Method of reducing corrosion in a crude unit

A crude oil distillation, system parameter technology, applied in the direction of corrosion prevention during distillation, distillation control/regulation of hydrocarbon oil, measurement devices, etc., can solve the problem that refiners have not adopted unique and effective online equipment process chemistry procedures, have not been successful, etc. problems, to achieve the effect of rapid stabilization of operating parameters, reduction of unqualified oil processing, and optimization of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

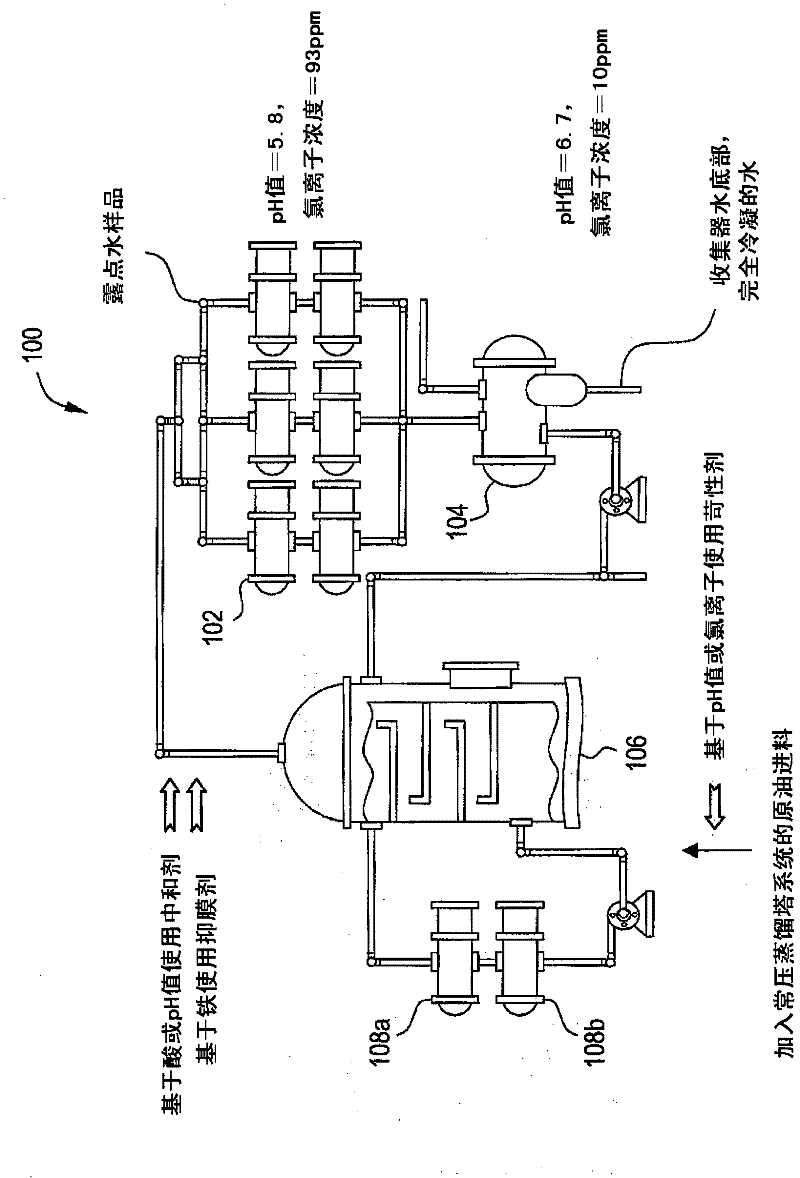

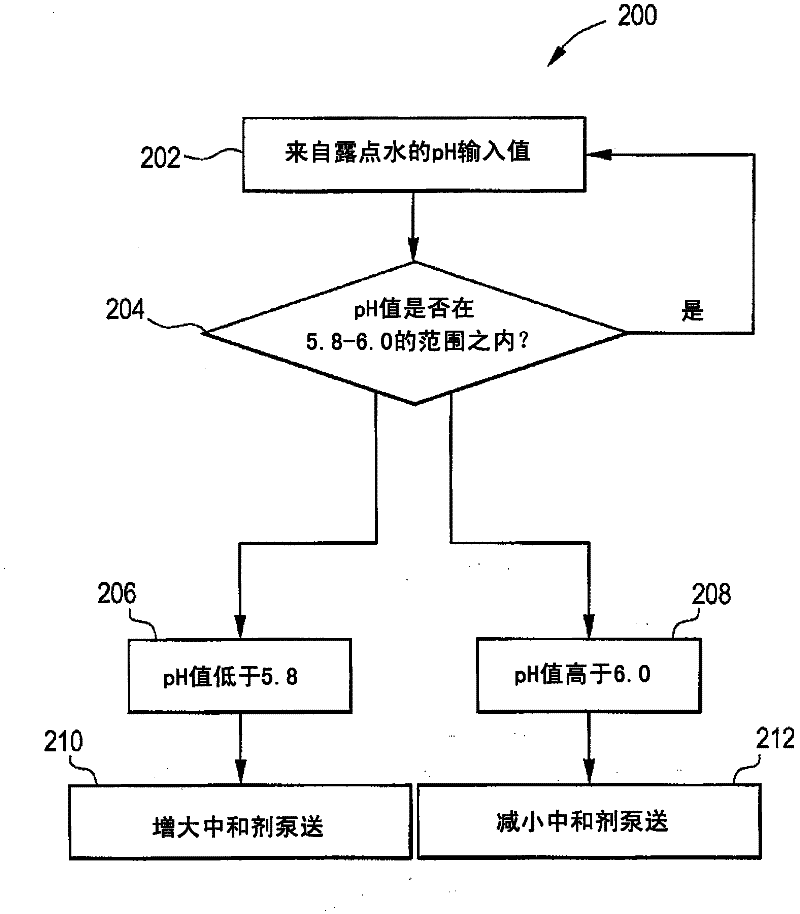

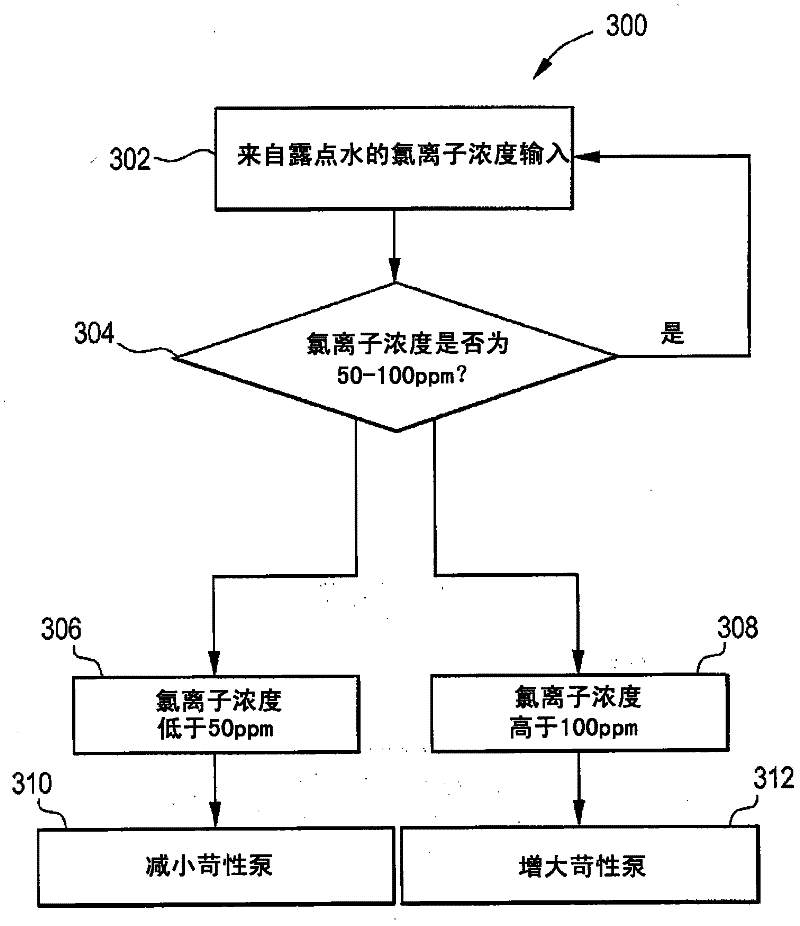

[0061] An exemplary embodiment of the invention consists of a cluster of on-line analyzers within an explosion proof enclosure that receives a water sample from a dew point water sampling device. The data generated by these analyzers can be appropriately conditioned to deliver control signals to the various process chemical injection pumps. A programmable logic controller (PLC), programmed by one skilled in the art, would convert the raw data into pump control signals. A typical system includes one or more of the following components: Chloride Analyzer; Iron Analyzer; Corrosion Rate Monitor; Conductivity Meter; pH Meter; Dew Point Water Sampling Device; PLC for output; logic programming to convert chloride, pH, and iron data into pump speed control; and wireless or hardwired connection from PLC to pump.

Embodiment 2

[0063] The present invention will provide improvements in the control of each of the three test parameters (chloride ion concentration, pH, and iron ion concentration). Of these three parameters, chloride ions usually cause the most damage if not properly controlled. Figure 6 Shows how the present invention improves control of chloride ion concentration (dotted line indicates optimal concentration). A similar concept of better control by the method of the present invention can be applied to pH, iron ion concentration, and other system parameters, ultimately resulting in reduced corrosion rates from previous levels, extending equipment life.

[0064] Figure 6 Shows many peaks of chloride ion concentration above the upper control limit for actual data from a crude distillation unit. Chloride peaks were destructive to equipment, and retrospective inspection of the data revealed increased corrosion and fouling in the process. Such peaks are more frequent and more damaging whe...

Embodiment 3

[0066] Figure 7 The pH and chloride ion concentration values of the actual crude distillation unit are shown as a function of time (the dotted line indicates the optimal concentration). It can be seen that the decrease in pH is usually accompanied by an upward peak in chloride ion concentration. This decrease in pH generally results in increased corrosion and fouling of heat exchange equipment (due to corrosion by-products). The portion of the figure labeled "Exercise Control" shows that the method of the present invention can be used to stabilize chloride ion concentration and pH, thereby reducing corrosion and fouling in the system. The smooth change in chloride value allows tighter pH control and more stable and predictable chemical applications.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com