Patents

Literature

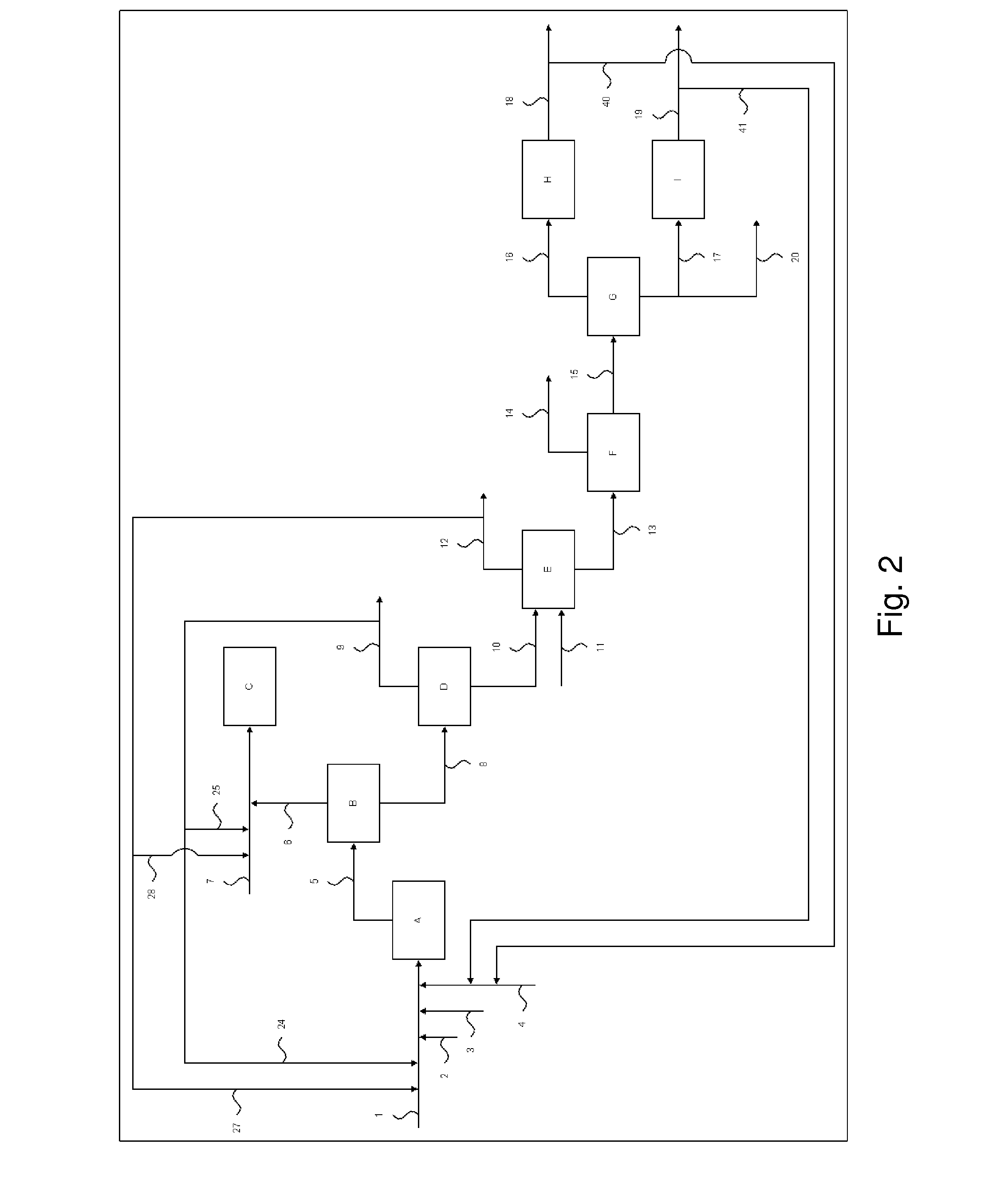

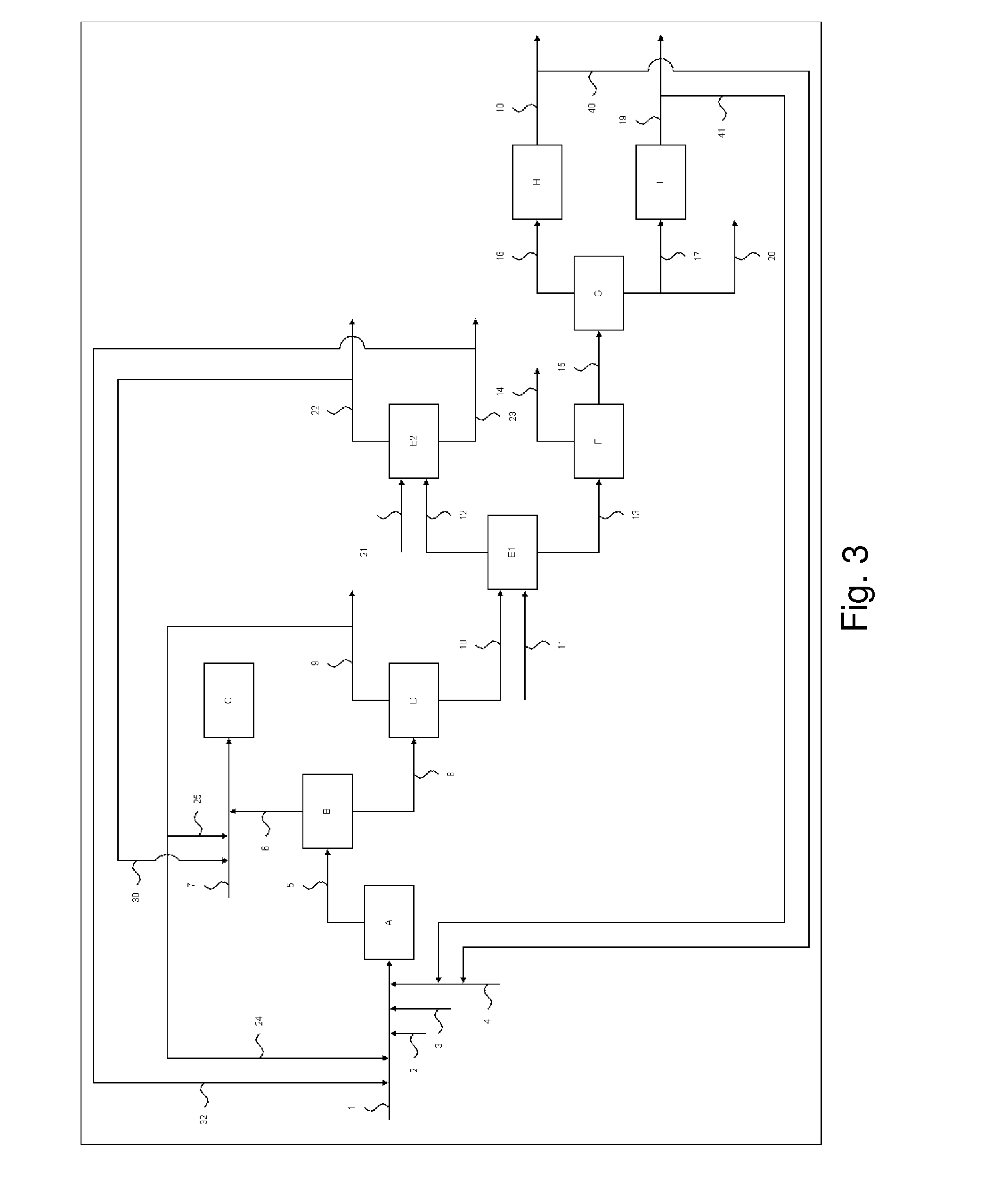

50results about How to "Reduces coke formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for catalytic hydrotreatment of a pyrolysis oil

ActiveUS20110119994A1Reduces coke formationLiquid carbonaceous fuelsLiquid hydrocarbon mixture productionCellulosePyrolysis oil

Owner:SHELL USA INC

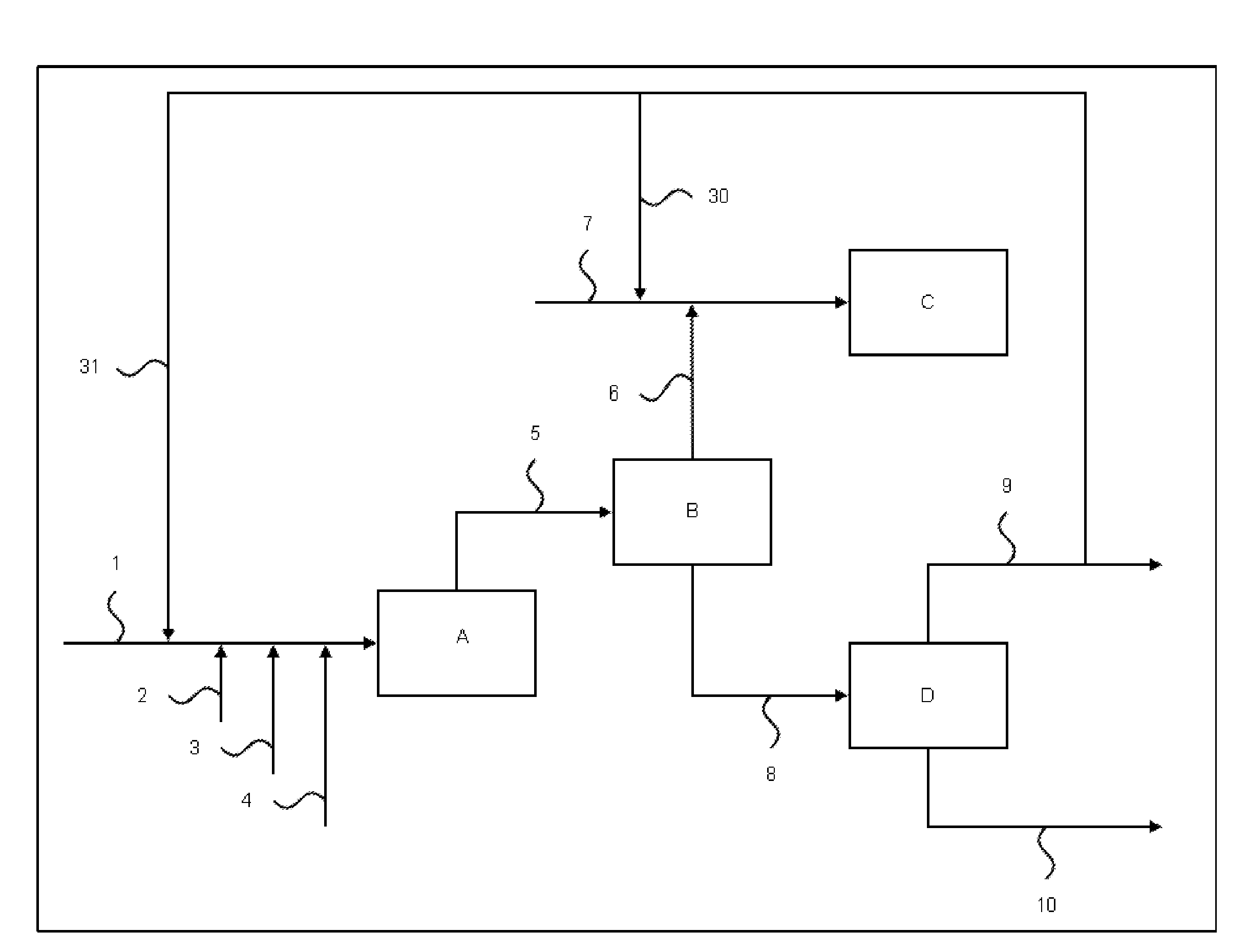

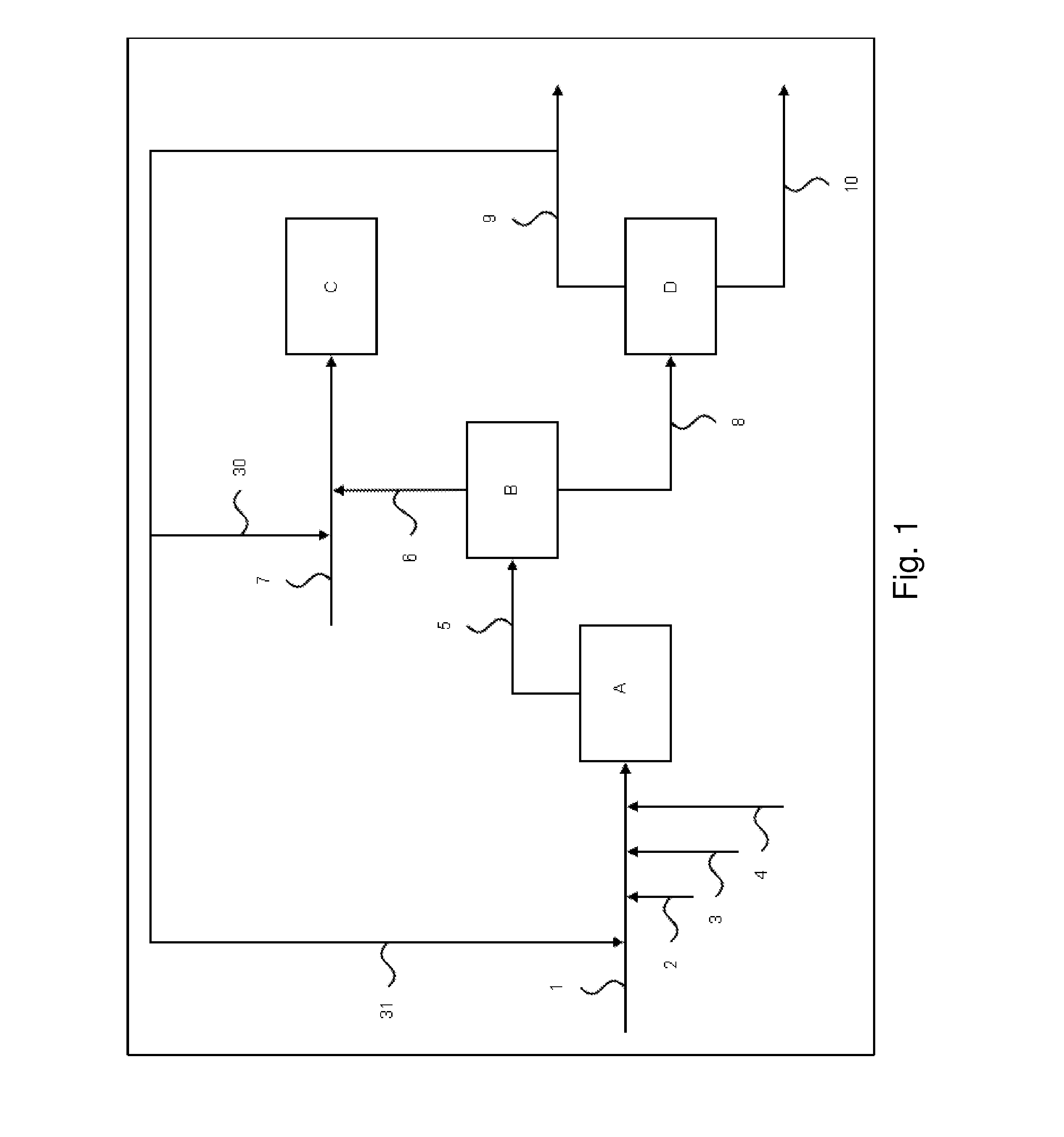

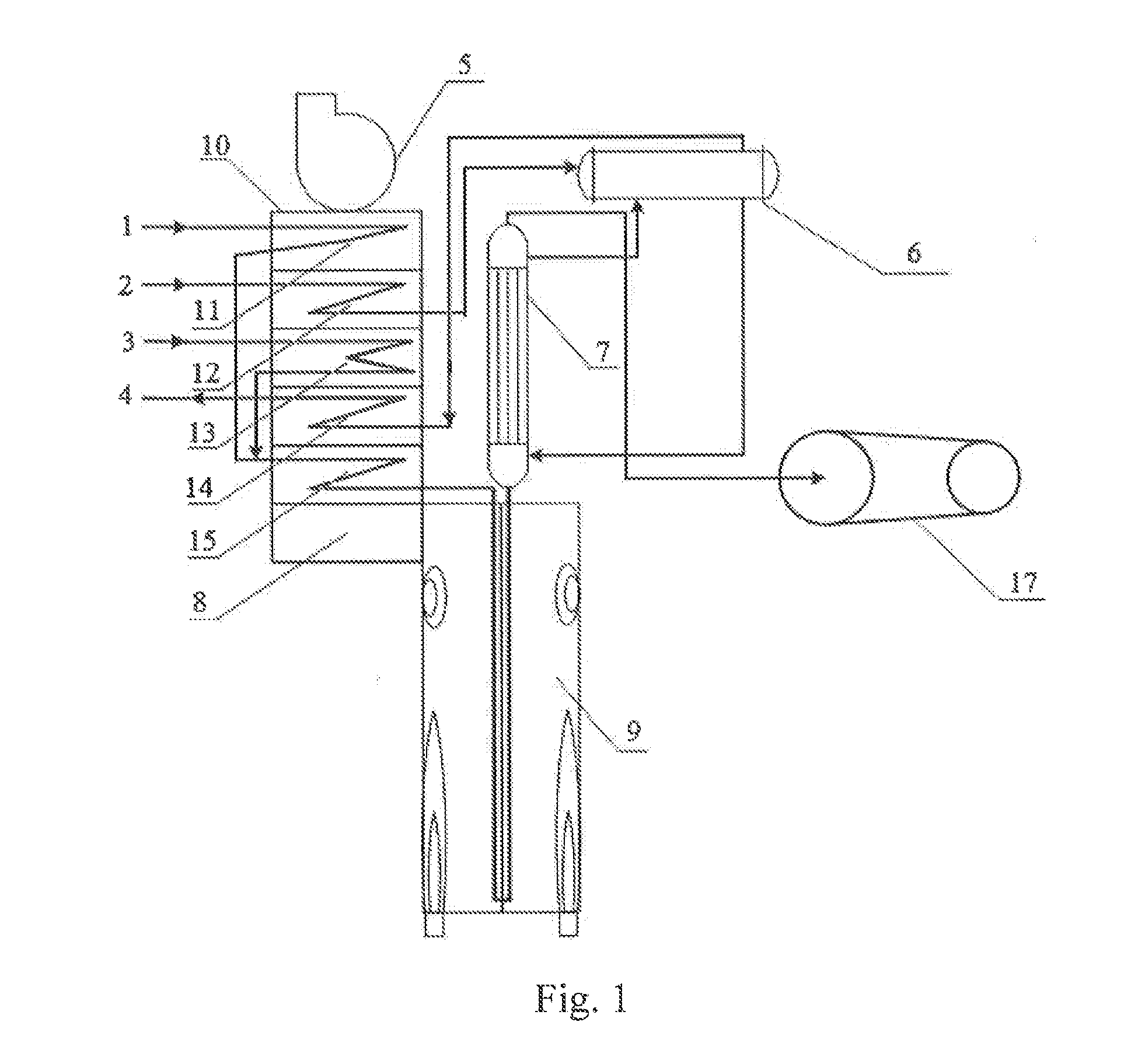

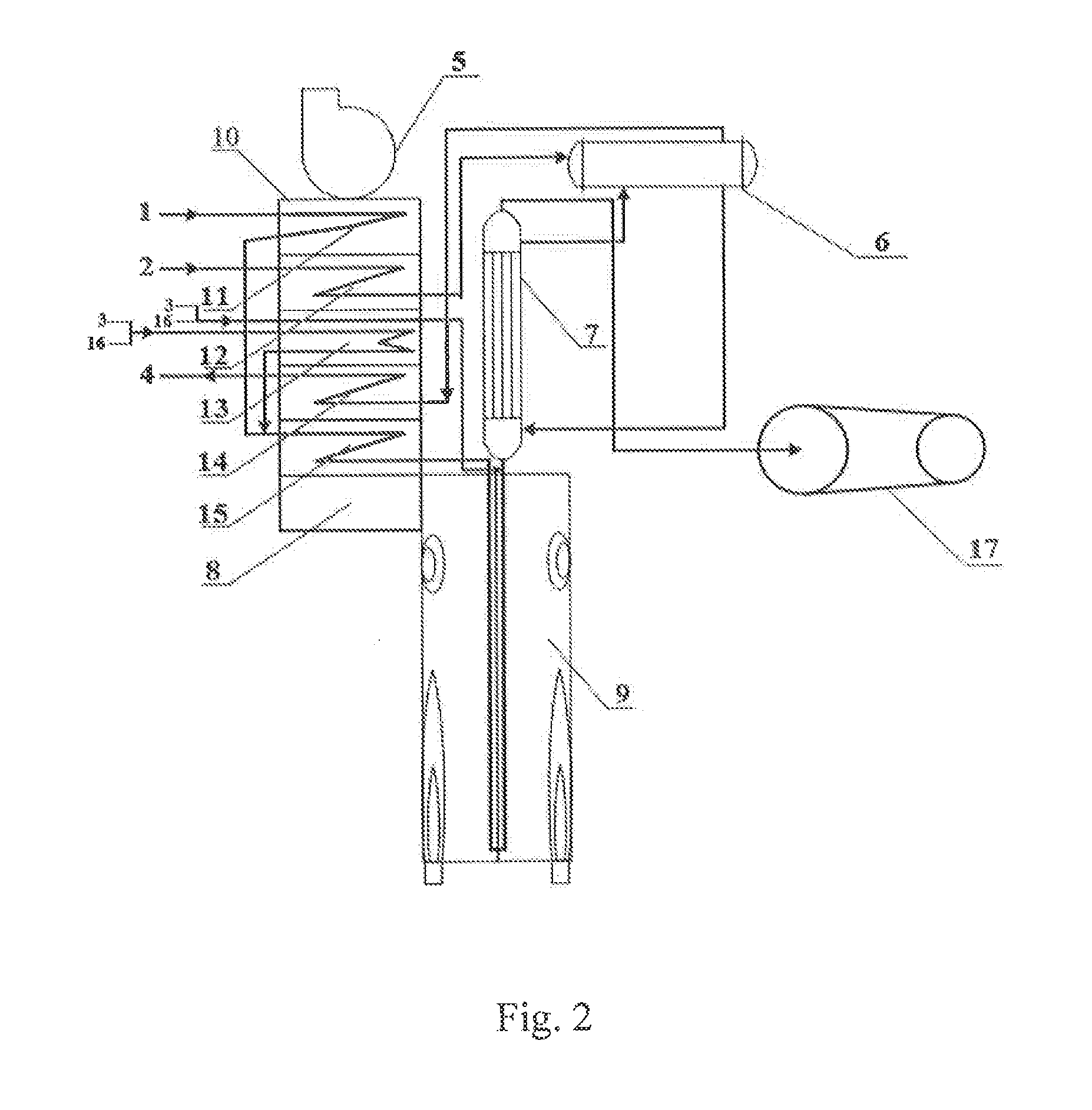

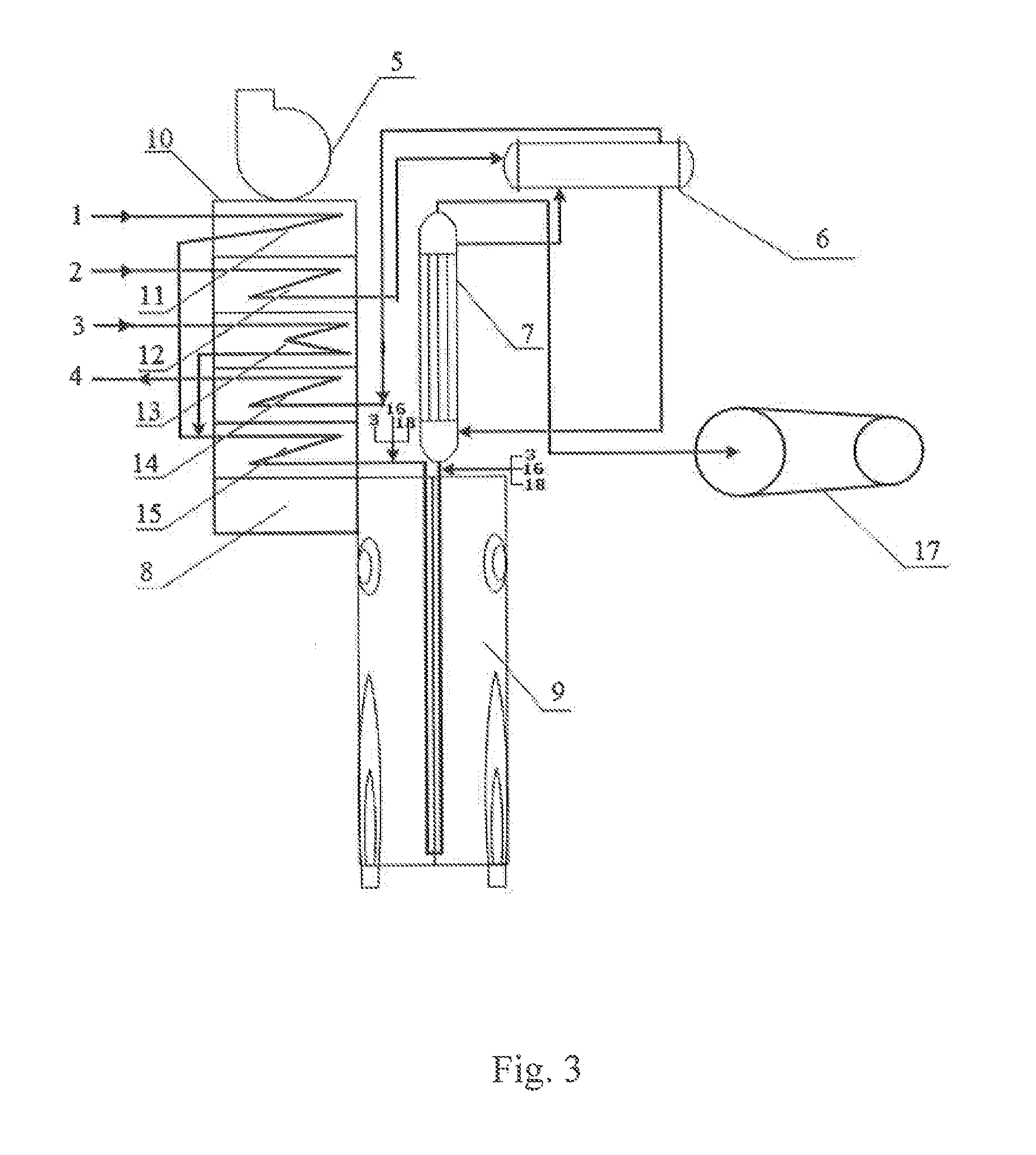

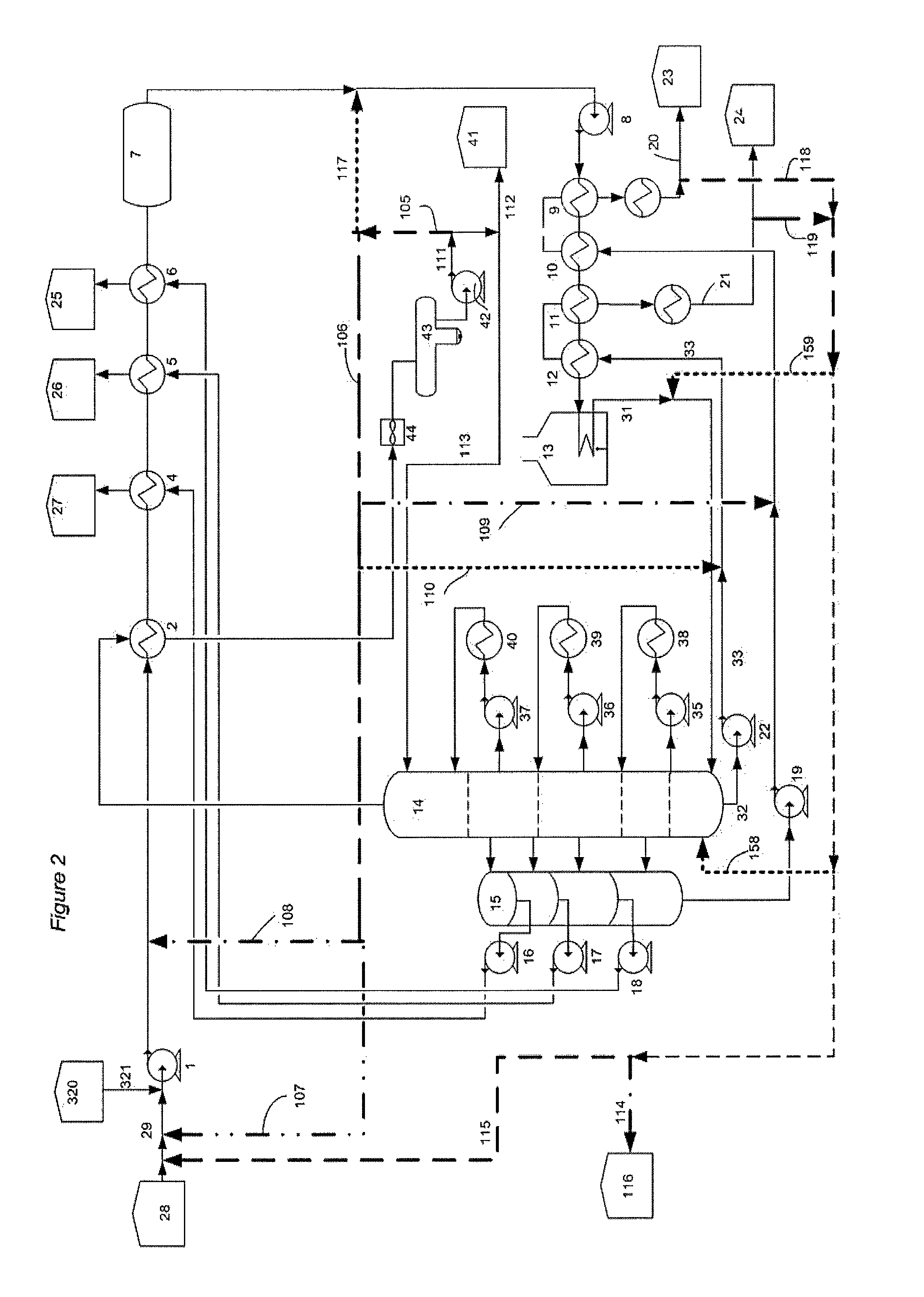

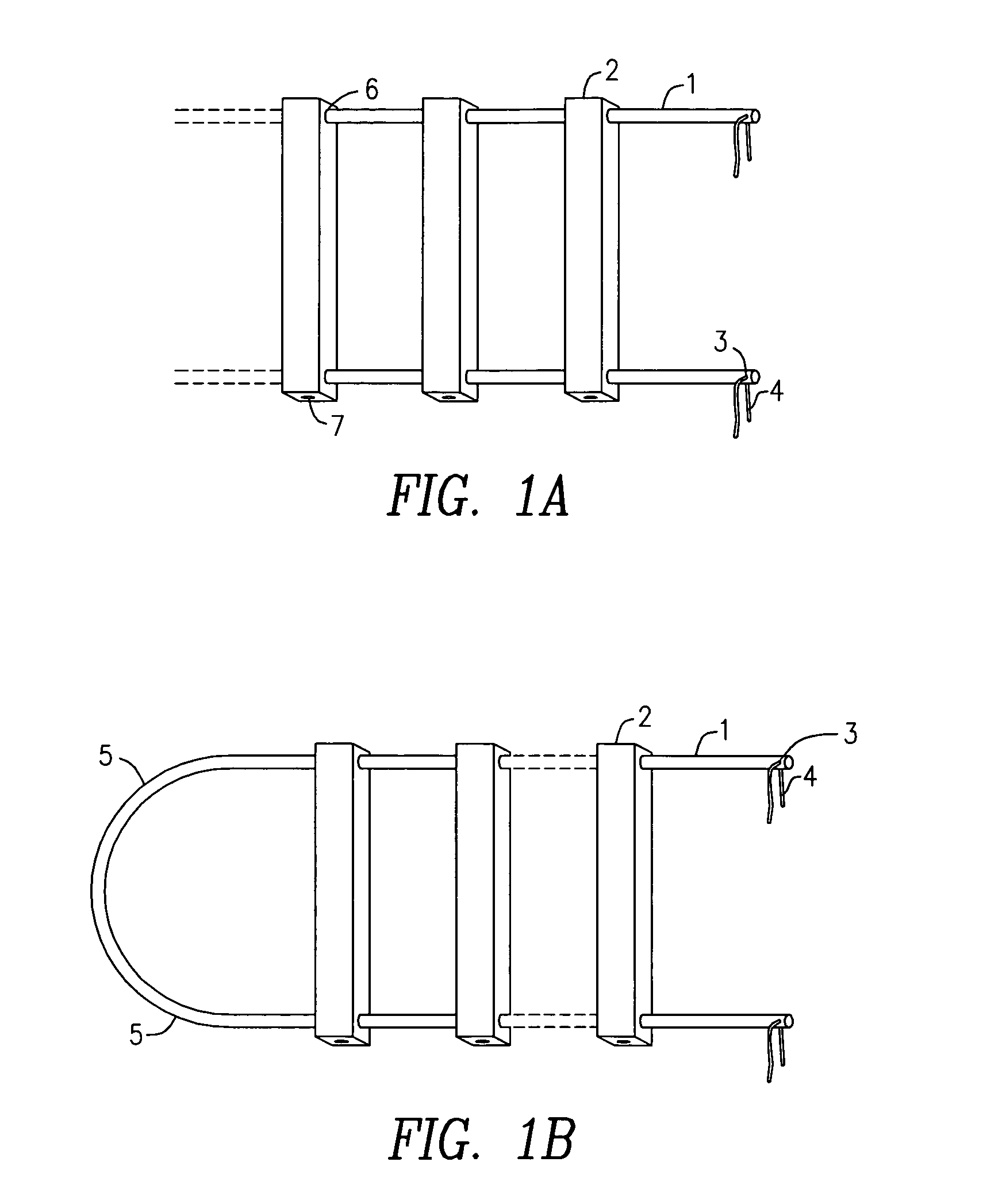

Method, apparatus and chemical products for treating petroleum equipment

ActiveUS20130270157A1Reduce reunionReduces coke formationThermal non-catalytic crackingLighting and heating apparatusEnvironmental engineeringChemical products

The present invention provides a method, an apparatus and chemical products for treating petroleum equipment wherein a fluid is flowing, preferably of the hydrocarbon type, and wherein treating is performed by establishing a closed or semi-closed flow circulation loop, during the normal production operations of the equipment. The treatment can refer to the cleaning of equipment, to yield improvement as compared to normal run conditions and / or to a reduction of coke formation and / or to coke removal on catalysts.

Owner:FERRARA MARCELLO

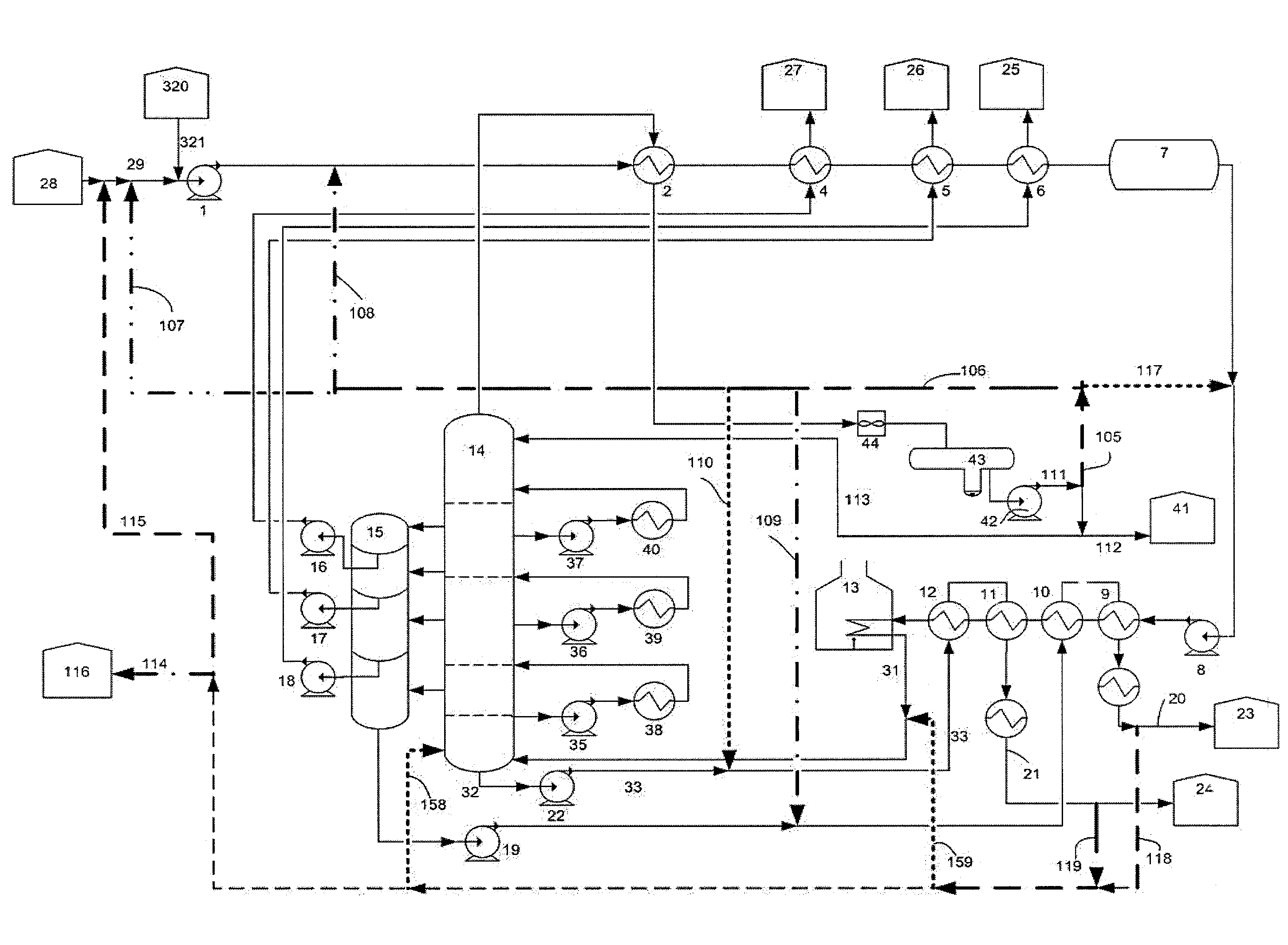

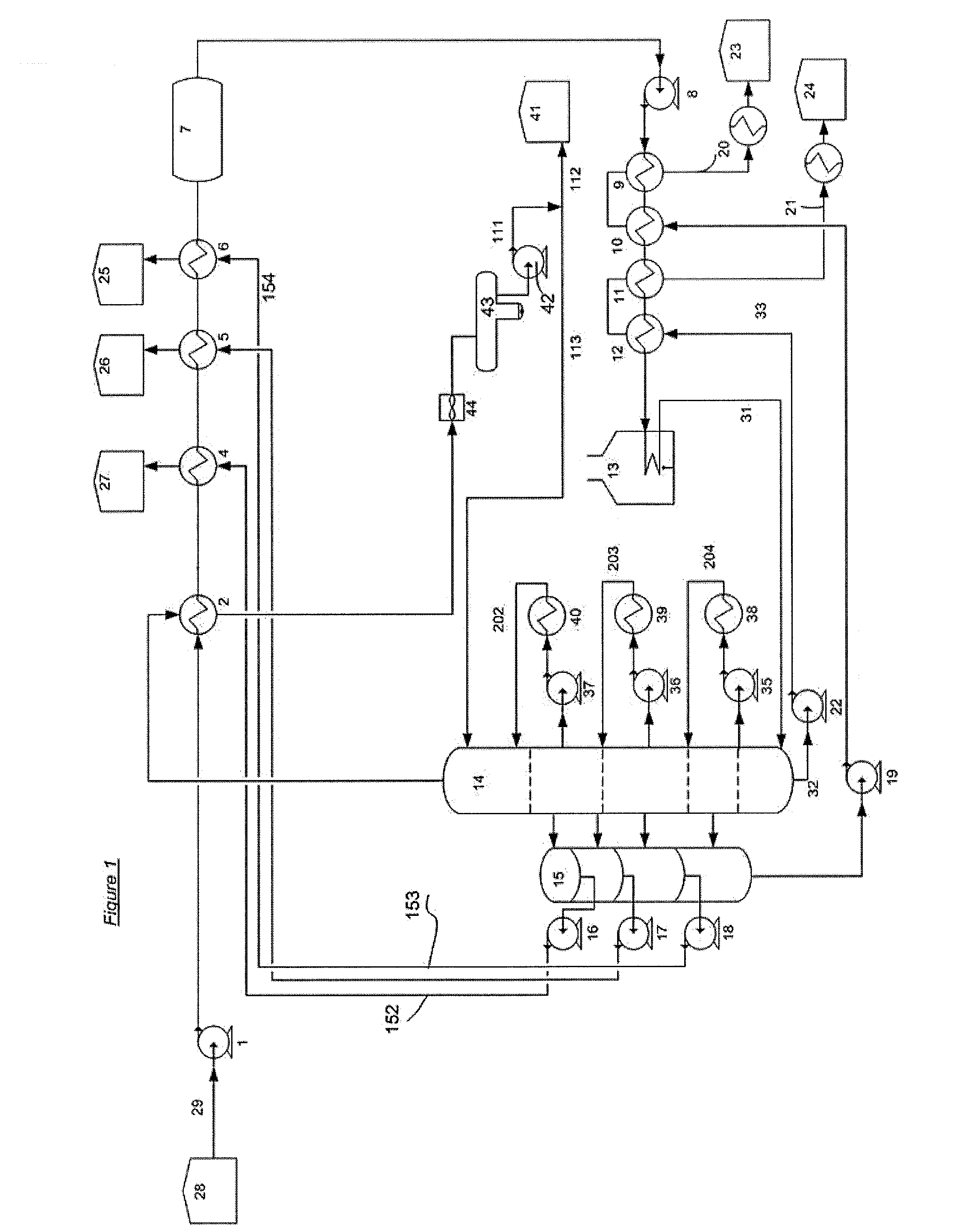

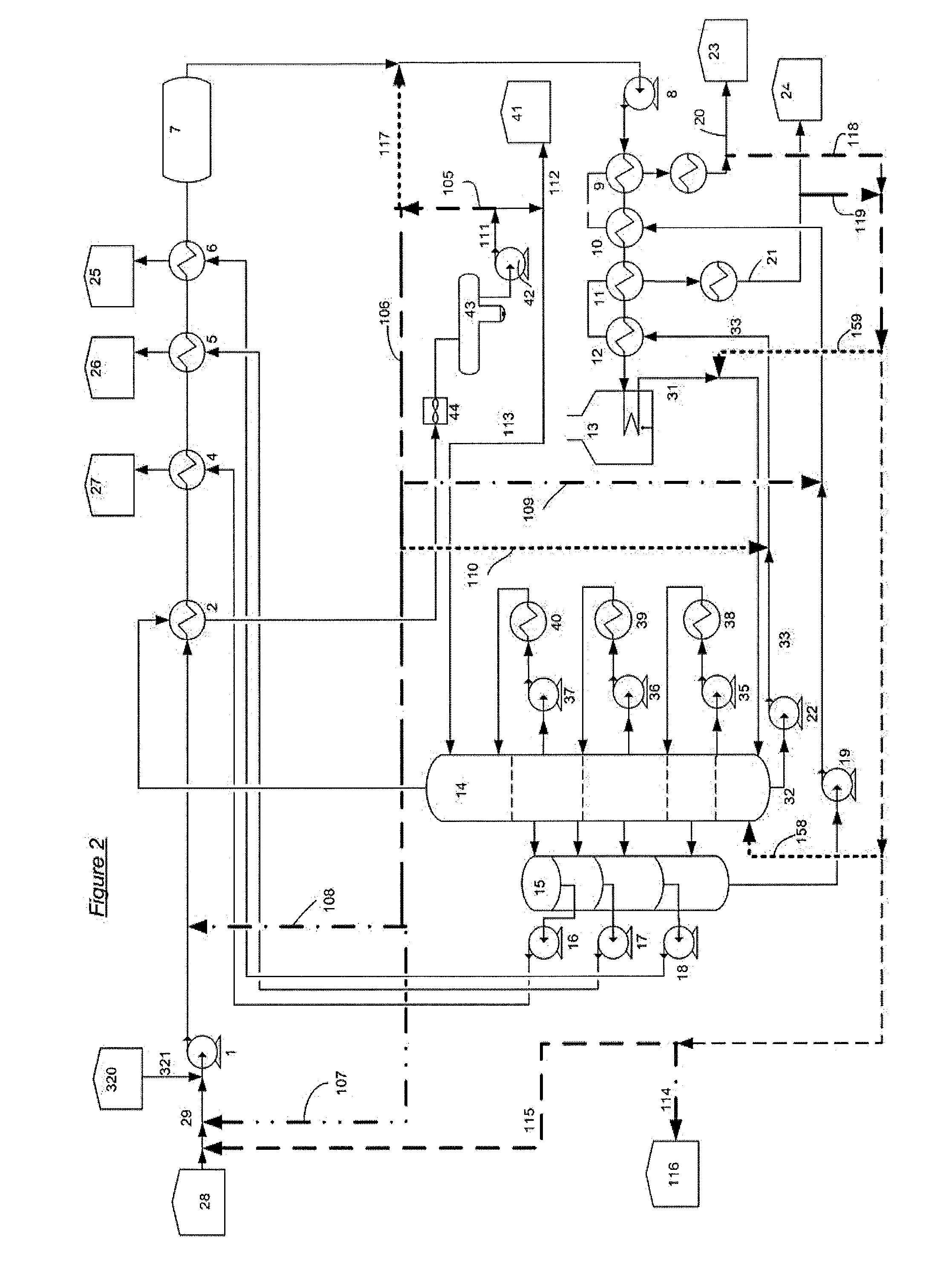

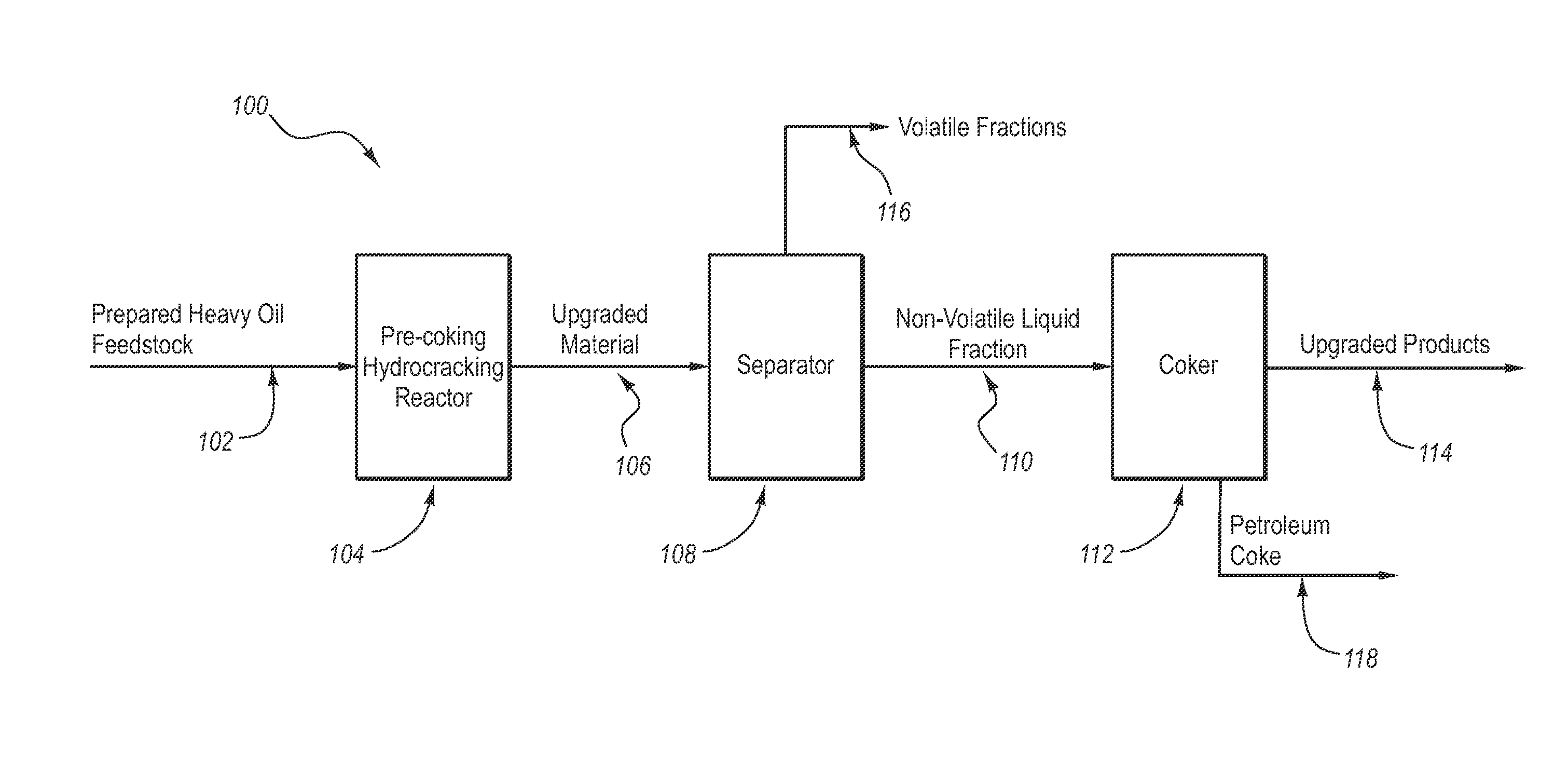

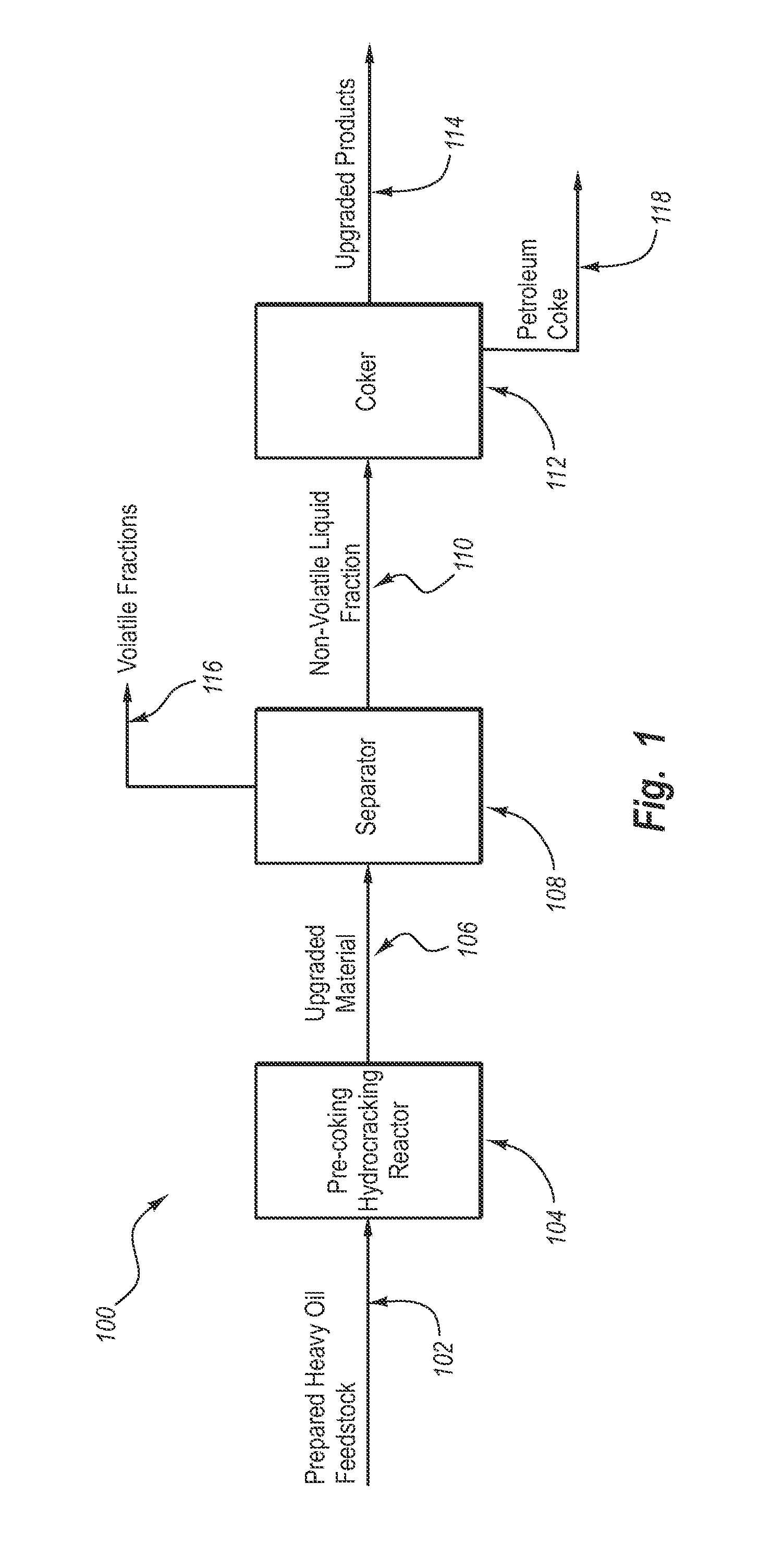

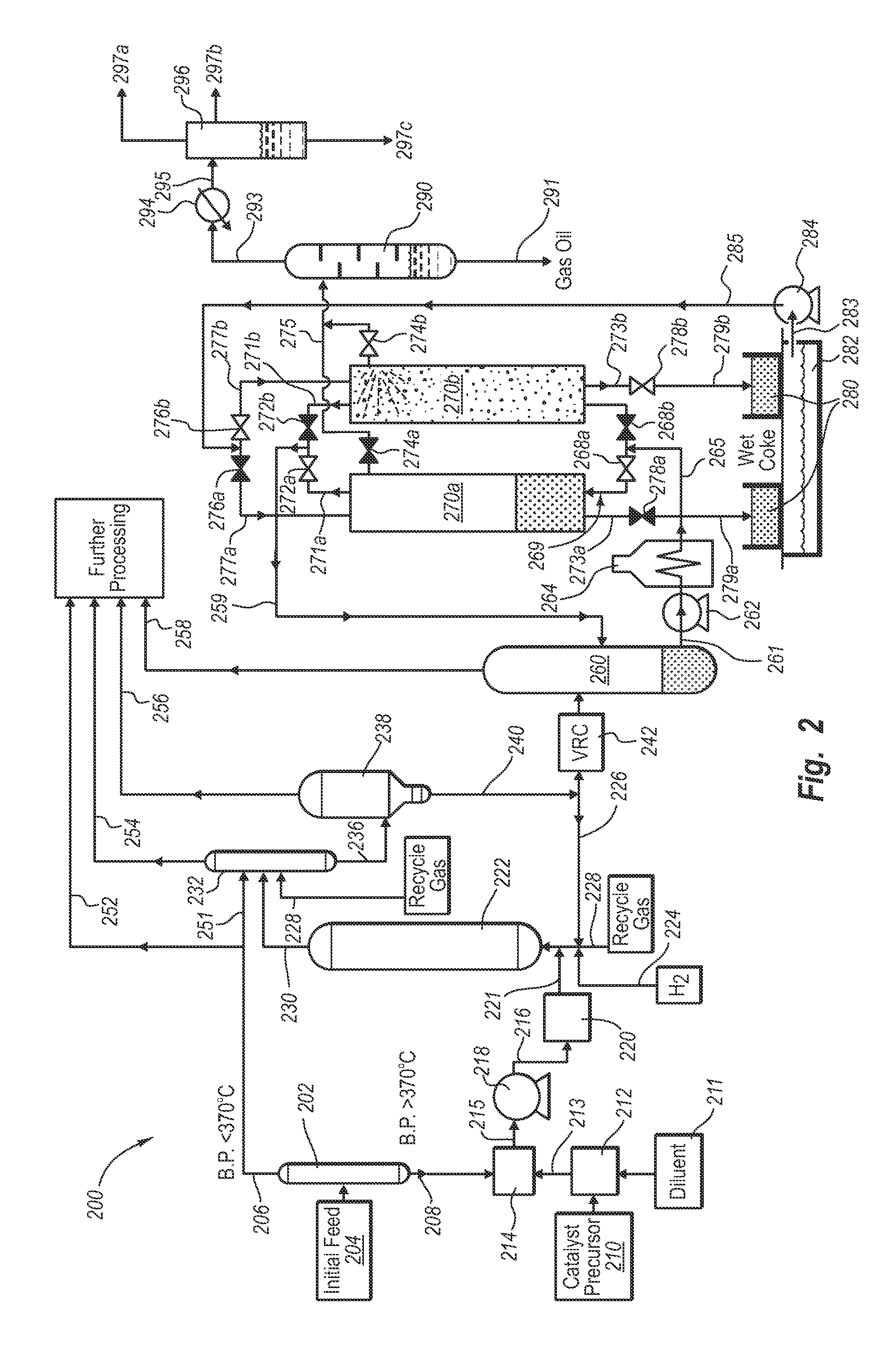

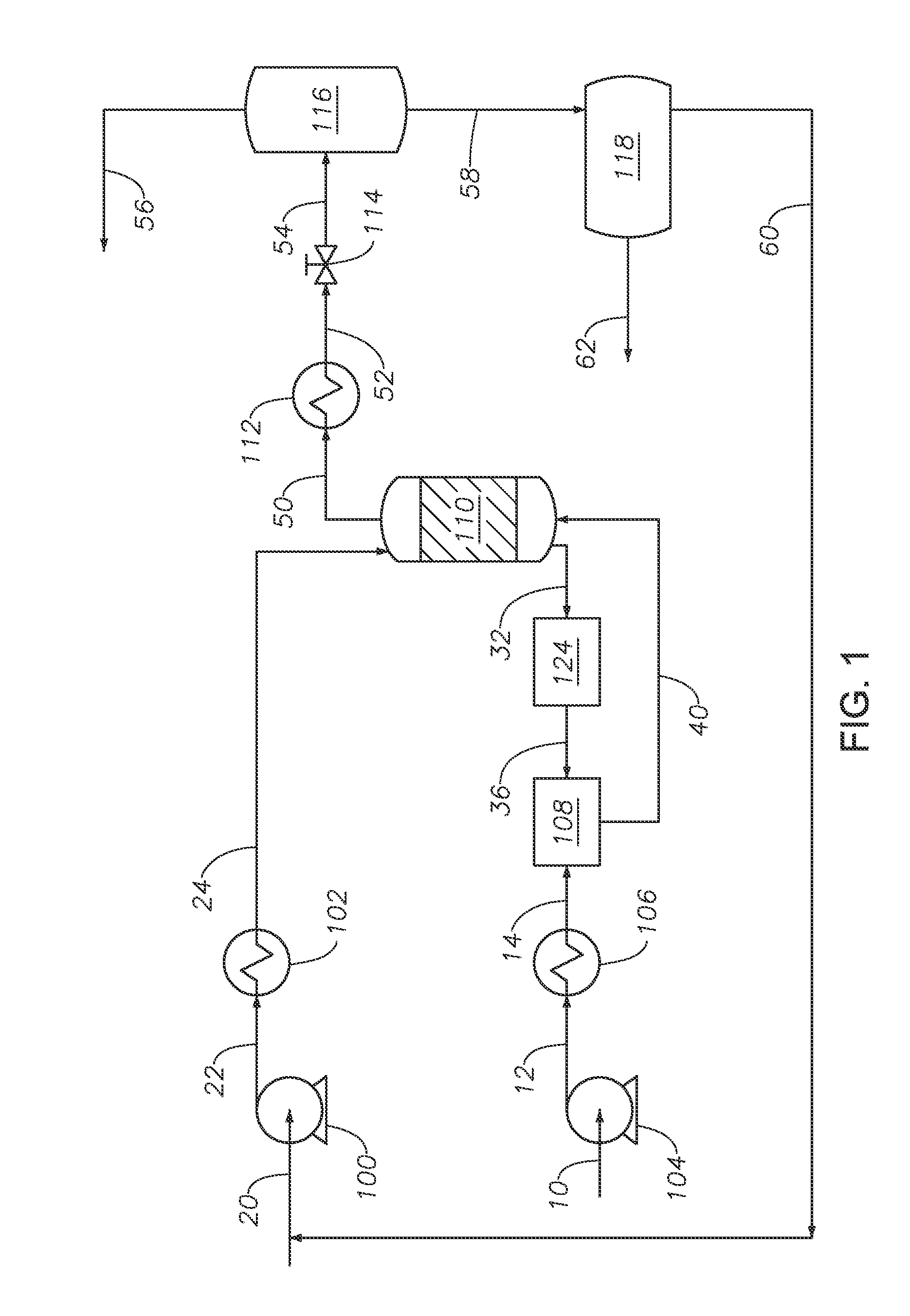

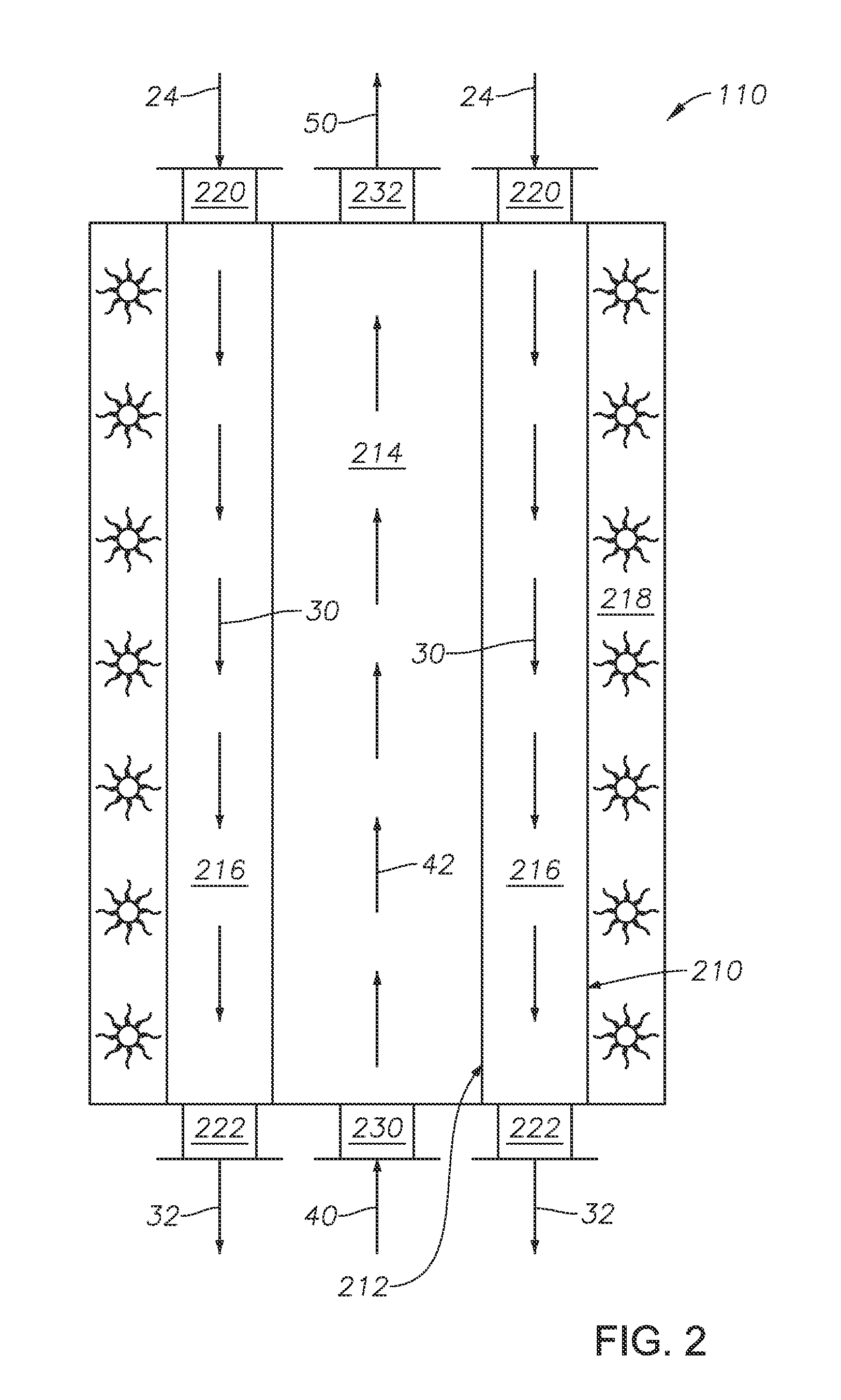

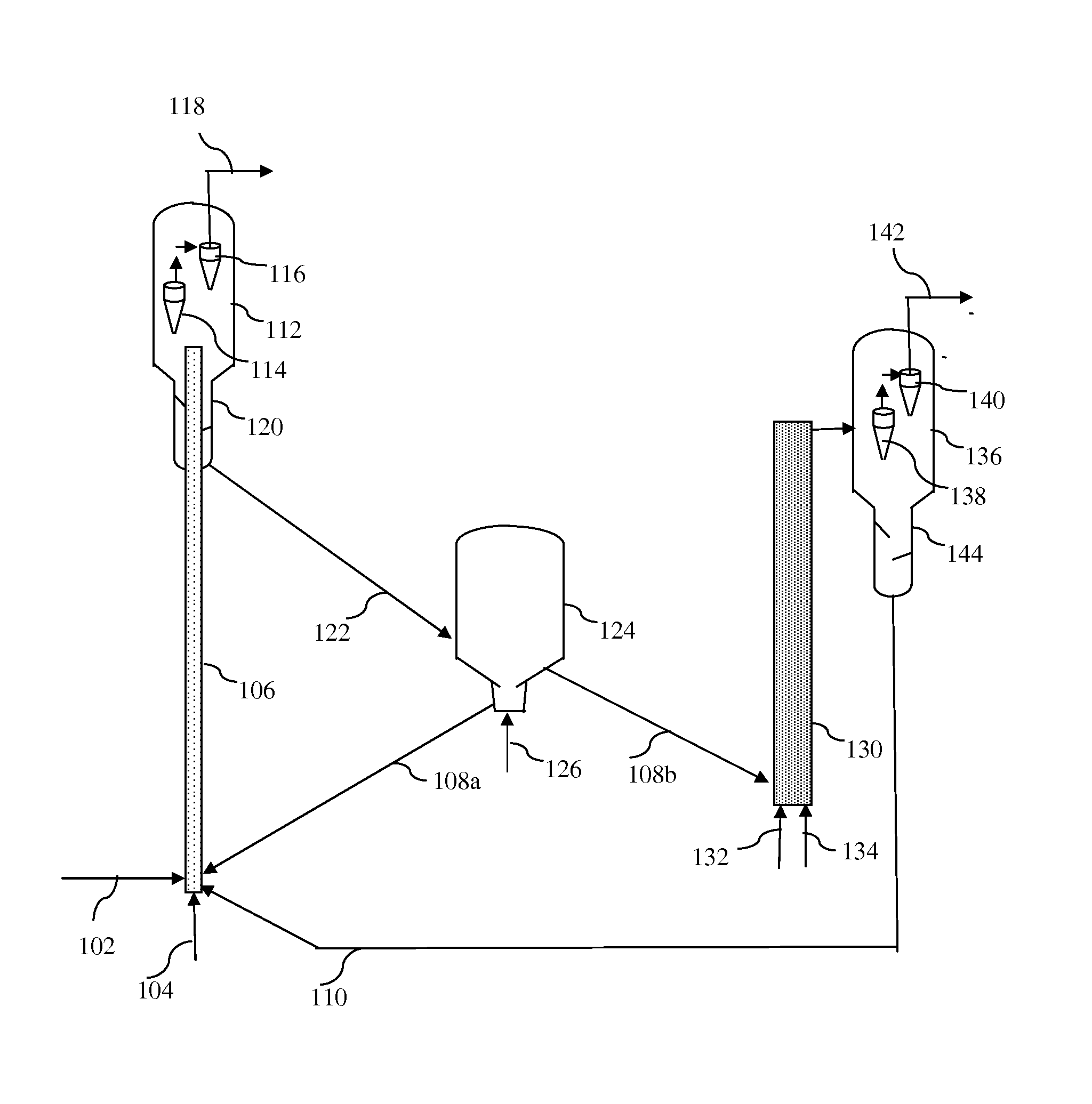

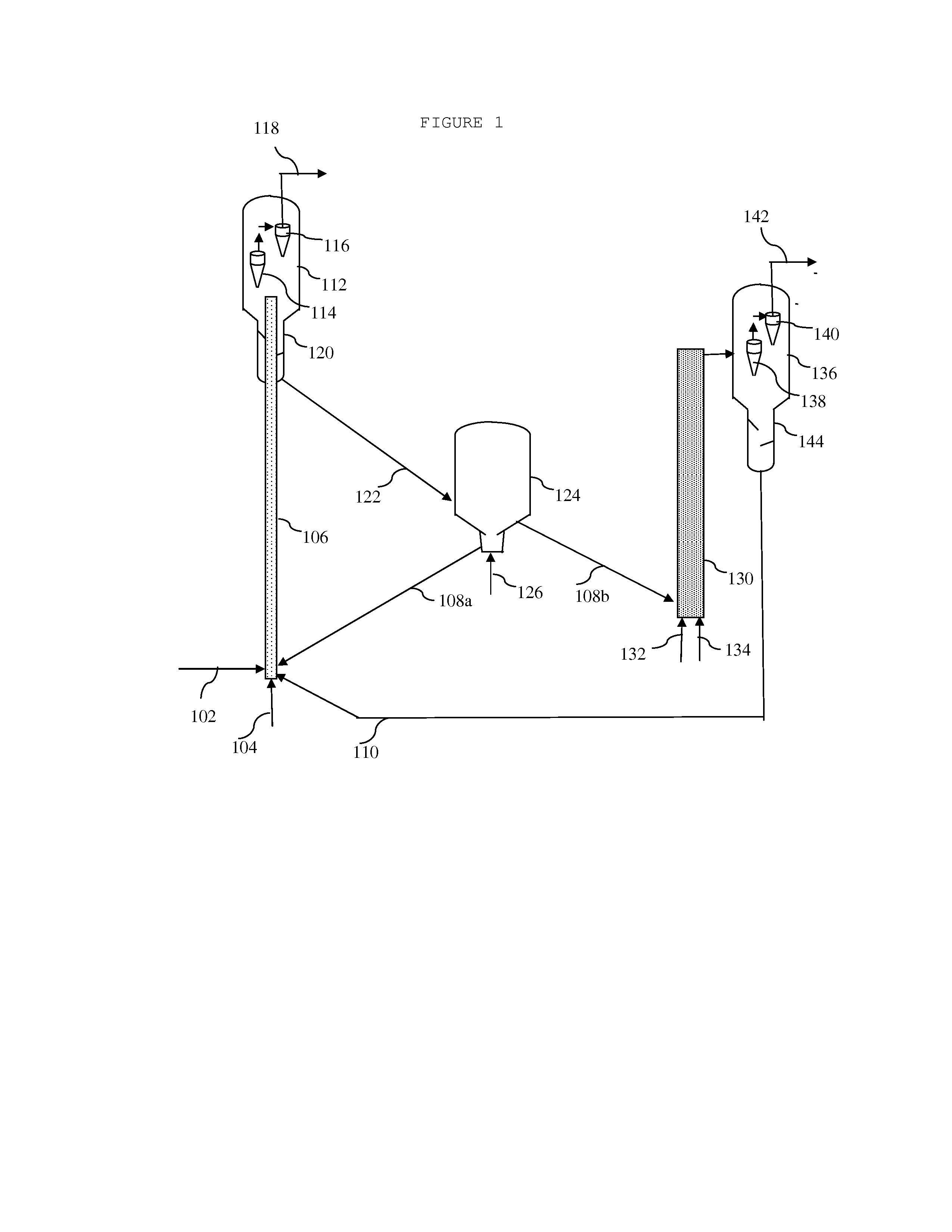

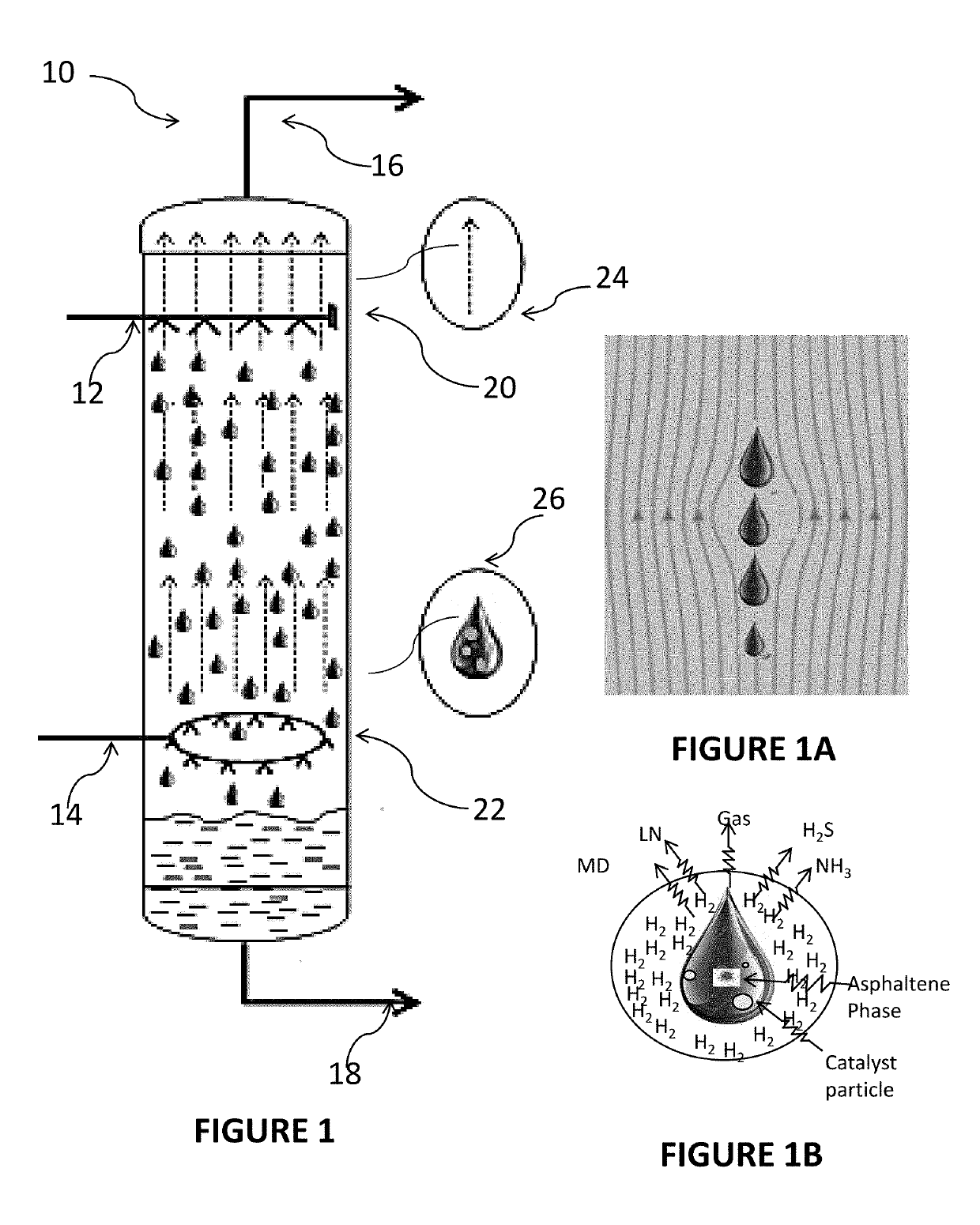

Methods and systems for upgrading heavy oil using catalytic hydrocracking and thermal coking

ActiveUS20140027344A1Speed up the conversion processImprove distillation yieldThermal non-catalytic crackingCatalyst activation/preparationHydrogenBoiling point

Methods and systems for hydroprocessing heavy oil feedstocks to form upgraded material use a colloidal or molecular catalyst dispersed within heavy oil feedstock, pre-coking hydrocracking reactor, separator, and coking reactor. The colloidal or molecular catalyst promotes upgrading reactions that reduce the quantity of asphaltenes or other coke forming precursors in the feedstock, increase hydrogen to carbon ratio in the upgraded material, and decrease boiling points of hydrocarbons in the upgraded material. The methods and systems can be used to upgrade vacuum tower bottoms and other low grade heavy oil feedstocks. The result is one or more of increased conversion level and yield, improved quality of upgraded hydrocarbons, reduced coke formation, reduced equipment fouling, processing of a wider range of lower quality feedstocks, and more efficient use of supported catalyst if used with the colloidal or molecular catalyst, as compared to a conventional hydrocracking process or a conventional thermal coking process.

Owner:HEADWATERS TECH INNOVATION LLC

Hydroprocessing Catalysts and Methods for Making Thereof

ActiveUS20120152805A1Reduces coke formationReduce formation of sedimentMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystReactor system

A method to upgrade heavy oil feedstock using an ebullated bed reactor and a novel catalyst system is provided. The ebullated bed reactor system includes two different catalyst with different characteristics: an expanded catalyst zone containing particulate catalyst having a particle size of greater than 0.65 mm; and a slurry catalyst having an average particle size ranging from 1 to 300 μm. The slurry catalyst is provided to the ebullated bed system containing the heavy oil feedstock, and entrained in the upflowing hydrocarbon liquid passing through the ebullated bed reaction zone. The slurry catalyst reduces the formation of sediment and coke precursors in the ebullating bed reactor system. The slurry catalyst is prepared from rework materials, which form a slurry catalyst in-situ upon mixing with the heavy oil feedstock.

Owner:CHEVROU USA INC

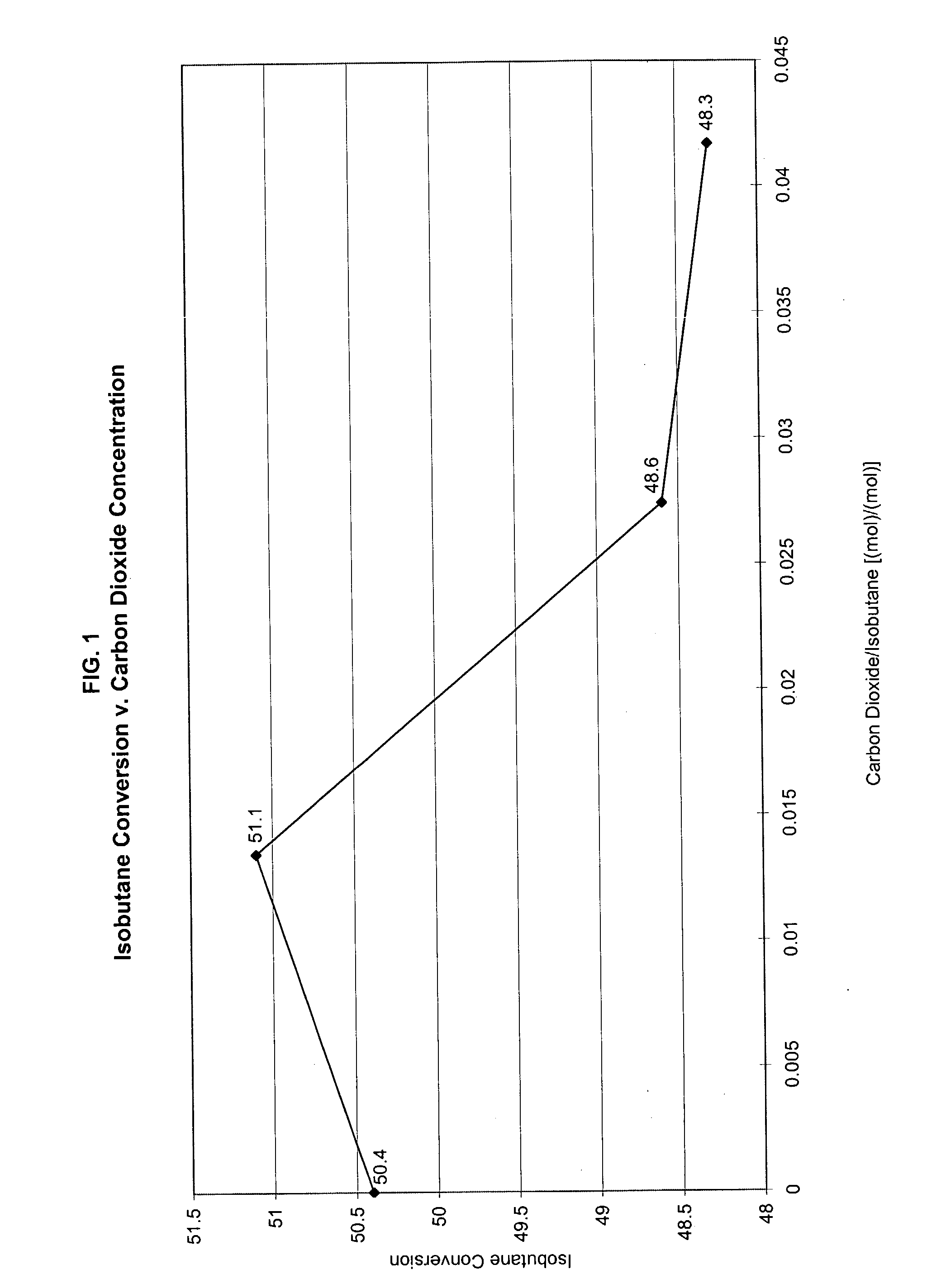

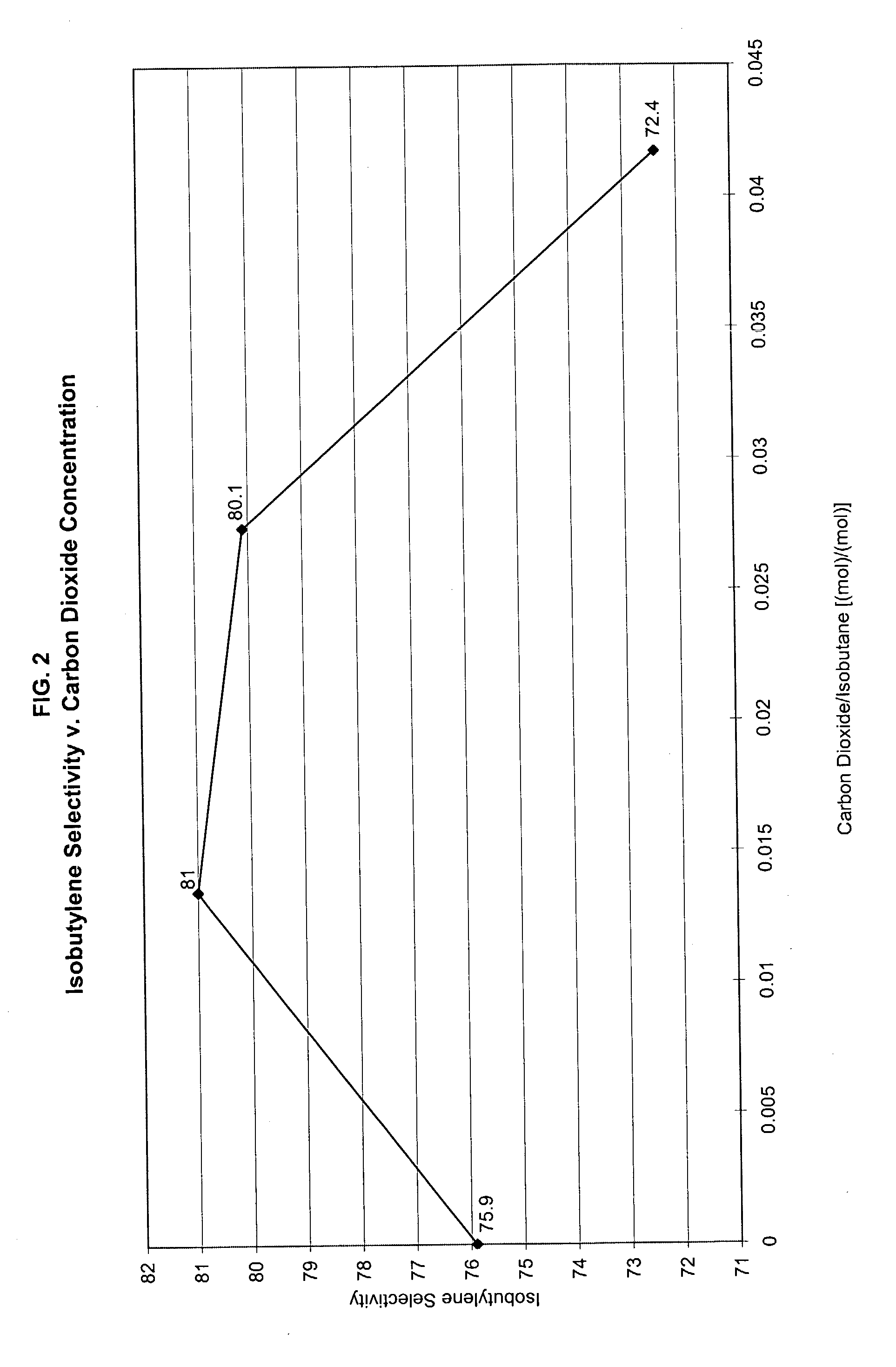

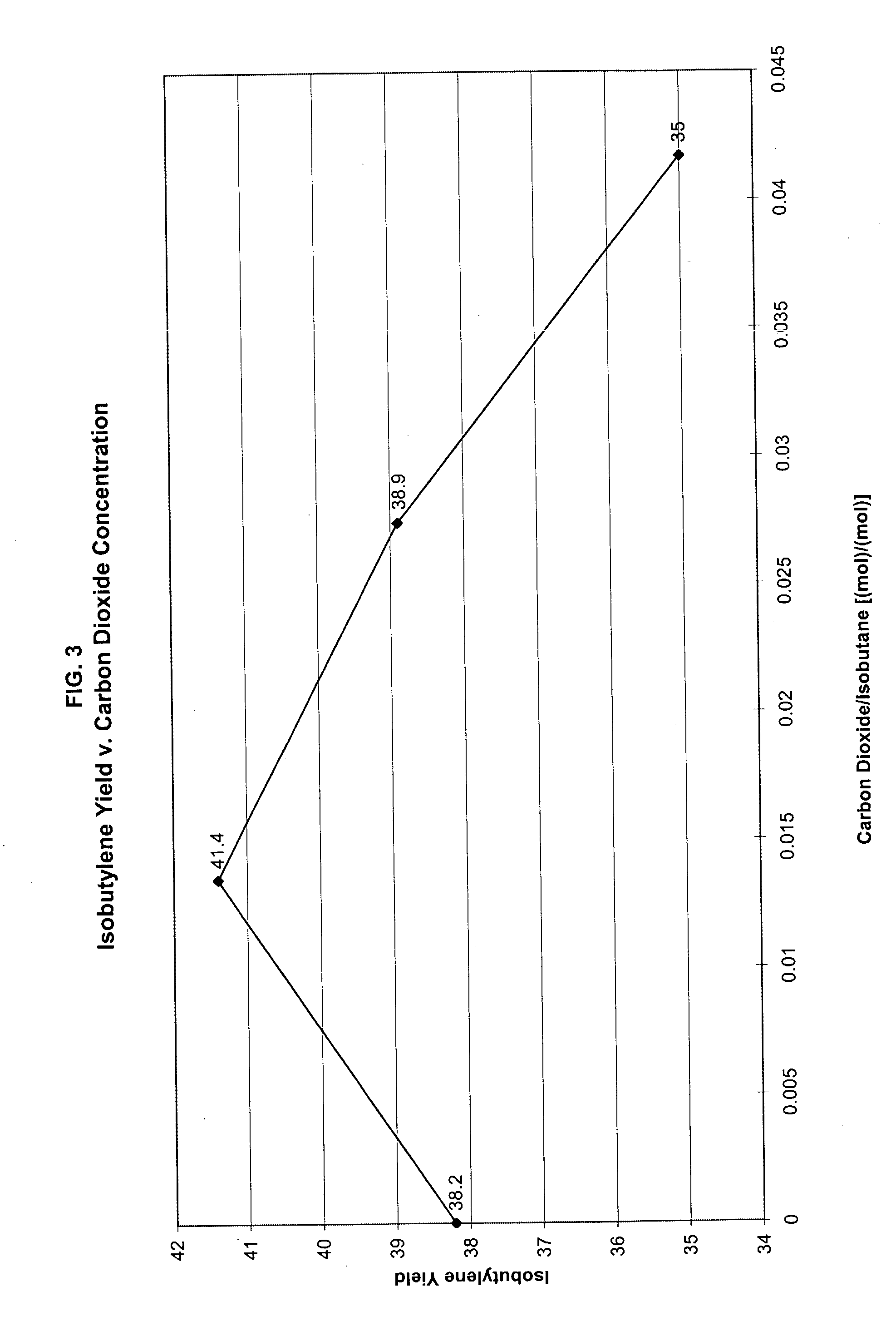

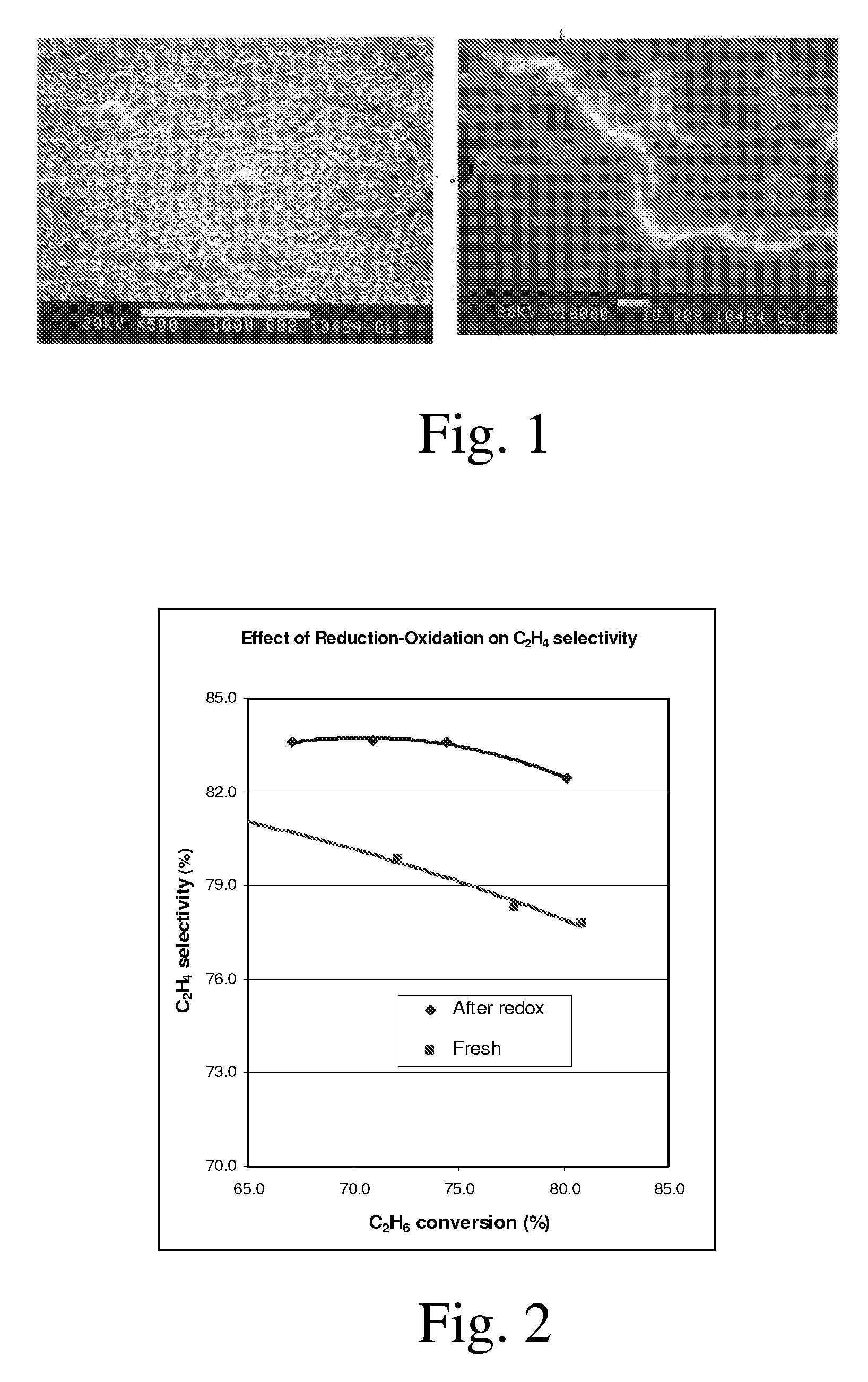

Carbon dioxide promoted dehydrogenation process for olefins

InactiveUS20040181107A1High yieldProlong lifeCatalystsHydrocarbon preparation catalystsAlkaneDehydrogenation

A process for the dehydrogenation of alkane hydrocarbons is disclosed. The process comprises contacting the alkane with a chromium-based dehydrogenation catalyst in the presence of carbon dioxide at a temperature of from about 400° C. to about 700° C., a pressure of from about 0.1 to about 10 atmospheres, wherein the alkane to carbon dioxide molar ratio is about 1:0.0001 to 1:0.045.

Owner:SAUDI BASIC IND CORP SA

Process for catalytic hydrotreatment of a pyrolysis oil

ActiveUS8748680B2Reduces coke formationCatalytic crackingLiquid carbonaceous fuelsCellulosePyrolysis oil

Owner:SHELL USA INC

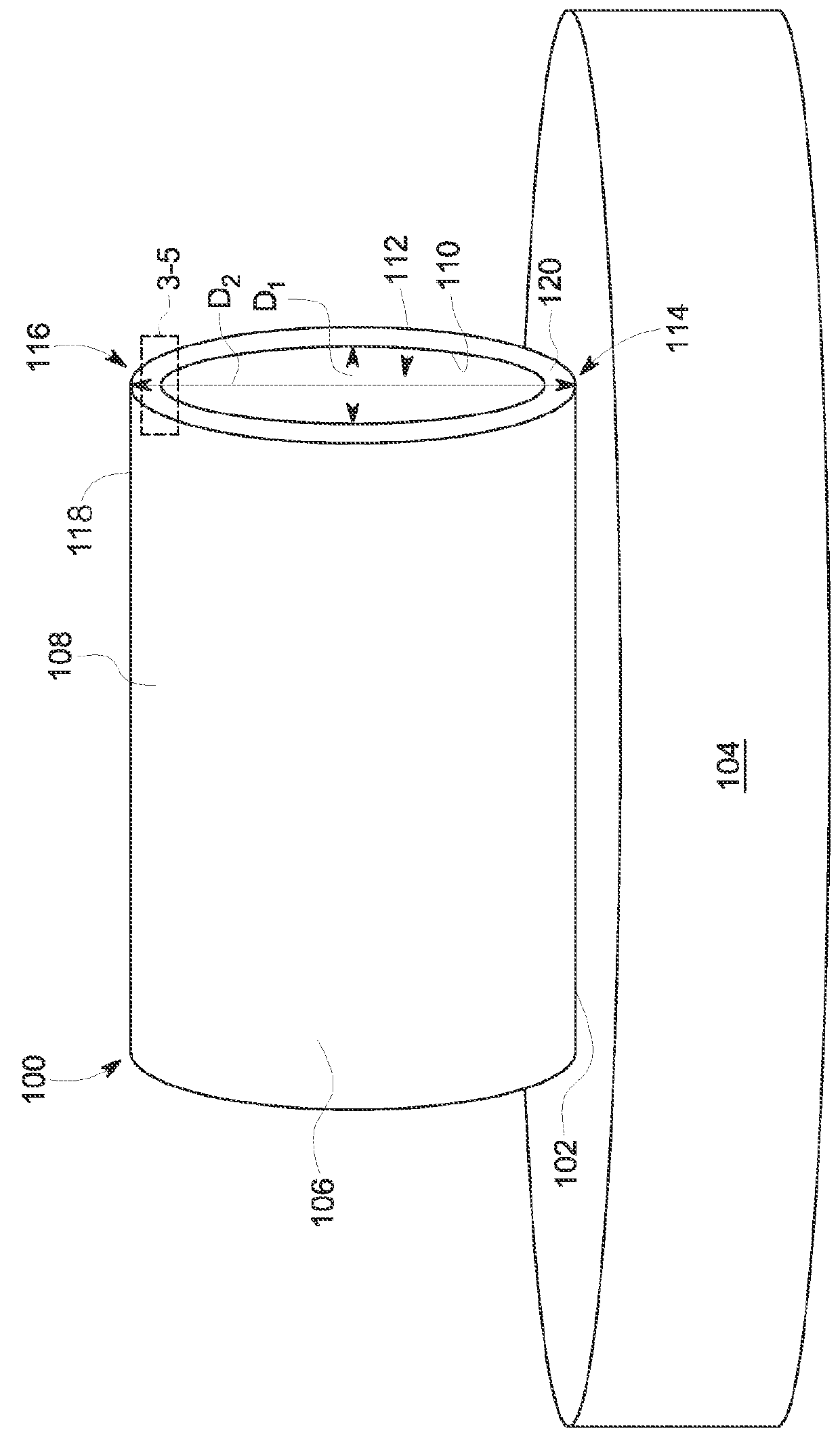

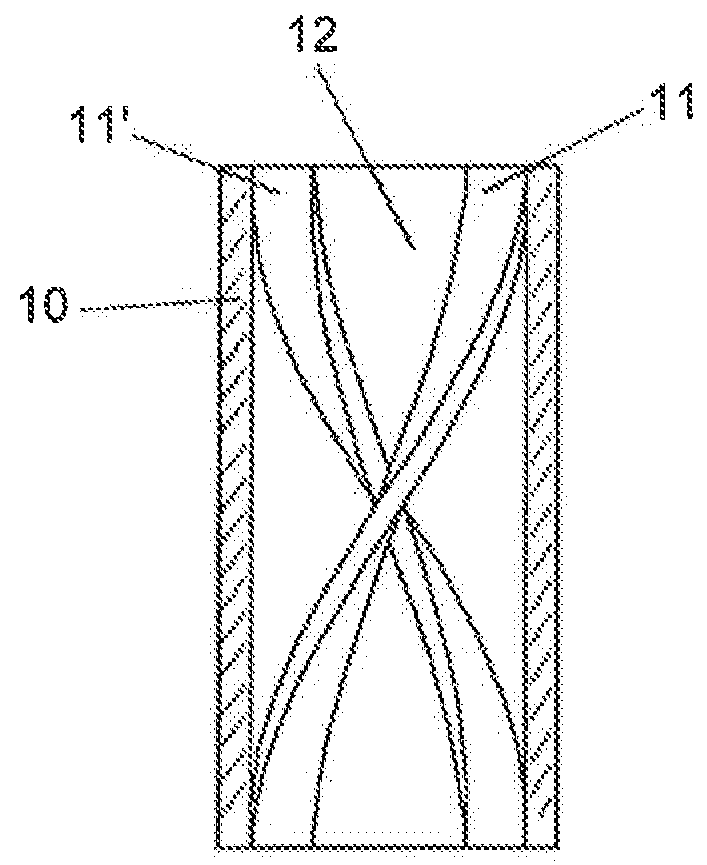

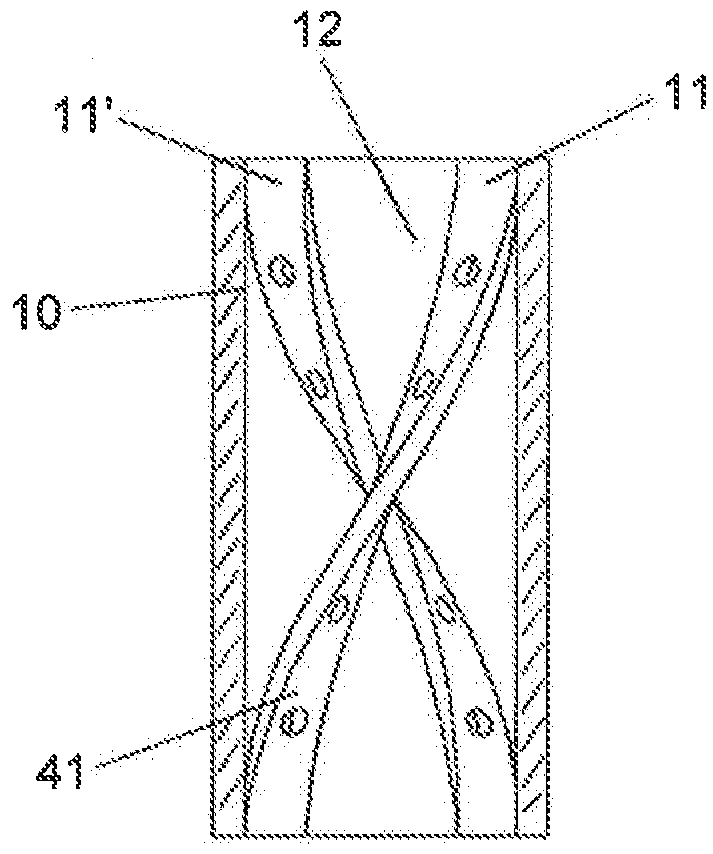

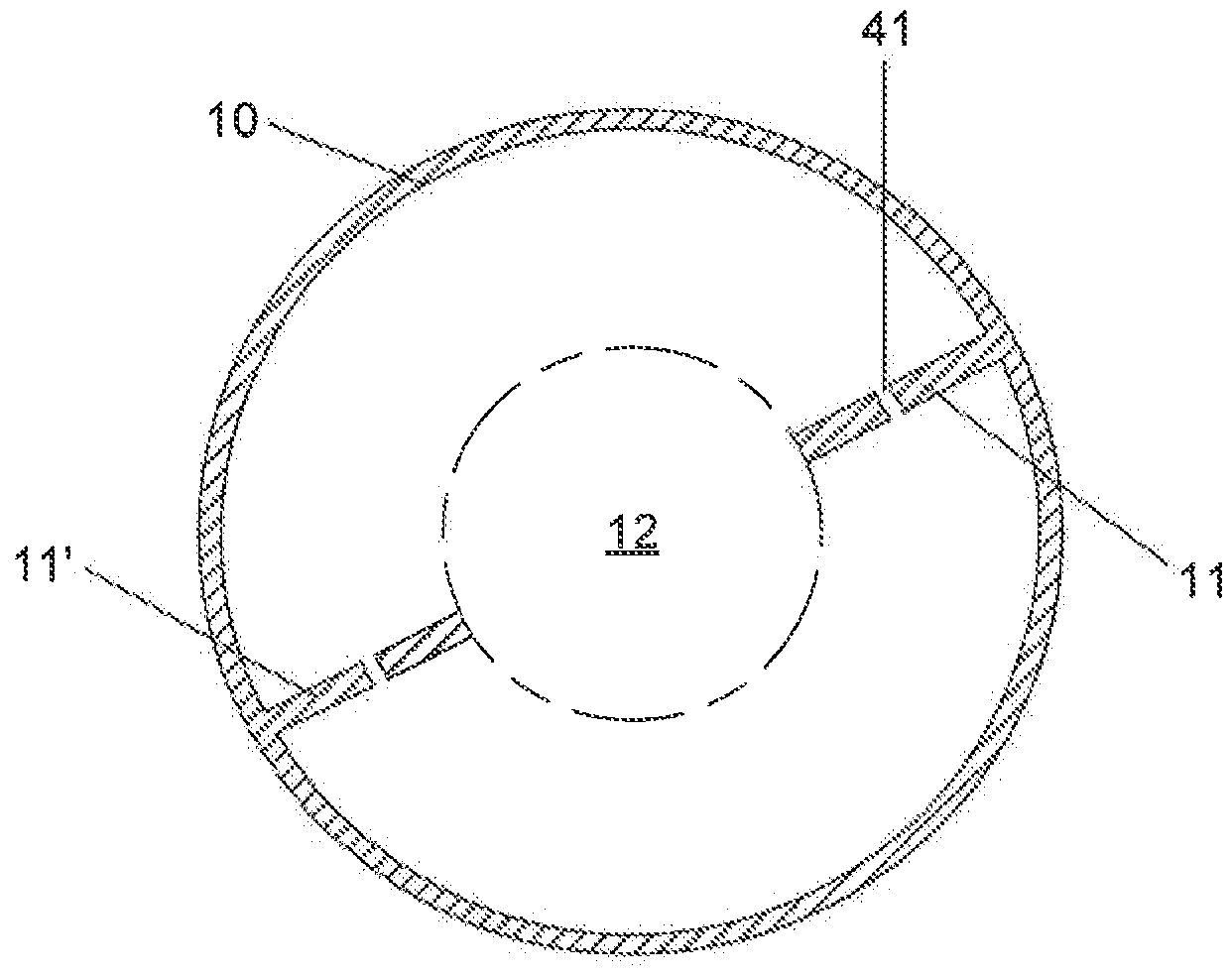

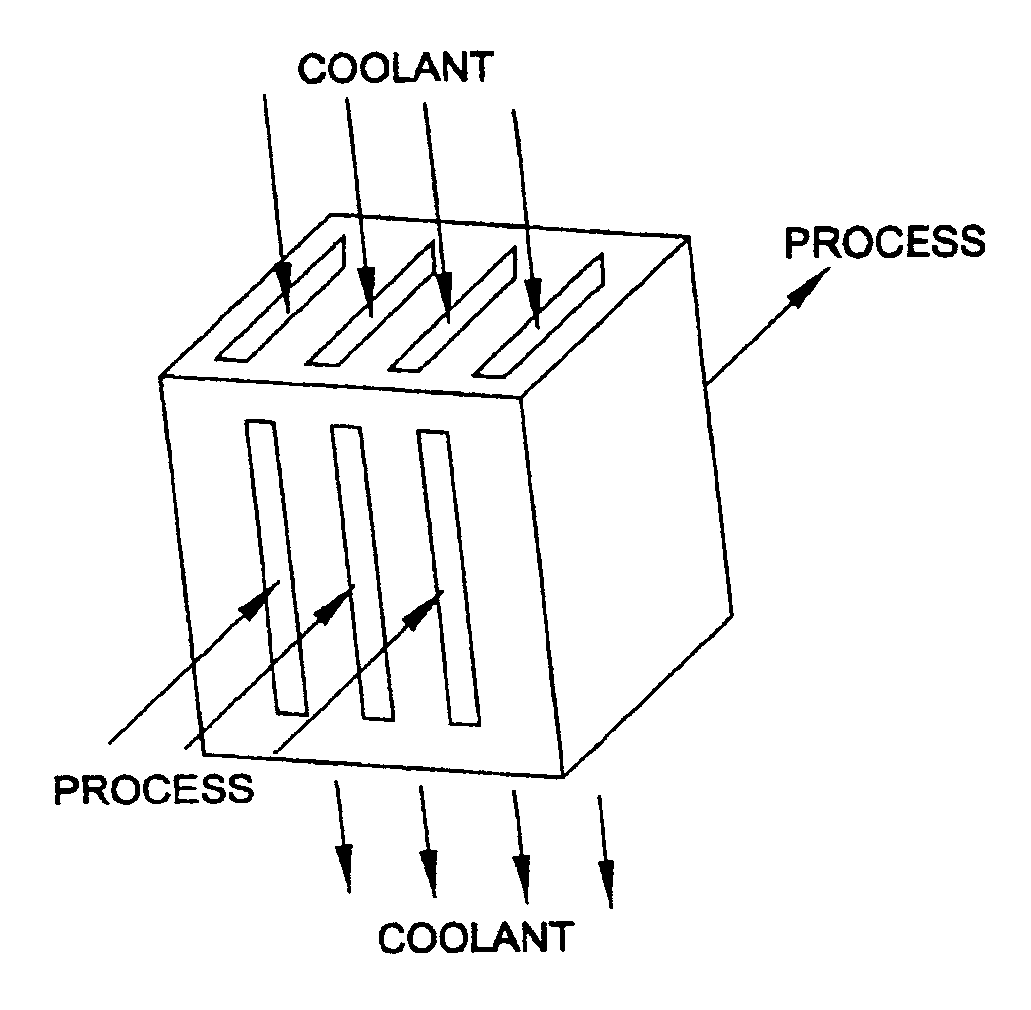

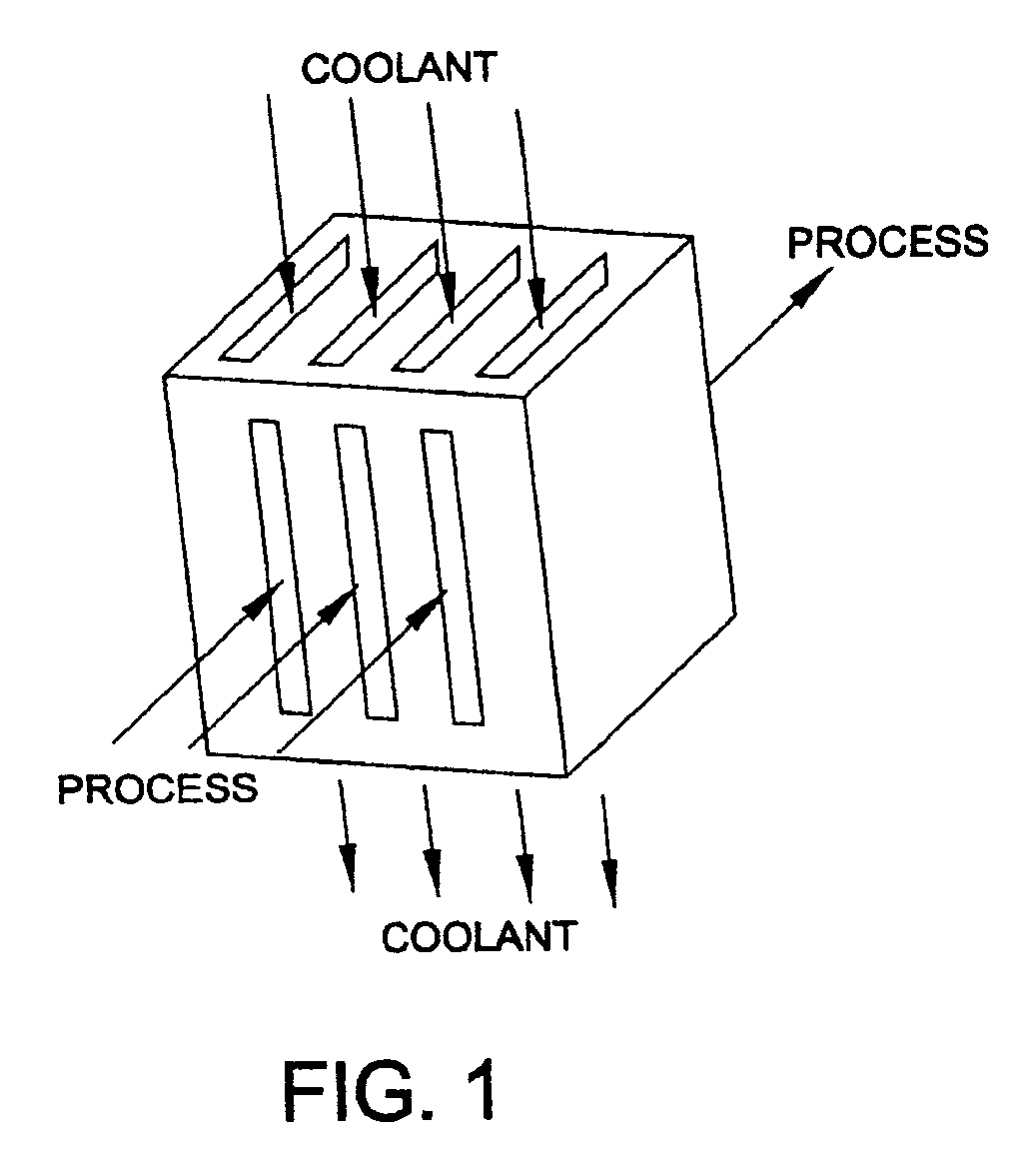

Process for heavy oil upgrading in a double-wall reactor

ActiveUS20160145499A1Reduces coke formationMaintain reaction temperatureThermal non-catalytic crackingCatalytic crackingHeat flowReaction temperature

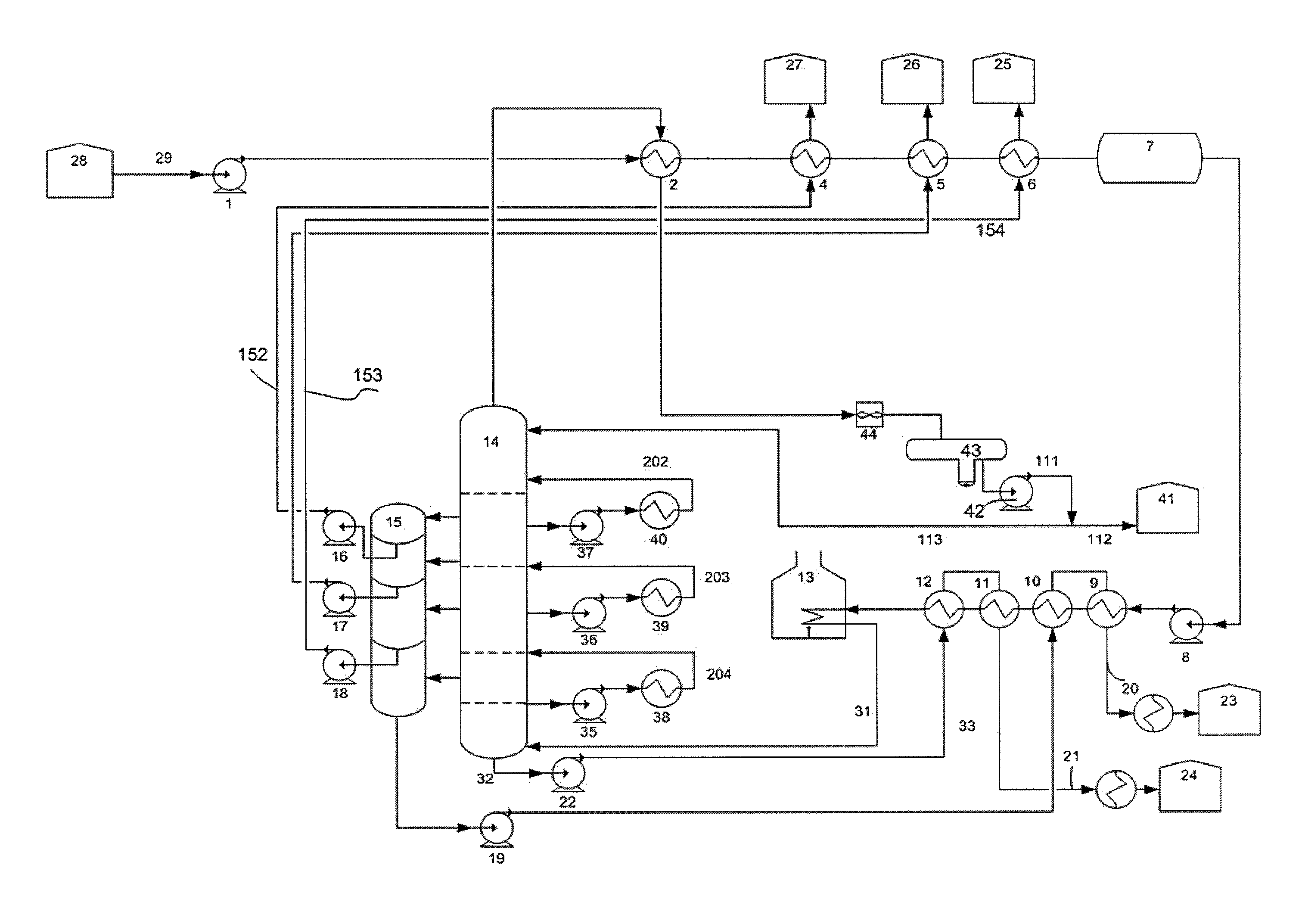

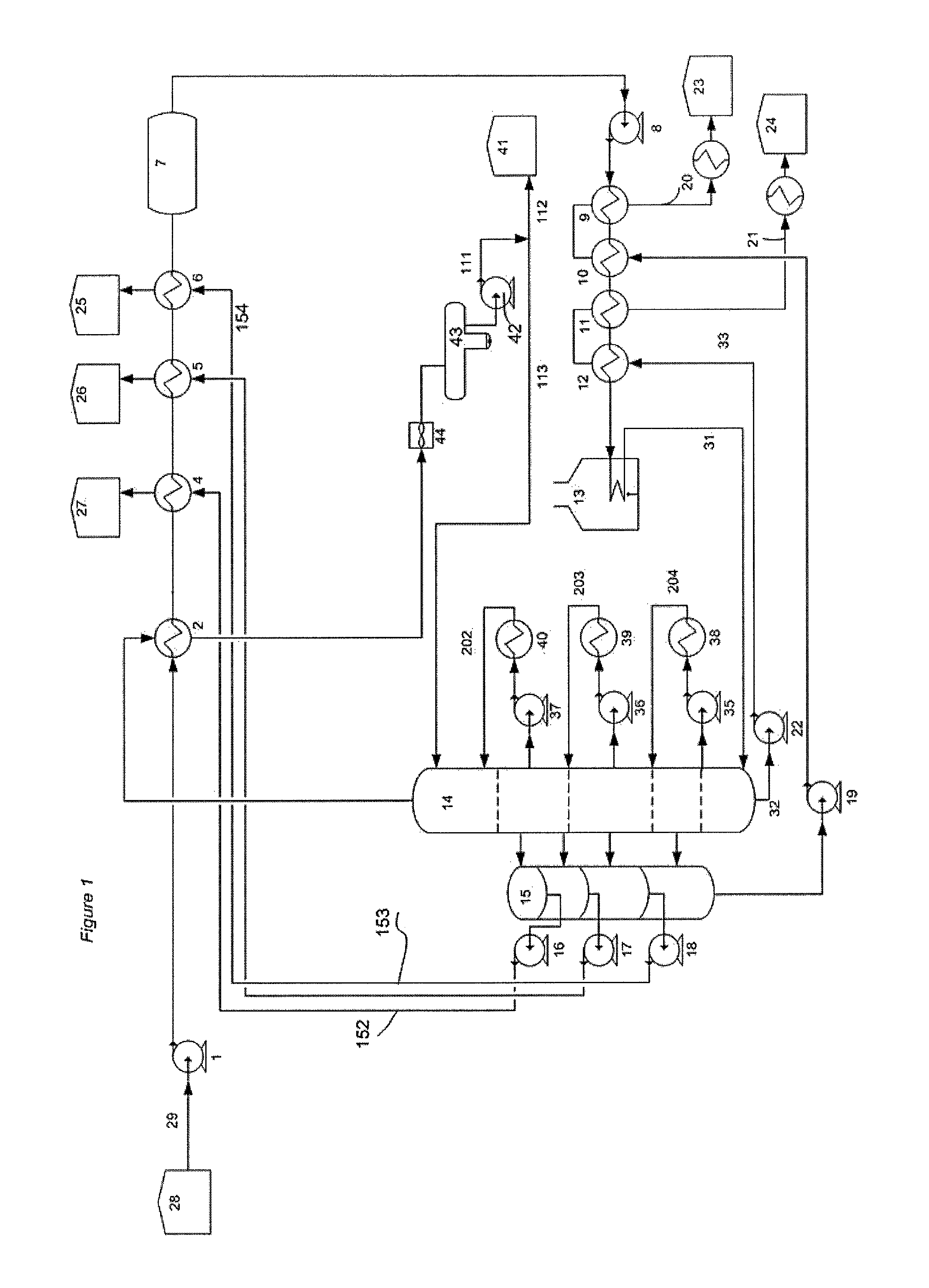

A process for reducing coke formation during hydrocarbon upgrading reactions using a double-wall reactor comprising the steps of feeding a heated feed water to a shell-side volume of the double-wall reactor to produce a heat transfer stream, the double-wall reactor comprising an exterior wall and an interior wall, a reaction section volume, a heating element configured to heat the heat transfer stream, wherein heat is transferred from the heat transfer stream to the reaction section volume, feeding the hot water return exiting the shell-side volume through a filter; mixing the filtered water stream with a heated hydrocarbon feedstock; feeding the mixed stream to the reaction section volume in a configuration counter-current to the heat transfer stream; reacting the reaction flow stream at a reaction temperature, wherein the heat transferred to the reaction section volume is operable to maintain the reaction temperature above the critical temperature of water.

Owner:SAUDI ARABIAN OIL CO

Process for the hydroconversion of petroleum feedstocks via slurry technology allowing the recovery of metals from the catalyst and feedstock using a leaching step

InactiveUS20130087481A1Promote hydrogenationReduces coke formationThermal non-catalytic crackingCatalytic crackingCombustionFuel oil

A process for the hydroconversion of heavy oil feedstocks comprises a step for hydroconversion of the feedstock in at least one reactor containing a catalyst in slurry mode used to recover metals from the residual unconverted fraction, especially those used as catalysts. The process comprises a hydroconversion step, a gas / liquid separation step, a liquid / liquid extraction step, a grinding step, a leaching step, a combustion step, a metals extraction step and a step for the preparation of catalytic solutions which are recycled to the hydroconversion step.

Owner:INTREVEP SA

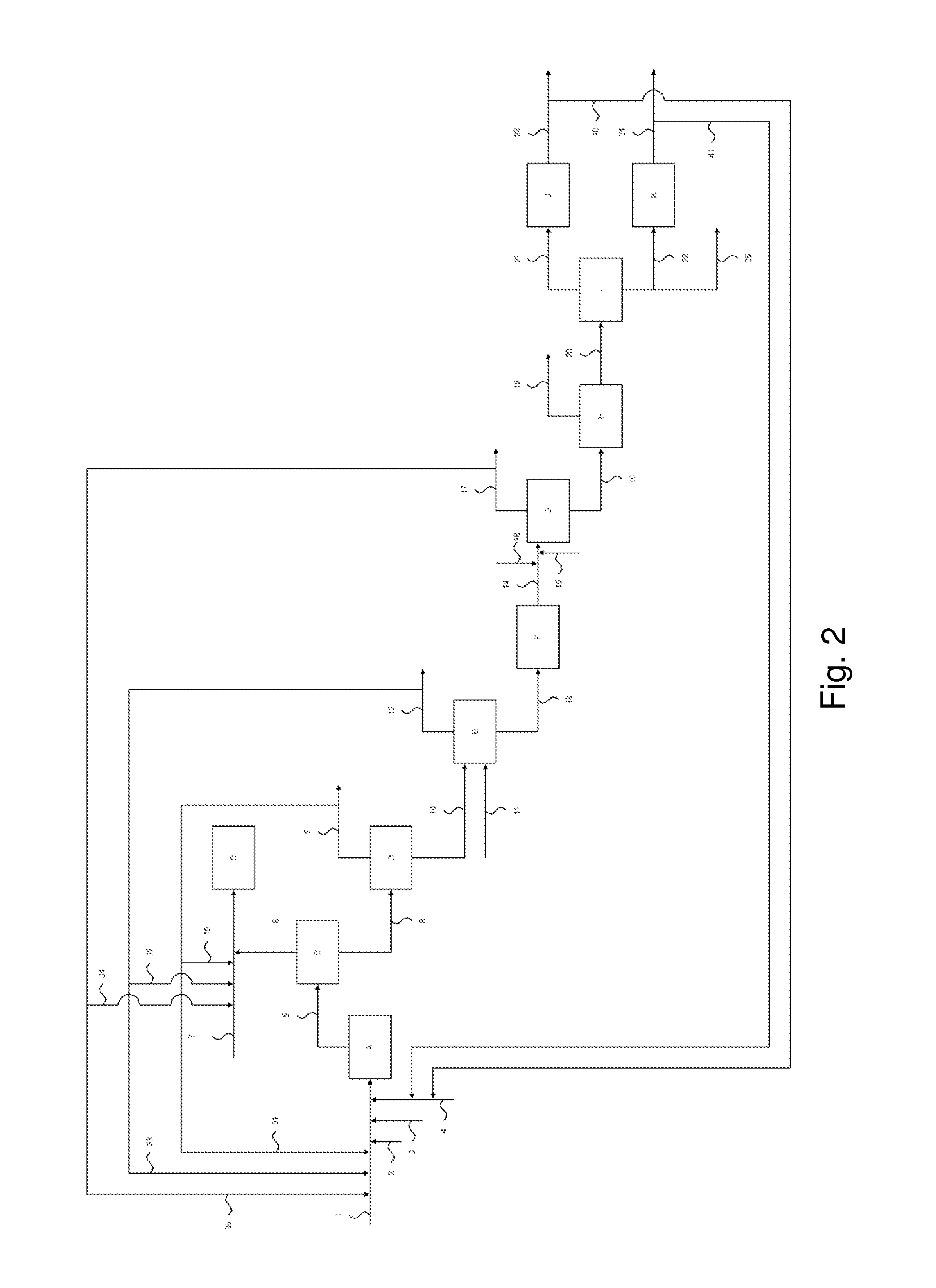

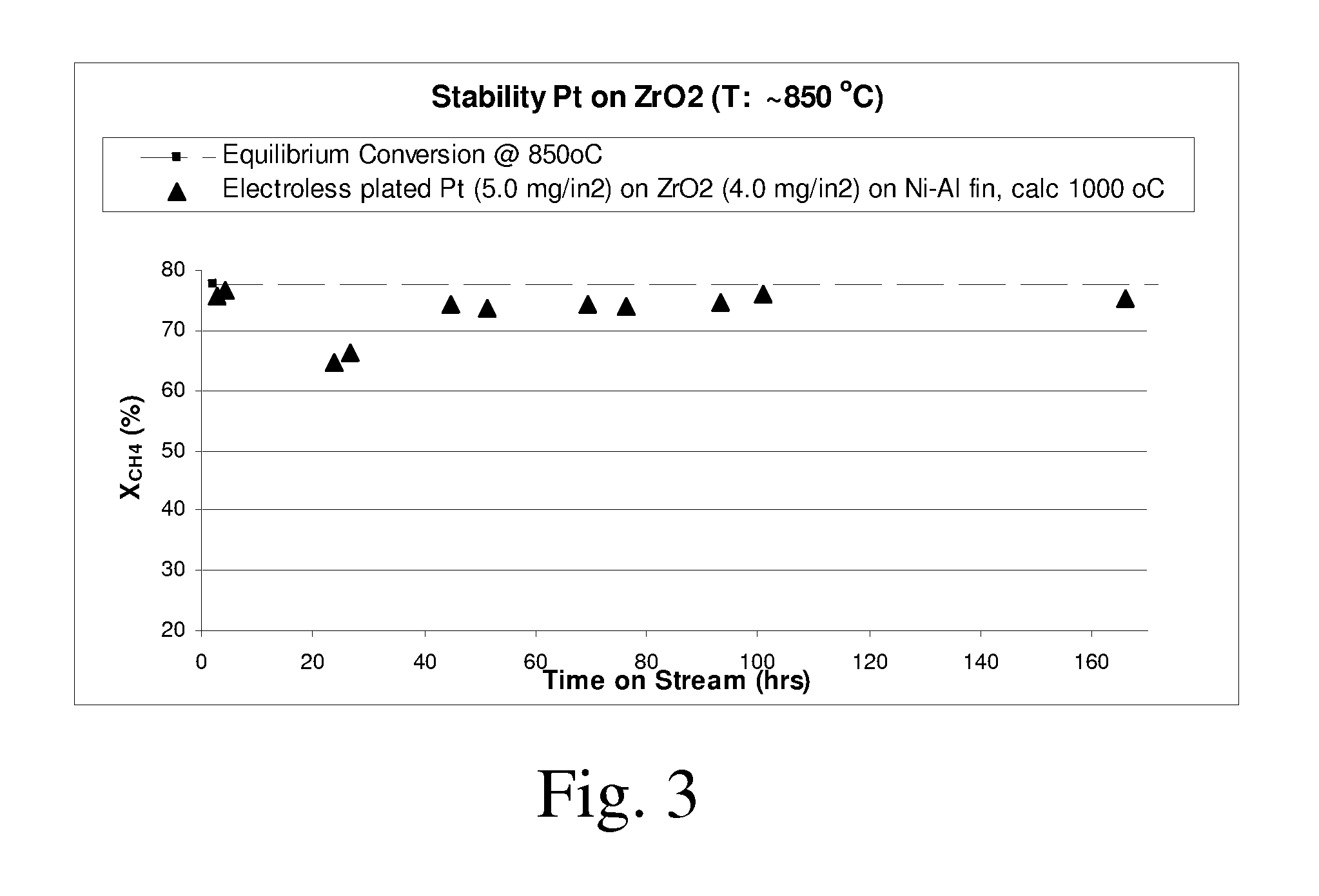

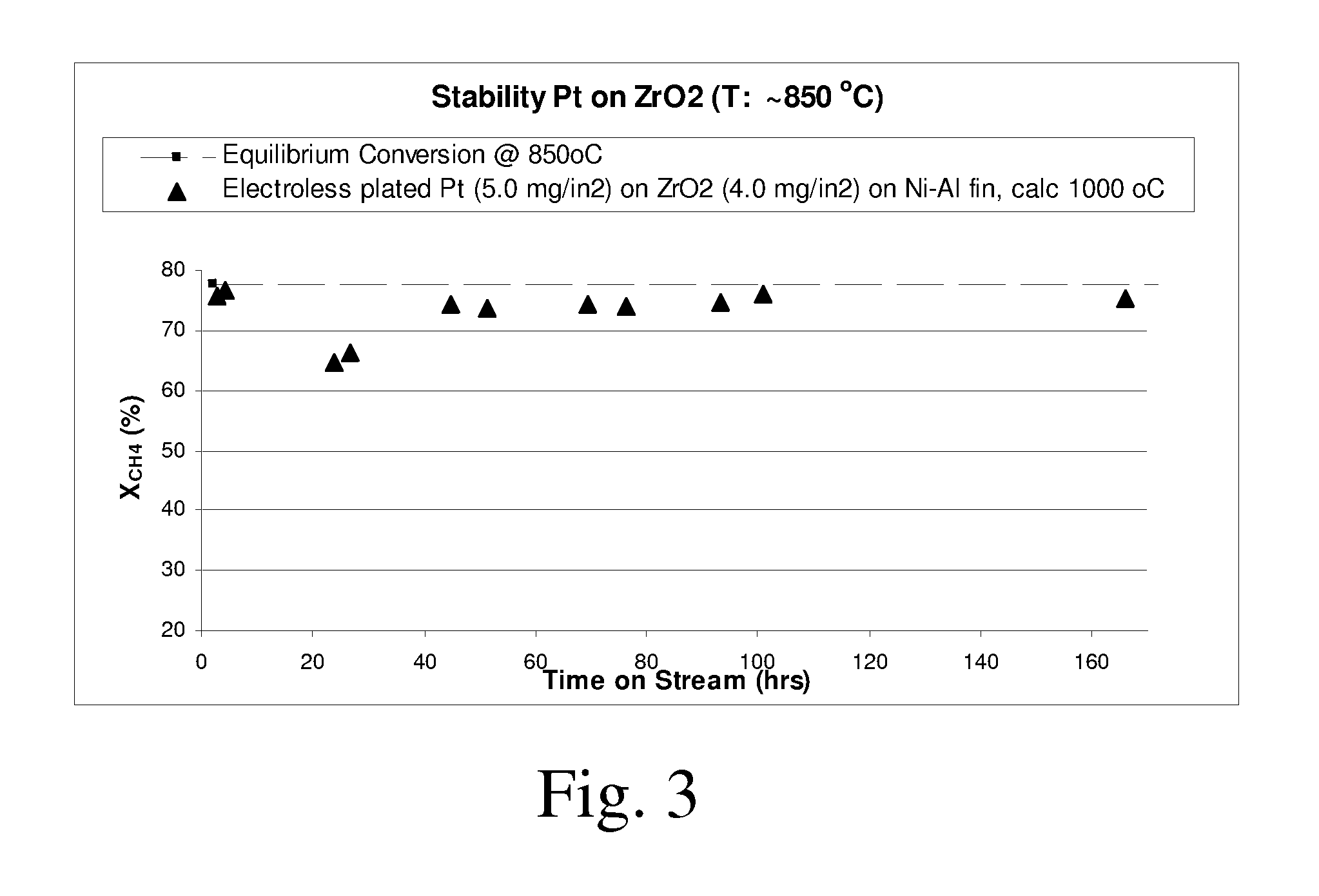

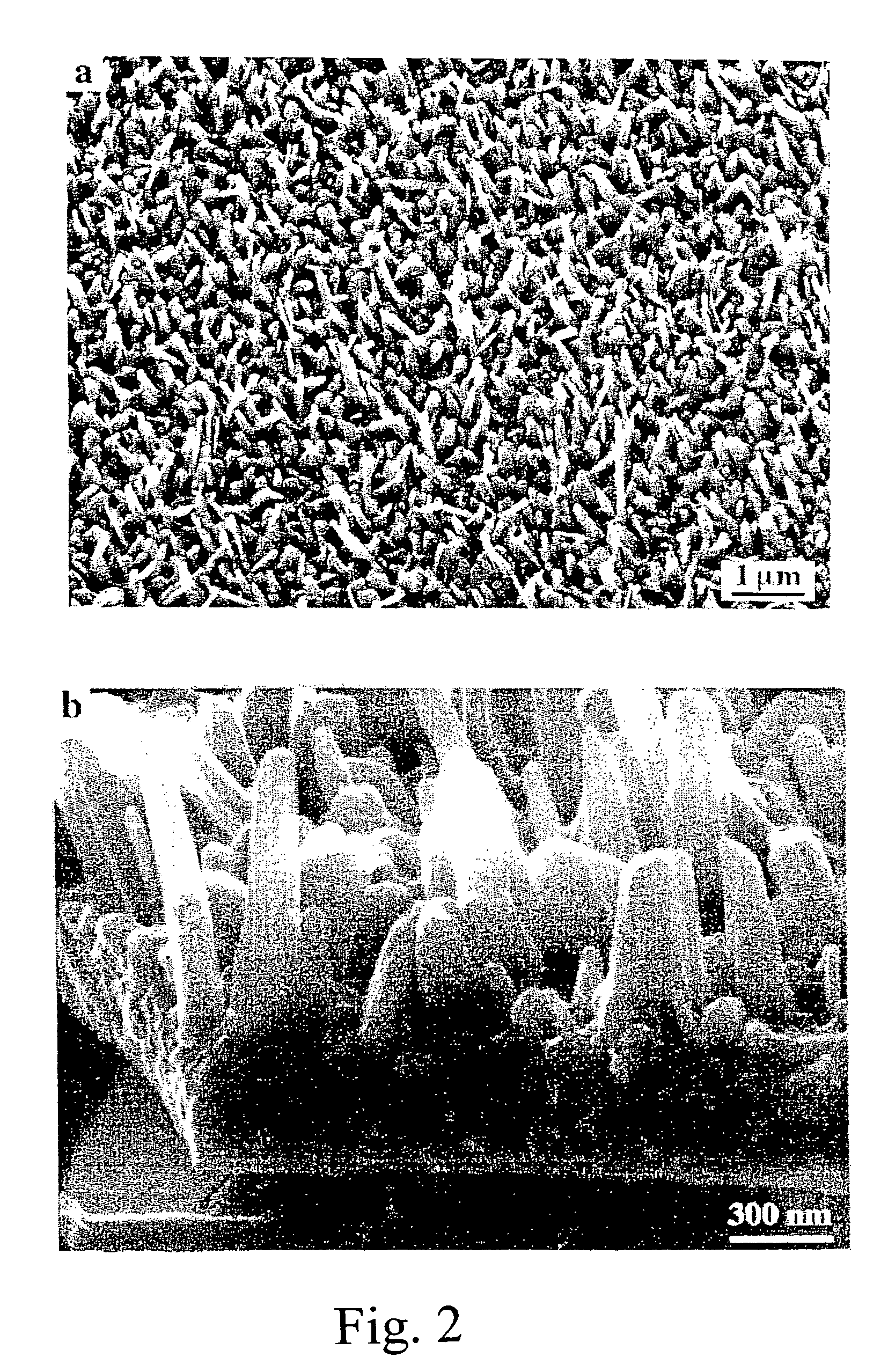

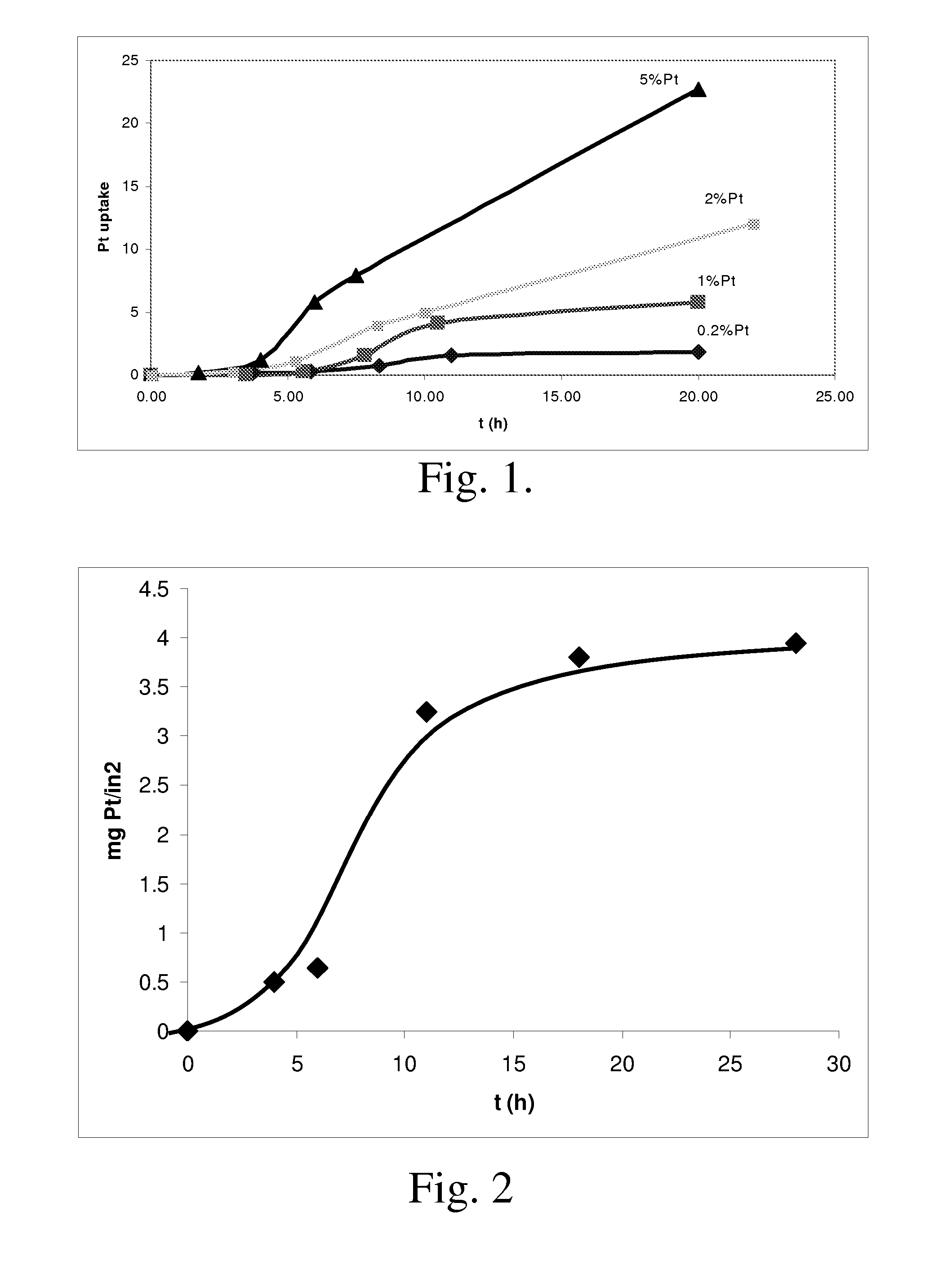

Electroless plating in microchannels

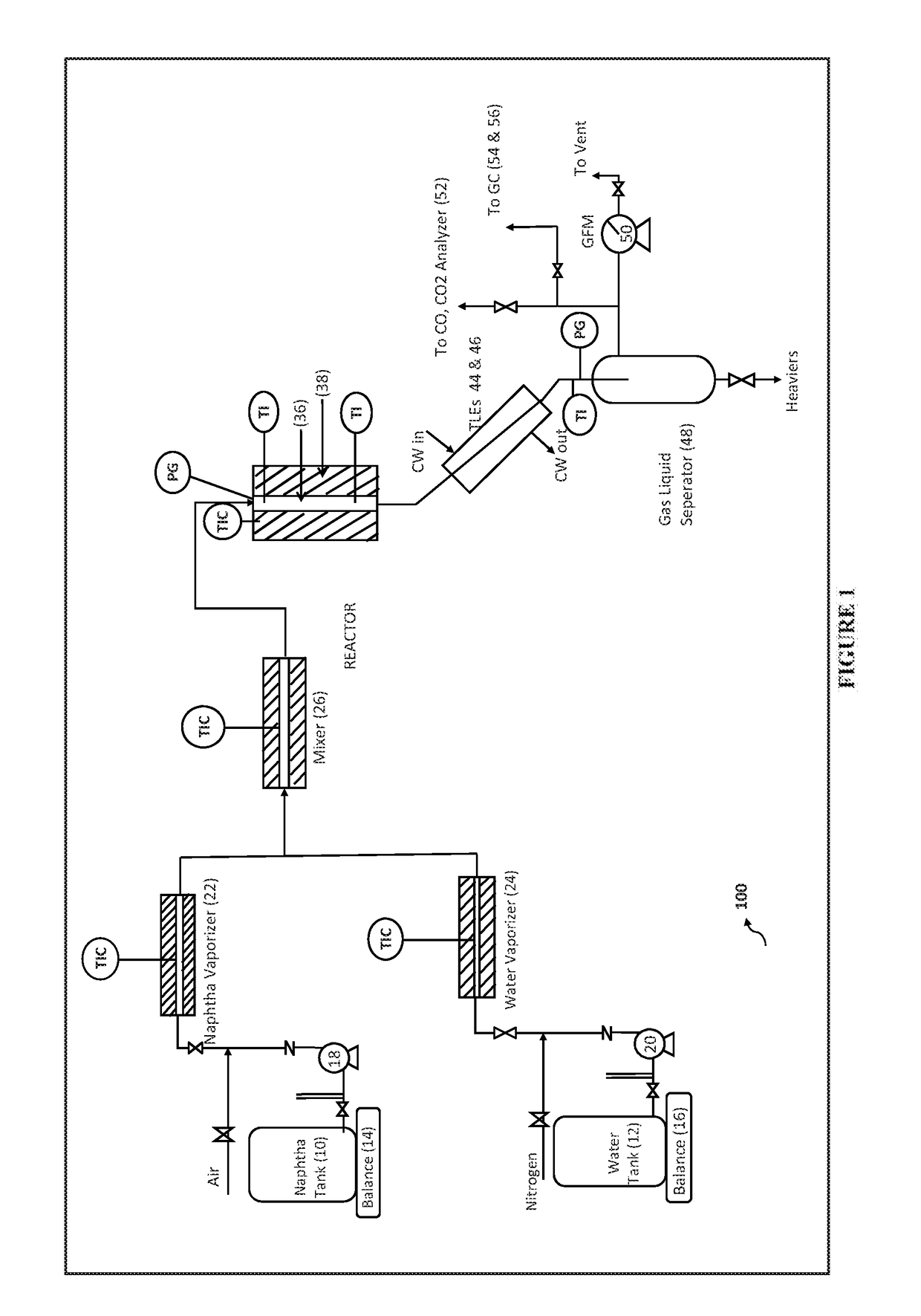

InactiveUS20080214884A1High plating rateReduces coke formationLiquid surface applicatorsChemical/physical/physico-chemical microreactorsSteam reformingCombustion

Novel methods of electroless plating are described. Catalyst coatings can be applied within microchannel apparatus. Various reactions, including combustion and steam reforming, can be conducted over electroless catalyst coatings.

Owner:VELOCYS CORPORATION

Steam cracking processes

ActiveUS20140121432A1Promote rapid vaporization of the liquid feed stockReduces coke formationThermal non-catalytic crackingPressurized chemical processCracking reactionConvection

The present disclosure provides a steam cracking process, comprising heating a liquid feed stock in a convection section of a cracking furnace and subsequently conveying the material to a radiant section of the cracking furnace for cracking reaction therein, wherein a monoolefin-containing stream is conveyed to the cracking furnace for cracking reaction through at least one of modes A to C.

Owner:CHINA PETROCHEMICAL CORP +1

Process for making a distillate product and/or c2-c4 olefins

InactiveUS20130178672A1Reduces coke formationLow yieldCatalytic crackingLiquid hydrocarbon mixture productionCelluloseHydrocarbon

A process for making a distillate product and one or more C2-C4 olefins from a FCC feedstock containing a cellulosic material and a hydrocarbon co-feed is provided.

Owner:SHELL OIL CO

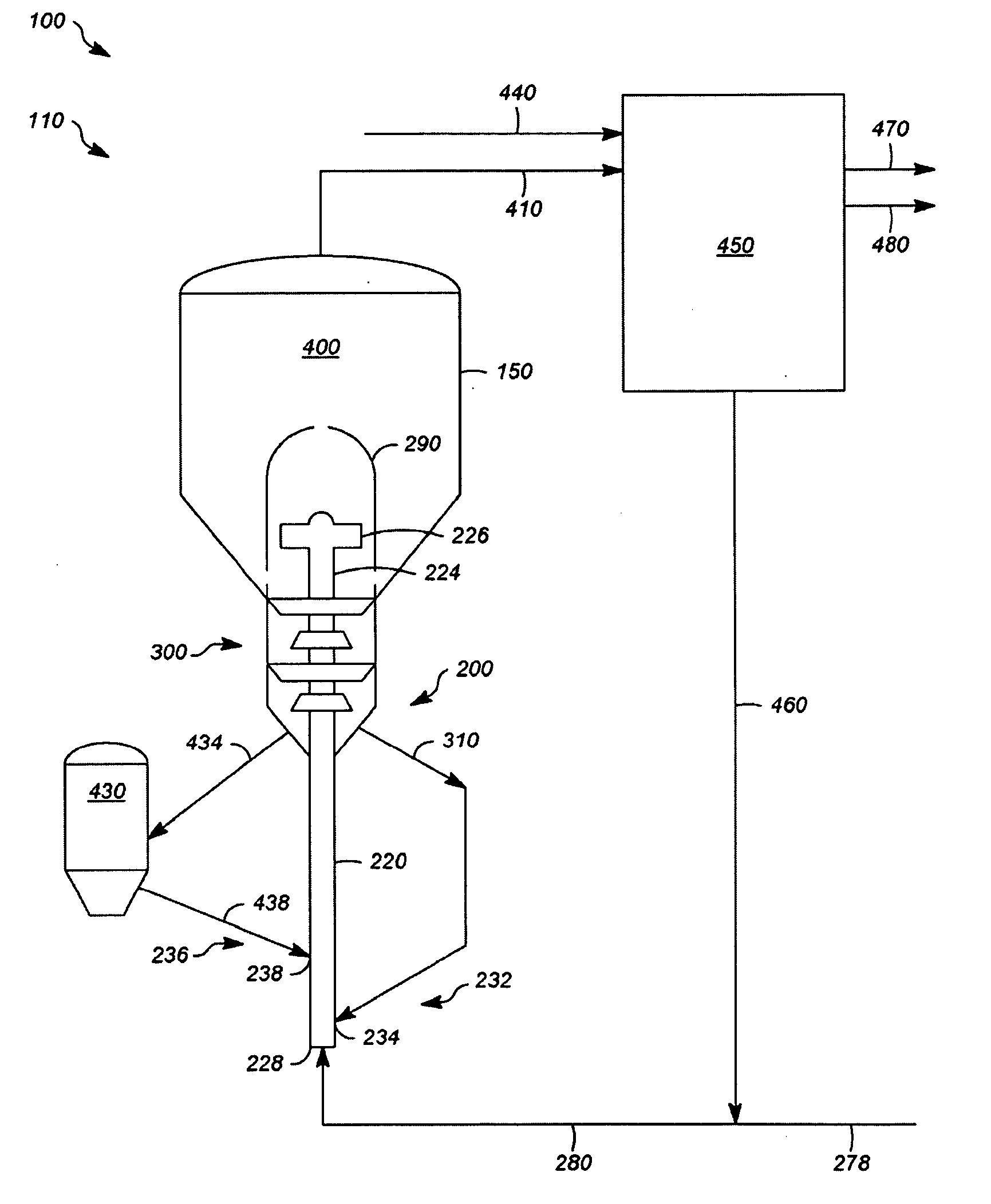

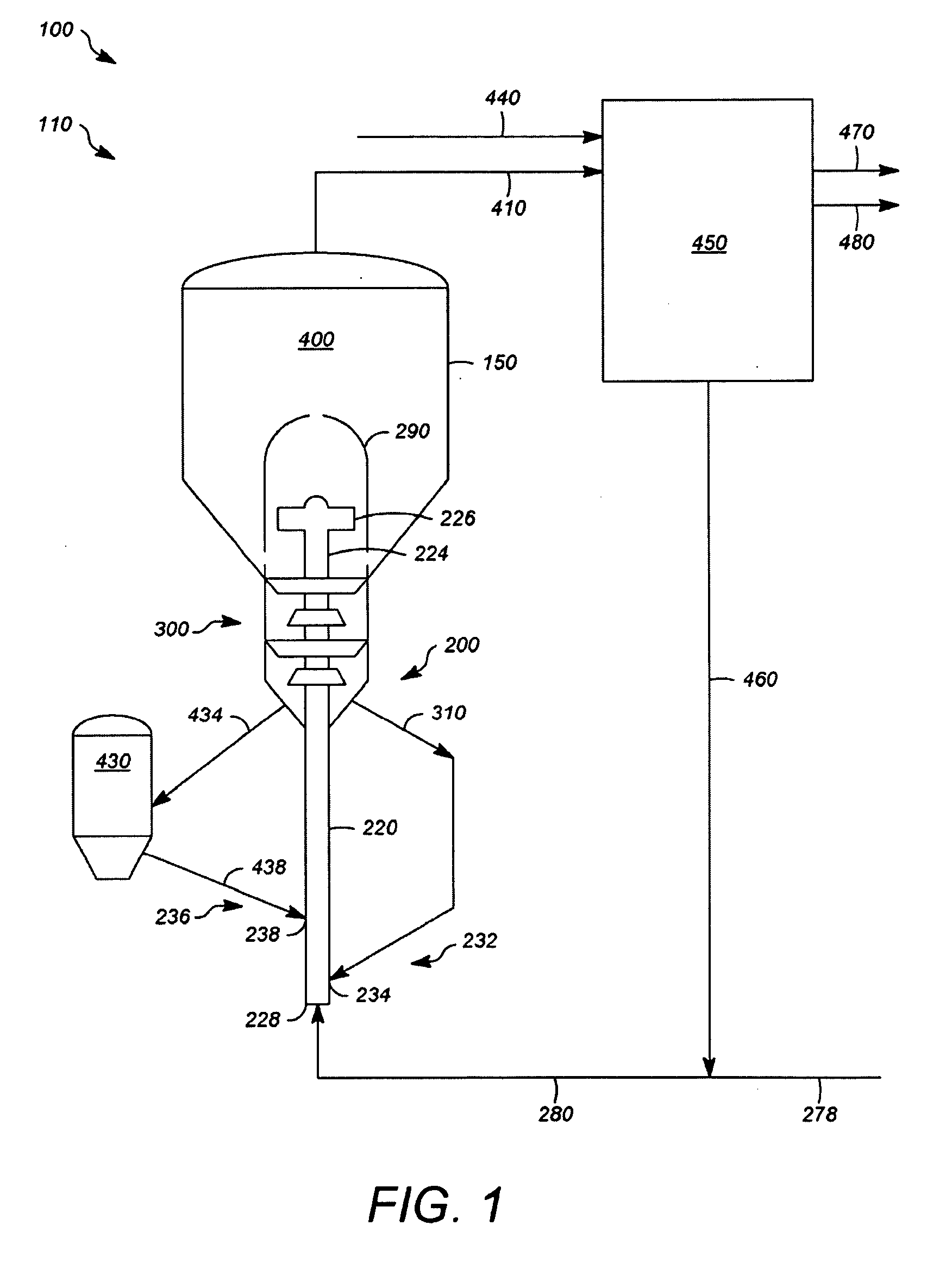

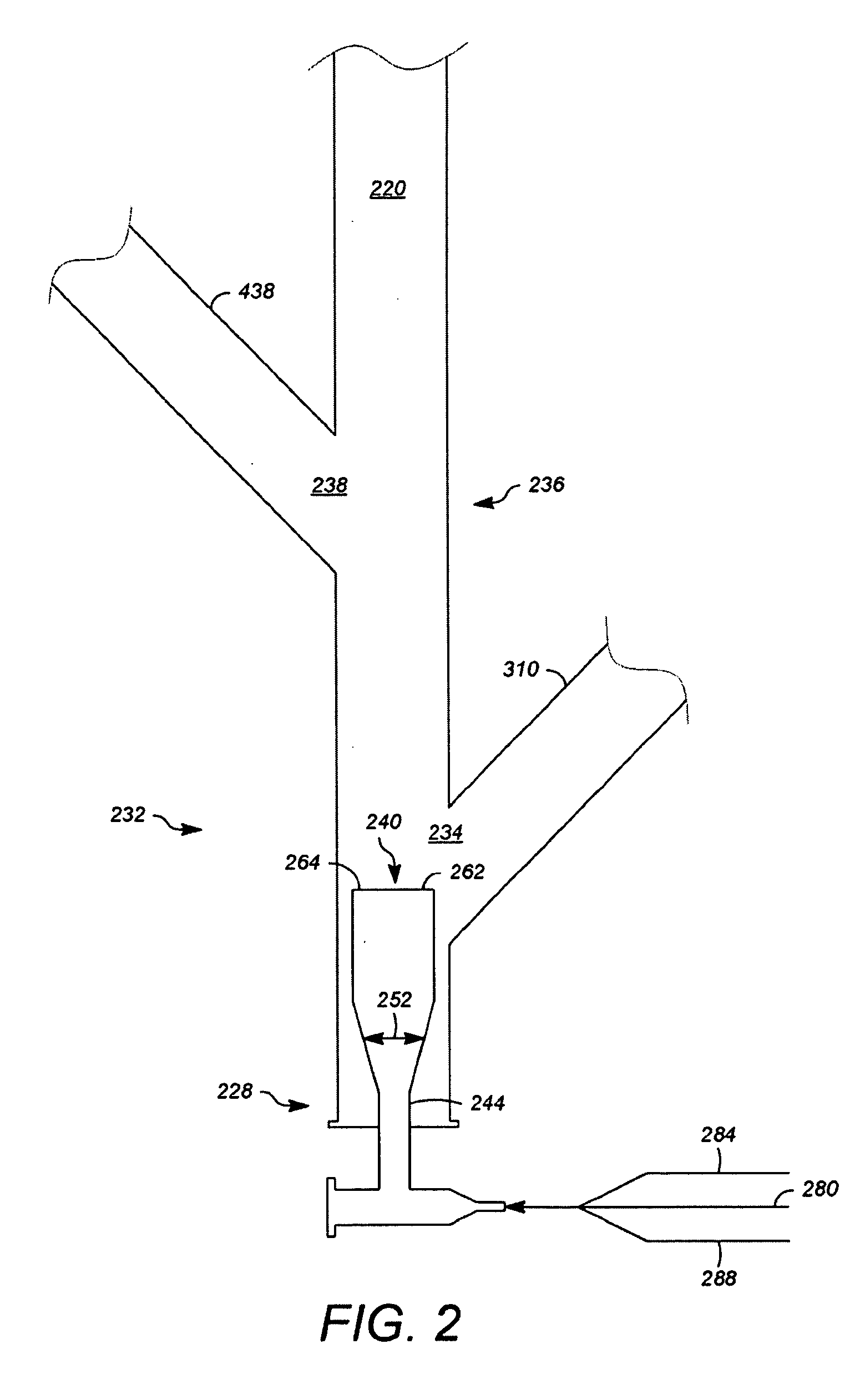

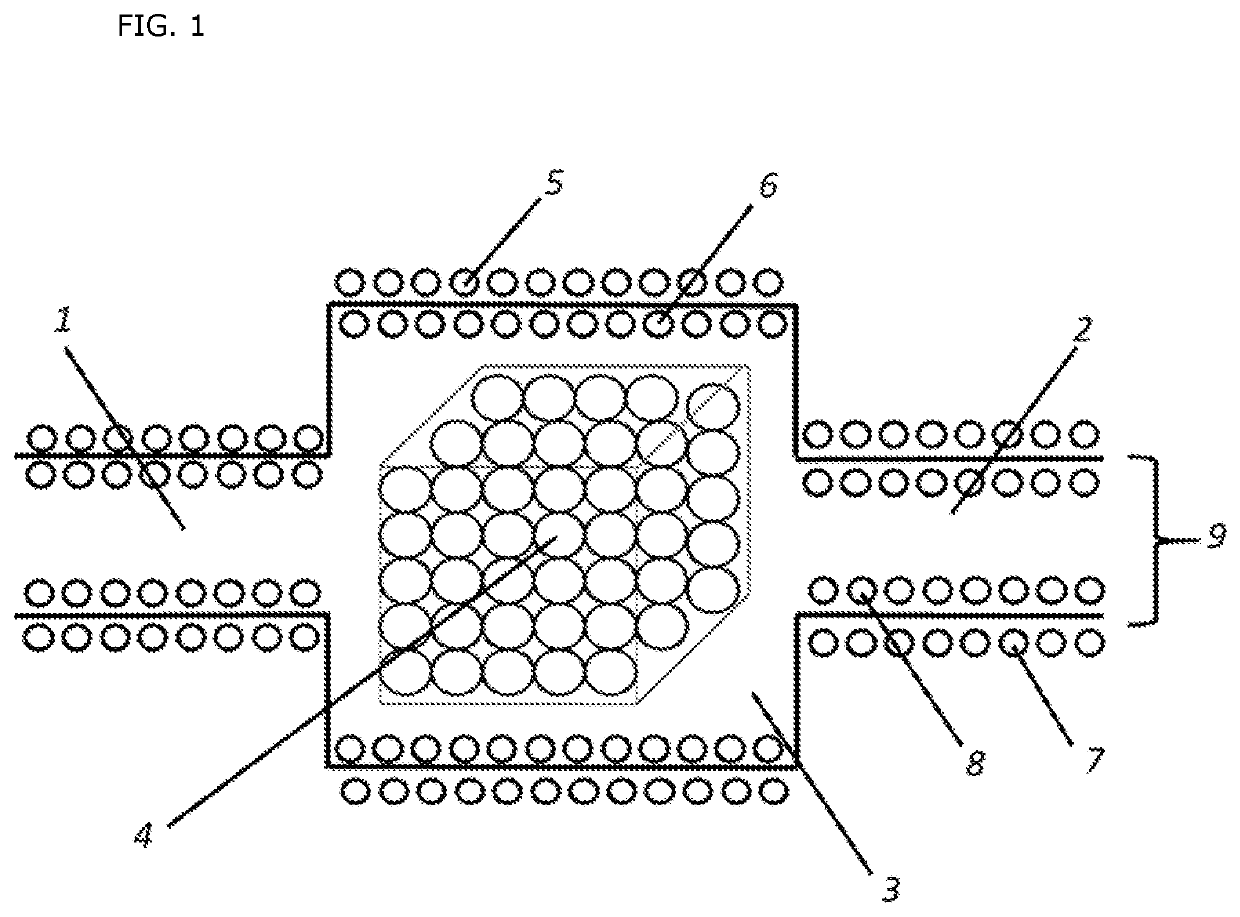

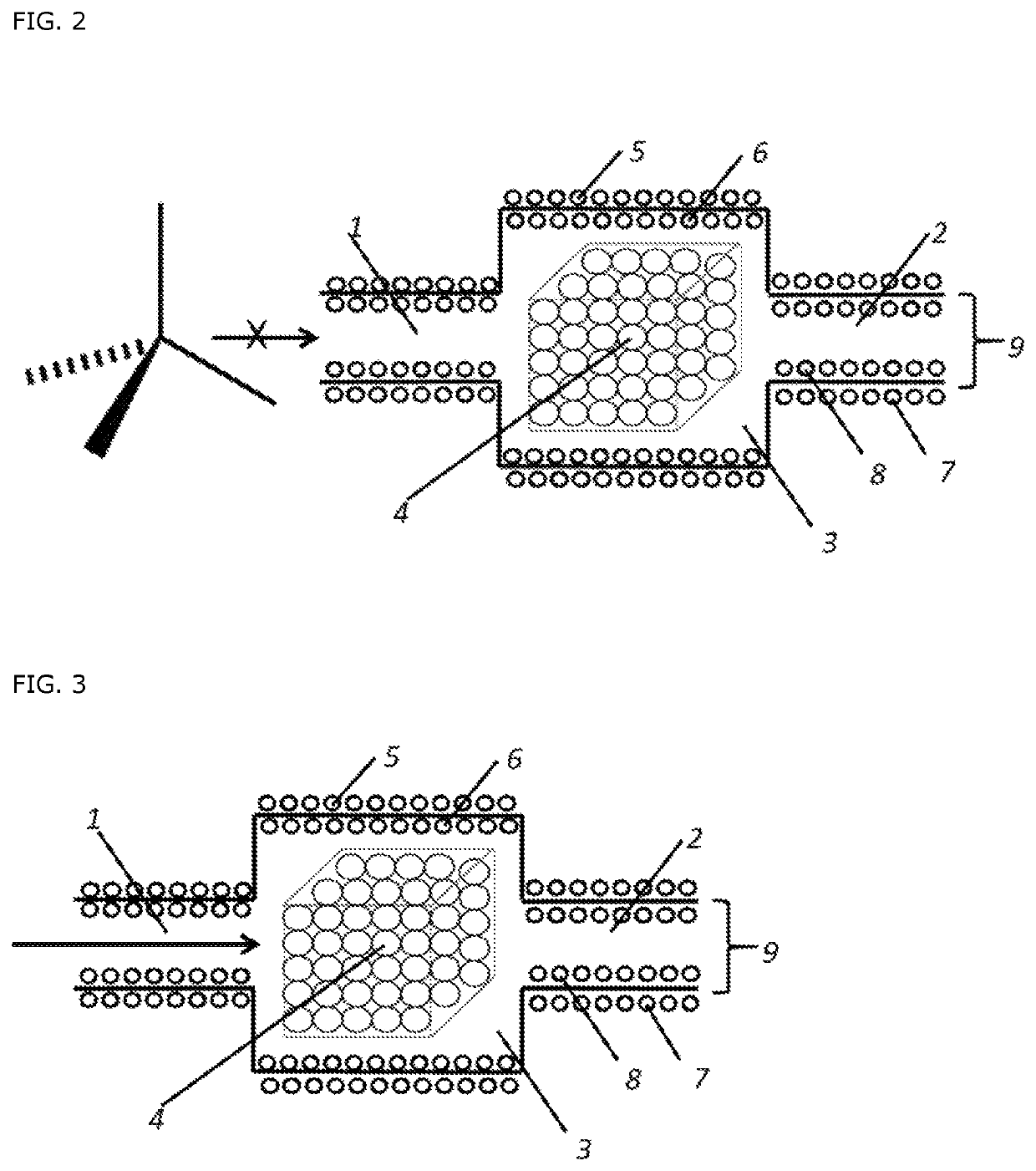

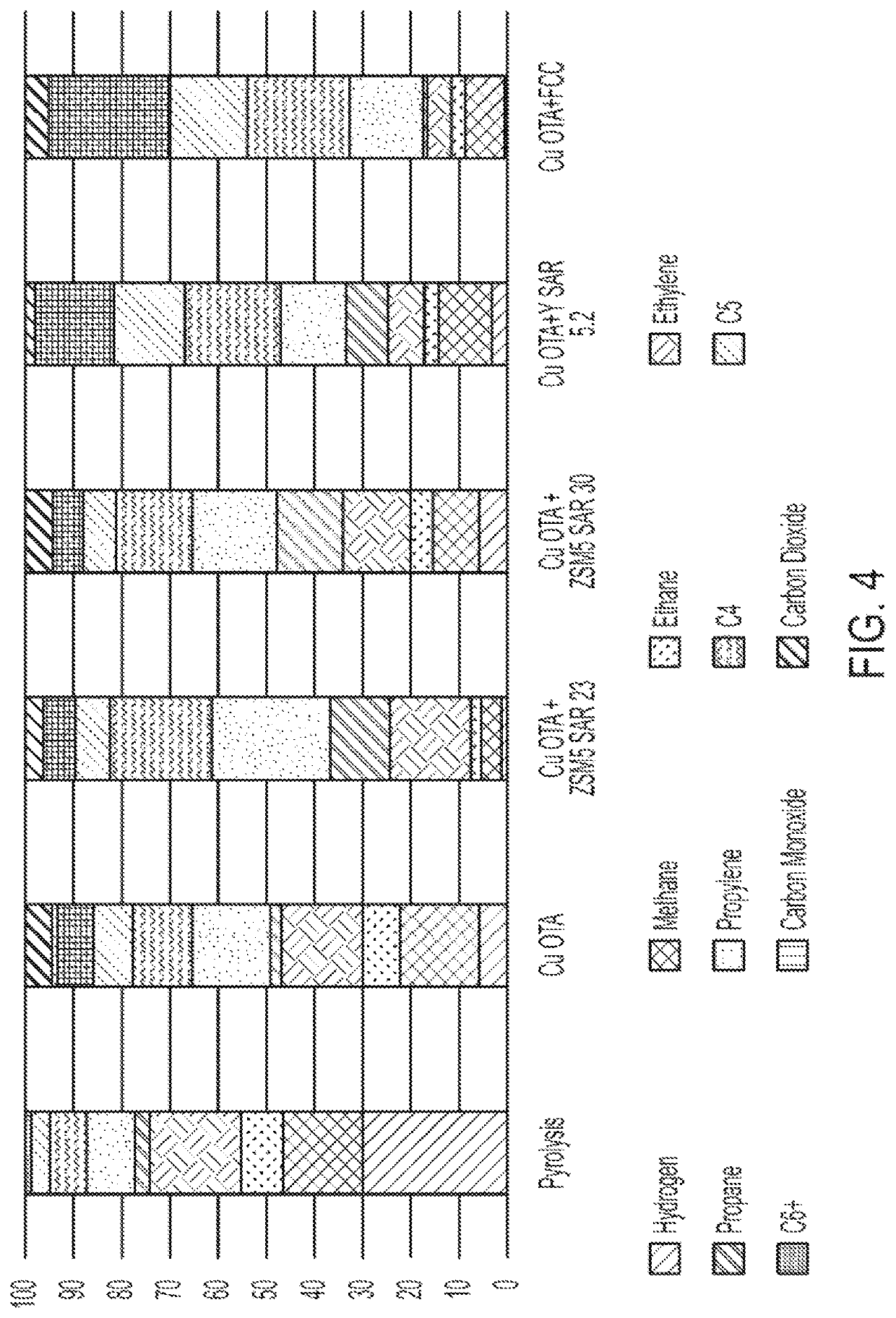

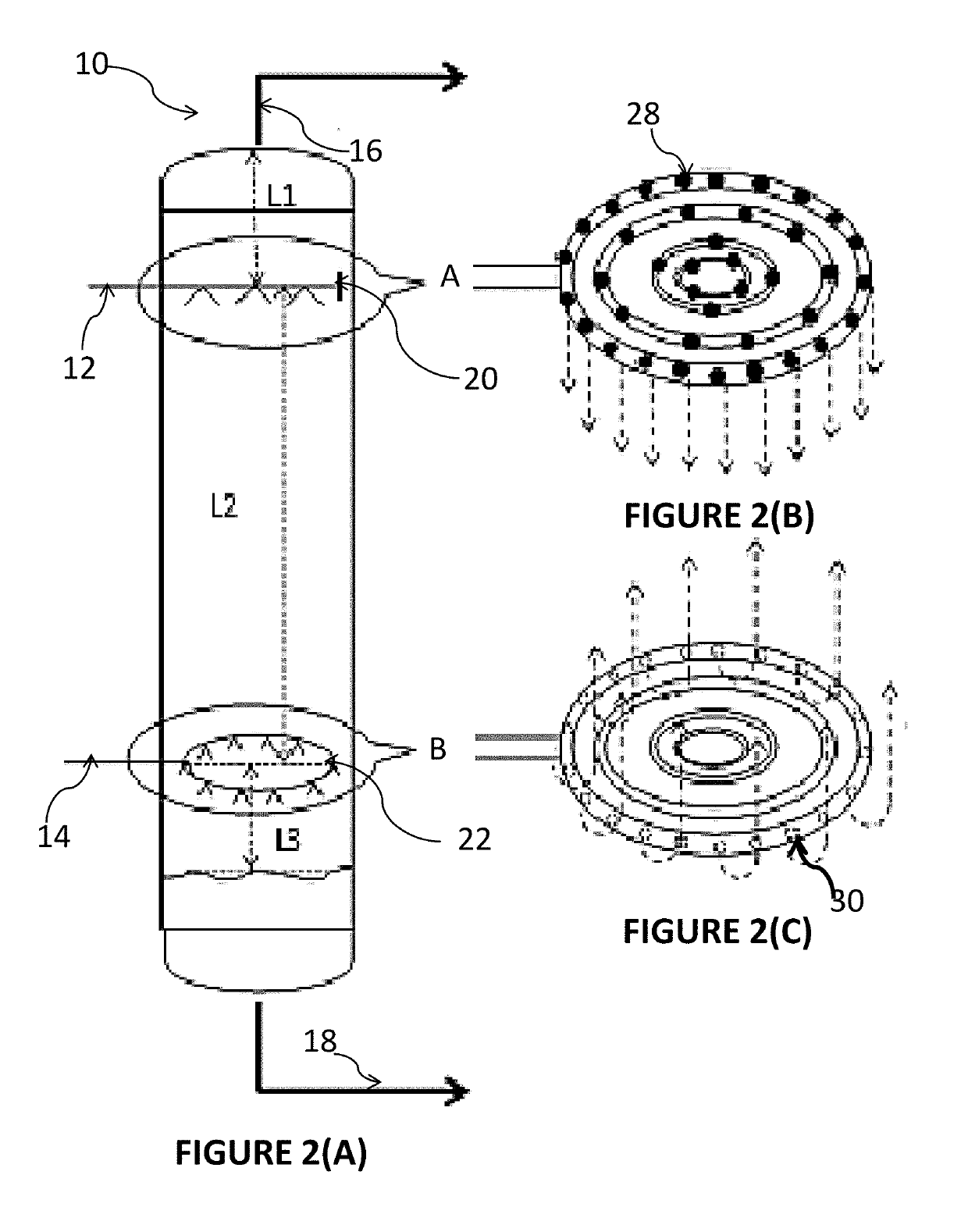

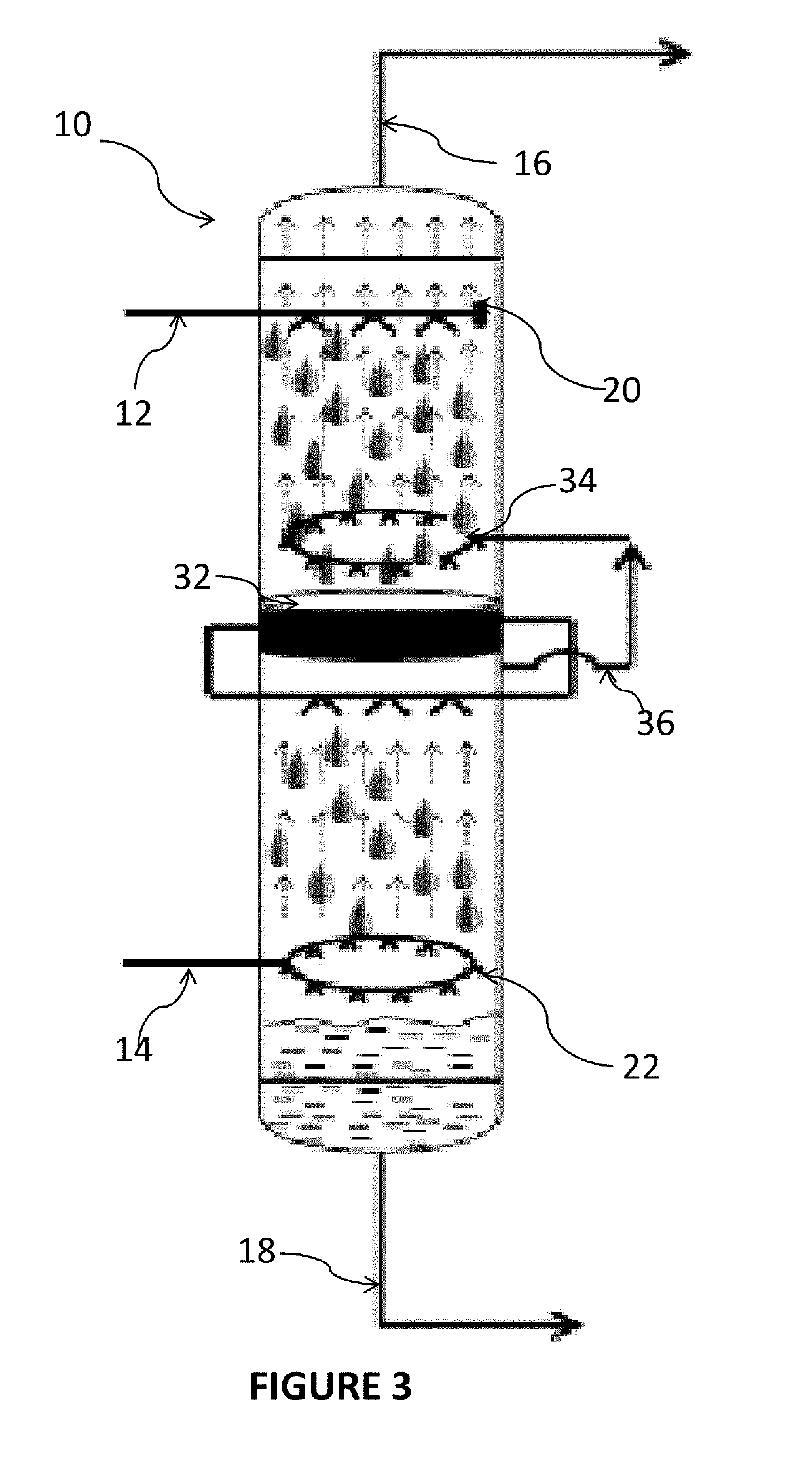

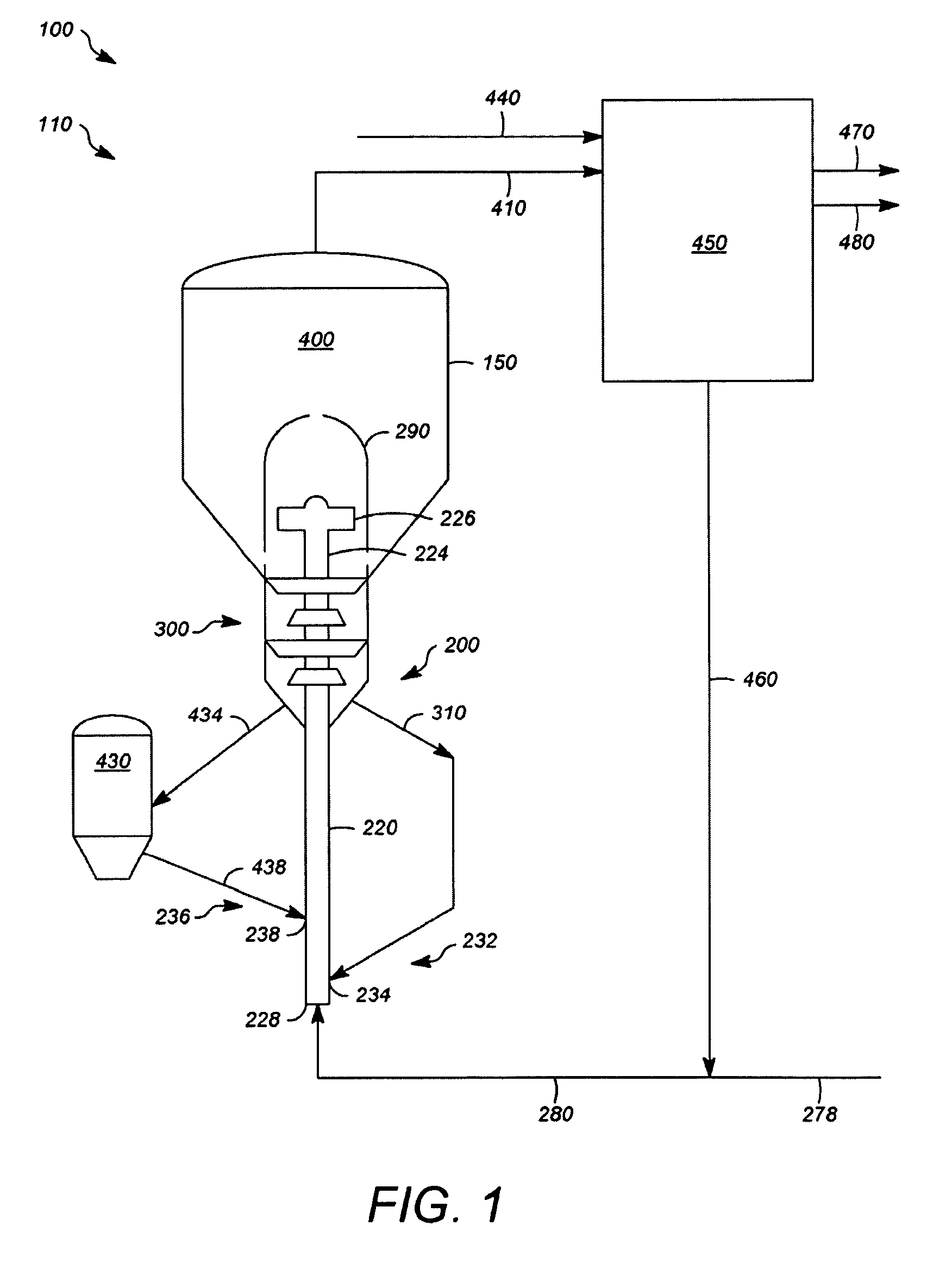

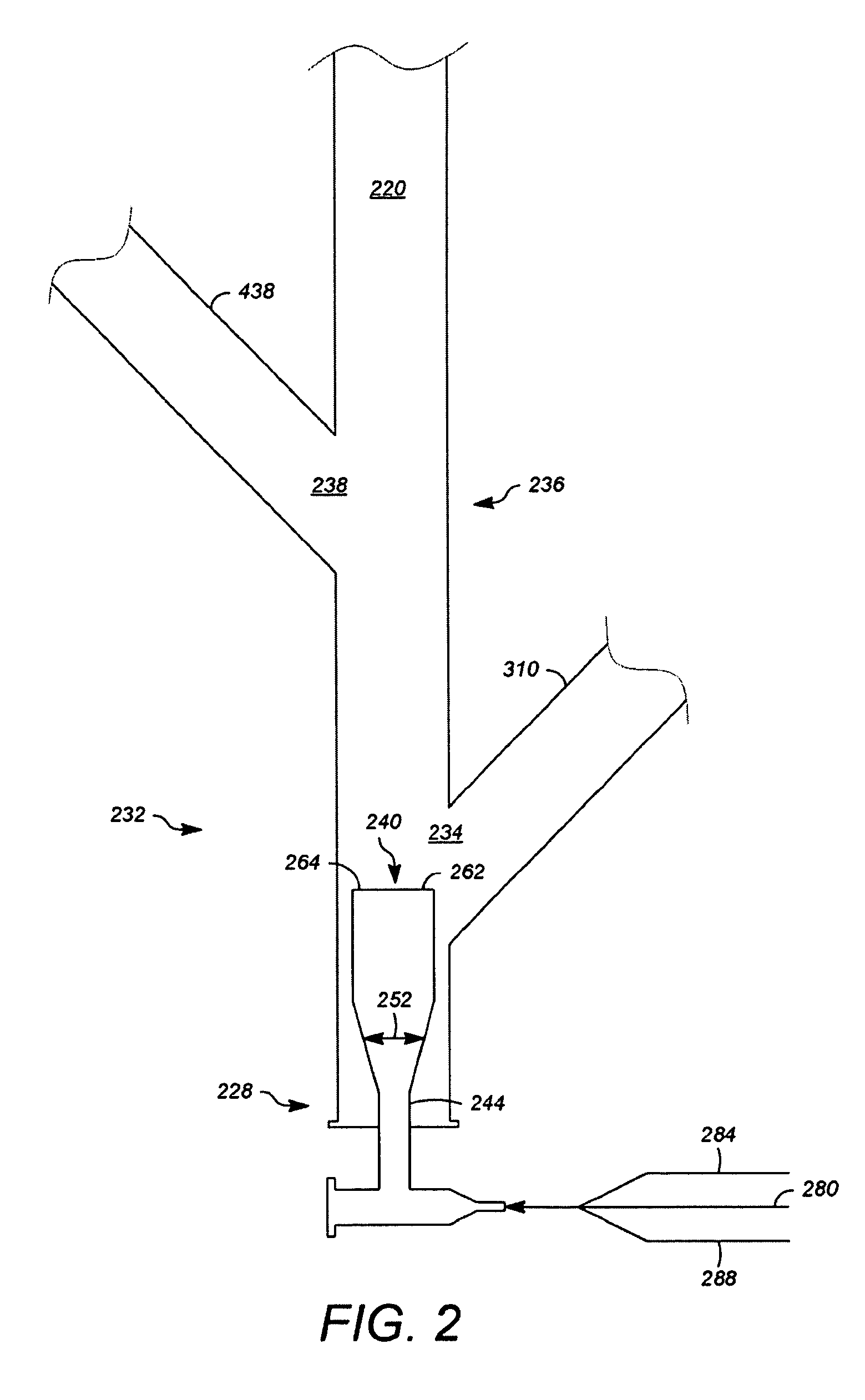

System, apparatus, and process for cracking a hydrocarbon feed

ActiveUS20100152515A1Prevent over-crackingReduces coke formationCatalytic crackingMolecular sieve catalystEngineeringReaction zone

One exemplary embodiment can be a fluid catalytic cracking system. The fluid catalytic cracking system can include a reaction zone including a riser having a top and a bottom adapted to receive spent catalyst at a first elevation and regenerated catalyst at a second elevation. Typically, the first elevation is lower than the second elevation. Additionally, the fluid catalytic cracking system can include a gas distributor contained near the bottom of the riser in communication with a hydrocarbon feed.

Owner:UOP LLC

Method for the hydroconversion of oil feedstocks using slurry technology, allowing the recovery of metals from the catalyst and the feedstock, comprising an extraction step

InactiveUS20130081976A1Promote hydrogenationReduces coke formationTreatment with plural serial cracking stages onlyCoke ovensCombustionSlurry

A process for the hydroconversion of heavy oil feedstocks comprises a step for hydroconversion of the feedstock in at least one reactor containing a catalyst in slurry mode used to recover metals from the residual unconverted fraction, especially those used as catalysts. The process comprises a hydroconversion step, a gas / liquid separation step, at least one liquid / liquid extraction step, a combustion step, a metals extraction step and a step for the preparation of catalytic solutions which are recycled to the hydroconversion step.

Owner:INTREVEP SA

Method, apparatus and chemical products for treating petroleum equipment

ActiveUS9328300B2Reduce reunionReduces coke formationThermal non-catalytic crackingLighting and heating apparatusPtru catalystProcess engineering

Owner:FERRARA

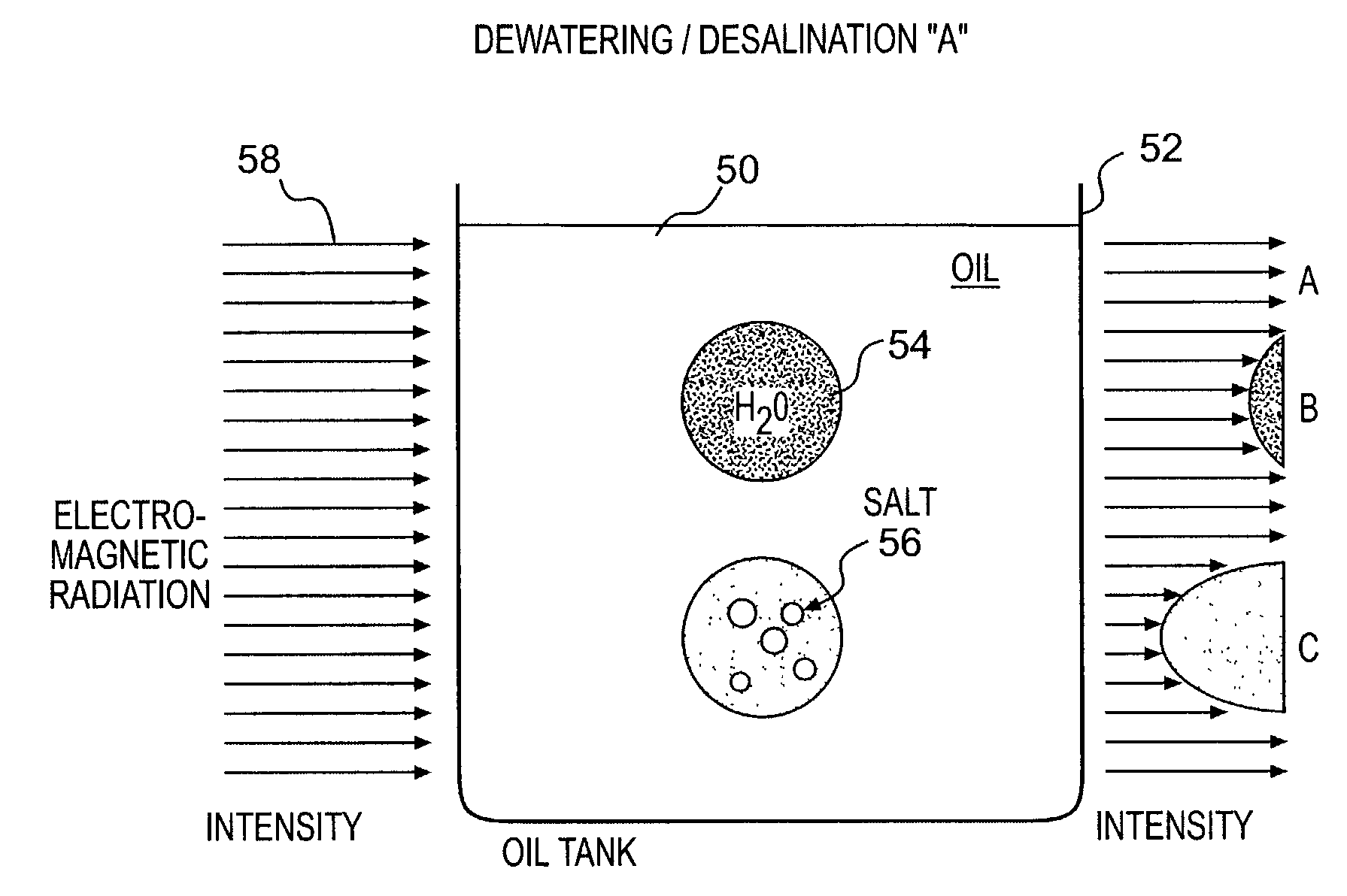

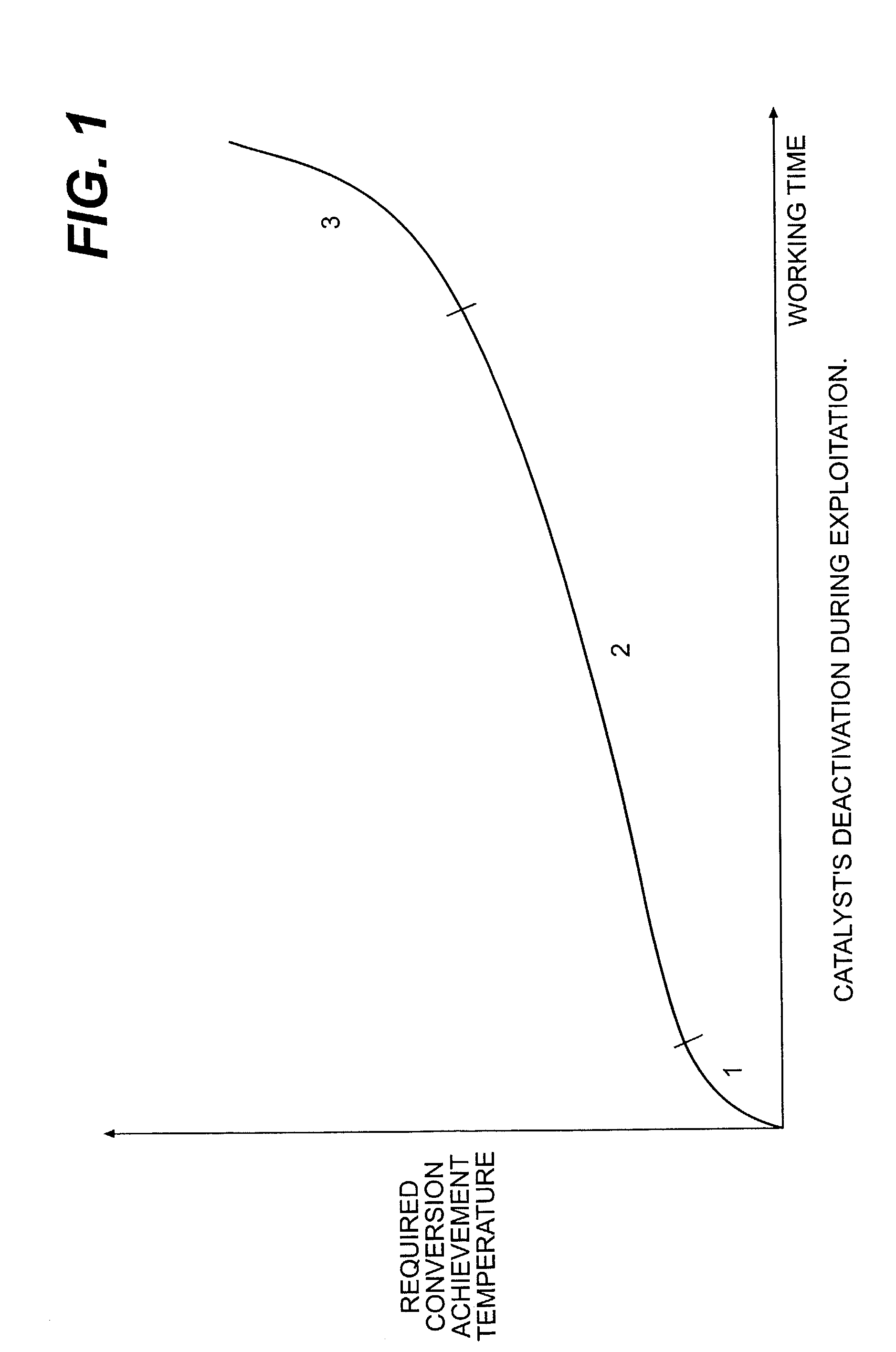

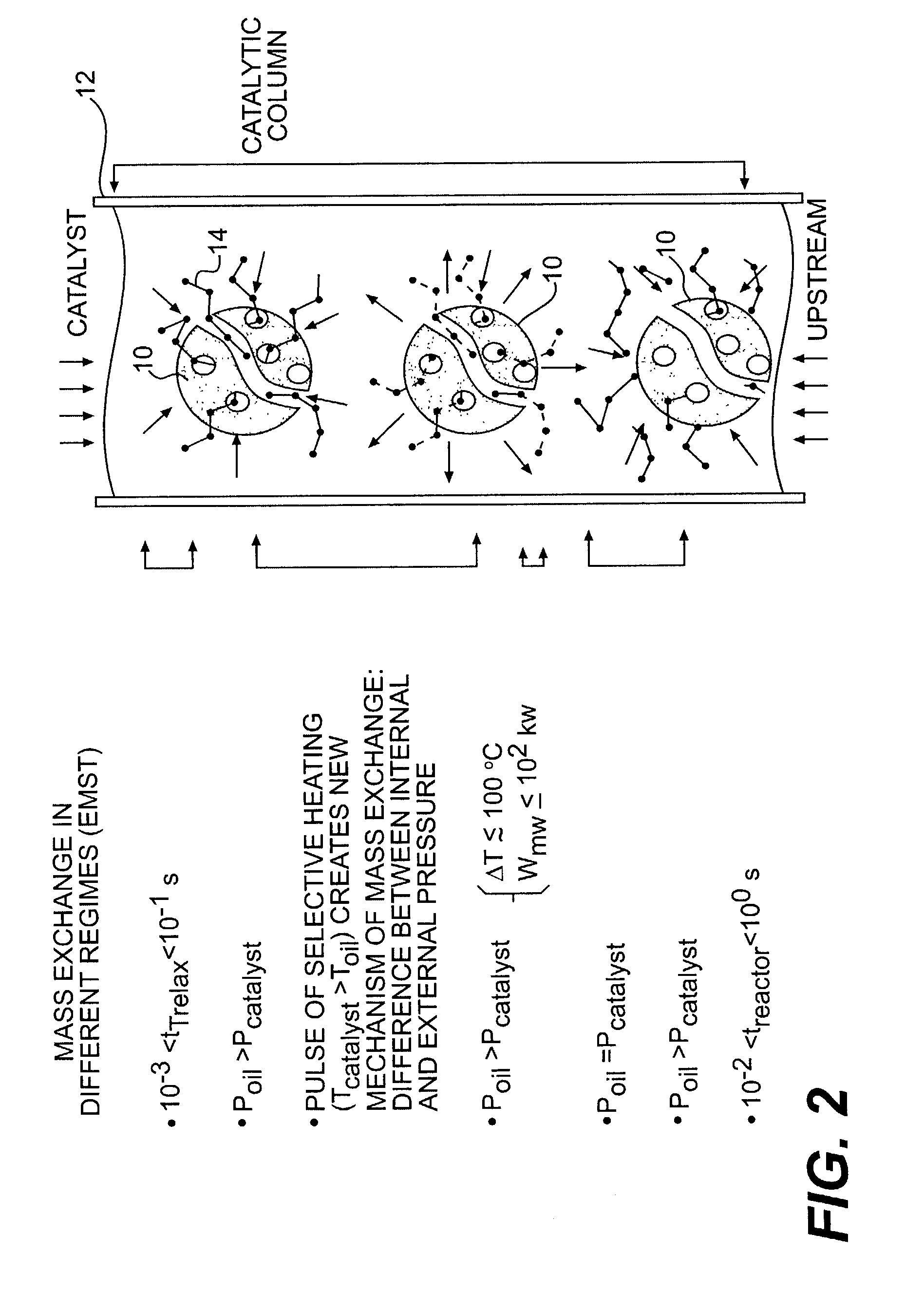

High frequency energy application to petroleum feed processing

InactiveUS6994774B2Reduces coke formationIncrease temperatureGroup 1/11 element organic compoundsHydrocarbon oil cracking processInternal pressureElectromagnetic pulse

The present invention provides a method and apparatus for maintaining the active life of a catalyst in organic feed processing by applying a series of electromagnetic radiation pulses to the catalyst in a reactor. The pulsing of the catalyst selectively heats and cools the catalyst and can regulate the relative internal pressure of the catalyst particles to stimulate the acceleration of oil macromolecules mass-exchange through the catalyst pores and surface. This allows for the removal of cracked oil molecules from the particles. The application of electromagnetic pulses also regulates the activity of the catalyst. The electromagnetic radiation reduces the formation of coke on the catalyst and increases the life of the catalyst in the reactor. Further, the present invention provides a method and apparatus for removing water and salt from an organic feed. Water and salt is removed by applying a series of electromagnetic radiation pulses to the organic feed. A first pulse condenses water contained in the feed and induces salt to dissolve in the condensed water. A second pulse vaporizes a portion of the condensed water droplets to bring the droplets to the surface of the organic feed.

Owner:BURKITBAEV SERIK M

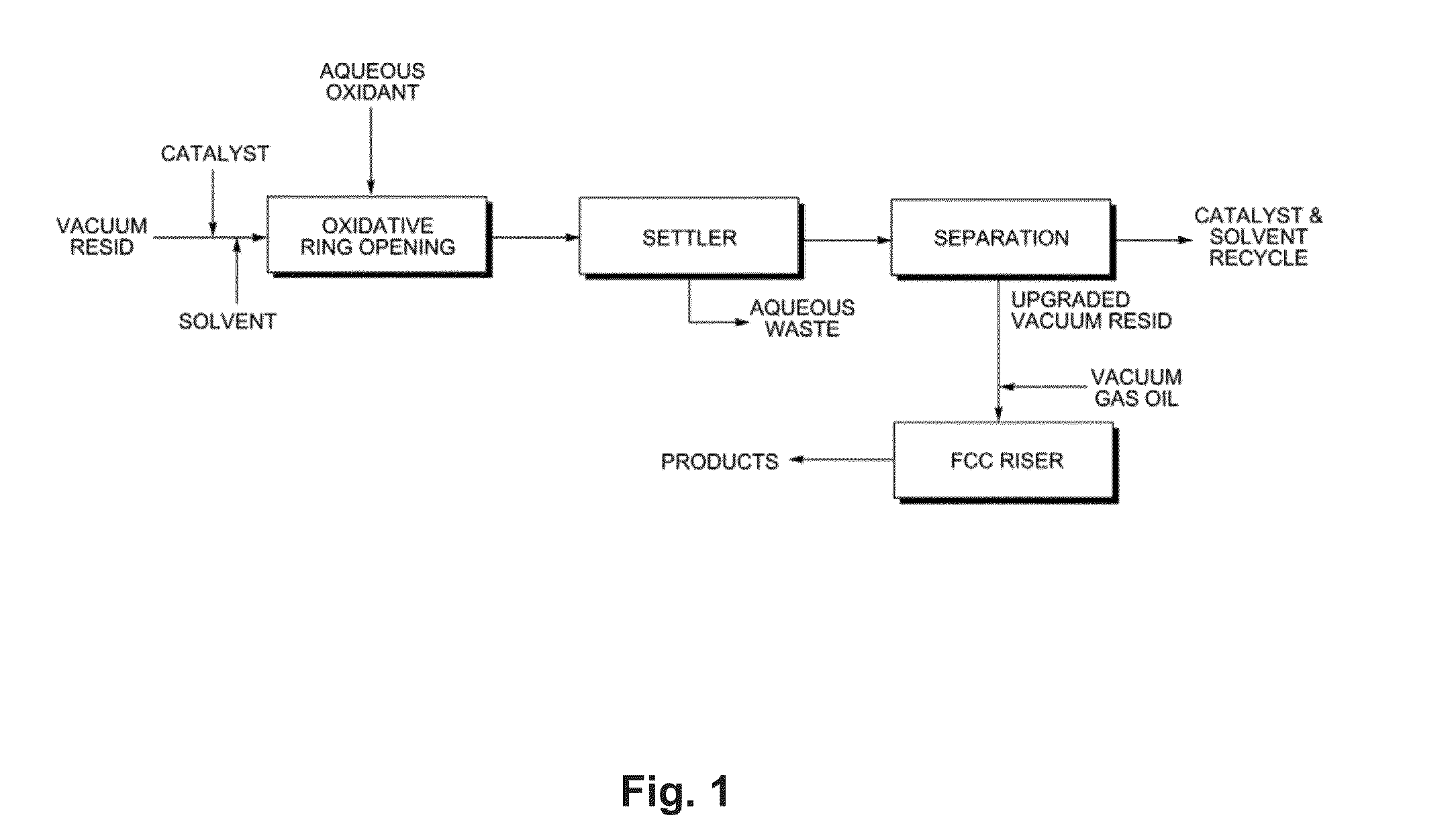

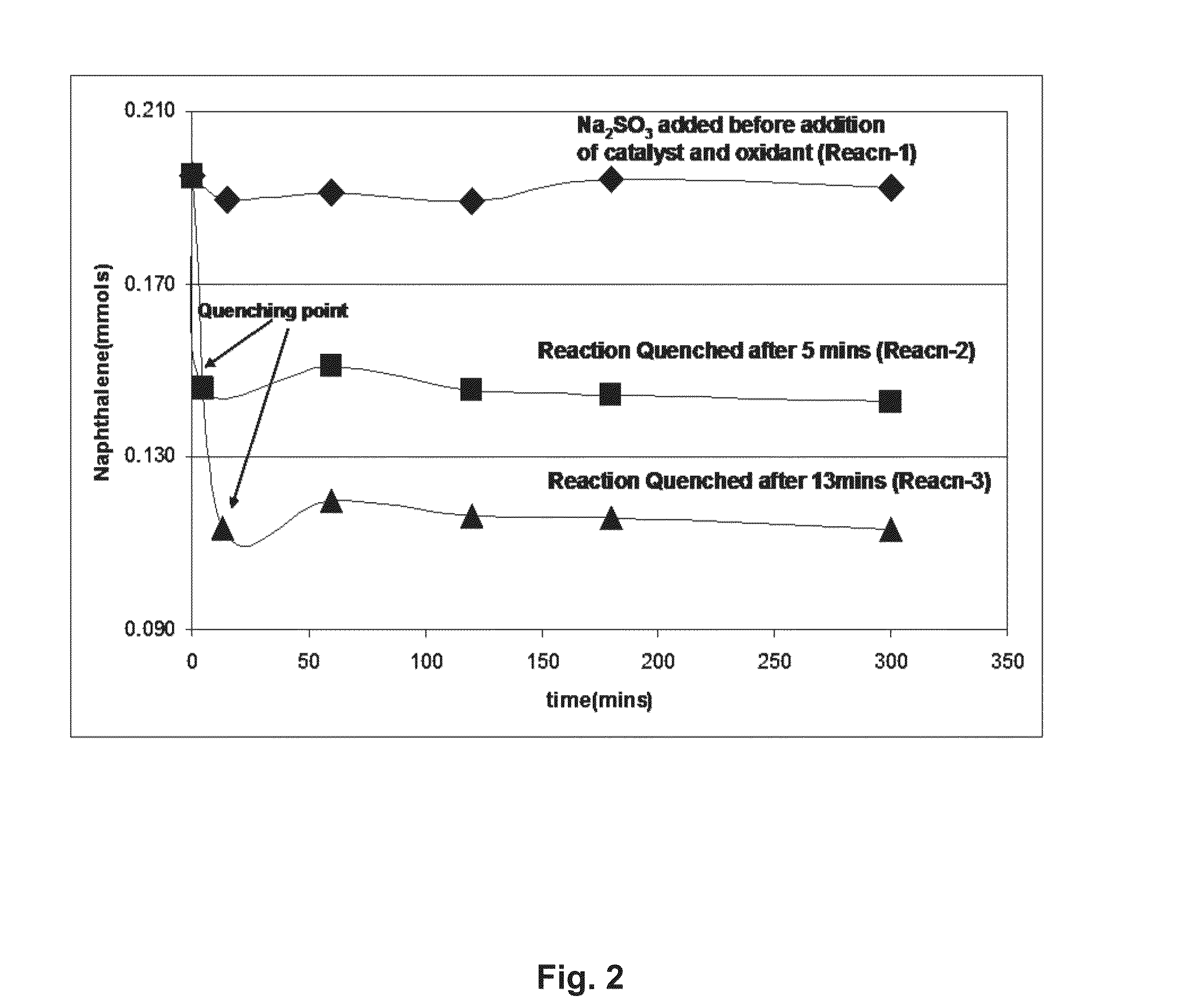

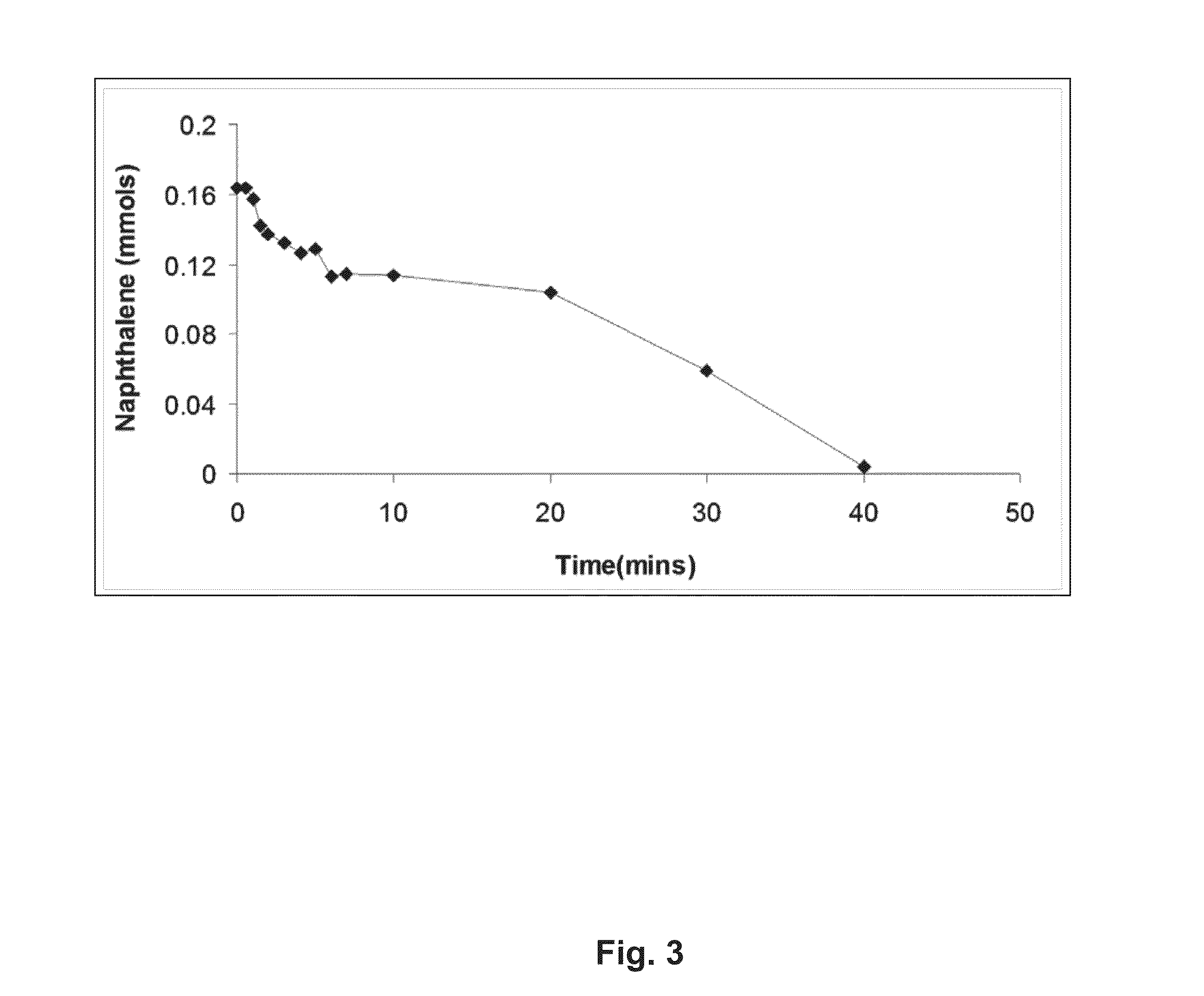

Upgrading heavy oils by selective oxidation

InactiveUS20160060550A1Easy to crackCrackability improvedThermal non-catalytic crackingCatalytic crackingPartial oxidationCatalytic oxidation

A heavy petroleum oil feed is upgraded by having its amenability to cracking improved by subjecting the oil to selective partial oxidation with a catalytic oxidation system to partially oxidize aromatic ring systems in the heavy oil. The partially oxidized oil can then be cracked in the conventional manner but at lower severities to lower molecular weight cracking products. The cracking following the partial oxidation step may be thermal in nature as by thermal cracking, delayed, contact or fluid coking or fluid catalytic cracking or hydrogenative as in hydrocracking.

Owner:EXXON RES & ENG CO

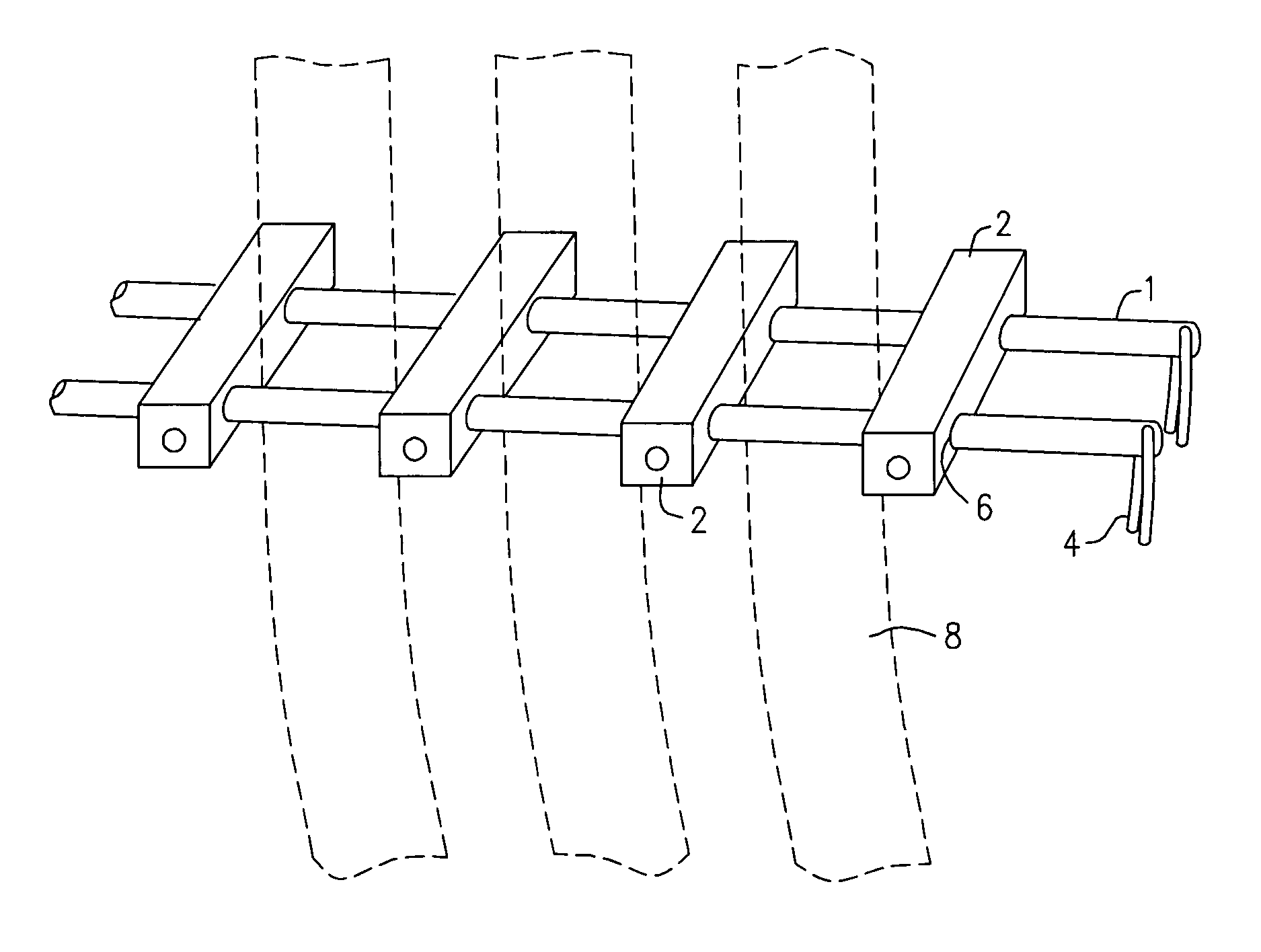

Systems and apparatuses for stabilizing reactor furnace tubes

InactiveUS7048041B2Reduce harmful stressDistorting shapeThermal non-catalytic crackingHeat exchanger casingsProcess engineeringHeat exchanger

Systems and apparatuses for stabilizing the movement of the reactor furnace tubes of a fired heater, furnace, heat exchanger or other device utilizing reactor furnace tubes to thereby reduce harmful stresses on the tubes, extend the useful life of the tubes, increase the efficiency and safety of reaction processes and allow for the streamlining the design of the tubes.

Owner:STONE & WEBSTER PROCESS TECH

Methods for manufacturing an additively manufactured fuel contacting component to facilitate reducing coke formation

ActiveUS9334806B2Promote formationReduces coke formationAdditive manufacturing apparatusGas turbine plantsSlurryAqueous solution

A method for manufacturing a fuel contacting component that facilitates reducing coke formation on at least one surface of the fuel contacting component is disclosed herein. The method includes applying a slurry composition including a powder including aluminum to the component surface, wherein the fuel contacting component is formed by an additive manufacturing process. The slurry composition is heat treated to diffuse the aluminum into the component surface. The heat treatment comprises forming a diffusion aluminide coating on the component surface, wherein the diffusion coating comprises a diffusion sublayer formed on the component surface and an additive sublayer formed on the diffusion sublayer. The method further comprises removing the additive sublayer of the diffusion aluminide coating with at least one aqueous solution such that the diffusion sublayer and the component surface are substantially unaffected, wherein the diffusion layer facilitates preventing coke formation on component surface.

Owner:GENERAL ELECTRIC CO

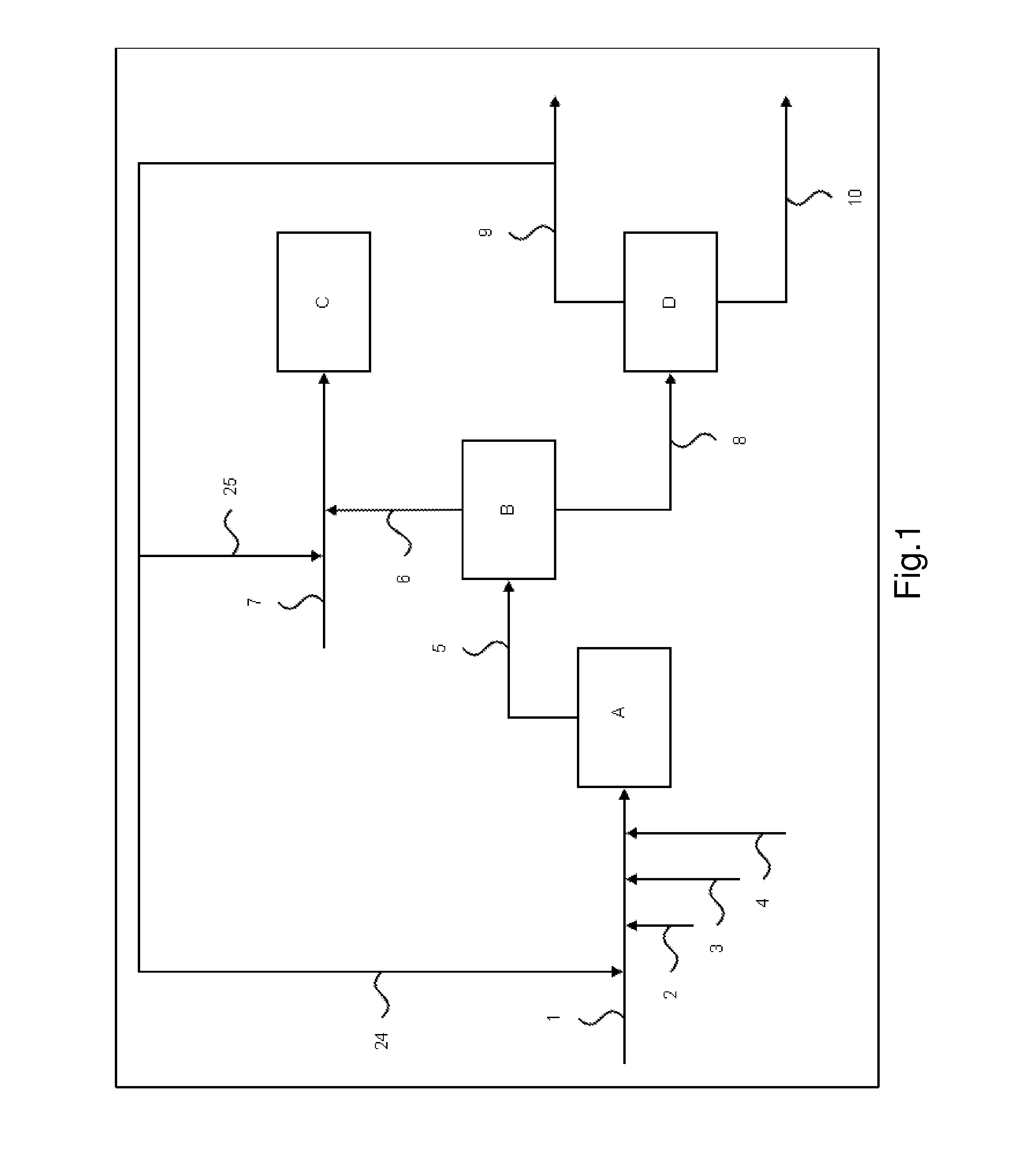

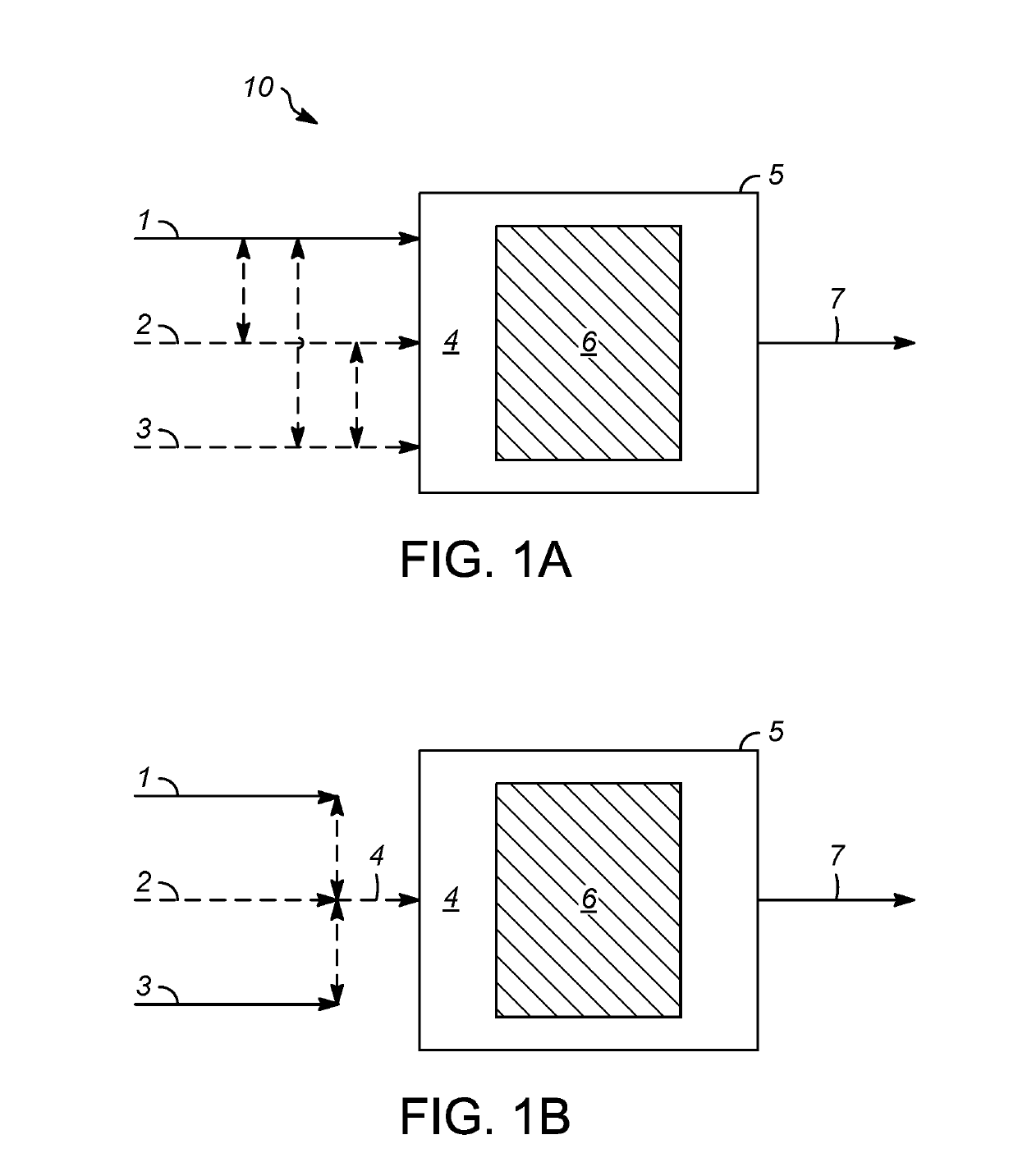

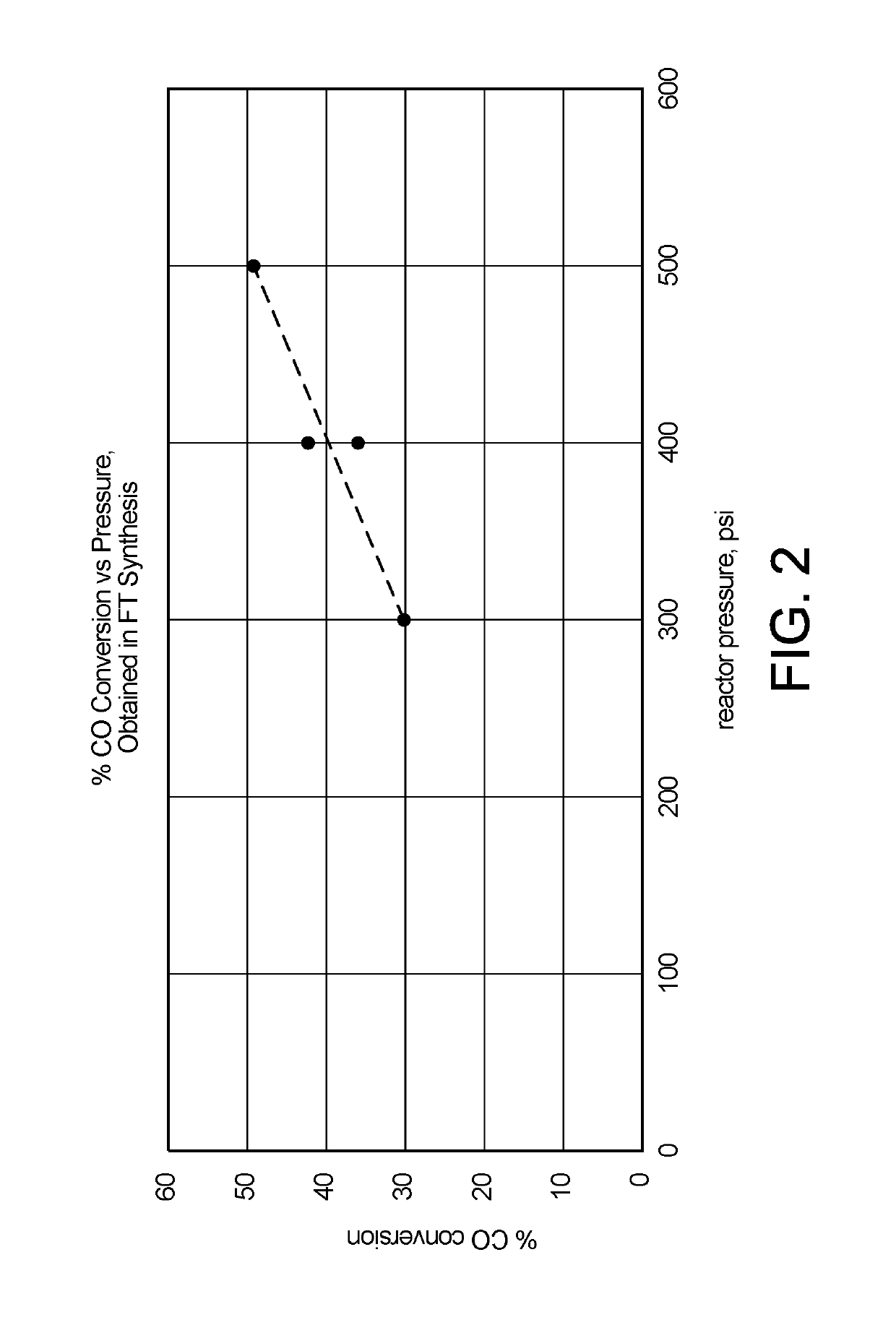

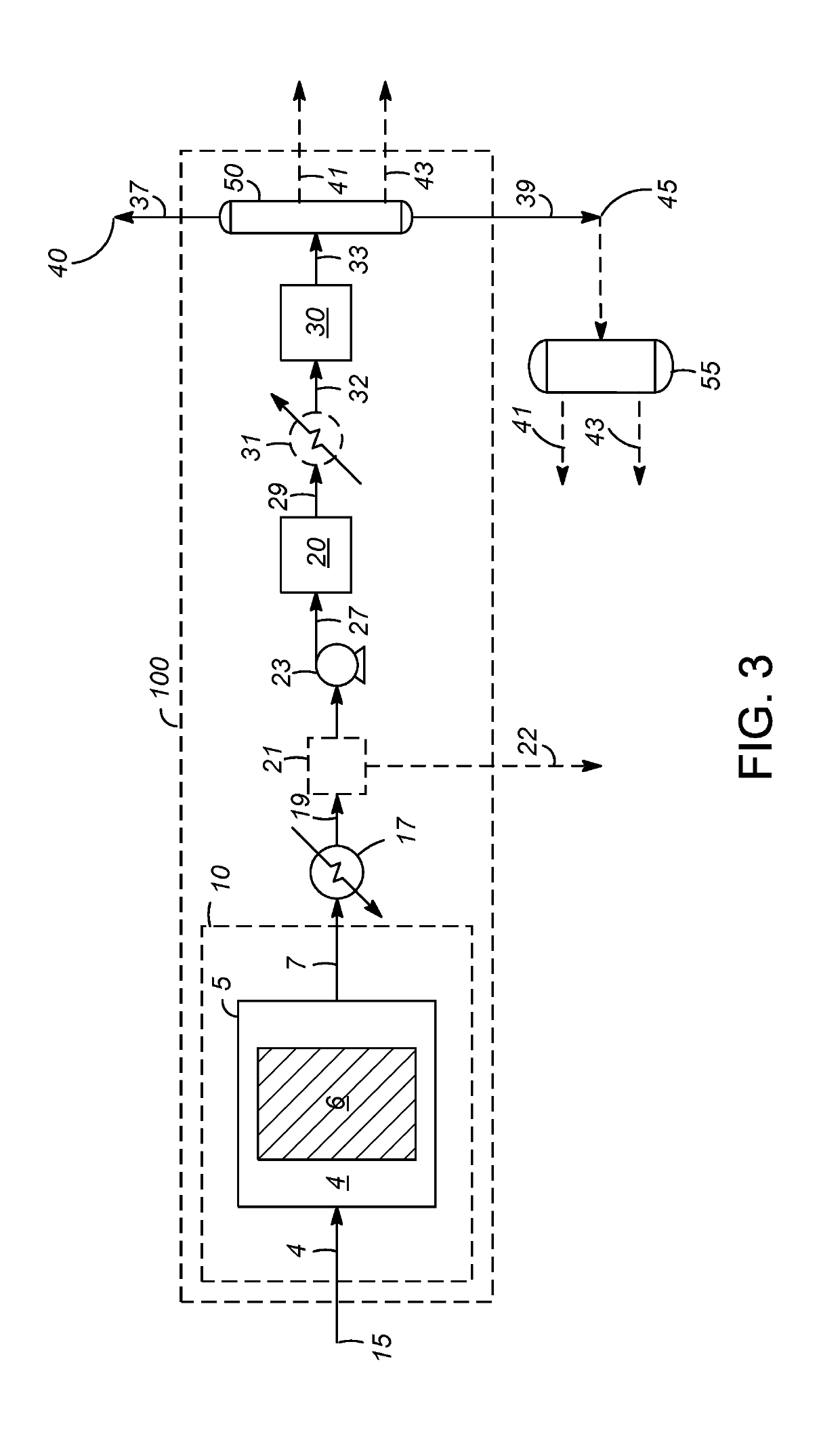

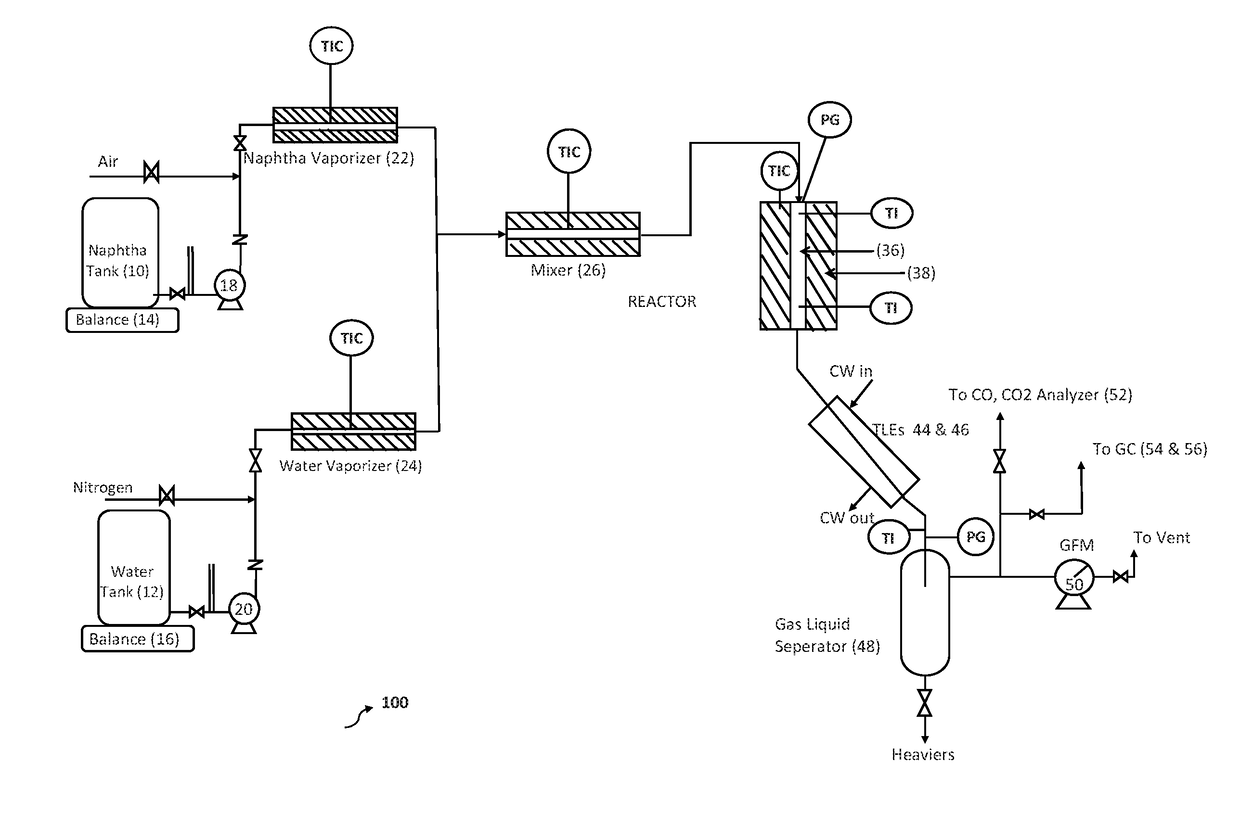

Processes and systems for reforming of methane and light hydrocarbons to liquid hydrocarbon fuels

ActiveUS20190144765A1Improved thermodynamicsReducing endothermicityHydrocarbon from carbon oxidesCarbon compoundsSteam reformingWax

Processes for converting methane and / or other hydrocarbons to synthesis gas (i.e., a gaseous mixture comprising H2 and CO) are disclosed, in which at least a portion of the hydrocarbon(s) is reacted with CO2. At least a second portion of the methane may be reacted with H2O (steam), thereby improving overall thermodynamics of the process, in terms of reducing endothermicity (ΔH) and the required energy input, compared to “pure” dry reforming in which no H2O is present. Such dry reforming (reaction with CO2 only) or CO2-steam reforming (reaction with both CO2 and steam) processes are advantageously integrated with Fischer-Tropsch synthesis to yield liquid hydrocarbon fuels. Further integration may involve the use of a downstream finishing stage involving hydroisomerization to remove FT wax. Yet other integration options involve the use of combined CO2-steam reforming and FT synthesis stages (optionally with finishing) for producing liquid fuels from gas streams generated in a number of possible processes, including the hydropyrolysis of biomass.

Owner:GAS TECH INST

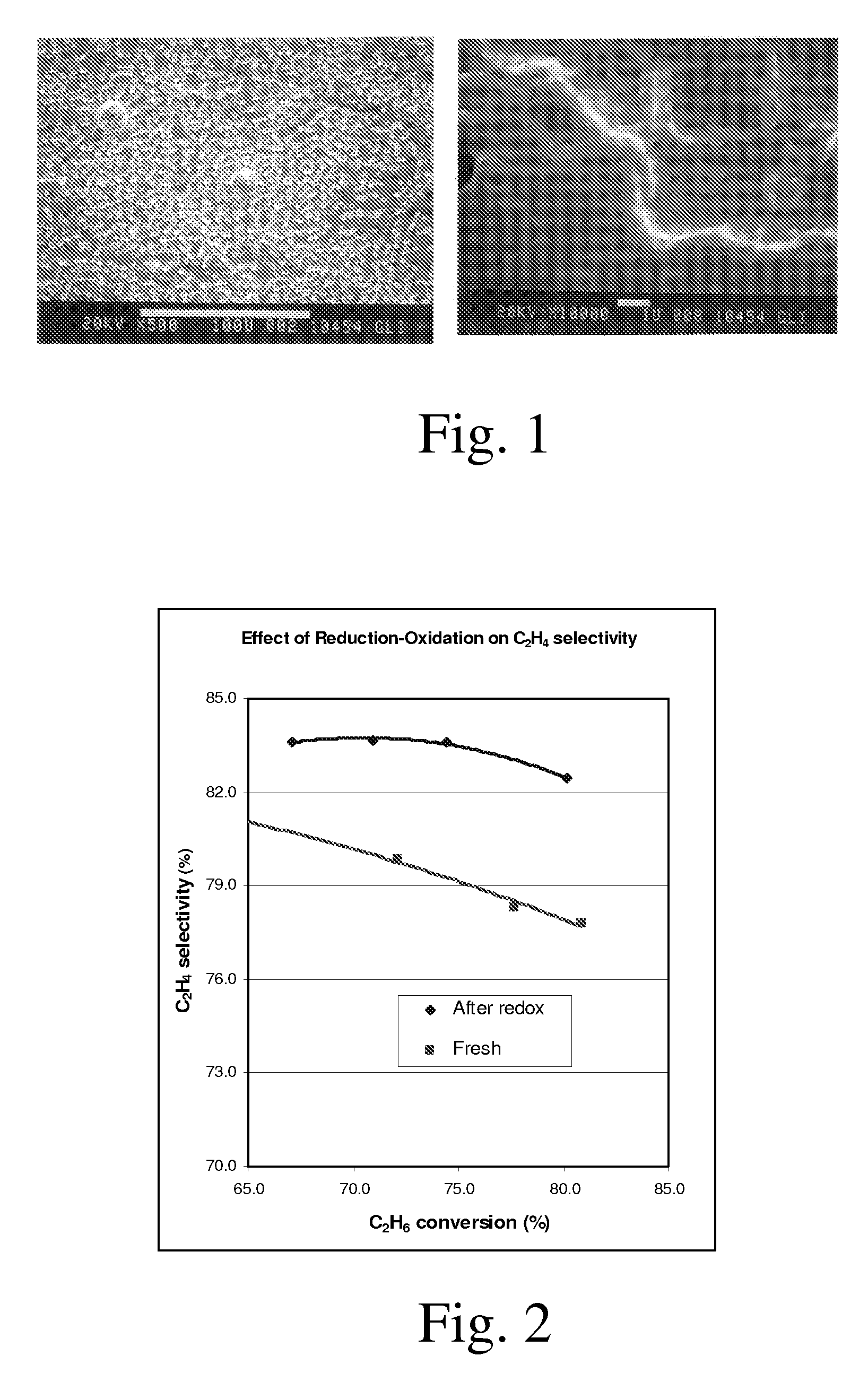

Oxidative cracking of hydrocarbons

ActiveUS11046892B1Reduce security risksImproved heat managementCatalytic crackingLiquid hydrocarbon mixture productionPtru catalystOxidative cleavage

Aspects of the invention relate to producing olefins and other products by oxidative dehydrogenation cracking of a hydrocarbon feed. In one embodiment, the method includes oxidative cracking a hydrocarbon feed comprised of plastic waste. Methods of the present invention employ dual functional catalyst comprising solid acids and metal oxides, which are capable of selectively oxidizing hydrogen to water rather than combustion of the hydrocarbon feeds or products. Additional aspects of the invention demonstrate catalyst synthetic methods for encapsulating metal oxides in the internal channels and cages of solid acids, thereby improving the selective oxidation of hydrogen to water and decreasing feed and product oxidation. The re-oxidation of the thus reduced metal oxide transfer agents supplies heat to drive the endothermic cracking of the feed.

Owner:ECOCATALYTIC INC

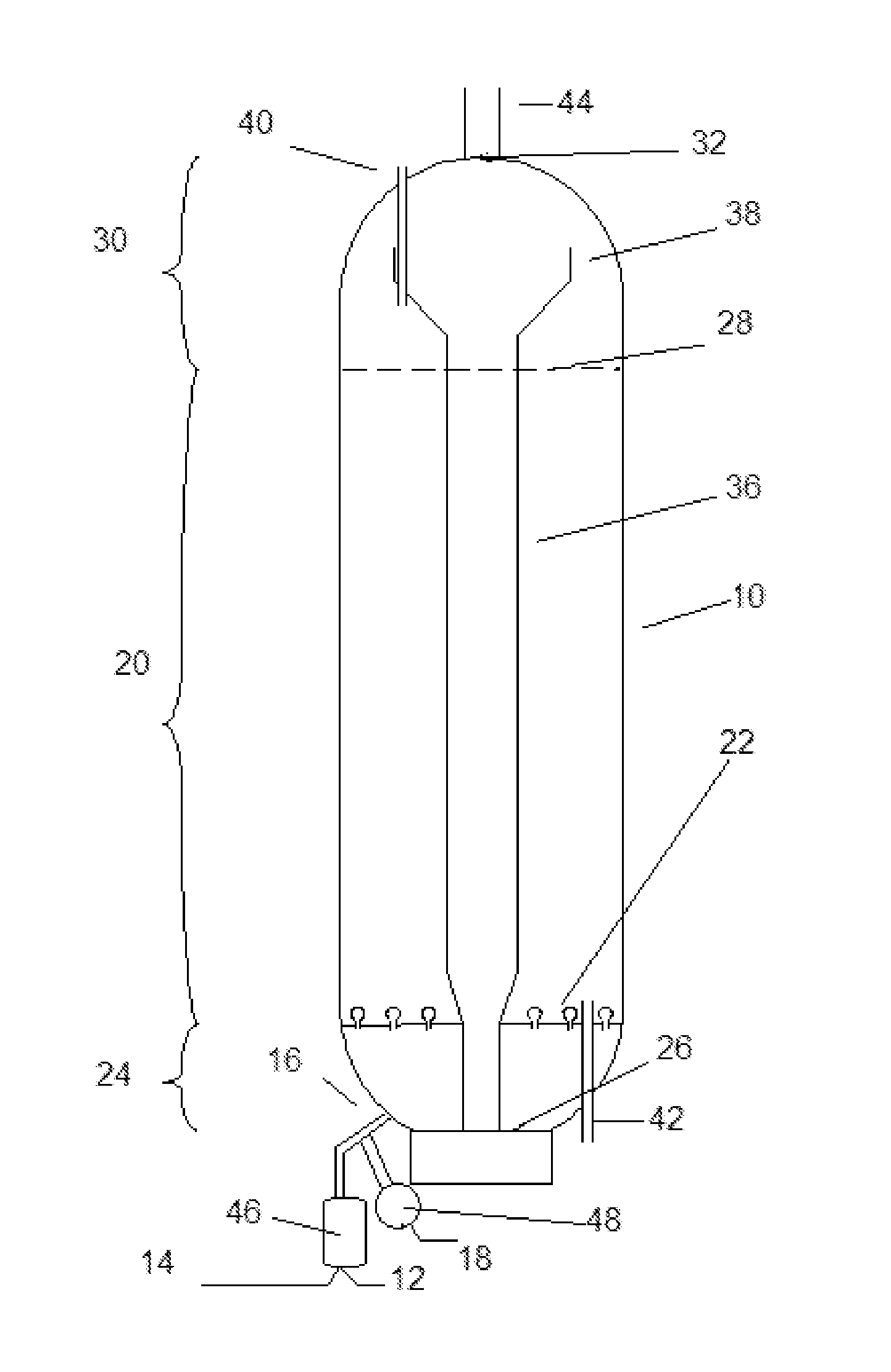

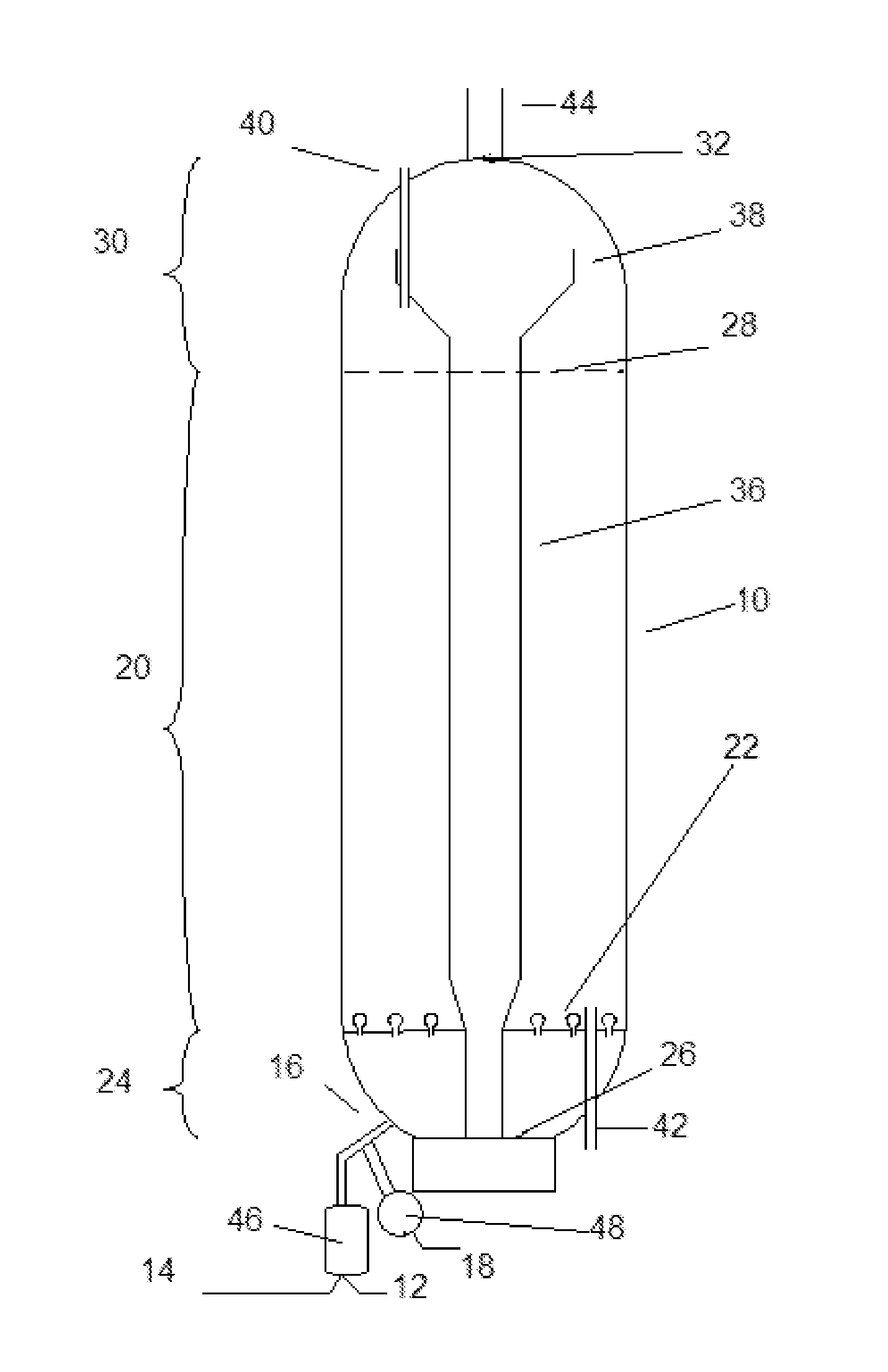

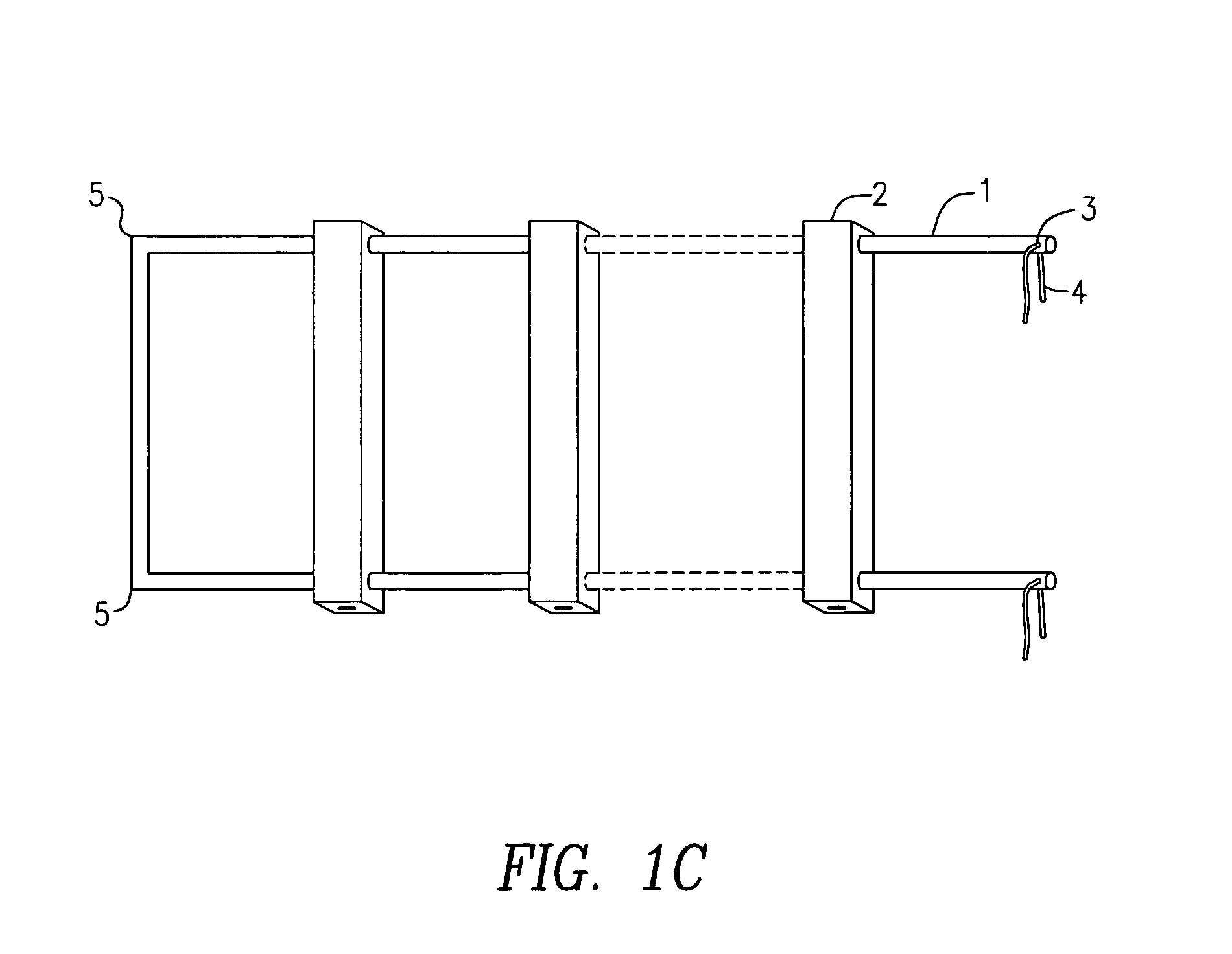

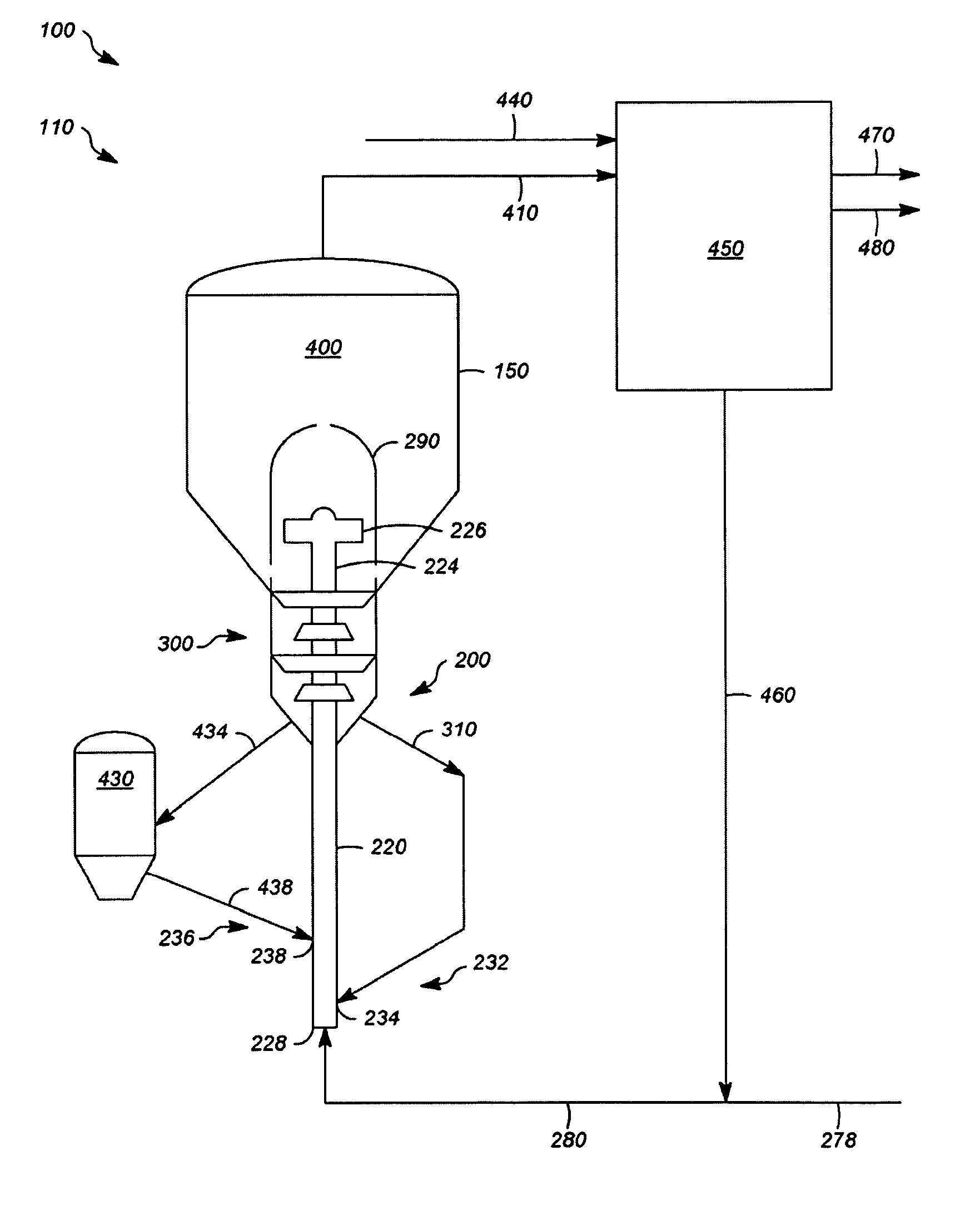

Reactor system and process for upgrading heavy hydrocarbonaceous material

ActiveUS20190100705A1None provides advantagesPromote conversionHydrocarbon oil crackingFeed devicesHydrogenReactor system

The present invention relates to a hydrocracking reactor system and a process utilizing the same for upgrading heavy hydrocarbonaceous material to value-added products. Accordingly, an aspect of the present invention includes dispersing a liquid feedstock pre-mixed with a catalyst from top of a reactor vessel to obtain dispersed droplets having a predetermined droplet size less than 500 μm, introducing a gaseous feed comprising primarily of hydrogen from bottom of the reactor vessel to form a continuous gaseous phase throughout a cross-section of the reactor vessel, and allowing the dispersed droplets to contact the continuous gaseous phase throughout the cross-section of the reactor vessel to form reaction effluent comprising one or more lighter product hydrocarbons. The method may further include removing at least a top portion and at least a bottom portion of the reaction effluent from the reactor vessel.

Owner:INDIAN OIL CORPORATION

Electroless plating in microchannels

InactiveUS8648006B2High plating rateReduces coke formationLiquid surface applicatorsChemical/physical/physico-chemical microreactorsSteam reformingCombustion

Novel methods of electroless plating are described. Catalyst coatings can be applied within microchannel apparatus. Various reactions, including combustion and steam reforming, can be conducted over electroless catalyst coatings.

Owner:VELOCYS CORPORATION

Heat transfer tube and cracking furnace using the heat transfer tube

ActiveUS9359560B2Improve heat transfer performanceIncrease tangential speedThermal non-catalytic crackingFluid dynamicsEngineeringClosed circle

The present disclosure relates to a heat transfer tube and a cracking furnace using the heat transfer tube. The heat transfer tube comprises a twisted baffle arranged in an inner wall of the tube, said twisted baffle extending spirally along an axial direction of the heat transfer tube. The twisted baffle defines a closed circle viewed from an end of the heat transfer tube. Along the trajectory of the circle a casing is arranged, which is fixedly connected to a radial inner end of the twisted baffle. The twisted baffle is provided with a plurality of holes. The heat transfer tube according to the present disclosure has a good heat transfer effect and small pressure loss.

Owner:CHINA PETROCHEMICAL CORP +1

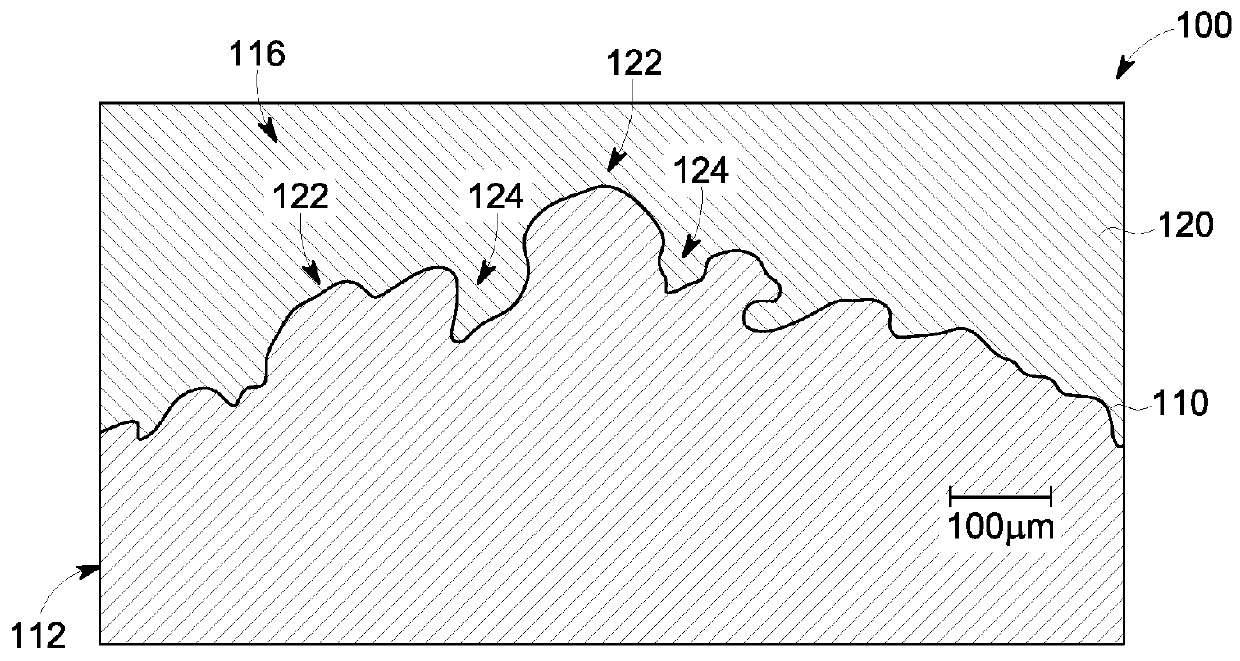

Protected alloy surfaces in microchannel apparatus and catalysts, alumina supported catalysts, catalyst intermediates, and methods of forming catalysts and microchannel apparatus

InactiveUS7874432B2Reduces coke formationReduce metal dustingHydrocarbon purification/separationChemical/physical/physico-chemical microreactorsMetalChemical process

The invention describes microchannel apparatus and catalysts that contain a layer of a metal aluminide or are made in a process in which a metal aluminide layer is formed as an intermediate. Certain processing conditions have surprisingly been found to result in superior coatings. The invention includes chemical processes conducted through apparatus described in the specification. Other catalysts and catalyst synthesis techniques are also described.

Owner:VELOCYS INC

System, apparatus, and process for cracking a hydrocarbon feed

ActiveUS8007728B2Prevent over-crackingMeet cutting requirementsCatalytic crackingMolecular sieve catalystEngineeringReaction zone

One exemplary embodiment can be a fluid catalytic cracking system. The fluid catalytic cracking system can include a reaction zone including a riser having a top and a bottom adapted to receive spent catalyst at a first elevation and regenerated catalyst at a second elevation. Typically, the first elevation is lower than the second elevation. Additionally, the fluid catalytic cracking system can include a gas distributor contained near the bottom of the riser in communication with a hydrocarbon feed.

Owner:UOP LLC

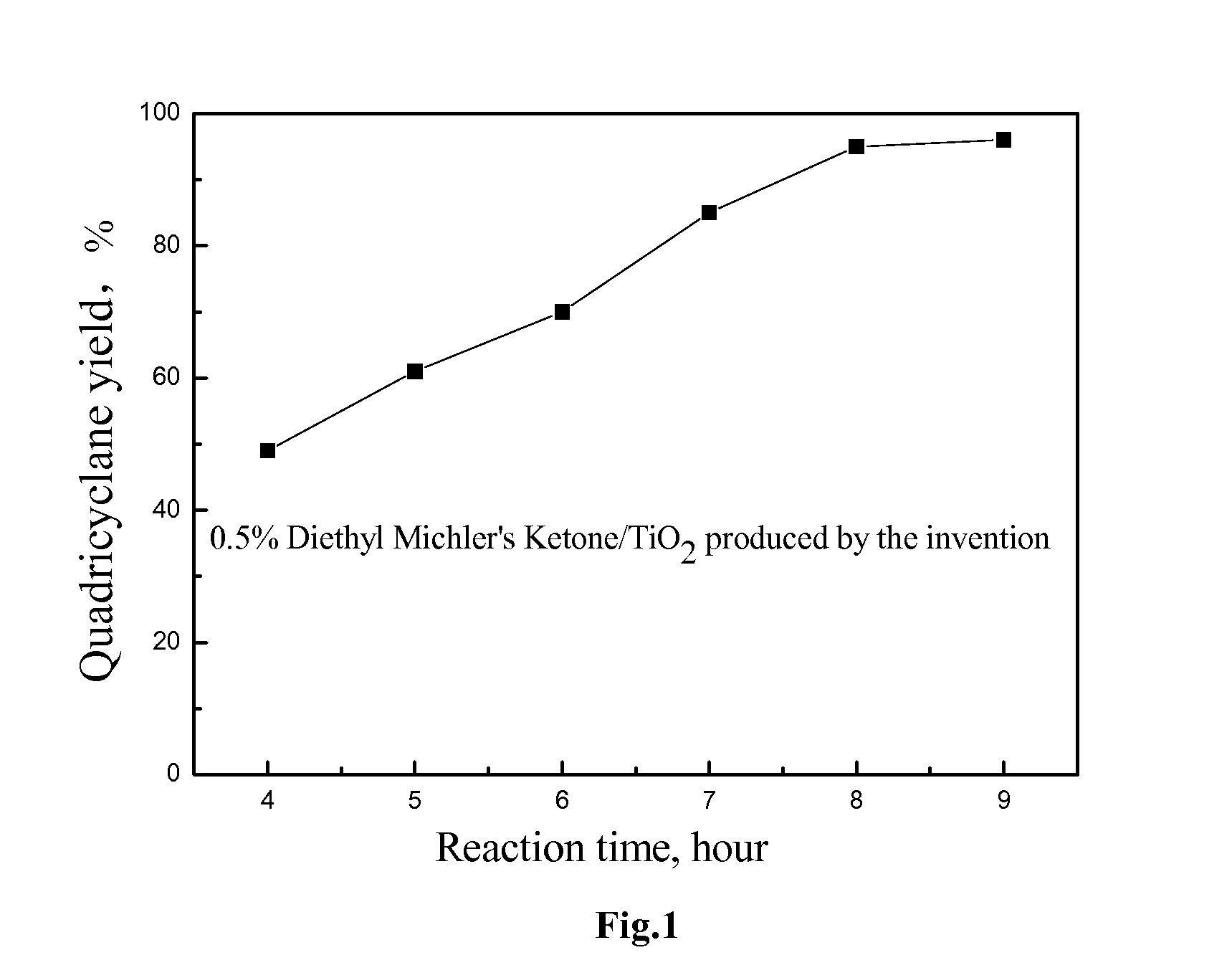

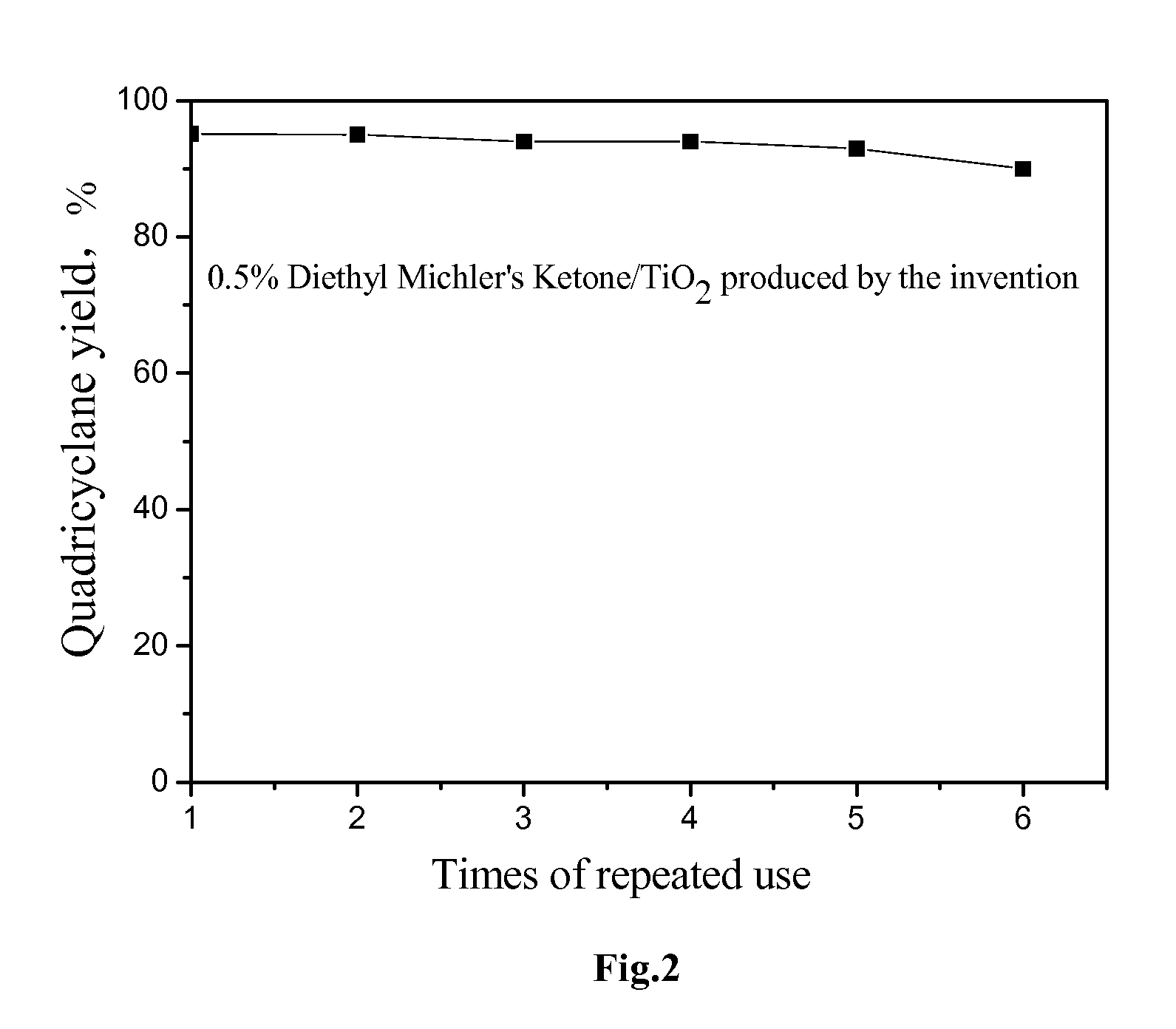

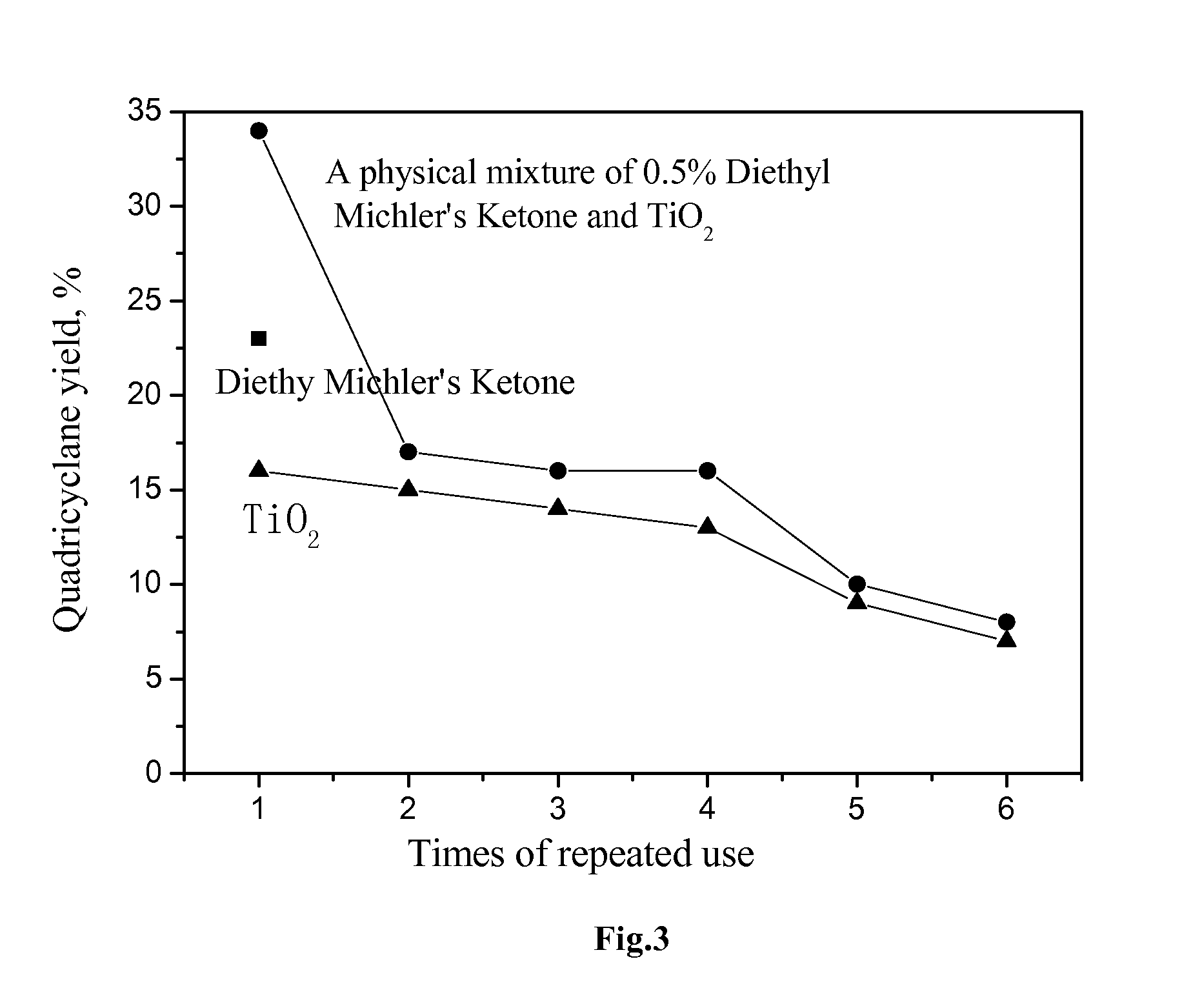

Continuous Preparation Method of High-Purity Quadricyclane

ActiveUS20160340273A1Improve efficiencyImprove responseHydrocarbon by isomerisationOrganic compound preparationPhotosensitizerHigh activity

The invention discloses a continuous process for producing high-pure quadricyclane, in which “a reaction-rectification integral process” or “a reaction followed by rectification process” may be employed. The two processes both use a novel composite catalyst which is obtained by loading an organic photo-sensitizer on a solid photocatalyst, and the composite catalyst has a high activity and a good stability. In the reaction-rectification integral process, the composite catalyst is used by being blended with rectification fillers or covering the rectification fillers, so as to achieve the integration of the reaction and the rectification. In the reaction followed by rectification process, the composite catalyst and the rectification fillers are placed separately from each other. The two processes achieve a relatively short residence time of reactants, produce highly-pure quadricyclane, and reduce the formation of cokes.

Owner:TIANJIN UNIV

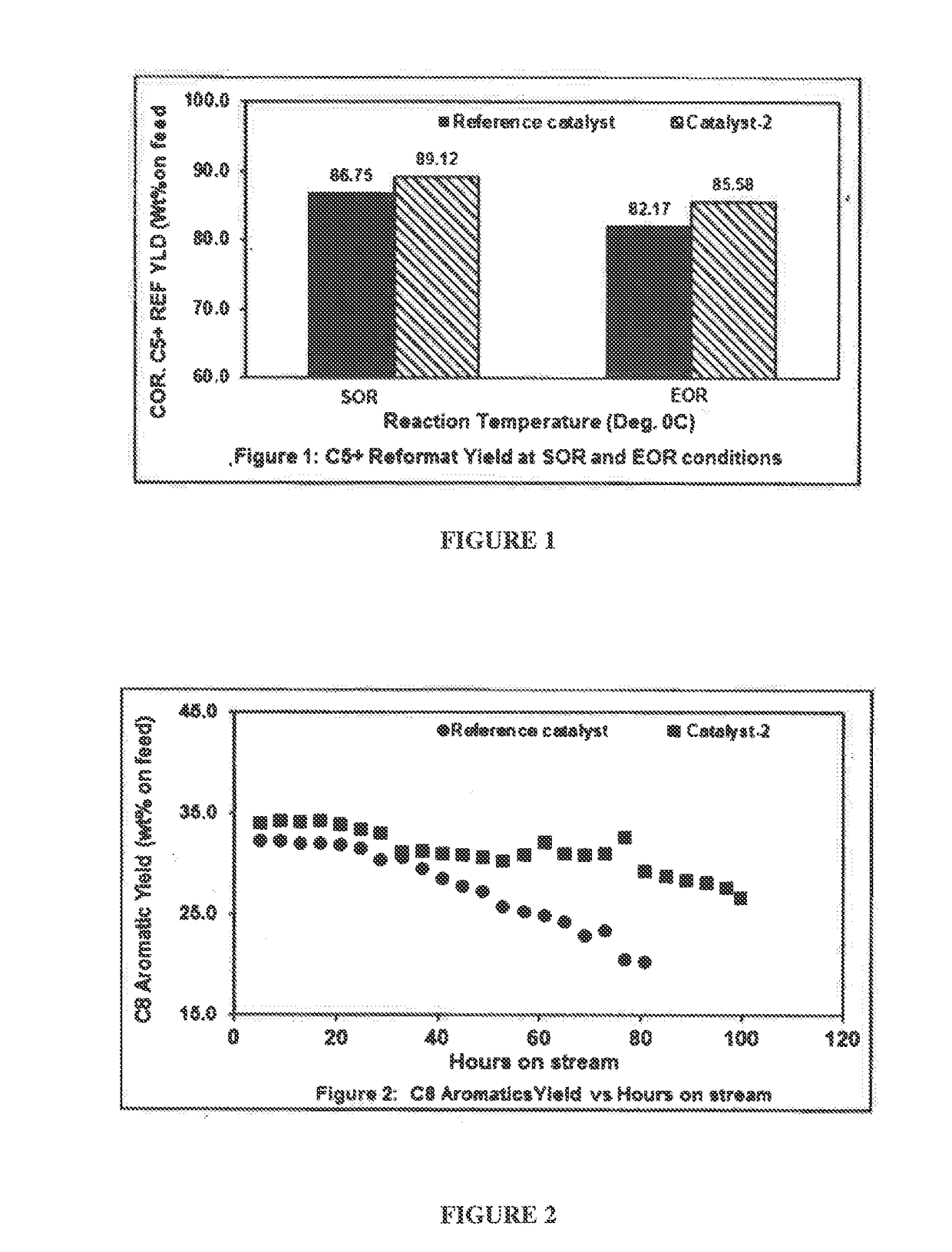

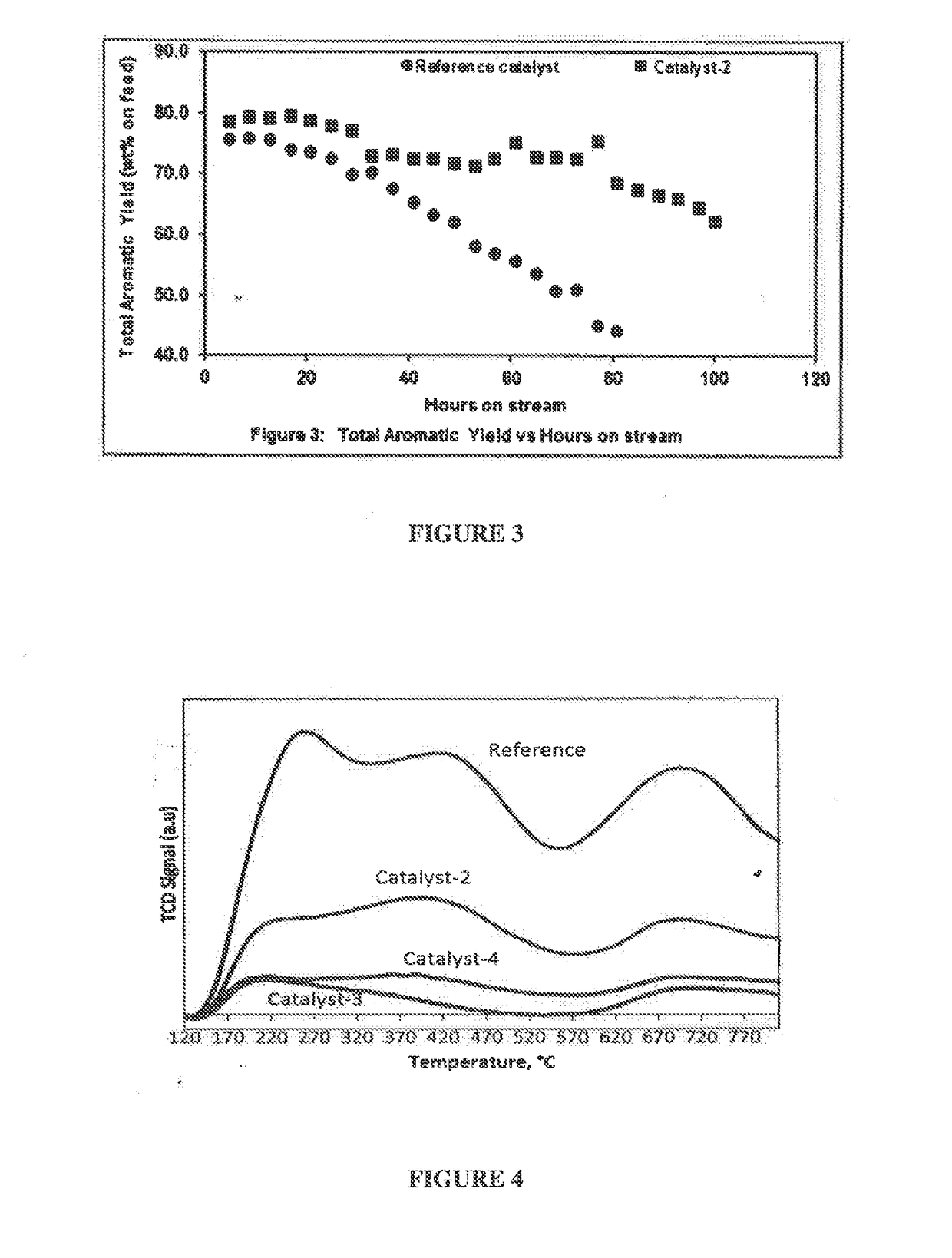

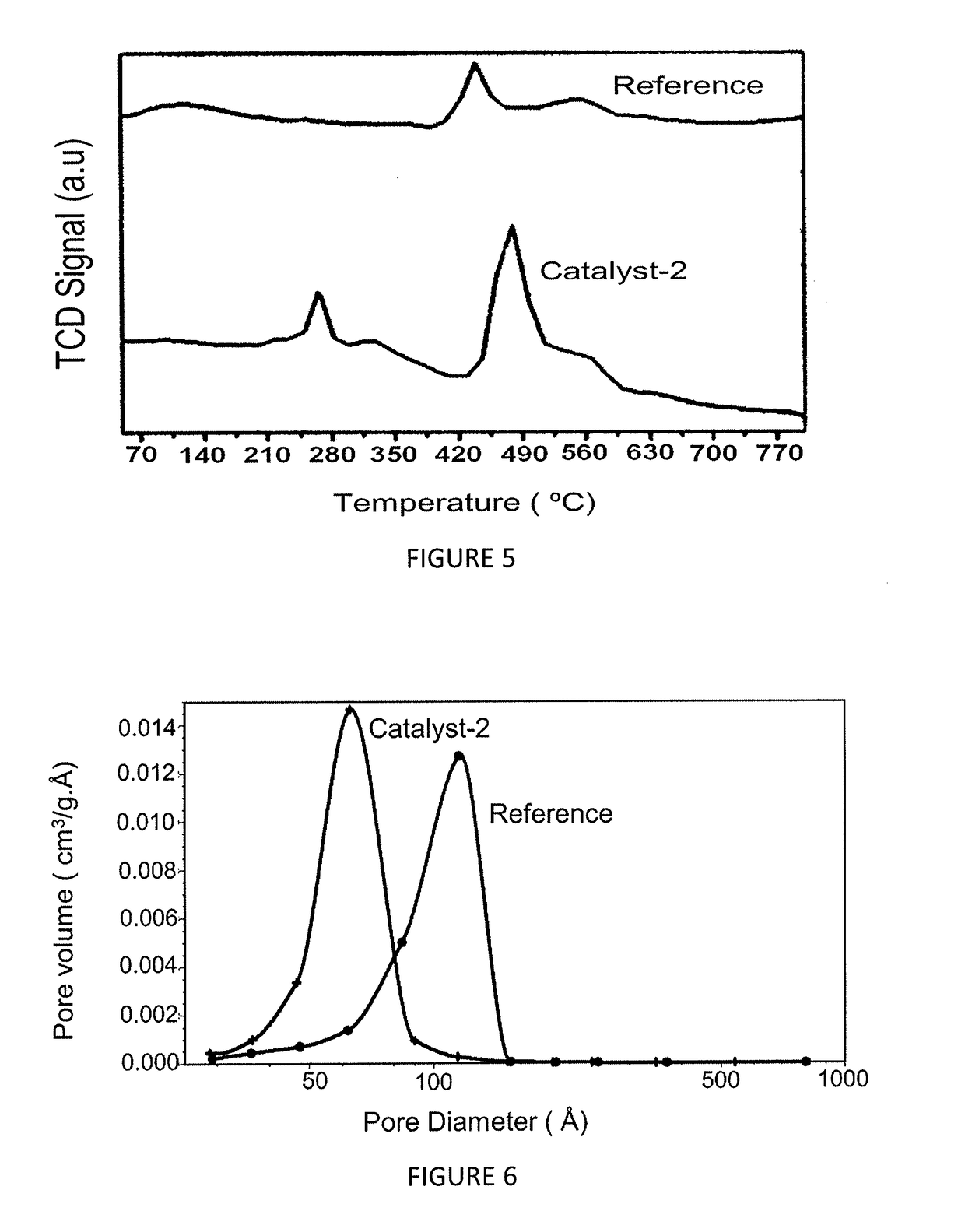

Catalyst, a process for preparation of the catalyst and application thereof

InactiveUS20170106352A1Reduces coke formationReduce inactivation rateCatalytic crackingHeterogenous catalyst chemical elementsNaphthaSupport matrix

The present disclosure relates to a composition, wherein the composition is a catalyst comprising support matrix, active metal, promoter metal and halide, wherein the support matrix is additionally subjected to a modifier to obtain a modified support matrix. The catalyst in the reaction reduces the percentage coke formation and provides for an enhanced reformate yield having an increase total aromatic yield and C8 aromatic yield when compared to the known / commercially available catalyst for naphtha reforming process, and also improves the quality of reformate obtained at end of the reaction. The disclosure further relates to process of preparation of the catalyst, the catalyst of the present disclosure derived from the process described, displays lower deactivation during the reaction demonstrating increased stability and reduction in the regeneration frequency and thereby making the catalyst economically feasible.

Owner:RELIANCE INDUSTRIES LIMITED

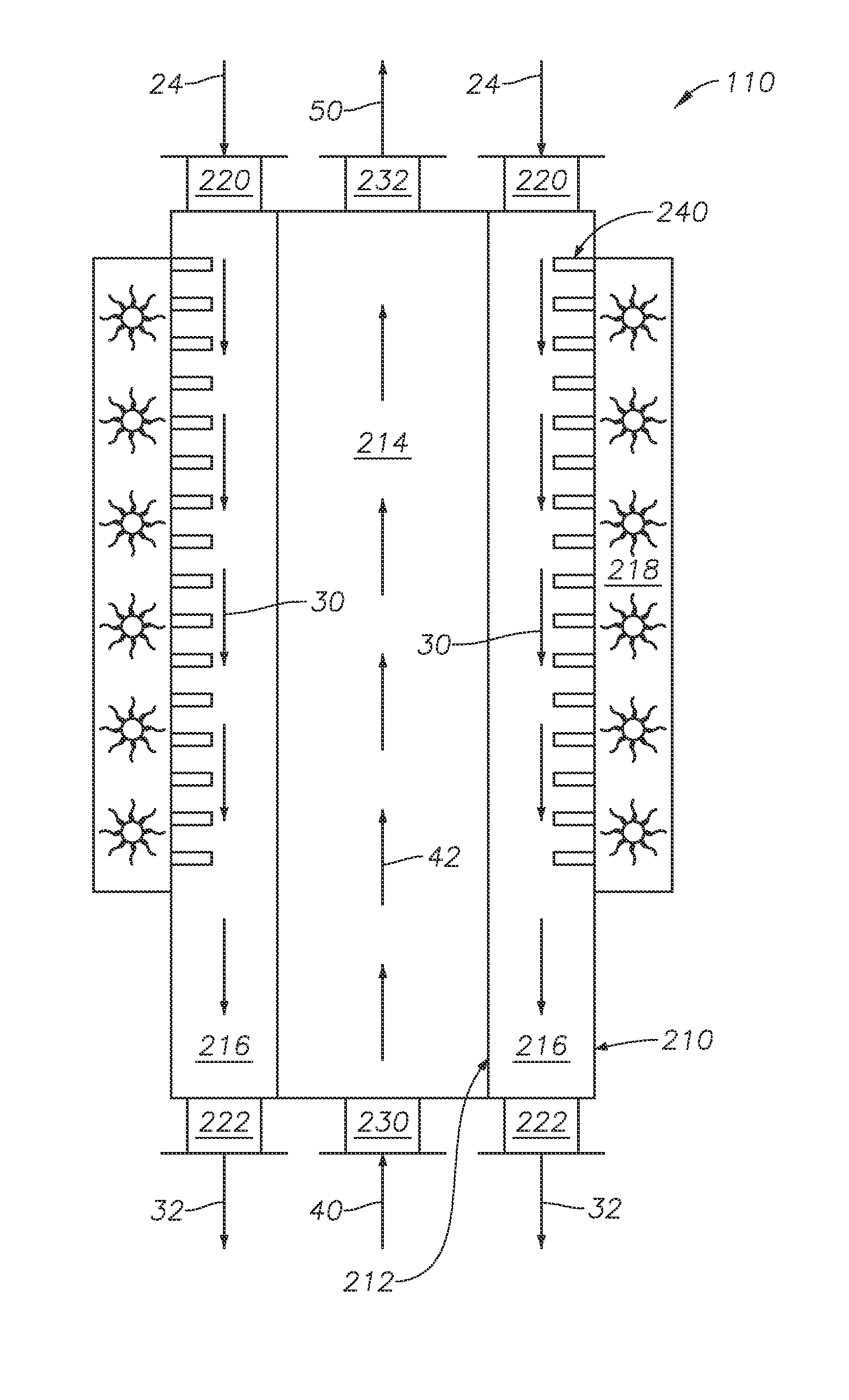

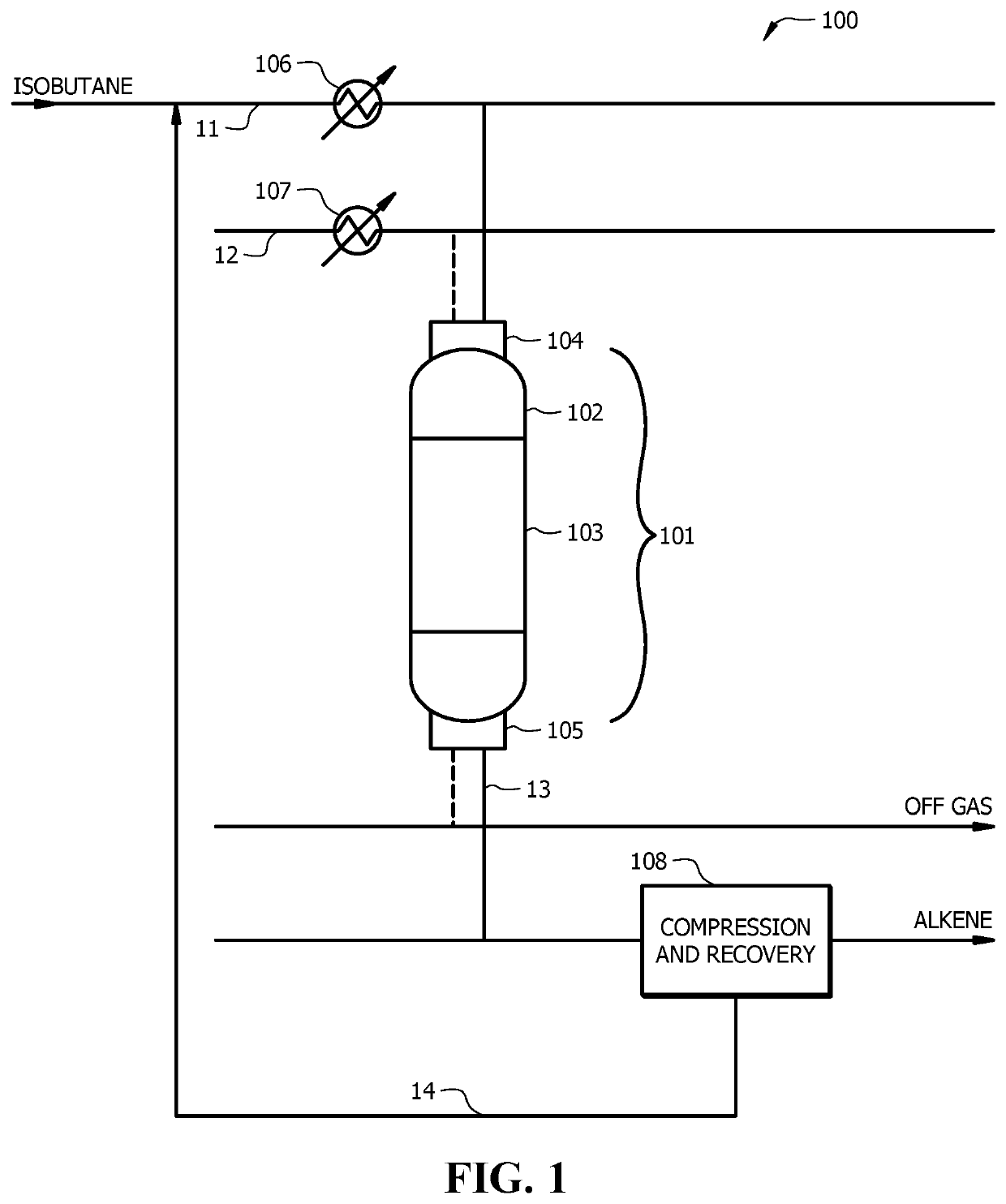

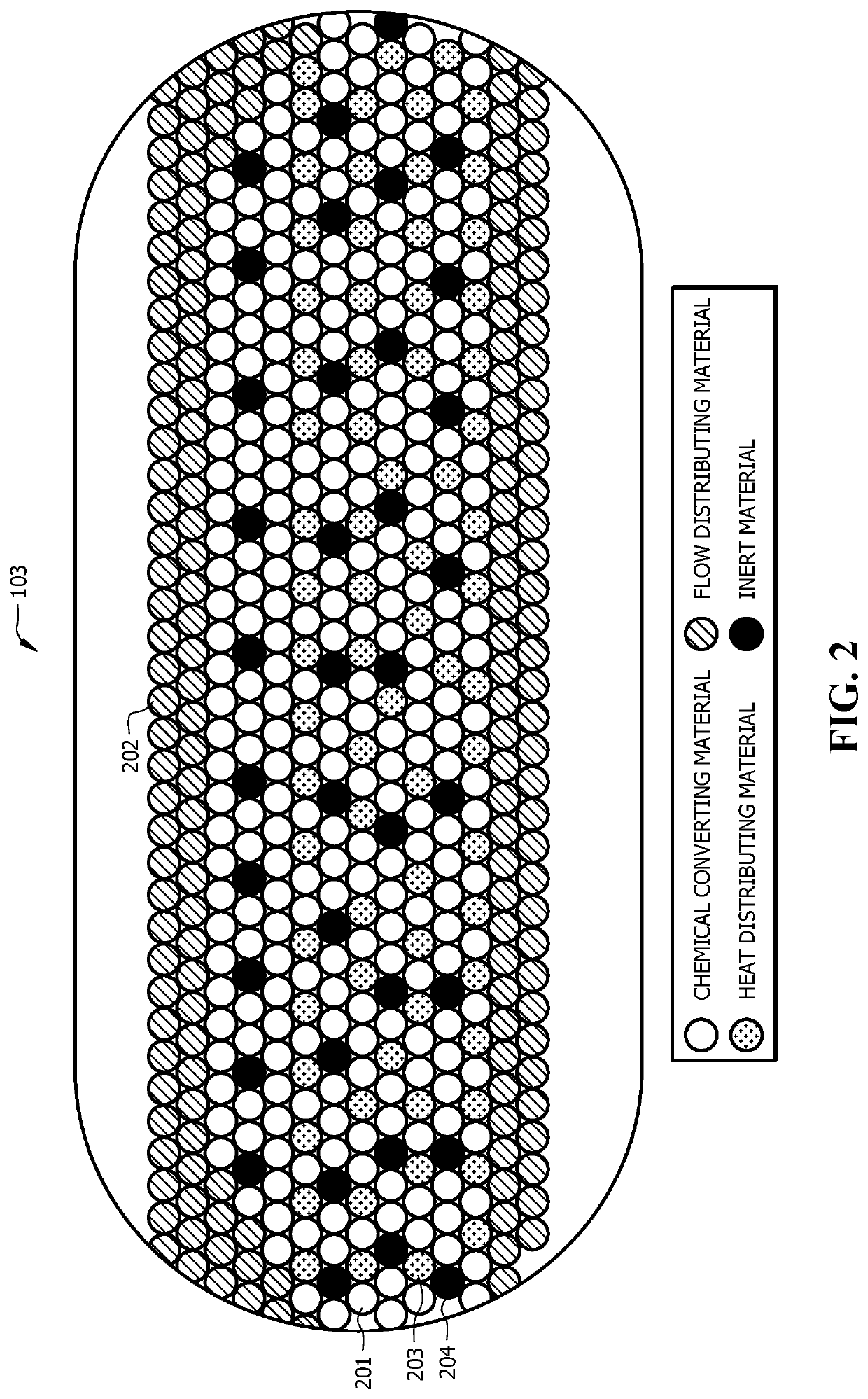

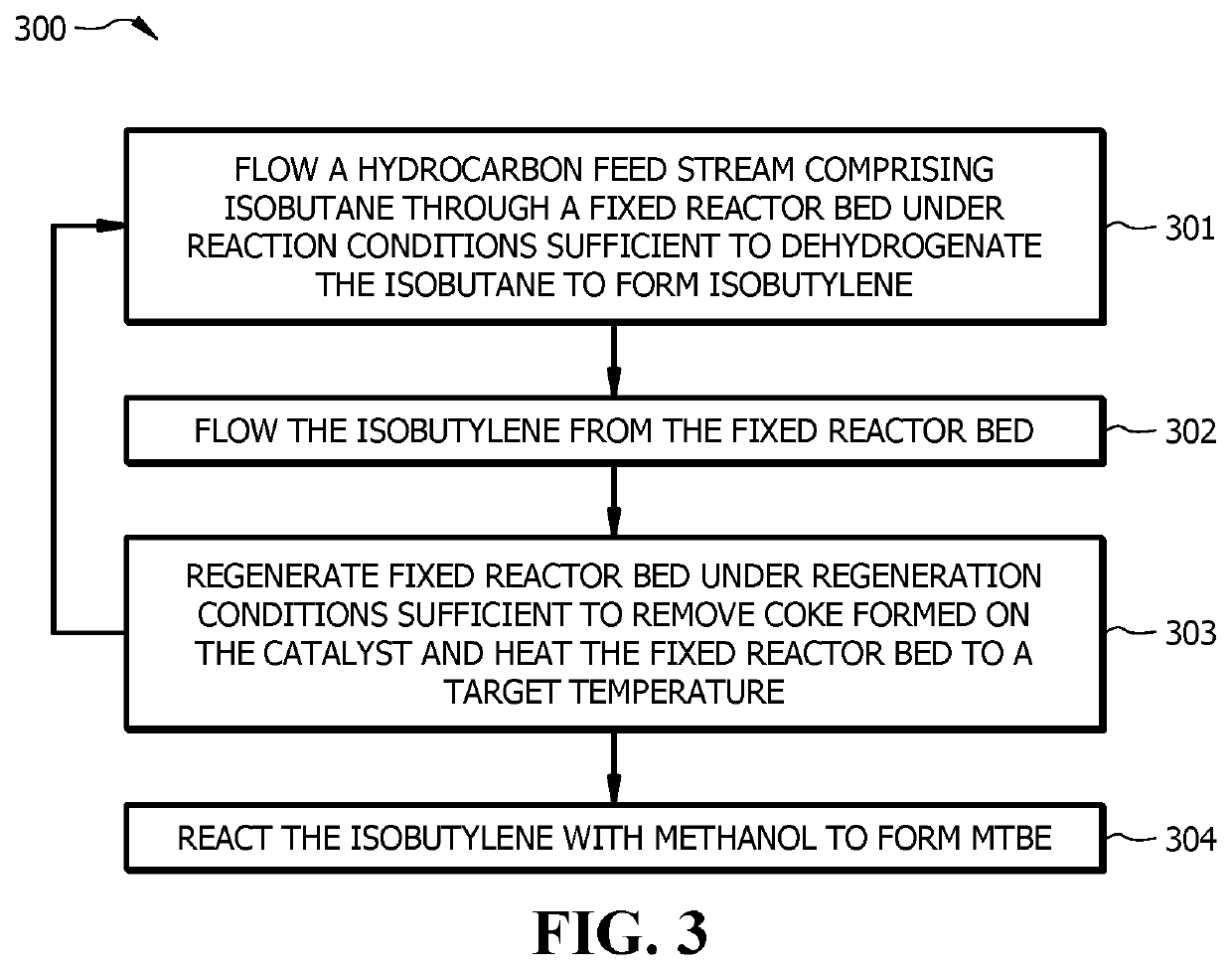

System and method for dehydrogenating isobutane to isobutylene

InactiveUS20200239386A1Improve conversion rateEqually distributedHydrocarbonsEther preparation by compound additionThermodynamicsChemical physics

A system and a method for dehydrogenating isobutane to isobutylene are disclosed. The system comprises a fixed bed dehydrogenation reactor. The fixed reactor bed in the fixed bed dehydrogenation reactor includes a catalyst layer, a first material adapted to improve the flow distribution in the fixed reactor bed, a second material adapted to improve the thermal distribution in the fixed reactor bed, and a third material adapted to improve both the flow distribution and the thermal distribution in the fixed reactor bed. The first material covers a top, a bottom, and at least a portion of a side surface of the catalyst layer of the fixed reactor bed. The second material and the third material both are evenly distributed in the catalyst layer.

Owner:SABIC GLOBAL TECH BV

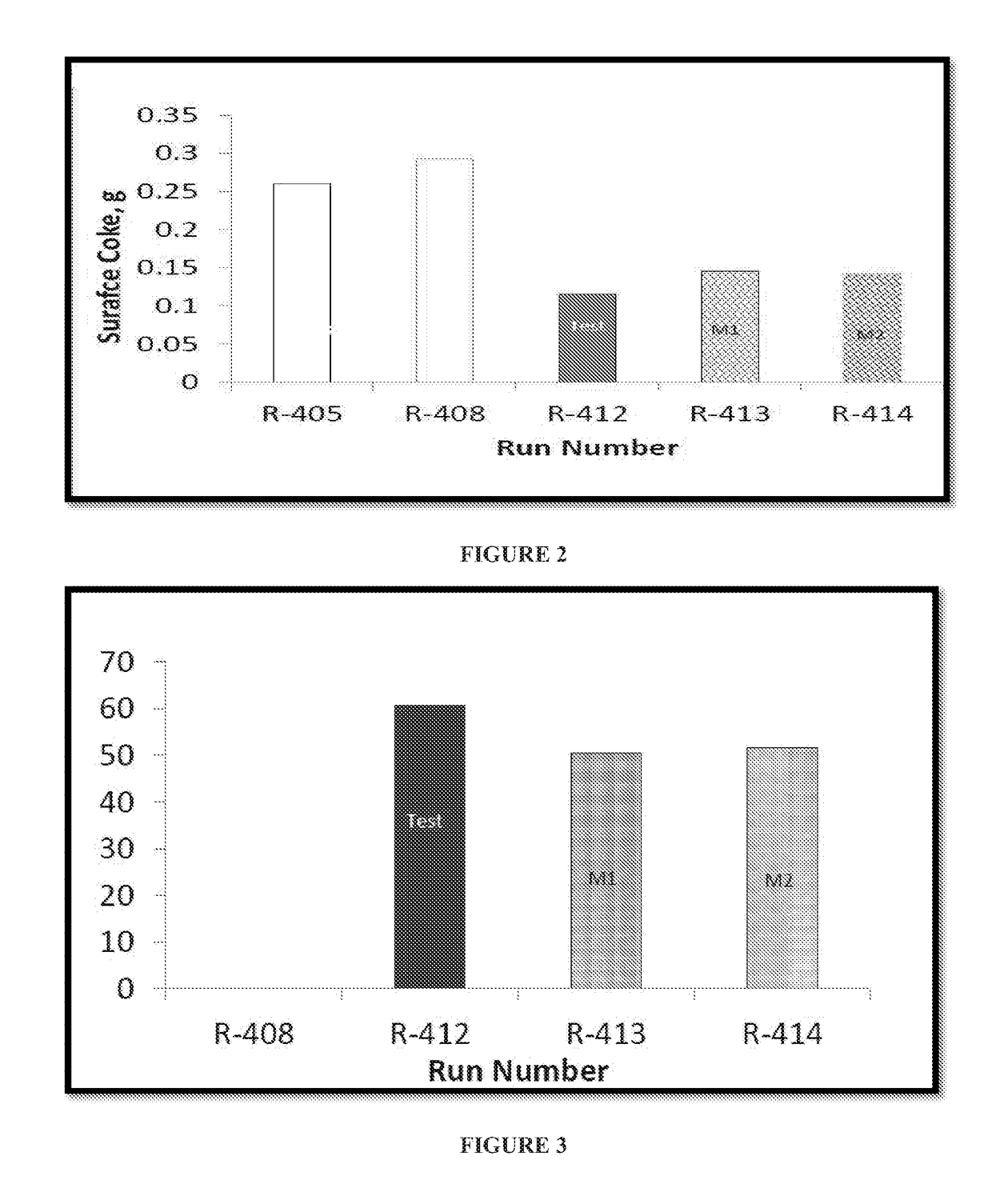

A composition, method and applications thereof

InactiveUS20180208856A1Reduce coke depositionReduces coke formationThermal non-catalytic crackingTreatment apparatus corrosion/fouling inhibitionAcetic acidPotassium carbonate

The instant disclosure relates to a composition comprising potassium carbonate and calcium acetate, optionally along with sulfur containing compound. The composition of the present disclosure reduces coke formation during hydrocarbon cracking, particularly reduces surface coke and spalled coke during hydrocarbon cracking when compared to hydrocarbon cracking without the said composition. The disclosure further relates to a method for reducing formation and / or deposition of coke during pyrolysis or cracking of hydrocarbons.

Owner:RELIANCE INDUSTRIES LIMITED

Microchannel apparatus comprising a platinum aluminide layer and chemical processes using the apparatus

InactiveUS20070154360A1Reduces coke formationReduce metal dustingChemical/physical/physico-chemical microreactorsCatalyst activation/preparationPlatinumCompound (substance)

Owner:VELOCYS CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com