A composition, method and applications thereof

a technology of composition and method, applied in the field of organic chemistry, can solve the problems of frequent decoking and deterioration of coil metal of the reactor, and stop the production of ethylene and other industrial products, and achieve the effect of reducing coke deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

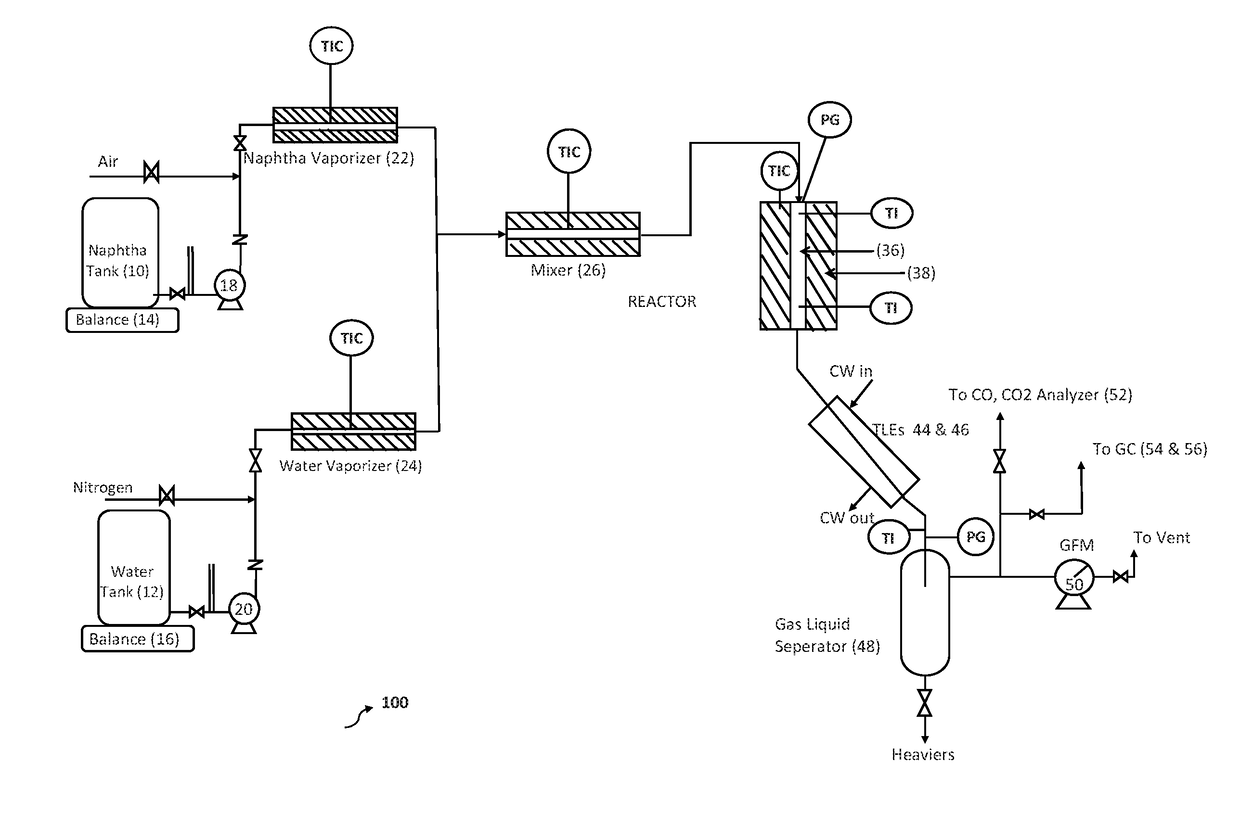

Method used

Image

Examples

example 1

on Cracking with Water as Steam and without Employing the Composition of the Present Disclosure (Control Run)

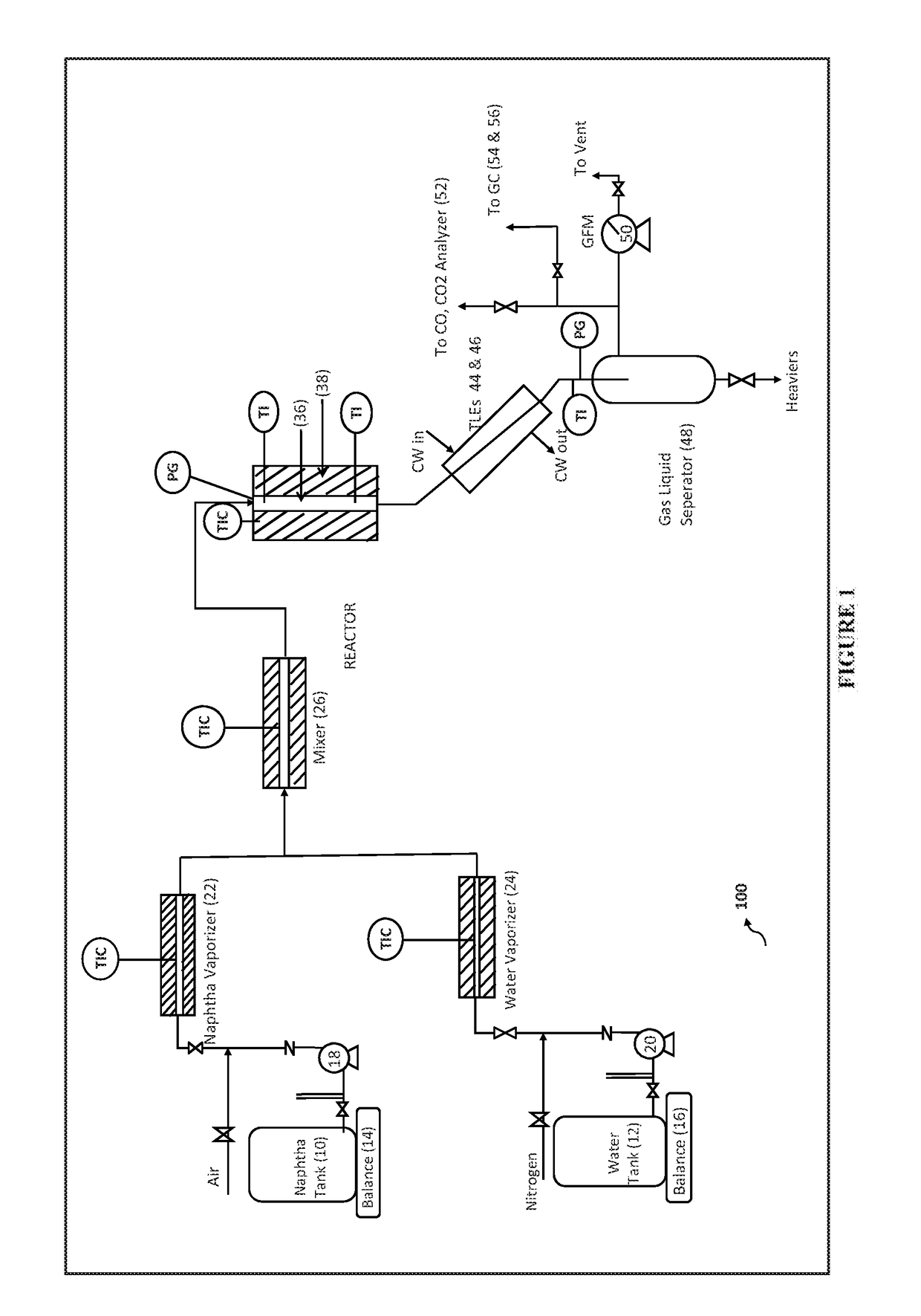

[0079]An experimental run (R-405) is carried out in a bench scale cracker having a cracker coil made of Incoloy 800HT and using naphtha as the feed. The coil outlet temperature is maintained at a temperature of about 825° C. and steam dilution is at a ratio of about 0.32. The corresponding residence time is around 0.5 seconds. The feed olefin content is found to be about 1.94%. Blank run is carried out using distilled water for steam for a time period of about 48 hours. The surface coke deposited on the surface of thermowell is recorded as 0.26 g at the end of 48 hour run when the furnace is opened after cooling. The reproducibility of the run is tested by repeating the run under same conditions.

example 2

on Cracking with Plant Steam Condensate as Water without Employing the Composition of the Present Disclosure (Control Run)

[0080]An experimental run (R-408) is carried out under the same conditions as the blank run described in example 1, except that the plant steam condensate obtained from quench water comprised of caustic (NaOH), which is being added for pH adjustment in place of water. The blank run is carried out for about 48 hours and the surface coke deposited in presence of caustic is found to be about 0.293 g same range as that of the base runs (Example 1). The quantity of spalled coke from the reactor is found to be 13.28 g. This data is considered as bench mark in assessing the composition of the present disclosure for coke reduction estimation.

example 3

on Cracking in Presence of the Composition of the Present Disclosure

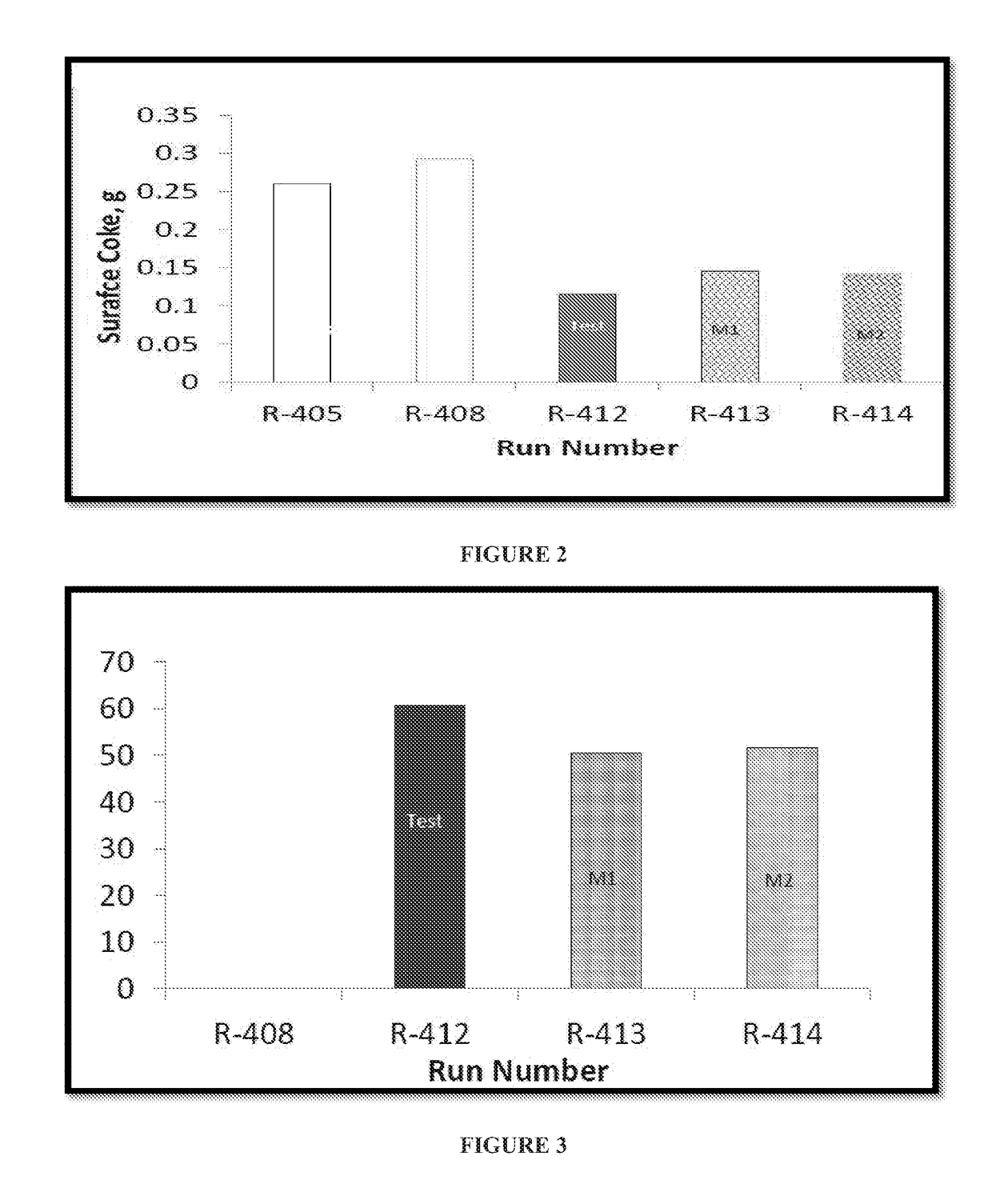

[0081]An experimental test run (R-412) is carried out under the same conditions as the blank run described in example 1, wherein along with the plant steam condensate the composition of the present disclosure is introduced, by dissolving the composition in plant steam condensate at a concentration of about 4 ppmw, wherein calcium acetate is about 65 wt % and potassium carbonate is about 35 wt %. The concentration of the composition is maintained at 4 ppmw throughout the 48 h run of the experiment. The amount of surface coke that is formed during the reaction is found to be much lesser than the runs in Examples 1 and 2 above, and is found to be 0.115 g, as disclosed in FIG. 2. The amount of surface coke that is formed during the reaction comprising the composition of the present disclosure is reduced by about 60% when compared to benchmark base run performed in Example 2 and as described in FIG. 3. The amount of spal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com