carbon supersaturated metal dusting environment. Advantages exhibited by the disclosed alloy compositions include improved metal dusting corrosion resistance at high temperatures in carbon-supersaturated environments having relatively low oxygen partial pressures. The disclosed alloy compositions are suitable for use as the inner surfaces in reactor systems and refinery apparatus.

Owner:EXXON RES & ENG CO

New additive for inhibiting acid corrosion and method of using the new additive

ActiveUS20110214980A1Reduce phosphorus contentImprove thermal stabilityThermal non-catalytic crackingDistillation corrosion inhibitionDistillationThiophosphate

The present invention relates to the field of corrosion inhibition in hydrocarbon fluid processing units. The present invention comprises a new additive for inhibiting acid corrosion comprising polymeric thiophosphate ester, which is obtained by reaction of a polymer compound having mono, di or poly hydroxyl group, preferably polymer compound which is hydroxyl-termination, more preferably said polymer compound comprising hydroxyl-terminated polyisobutylene or polybutene and phosphorous pentasulphide. Said polymeric thiophosphate ester is further reacted with any oxide selected from group consisting of ethylene oxide, butylenes oxide or propylene oxide or such other oxide, preferably ethylene oxide, capably forming ethylene oxide derivative of thiophosphate ester. The invention is useful effecting acid corrosion inhibition on the metal surfaces of a distillation unit, distillation column, trays, packing and pump around piping.

Owner:DORF KETAL CHEM (I) PTE LTD

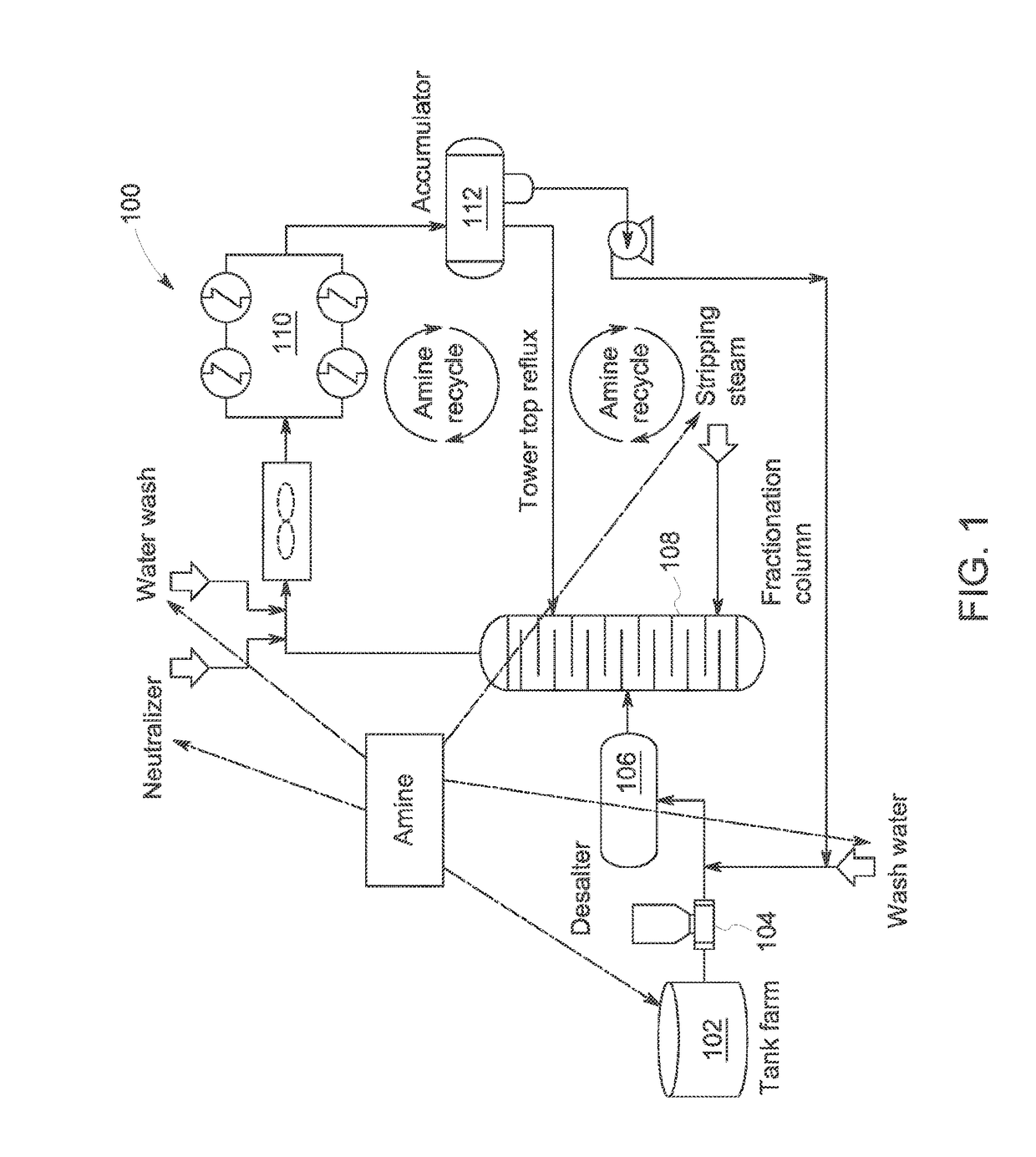

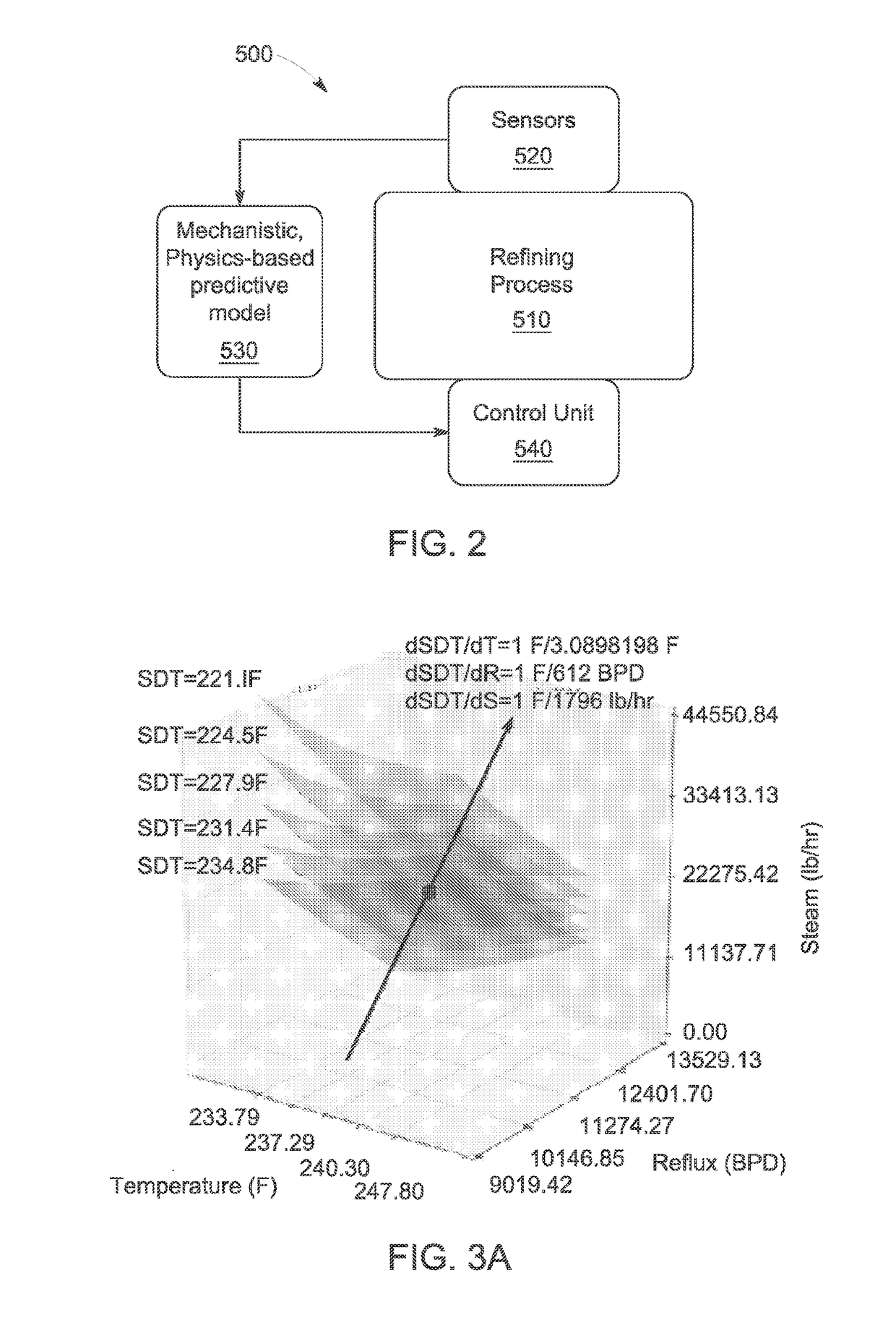

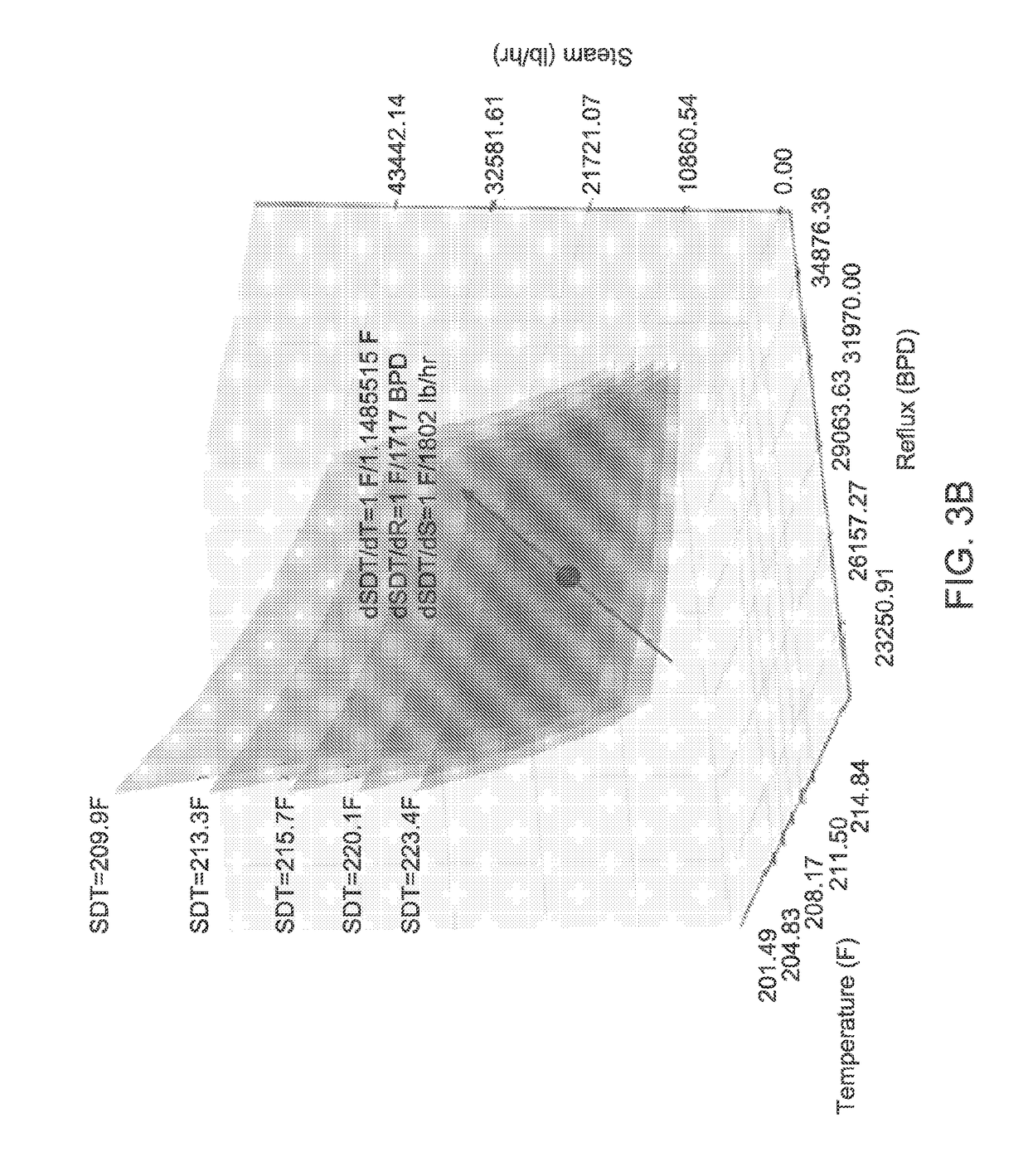

System and method of predictive analytics for control of an overhead crude section of a hydrocarbon refining process

ActiveUS20180355258A1Maximize productionMinimizes operation riskProgramme controlDistillation corrosion inhibitionRisk indicatorProcess engineering

Described herein are systems and methods for control of an overhead crude section of a hydrocarbon refining process. In one aspect, the method comprises monitoring a plurality of operating conditions of an overhead crude section of a refinery; determining hydrogen chloride and amine conditions of the overhead crude section of the refinery at current operating conditions of the overhead crude section; determining a plurality of fields of action by simulating a variation of one or more of the plurality of conditions; determining a risk indicator of salting for each of the plurality of fields of action; and providing a recommended change in operation of the overhead crude section to one of the plurality of fields of action while adhering to one or more constraints.

Owner:BL TECH INC

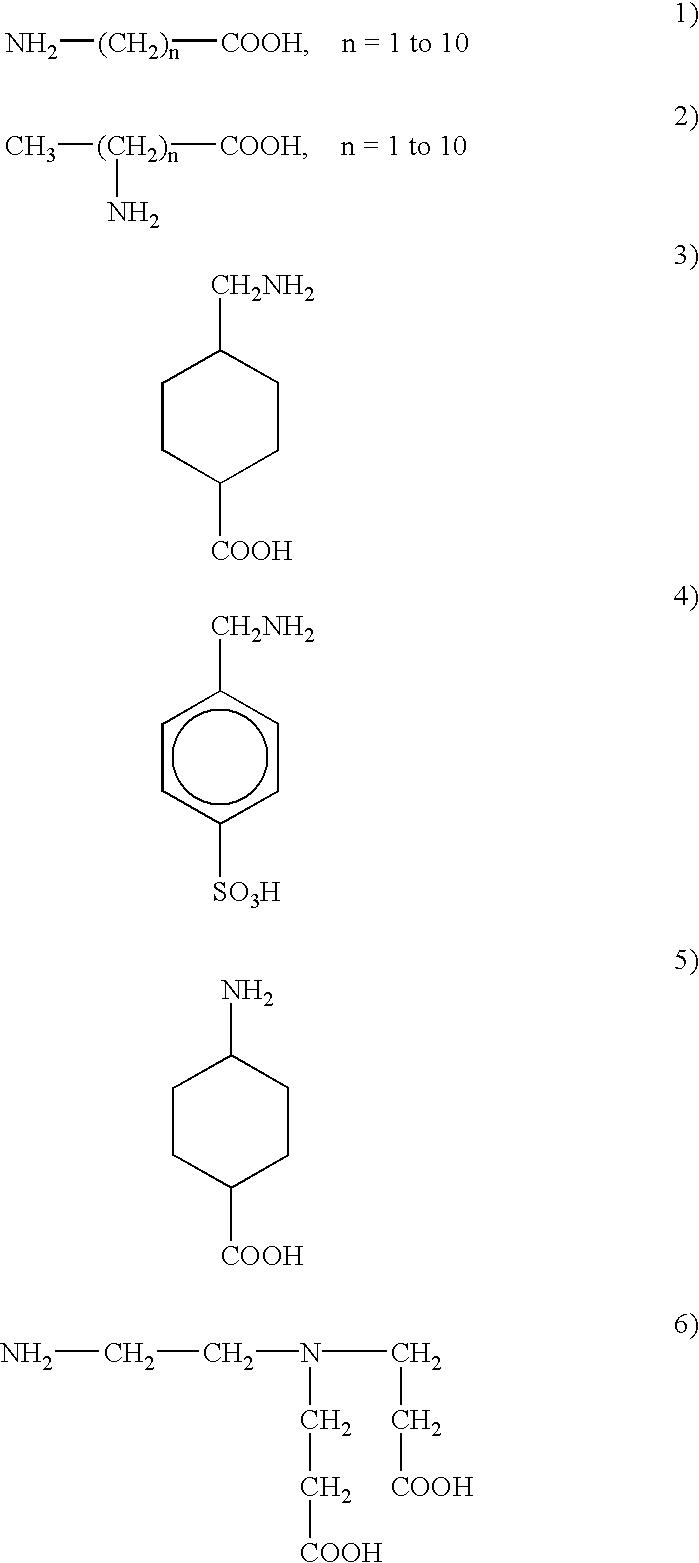

Multi-amine neutralizer blends

ActiveUS7381319B2Minimizes reduces depositNeutralizing acid environmentsThermal non-catalytic crackingCatalytic crackingDistillationNuclear chemistry

Amine and amine blend compositions neutralize acid environments in distillation overheads of hydrocarbon processing facilities. The neutralizers are composed of certain combinations of amines which are relatively stronger bases and more resistant to hydrochloride salt formation. The amines, when blended together, provide greater neutralization of condensed water present without increased potential for corrosive hydrochloride salt formation.

Owner:BAKER HUGHES INC

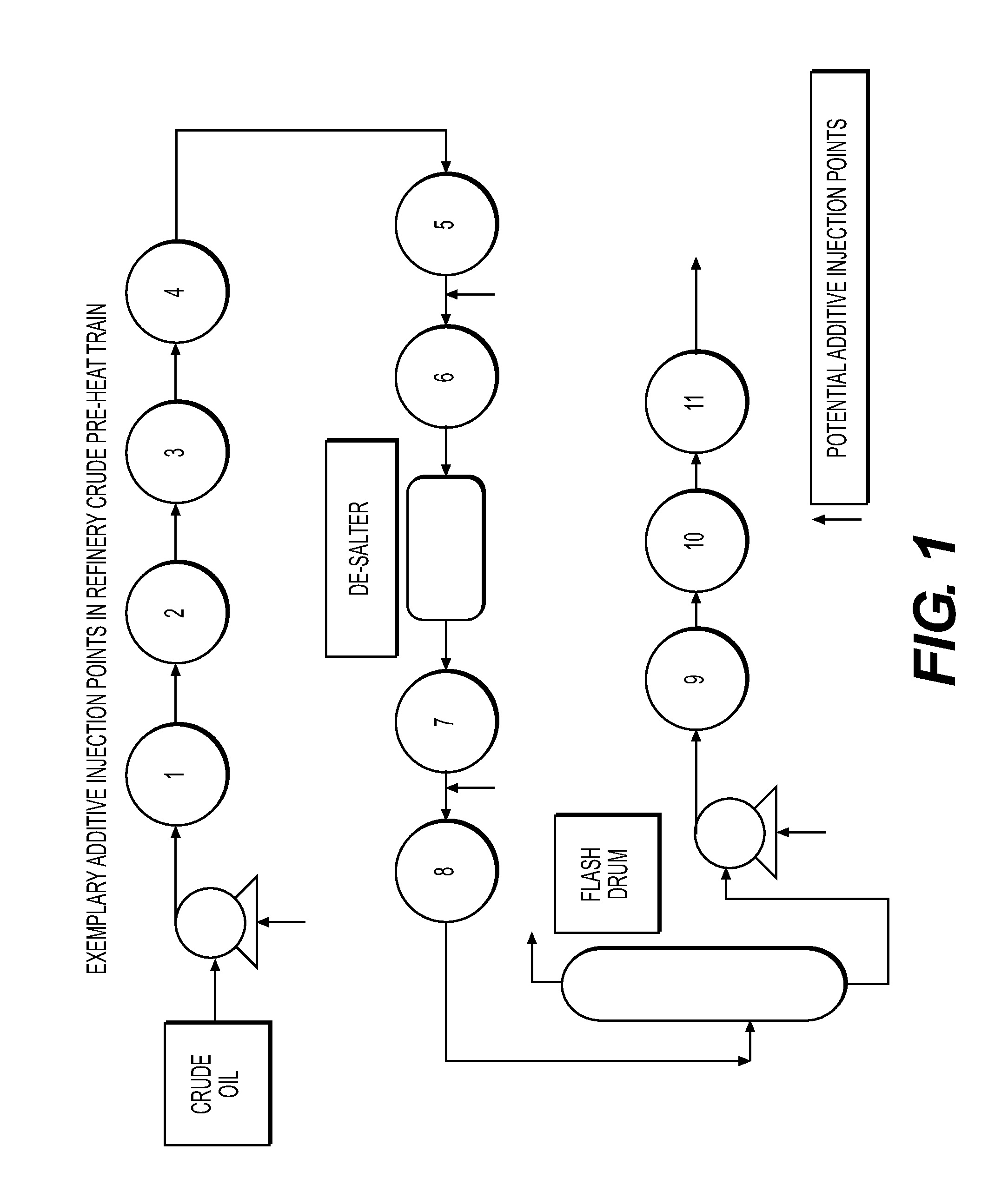

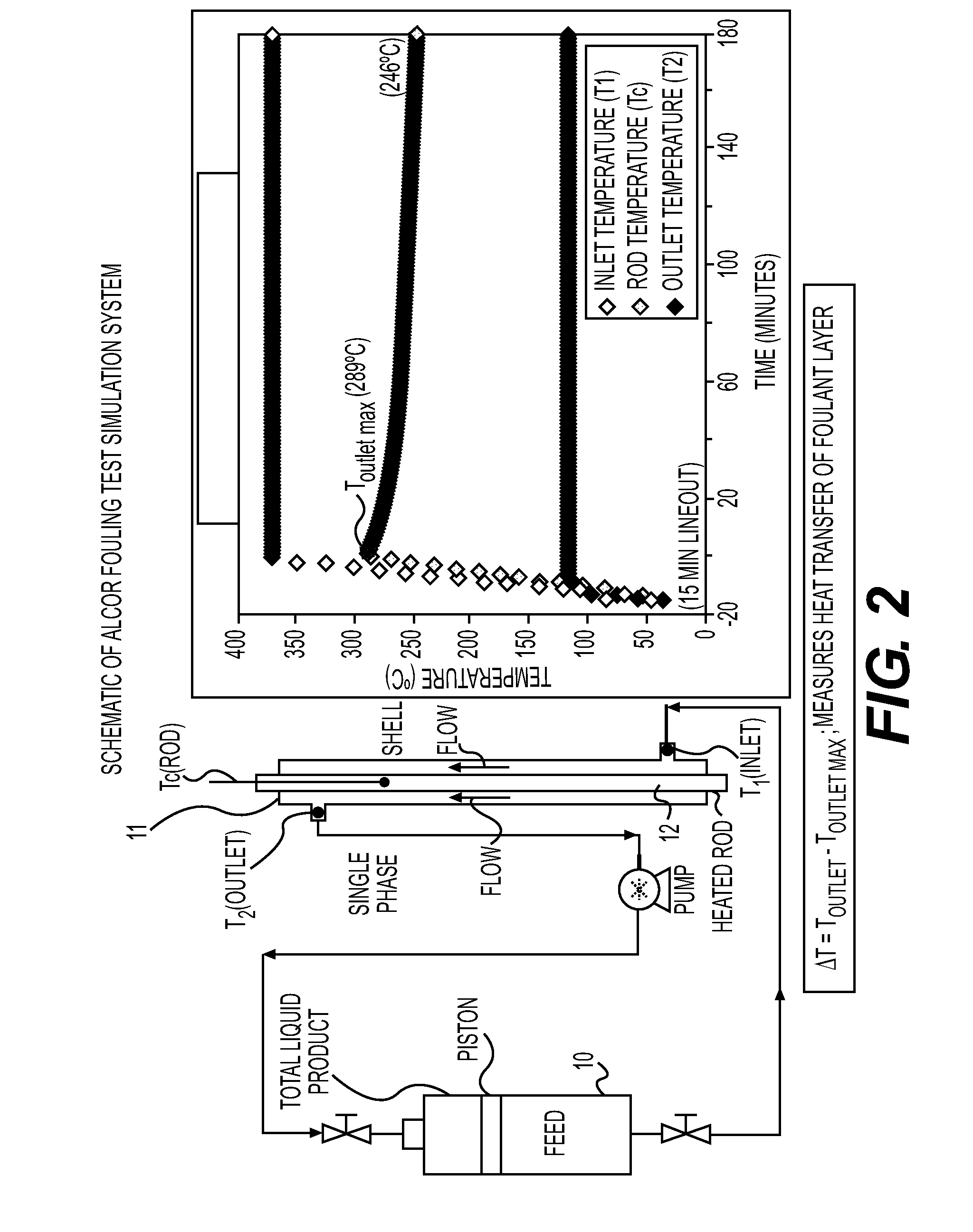

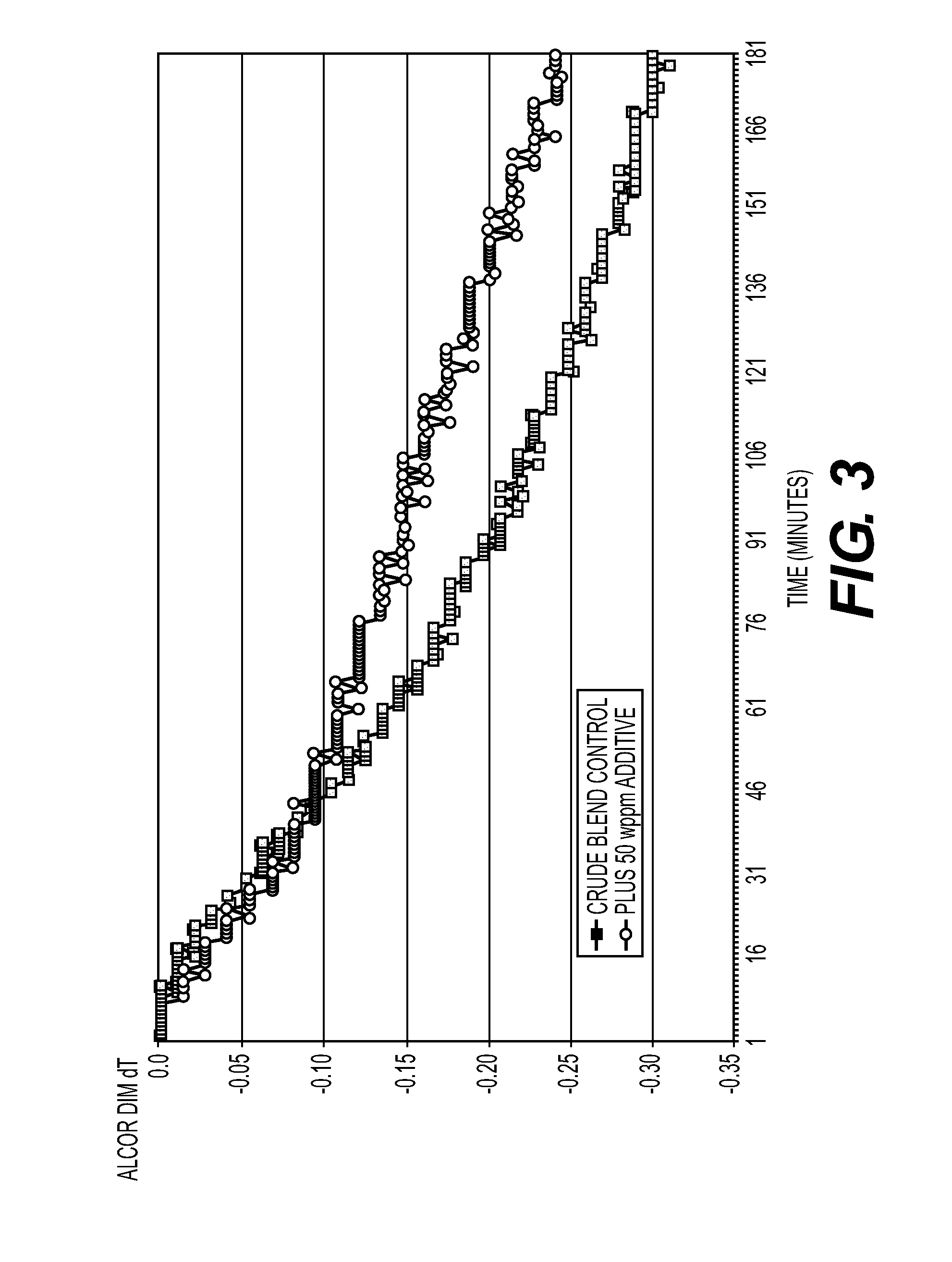

Method for Reducing Fouling in Furnaces

ActiveUS20090211947A1Reducing heat exchanger foulingThermal non-catalytic crackingDistillation corrosion inhibitionAlkylphosphateAlpha-olefin

Heat exchanger fouling in organic chemical production processes may be reduced using an antifoulant additive. The antifoulant additive may have one component selected from the group consisting of an alkylphosphate ester, and an alpha olefin maleic anhydride copolymer; or it may have two components selected from the group consisting of a metallic overbase, an alkylphosphate ester, and an alpha olefin maleic anhydride copolymer, wherein at least one of the two components in not an overbase. An additive having three components: a metallic overbase, an alkylphosphate ester, and an alpha olefin maleic anhydride copolymer; is also within the scope of the disclosure. The abstract is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims. 37 CFR 1.72(b)

Owner:BAKER HUGHES INC

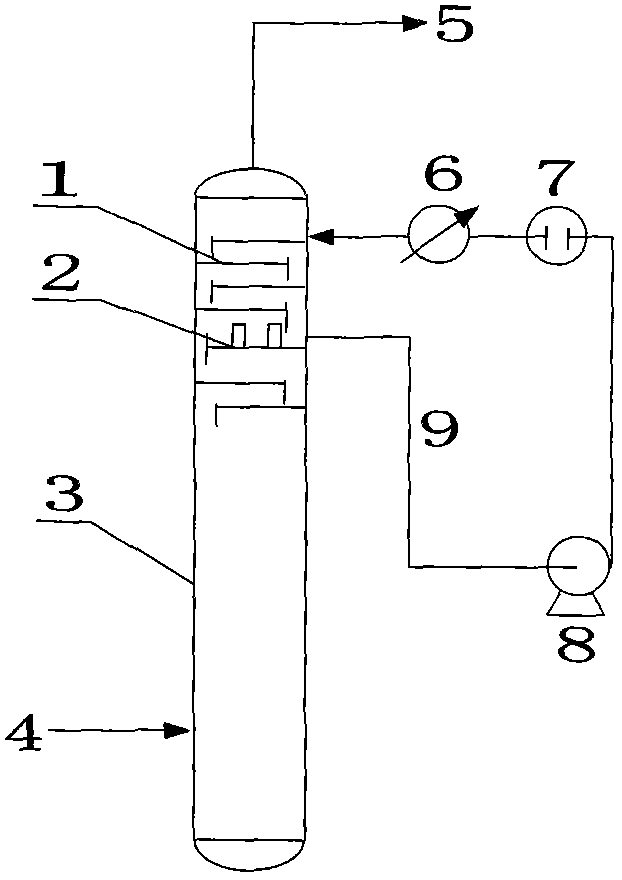

Online cleaning method of deposited salt of tower tray of normal-pressure tower

ActiveCN101880543AReduce the impact of normal productionReduce processing timeDistillation corrosion inhibitionSolubilityEngineering

The invention relates to an online cleaning method of deposited salt of a tower tray of a normal-pressure tower. Particularly, the method comprises the following steps that: based on the original process, a cleaning pipeline is bridged between the input end of an overhead backflow regulating valve and the output end of an electro-desalting water injection regulating valve, and is provided with a bridging valve; by temporary process of communicating the bridged cleaning pipeline and an electro-desalting water injection pump and adjustment of a series of operating parameters, the temperature from the normal-pressure tower top to the tower tray of a normal-first-line pumping section is controlled to 90-100 DEG C, the normal-pressure tower top is driven into washing water, the washing water is pumped after reaching a normal-first-line distillate outlet, hot water is used for washing the tower tray of a salt depositing section continuously so as to solve the desalting problem of the deposited salt of a tower plate of the normal-pressure tower. Since the washing temperature is maintained to be constant by controlling technological parameters and the salt solubility is larger than normaltemperature, the deposited salt of the tower tray is dissolved and washed thoroughly, the device is guaranteed not to be stopped, and the whole online salt-washing treatment process needs about 8 hours; and therefore, the online cleaning method greatly shortens the treatment time, saves cost for starting and stopping the device, and furthest reduces the influence on normal production of an enterprise.

Owner:SHENYANG PARAFFIN CHEM

Polyalkylene epoxy polyamine additives for fouling mitigation in hydrocarbon refining processes

InactiveUS8951409B2Reduce dirtThermal non-catalytic crackingDistillation corrosion inhibitionEpoxyParticulates

Owner:EXXON RES & ENG CO

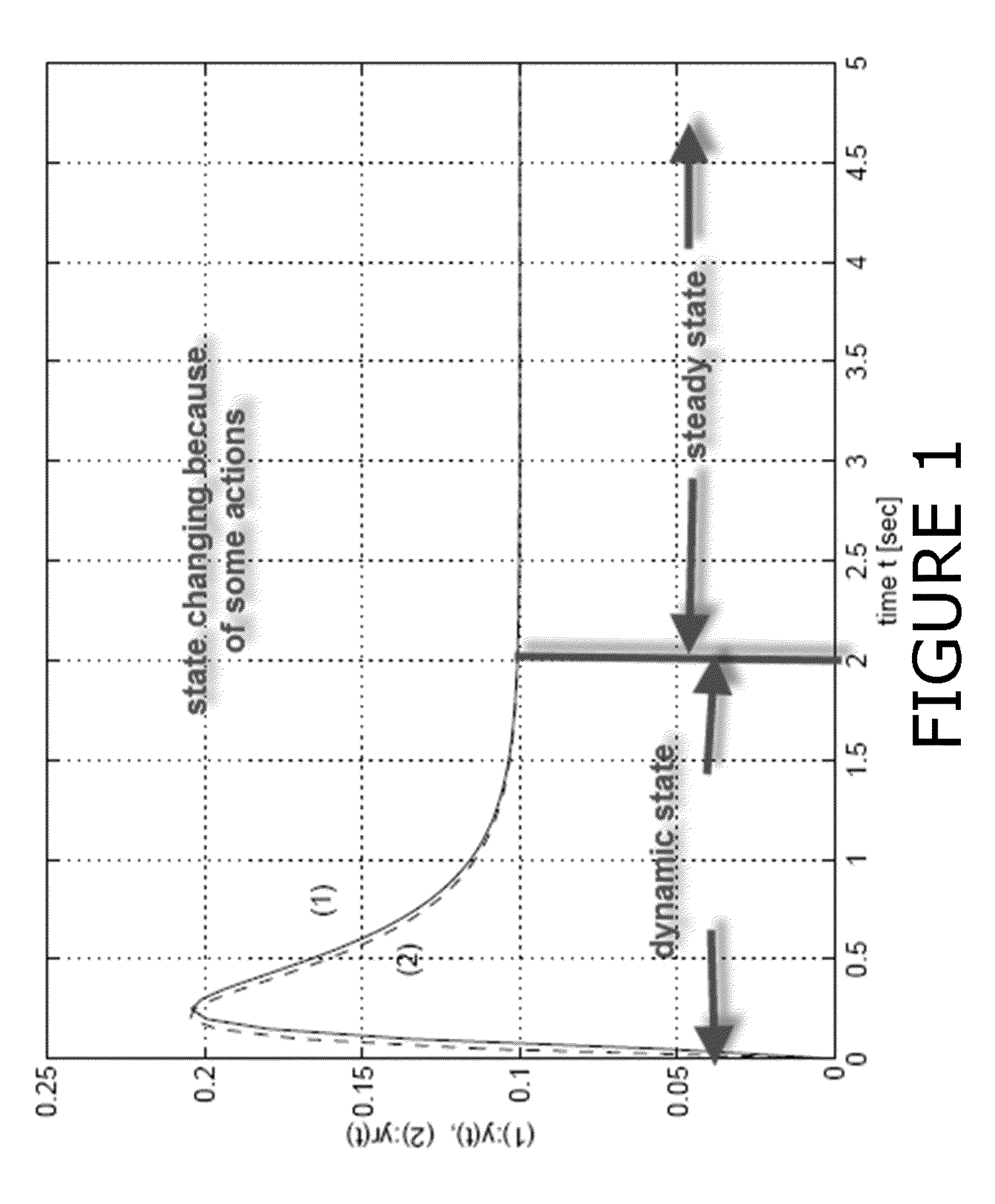

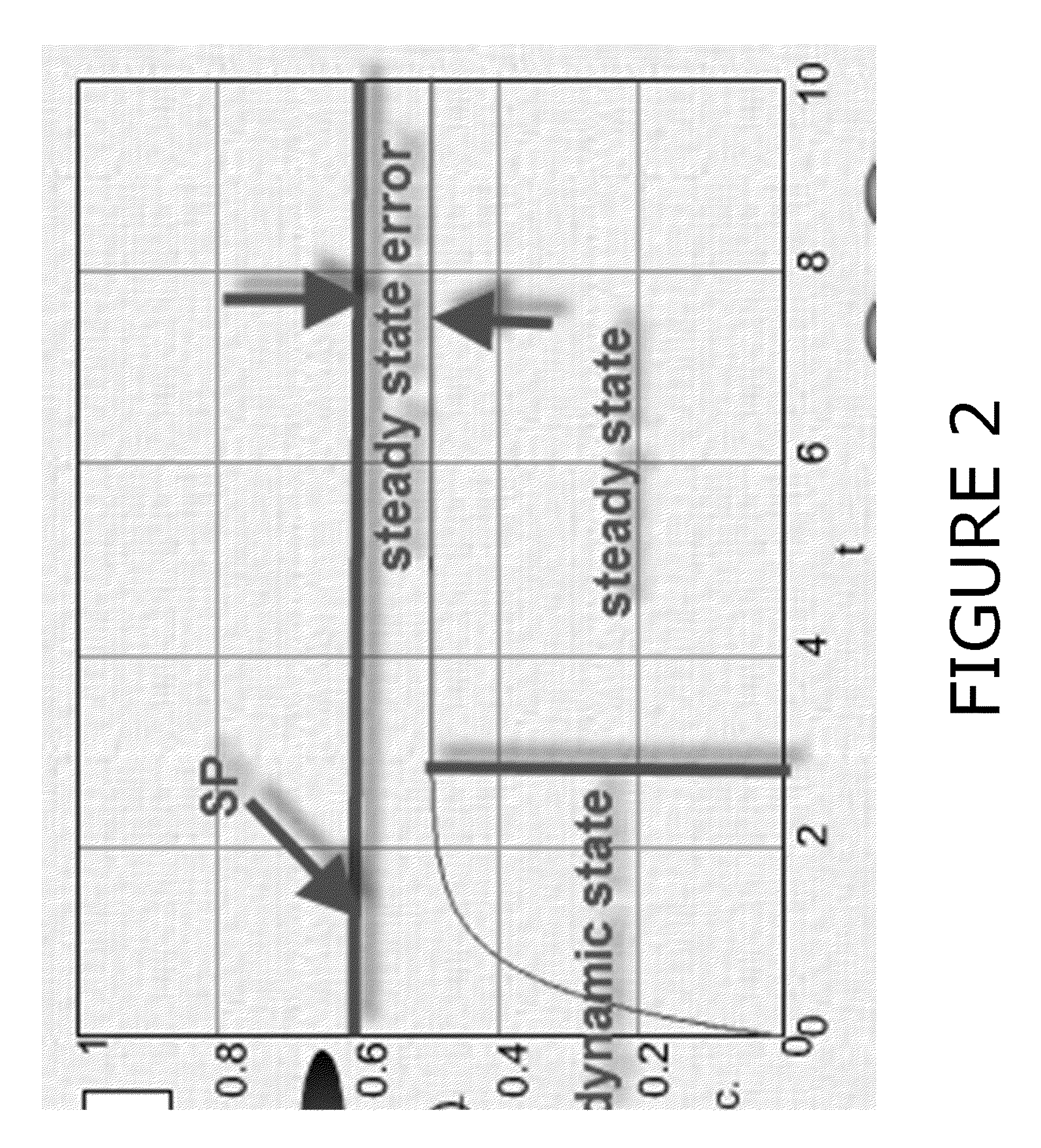

Design development and implementation of analyzer based control system and algorithm

ActiveUS20130048535A1The effect is accurateCorrection errorWave based measurement systemsDistillation corrosion inhibitionControl systemComputer science

A method of correcting measurements of a chemical sensor used in an industrial facility. The method involves correcting for errors known to occur in the steady state and the dynamic state for specifically recognized situations. This method allows for correcting errors that occur due to deadtime, false zero measurements, and non-linear disturbances. The method combines automated measurement techniques and human know how to progressively learn and refine the accuracy of the corrections.

Owner:ECOLAB USA INC

Method of removal of carbonyl compounds along with acid gases from cracked gas in ethylene process

InactiveUS20050224394A1Reduce concentrationPreventing plugging and foulingThermal non-catalytic crackingCatalytic crackingCaprolactamCaproic Acid

A method for mitigating fouling in a wash unit used in a hydrocarbon cracking process wherein the fouling is due to the presence of polymers and deposits thereof formed by condensation of carbonyl compounds contained within a feed stream of the wash unit. In one embodiment, the invention provides a method of mitigating fouling in a wash unit by introducing into the feed stream an effective amount of an additive including: an inorganic salt of dithionite; and an epsilon caprolactam or a 6-amino caproic acid derivable therefrom. The additive scavenges the carbonyl compounds contained within the feed stream and dissolves deposits of the polymers to thereby mitigate fouling in the wash unit.

Owner:DORF KETAL CHEM

Popular searches

Liquid carbonaceous fuels Distillation separation Hydrocarbon oils refining Pretreated surfaces Treatment with hydrotreatment processes Chemical/physical/physico-chemical processes Filter regeneration Hydrocarbon oils treatment products Treatment with plural serial cracking stages only Inorganic chemistry

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com