Process for making a distillate product and/or c2-c4 olefins

a distillate product and olefin technology, applied in the field of distillate products and/or c2c4 olefins, can solve the problems of fcc feedstock use as food, the total imbalance of the rate at which biomass is converted to fossil resources, and the competition of plant oils and/or animal fats as fcc feedstocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016]It would be more preferred to use non-edible renewable energy sources, such as some cellulosic materials such as wood, as an FCC feedstock.

[0017]It would therefore be an advancement in the art to provide an FCC process for the production of a distillate and C2-C4 olefins, that allows one to use a non-edible renewable energy source, such as a cellulosic material, as a feedstock.

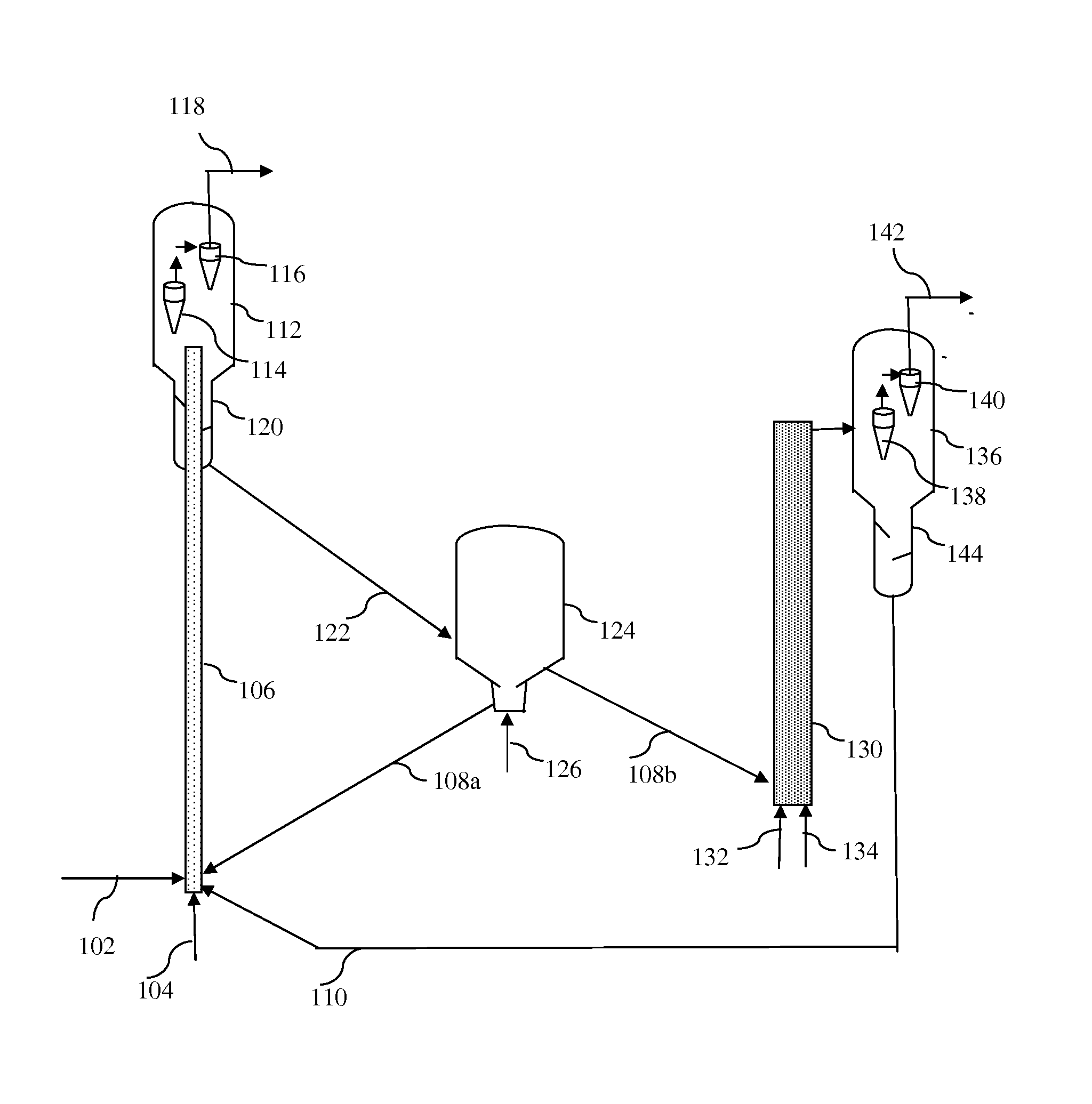

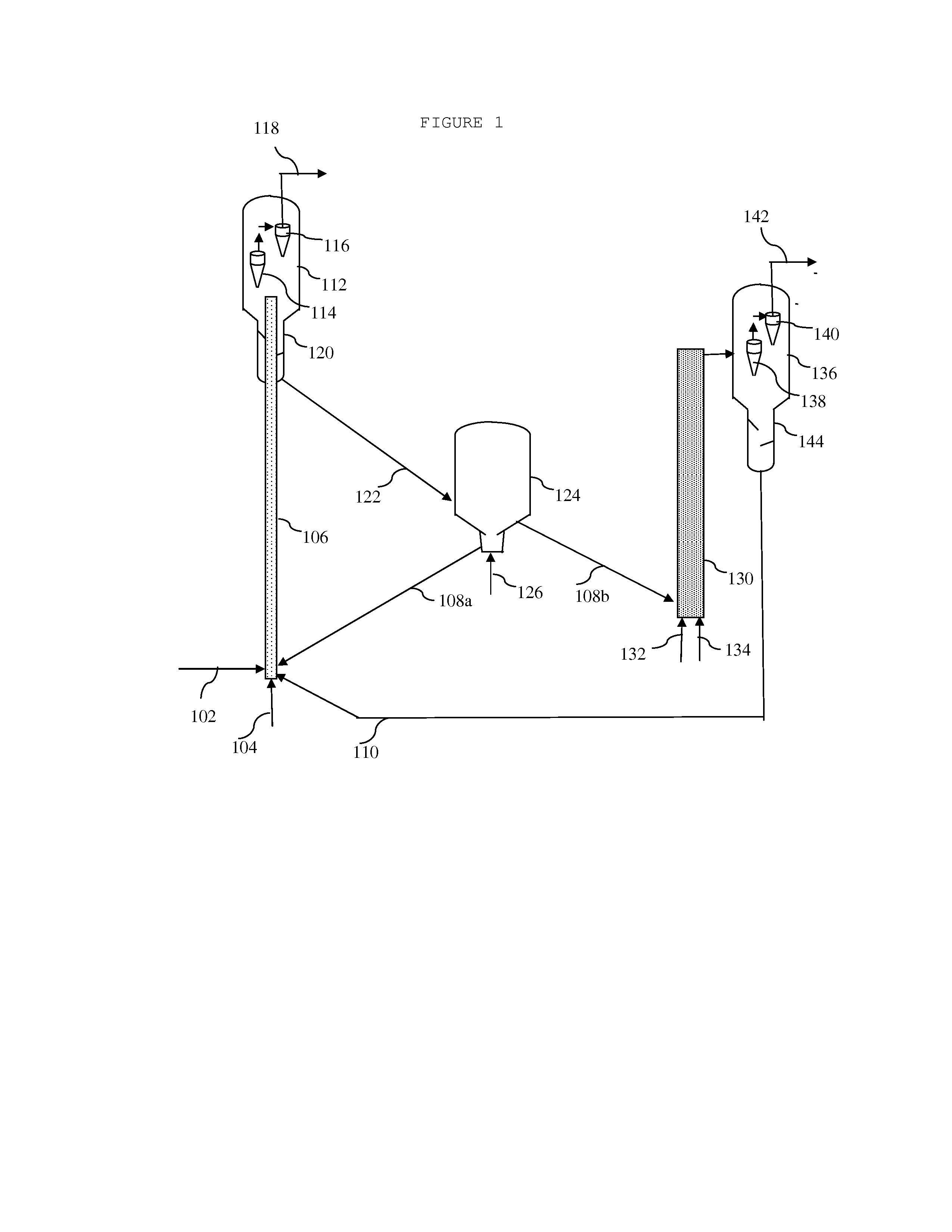

[0018]Accordingly, in an embodiment provides a process for making a distillate product and one or more C2-C4 olefins comprising:

a) contacting a FCC feedstock with a FCC catalyst at a temperature of equal to or more than 400° C. in a riser reactor to produce a distillate product and a spent FCC catalyst, wherein the FCC feedstock comprises a cellulosic material and a hydrocarbon co-feed;

b) separating at least part of the distillate product from the spent FCC catalyst;

c) regenerating the spent FCC catalyst to produce a regenerated FCC catalyst;

d) contacting an intermediate reactor feedstock with at least p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| molar ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com