Patents

Literature

941results about "Treatment apparatus corrosion/fouling inhibition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Grafted polymers as gas hydrate inhibitors

InactiveUS6867262B1Low ground water pollution classificationReduce security risksThermal non-catalytic crackingUsing liquid separation agentPolymerHydrate

Owner:BASF AG

Polyalkyl succinic anhydride derivatives as additives for fouling mitigation in petroleum refinery processes

InactiveUS20100170829A1Thermal non-catalytic crackingOrganic chemistryParticulatesFouling mitigation

The present invention provides a method for reducing fouling, including particulate-induced fouling, in a hydrocarbon refining process including the steps of providing a crude hydrocarbon for a refining process; adding at least one polyalkyl succinic anhydride derivative additive disclosed herein. The additive can be complexed with a boronating agent, such as boric acid, to yield a boron-containing polyalkyl succinic anhydride derivative.

Owner:EXXON RES & ENG CO

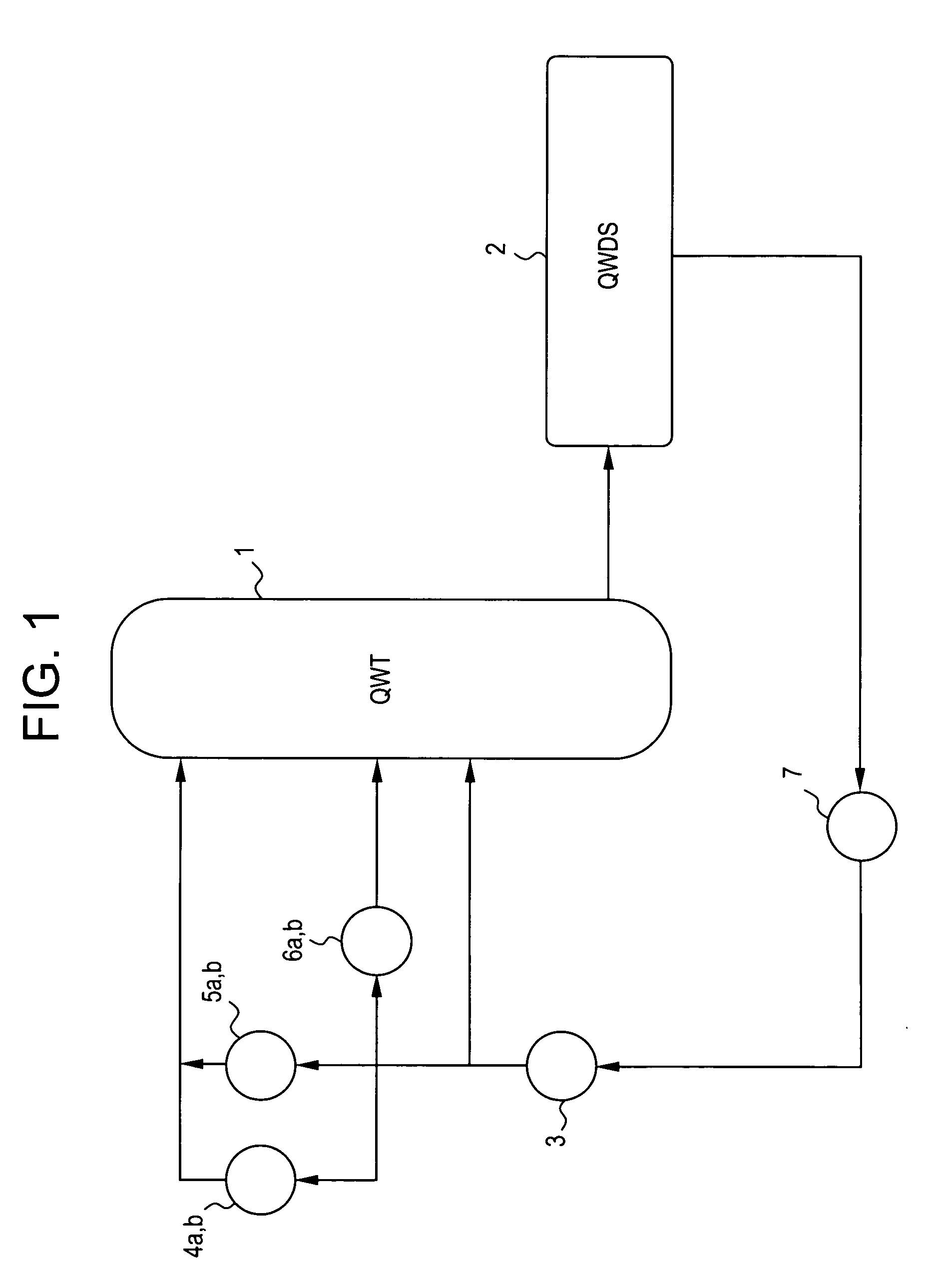

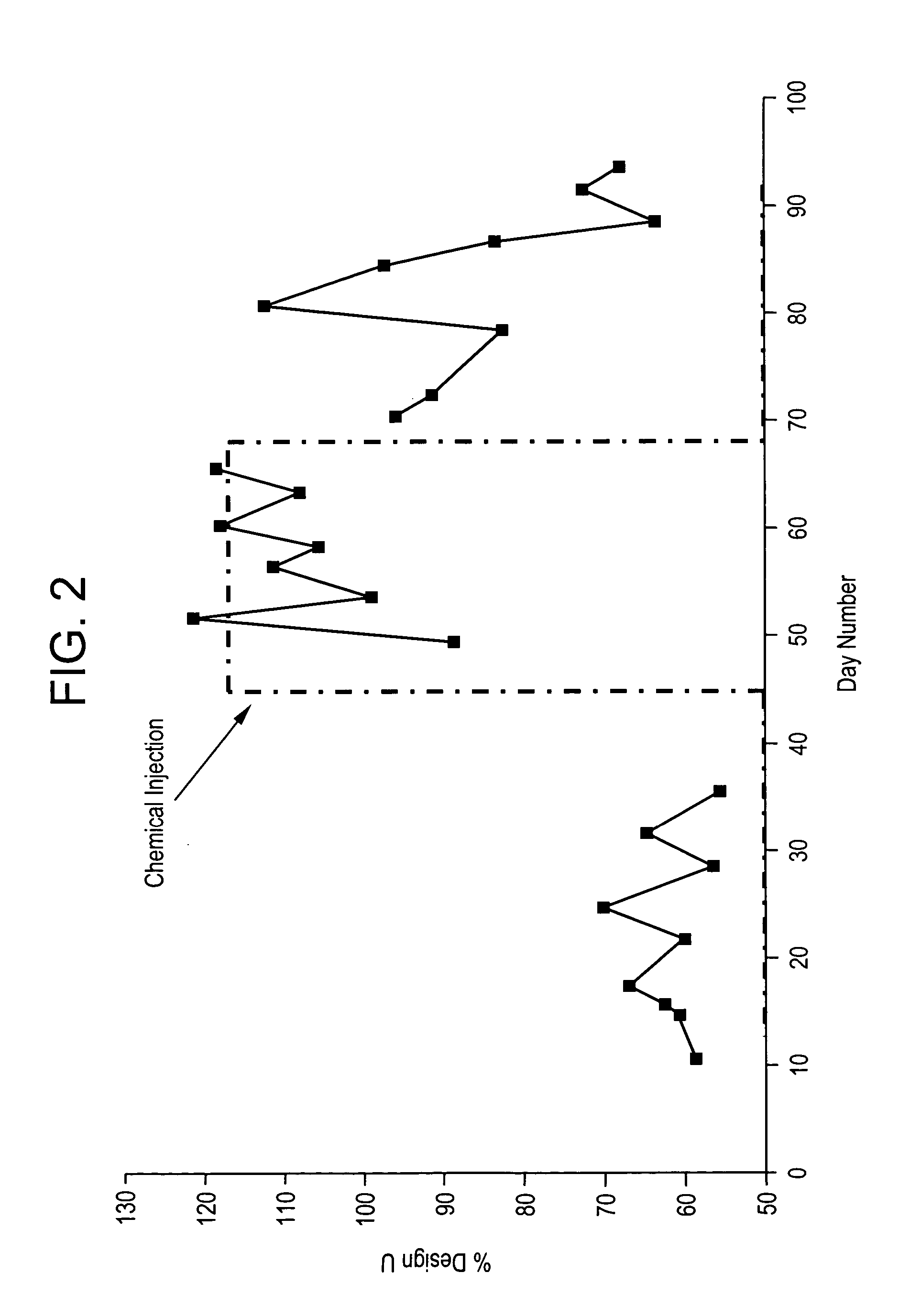

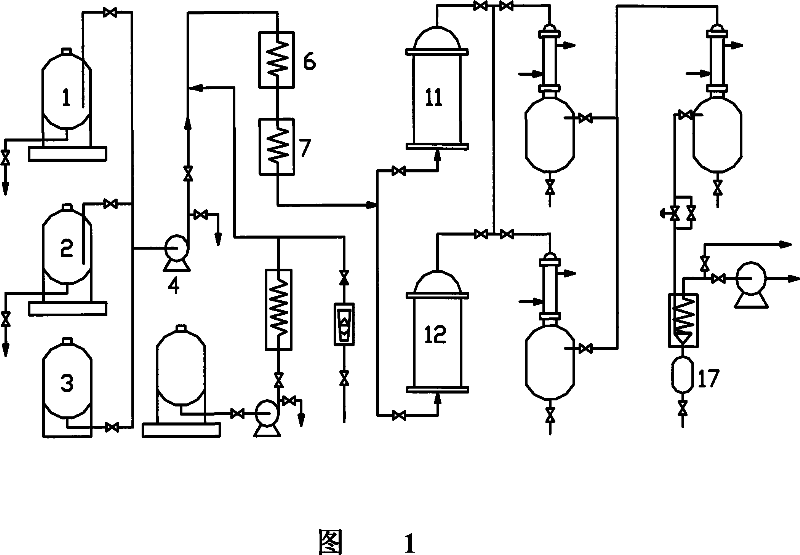

Supercritical water process to upgrade petroleum

ActiveUS20130140214A1Proceed efficientlyThermal non-catalytic crackingCatalytic crackingSludgePetroleum

Provided is a process for the supercritical upgrading of petroleum feedstock, wherein the process includes the use of a start-up agent, wherein the use of the start-up agent facilitates mixing of the petroleum feedstock and water, thereby reducing or eliminating the production of coke, coke precursor, and sludge.

Owner:SAUDI ARABIAN OIL CO

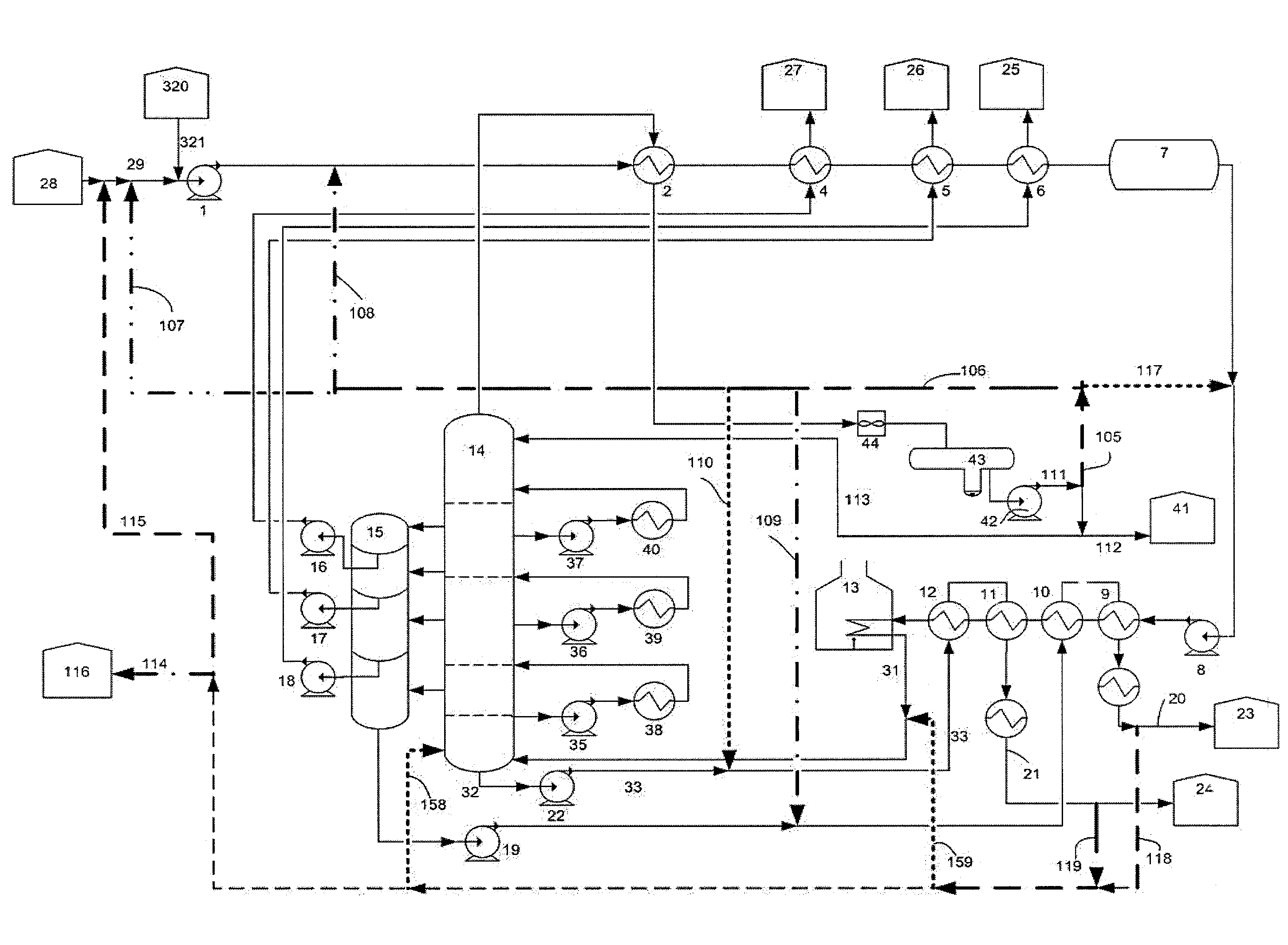

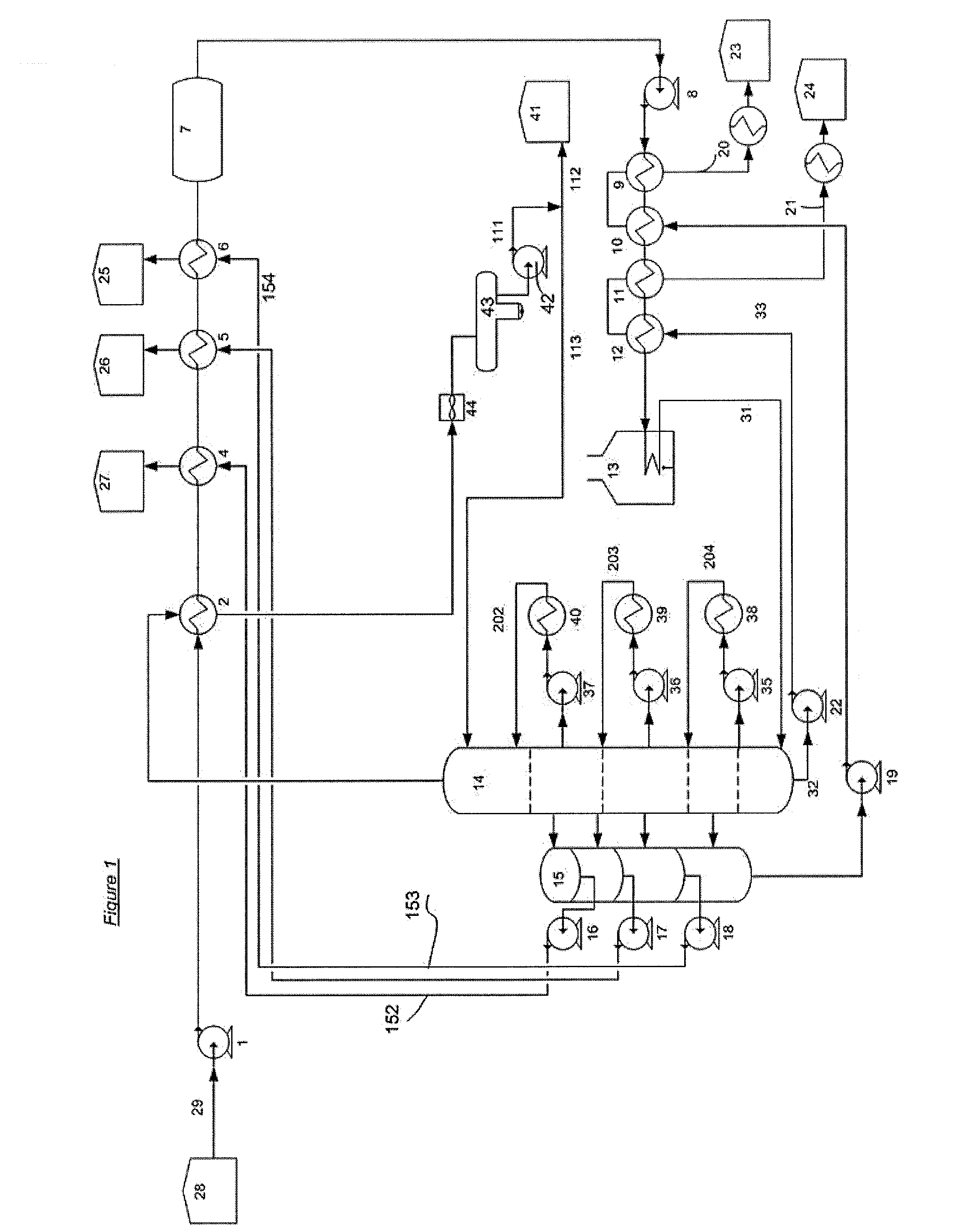

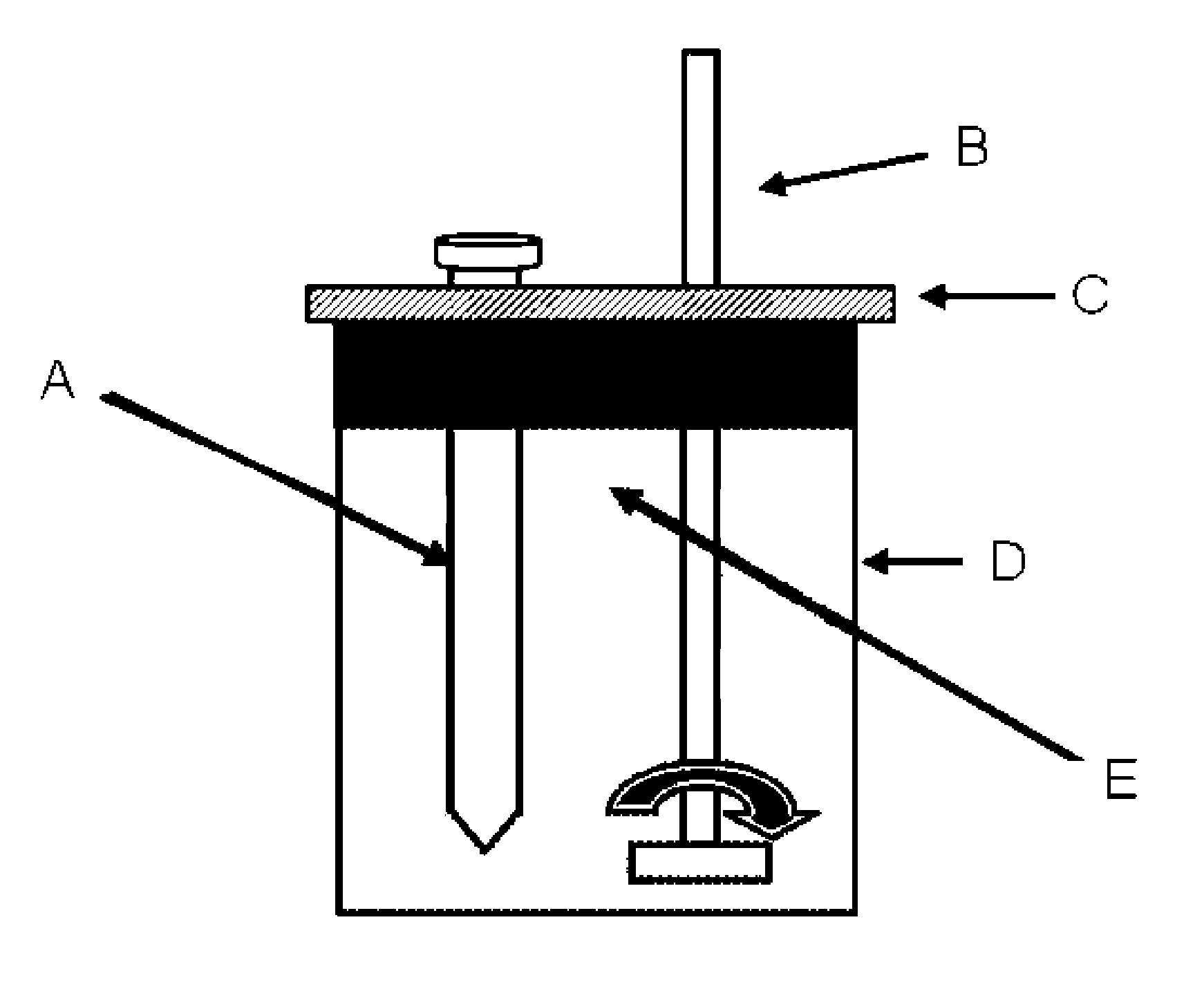

Method, apparatus and chemical products for treating petroleum equipment

ActiveUS20130270157A1Reduce reunionReduces coke formationThermal non-catalytic crackingLighting and heating apparatusEnvironmental engineeringChemical products

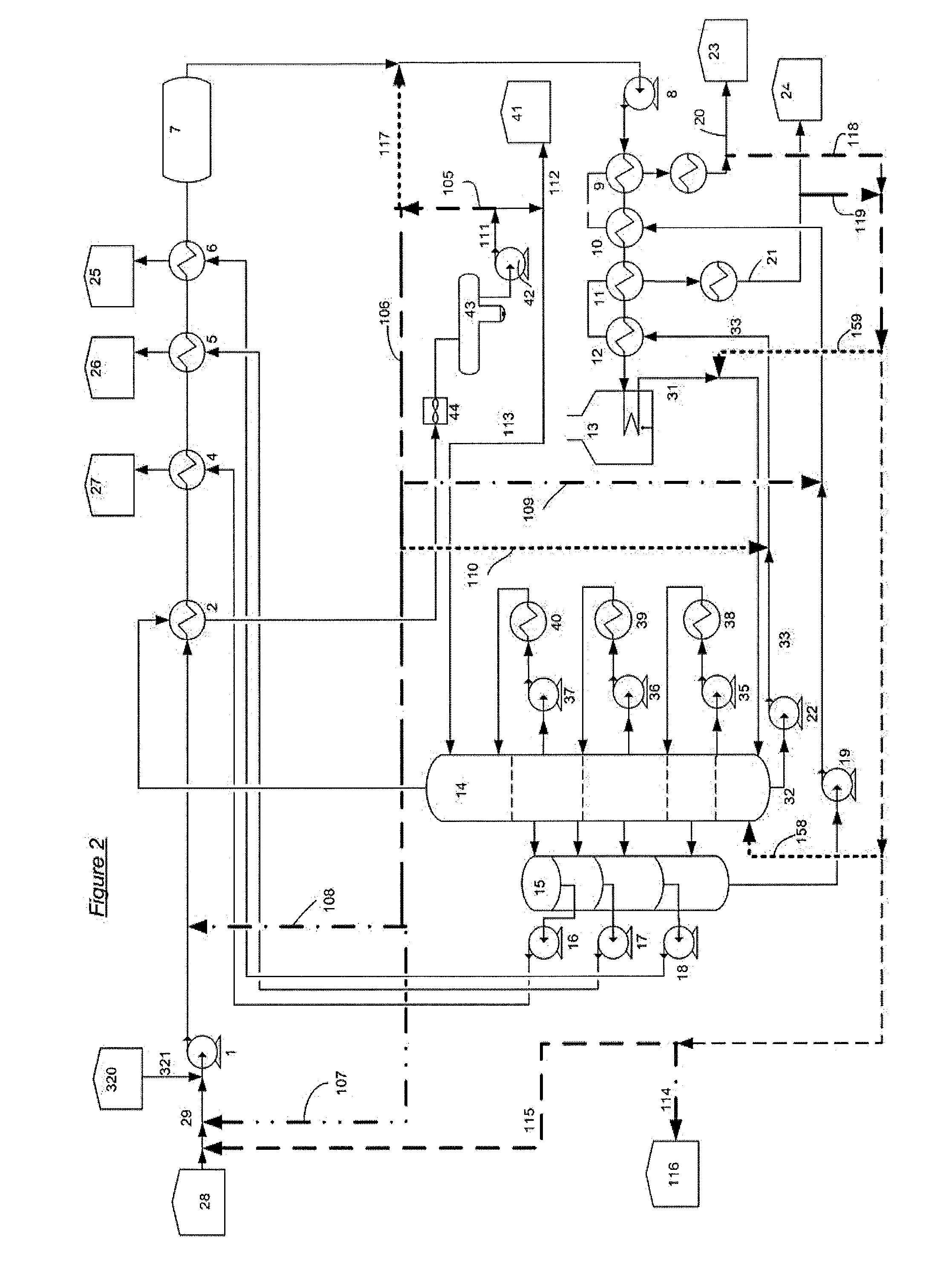

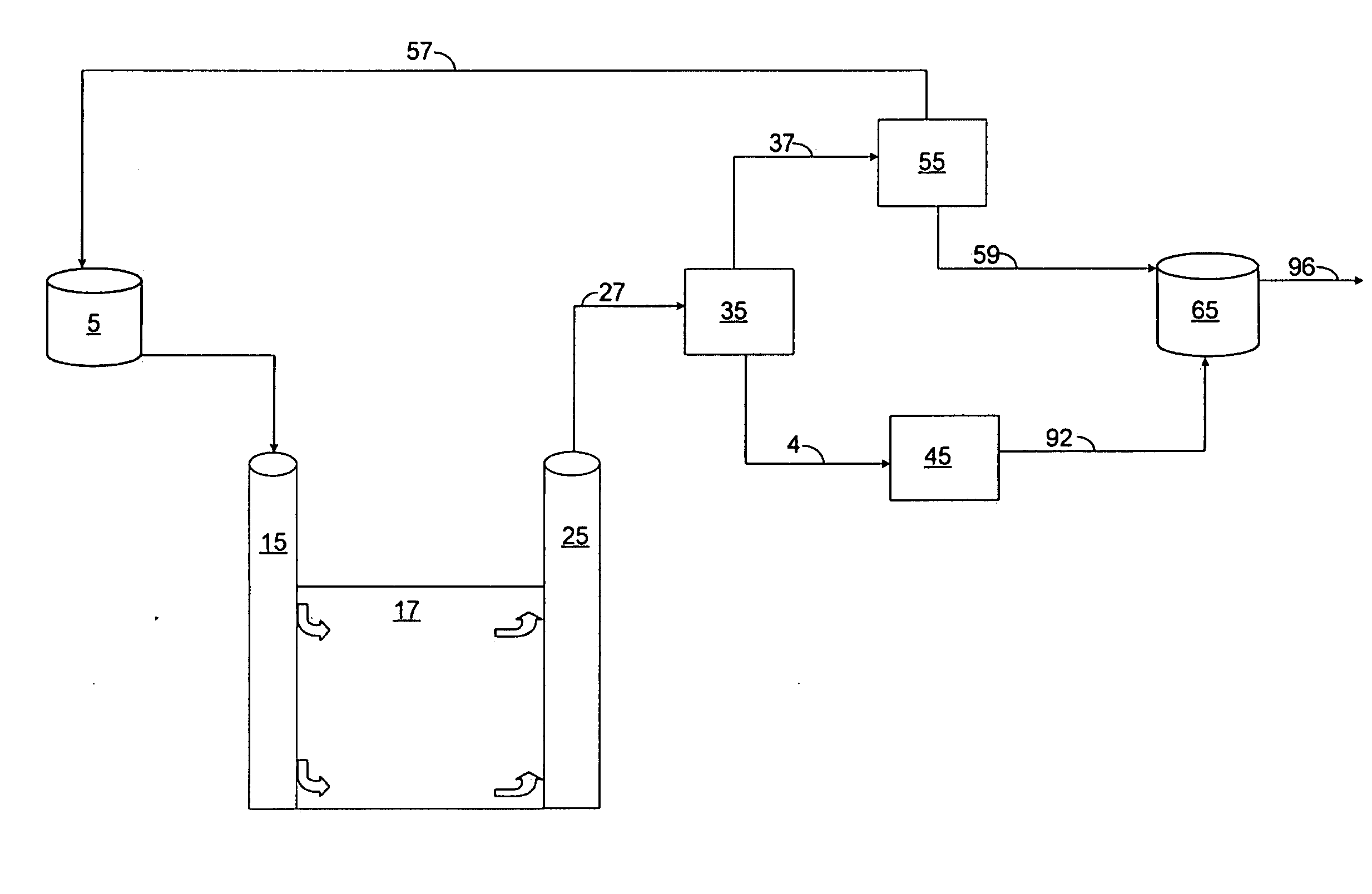

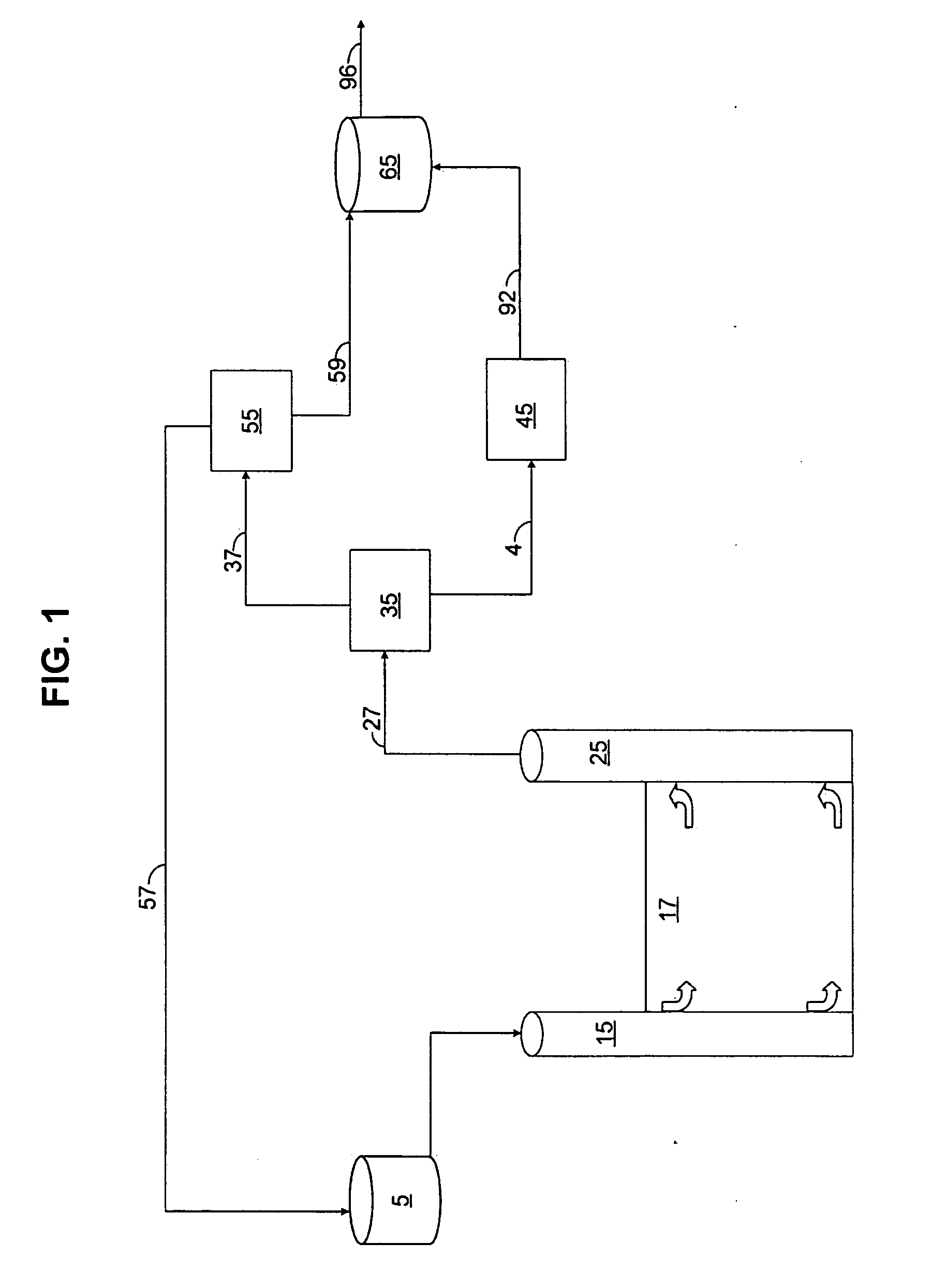

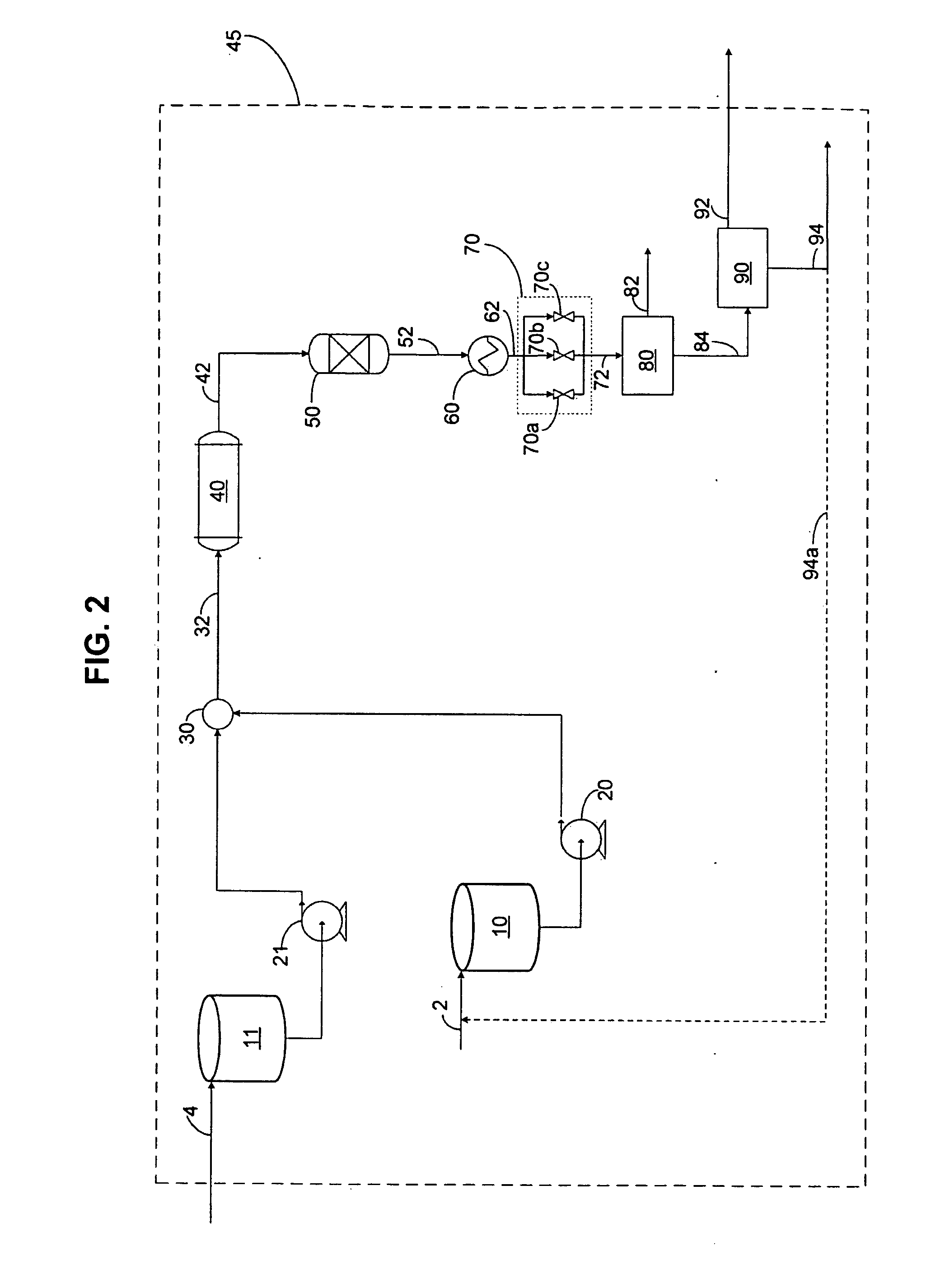

The present invention provides a method, an apparatus and chemical products for treating petroleum equipment wherein a fluid is flowing, preferably of the hydrocarbon type, and wherein treating is performed by establishing a closed or semi-closed flow circulation loop, during the normal production operations of the equipment. The treatment can refer to the cleaning of equipment, to yield improvement as compared to normal run conditions and / or to a reduction of coke formation and / or to coke removal on catalysts.

Owner:FERRARA MARCELLO

Process for producing gasoline with a low sulphur content

InactiveUS6334948B1Treatment with hydrotreatment processesMetal/metal-oxides/metal-hydroxide catalystsGasolineMetal

A process for producing a gasoline with a low sulphur content comprises: separating a sulphur-containing gasoline into a light fraction and a heavy fraction, hydrodesulphurising the light gasoline on a nickel-based catalyst, hydrodesulphurising the heavy fraction on a catalyst comprising at least one group VIII metal and / or at least one group VIB metal, and mixing the desulphurised fractions.

Owner:INST FR DU PETROLE

Method to decrease iron sulfide deposits in pipe lines

InactiveUS6866048B2Inorganic/elemental detergent compounding agentsAnionic surface-active compoundsPhosphoniumSulfate

This invention provides a method of treating a dry or processed fluid pipe line susceptible to the build-up of iron sulfide deposits by complexing the iron sulfide in the pipe lines. The method of the present invention introduces the composition on a continuous or a batch basis to a gas pipe line. The composition is made of a solution of 1) water, 2) [tetrakis(hydroxymethyl)phosphonium]sulfate or chloride, and 3) a soluble ammonium salt, such as ammonium chloride or the like.

Owner:COASTAL CHEM CO L L C

Process to upgrade whole crude oil by hot pressurized water and recovery fluid

ActiveUS20090139715A1Upgraded more easilyLess coke formationThermal non-catalytic crackingRefining by water treatmentSulfurLow nitrogen

A process for upgrading whole crude oil utilizing a recovery fluid, depressurizing an extracted whole crude oil / recovery fluid mixture in a step-wise fashion, and subsequently contacting at least a portion of the whole crude oil with supercritical water fluid to produce high value crude oil having low sulfur, low nitrogen, and low metallic impurities for use as hydrocarbon feedstock.

Owner:SAUDI ARABIAN OIL CO

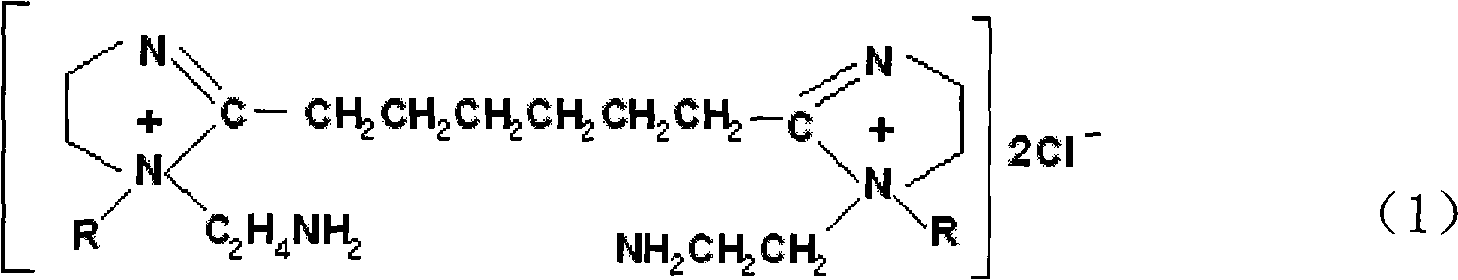

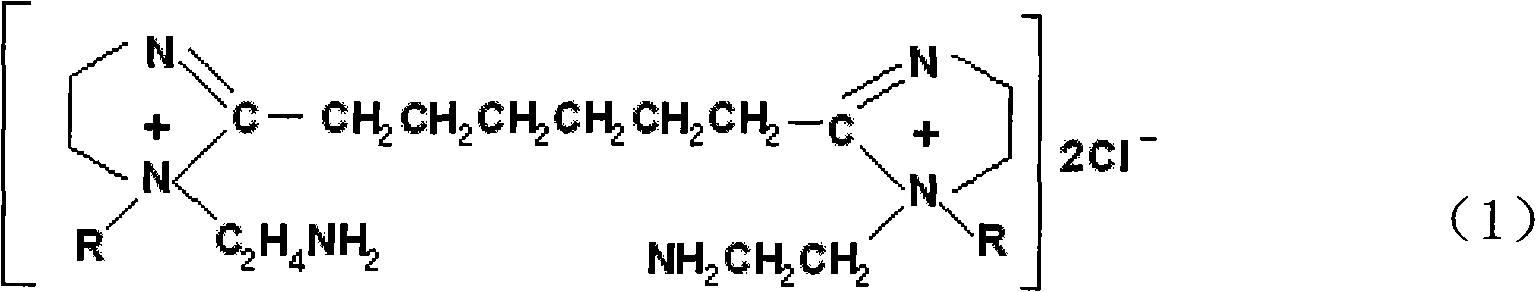

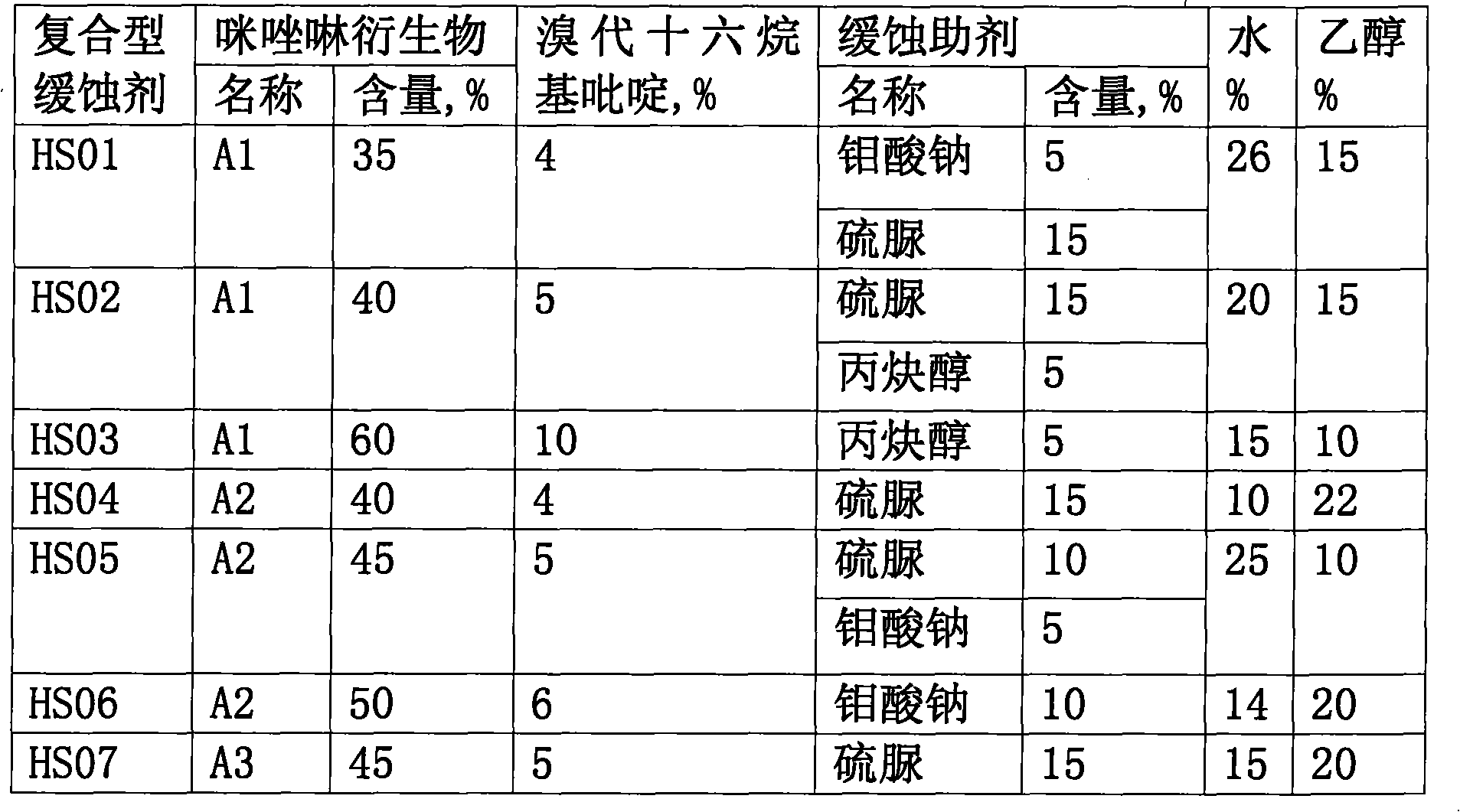

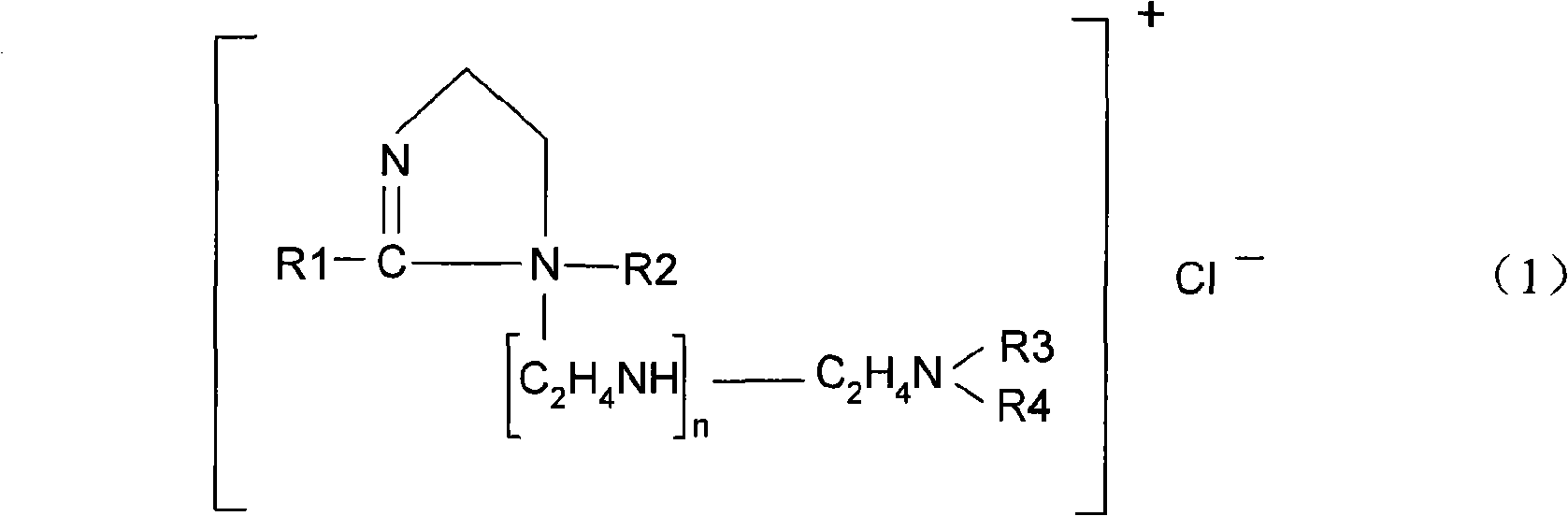

Composite inhibiter and preparation method and application thereof

ActiveCN101613622AGood corrosion inhibitionGood film formingTreatment apparatus corrosion/fouling inhibitionSolventPyridine

The invention discloses a composite inhibiter and a preparation method and an application thereof. The composite inhibitor is a composition with the components and contents being as follows: (A) 10wt%-60wt% of auaternary ammonium bis-imidazoline; (B) 1wt%-10wt% of pyridine derivatives; (C) 1wt%-30wt% of corrosion inhibition assistant; and (D) 10wt%-50wt% of solvent. The inhibitor in the invention has fine effect on preventing low-temperature lightweight oil part equipment from being corroded in an oil refinery.

Owner:CHINA PETROCHEMICAL CORP +2

Oilfield cleaner and corrosion inhibitor

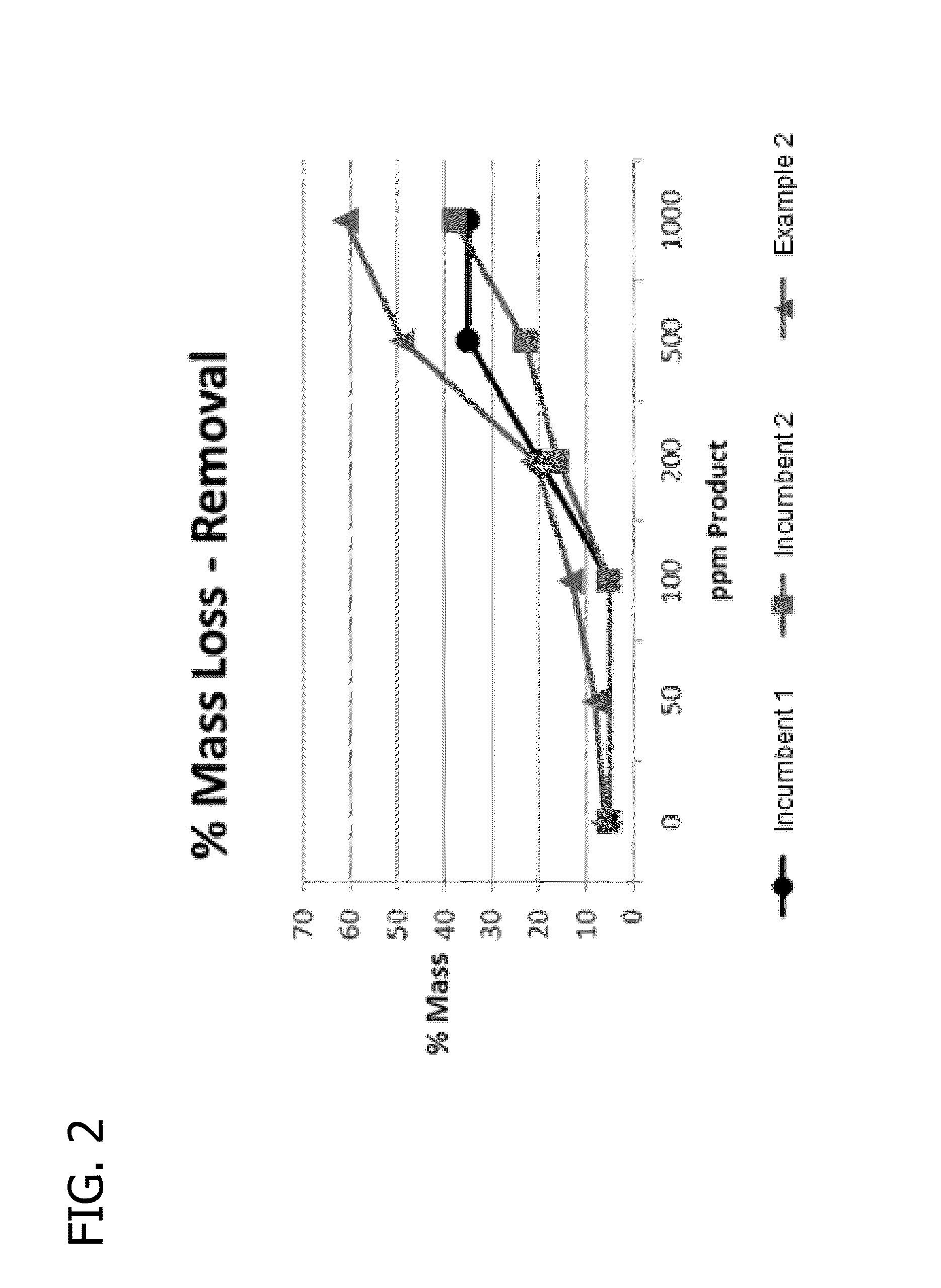

ActiveUS20150011453A1Avoid corrosionOrganic detergent compounding agentsOrganic chemistryNuclear chemistryCorrosion inhibitor

Disclosed herein are cleaner / corrosion inhibiting compositions useful in applications relating to the production, transportation, storage, and separation of crude oil and natural gas. Also disclosed herein are methods of using the compositions as cleaners / corrosion inhibitors, particularly in applications relating to the production, transportation, storage, and separation of crude oil and natural gas.

Owner:CHAMPIONX USA INC

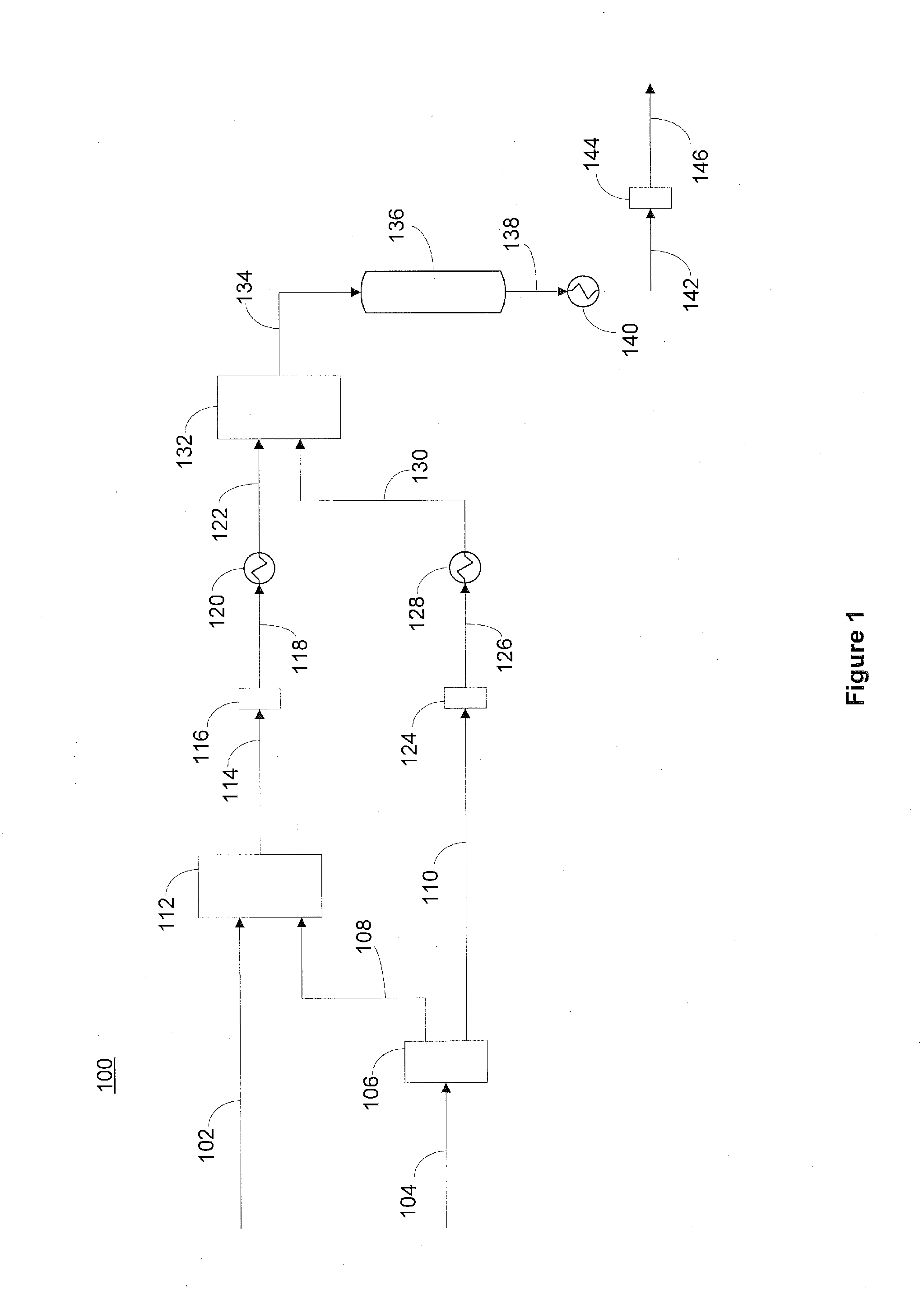

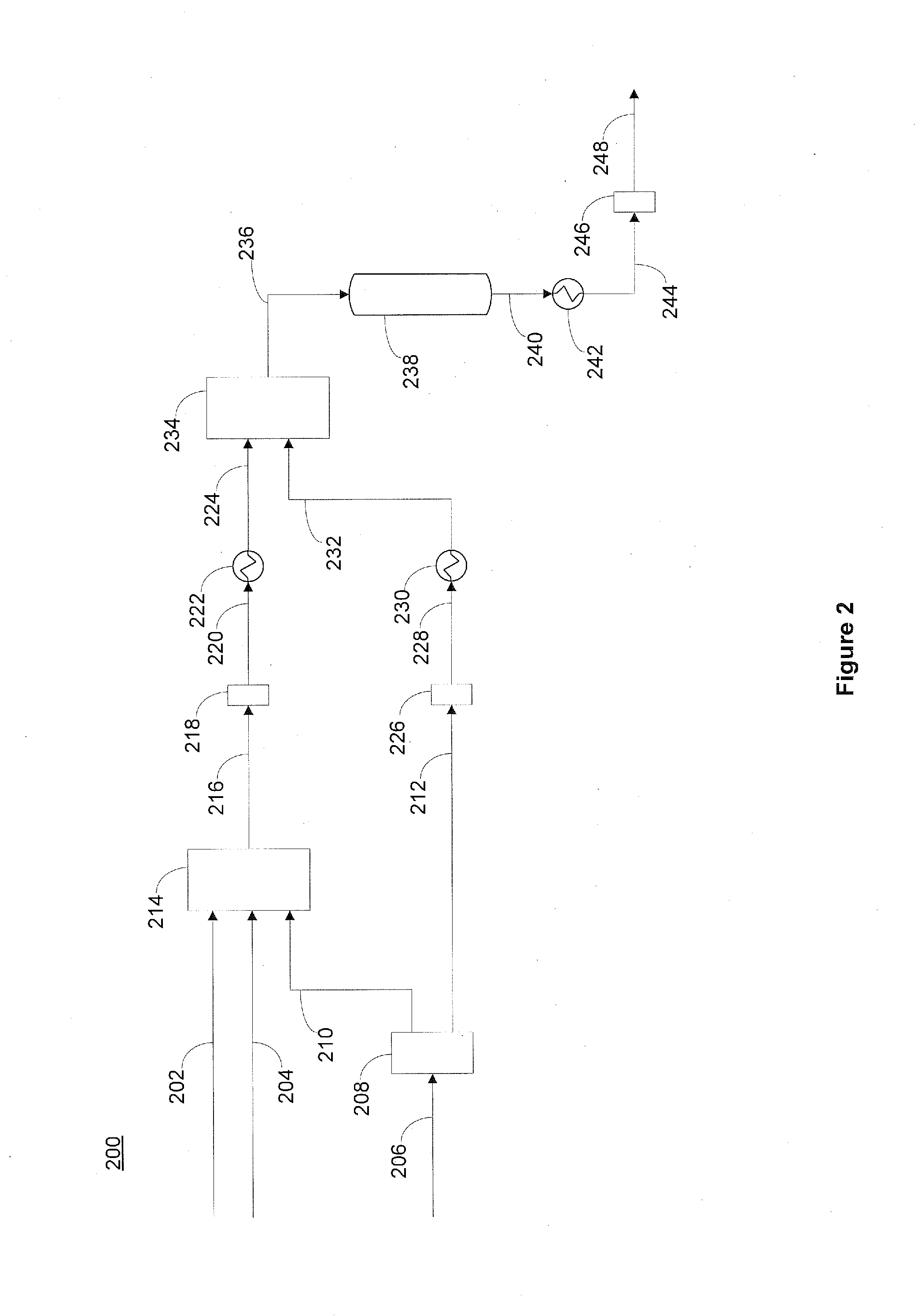

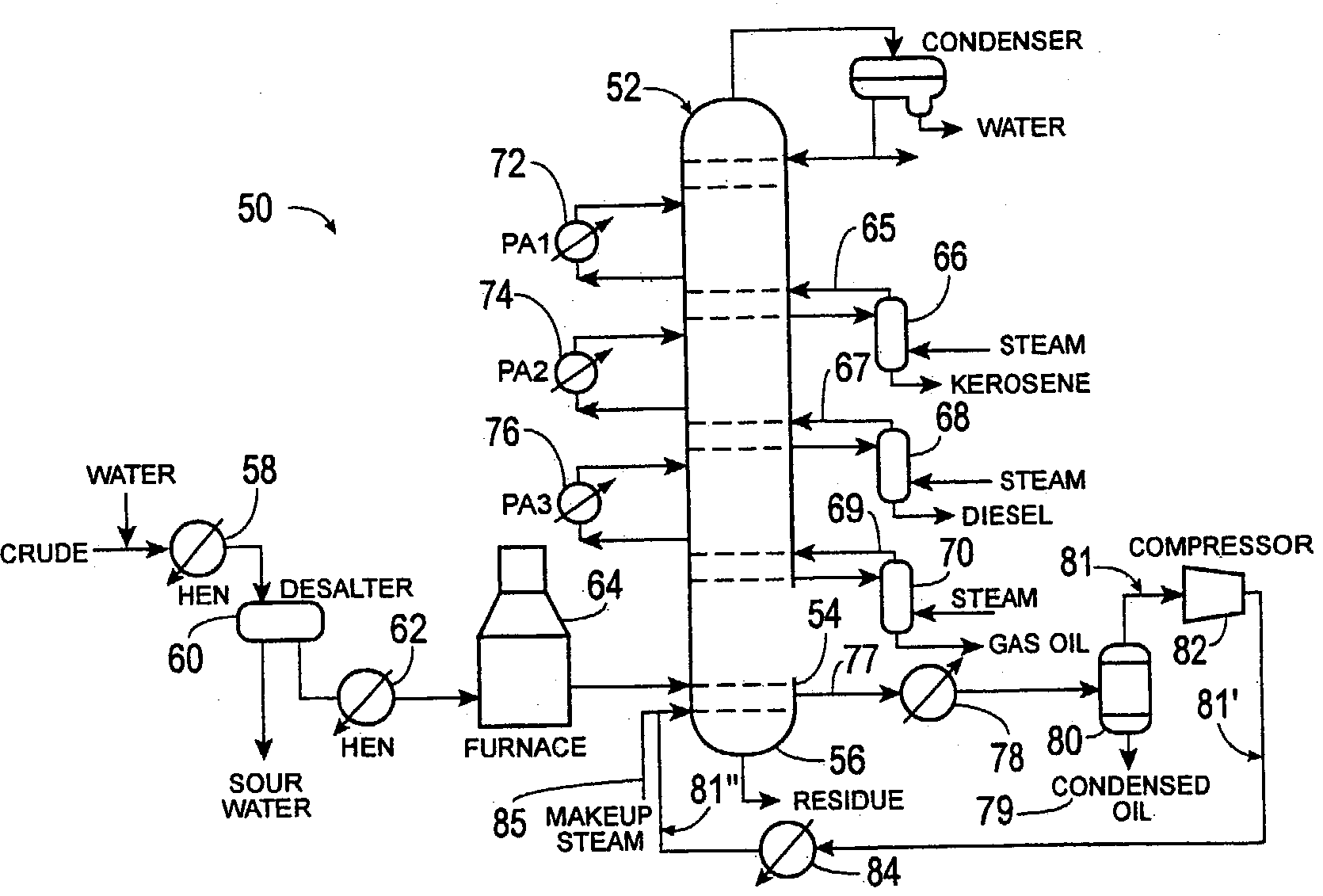

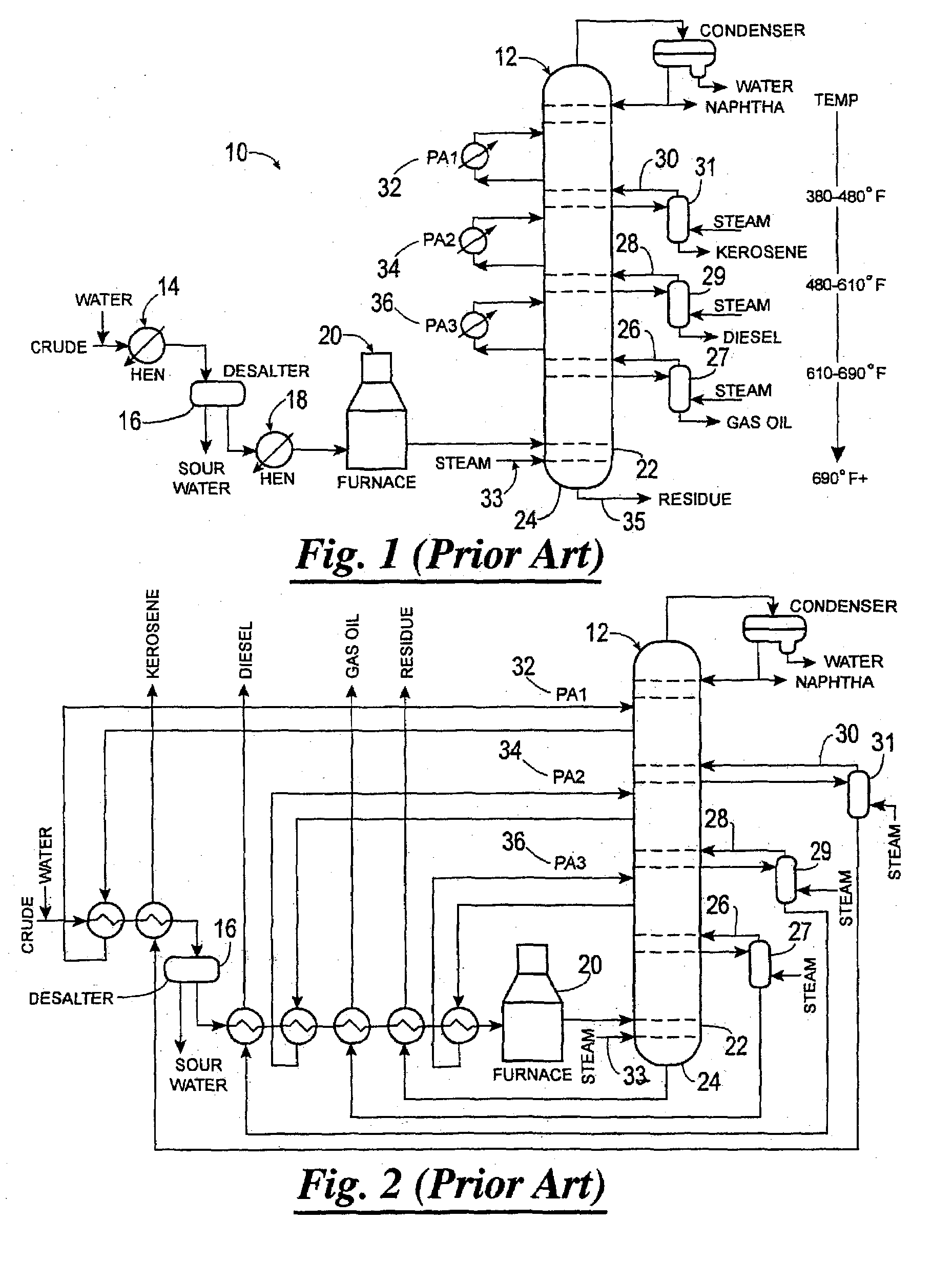

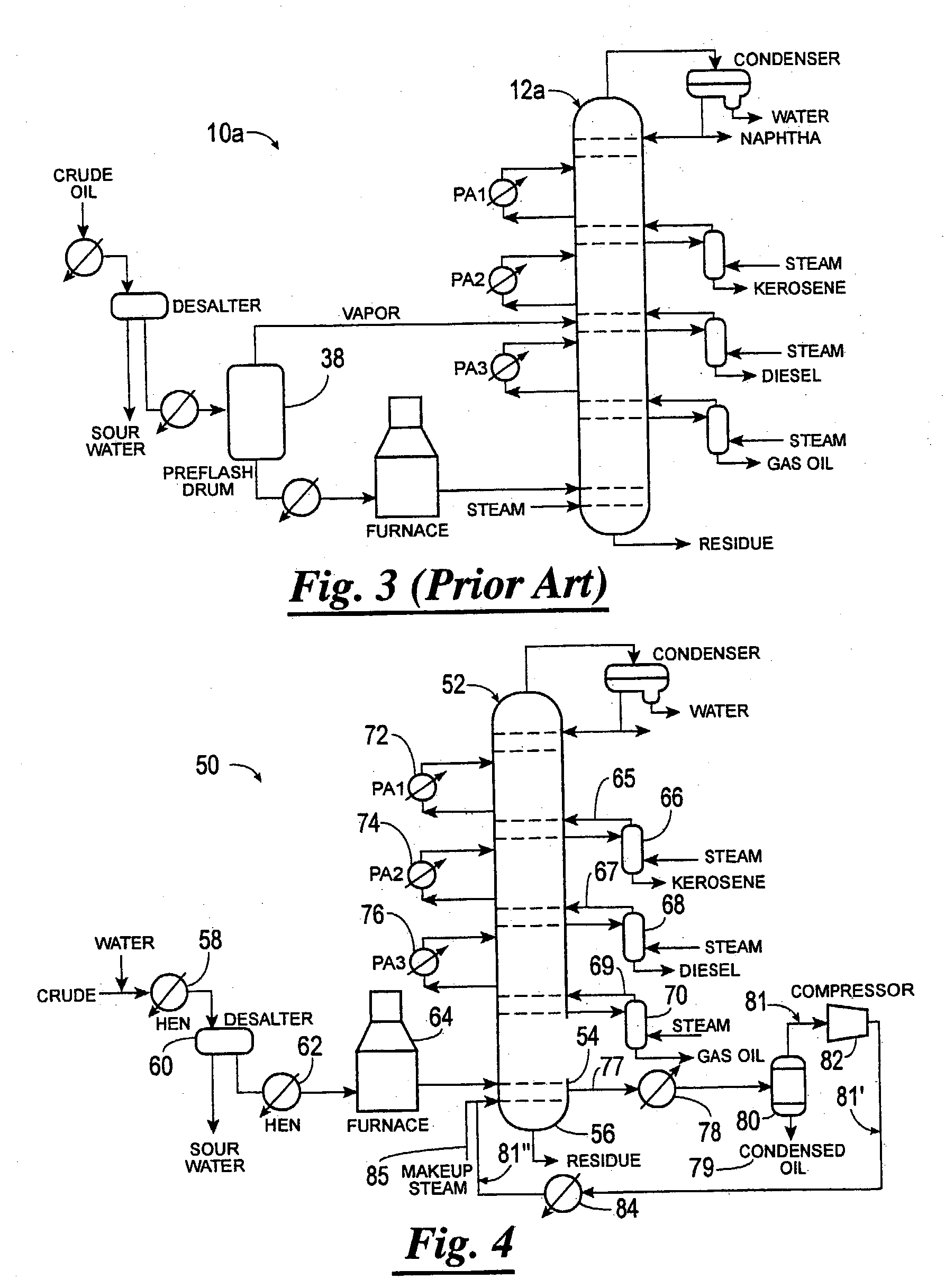

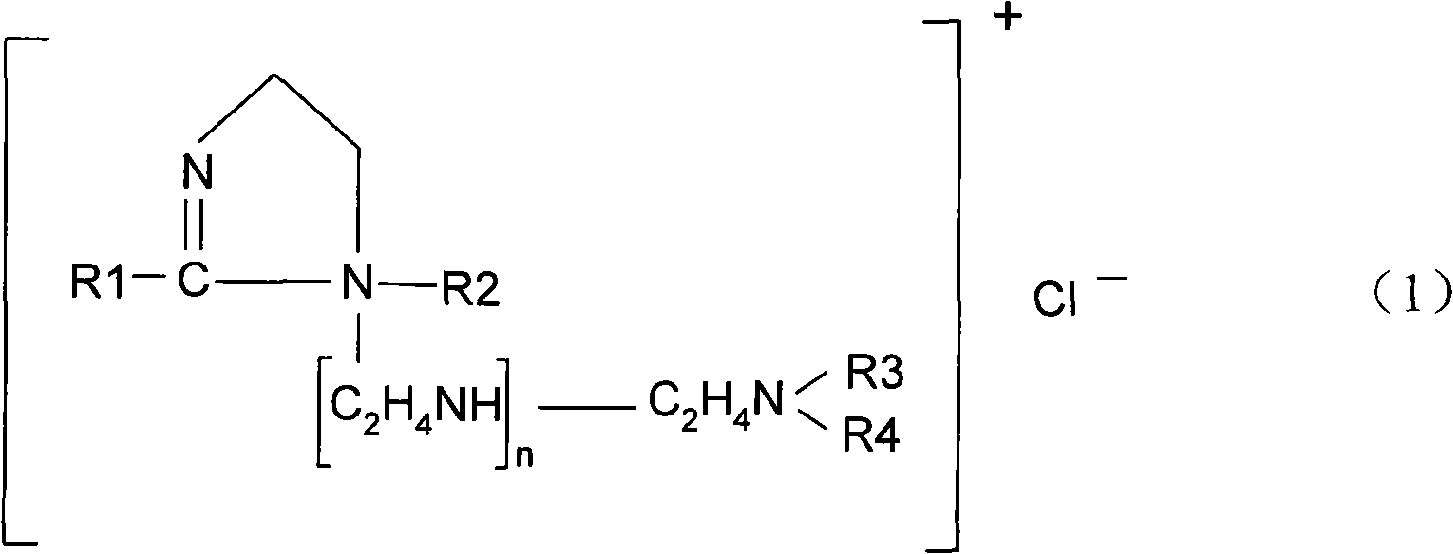

Method of increasing distillates yield in crude oil distillation

Methods of separating components of a mixture, such as crude oil, are disclosed which increase the yield of individual components while decreasing the yield of residue. In one method, a heated mixture is fed to a column, a vapor stream is withdrawn from the column and separated, and a portion of the vapor stream is recycled back to the column. In another method, a mixture is separated into streams composed substantially of components having light, intermediate or heavy molecular weight and / or low, intermediate or high boiling point, respectively, and the streams are fed into the column at different positions. In both methods, individual light, intermediate and / or heavy molecular weight and / or low, intermediate and / or high boiling point component streams are then selectively withdrawn from the column.

Owner:THE BOARD OF RGT UNIV OF OKLAHOMA

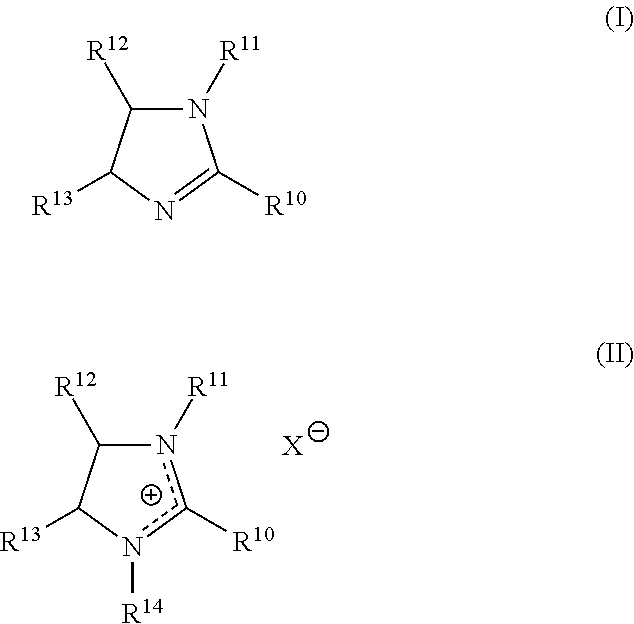

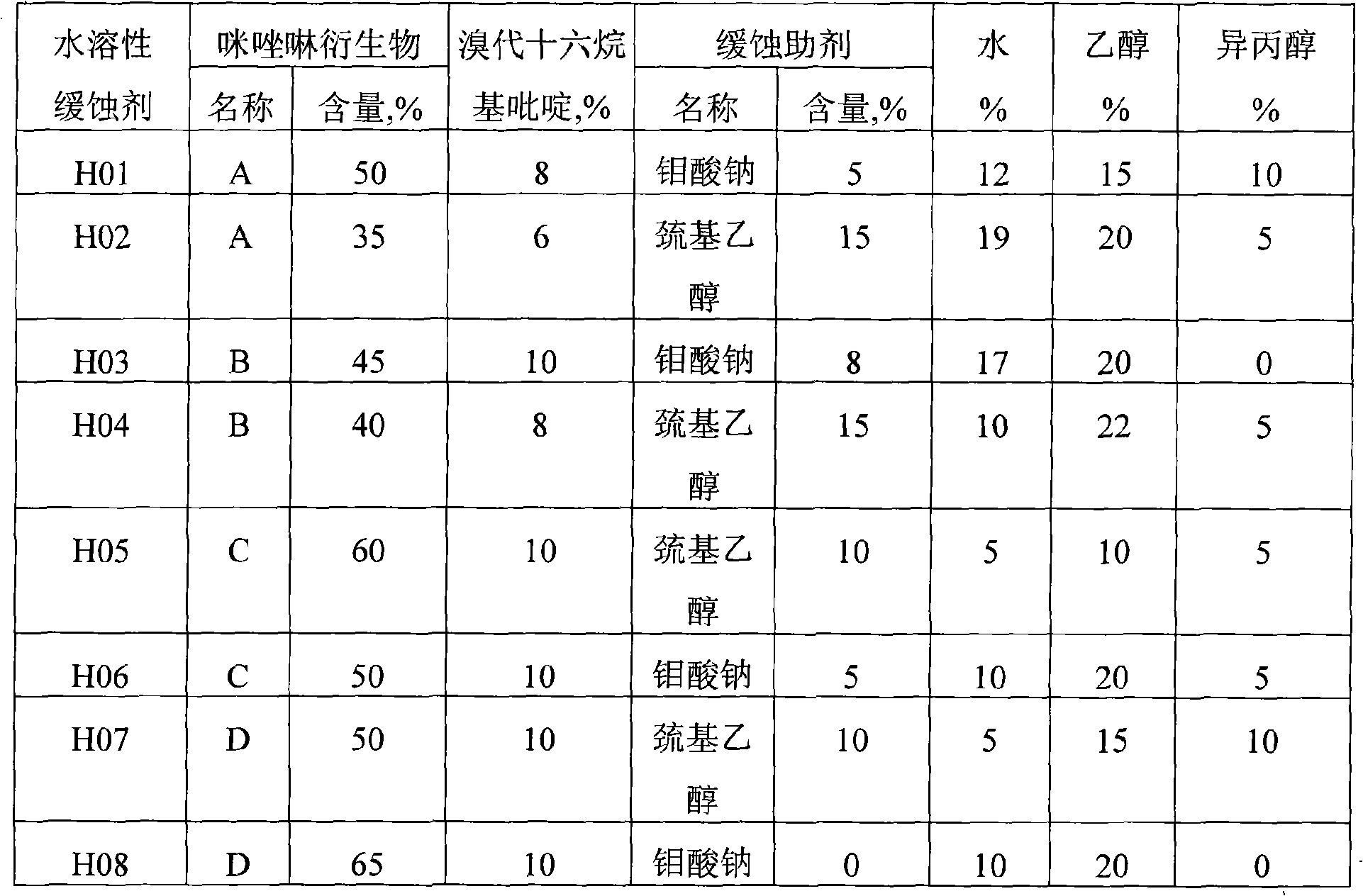

Water-soluble corrosion inhibitor, preparation and application thereof

InactiveCN101280222AHigh corrosion inhibition efficiencyGood chemical stabilityTreatment apparatus corrosion/fouling inhibitionWater solubleImidazoline derivatives

The invention discloses a water soluble corrosion inhibitor, the preparation method and the application of the corrosion inhibitor, solving the defect of narrow application range of the corrosion inhibitor pH in the prior art; the water soluble corrosion inhibitor is composed of 20-70 weight proportion of imidazolines derivates, 1-10 weight proportion of pyridine derivates, 1-20 weight proportion of corrosion inhibition auxiliary agent and 10-50 weight proportion of solvent, based on the total weight of the corrosion inhibitor as the reference. The water soluble corrosion inhibitor in the invention has corrosion inhibition effect on the metal material in the medium with wide PH variation range (pH equals to 1-10) and good metal surface film formation property.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

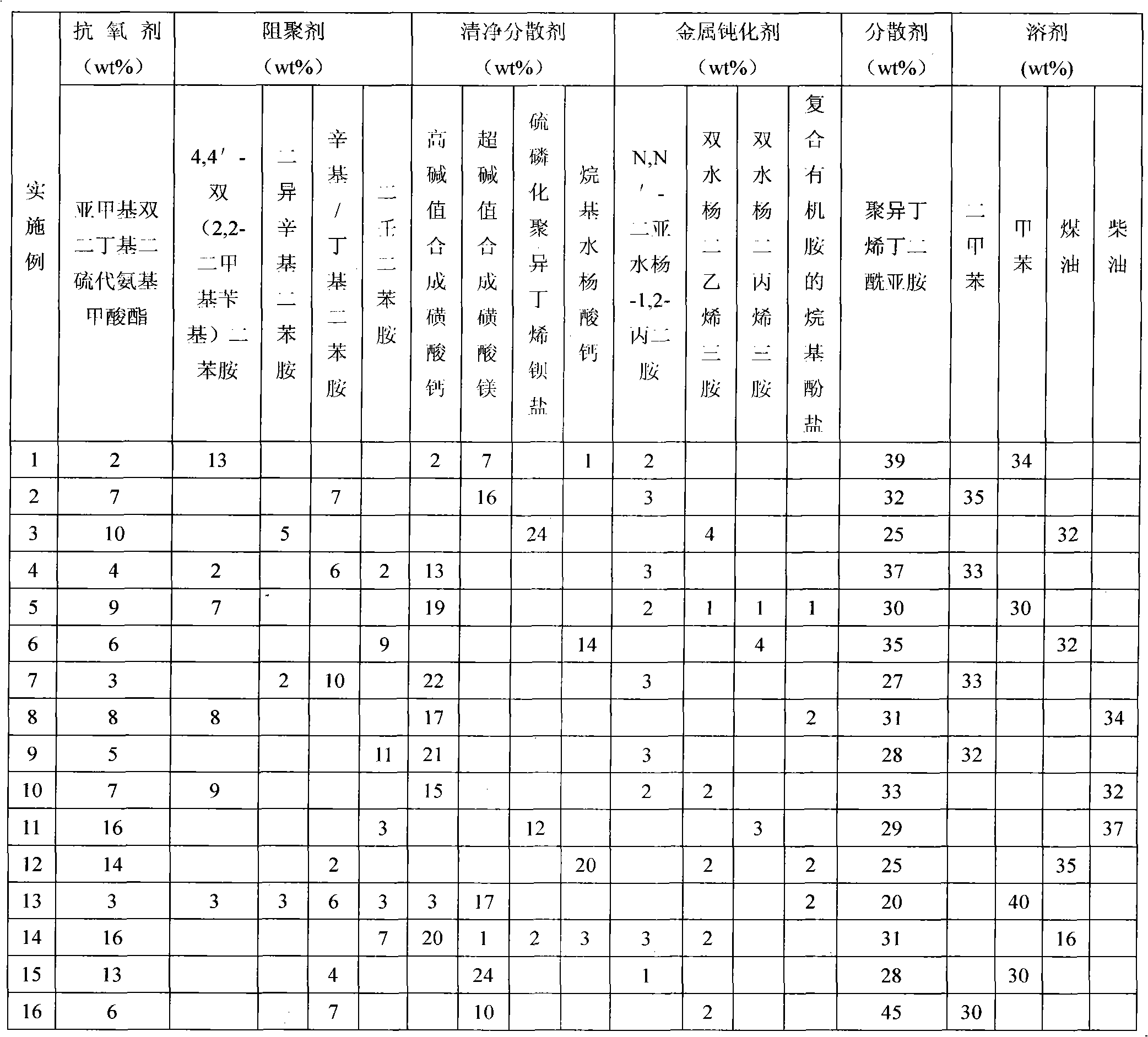

Butter inhibitor for ethylene unit alkaline washing tower

InactiveCN101838553ASuppress generationAntioxidantGaseous mixture working upTreatment apparatus corrosion/fouling inhibitionAnoxomerMaterials science

The invention relates to a butter inhibitor used for an ethylene unit alkaline washing tower. Problems of the background technology are solved, so the butter inhibitor has the performance of oxidation resistance, polymerization inhibition, cleanness, dispersion, metallic ion passivation and a better inhibition effect. The butter inhibitor is prepared from the following raw materials of: 1 to 30 percent of antioxidant, 5 to 40 percent of polymerization retarder, 2 to 30 percent of dispersant, 5 to 25 percent of metallic ion passivating agent and the balance of solvent; and the butter inhibitor is prepared by heating, uniformly mixing and cooling the materials.

Owner:浙江杭化科技股份有限公司

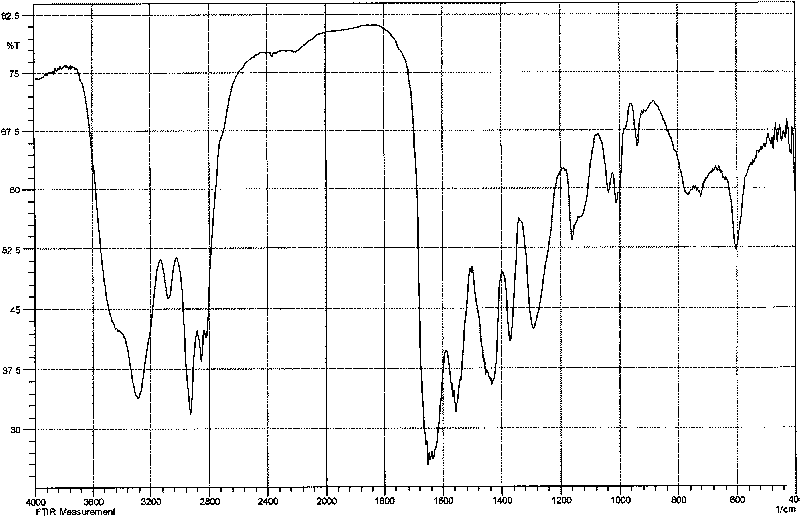

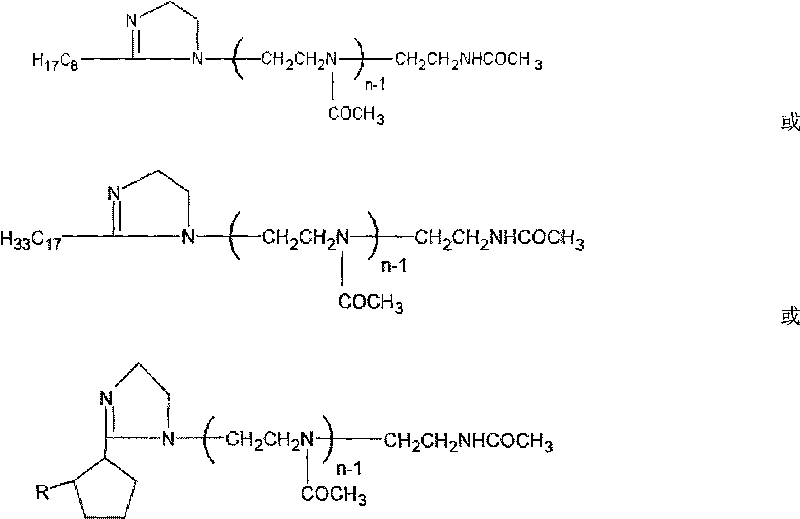

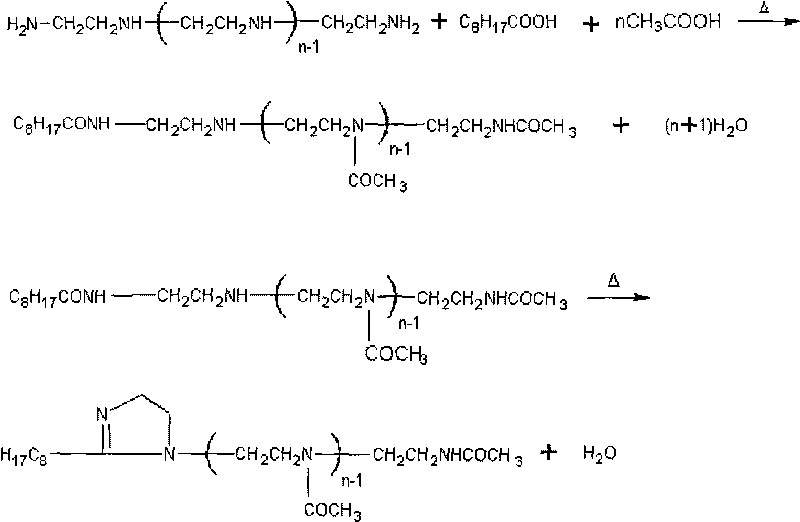

Water-soluble imidazoline amide corrosion inhibitor, preparation method thereof and using method thereof

InactiveCN101705112AEasy to useLow costOrganic chemistryTreatment apparatus corrosion/fouling inhibitionFatty acidRaw material

The invention provides a water-soluble imidazoline amide corrosion inhibitor, a preparation method thereof and a using method thereof, and belongs to the technical field of oil refining. The corrosion inhibitor consists of the following components in percentage by mass: 10 to 30 percent of water-soluble imidazoline amide, 0 to 15 percent of ethylene diamine, 0 to 20 percent of ammonia water with a mass concentration of 25 to 28 percent, 0 to 20 percent of ethanol and 40 to 90 percent of water, wherein the water-soluble imidazoline amide is prepared by the amidation reaction and the ring-closing reaction of polyethylene polyamines, glacial acetic acid and fatty acid serving as raw materials and toluene serving a solvent. When the corrosion inhibitor is continuously added to the top part of a primary distillation tower, the top part of a atmospheric distillation tower, the top part of a vacuum distillation tower or the top part of a hydrogenation fractional distillation tower of an oil refinery, the corrosion of a HCL-H2S-H2O medium on the top part of the tower is inhibited, and simultaneously, the quality of products on the top part of the tower is not affected. In the method for preparing the corrosion inhibitor, water is used as the solvent, so that the method has the advantages of being safely used, having low cost and facilitating the addition of a neutralizing agent.

Owner:SHENYANG POLYTECHNIC UNIV +1

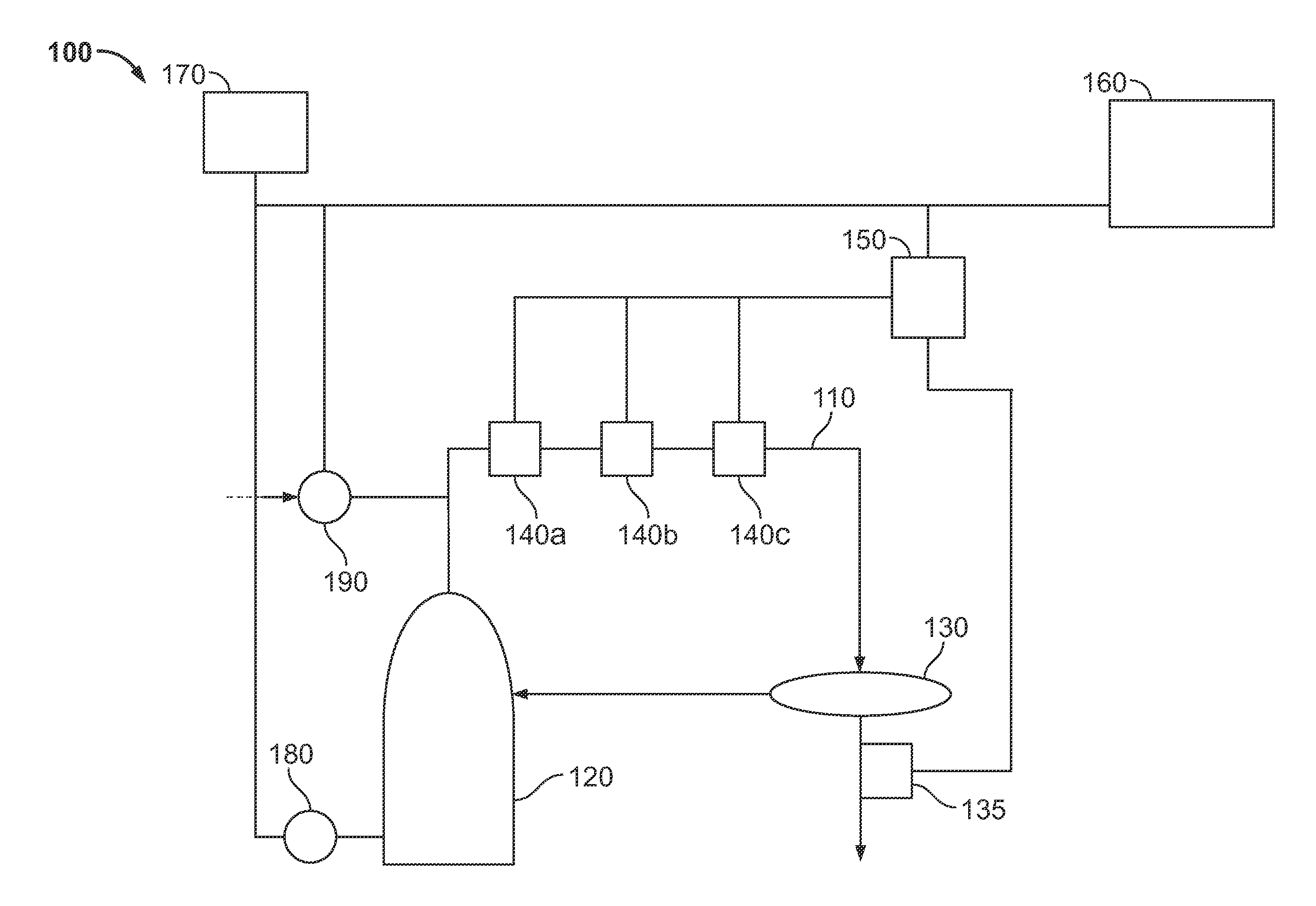

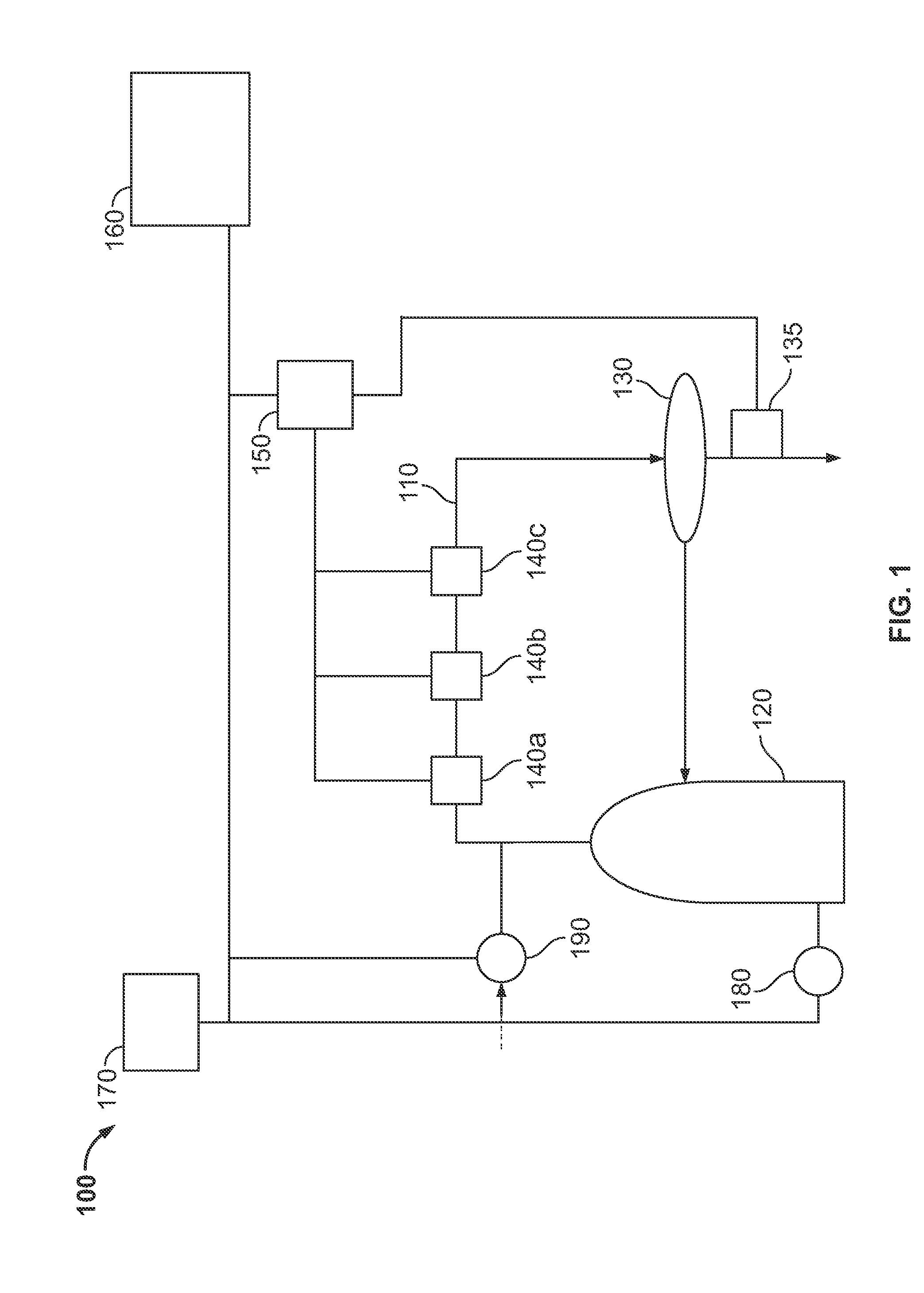

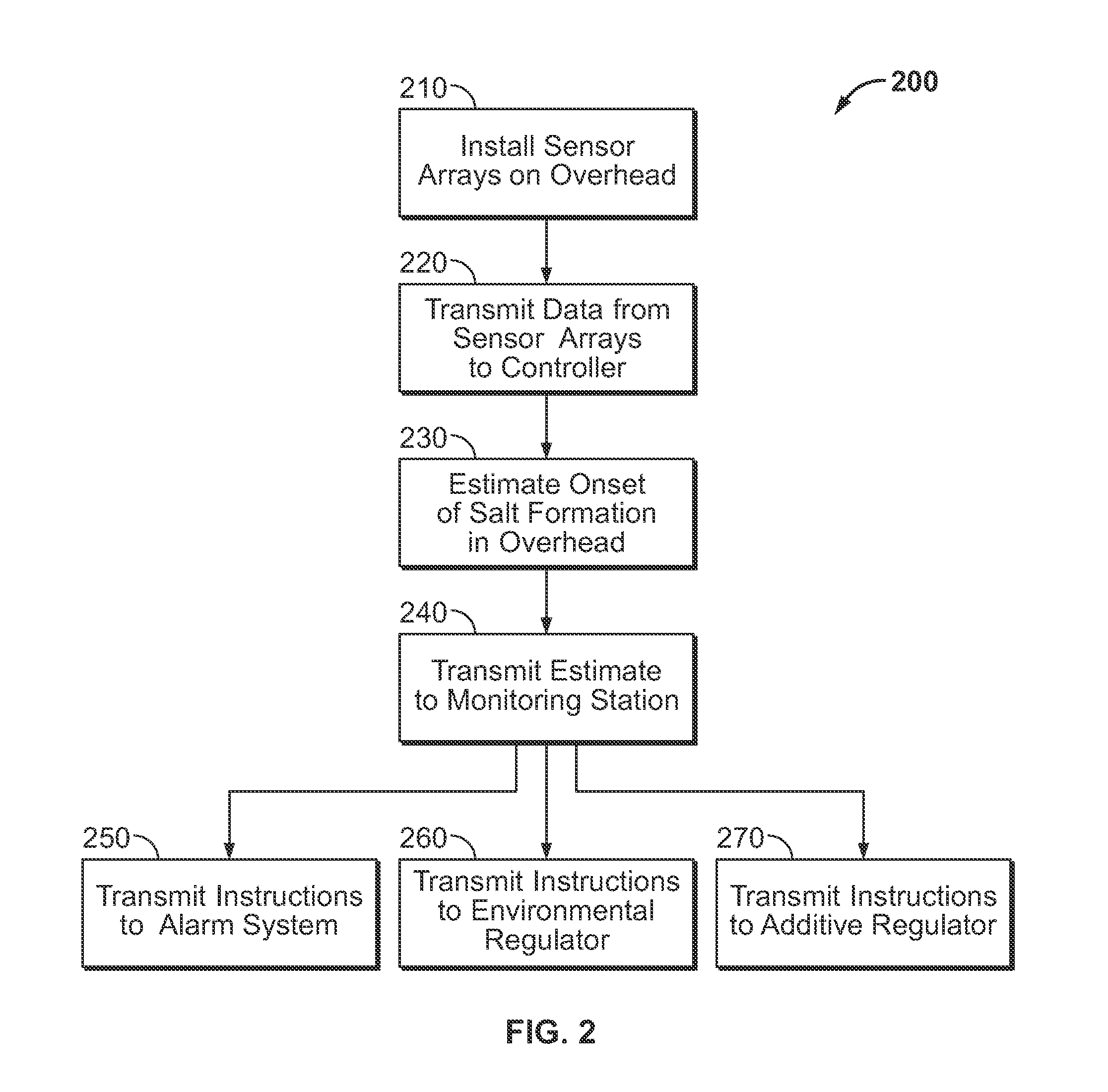

On-line monitoring and prediction of corrosion in overhead systems

InactiveUS20120053861A1Flow propertiesFluid pressure measurement by mechanical elementsSensor arrayDistillation

The present disclosure describes a method and system for estimating the onset of salt formation in an overhead fluid system. The method may include measuring parameters of a process stream by collecting data from one or more sensor arrays on an overhead line, such as from a distillation column, and then estimating the onset of salt formation corrosion using the data from the sensor arrays. The method may be implemented in real-time. The method may include transmitting data to monitoring facilities and / or sending instructions to alarms and / or regulators. Also described is a system for performing the method.

Owner:BAKER HUGHES INC

Method of dispersing hydrocarbon foulants in hydrocarbon processing fluids

ActiveUS20050263437A1Reducing overhead entrainmentLow vapor pressureThermal non-catalytic crackingLiquid carbonaceous fuelsOrganic solventTar

A method of dispersing, dissolving, or reducing the viscosity of hydrocarbon foulants including heavy oil, tars, asphaltenes, polynuclear aromatic hydrocarbons, coke, polymers, light oil, oxidized hydrocarbon and thermal decomposition products, and the like in fluids in contact with hydrocarbon processing equipment comprising contacting the foulant with an effective amount of a halogen-free organic solvent having a density greater than water at the processing temperature.

Owner:ECOLAB USA INC +1

Method for removing asphaltene deposits

InactiveUS20080020949A1Reduce and prevent formationPreventing and reducing precipitationWorking-up pitch/asphalt/bitumen by chemical meansFlushingKeroseneFuel oil

Compositions comprising at least one C4-C30 olefin or oxidation product thereof and kerosene or an aromatic solvent are particularly effective for use in removing asphaltene and asphaltene-containing organic deposits and in preventing or reducing the precipitation and deposition of asphaltenes from hydrocarbon fluids. When added to heavy oils comprising asphaltenes, alone or in combination with dispersants and further inhibitors, the invented compositions lower viscosity and pour point, and aid in preventing asphaltene precipitation during transport and in combustion.

Owner:INEOS USA LLC

Coking inhibitor and preparation method and application thereof

InactiveCN101037618AImprove performanceImprove hydrogen supply capacityTreatment apparatus corrosion/fouling inhibitionHydrocarbon mixturesBoiling point

The invention discloses a agglomerating inhibiting agent, preparing method and application thereof. The agglomerating inhibiting agent is selected from one or more hydrogenizating upgrading products of hydrocarbon mixture of coal oil, ethylene tar oil, catalytic crackingre cycle stock, catalytic crackingre slurry oil, catalytic crackingre heavy oil, catalytic crackingre extract oil and coking hydrowax, which contain 65-100 wt% of cyclane and arene, boilingpoint is 150 DEG C to 500 DEG C. The agglomerating inhibiting agent is used for preventing, slowing and removing agglomerating of apparatus and pipilines in process of petroleum refining and petrochemical processing.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

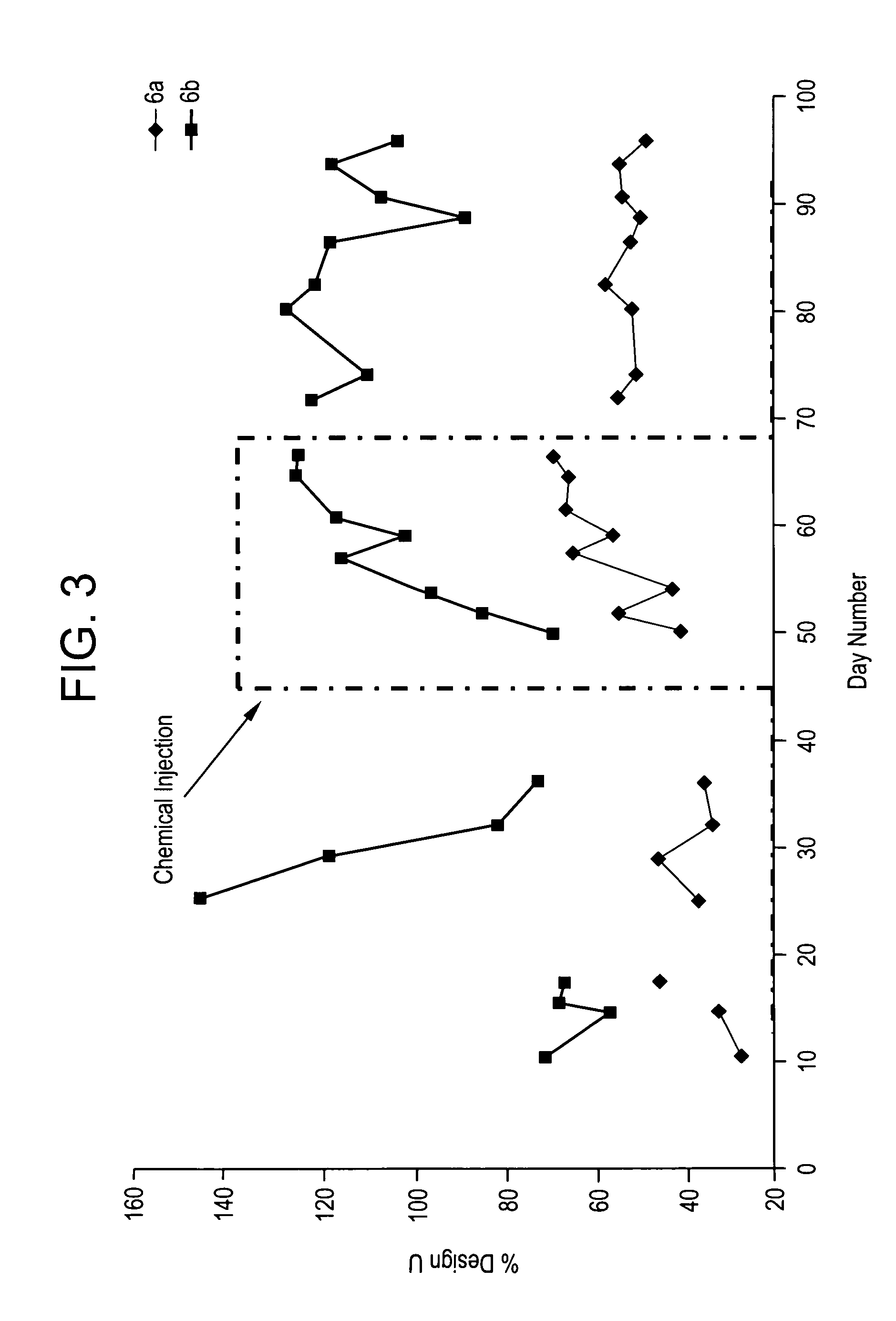

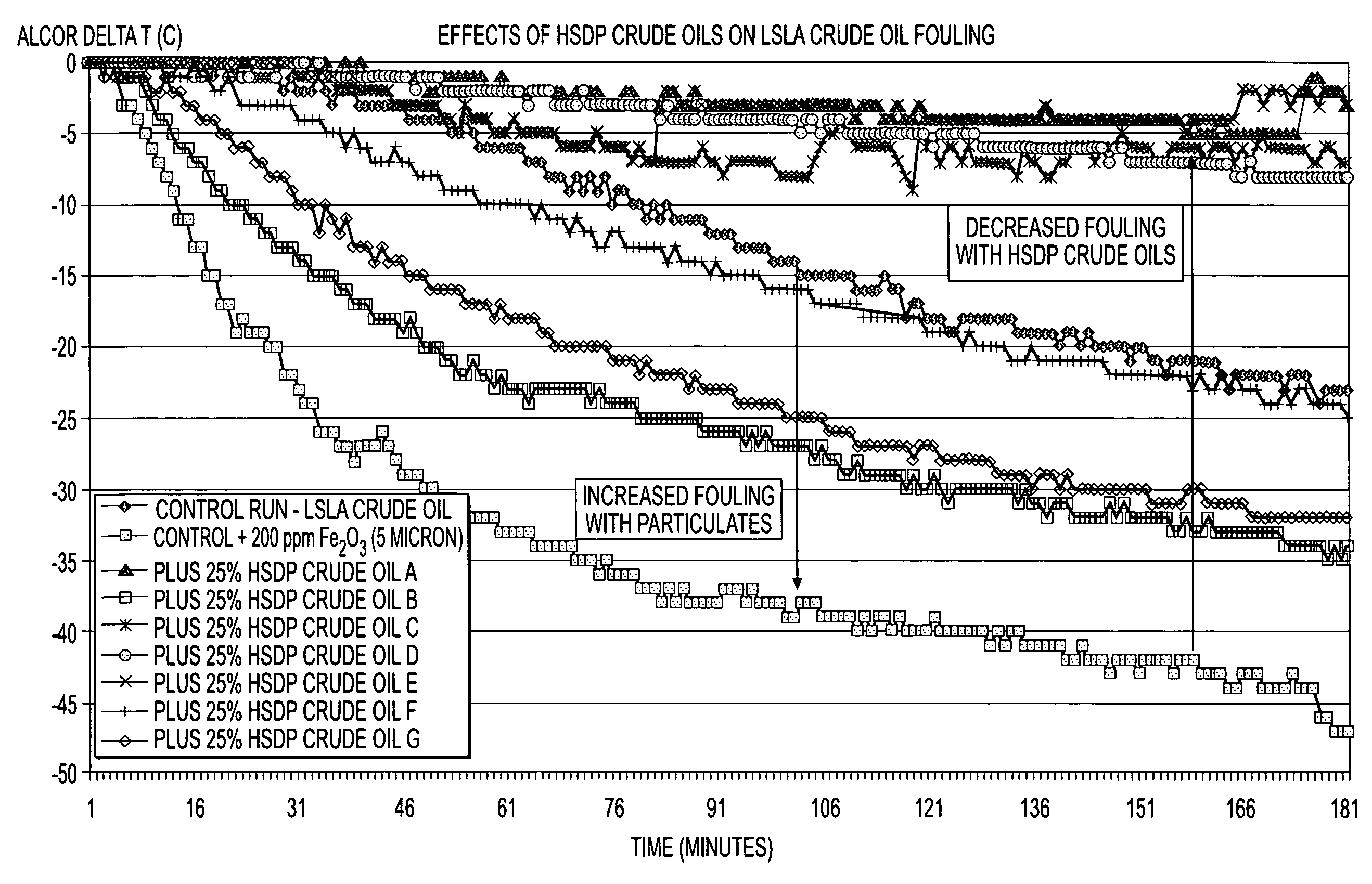

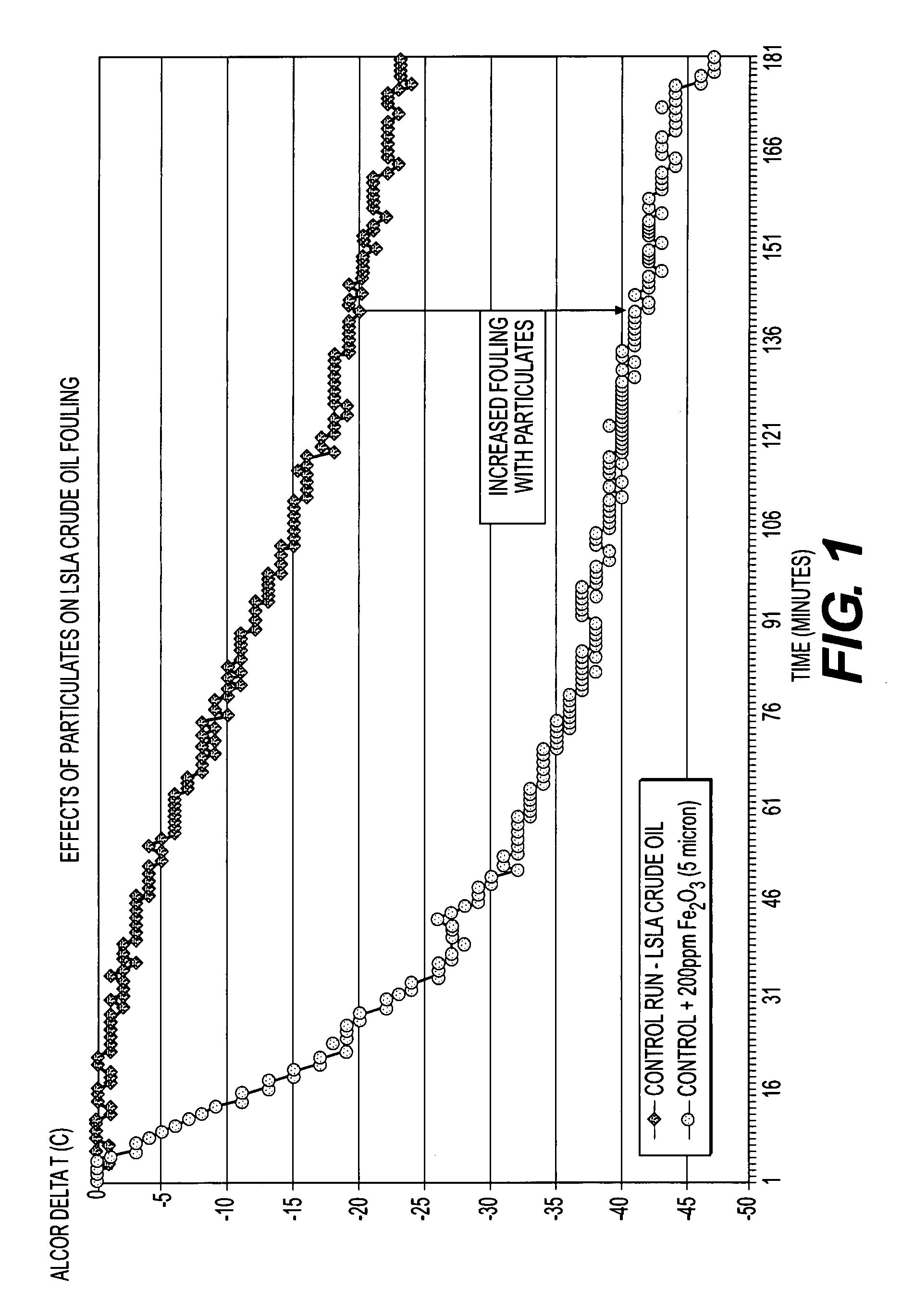

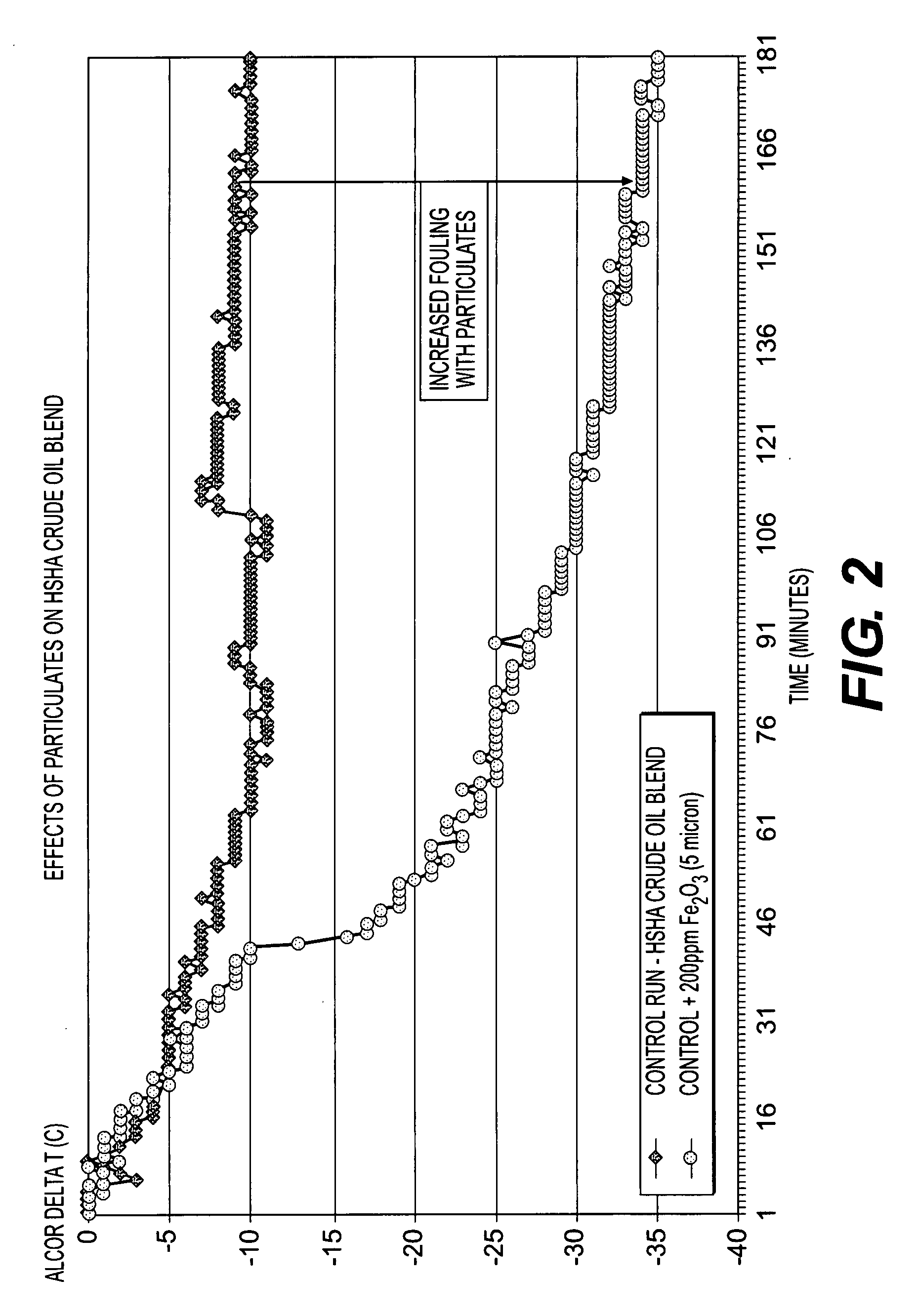

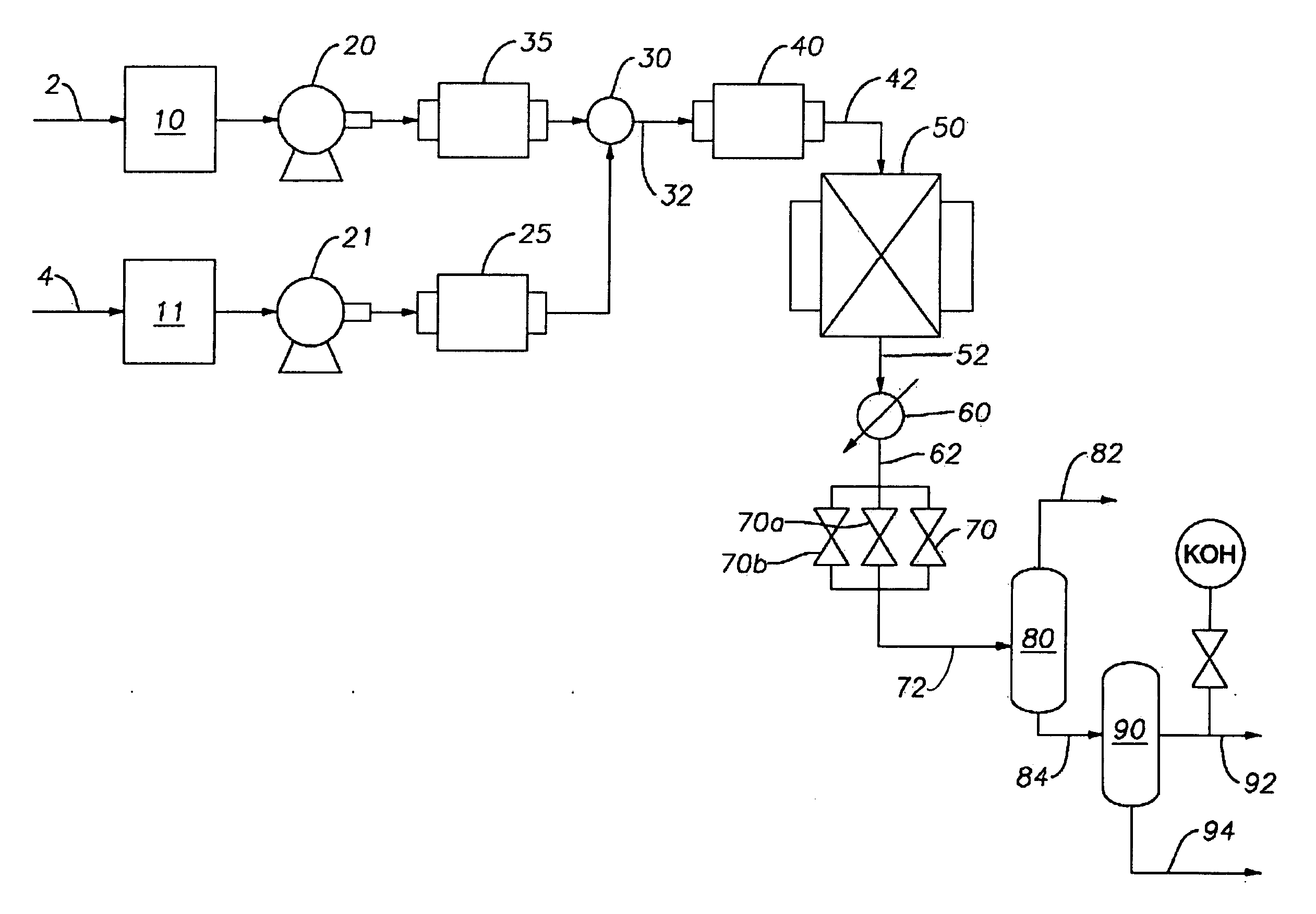

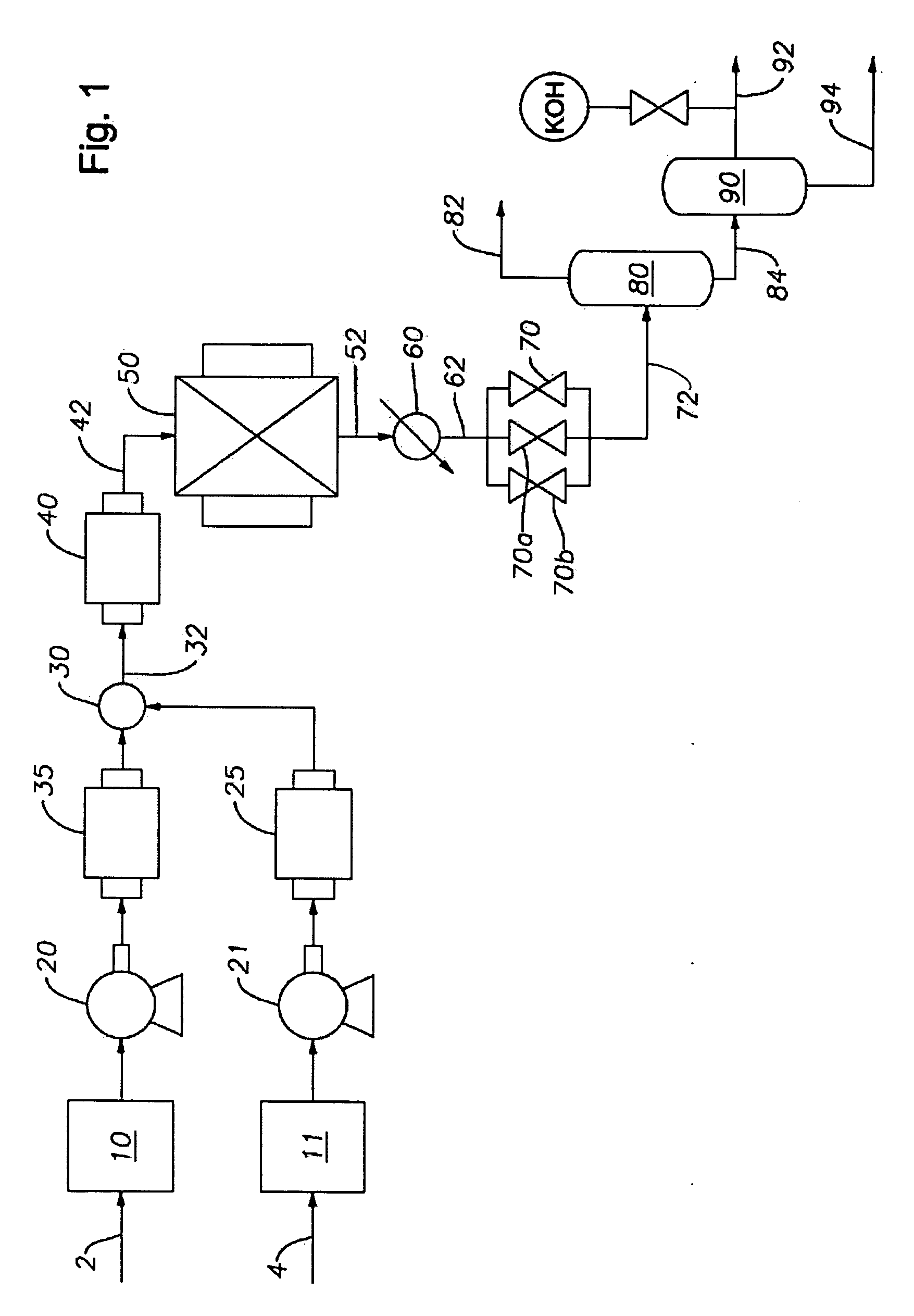

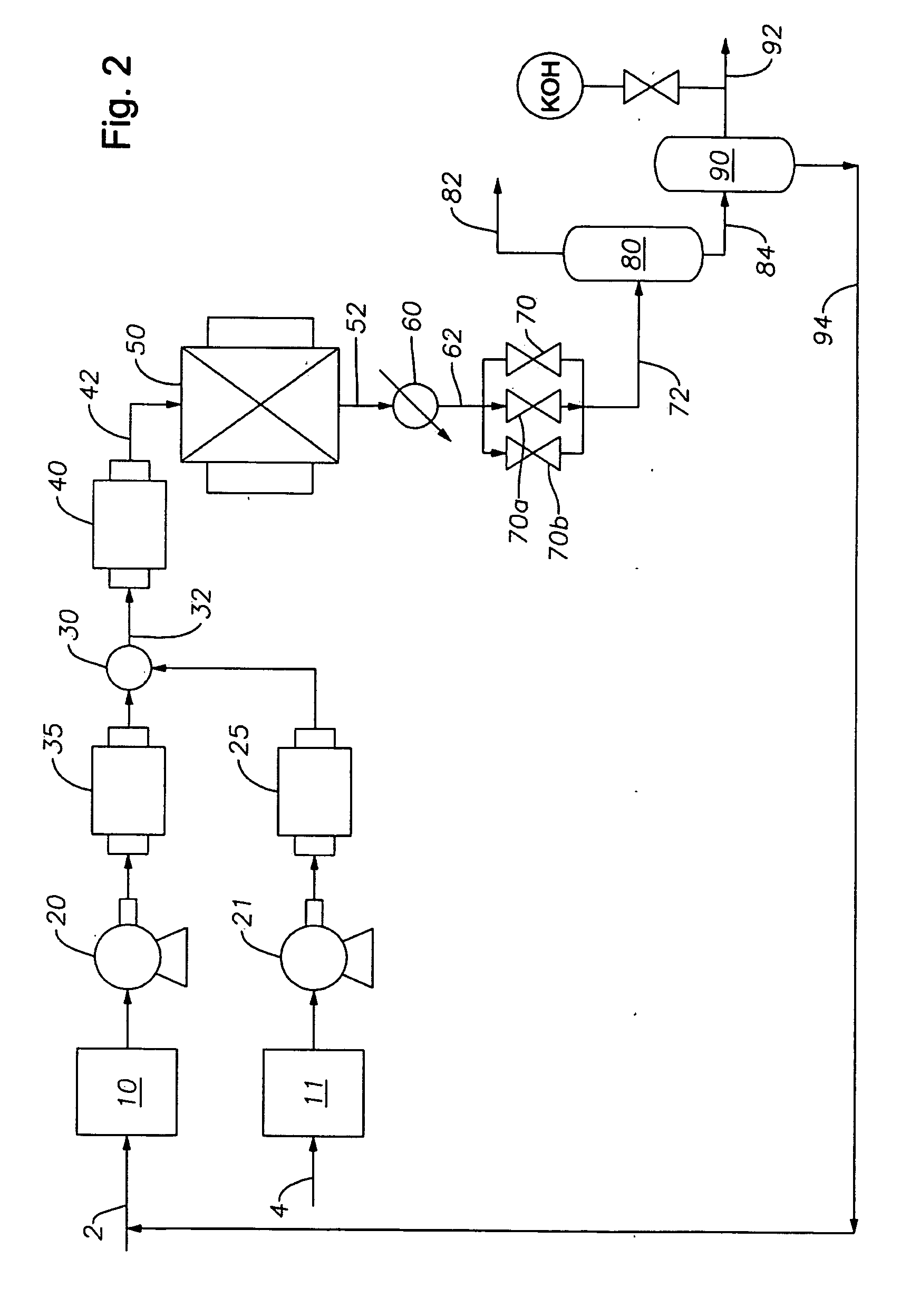

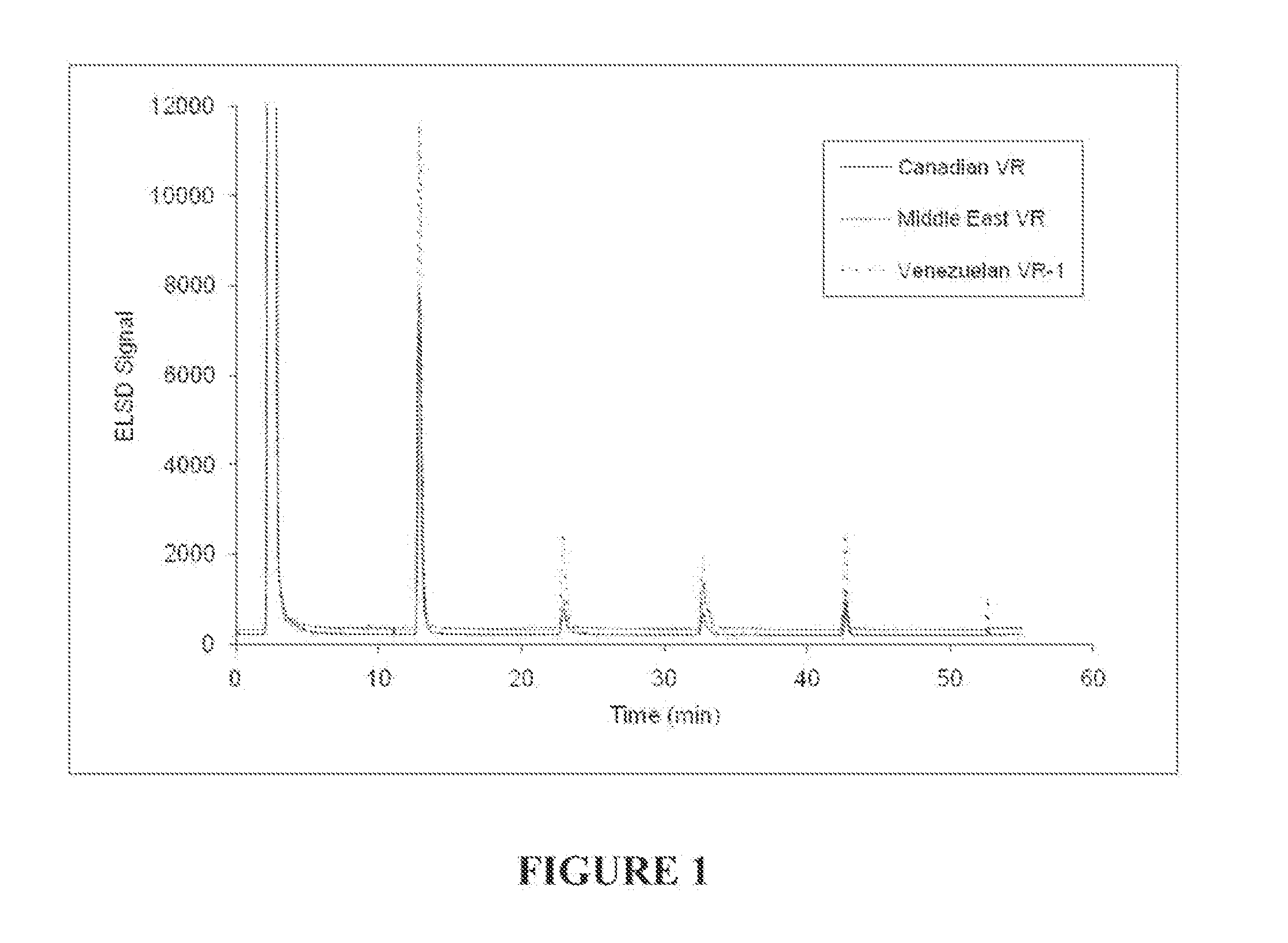

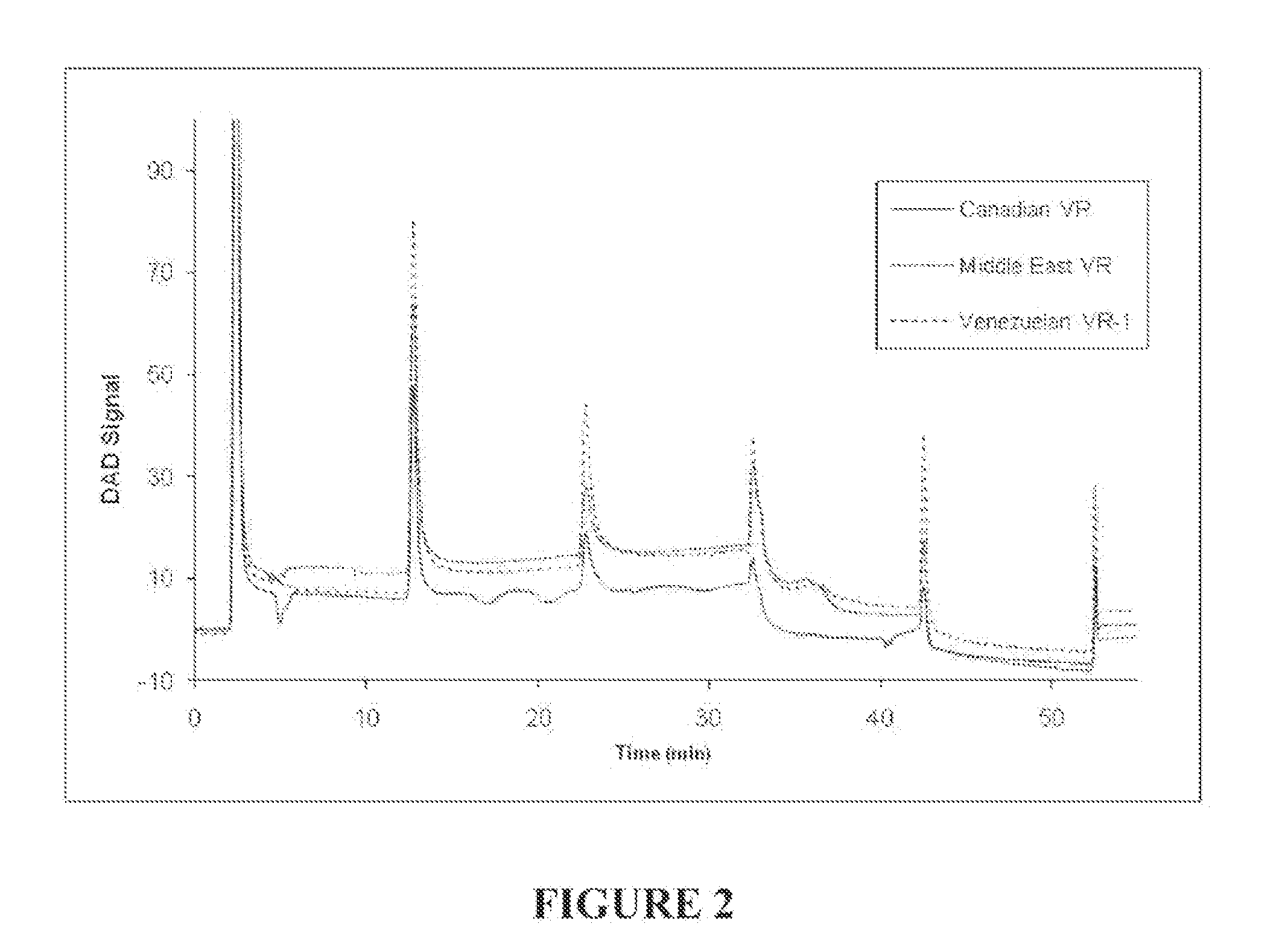

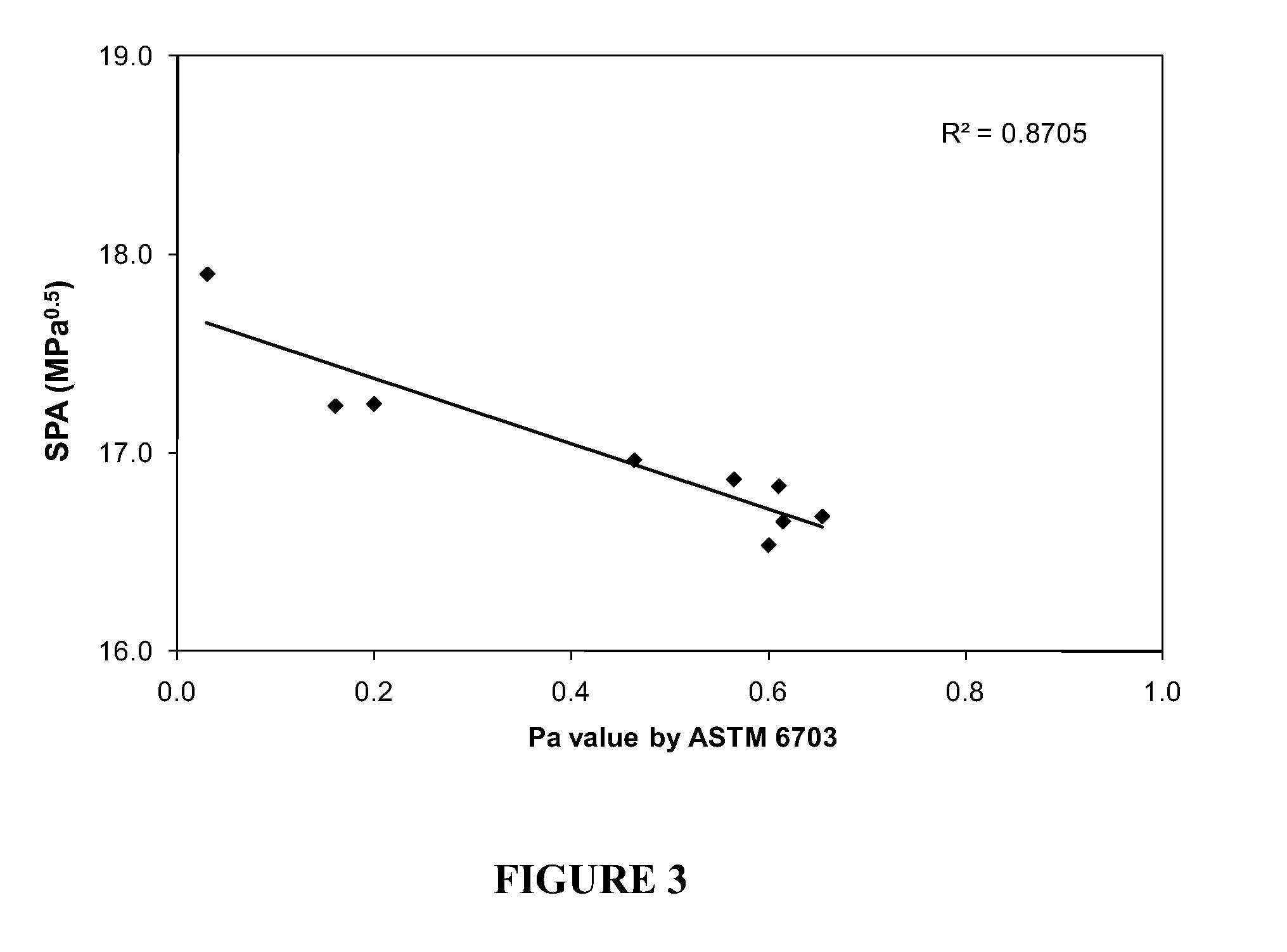

Method of blending high tan and high SBN crude oils and method of reducing particulate induced whole crude oil fouling and asphaltene induced whole crude oil fouling

InactiveUS20080041762A1Reduce dirtHigh molecular weightLiquid organic insulatorsLiquid carbonaceous fuelsParticulatesSediment

A high solvency dispersive power (HSDP) crude oil is added to a blend of incompatible oils to proactively address the potential for fouling heat exchange equipment. The HSDP component dissolves asphaltene precipitates and maintains suspension of inorganic particulates before coking affects heat exchange surfaces. An HSDP oil is also flushed through heat exchange equipment to remove any deposits and / or precipitates on a regular maintenance schedule before coking can affect heat exchange surfaces.

Owner:EXXON RES & ENG CO

Process to reduce acidity of crude oil

ActiveUS20090159504A1Reduce corrosionSimple methodThermal non-catalytic crackingRefining with metalsOrganic acidNaphthenic acid

Owner:SAUDI ARABIAN OIL CO

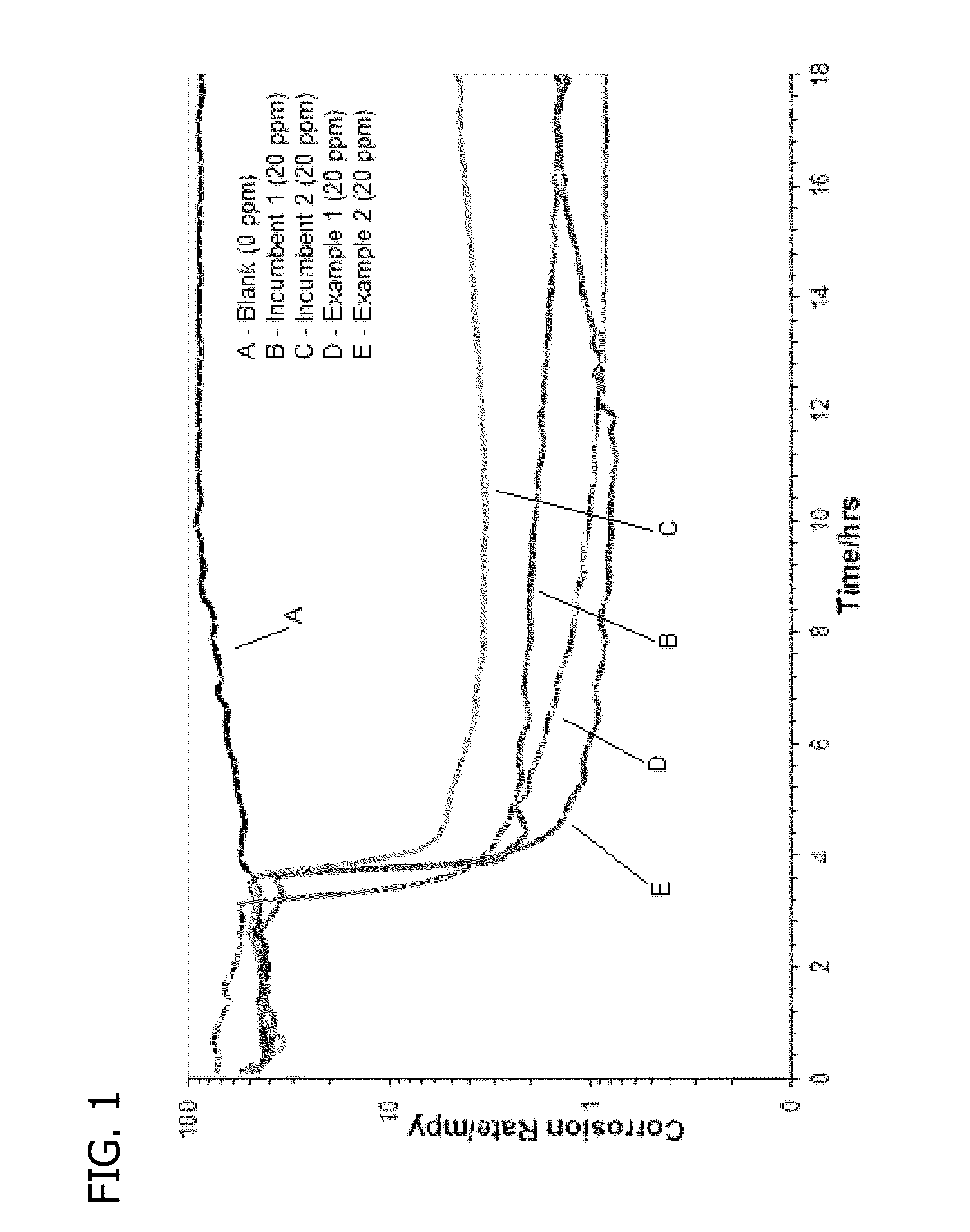

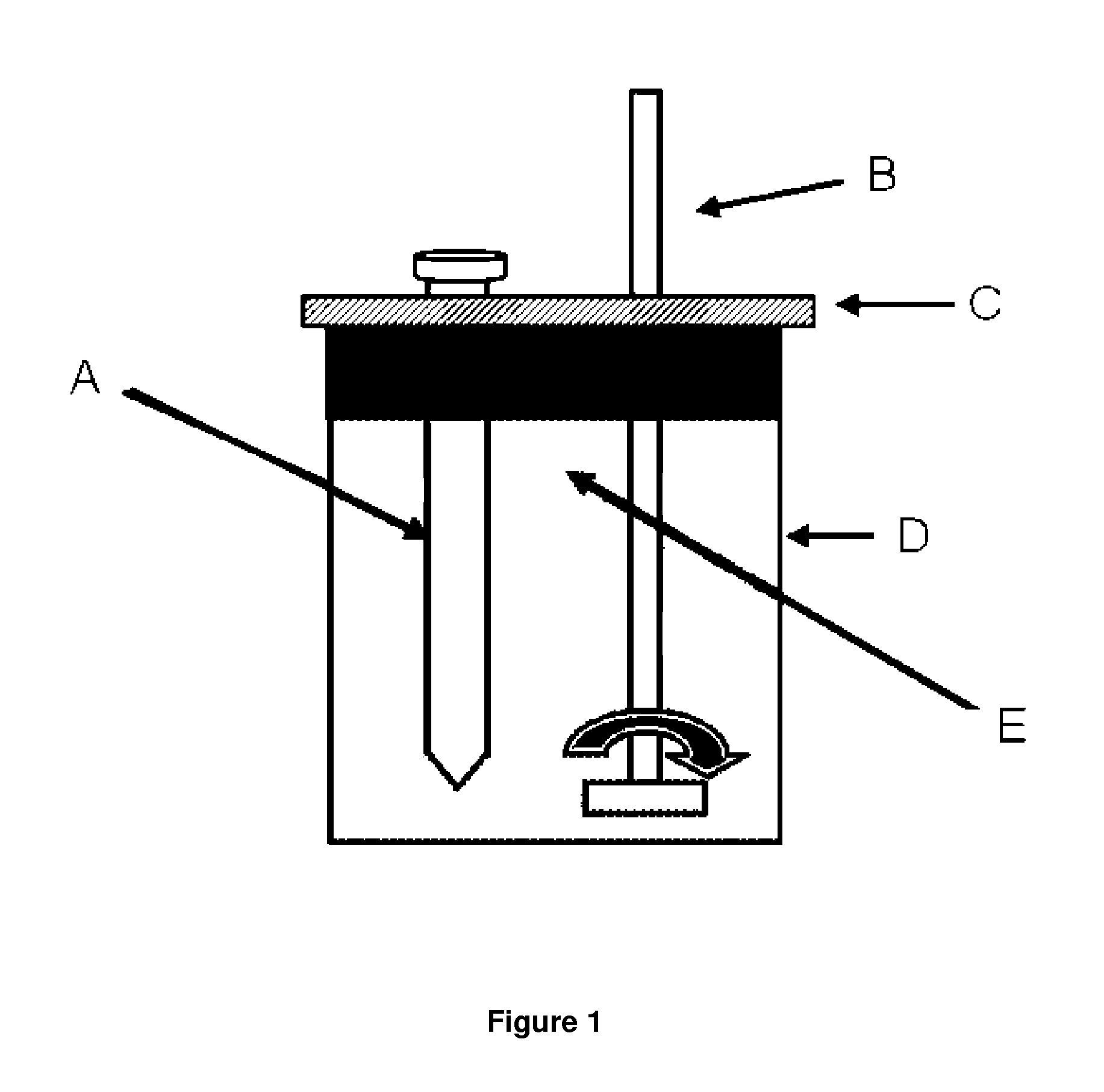

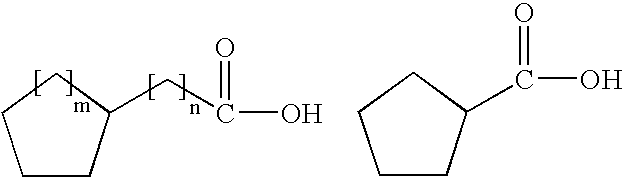

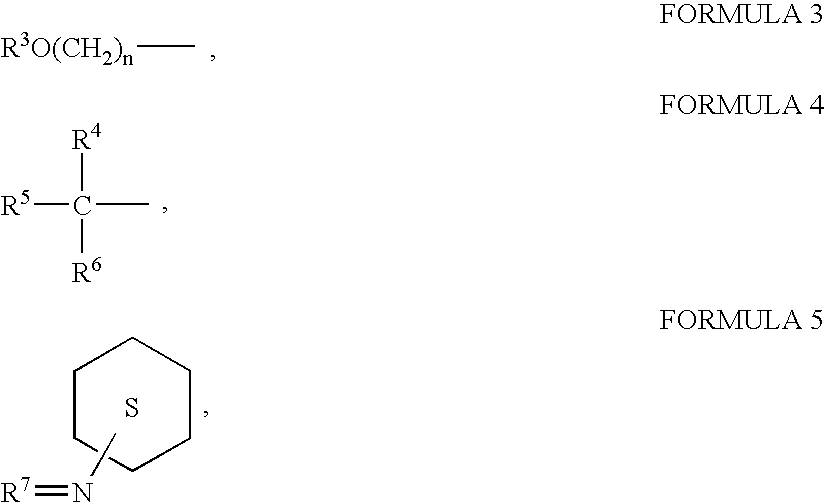

Gemini surfactants, process of manufacture and use as multifunctional corrosion inhibitors

ActiveUS20110138683A1Avoid corrosionOrganic detergent compounding agentsOrganic compound preparationArylPetrochemical

The disclosure relates to new surfactants of bis-N-alkyl polyether, bis-N-alkenyl polyether, bis-N-cycloalkyl polyether, bis-N-aryl polyether bis-beta or alpha-imino acids or their salts, process for obtaining and using mainly as multifunctional corrosion inhibitors, which protect and prevent corrosion of ferrous metals exposed to acidic, basic and neutral when transporting or storing crude oil and liquid fuels, or to the equipment and pipes used in cooling systems industry petroleum and petrochemical industries. Gemini surfactants have the structural formula:where:R1 is a radical represented by —H or —CH3,R2 is an alkyl or alkenyl chain, or cycloalkyl or aryl;R3 is a radical represented by —H, —CH3, —CH═CH—CH3, or —COOX;R4 is a radical represented by —H, —CH3, or —CH2—COOX;R5 is a radical represented by —H, an alkyl or alkenyl, cycloalkyl or aryl group, or a metal;R6 is a radical represented by an alkyl, alkenyl, cycloalkyl or aryl group;n and m can have values from 1 to 250, depending on the molecular weight of polyether used; andi can have values of 0 and 1:In the radical —COOX used in R3 and R4, X is represented by:—H, an alkyl, alkenyl group, a cycloalkyl or aryl group, or a metal.

Owner:INST MEXICANO DEL GASOLINEEO

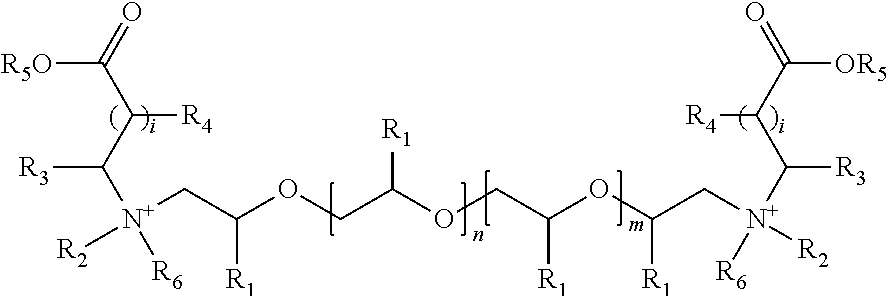

Method for predicting reactivity of a hydrocarbon-containing feedstock for hydroprocessing

InactiveUS20110066441A1Maximize residue conversionMaximize product yieldData processing applicationsComponent separationSolubilitySolvation

Disclosed herein is a method involving the steps of (a) precipitating an amount of asphaltenes from a liquid sample of a first hydrocarbon-containing feedstock having solvated asphaltenes therein with one or more first solvents in a column; (b) determining one or more solubility characteristics of the precipitated asphaltenes; (c) analyzing the one or more solubility characteristics of the precipitated asphaltenes; and (d) correlating a measurement of feedstock reactivity for the first hydrocarbon-containing feedstock sample with a mathematical parameter derived from the results of analyzing the one or more solubility characteristics of the precipitated asphaltenes.

Owner:CHEVROU USA INC

Oil slurry scale inhibitor

ActiveCN103351888AInhibition of polymerizationLow viscosityTreatment apparatus corrosion/fouling inhibitionAntioxidantSlurry

The invention provides oil slurry scale inhibitor which is used for inhibiting an oil slurry system from being coked, increasing steam yield of a steam generating system, and reducing the dismounting and cleaning frequency of an oil slurry heat exchanger, as well as a preparation method of the oil slurry scale inhibitor. The scale inhibitor mainly comprises a purification dispersant, an antioxidant, a polymerization inhibitor, an emulsifier, a surface active agent and a co-solvent. The scale inhibitor adopting the proportion can be used for reducing the oil slurry specific gravity, viscosity and external throwing amount, effectively inhibiting the devices including the oil slurry system, a pipeline, a heat exchanger and the like from being coked, and ensuring the safe and stable operation of the device. Meanwhile, the steam generating amount is increased and the yield of light oil is improved.

Owner:山东京博众诚清洁能源有限公司

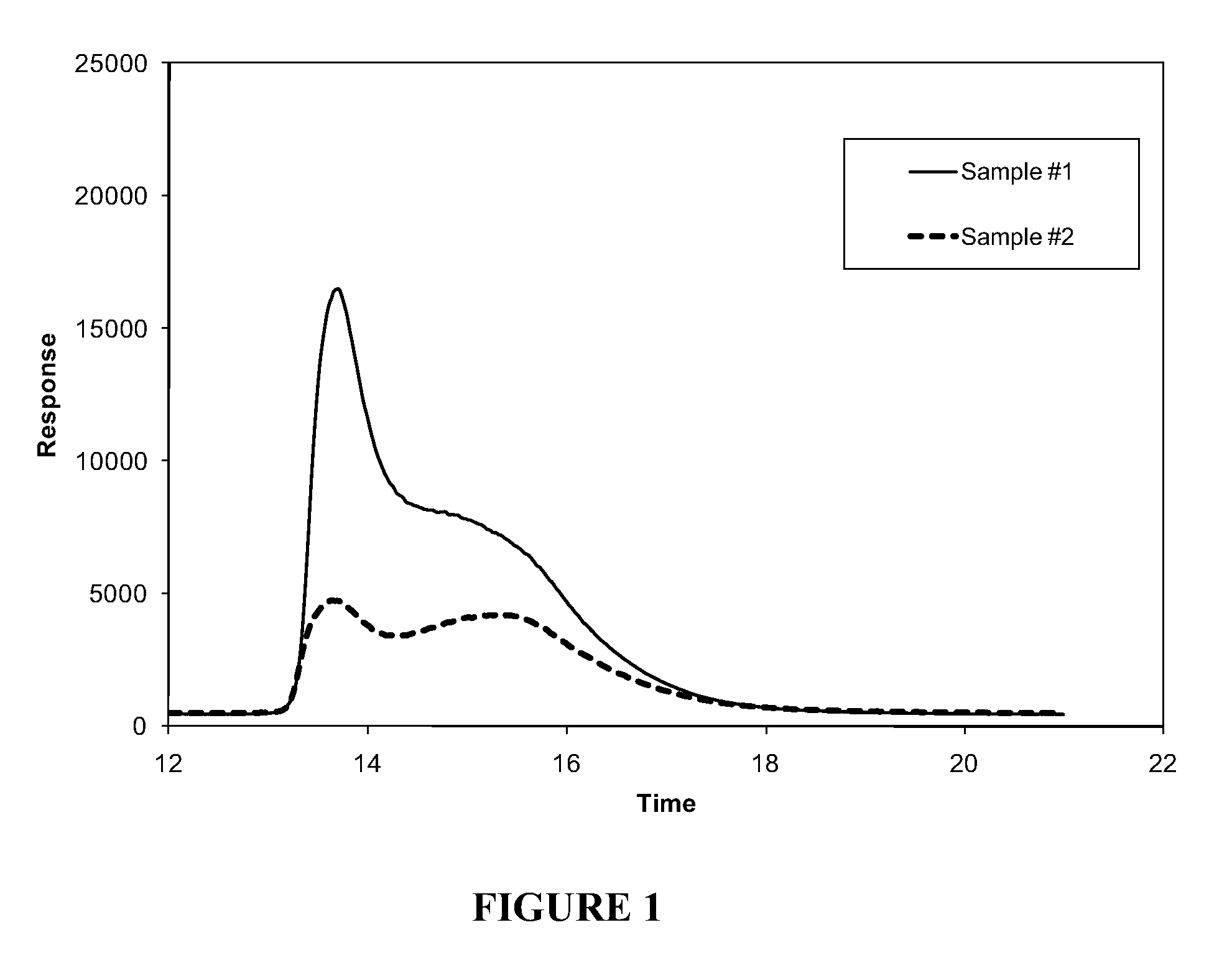

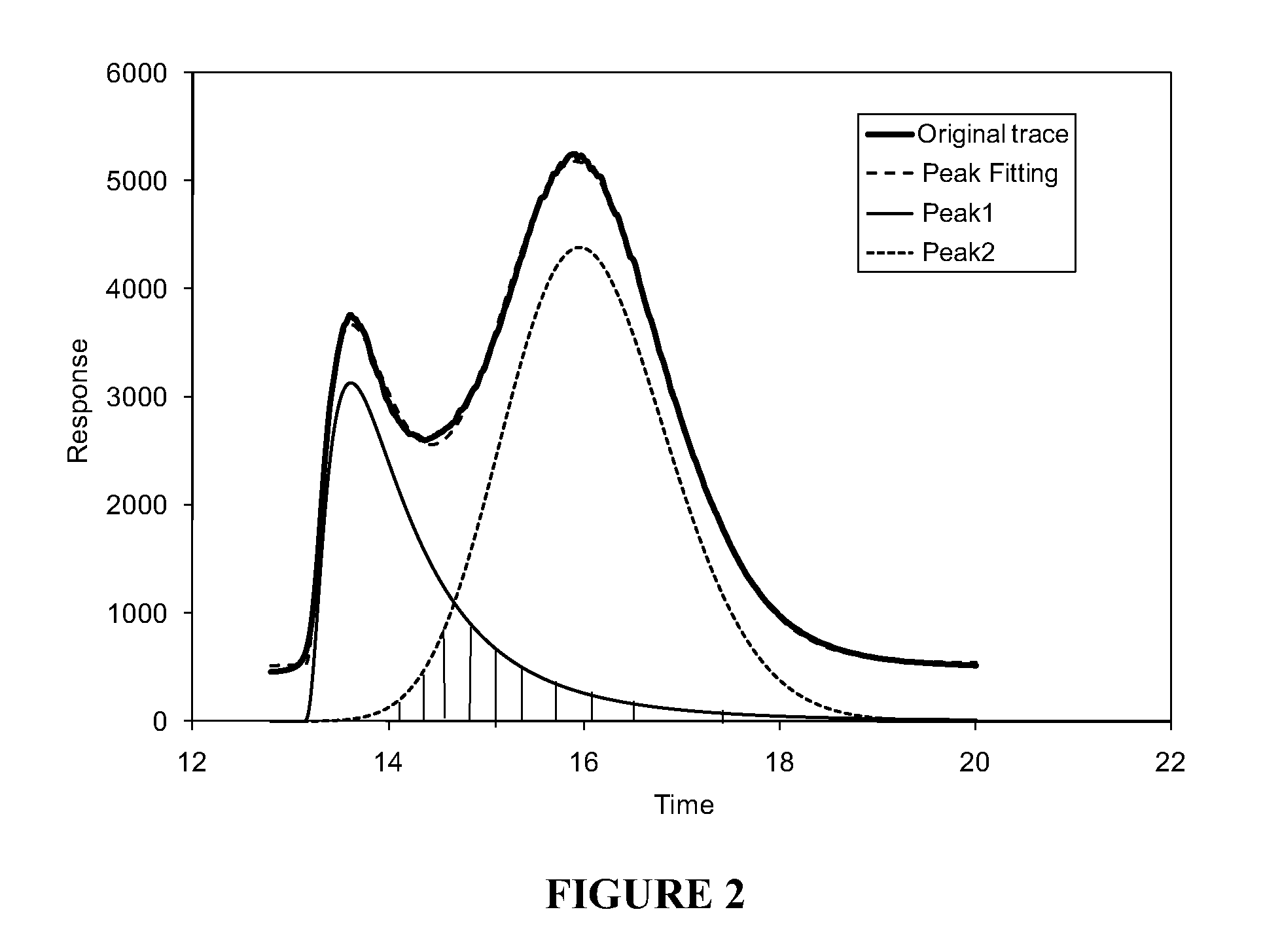

Method for determining asphaltene stability of a hydrocarbon-containing material

InactiveUS20110062058A1Low costWell representedThermal non-catalytic crackingData processing applicationsAlkaneSolubility

A method for determining asphaltene stability in a hydrocarbon-containing material having solvated asphaltenes therein is disclosed. The method involves the steps of: (a) precipitating an amount of the asphaltenes from a liquid sample of the hydrocarbon-containing material with an alkane mobile phase solvent in a column; (b) dissolving a first amount and a second amount of the precipitated asphaltenes by gradually and continuously changing the alkane mobile phase solvent to a final mobile phase solvent having a solubility parameter at least 1 MPa0.5 higher than the alkane mobile phase solvent; (c) monitoring the concentration of eluted fractions from the column; (d) creating a solubility profile of the dissolved asphaltenes in the hydrocarbon-containing material; and (e) determining one or more asphaltene stability parameters of the hydrocarbon-containing material.

Owner:CHEVROU USA INC

Corrosion inhibitor

InactiveUS20070119747A1Avoid corrosionInhibiting naphthenic acid corrosionDistillation corrosion inhibitionOther chemical processesSulfur hydrideCorrosion inhibitor

A composition and method of inhibiting corrosion caused by naphthenic acid in fluids includes using a combination of a thiophosphorus compound and a hydrogen sulfide scavenging compound. The hydrogen sulfide scavenging compound significantly enhances the performance of the thiophosphorus compound and may be included at relatively low levels in the composition. The treatment may be applied to fluids including crude oils and lighter fractions thereof.

Owner:BAKER HUGHES INC

Corrosion inhibitor compositions for oxygenated gasolines

ActiveUS20130227878A1Good storage stabilityReduce corrosionLiquid carbonaceous fuelsFuel additivesCarbon numberAlcohol

This invention relates to corrosion inhibitor additive combinations giving long acting performance in oxygenated gasoline blends comprising either low carbon number (<3) or high carbon number (greater than or equal to 4) alcohols or mixtures thereof and adapted for use in fuel delivery systems and internal combustion engines. The invention also is concerned with a process for conferring anti-corrosion properties to oxygenates in gasoline fuel mixtures wherein the oxygenate comprises biologically-derived butanol.

Owner:GEVO INC +1

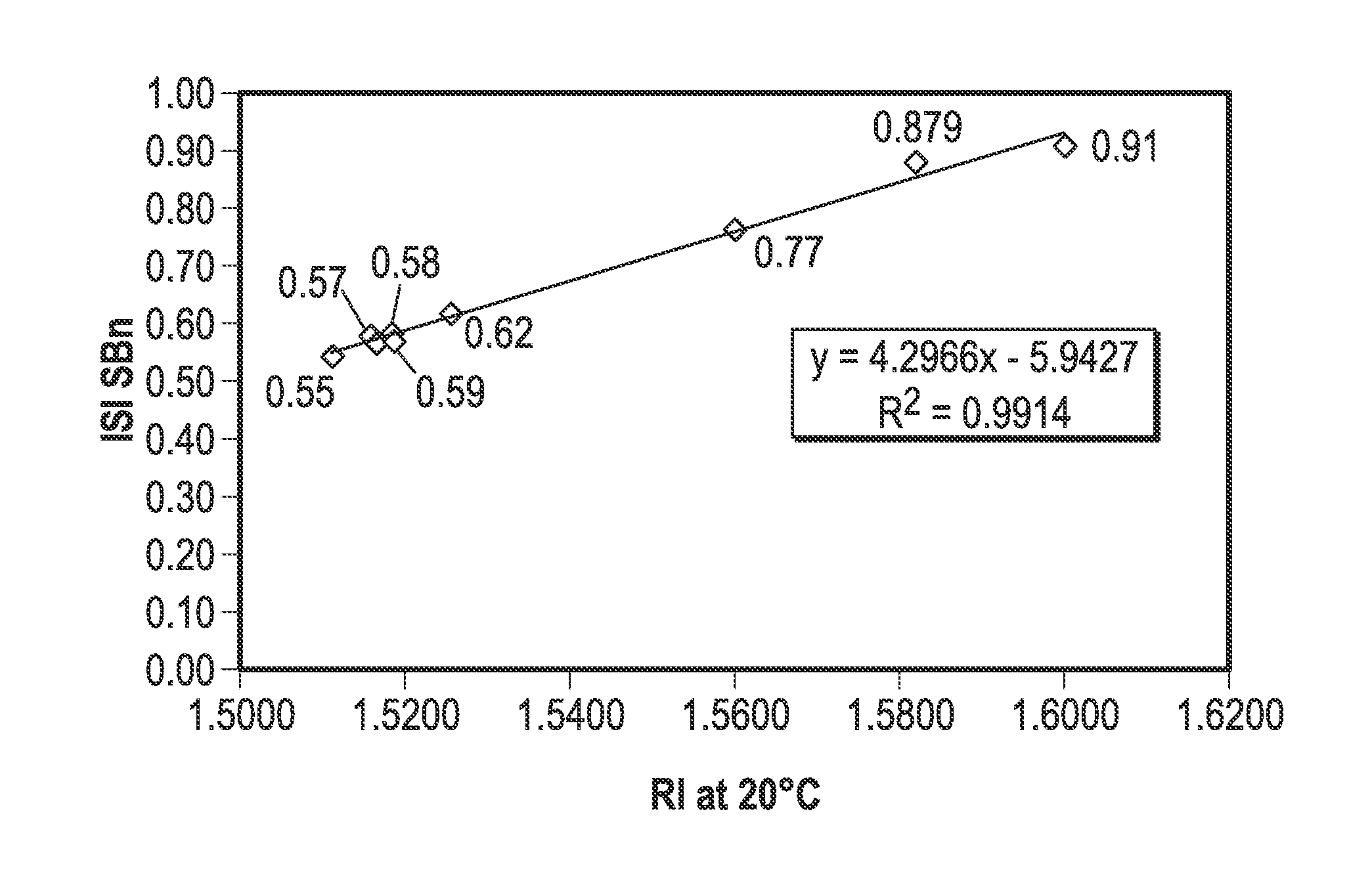

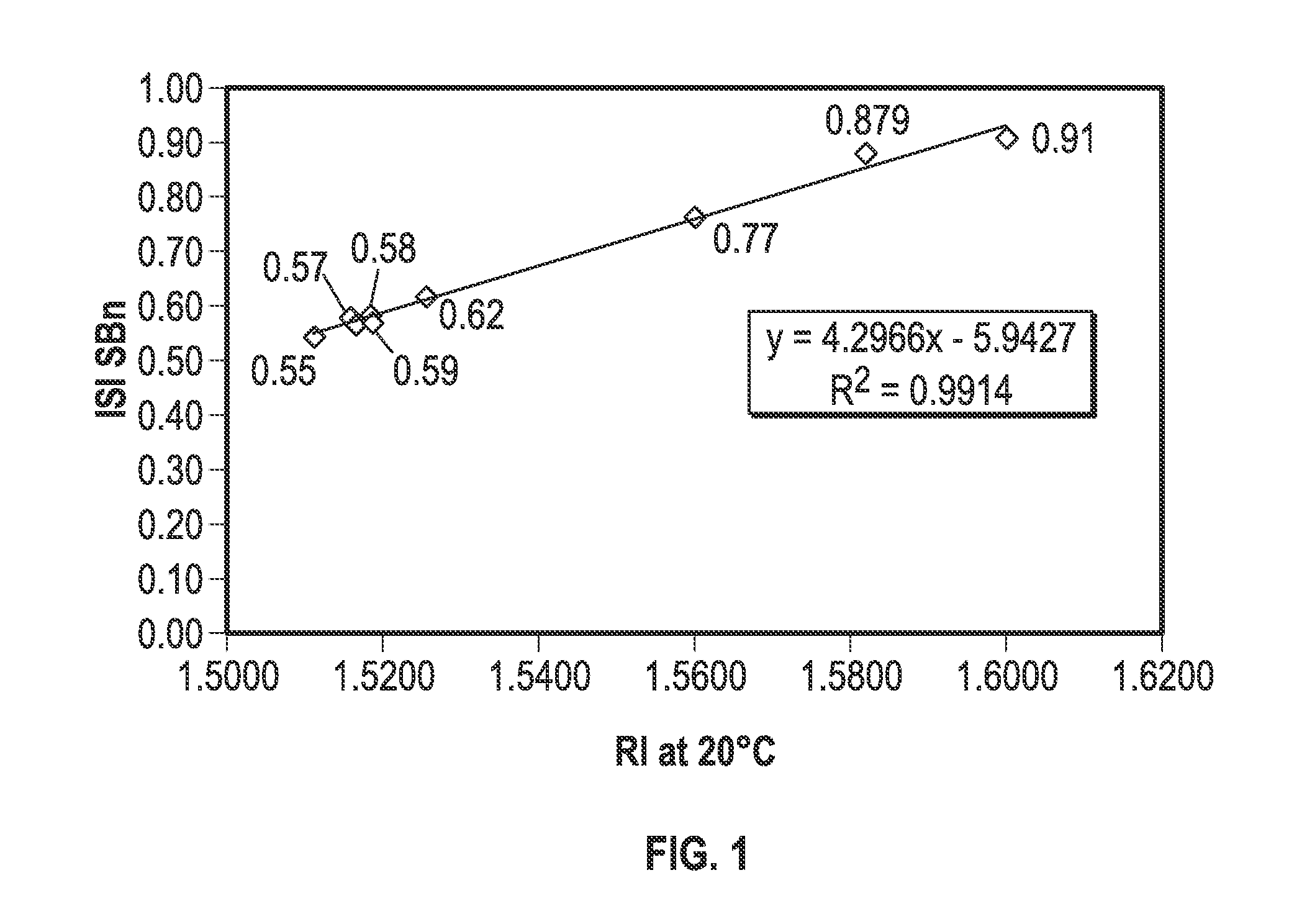

Process for prediciting the stability of crude oil and employing same in transporting and/or refining the crude oil

ActiveUS20130341241A1Reduce dirtLiquid organic insulatorsPhase-affecting property measurementsRefractive indexProcess engineering

A process for refining crude oil can be controlled to mitigate fouling by deploying a refractive index probe at a location suitable for making a crude oil stability determination, wherein the crude oil stability determination is relevant to controlling the refining process; making a measurement of crude oil stability; and then controlling the process for refining crude oil by maintaining the process or implementing a change to the process, based upon the determination of crude oil stability. This concept can also be applied to transporting, blending, and storing crude oil.

Owner:BAKER HUGHES INC

Scale inhibitor for catalytic cracking slurry system

InactiveCN101974348AThe effect of compound use is more thanGood anti-scaling effectTreatment apparatus corrosion/fouling inhibitionSlurrySolvent

The invention discloses a scale inhibitor, in particular a scale inhibitor for a catalytic cracking slurry system, which is characterized by being a composition consisting of 2 to 6 weight percent of antioxidant, 2 to 18 percent of polymerization inhibitor, 10 to 25 percent of detergent dispersant, 1 to 5 percent of metal passivator, 20 to 45 percent of dispersant and 16 to 40 percent of solvent. The scale inhibitor for the catalytic cracking slurry system has high pertinency and desirable scale inhibiting effect, and can help to solve the sintering and scaling problems of the slurry system and prolong the operation period of the device. The dosage of scale inhibitor is small, so the scale inhibitor is economic. The scale inhibitor can solve the scaling problem of a catalytic cracking device effectively and is the first scale inhibitor for the catalytic cracking slurry system. Thus, the scale inhibitor has high promotion and application values and a very good market prospect.

Owner:吉化集团吉林市星云化工有限公司

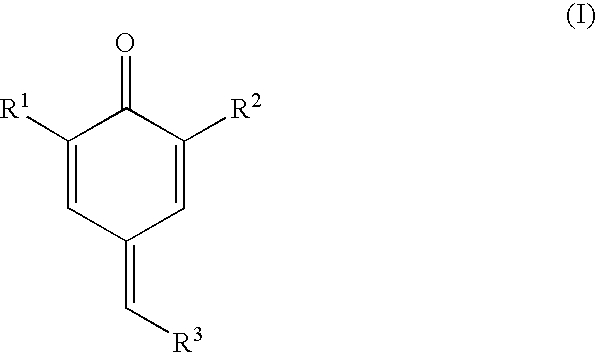

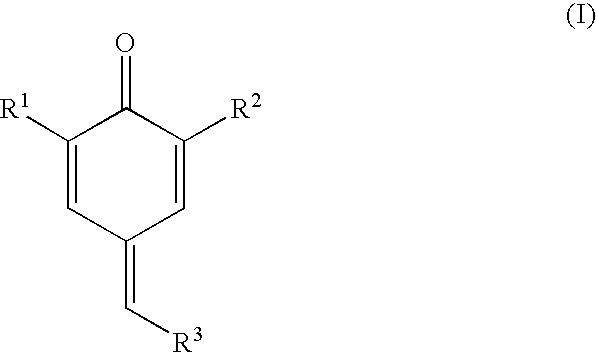

Inhibition of viscosity increase and fouling in hydrocarbon streams including unsaturation

A method of inhibiting fouling and viscosity increase in hydrocarbon streams including ethylenically unsaturated monomers is disclosed. The method includes the step of adding to the hydrocarbon stream an effective amount of one or more quinone methides of the formula: wherein R1, R2, and R3 are independently selected from the group consisting of H, —OH, —SH, —NH2, alkyl, cycloalkyl, heterocyclo, and aryl.

Owner:BETZ LAB INC

Polyalkylene epoxy polyamine additives for fouling mitigation in hydrocarbon refining processes

InactiveUS20110147275A1Reduce dirtHydrocarbon oil dewatering/demulsificationHydrocarbon oils refiningEpoxyParticulates

The present invention provides a method for reducing fouling, including particulate-induced fouling, in a hydrocarbon refining process including the steps of providing a crude hydrocarbon for a refining process and adding an antifouling agent containing a polymer base unit and a polyamine group to the crude hydrocarbon. The antifouling agent can be obtained by reacting an epoxidation reagent with a vinyl-terminated polymer, such as polypropylene or poly(ethylene-co-propylene), to form a terminal epoxy group, followed by reacting a polyamine with the epoxy group.

Owner:EXXON RES & ENG CO

Process for upgrading heavy and highly waxy crude oil without supply of hydrogen

ActiveUS20090145805A1Increase gravityReduce the amount requiredThermal non-catalytic crackingRefining by heating/coolingAlkaneHydrogen

A continuous process to upgrade heavy crude oil for producing more valuable crude feedstock having high API gravity, low asphaltene content, and high middle distillate yield, low sulfur content, low nitrogen content, and low metal co teat without external supply of hydrogen and / or catalyst. Heavy crude oil having substantial amount of asphaltene and heavy components is mixed with highly waxy crude oil having large amount of paraffinic components and water to decompose asphaltene compounds and remove sulfur, nitrogen, and metal containing substances under supercritical conditions. Product has higher API gravity, lower asphaltene content, high middle distillate yield, lower sulfur content, lower nitrogen content, and lower metal content to be suitable for conventional petroleum refining process.

Owner:SAUDI ARABIAN OIL CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com