Scale inhibitor of ethylene device process water system and using method thereof

A technology of ethylene device and antiscalant, which is applied in the field of antiscalant, can solve the problems of poor adaptability and poor antiscaling effect, and achieve the effects of prolonging the operation period, good antiscaling effect and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

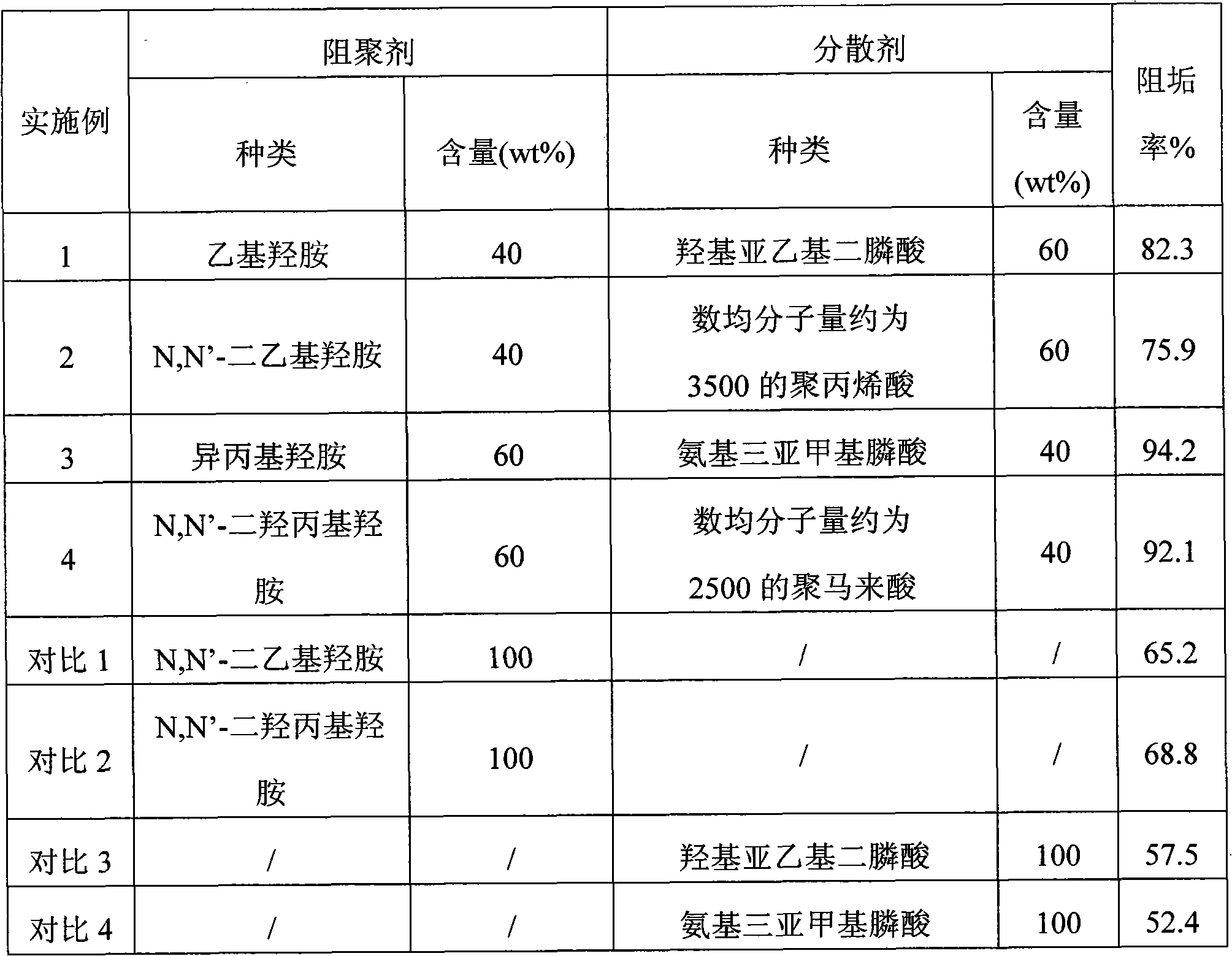

[0026] According to the formula in Table 1, the scale inhibitors for the process water system of ethylene plants in Examples 1 to 4 are prepared. The preparation method is as follows: After uniformly mixing the polymerization inhibitor and the dispersant according to the formula in Table 1, cool to room temperature, and filter. Can.

[0027] The method of using the scale inhibitor: Add the scale inhibitor of the process water system of the ethylene plant into the feed of the process water stripper of the ethylene plant, and the concentration of the scale inhibitor added to the process water system of the ethylene plant is 100ppm of the feed amount of the process water stripper .

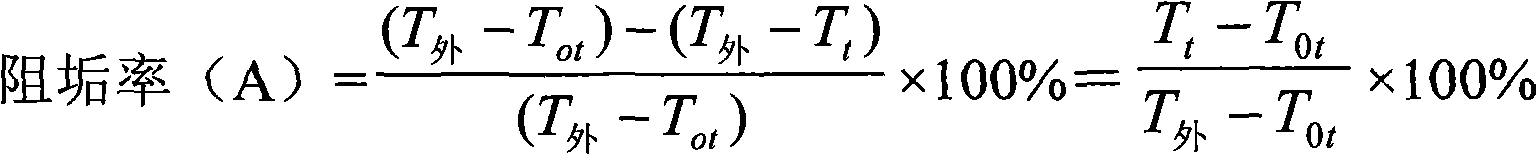

[0028] Specific conditions for scale inhibition performance evaluation: the evaluation medium is the water sample collected from the process water stripper before and after adding the scale inhibitor, the medium inlet temperature is 70°C, the temperature of the outer wall of the heat pipe is 85°C, th...

Embodiment 5~6

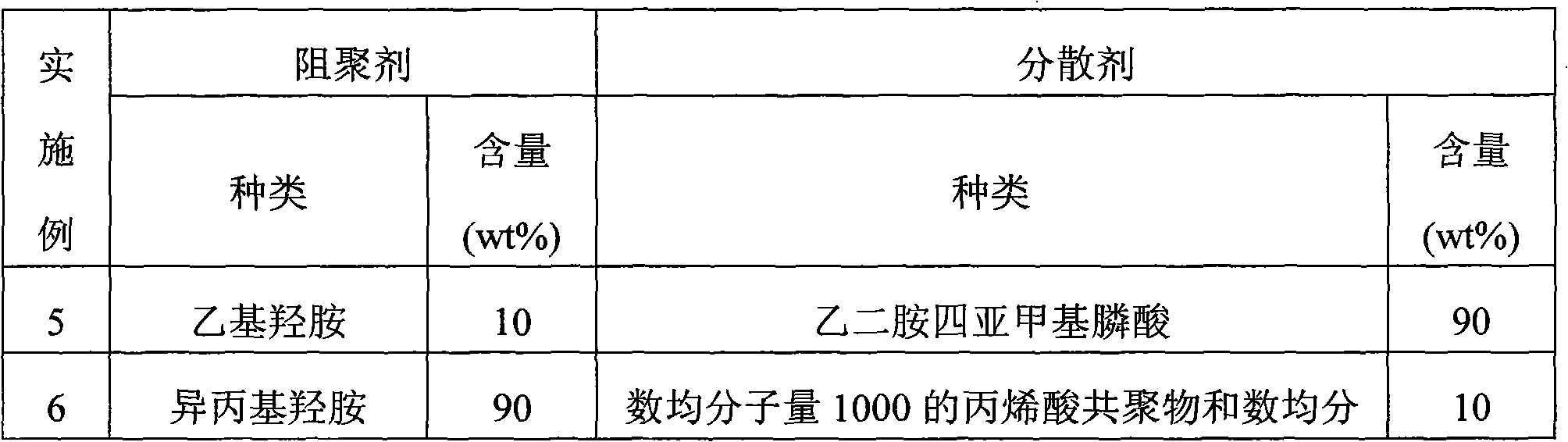

[0037] According to the formula in Table 2, the scale inhibitors for the ethylene plant process water system of Examples 5-6 are prepared. Can.

[0038] The method of using the scale inhibitor: Add the scale inhibitor of the process water system of the ethylene plant into the feed of the process water stripper of the ethylene plant, and the concentration of the scale inhibitor added to the process water system of the ethylene plant is 1000ppm of the feed amount of the process water stripper .

[0039] Specific conditions for scale inhibition performance evaluation: The evaluation medium is the collected water samples from the process water stripping tower before and after adding scale inhibitors. The inlet temperature of the medium is 70°C, the temperature of the outer wall of the heat pipe is 85°C, the flow rate of the medium is 100ml / min, and the test time is 120 hours.

[0040] After testing, the scale inhibition rates of the scale inhibitors prepared from the formulas of...

Embodiment 7~8

[0042]According to the formula in Table 2, the scale inhibitors of the ethylene plant process water system of Examples 7-8 are prepared. Can.

[0043] The method of using the scale inhibitor: Add the scale inhibitor of the process water system of the ethylene plant into the feed of the process water stripper of the ethylene plant, and the concentration of the scale inhibitor added to the process water system of the ethylene plant is 5ppm of the feed amount of the process water stripper .

[0044] Specific conditions for scale inhibition performance evaluation: the evaluation medium is the water sample collected from the process water stripper before and after adding the scale inhibitor, the medium inlet temperature is 70°C, the temperature of the outer wall of the heat pipe is 85°C, the medium flow rate is 100ml / min, the test Time 120 hours.

[0045] After testing, the scale inhibition rates of the scale inhibitors prepared from the formulas of Examples 7-8 are all above 75%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com