Scale inhibitor for catalytic cracking slurry system

A technology for catalytic cracking oil slurry and scale inhibitor, which is applied in the petroleum industry, hydrocarbon oil treatment, and treatment equipment corrosion/fouling inhibition, etc. Prolonged operation period and good anti-scaling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific embodiments.

[0031] Preparation

[0032] The first step is to put the solvent in the container, then start the agitator, raise the temperature of the solvent to 20°C-55°C, and add certain antioxidants and polymerization inhibitors in proportion to complete dissolution under stirring.

[0033] In the second step, add detergent and dispersant, metal deactivator and dispersant in proportion to the prepared solution in sequence, control the temperature to 40°C to 50°C, keep it constant, stir for 0.5 to 1 hour, and cool to room temperature to obtain This antiscalant product.

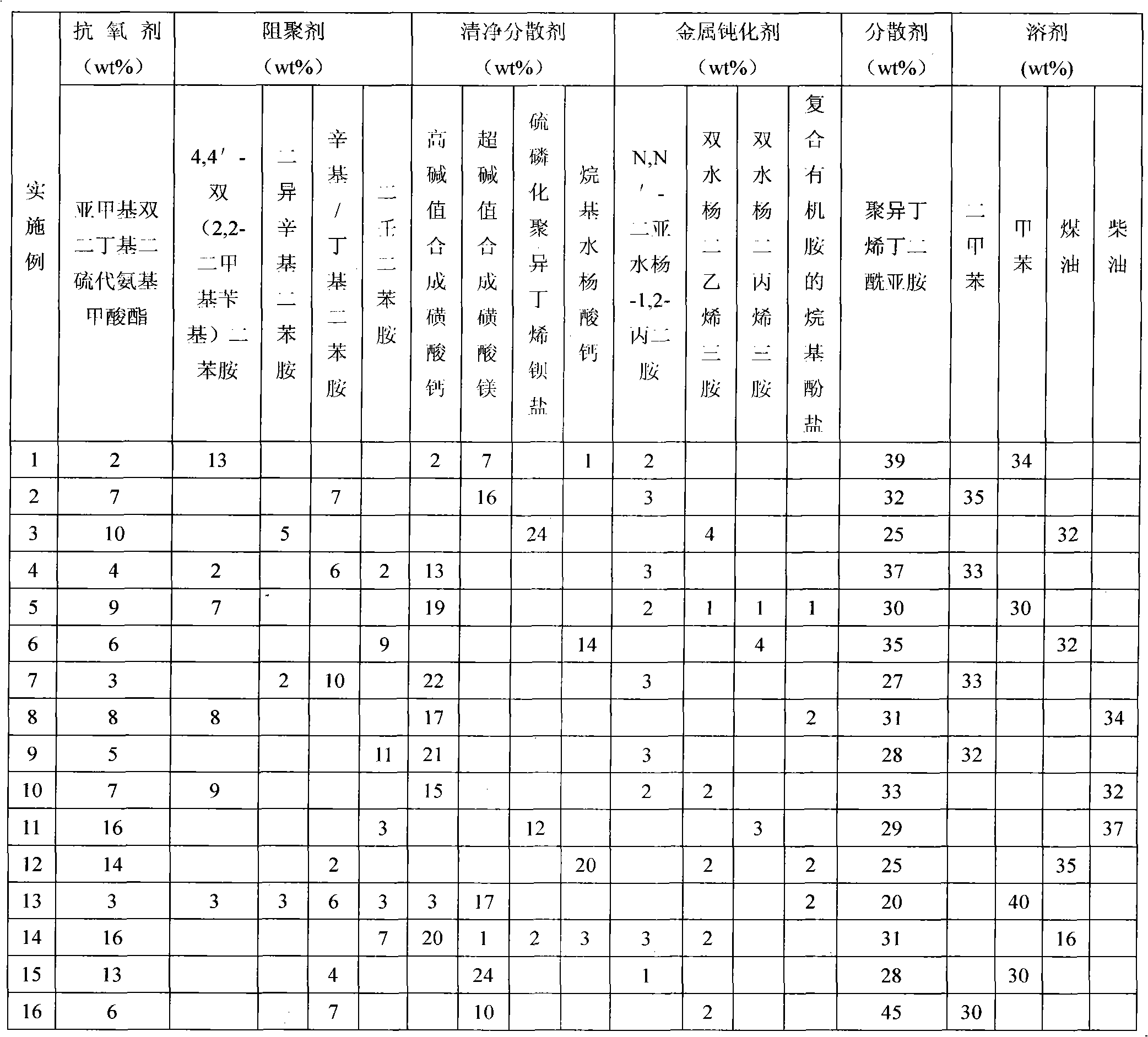

[0034] According to the above method, the scale inhibitor product examples 1-16 were prepared, and the results are listed in Table 1.

[0035] (2) Evaluation method

[0036] The evaluation of the antiscalant effect of the antiscalant in the oil slurry system is carried out in the laboratory, and the method is as fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com