Cleaning additive and cleaning method adopting the cleaning additive

A technology for cleaning additives and additives, which is applied in the direction of using liquid cleaning methods, detergent compounding agents, cleaning methods and utensils. Adsorption force, low corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

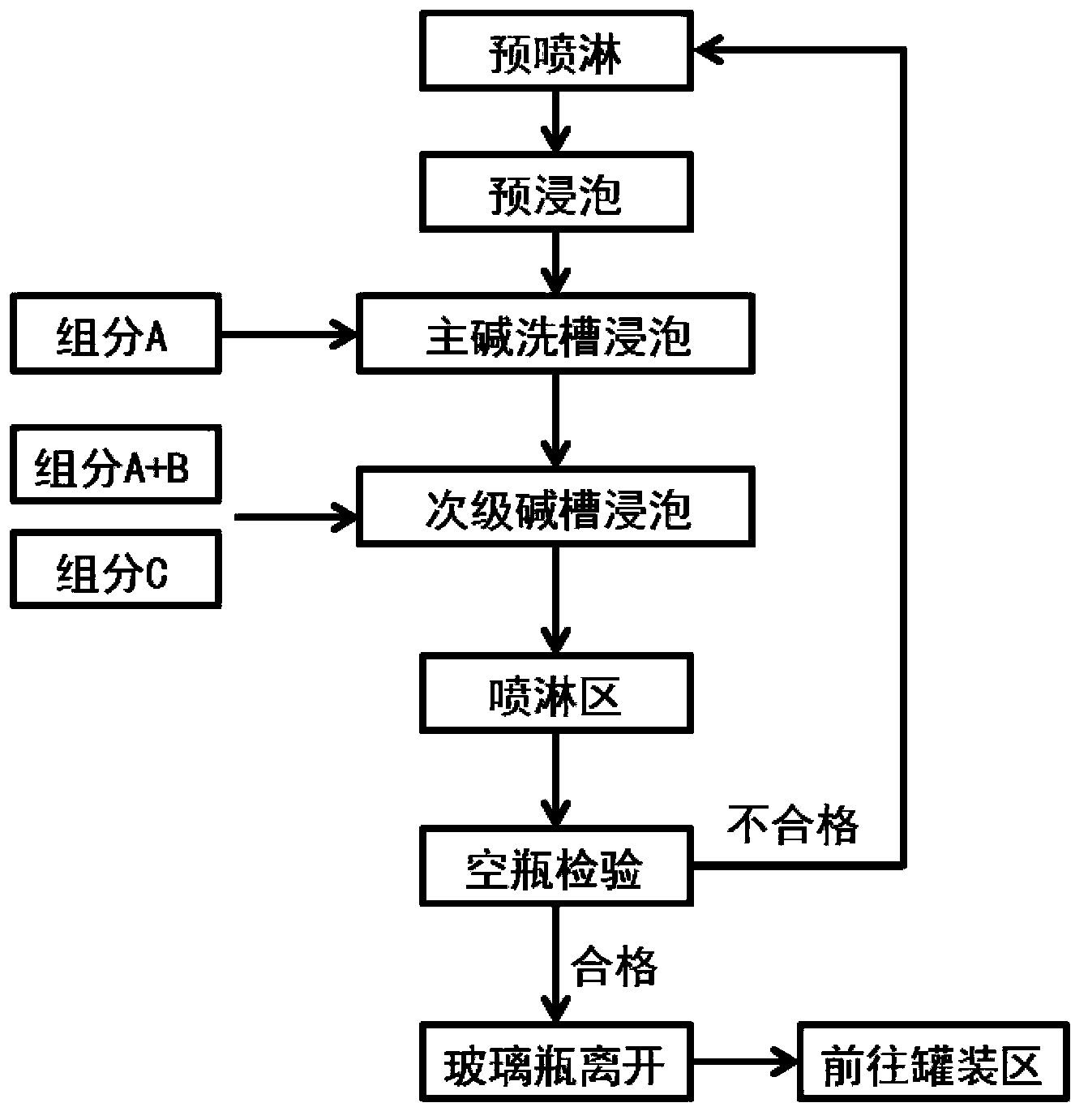

Method used

Image

Examples

Embodiment Construction

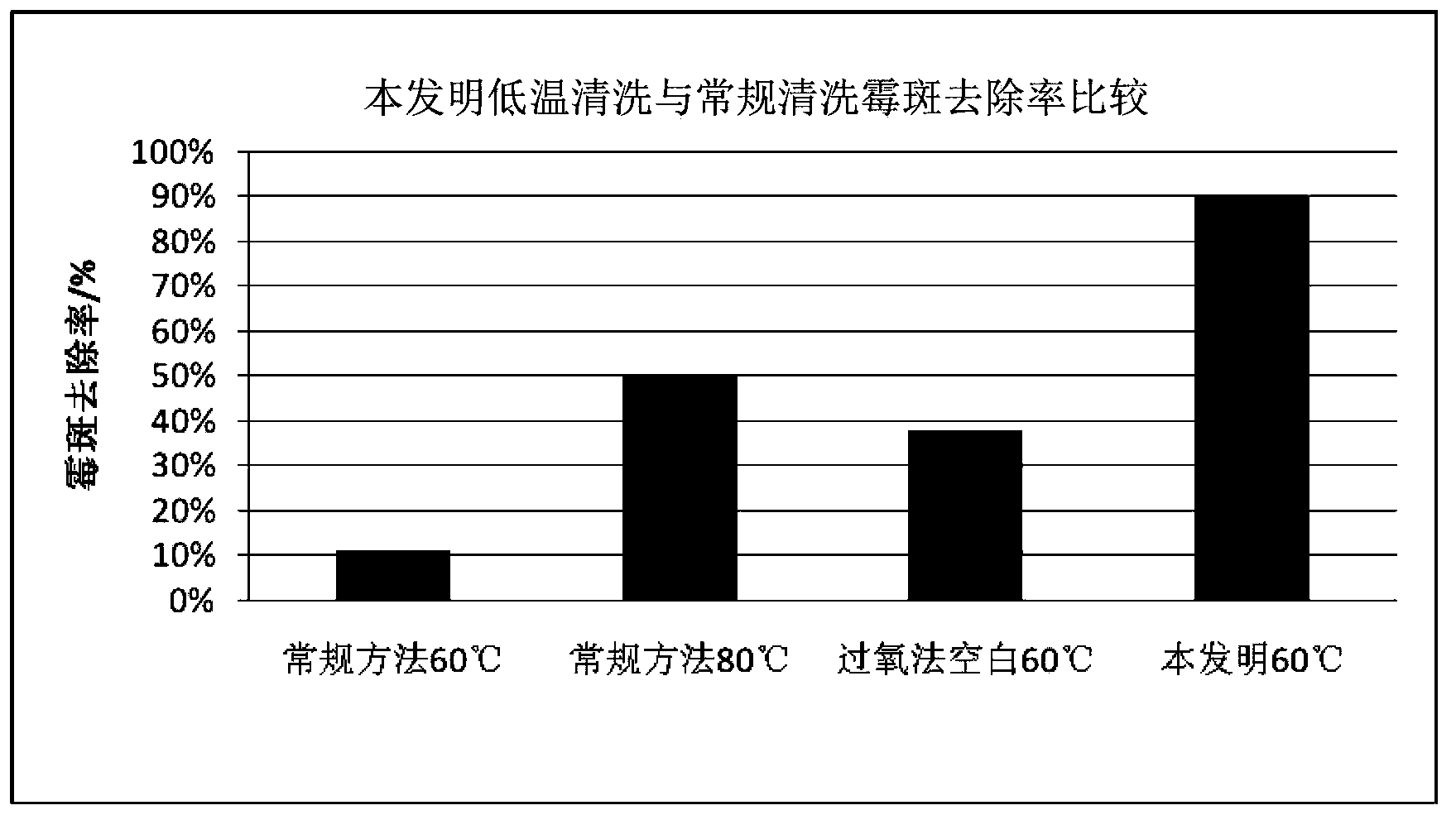

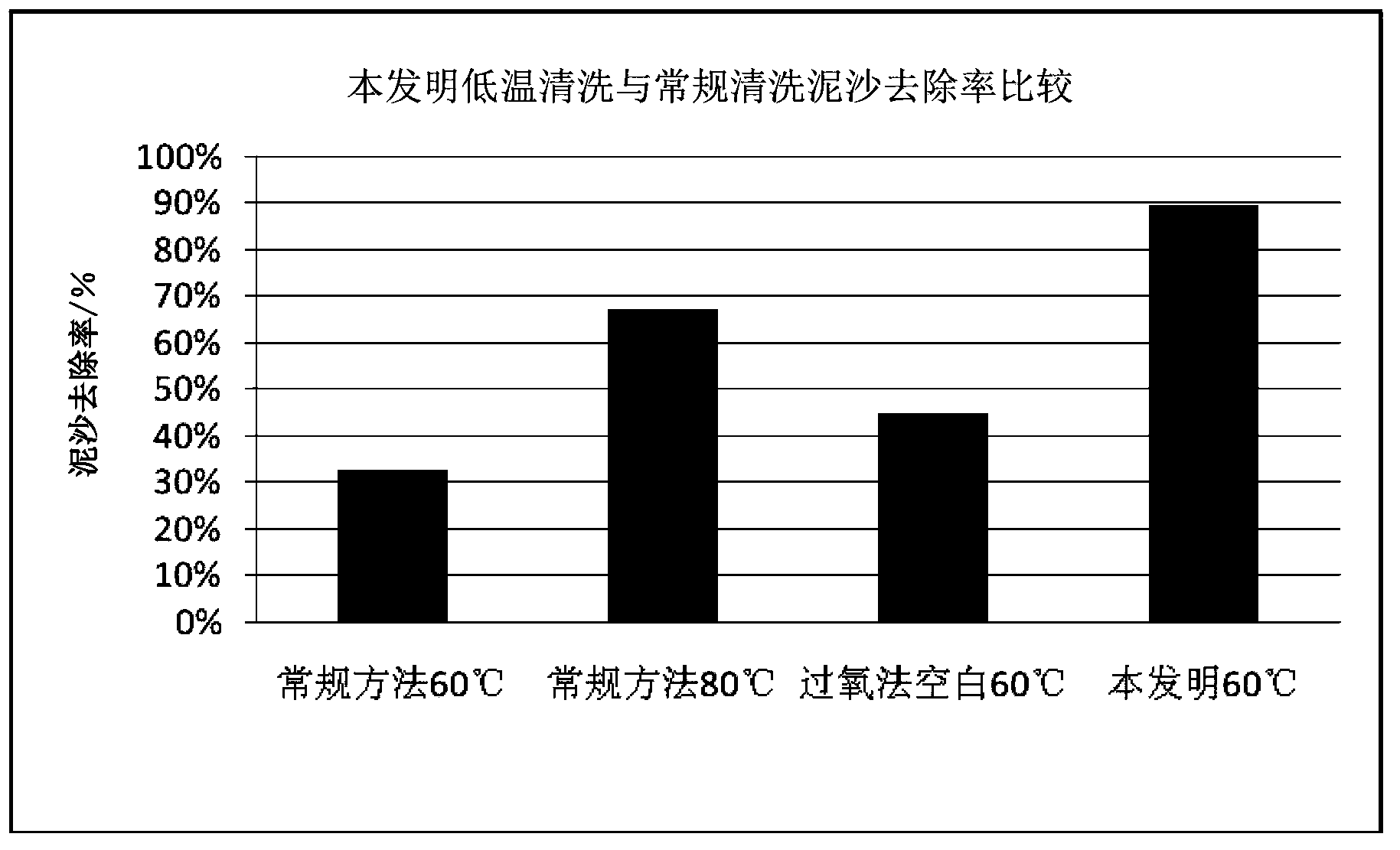

[0061] Generally speaking, the cleaning effect is affected by the following four factors:

[0062] Cleaning agent and its concentration

[0063] The choice of cleaning agent is related to the type of stain and the surface material to be cleaned. Different materials need to choose a suitable cleaning agent, which not only improves the cleaning effect but also prevents corrosion of the cleaned items. At the same time, increasing the cleaning agent concentration can properly shorten the cleaning time or make up for the lack of cleaning temperature. However, an increase in the concentration of the cleaning agent will increase the cleaning cost, and the increase in the concentration does not necessarily effectively improve the cleaning effect, and sometimes even leads to the extension of the cleaning time.

[0064] cleaning time

[0065] The longer the cleaning time of the cleaning agent, the better the cleaning effect will be. But the prolongation of cleaning time means th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com