Patents

Literature

40 results about "Bench scale" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

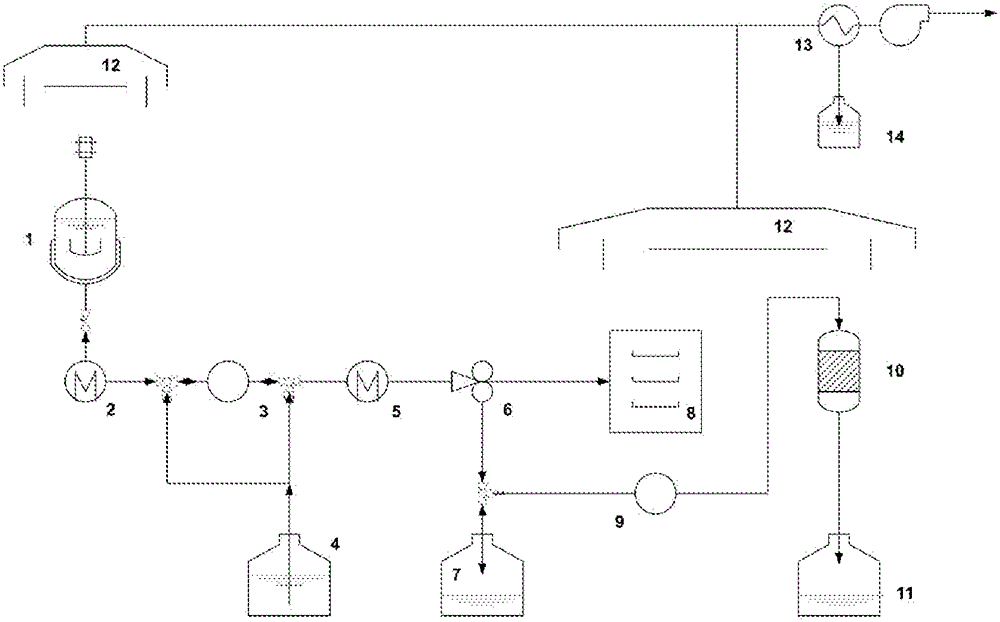

Method for preparing diethyl oxalate by coupling CO

ActiveCN101143821ANo pollution in the processImprove efficiencyPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsCyclic processContinuous use

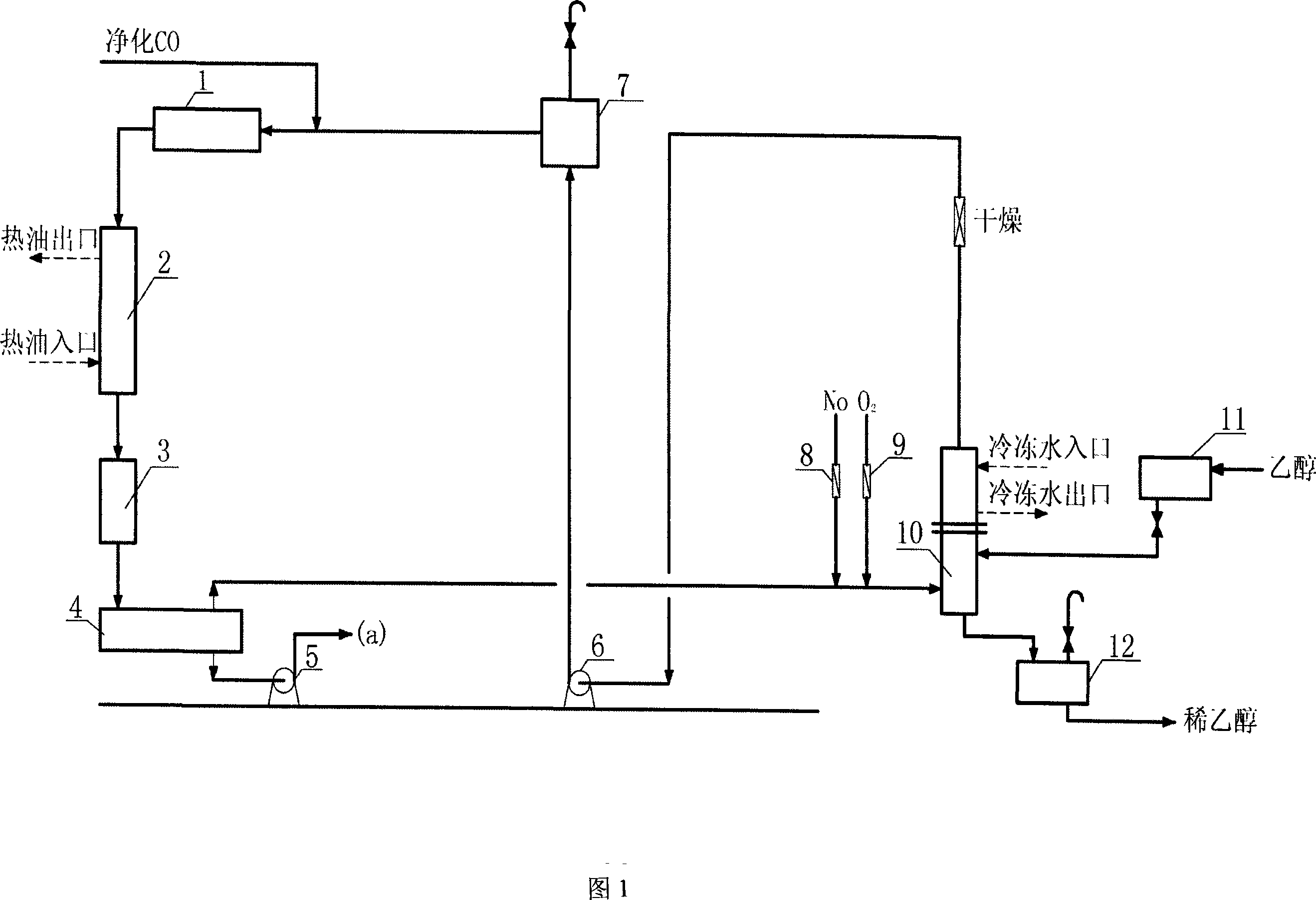

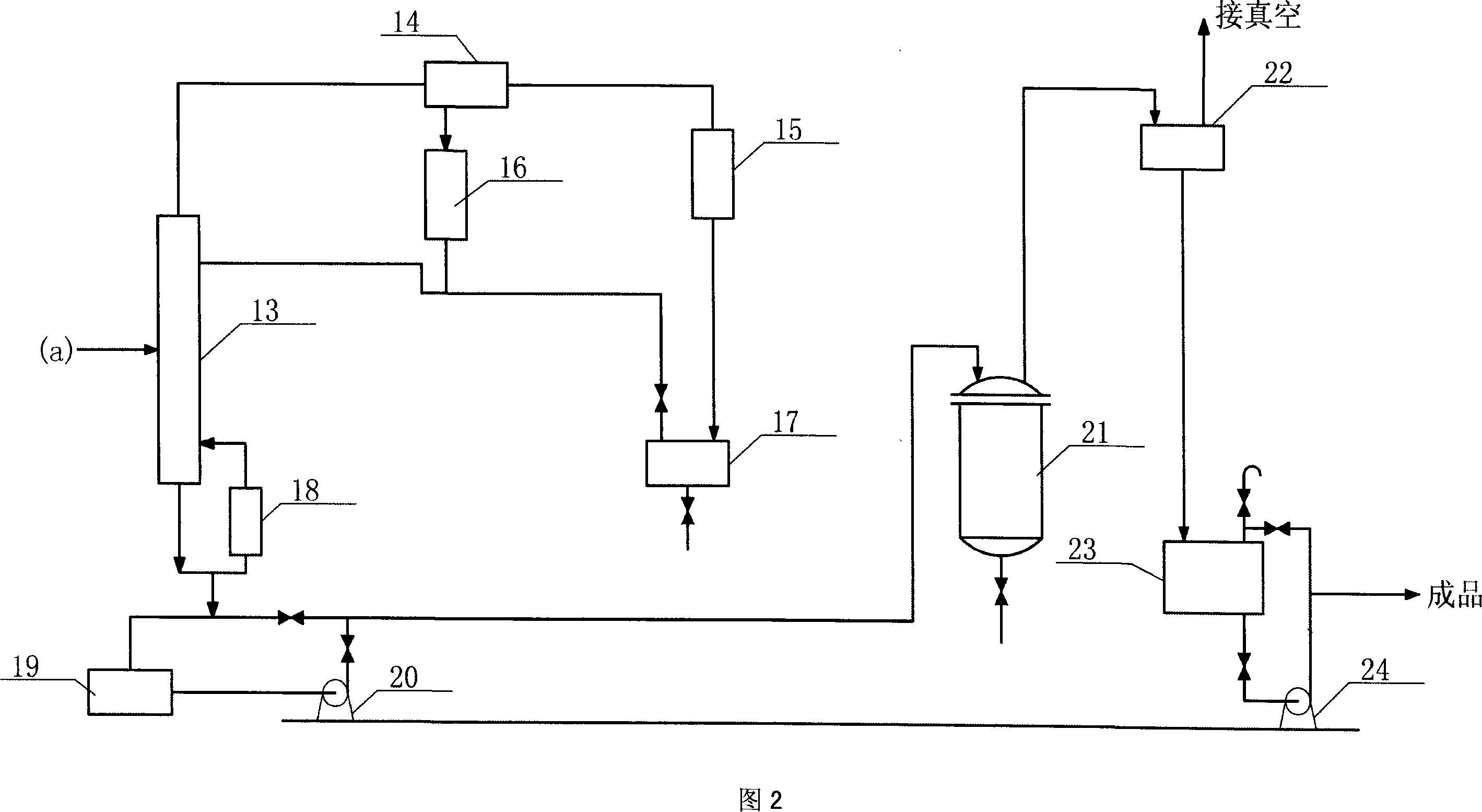

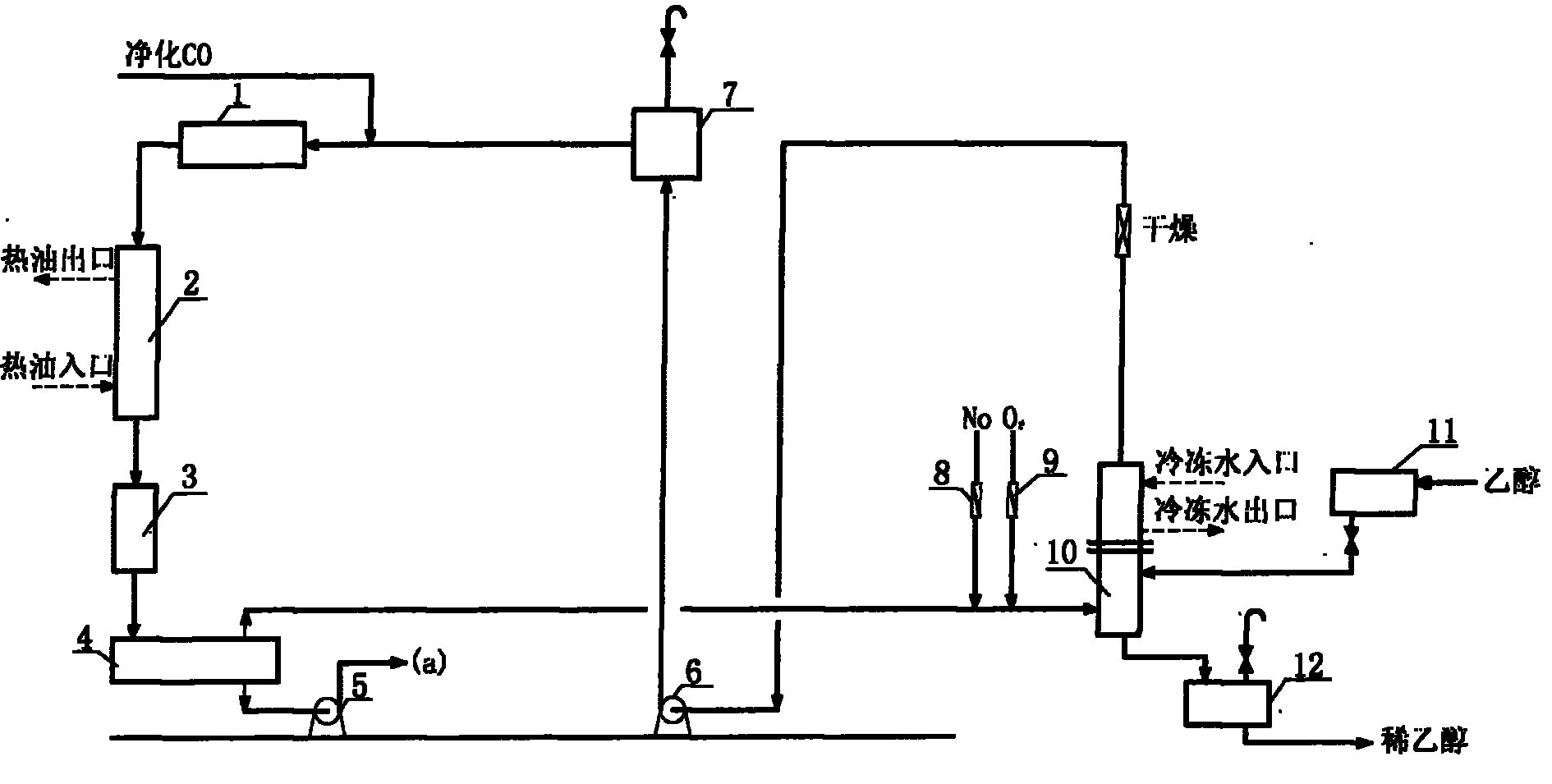

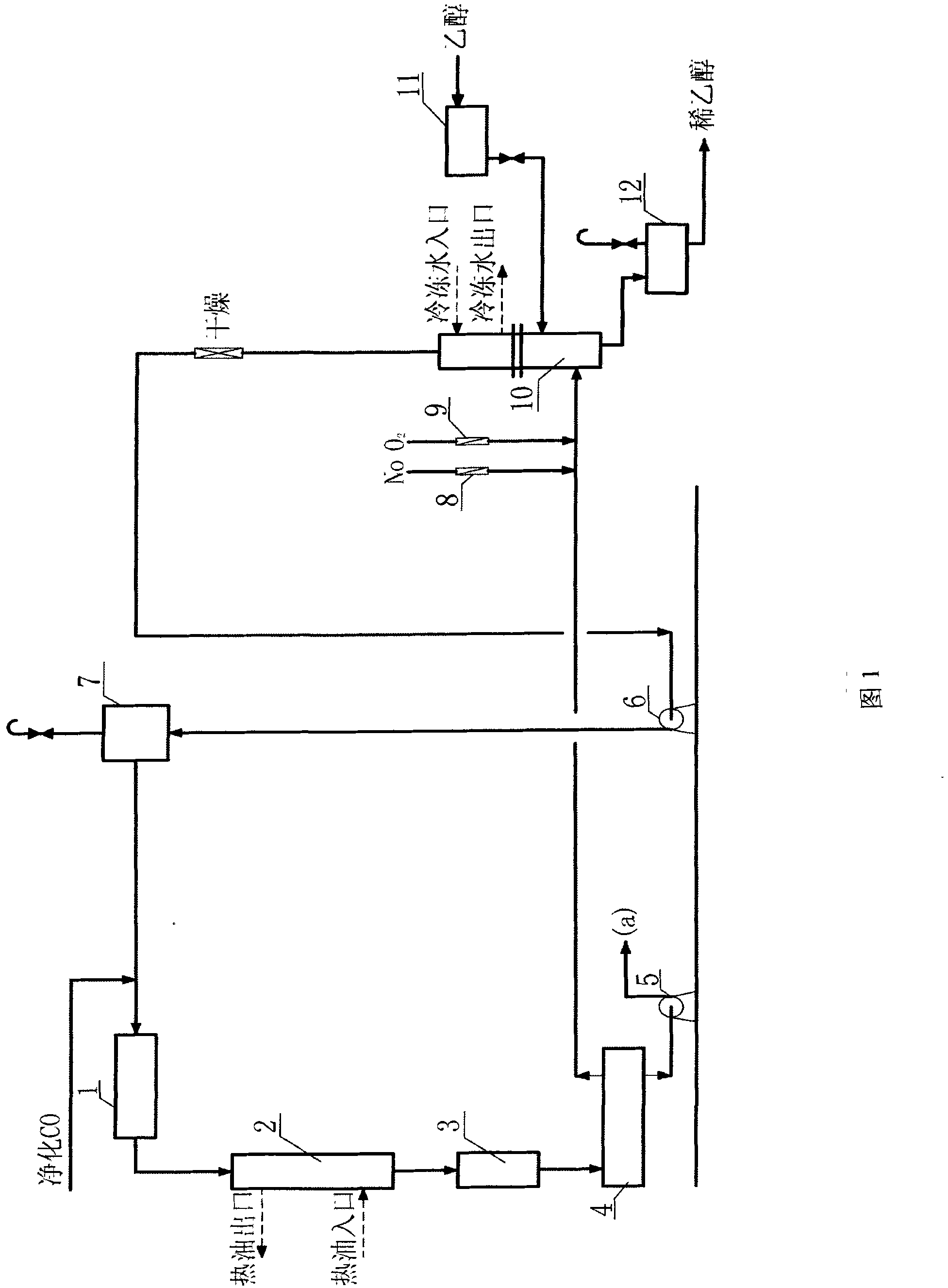

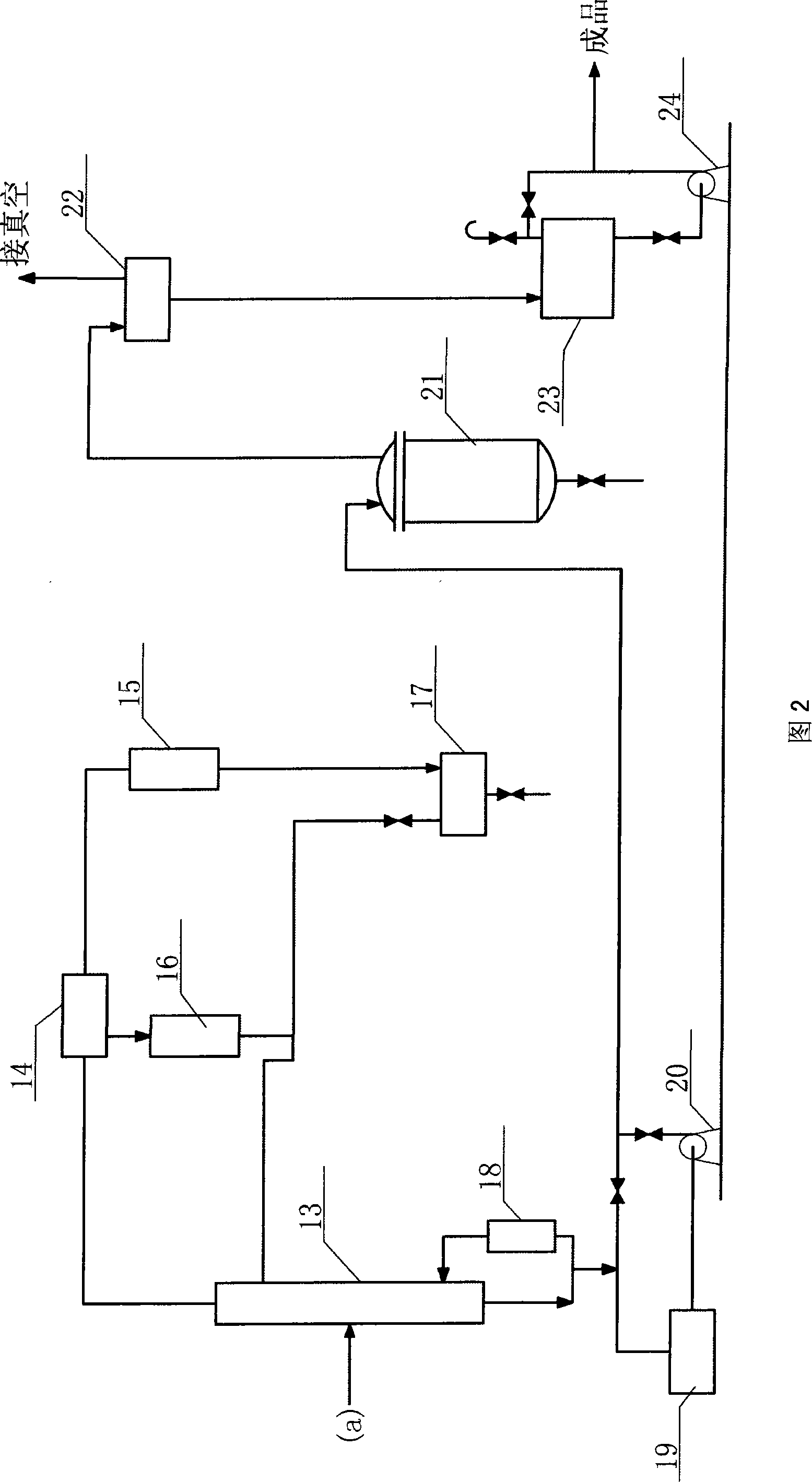

The invention discloses a method for preparing diethyl oxalate by CO coupling reaction. By applying a gas phase method, CO is coordinated with ethyl nitrite and is catalyzed by bimetallic supported catalyzer to couplingly generate crude diethyl oxalate, the reaction is a self-sealing circulation process, the CO gas mixed with the ethyl nitrite coming from a regeneration reactor is preheated and then enters into a coupling reactor, after the reaction, the gas is separated by condensation, so that the colorless and transparent condensed diethyl oxalate liquid is produced, and the uncondensed gas containing NO enters into the regeneration reactor to react with ethanol and oxygen in order to generate ethyl nitrite which is again circulated back to the coupling reactor for continuous use. The invention is carried out on the basis of previous laboratory research and under the background of industrial production and fulfils the continuous run examination of the bench scale test and pilot magnification under the condition of industrial operation, the temperature of the coupling reaction is low, and the concentration of products is increased. The method has the advantages of more energy saving, no pollution and high benefit. The total conversion rate of the CO generated by reaction is one hundred percent, and the selectivity of diethyl oxalate is over ninety six percent.

Owner:TIANJIN UNIV

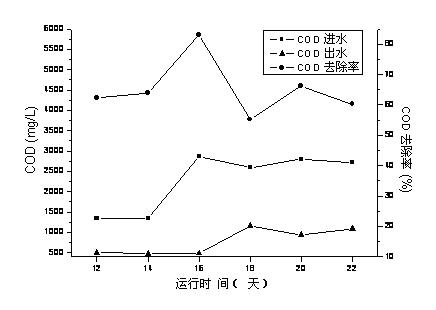

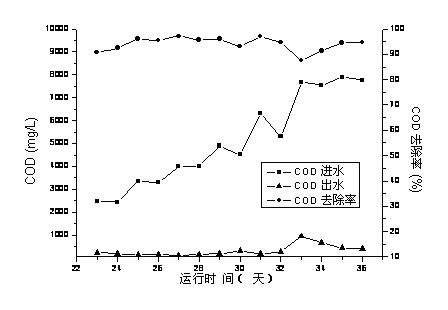

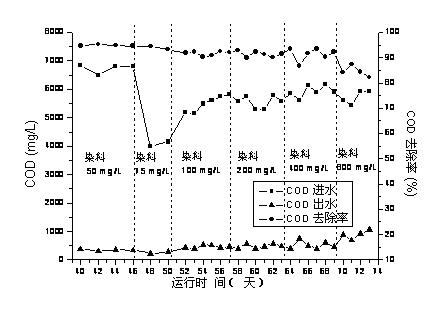

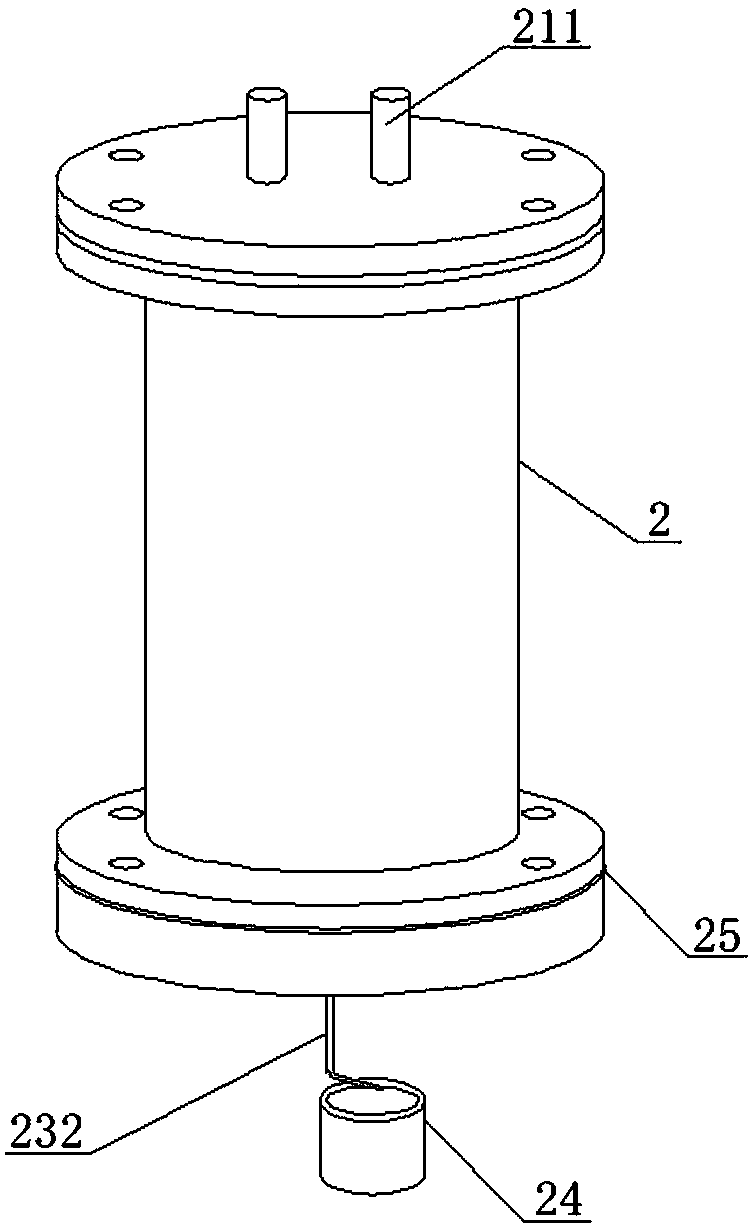

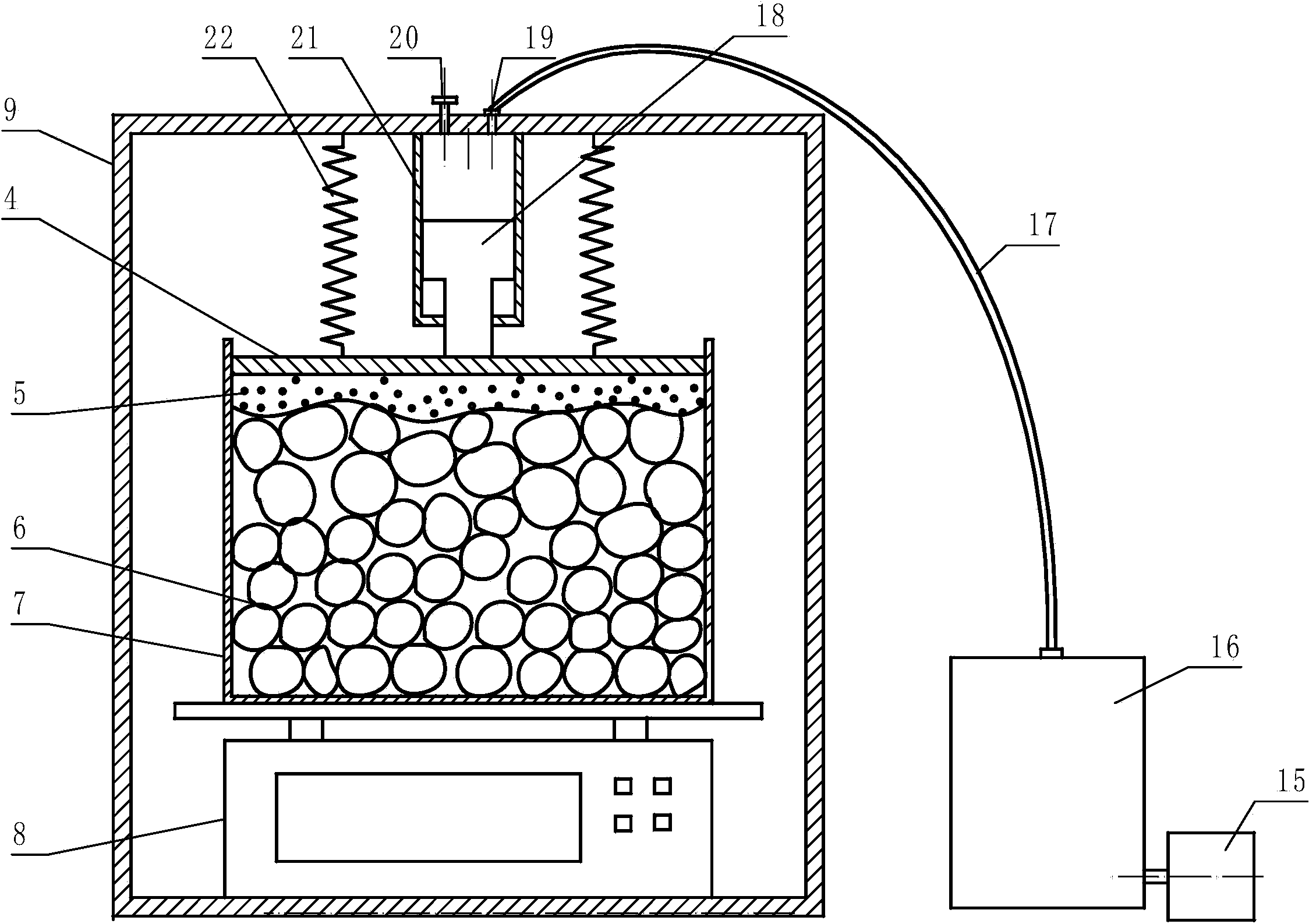

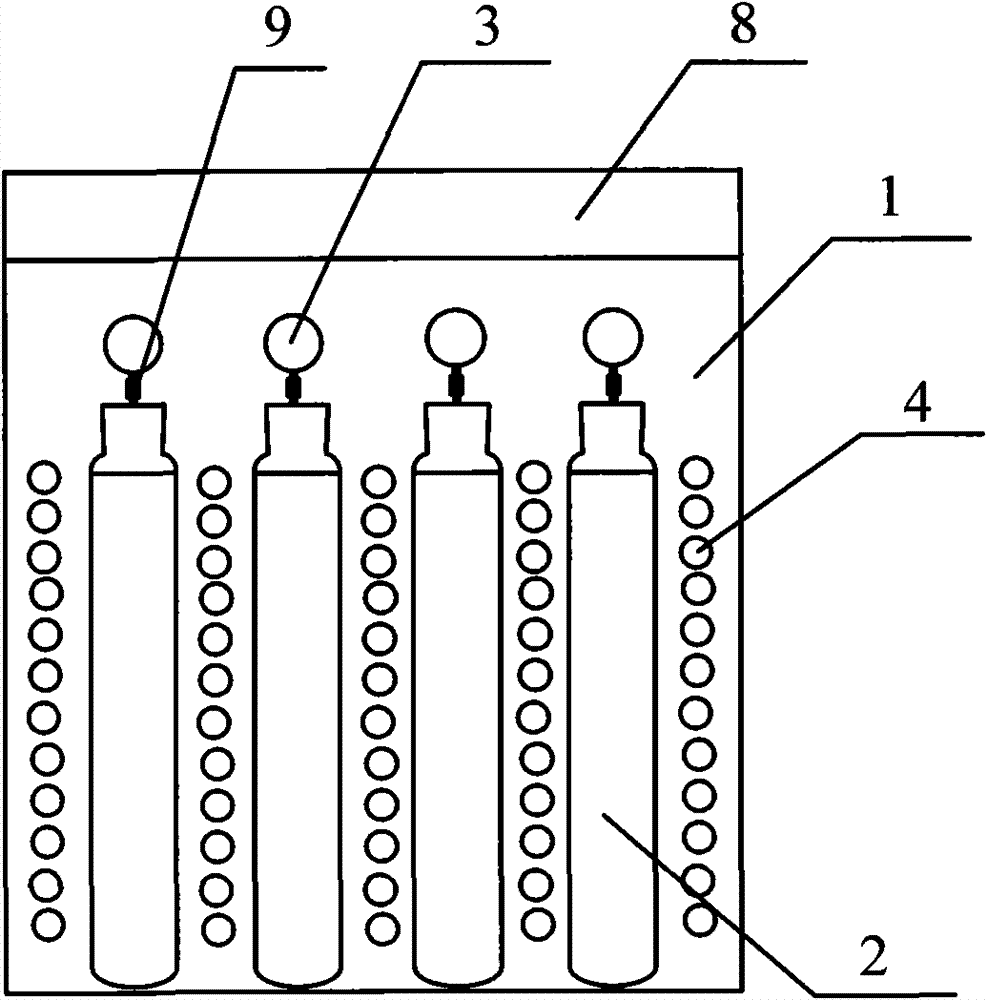

Electrically enhanced internal anaerobic zero-valent iron reactor

InactiveCN101928066APromote generationRegulated DissolutionTreatment with anaerobic digestion processesDecompositionDissolution

The invention discloses an electrically enhanced internal anaerobic zero-valent iron reactor, belonging to the technical field of water treatment. Two graphite electrodes are arranged inside an anaerobic reactor and connected with an external direct current regulated power supply through a wire to simulate growth of microorganisms; meanwhile, the oxidation reduction process of the graphite electrodes also strengthens reductive decoloration of azo dyes. The graphite electrodes are arranged in the anaerobic internal biological zero-valent iron reactor, dissolution of iron is regulated by applying micro-voltage, and the buffer capacity of the reactor to acidification is strengthened. Coupling of an external power supply and zero-valent iron can also accelerate sludge granulation, efficiently enhance the decomposition capacity to organic compounds and realize rapid starting and high-efficiency running of the anaerobic reactor. A bench scale experiment shows that after the micro-voltage is applied, the rapid starting and the sludge granulation of the anaerobic reactor can be realized within 41 days, and the electrically enhanced internal anaerobic zero-valent iron reactor has stronger shock resistance.

Owner:DALIAN UNIV OF TECH

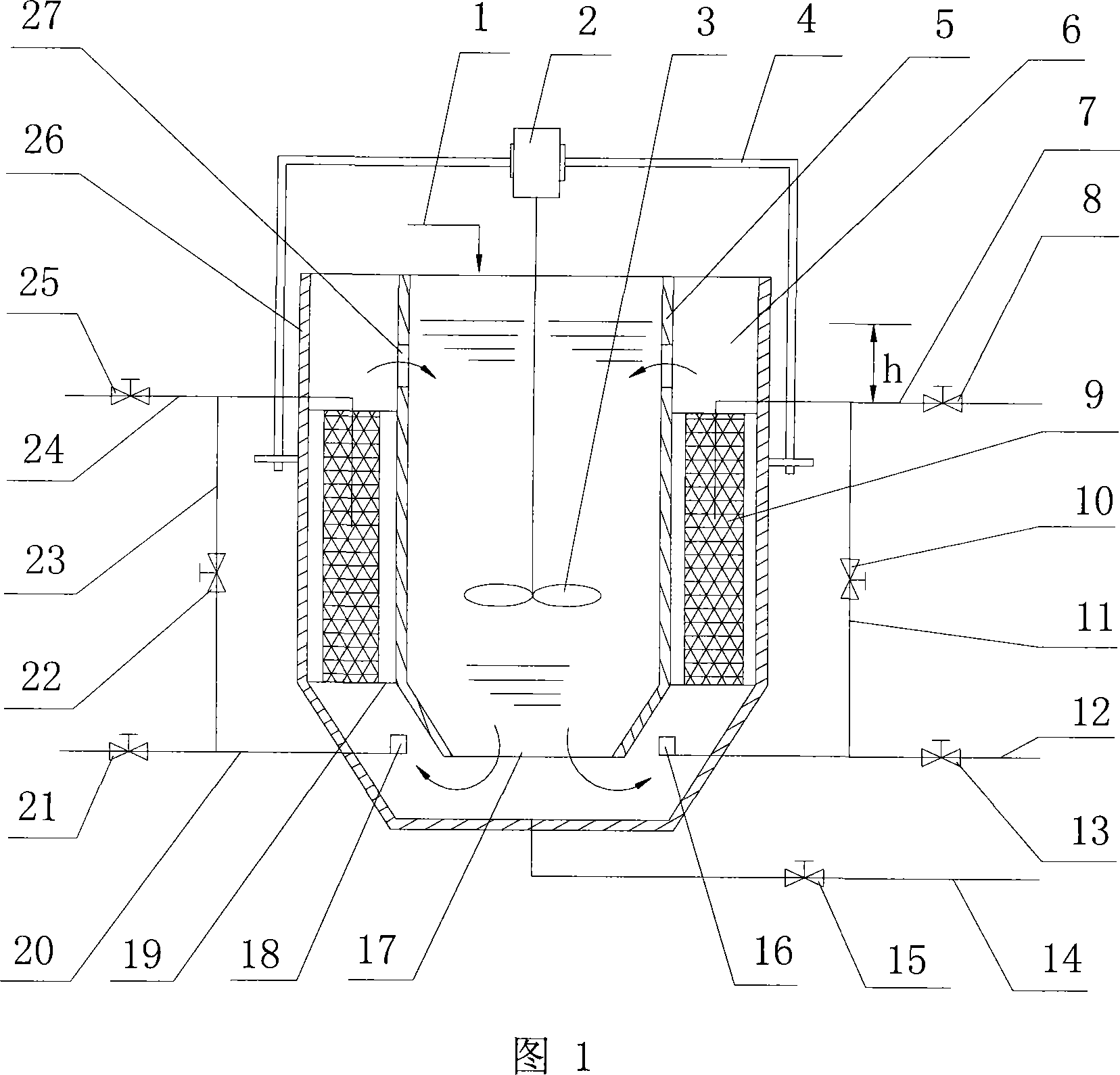

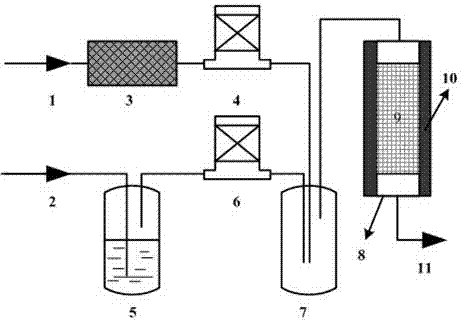

Integrated sequencing-batch method for treating sewage by plant micro-net dynamic membrane and apparatus therefor

InactiveCN101205098AImprove filtering effectGood removal effectSustainable biological treatmentBiological water/sewage treatmentSewageMembrane bioreactor

The invention relates to a method for treating sewage and a device thereof.The method for treating the sewage by integrative sequencing batch botanical bench-scale dynamic membrane is characterized in that the method comprises the following steps: (1) preparation of the device comprises the processes that: a separation bucket is arranged in cavity of a membrane bioreactor; the botanical bench-scale dynamic membrane is arranged in a dynamic membrane filter room which is between a fixed support of the up and under dynamic membrane; (2) sludge is poured into the cavity of the membrane bioreactor to a height of 45 percent to 50 percent of the height of the cavity from an entrance which is on the top of the separation bucket; (3) an outlet valve on a water pipe is closed, and then the sewage is poured into the cavity of the membrane bioreactor to a height of 90 percent to 98 percent of the height of the cavity from the entrance which is on the top of the separation bucket through a sewage inlet pipe; (4) after stirred for 2.0 to 4.0h, aeration is injected into the membrane bioreactor and stirring is kept for 2.0 to 4.0h; (5) after stopping stirring for 1.0 to 2.0h, the outlet valve on the outlet pipe is opened to drain water and aeration supply is stopped; (6) steps (3) to (5) are repeated to carry out the sequencing batch sewage treatment.The invention is characterized by good sewage treatment effect.

Owner:WUHAN UNIV OF TECH

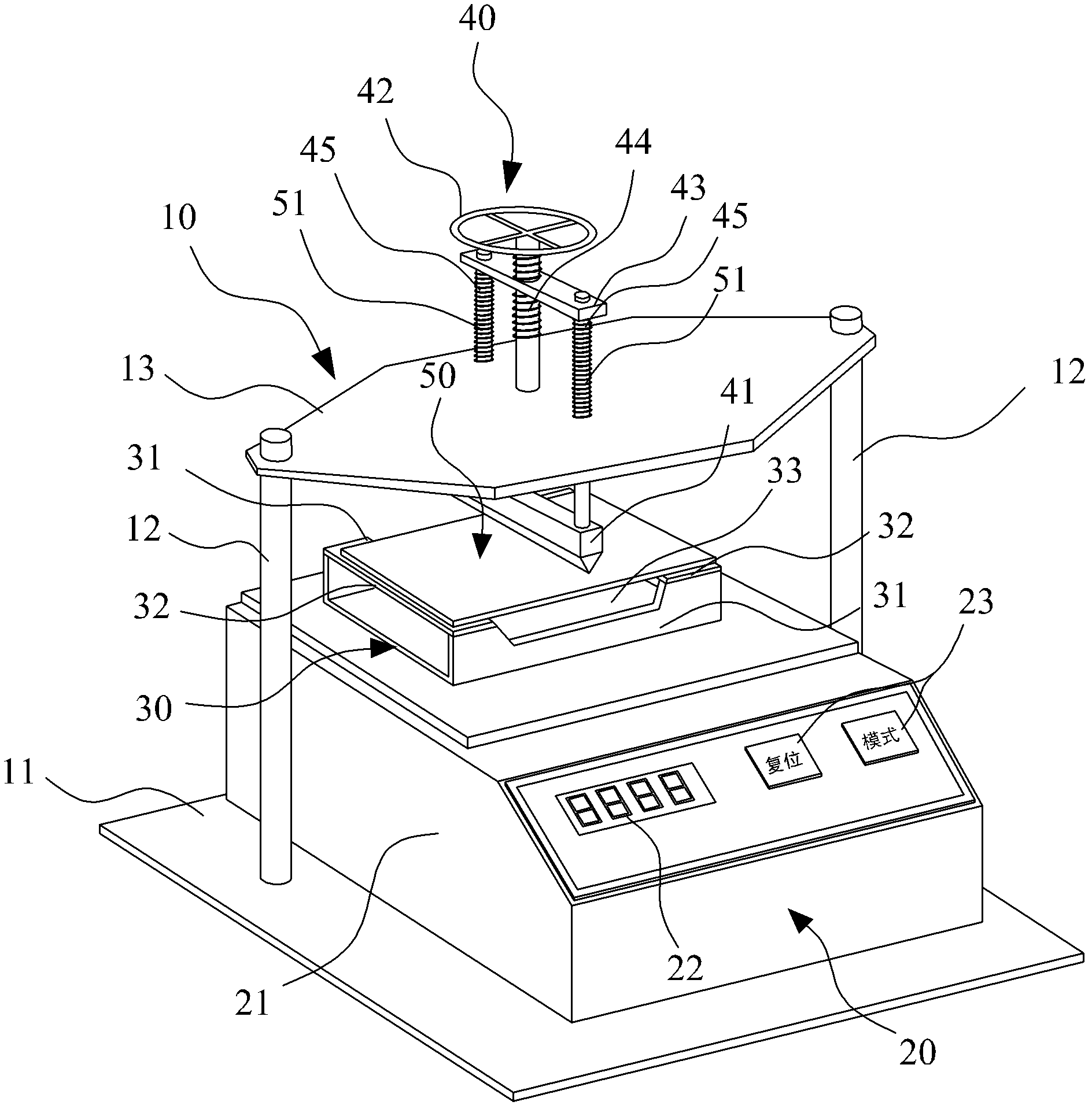

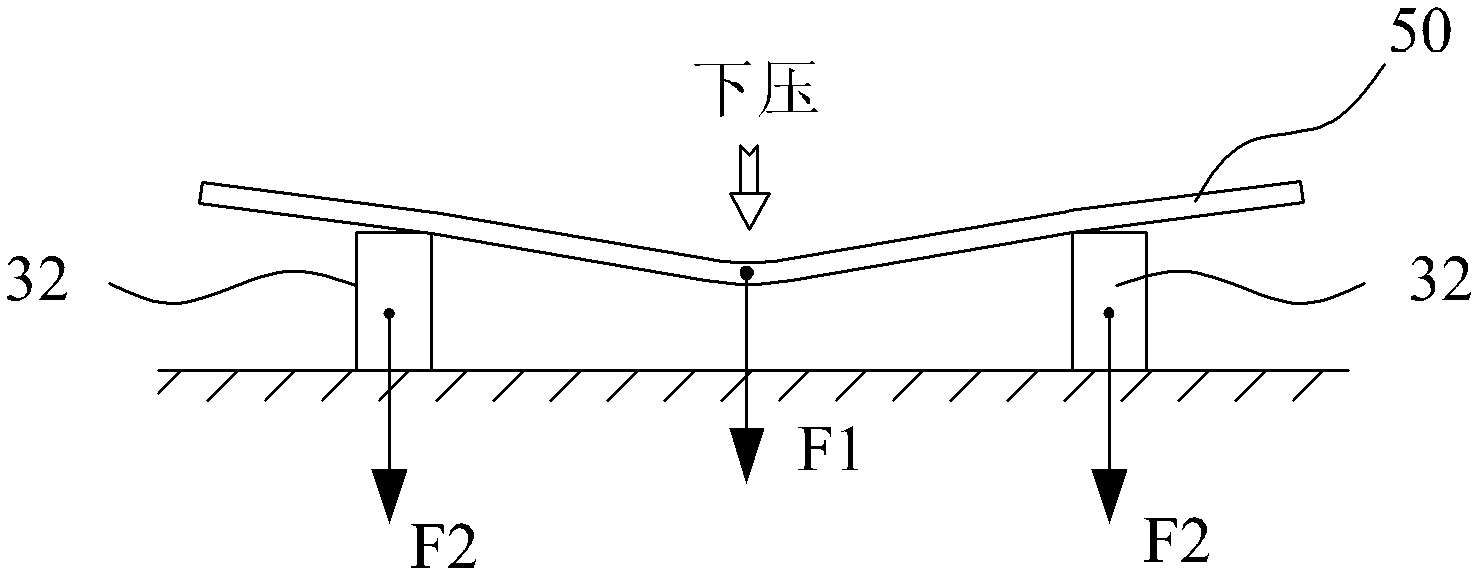

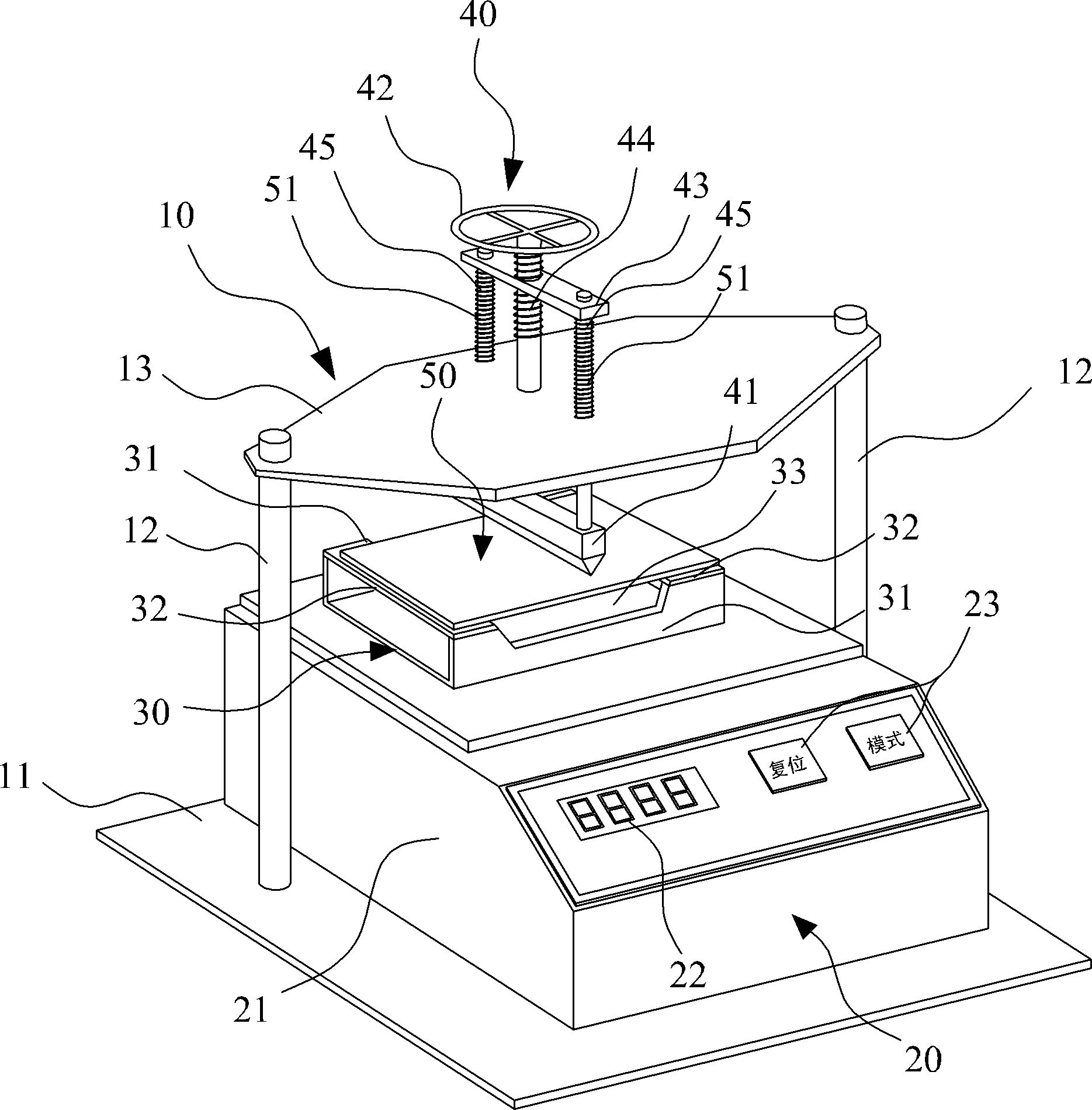

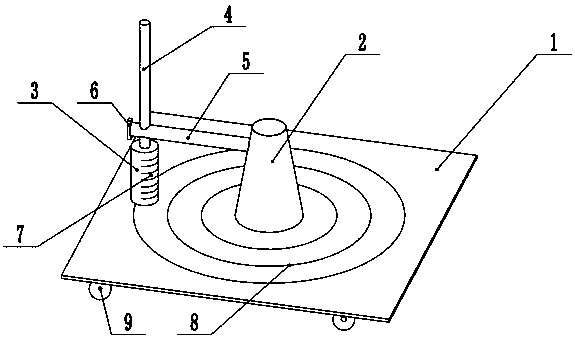

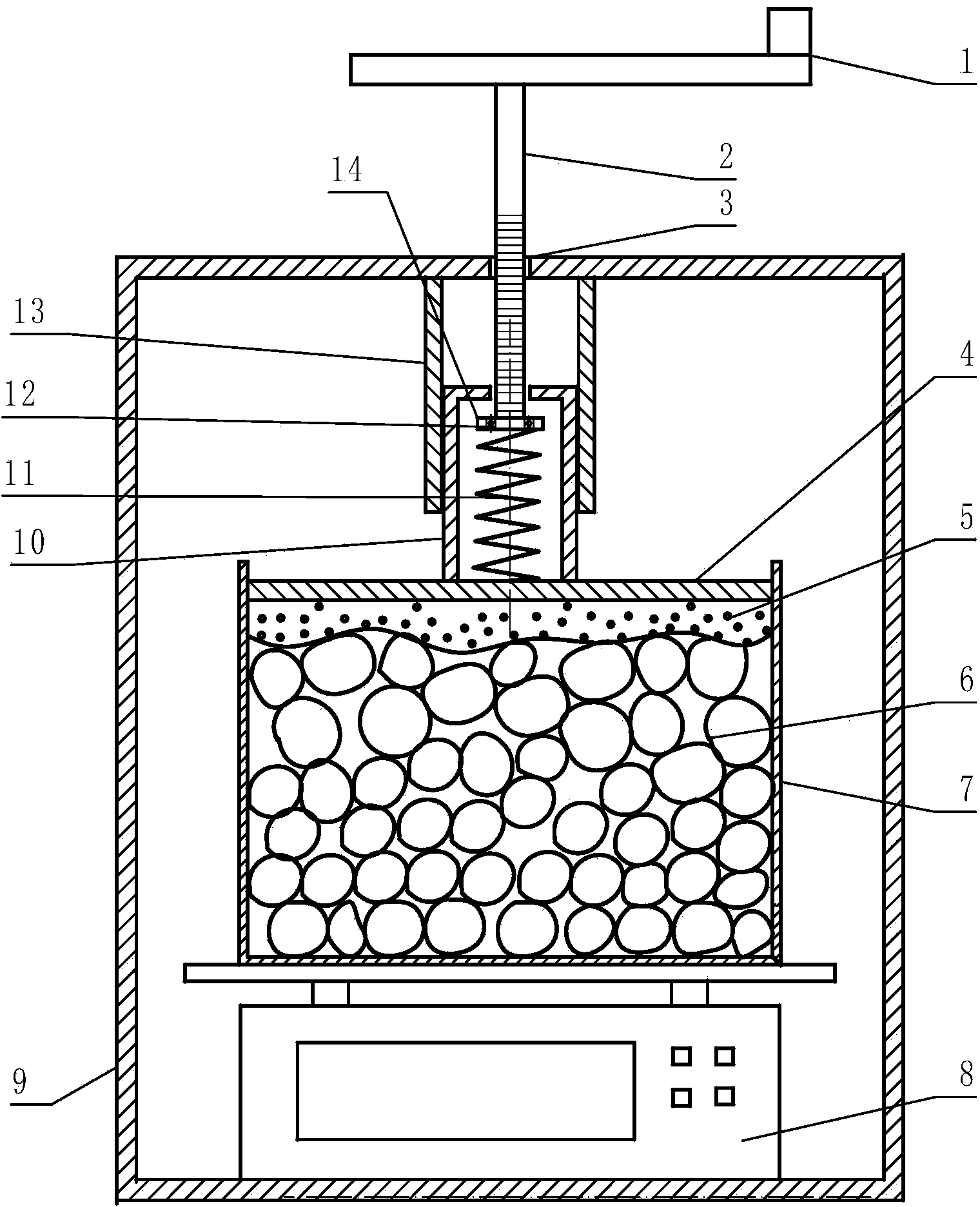

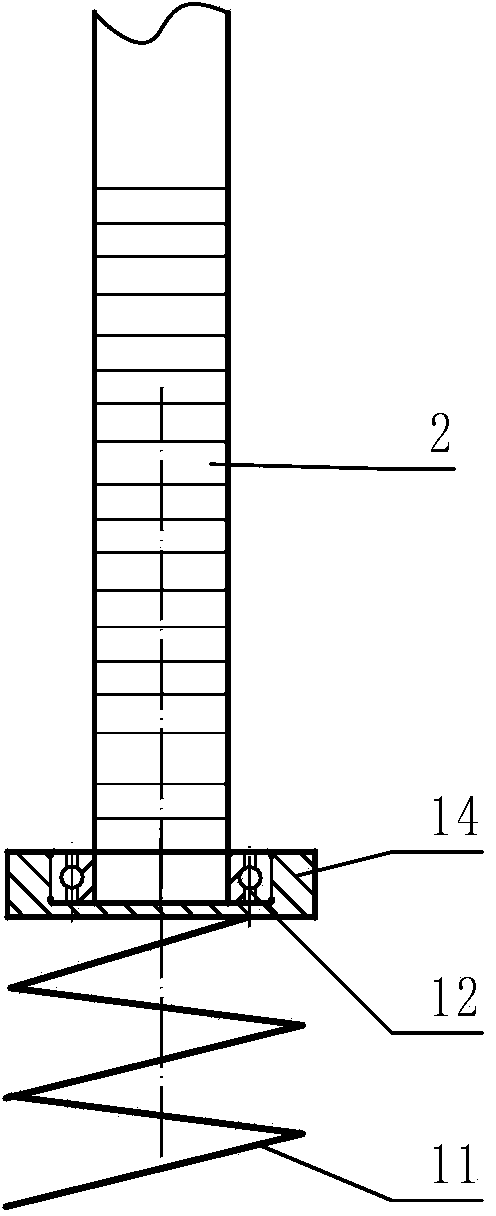

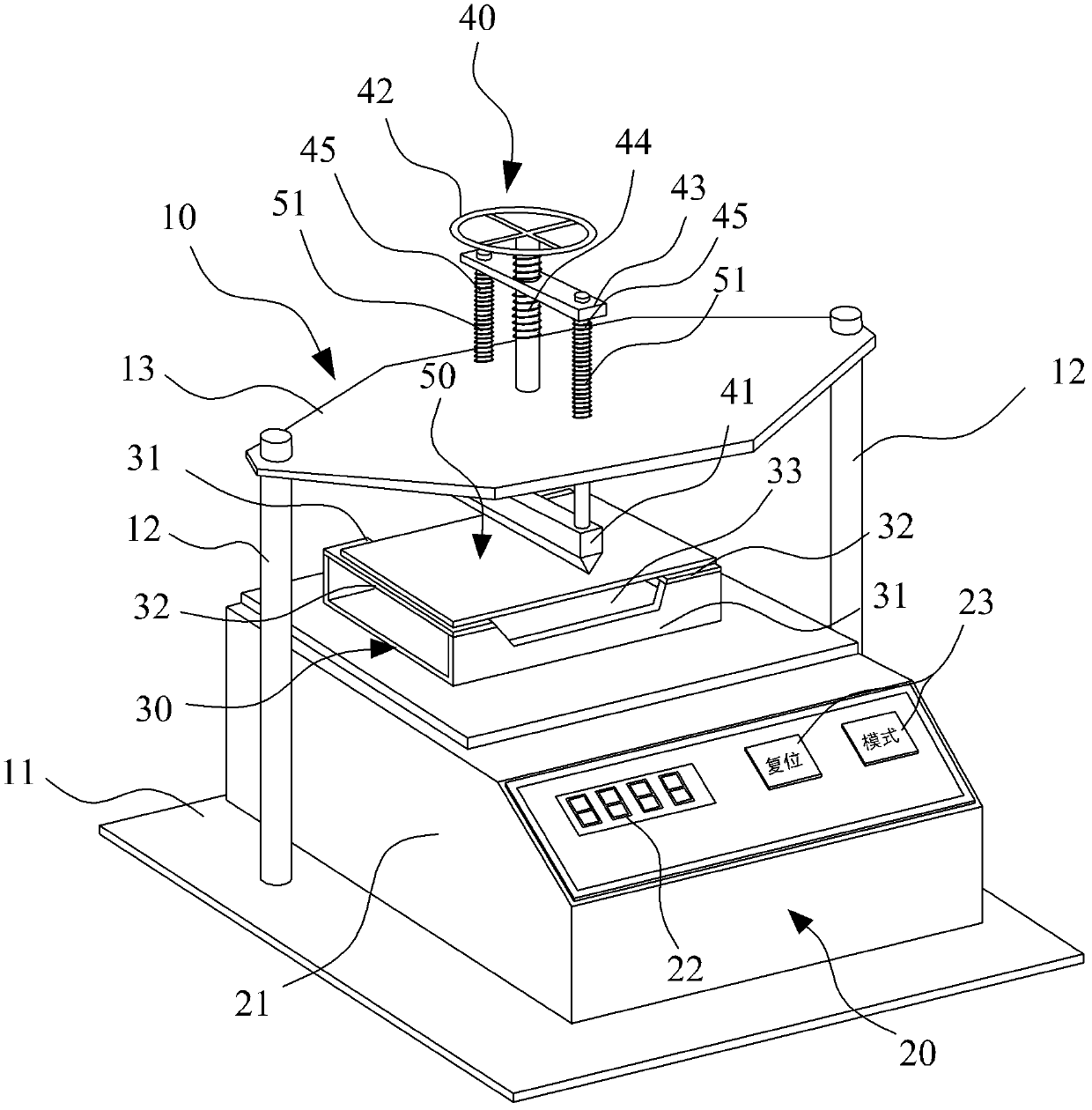

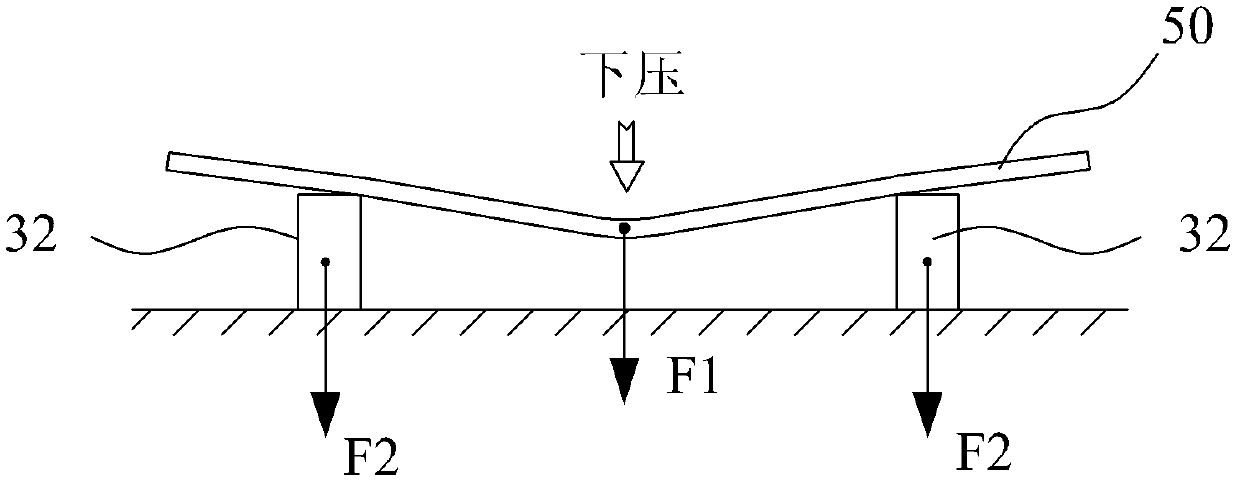

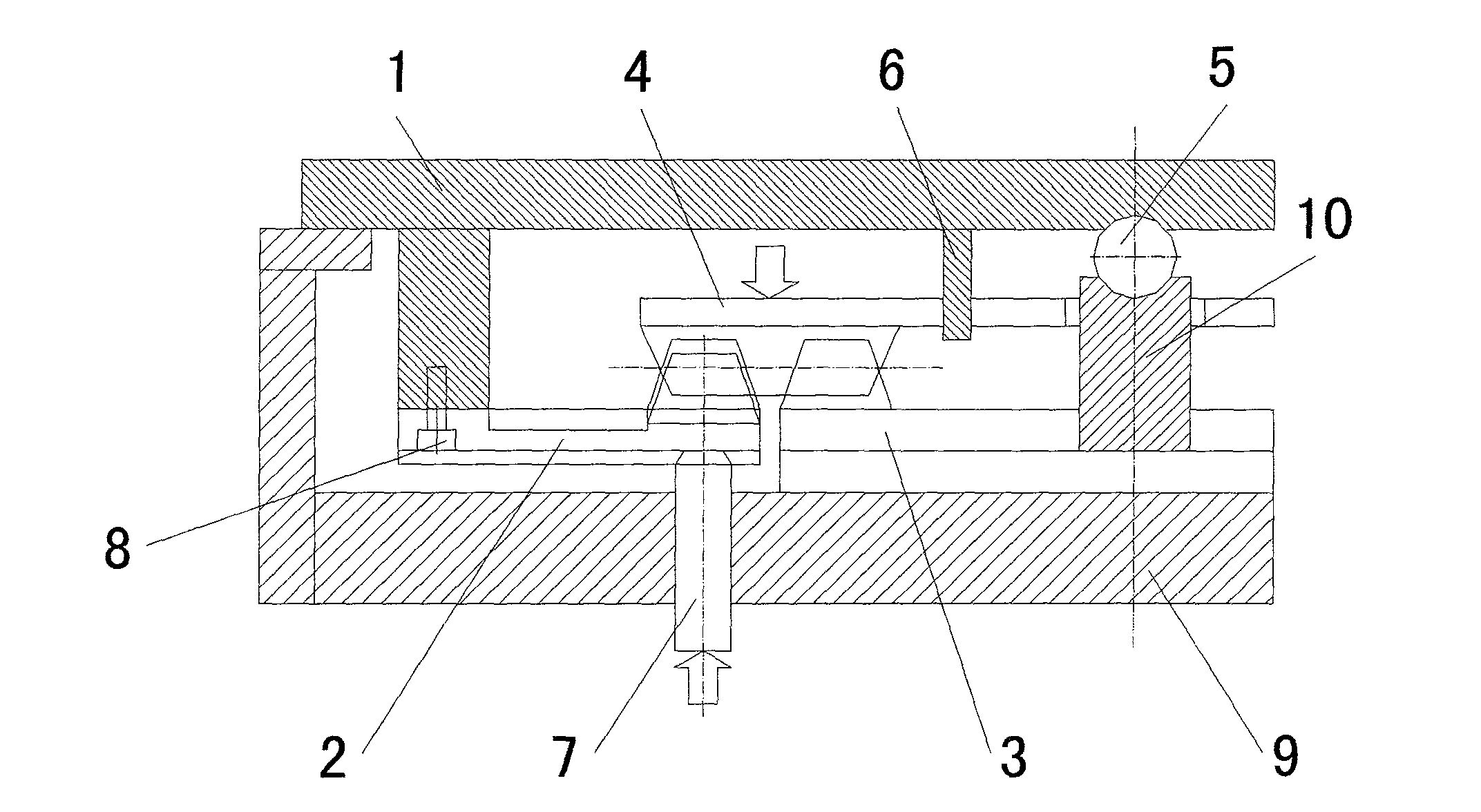

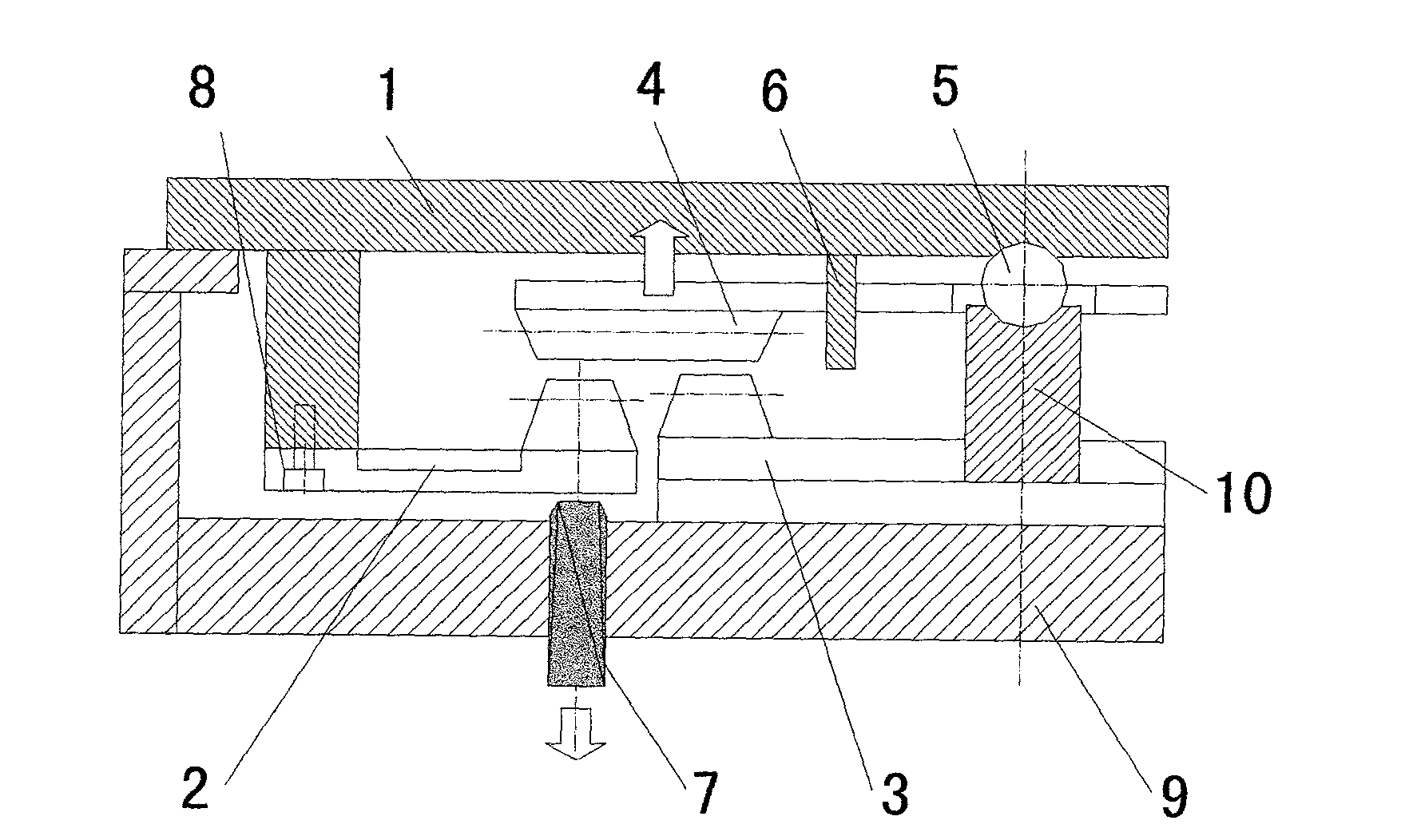

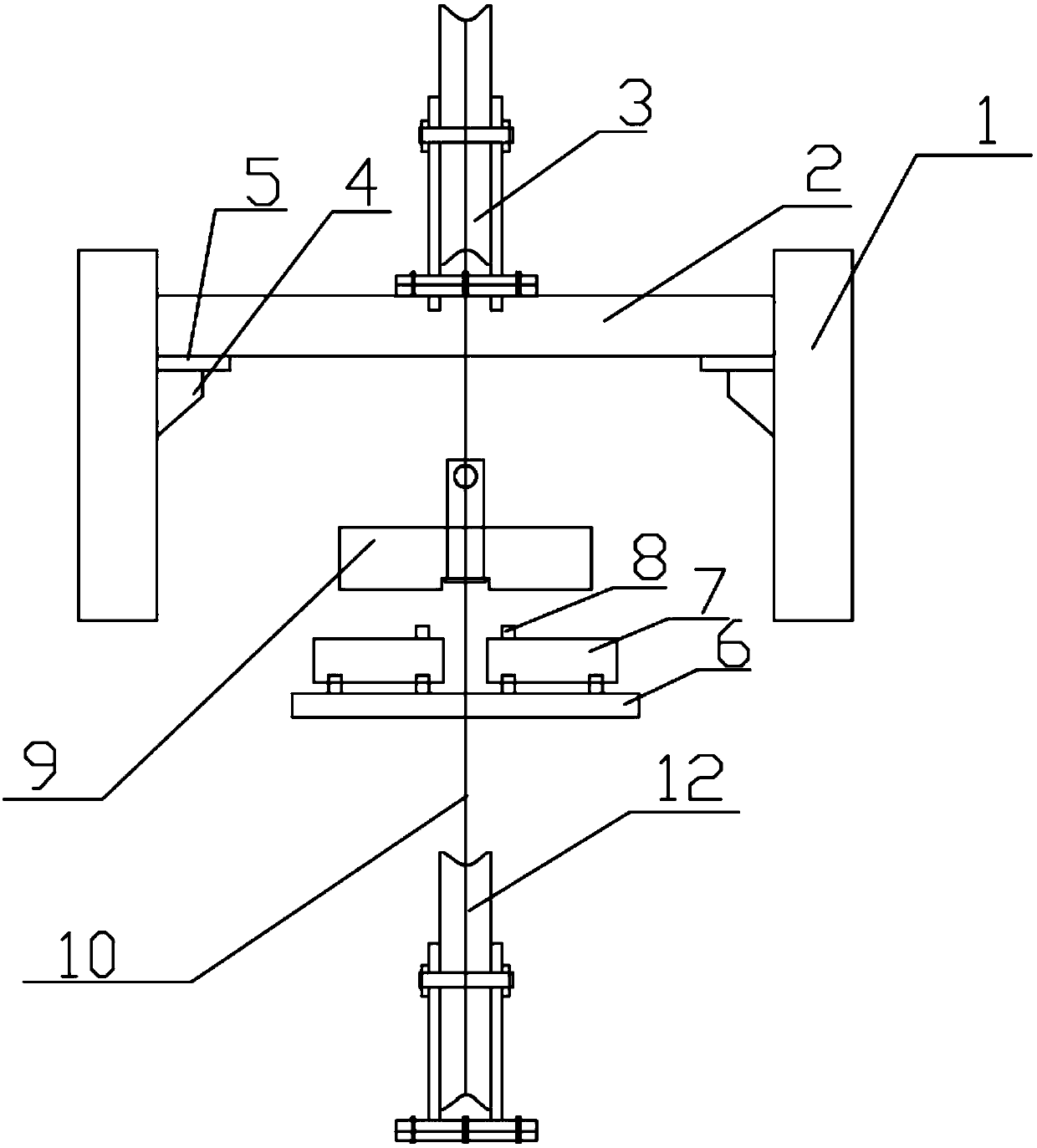

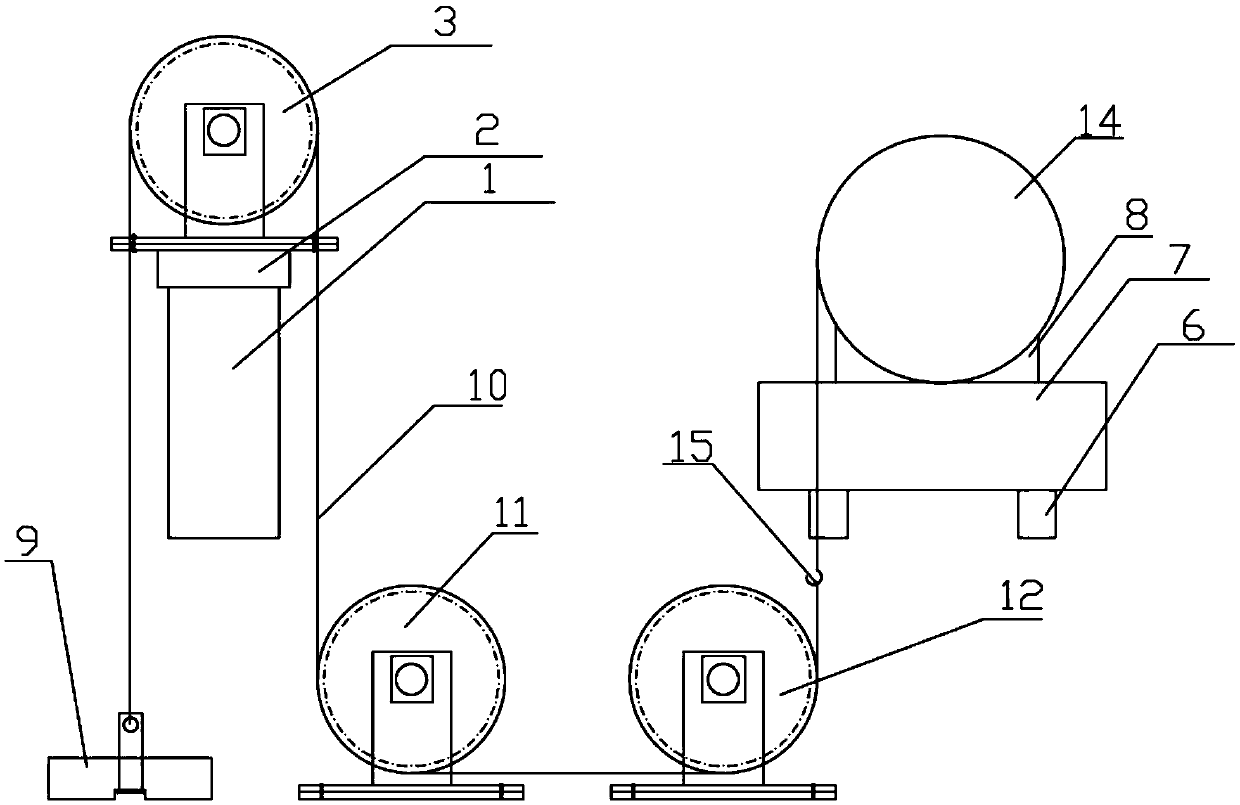

Simple fiberboard bending tester and testing method

InactiveCN102519806ARepetitiveEasy to useMaterial strength using steady bending forcesEngineeringFiberboard

The invention discloses a simple fiberboard bending tester and a testing method. The tester comprises a support, a bench scale, a pressure mechanism and a sample loading carrier, wherein the sample loading carrier is placed on the bench scale, the sample loading carrier is provided with two support cross bars for supporting the two ends of a fiberboard, and the pressure mechanism is arranged above the sample loading carrier and is liftably arranged on the support. According to the invention, when the fiberboard is detected, the pressure mechanism goes down to apply pressure on the central portion of the fiberboard, the fiberboard generates a certain elastic deformation, the fiberboard restores the elasticity because of the interaction of power, the two support cross bars receive the pressure generated by the elasticity recovery of the fiberboard, the pressure is transmitted to the bench scale, and the bench scale displays the bending resistance data. The tester utilizes the pressure mechanism and the sample loading carrier to simulate the bending handle, and utilizes the display of the bench scale display screen to calibrate the result data, thus the bending resistance of the fiberboard can be simply detected, and the bending resistance of products can be calibrated accurately.

Owner:福建鑫华股份有限公司

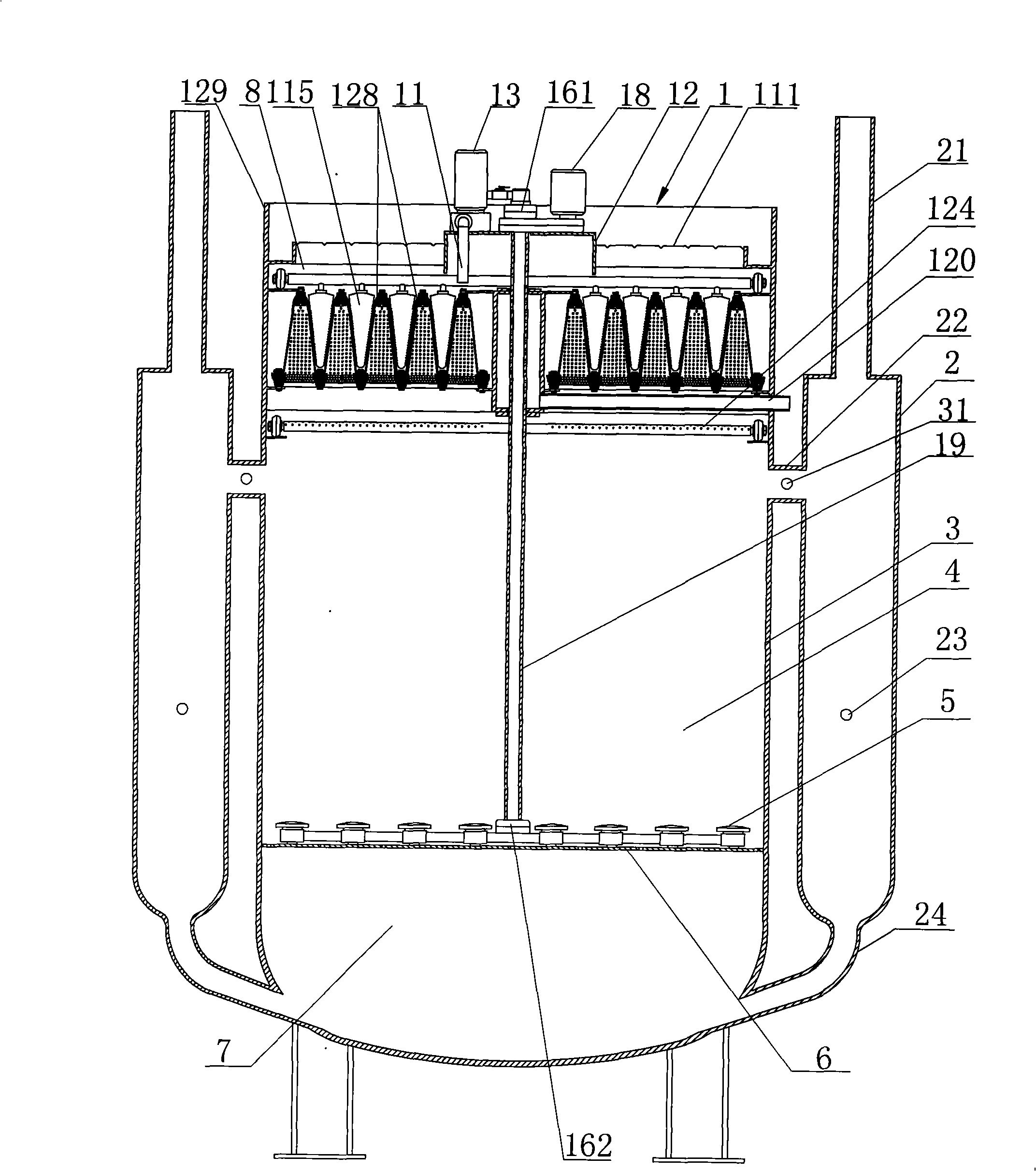

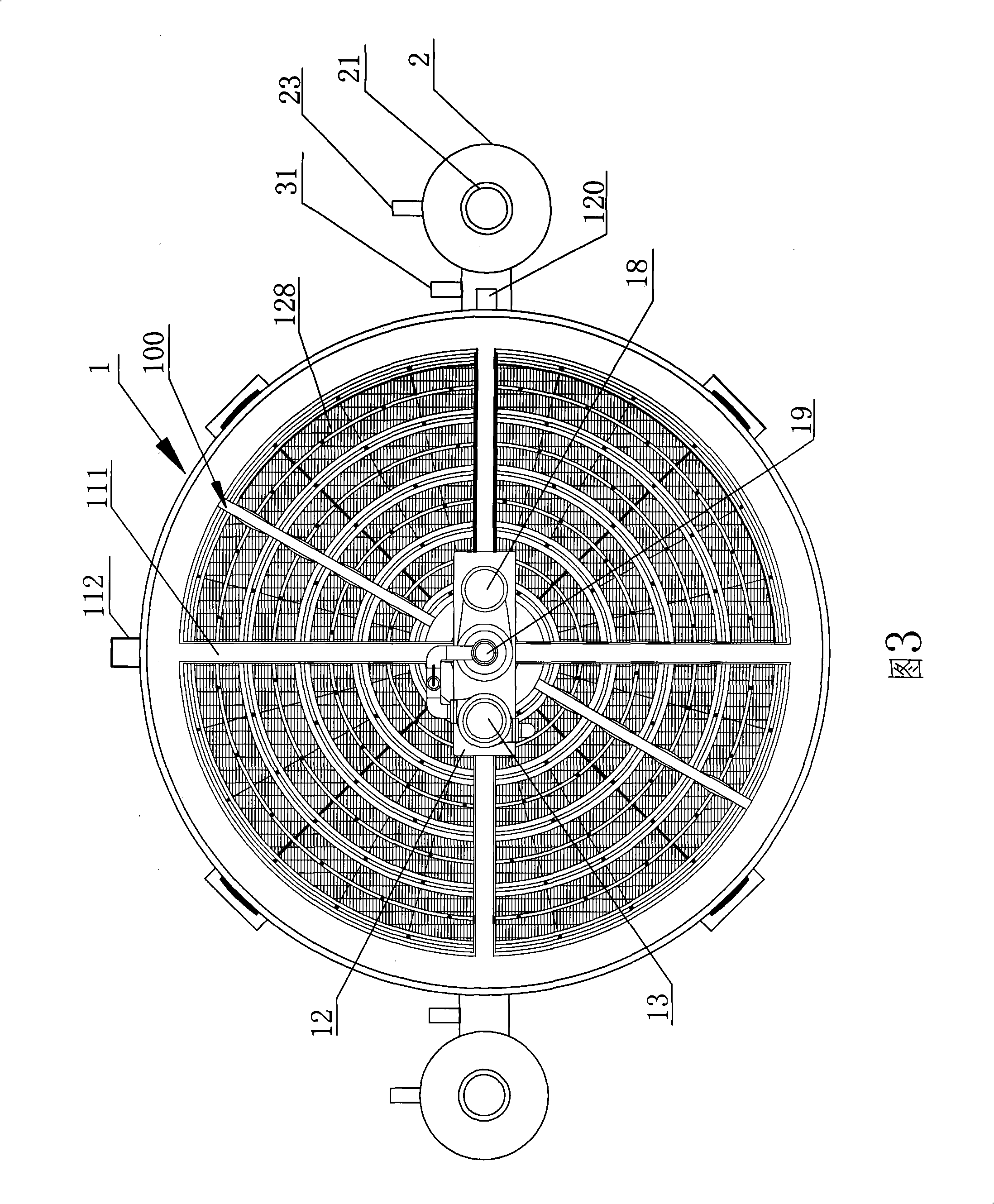

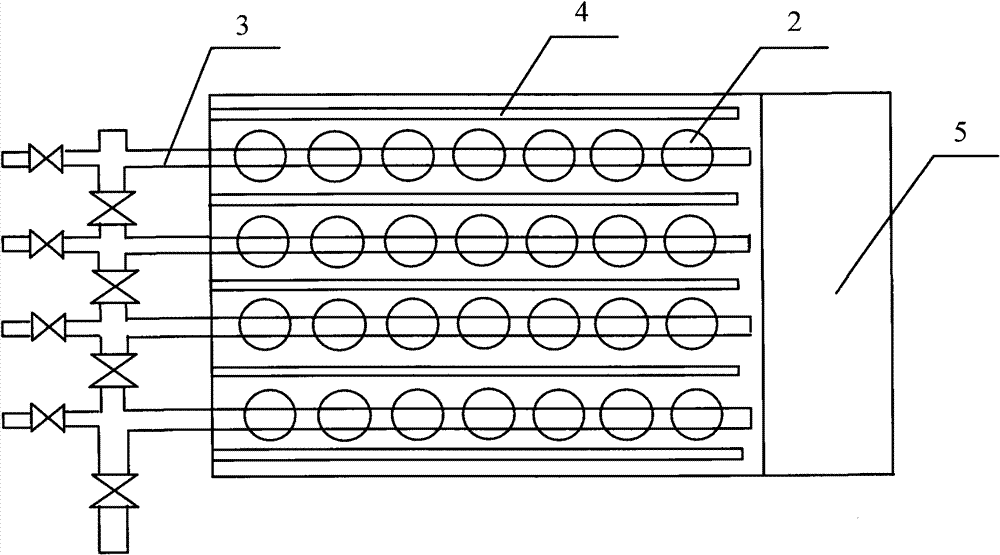

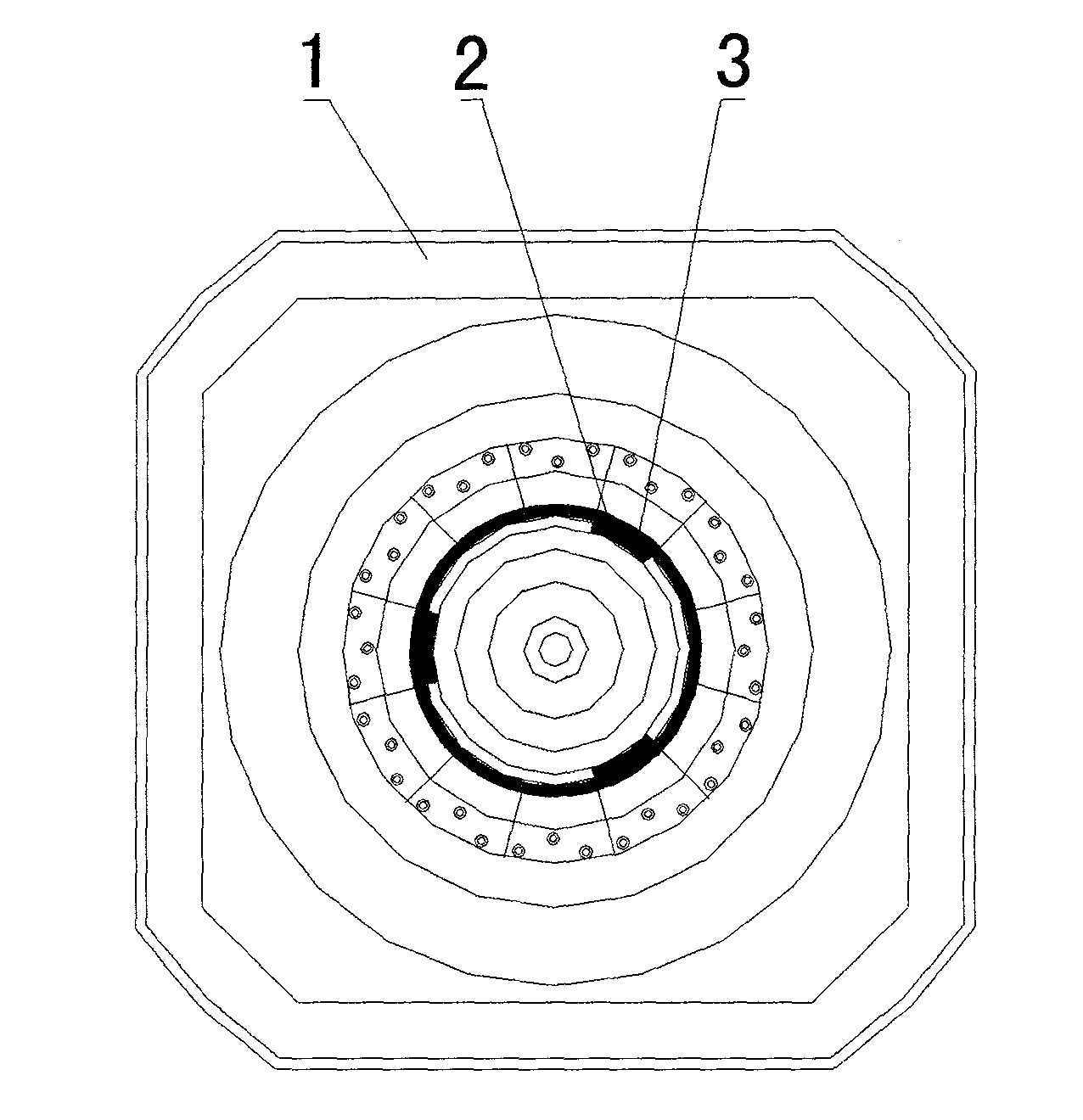

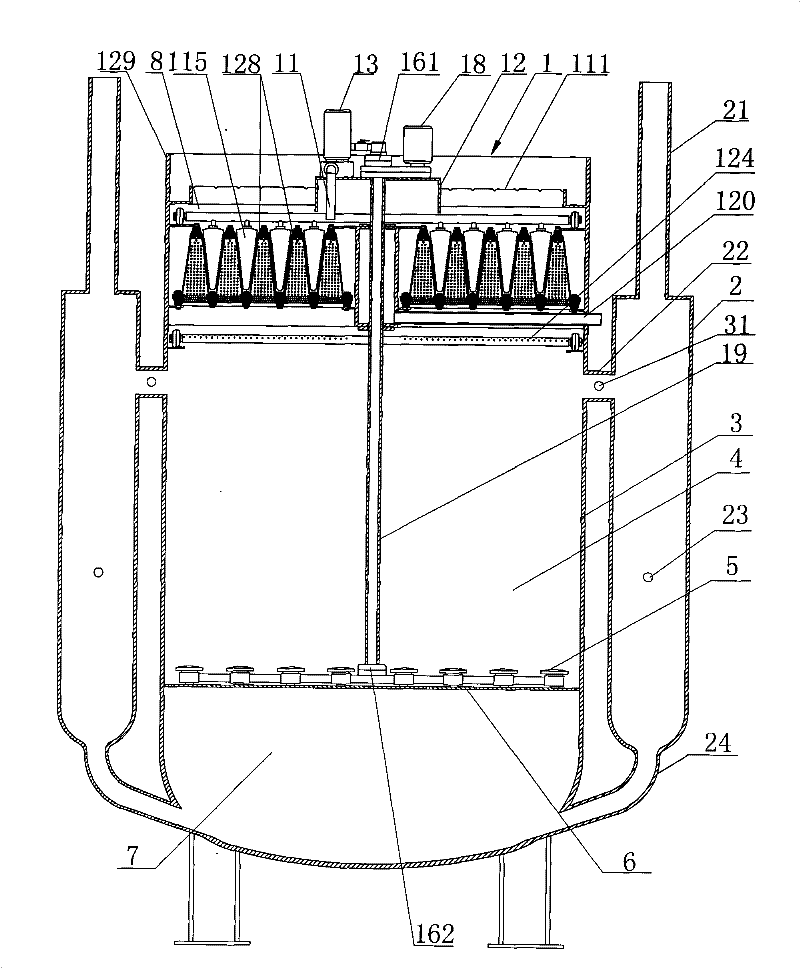

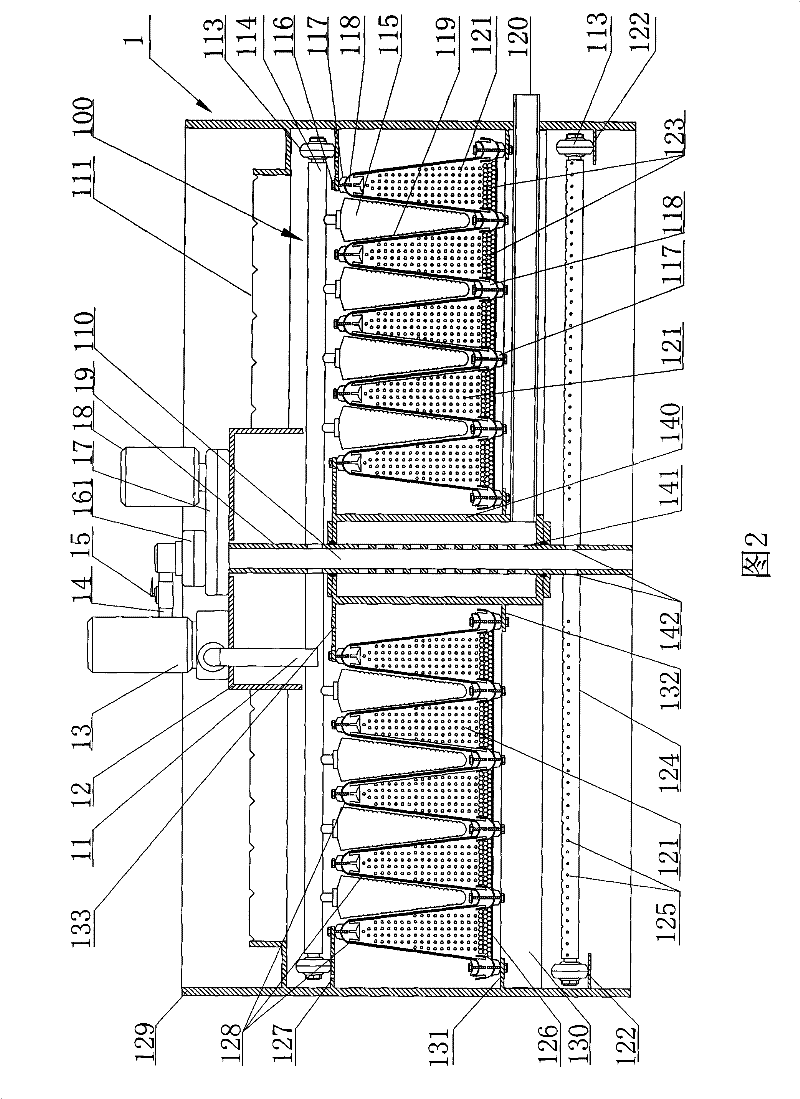

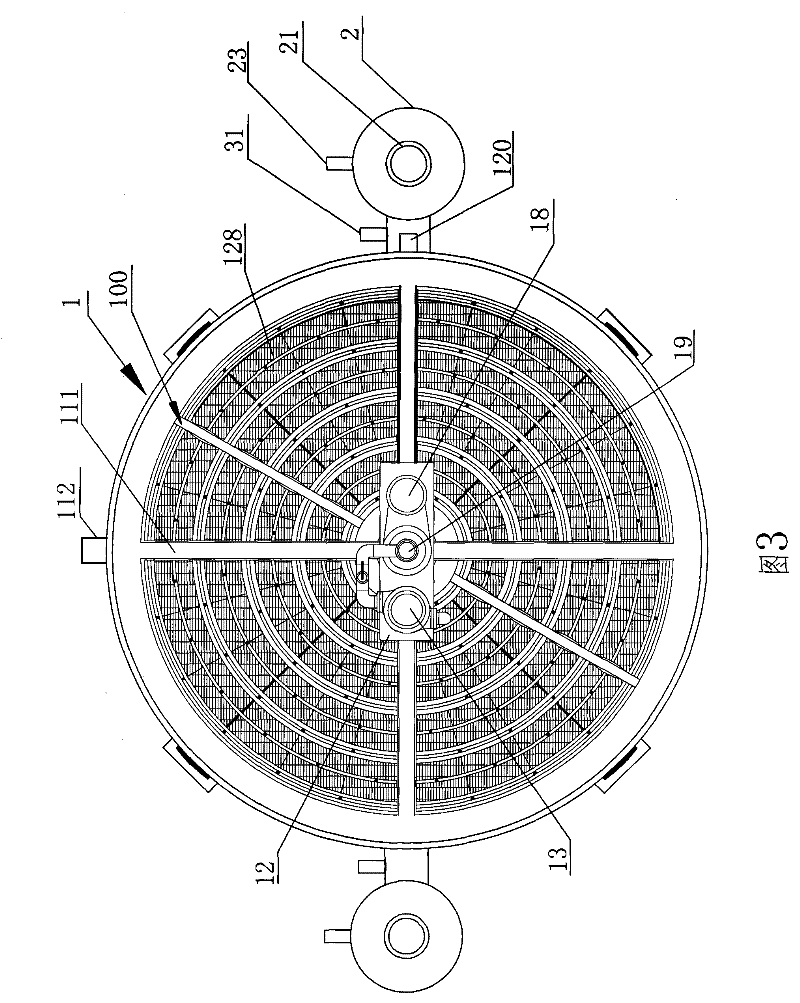

Micro-net dynamic membrane bioreactor for continuously updating dynamic membrane

ActiveCN101492202ALow priceImprove water qualityTreatment with aerobic and anaerobic processesWater/sewage treatment bu osmosis/dialysisVena contracta diameterMicrogrid

The invention relates to a bench-scale dynamic membrane bioreactor capable of continuously updating a dynamic membrane, which is characterized in that: a container is divided into an upper aerobic zone and a lower anoxic zone by a separating orifice plate, and an aerator group is arranged on the separating orifice plate; a microgrid component consists of a wave curve-shaped microgrid net body, a casing, a bottom net, 2 to 3 layers of spherical porcelain granules uniformly spread on the bottom net, a backwash nozzle, an air-jet wash-out brush head, a hollow shaft tube, and a rotation driving mechanism, wherein backwash nozzle and the air-jet wash-out brush head are arranged above and under the net body respectively and are positioned on the same plane, and the hollow shaft tube and the rotation driving mechanism drive the backwash nozzle and the air-jet wash-out brush head to rotate continuously; the microgrid component is arranged on the top of a tank horizontally; and the center of the microgrid net body is provided with the hollow tube the inside of which has a built-in separating plate, the part, above the separating plate, of the shaft tube is connected with the rotation driving mechanism, a water source and the backwash nozzle, the part, blow the separating plate, of the shaft tube is connected with an air source and the air-jet wash-out brush head, and the lower end of the hollow shaft tube rotates and is connected with the aerator group in a sealing mode. The invention has the advantages of improving denitrification and dephosphorization effect, achieving microfiltration solid-liquid separation effect, ensuring effluent flux and optimizing and simplifying power and control systems.

Owner:北京创未环境工程技术有限公司

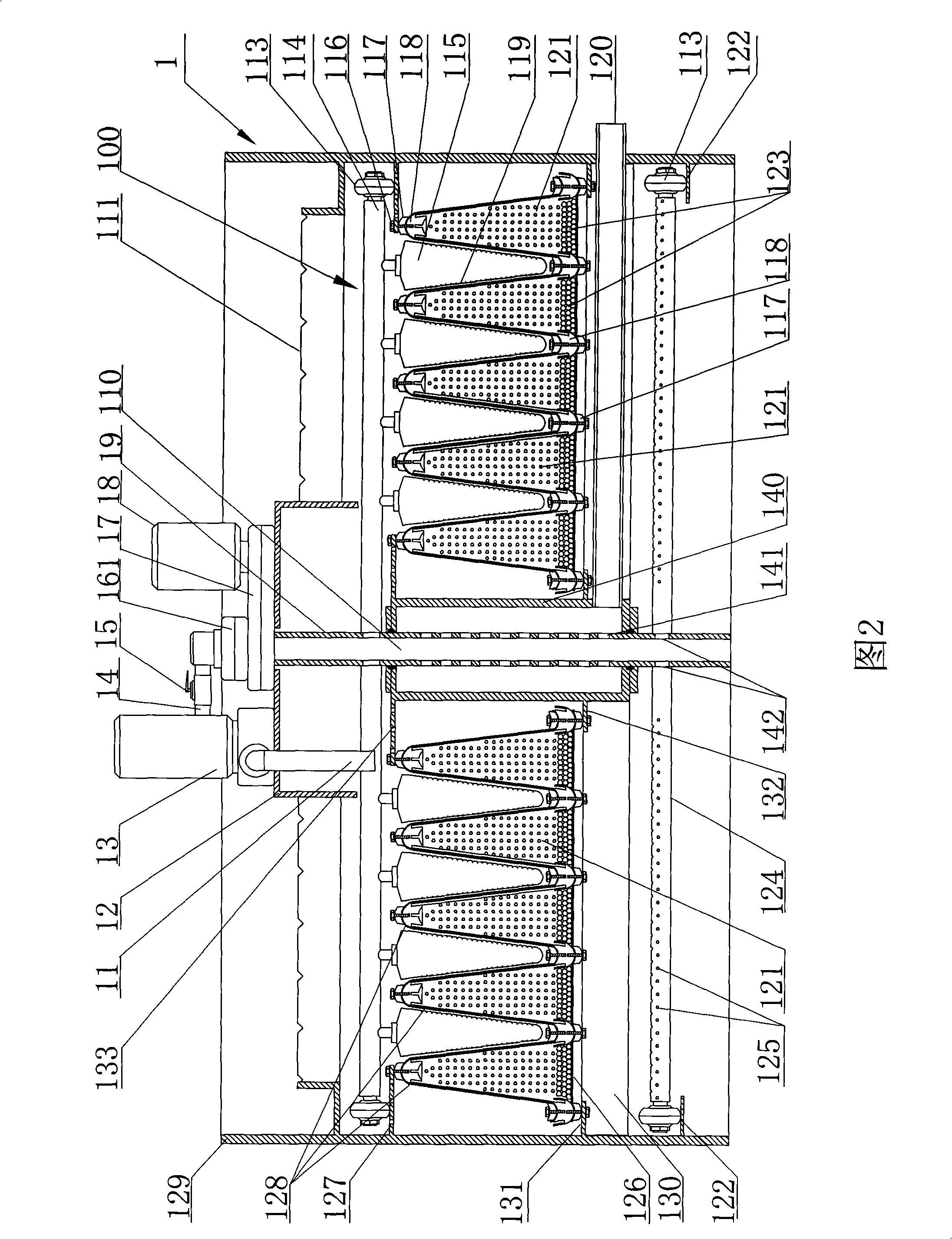

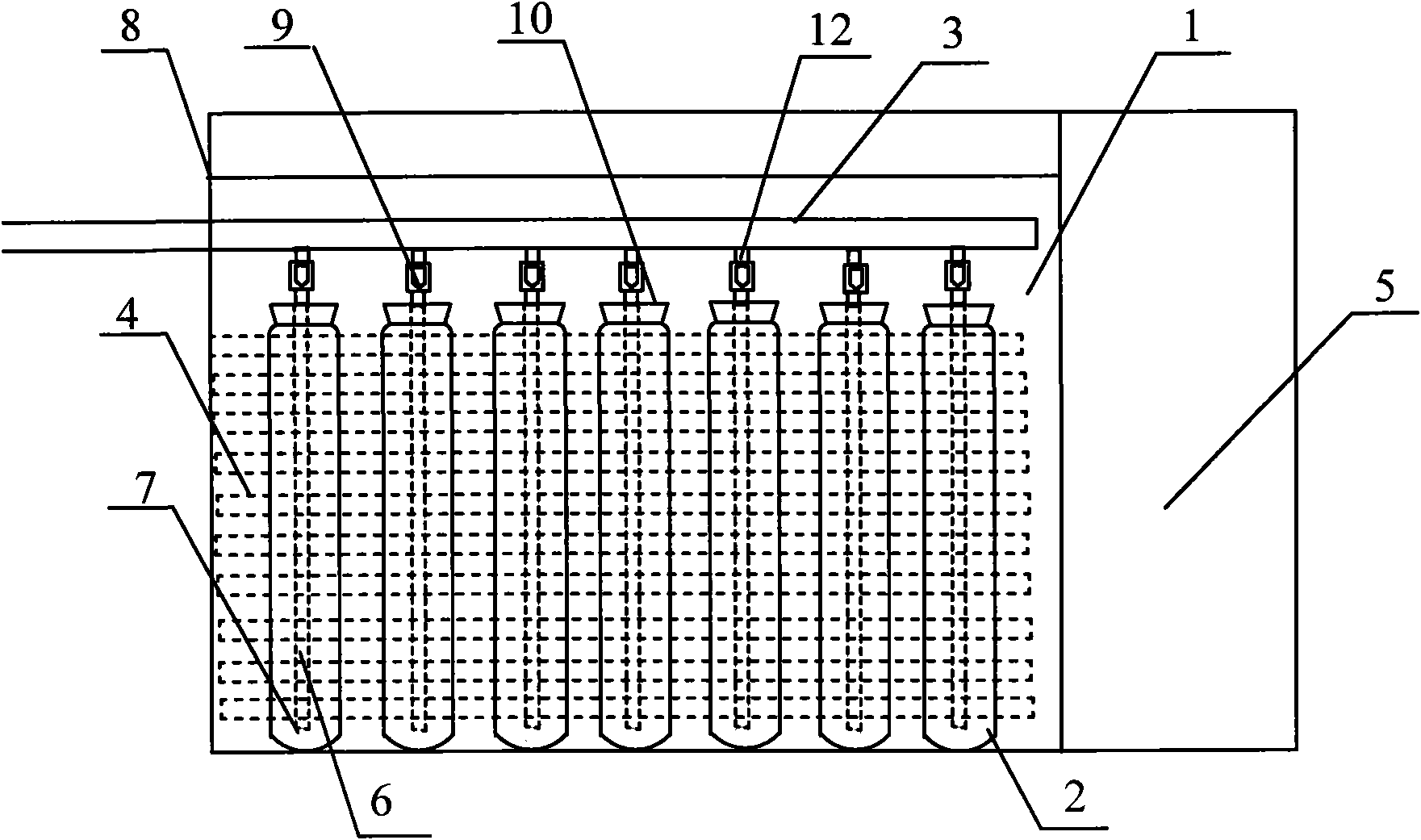

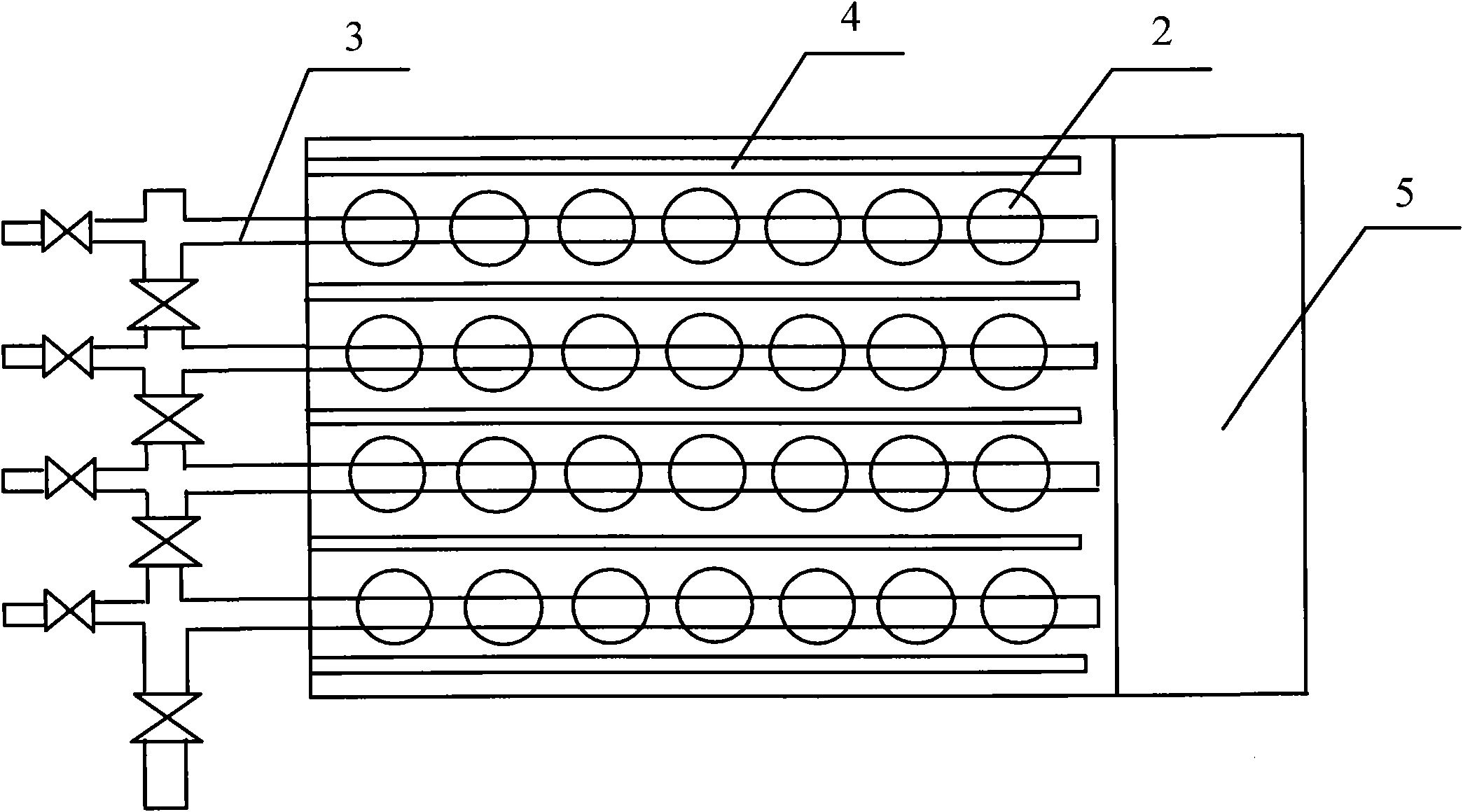

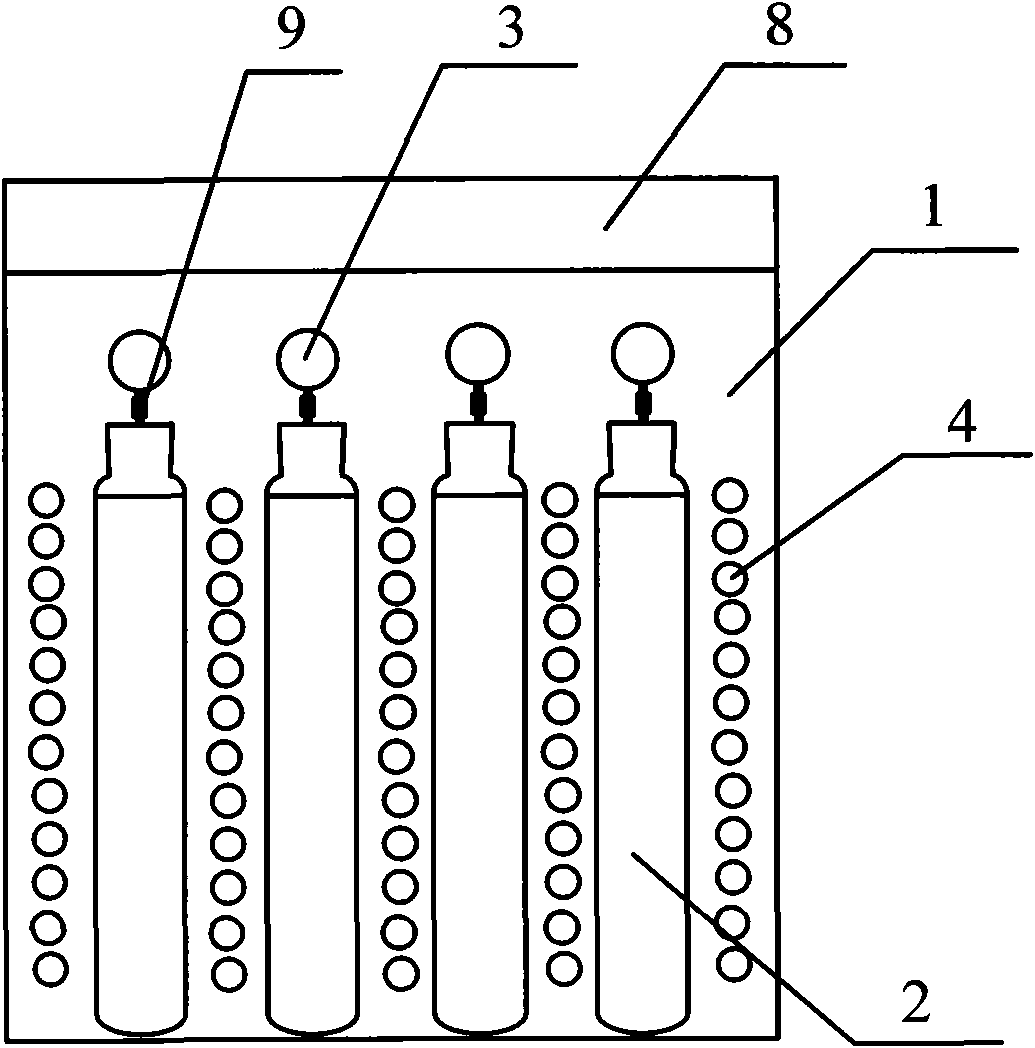

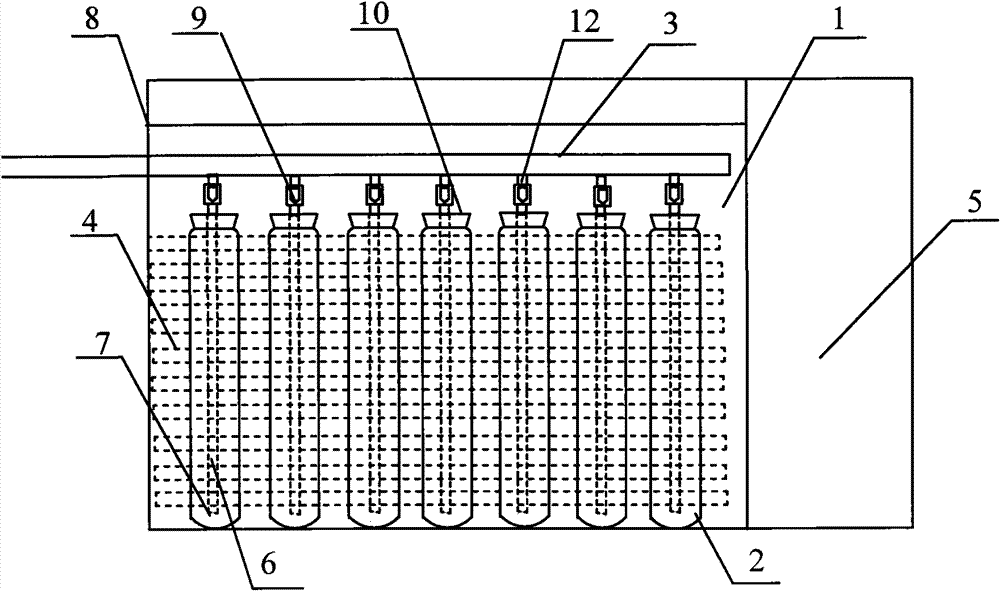

Multi-group bubbling type photobioreactor

InactiveCN101935610APrevent leakageIncrease light intensityBioreactor/fermenter combinationsBiological substance pretreatmentsTemperature controlControl system

The invention discloses a multi-group bubbling type photobioreactor which comprises a box body, bubbling type photobiologic reaction units, a main air duct, light sources and a control system, wherein at least two bubbling type photobiologic reaction units are placed in rows in the box body, the main air duct is connected to an air-blowing pipe and a gas distributor in each bubbling type photobiologic reaction unit through gas-distributing branch pipes, the light sources are placed at both sides of each bubbling type photobiologic reaction unit, and the control system comprises a temperature control system and a light source control system for controlling the temperature in the box body and the intensity of the light sources. The invention supplies a batched, controllable and mature facility for the microalgae culture in laboratory and bench scales.

Owner:NANJING UNIV OF TECH

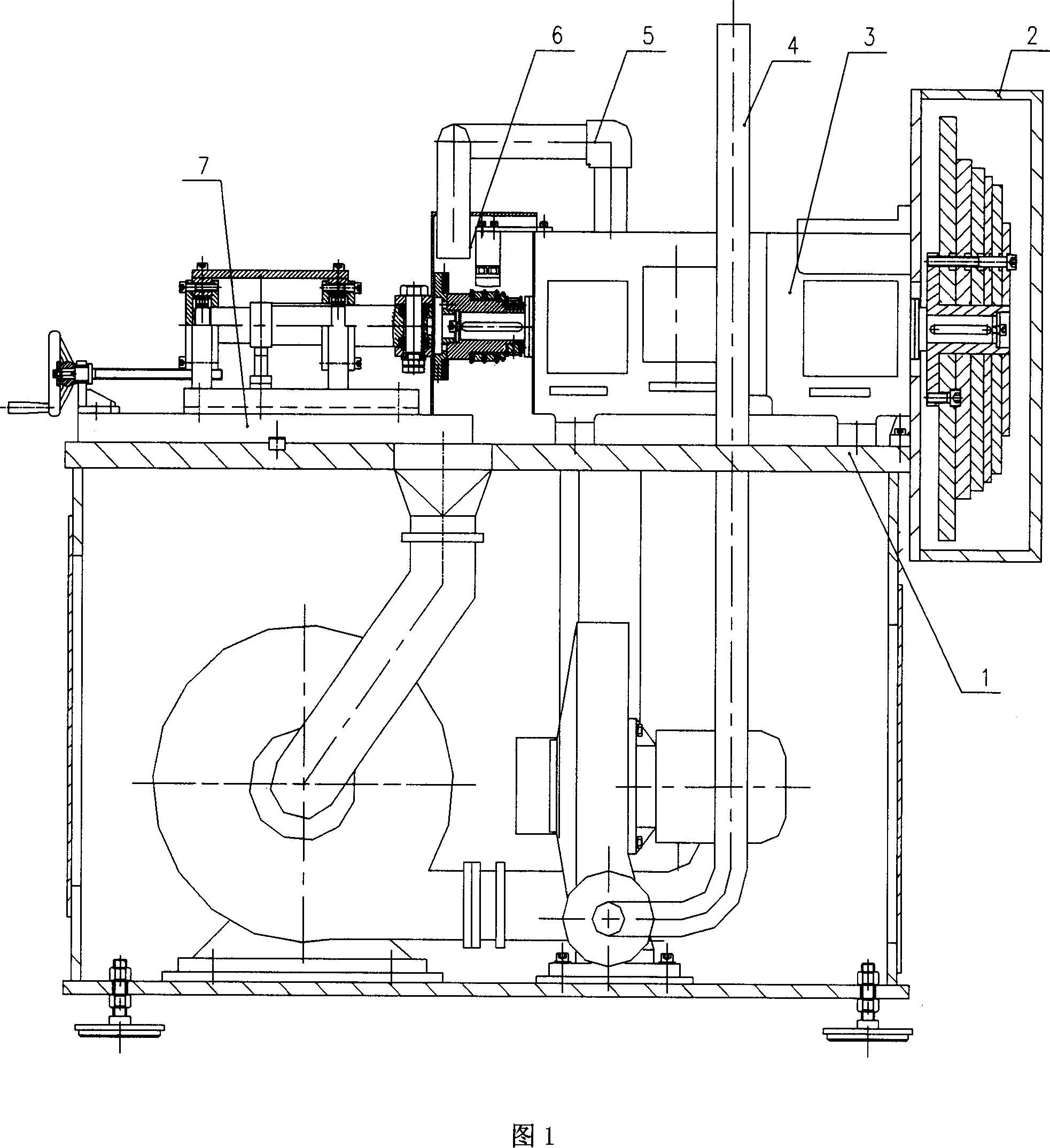

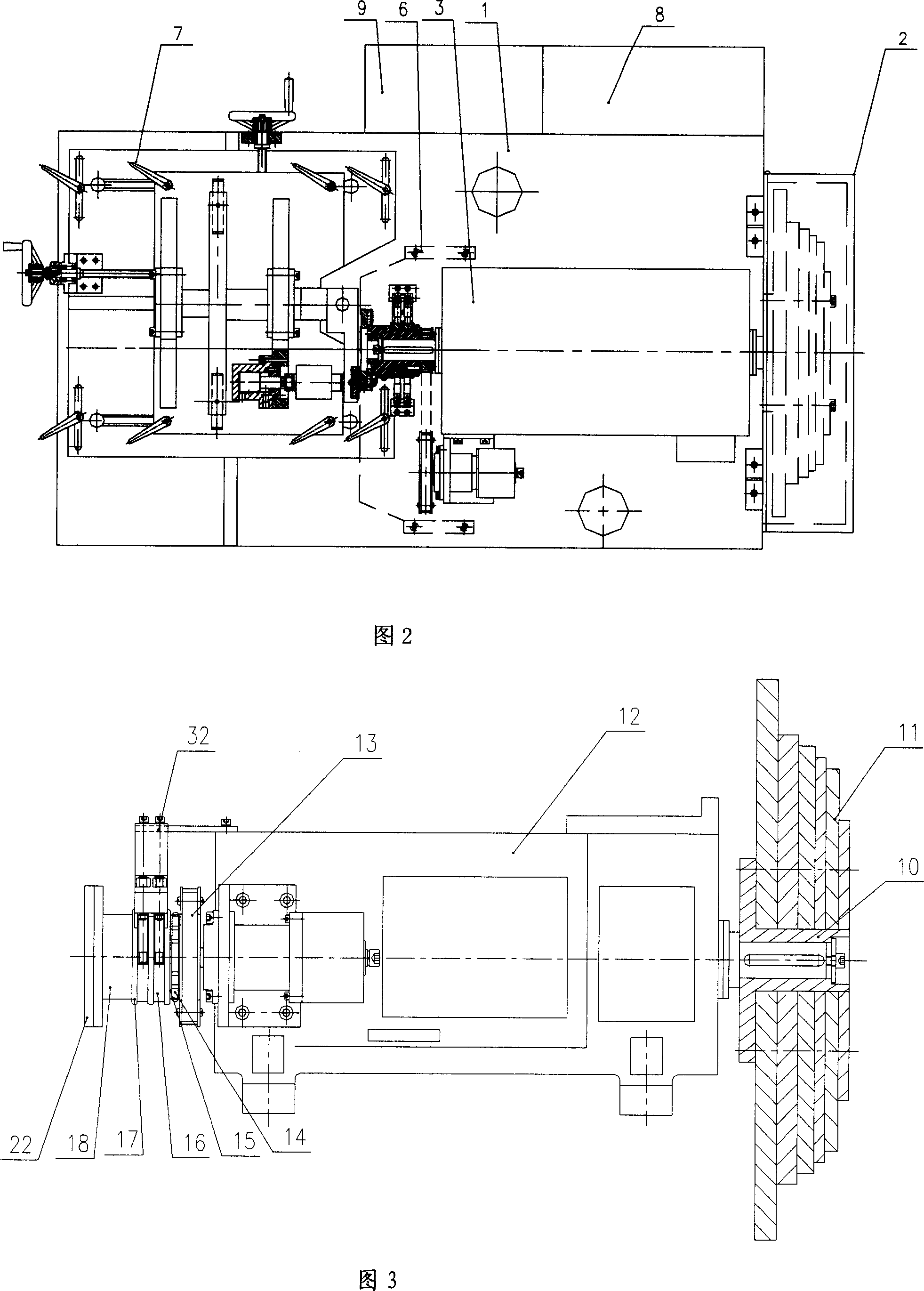

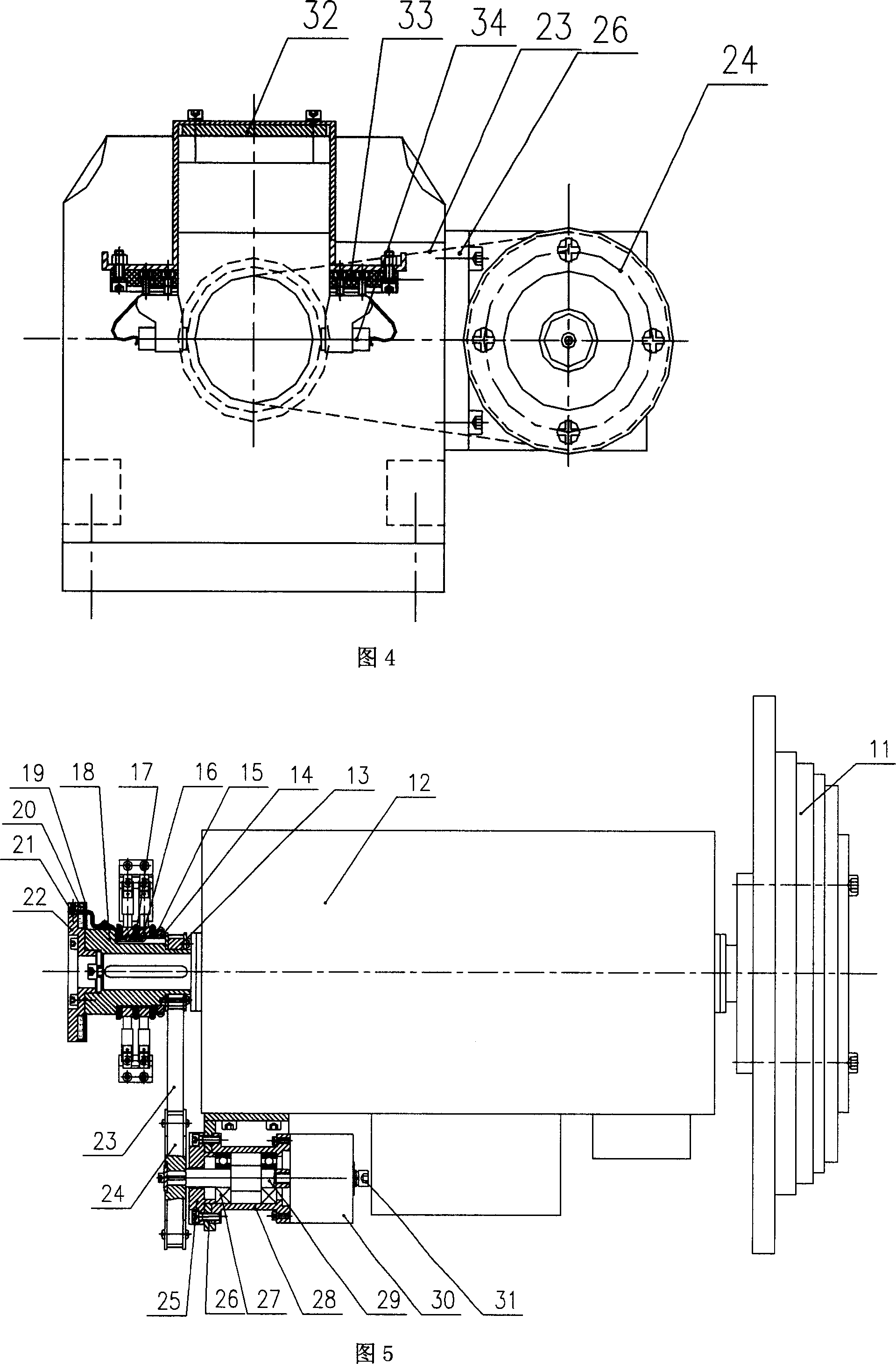

Friction test machine for small sample contracting ratio table

InactiveCN1987410AImprove the simulation effectFunction increaseUsing mechanical meansInvestigating abrasion/wear resistanceSmall samplePrice ratio

The invention discloses new structural bench frictional testing machine for hand sample assembled not from 1:1 real objects. The technical scheme fixes the principal axis drive system (PADS), which simulates different inertia and provides different rotate speed, on a frame; also installs the sliding table system (STS), which determines relative position between sample of friction material to be tested and friction brake disc, on the frame. Distance between spindle axis of PADS and working face on the frame is equal to distance between axis of bearing head in STS and working face on the frame. Moreover, the spindle axis is parallel to the axis of bearing head. The disclosed testing machine possesses same or similar functions of inertia bench scale testing machine, and uses same standard of test procedure. Features are: attachable inertia, raised precision of hand sample test, lower price ratio, suitable to develop new product, and monitor quality of production.

Owner:JILIN UNIV

Process method for producing ethanol by utilizing low-temperature cellulase to perform simultaneous saccharification and fermentation

InactiveCN102776242AQuality improvementImprove efficiencyBiofuelsMicroorganism based processesAlcoholCellulase

The invention provides a process method for producing ethanol by utilizing low-temperature cellulase to perform simultaneous saccharification and fermentation. The process method is characterized by simultaneously adding low-temperature cellulase and alcohol yeast for production into a fermentation tank and taking a raw material which is rich in the cellulase as a substrate to perform the simultaneous saccharification and fermentation, and the process method comprises the following steps: (1) simultaneously adding the low-temperature cellulase and the alcohol yeast into the fermentation tank and fermenting for 3-5 days; (2) harvesting a fermentation solution; (3) adding the initial cellulase raw material, a low-temperature cellulase fermentation solution and the alcohol yeast into the fermentation solution and performing the simultaneous saccharification and fermentation; and (4) getting cellulosic ethanol. The process method disclosed by the invention has the effects of improving efficiency and reducing cost, and when the produced cellulase is applied to the bench-scale-level simultaneous saccharification and fermentation, the biological ethanol with higher quality can be produced, so that application and market requirements can be well met.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

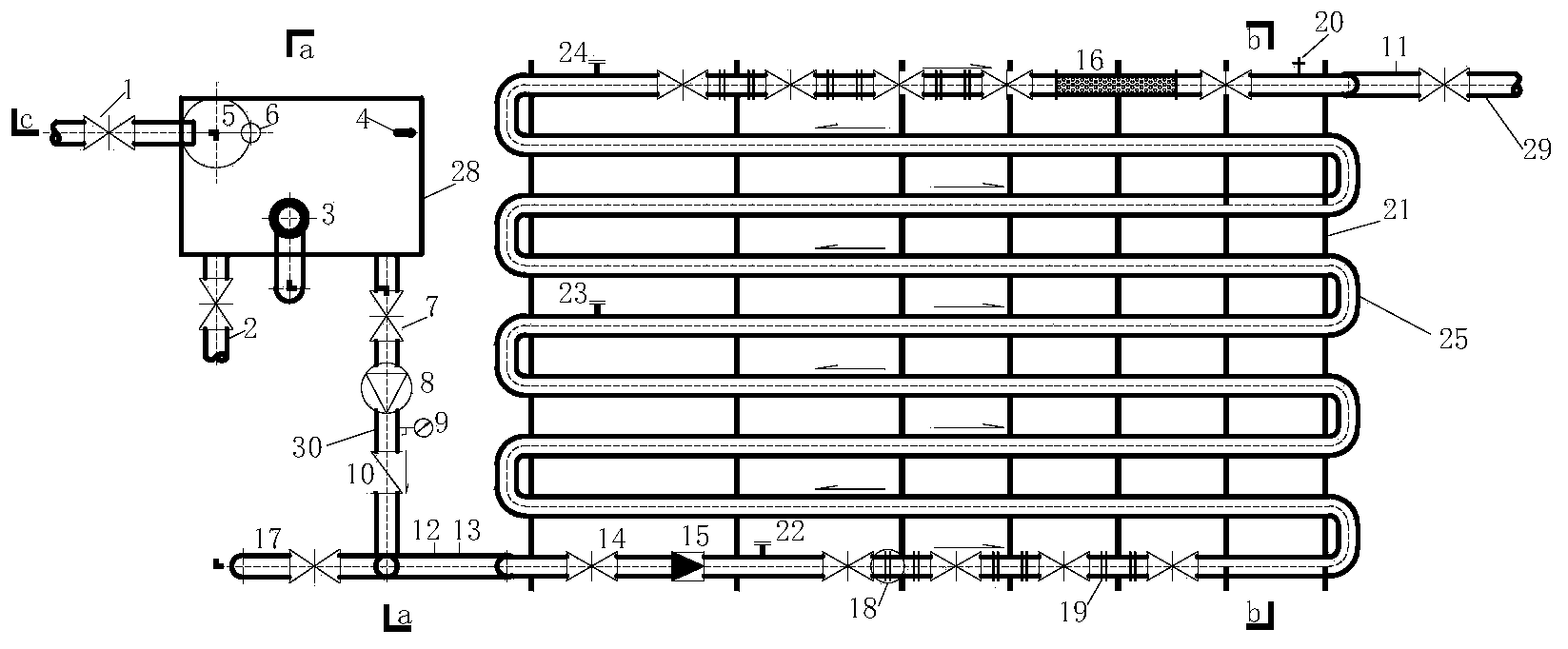

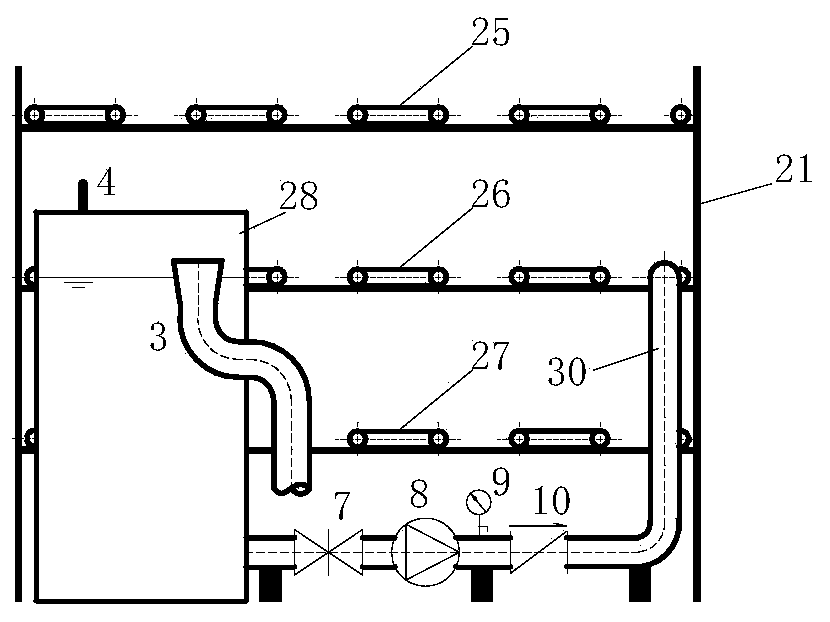

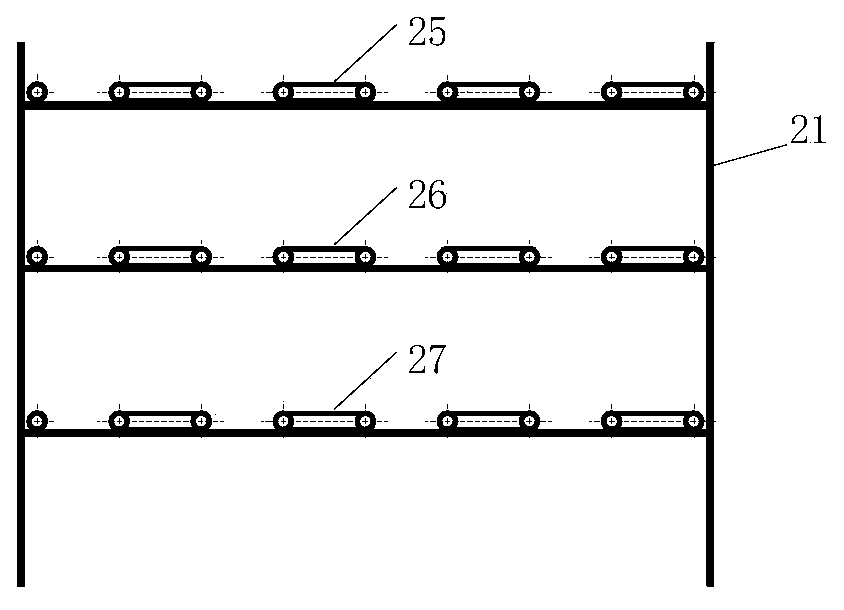

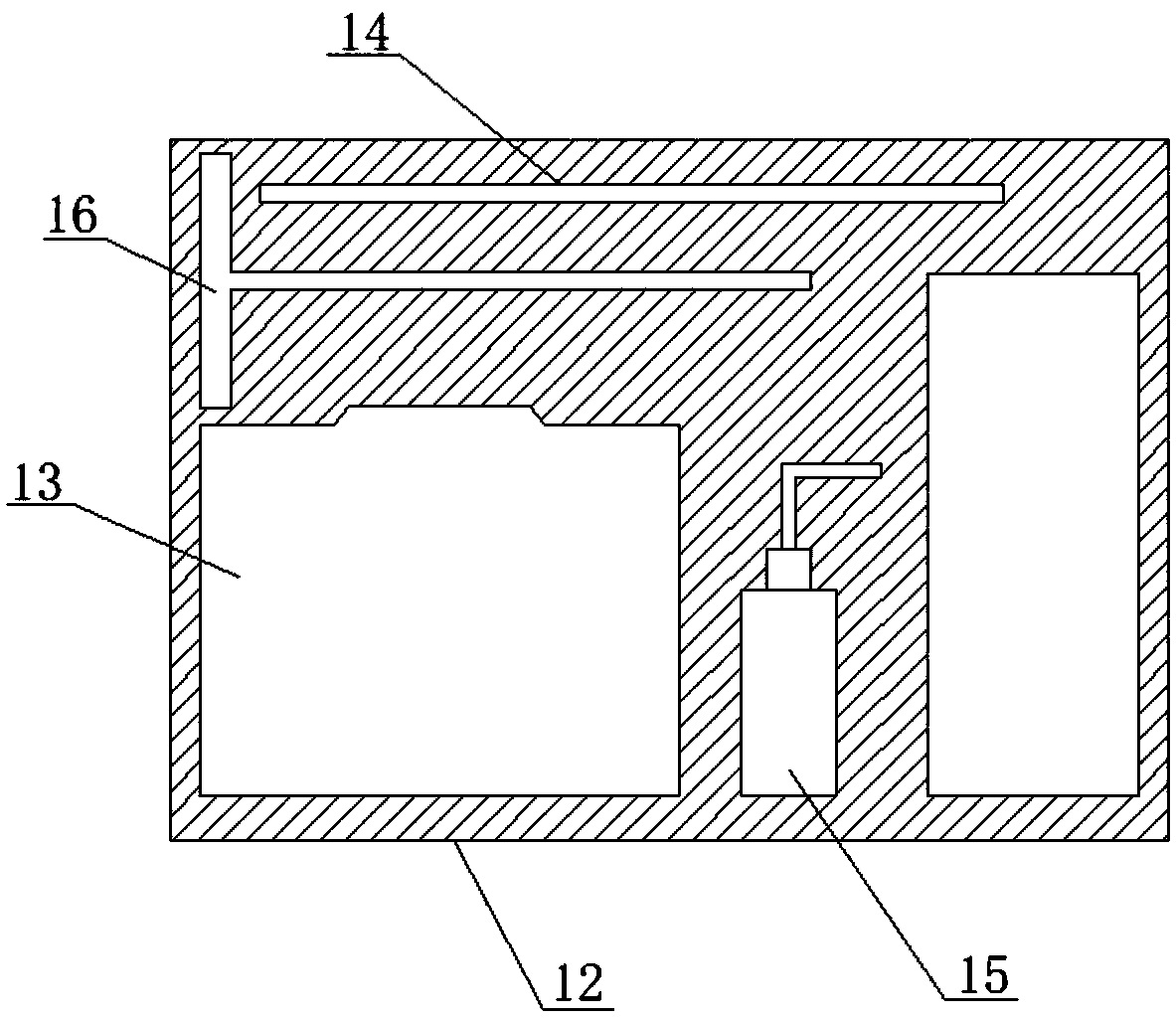

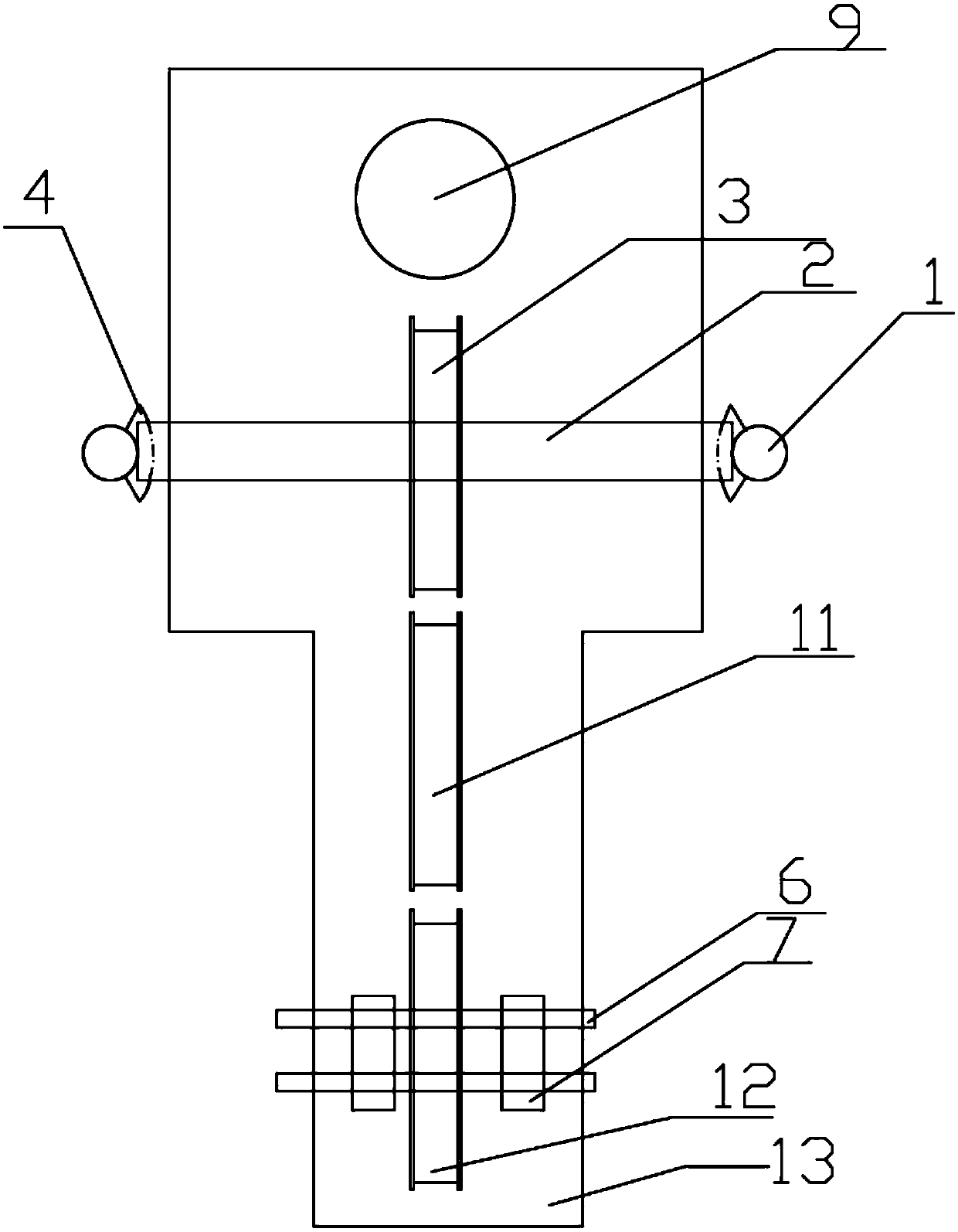

Bench-scale device of water supply pipe network microbiological test

ActiveCN103937660ASmall footprintContinuous non-cyclic operationBioreactor/fermenter combinationsBiological substance pretreatmentsDisinfectantEngineering

The invention relates to a bench-scale device of a water supply pipe network microbiological test. The device mainly comprises a water tank (28), a water inlet main pipe (30), a water outlet main pipe (29), a branch pipe a (25), a branch pipe b (26) and a branch pipe c (27), wherein the water tank (28) is connected with the water inlet main pipe (30) in series; two ends of each of the branch pipe a (25), the branch pipe b (26) and the branch pipe c (27) are connected with the water inlet main pipe (30) and the water outlet main pipe (29) in parallel. Compared with the prior art, the device disclosed by the invention can be used for realizing comprehensive study on micro-organisms in pipe wall and pipe network water under the conditions of different raw water, different pipe materials, different hydraulic conditions, different water ages, different disinfectants and the like.

Owner:TONGJI UNIV

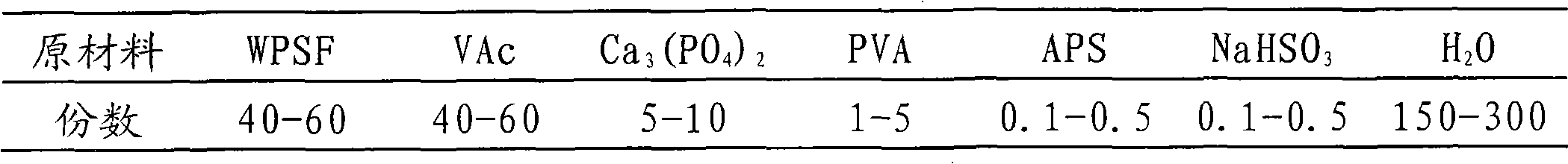

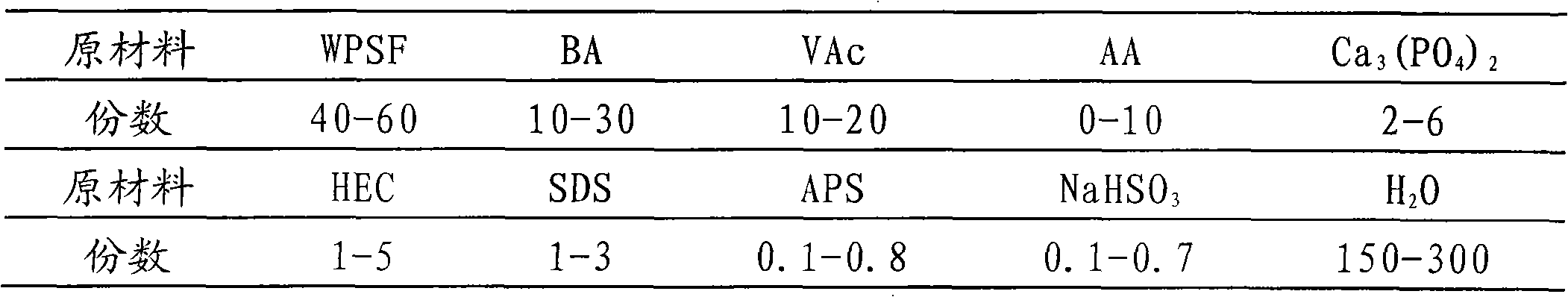

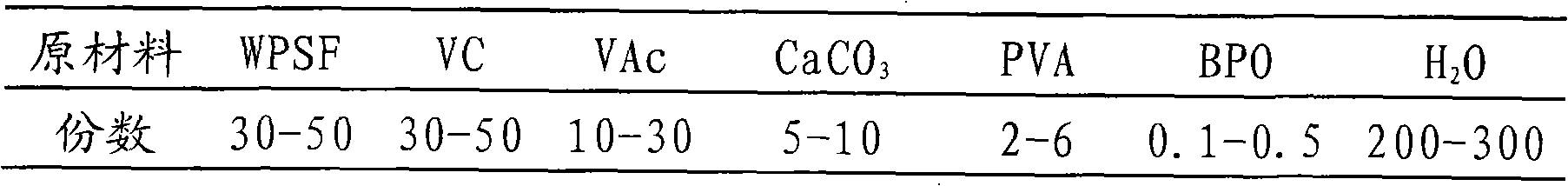

Novel technology for manufacturing hot melt resin from waste and old polystyrene foam

InactiveCN102731727ABroad thinkingConquering the Difficult to Reproduce Difficulty in DiameterGraft polymer adhesivesPolymer sciencePolystyrene bead

The invention relates to a novel technology for producing modified polystyrene beaded hot melt resin by the utilization of waste and old polystyrene foam and belongs to the technical field of synthetic resin. Under the condition of an initiator, graft copolymerization or interpenetrating network polymerization of polystyrene broken chain or free radical and vinyl acetate producing monomers is carried out to prepare the P(PVc / BA) beaded resin which is not easy to prepare from a styrene monomer and a vinyl acetate monomer, thus realizing 100% recovery of waste and old polystyrene plastics. Through adjusting the formula, resins with a plurality of applications, such as plastic film, hot melt adhesive, foaming products and the like, can be prepared. According to another advanced technology provided by the invention, a rotary viscometer is inserted into the preparation device to monitor rheological property of a polymerization system or viscosity at a certain shear rate on line. Therefore, the size of polymer particles can be controlled such that bench scale experiment which is conducted in a lab can be simply repeated in mass production. Therefore, the problem that the diameter of the polymer particles is difficult to reproduce during amplification of the polymerization device is solved.

Owner:HUBEI UNIV

Concrete slump testing device

InactiveCN107703026AGood technical effectLift at a constant speedFlow propertiesHydraulic cylinderHuman error

The invention relates to the technical field of concrete testing, and discloses a concrete slump test device, which includes a slump cylinder, the slump cylinder is located above the test bench, and a hydraulic cylinder is provided on one side of the test bench. The hydraulic cylinder is provided with a column, and the column is provided with a beam. One end of the beam is fixed on the slump cylinder, and the other end is connected to the column through a sleeve. The invention adopts a hydraulic cylinder to control the slump cylinder, which can be pressed tightly on the test bench, and can also be lifted at a constant speed, avoiding errors during manual operation; both the hydraulic cylinder and the test bench are equipped with scales, and the experiment is completed Finally, it can directly read and get the result, which is convenient and fast with high accuracy.

Owner:济宁市友领机械设备制造有限公司

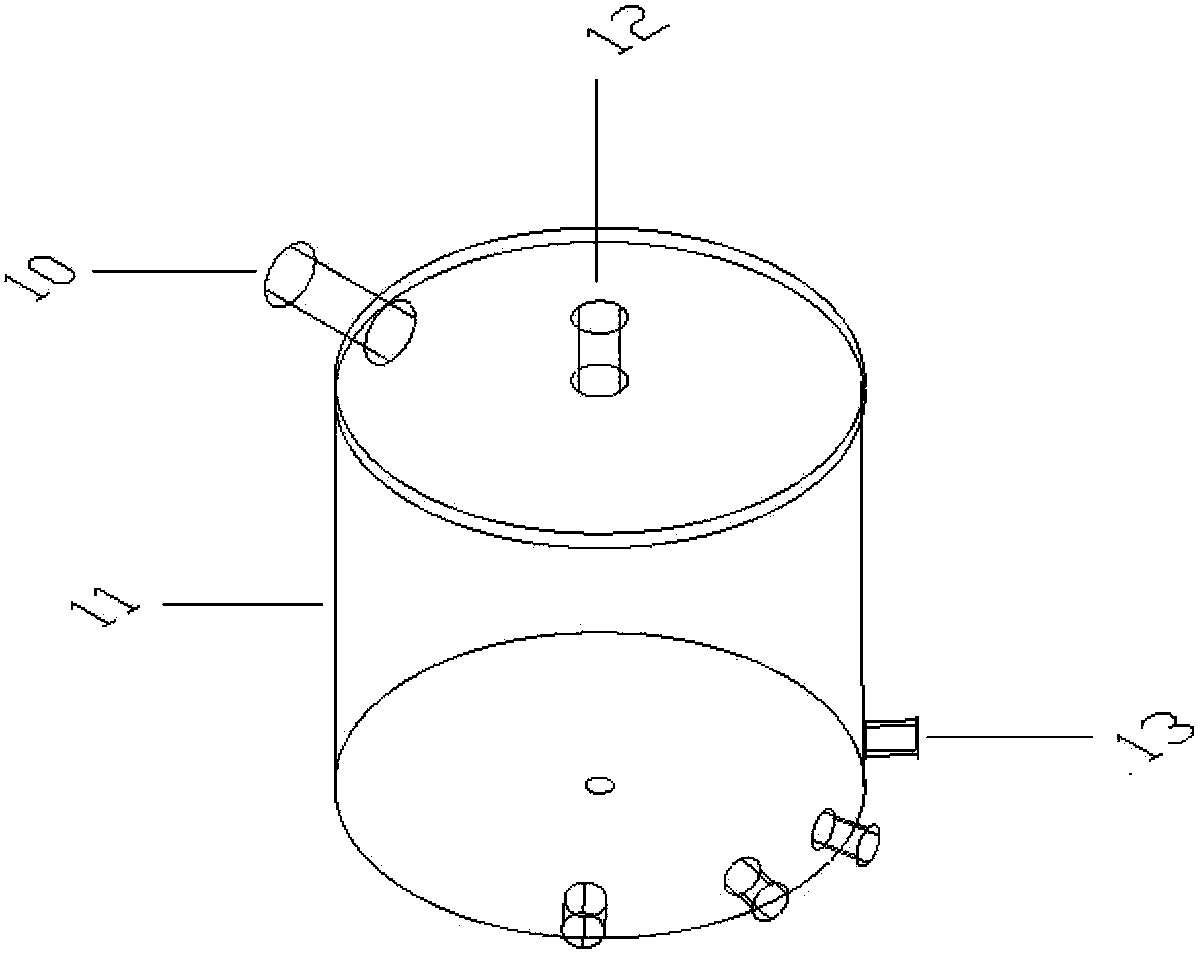

Sterile filling infusion system with automatic liquid feeding control

InactiveCN103863984AReduce stepsAutomatic control of liquid intakeLiquid materialLiquid bottlingPeristaltic pumpAutomatic control

The invention relates to a sterile filling infusion system with automatic liquid feeding control. The sterile filling infusion system comprises: a peristaltic pump, a terminal filter, a bench scale, an air filter, an infusion tube, a filling pump and a liquid storage tank, wherein the liquid storage tank comprises an upper cover and a tank body, the liquid inlet of the liquid storage tank is positioned on the upper end of the tank body, and is connected with the outlet of the terminal filter, the liquid outlet of the liquid storage tank is positioned on the lowest end of the tank body, and is connected with the filling pump through the infusion tube, the upper cover of the liquid storage tank is connected with the air filter, and the liquid storage tank is placed on the bench scale. With the agent filling infusion system of the present invention, the liquid feeding can be automatically controlled, the staff operation can be saved, the pollution during the sterile operation process can be reduced, and the product quality can be ensured.

Owner:SHANDONG LUYE PHARMA CO LTD

Portable sludge dewatering treatment small test experiment box and small test experiment method

PendingCN109264963AAvoid the problem of being scattered and inconvenient to carryShorten the timeSludge treatment by de-watering/drying/thickeningFiltrationW-box

The invention relates to the technical field of sludge dewatering, particularly to a portable sludge dewatering treatment small test experiment box and a small test experiment method. The portable sludge dewatering treatment small test experiment box comprises a lower box and an upper box cover, wherein the lower box and the upper box cover are detachably connected, and are respectively provided with a plurality of installing positions and a plurality of accommodating slots, a small pressure filtration device, a tool box, a moisture analyzer and a sampler are respectively arranged on the plurality of the installing positions of the lower box, a beaker, a raw material belt, filtering paper, a pipetting gun, a bench scale and an agent bottle are respectively placed on the plurality of the accommodating slots of the lower box, a CST meter and a gas pipe are respectively arranged on the plurality of the installing positions of the upper box cover, and a washing bottle and a movable handleare respectively placed on the plurality of the accommodating slots of the upper box cover. According to the present invention, the instruments, the devices and the materials for the small test at theearly stage of the sludge dewatering are integrated into the portable equipment box, such that the problem that the instruments are dispersed and are inconvenient to carry is avoided.

Owner:北京环球中科水务科技股份有限公司

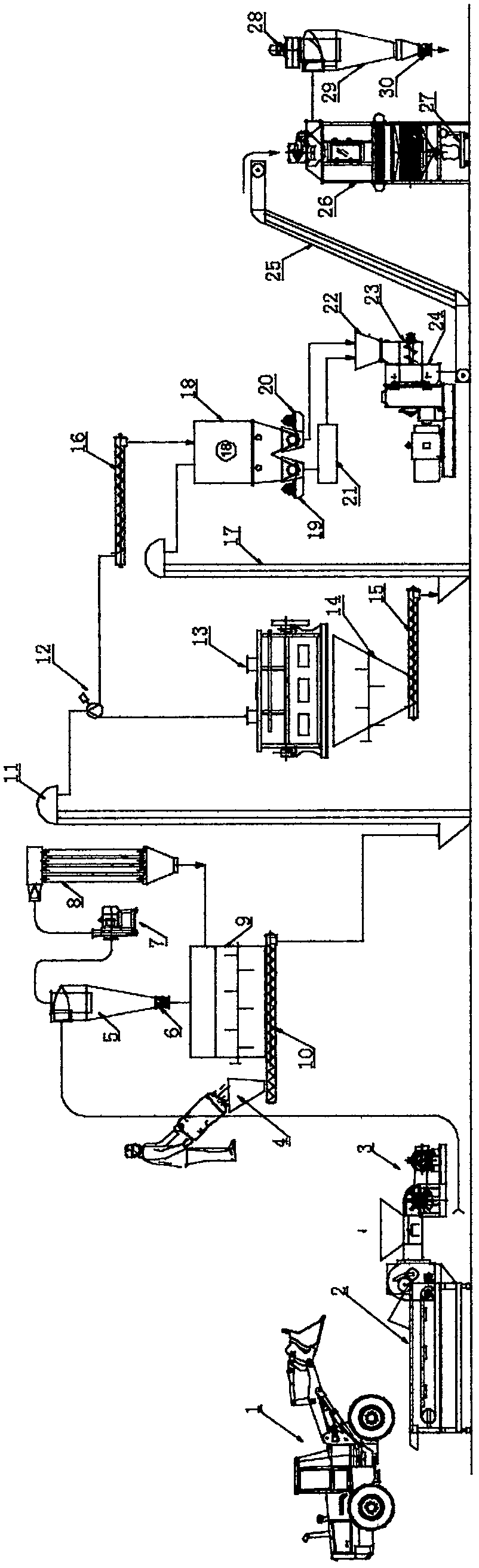

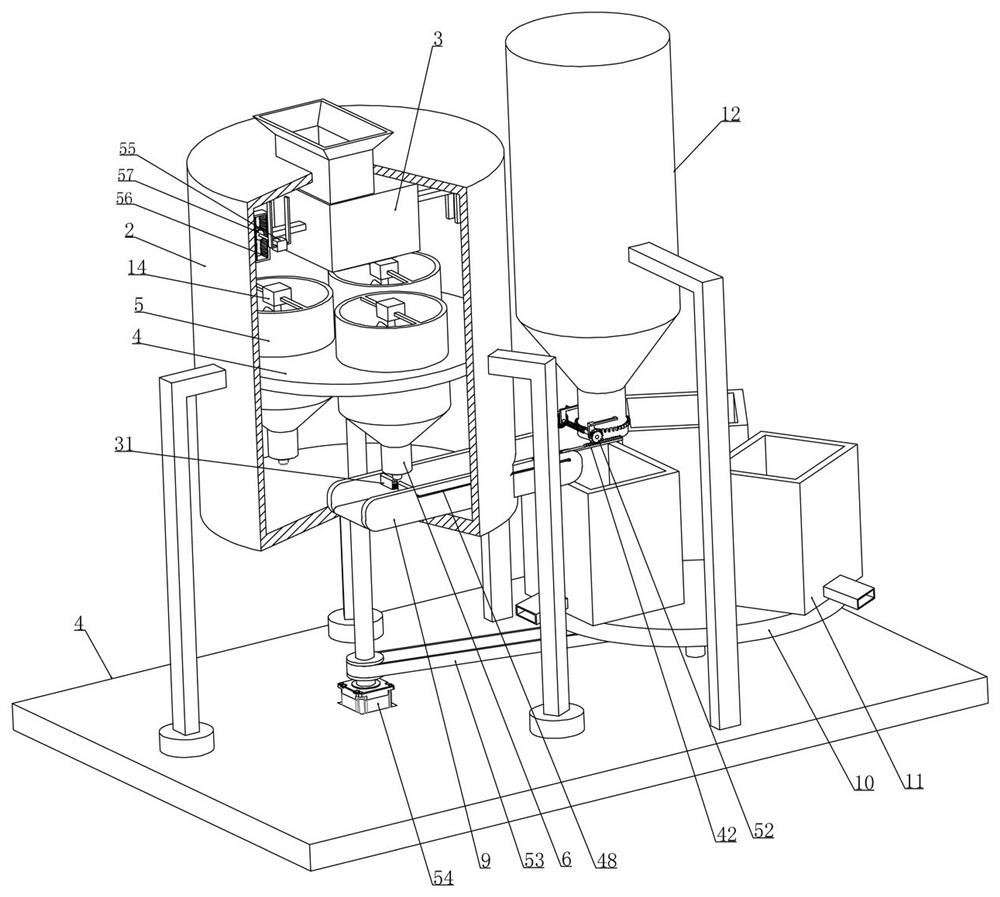

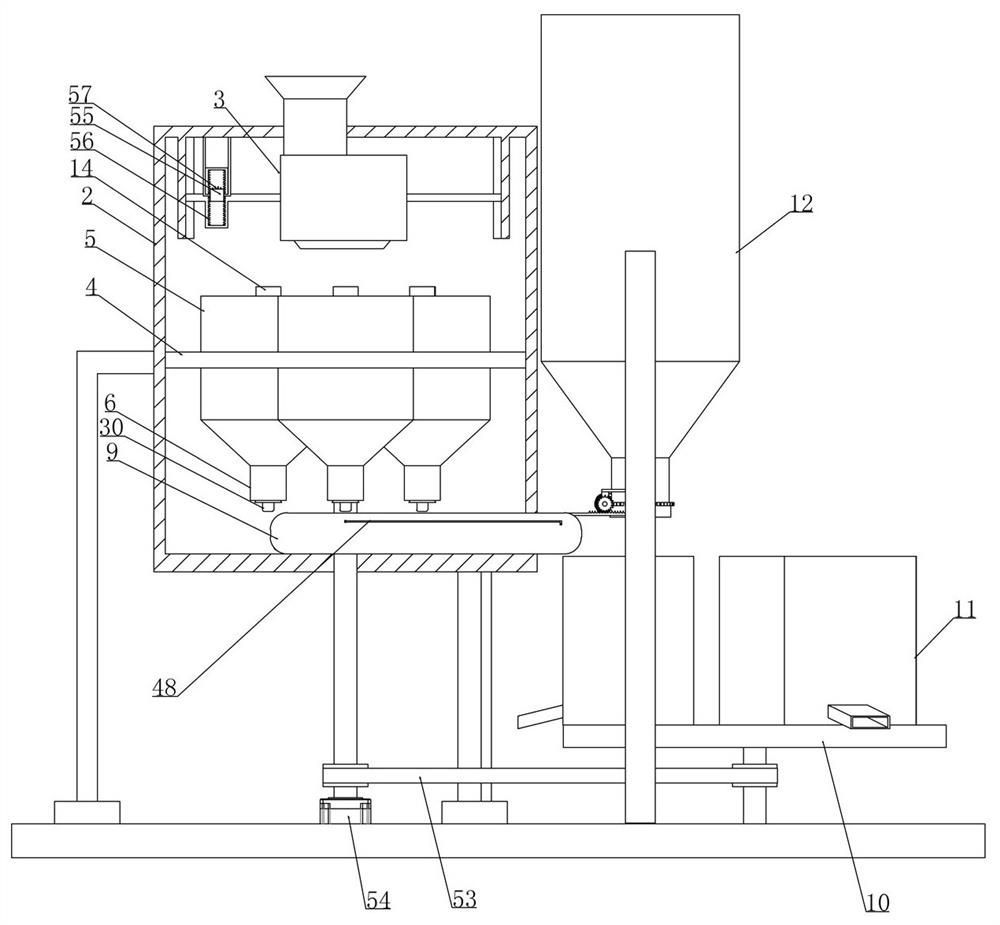

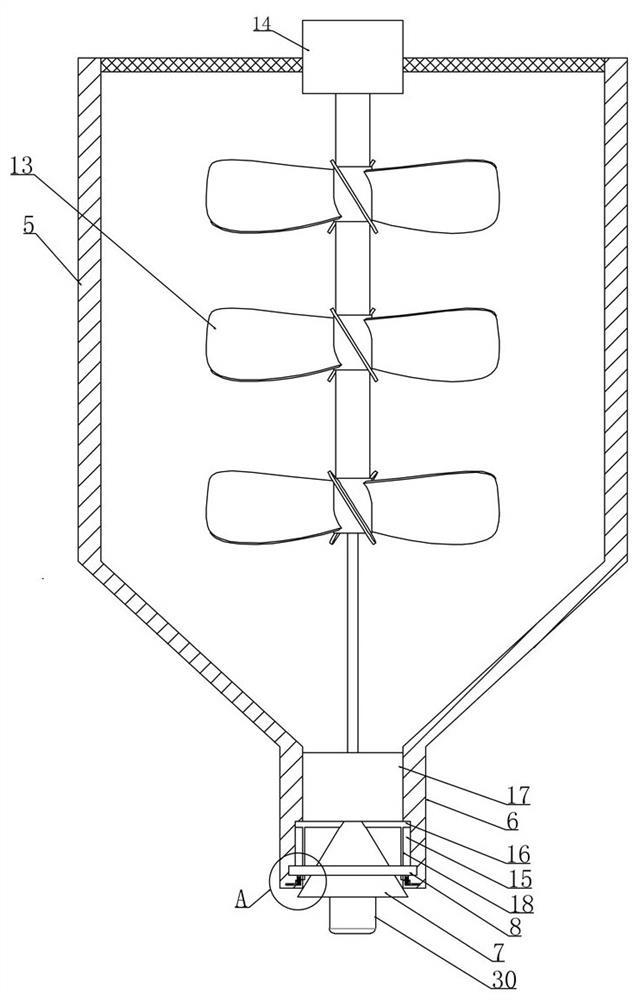

Granulating device for agriculture-forestry-husbandry waste

InactiveCN108126629ARealize resource regenerationGood workmanshipMaterial granulationFeed devicesCrusherBelt conveyor

The invention discloses a granulating device for agriculture-forestry-husbandry waste. The granulating device comprises a feeding and crushing mechanism, a mixing mechanism, a granulating mechanism and a cooling and packing mechanism, wherein the feeding and crushing mechanism comprises a conveyor, a crusher, a first cyclone dust collector, a first fan, a crushing and storing bin and a first packing auger; the mixing mechanism comprises a first elevator, an electric three-way valve, a spiral ribbon mixer, a mixing and buffering bin and a second packing auger; the granulating mechanism comprises a second elevator, a granulation-to-be-performed bin, a first packing auger feeder, a second packing auger feeder, a modulator, a granulating and buffering bin, a forced feeder and a granulator; thecooling and packing mechanism comprises a belt conveyor, a cooling vibrating screen, a packaging bench scale, a second fan and a second cyclone dust collector. The granulating device for the agriculture-forestry-husbandry waste is multiple in function, smooth in process and high in degree of automation, is safe, high-efficiency, energy-saving and environmentally friendly, can resist severe cold,can be used for granulation in the open, does not need a factory building and heat supply, is detachable, and is less in investment and easy to popularize.

Owner:溧阳日进农牧装备有限公司

Device for measuring pressure resistance of processed tomatoes

InactiveCN104181050ASolve the problem of lack of rapid detection device for fruit pressure resistanceEasy to operateMaterial strength using tensile/compressive forcesCushionBench scale

The invention relates to a device for measuring the pressure resistance of processed tomatoes, in particular to a device for measuring and comparing the pressure resistance of different varieties of processed tomatoes. The device comprises a hollow shell, wherein a weighing bench scale is arranged in the hollow shell, a fruit vessel with an opening at the upper end is arranged on the weighing bench scale, a sliding pressure plate capable of moving up and down is arranged at the opening of the fruit vessel, the sliding pressure plate is adaptive to the opening of the fruit vessel in shape and size, a sand cushion or a water cushion is arranged under the sliding pressure plate, a pressing device is arranged above the sliding pressure plate, the pressing device acts on the sliding pressure plate downwards to enable the sliding pressure plate to move downwards. The device has simplicity in operation, is economic and practical, is an effective device for measuring the pressure resistance of different varieties of processed tomatoes, and can improve the measurement efficiency.

Owner:XINJIANG ACADEMY OF AGRI & RECLAMATION SCI

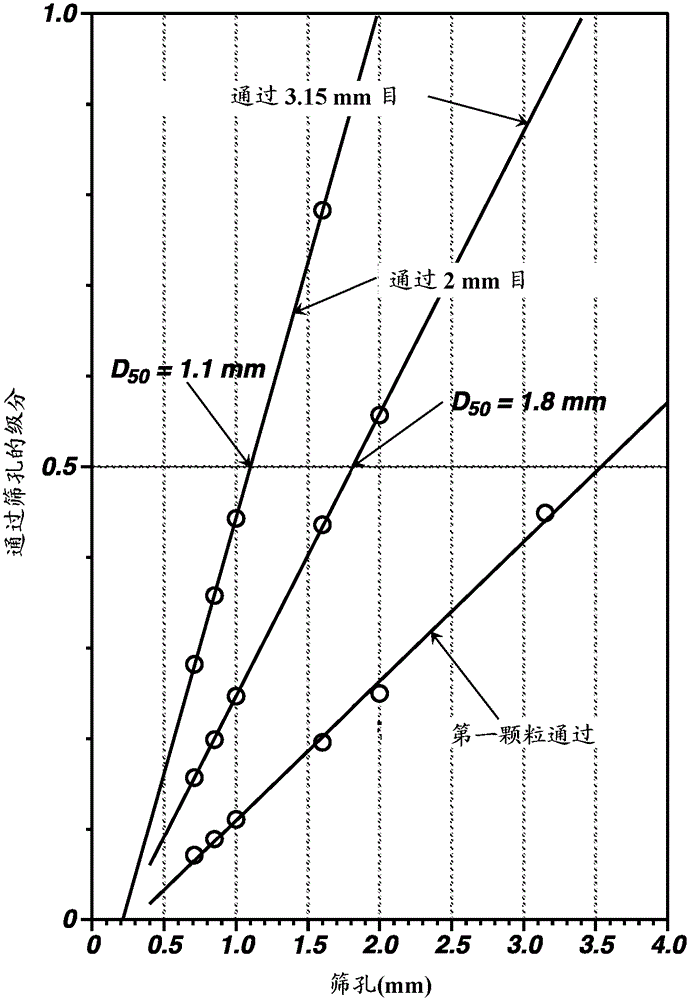

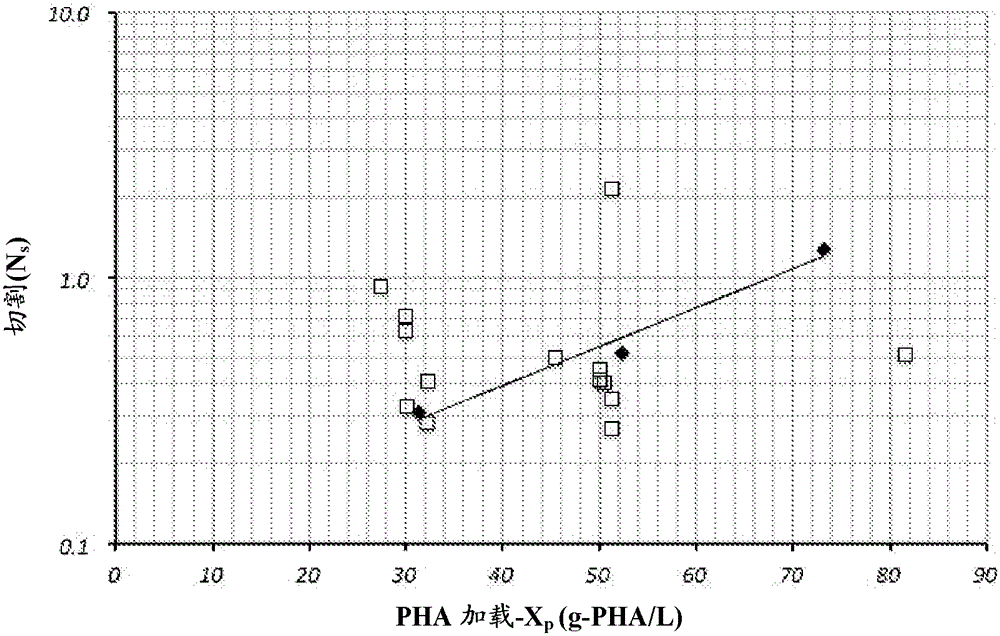

Process for the extraction of polyhydroxyalkanoates from biomass

InactiveCN105121503AGuaranteed qualityMaintain strict standards of qualityFermentationSolid solvent extractionBatch extractionProcess engineering

Owner:VEOLIA WATER SOLUTIONS & TECH SUPPORT

Multi-group bubbling type photobioreactor

InactiveCN101935610BPrevent leakageIncrease light intensityBioreactor/fermenter combinationsBiological substance pretreatmentsTemperature controlControl system

The invention discloses a multi-group bubbling type photobioreactor which comprises a box body, bubbling type photobiologic reaction units, a main air duct, light sources and a control system, wherein at least two bubbling type photobiologic reaction units are placed in rows in the box body, the main air duct is connected to an air-blowing pipe and a gas distributor in each bubbling type photobiologic reaction unit through gas-distributing branch pipes, the light sources are placed at both sides of each bubbling type photobiologic reaction unit, and the control system comprises a temperature control system and a light source control system for controlling the temperature in the box body and the intensity of the light sources. The invention supplies a batched, controllable and mature facility for the microalgae culture in laboratory and bench scales.

Owner:NANJING TECH UNIV

Simple fiberboard bending tester and testing method

InactiveCN102519806BRepetitiveEasy to useMaterial strength using steady bending forcesEngineeringFiberboard

The invention discloses a simple fiberboard bending tester and a testing method. The tester comprises a support, a bench scale, a pressure mechanism and a sample loading carrier, wherein the sample loading carrier is placed on the bench scale, the sample loading carrier is provided with two support cross bars for supporting the two ends of a fiberboard, and the pressure mechanism is arranged above the sample loading carrier and is liftably arranged on the support. According to the invention, when the fiberboard is detected, the pressure mechanism goes down to apply pressure on the central portion of the fiberboard, the fiberboard generates a certain elastic deformation, the fiberboard restores the elasticity because of the interaction of power, the two support cross bars receive the pressure generated by the elasticity recovery of the fiberboard, the pressure is transmitted to the bench scale, and the bench scale displays the bending resistance data. The tester utilizes the pressure mechanism and the sample loading carrier to simulate the bending handle, and utilizes the display of the bench scale display screen to calibrate the result data, thus the bending resistance of the fiberboard can be simply detected, and the bending resistance of products can be calibrated accurately.

Owner:福建鑫华股份有限公司

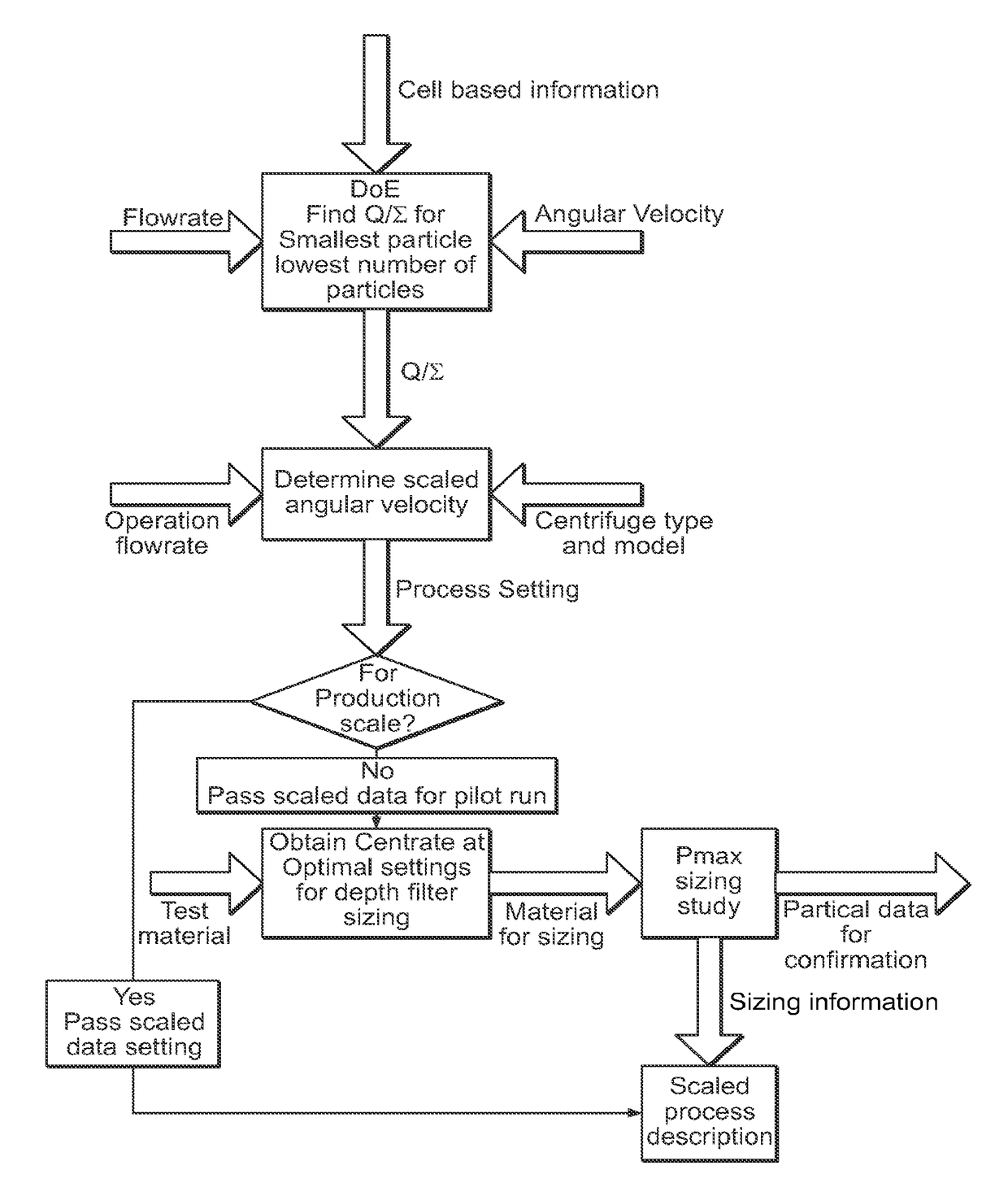

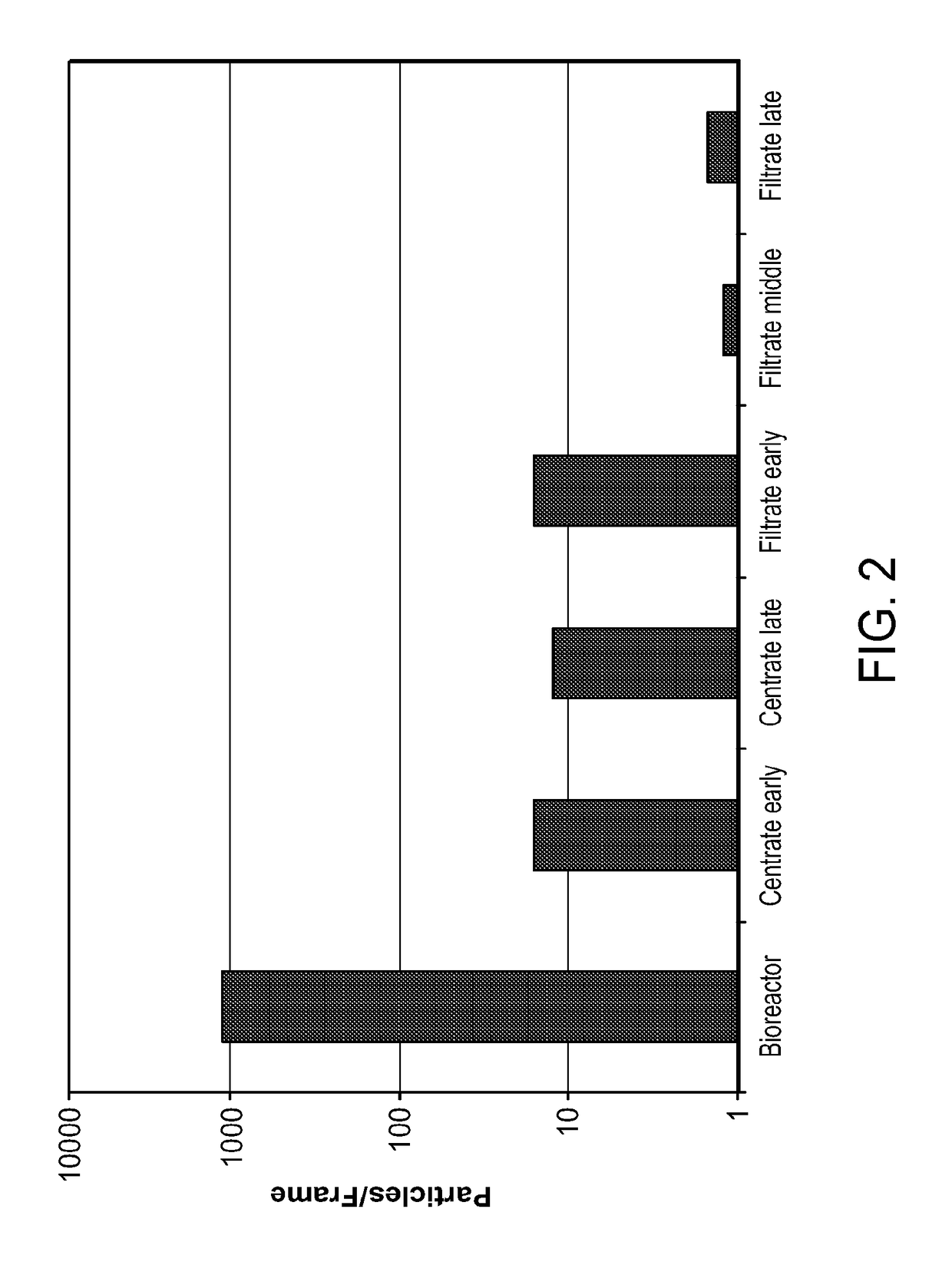

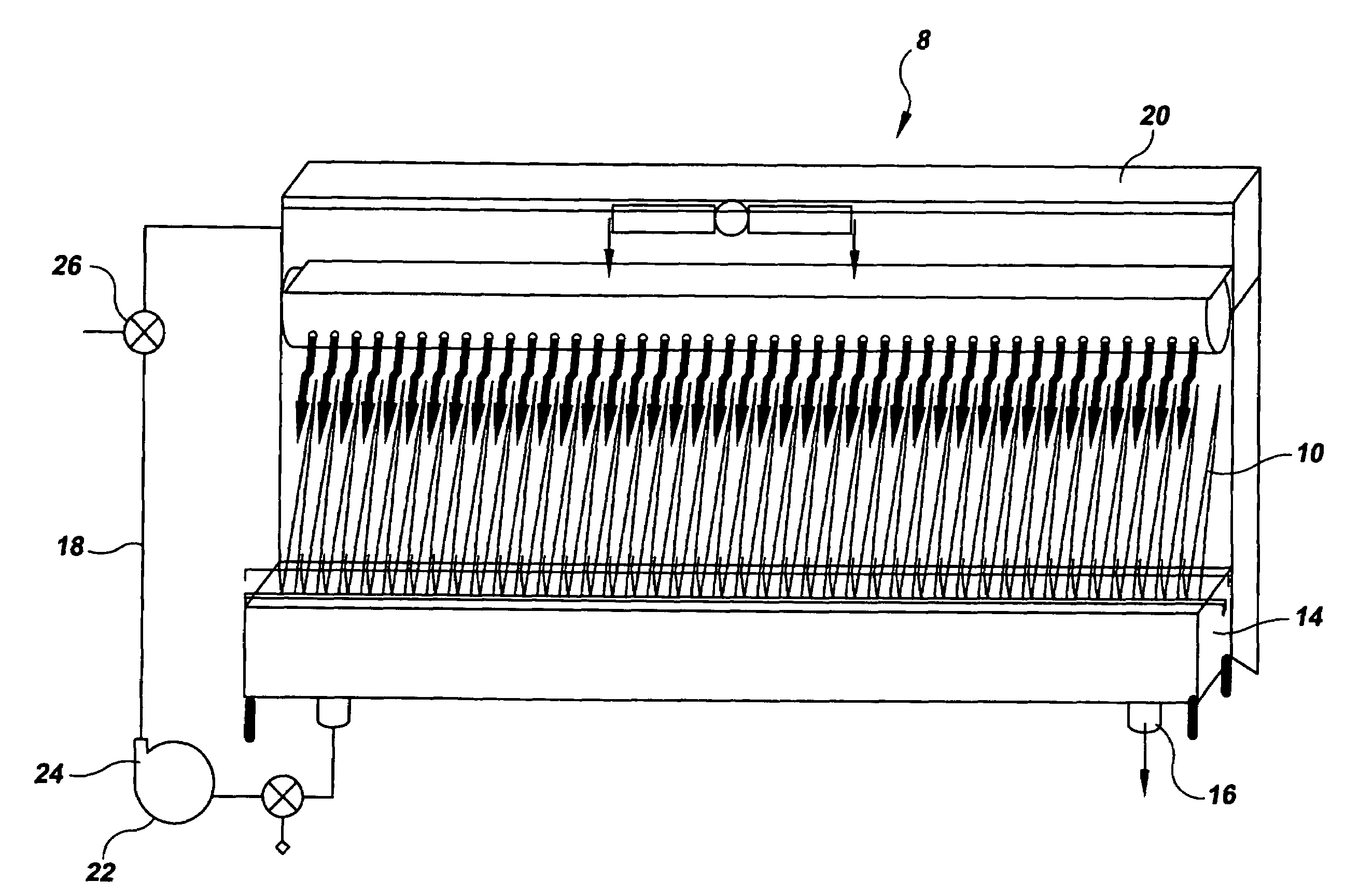

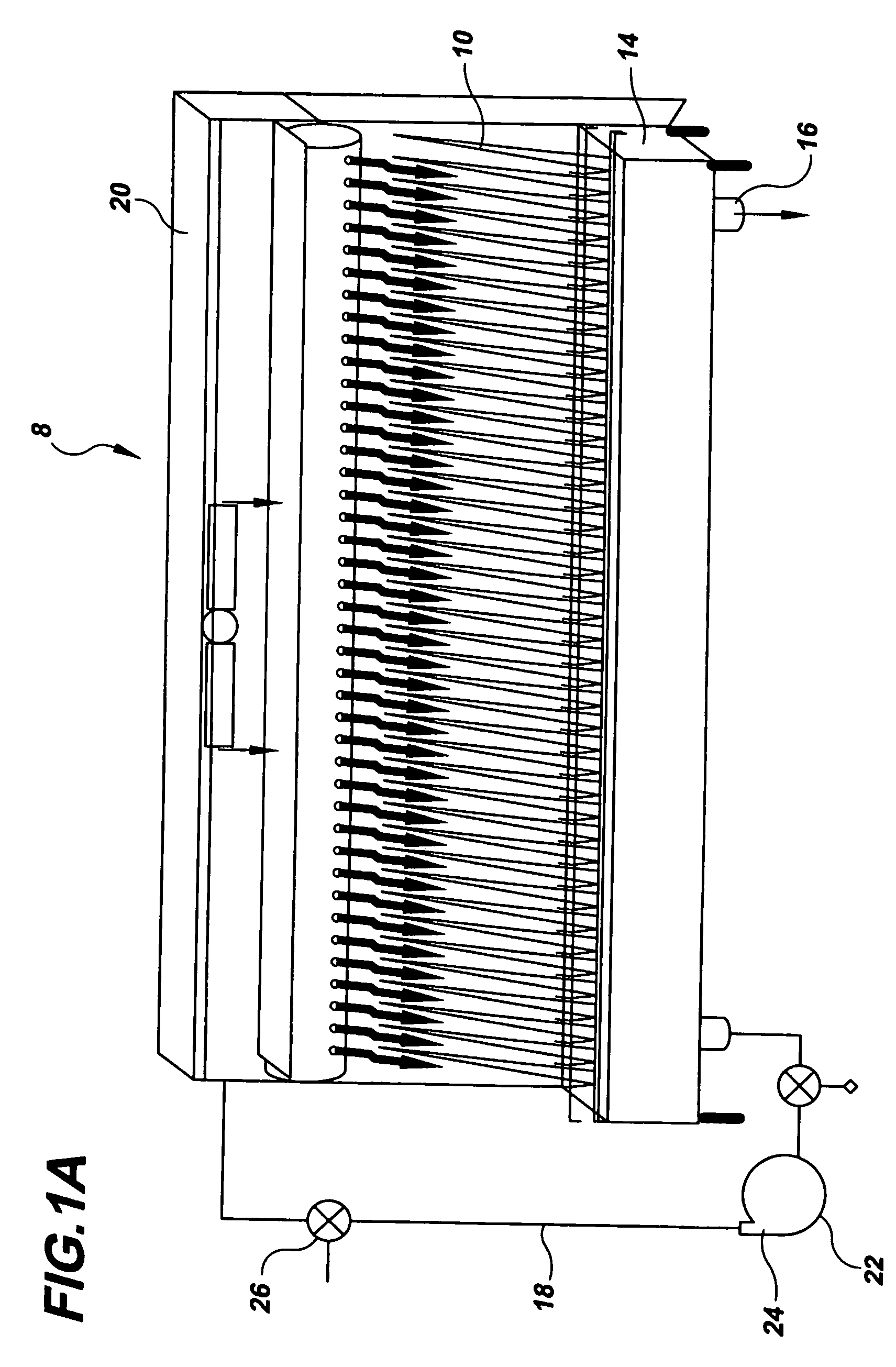

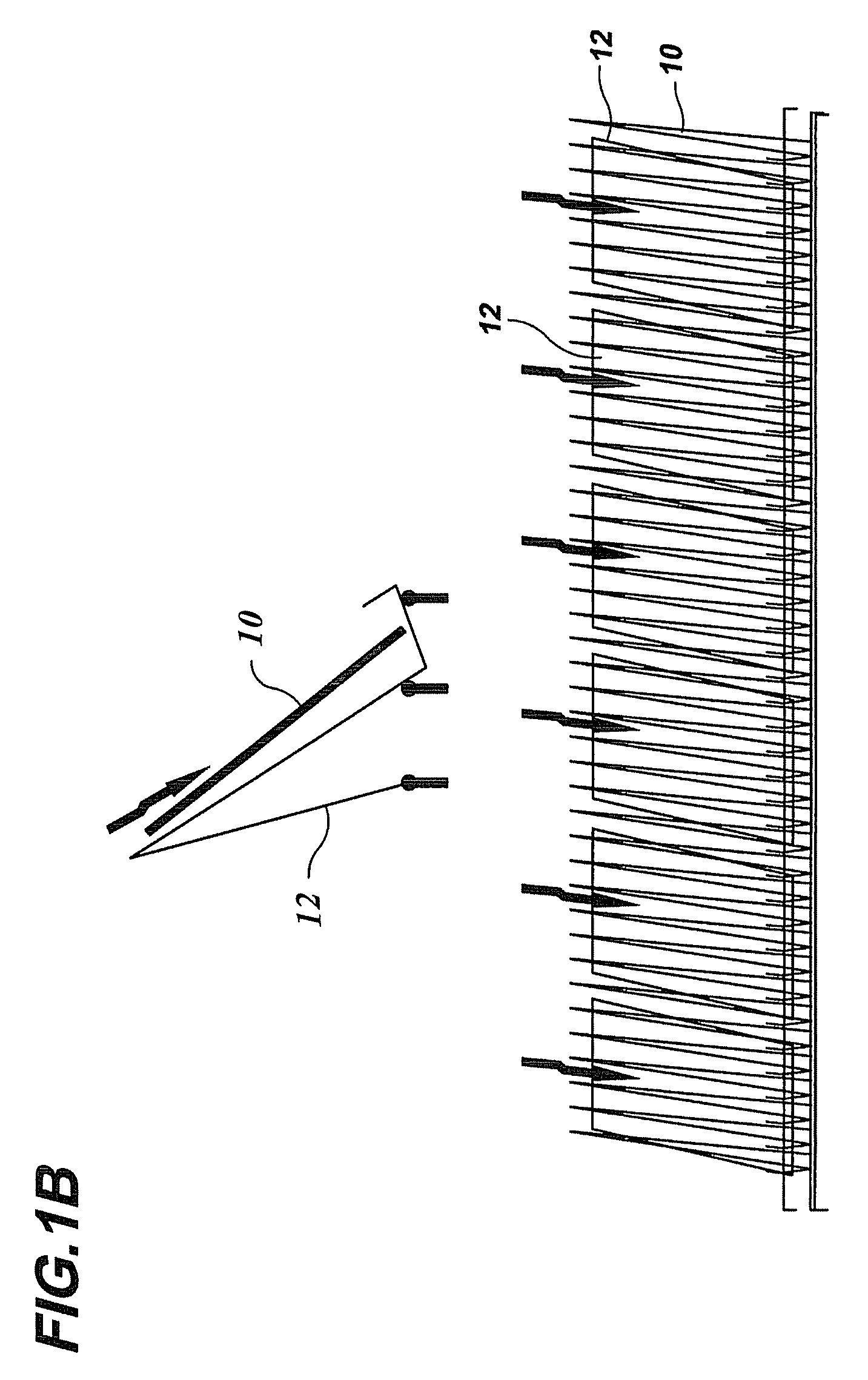

Methods for the harvesting of cell cultures

InactiveUS20180330043A1Reduce cloggingLow costCulture processBiomass after-treatmentCentrifugation3D cell culture

Owner:TAKEDA PHARMA CO LTD

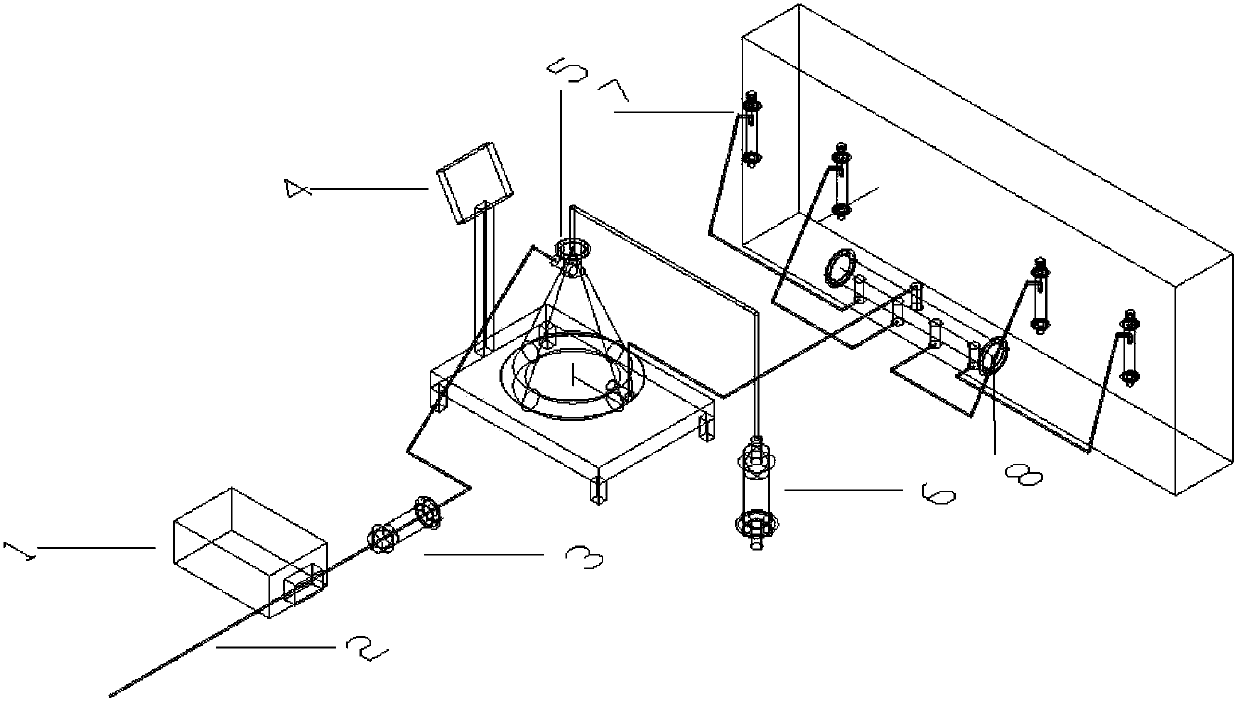

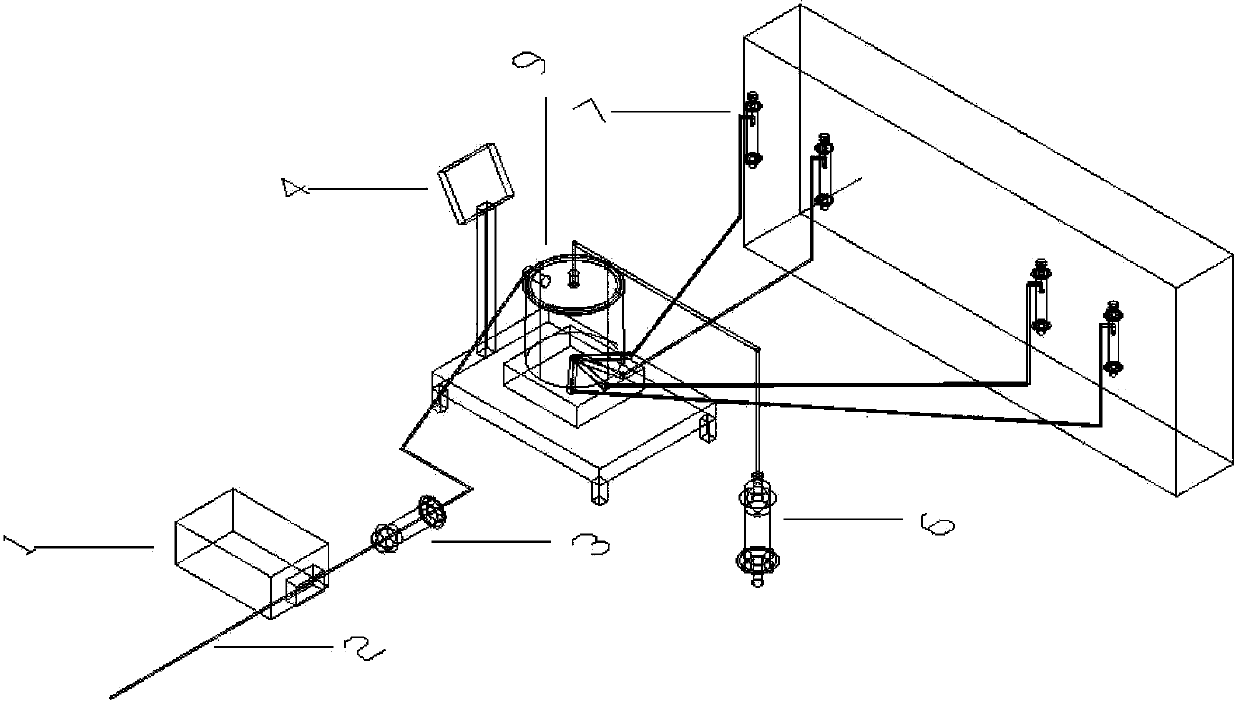

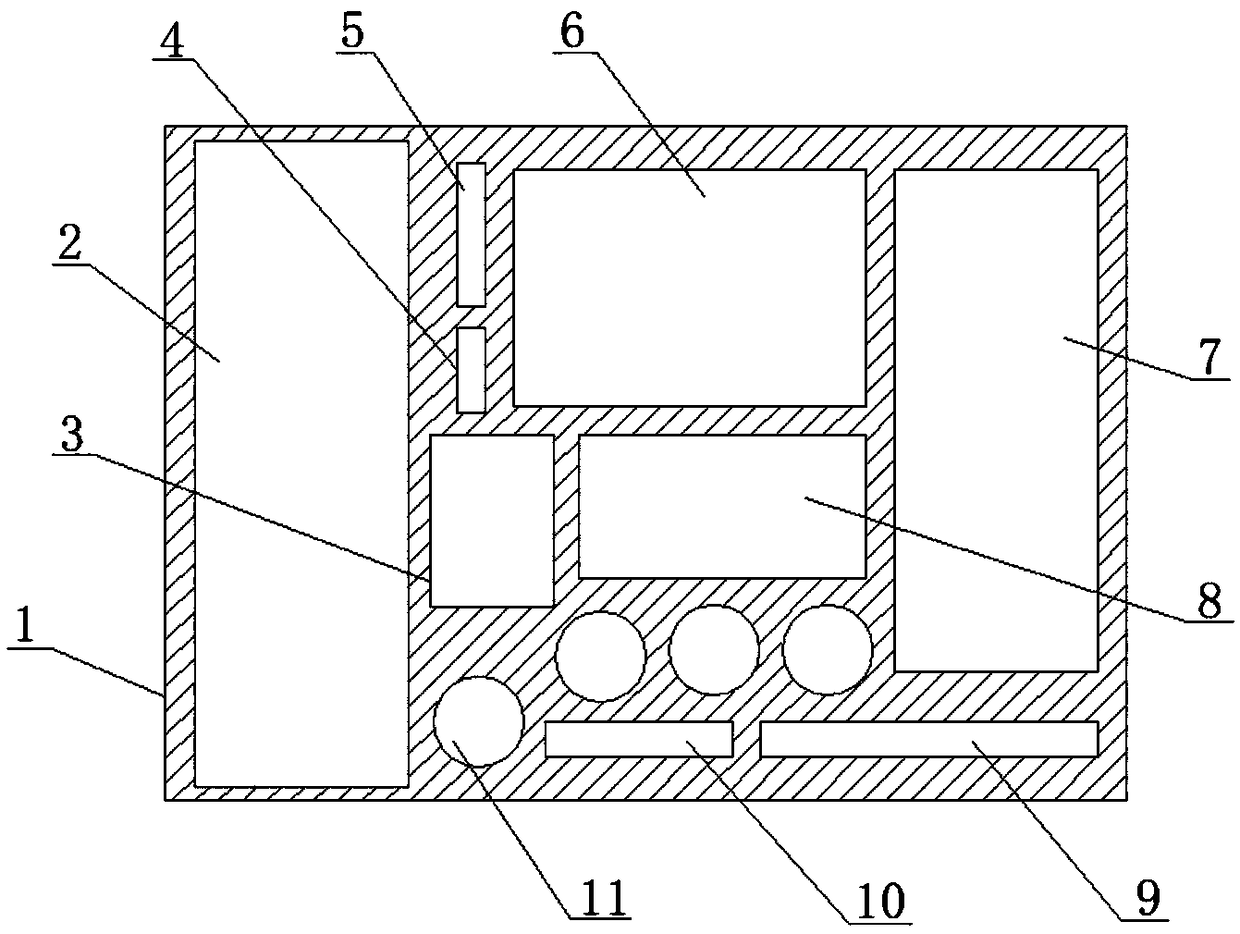

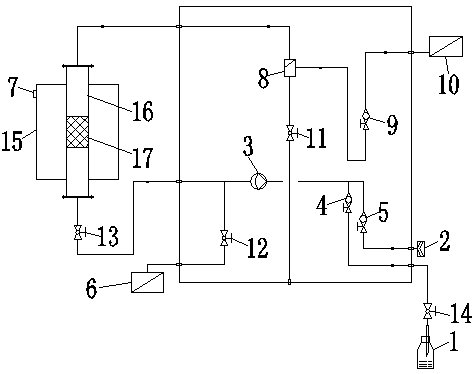

Bench-scale experiment device for nitrogen containing organic waste gas heat storage type incinerator

PendingCN108224451AReasonable structureResponsive adjustmentEmission preventionIncinerator apparatusAir filterNitrogen

The invention relates to a bench-scale experiment device for a nitrogen containing organic waste gas heat storage type incinerator. The bench-scale experiment device comprises an organic waste gas generator and an air filter. The organic waste gas generator is connected with a sucking pump through a gas inlet pipe I. The air filter is connected with the sucking pump through a gas inlet pipe II. Aflowmeter I is arranged on the gas inlet pipe I. A flowmeter II is arranged on the gas inlet pipe II. The sucking pump is connected with a simulated incineration device through a main pipe. A waste gas VOC detector is connected with the main pipe between the sucking pump and the simulated incineration device through a branch pipe I. The bench-scale experiment device can implement simulated incineration under the conditions of different temperatures and different organic matter concentrations.

Owner:宜兴市宝沃技术服务有限公司

Method for continuous generation of SO3 gas

InactiveCN107973278ASolve problems that are difficult to use directlyLess investmentSulfur compoundsBuffer tankReaction temperature

The invention provides a method for continuous generation of SO3 gas, belonging to the technical field of sulfonation. The method comprises the following steps: subjecting SO2 gas to acid pickling andthen allowing the pickled SO2 gas to enter a buffer tank under the control of a mass flowmeter; drying air, metering the dried air with the mass flowmeter, and then allowing the air to enter the buffer tank for mixing with the SO2 gas; allowing a gas mixture obtained in the previous step to enter a reactor filled with a catalyst and controlling a certain reaction temperature; and discharging generated SO3 gas from a discharging pipe, wherein SO3 gas with stable flow and concentration can be obtained by controlling the feed amounts of the SO2 and air. The method is mainly used for providing raw SO3 gas for bench-scale or pilot-scale sulfonation in a laboratory and has the advantages of safety, stability, environmental friendliness, accuracy, controllability, low investment, etc.

Owner:CHINA PETROLEUM & CHEM CORP +1

Digital controlled machine tool working bench scaling device

InactiveCN100515669CHigh indexing accuracyRotary vibration is smallPrecision positioning equipmentNumerical controlCircular cone

The invention relates to the indexing of the workbench of a machine tool. The technical proposal is: comprising a rotary indexing workbench, a movable toothed plate, a fixed toothed plate, a fastening toothed plate and a base. The center of the base is fixed with a concave conical upper end. The lower support seat of the hole, the concave conical hole is equipped with a rotary ball, the upper part of the rotary ball is exposed from the concave conical hole, and the upper part of the rotary ball is contained in the concave shape at the center of the lower side of the rotary indexing table. In the conical hole, the movable toothed plate is divided into 12 equal parts along the direction of the fan-shaped surface, and the fixed toothed plate is processed with three 30° conical tooth surfaces. The angle between the centerlines of two adjacent tooth surfaces is 120°, the fixed tooth disc between two adjacent tooth surfaces is a smooth surface.

Owner:WEIHAI HUADONG AUTOMATION +1

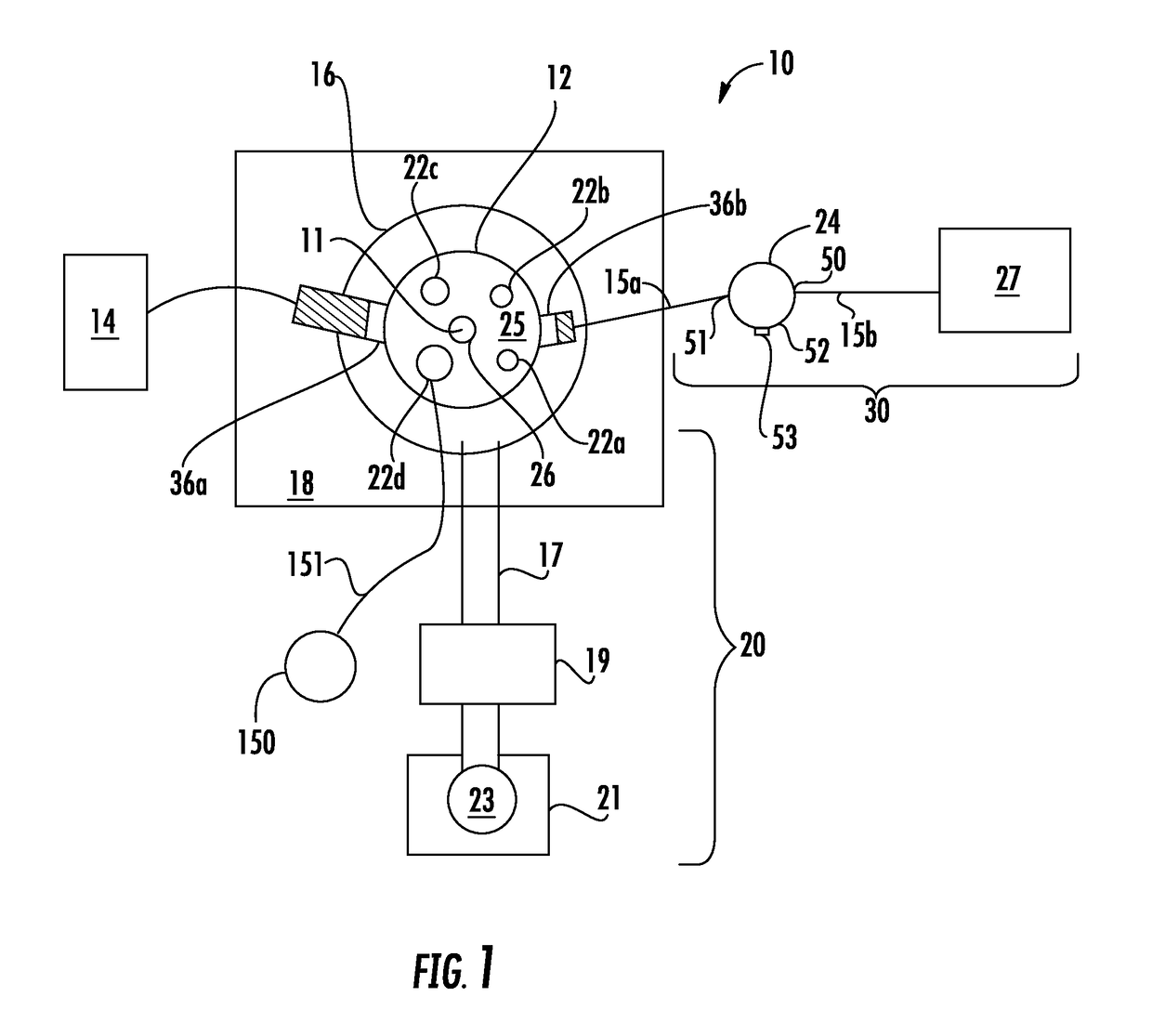

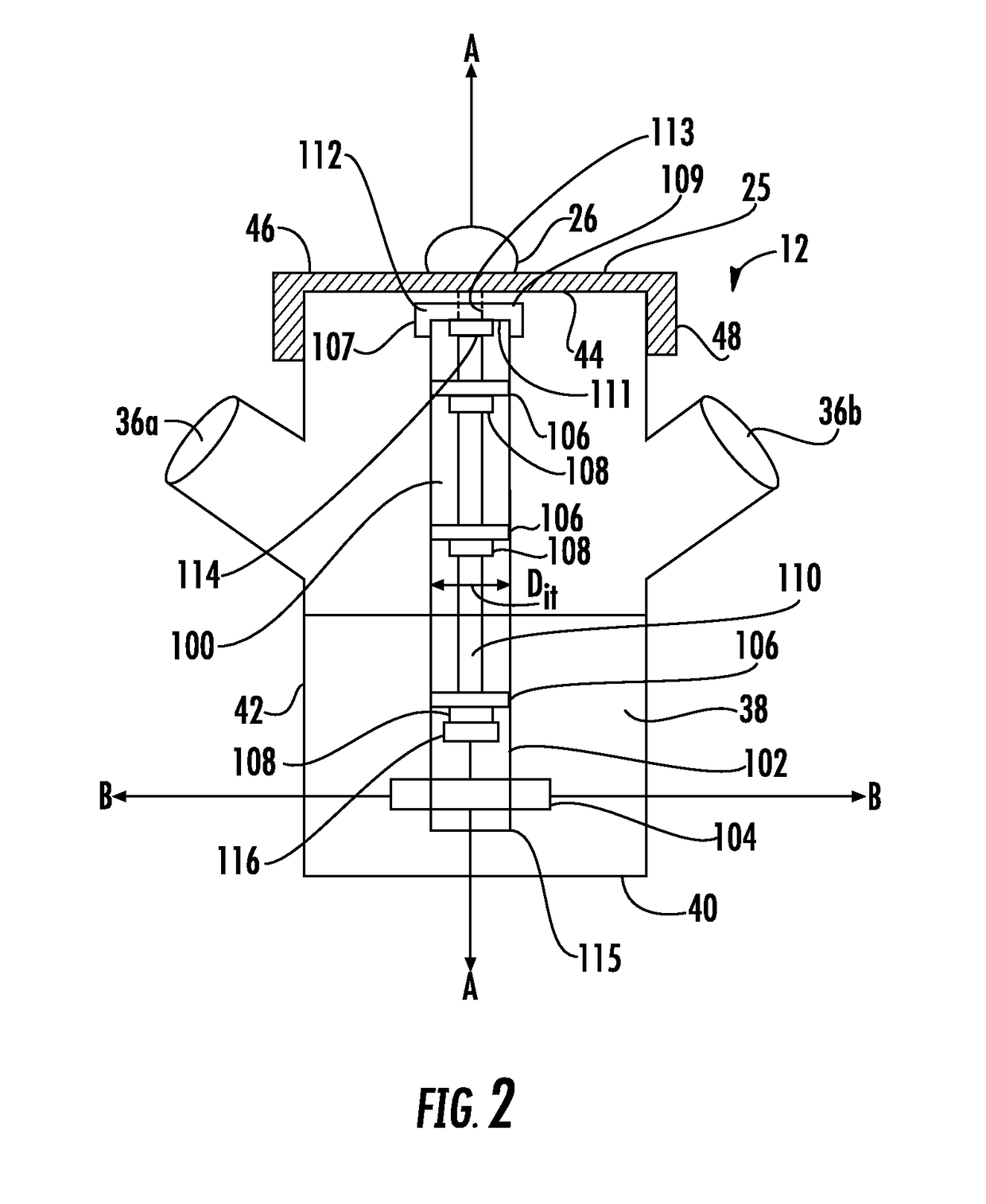

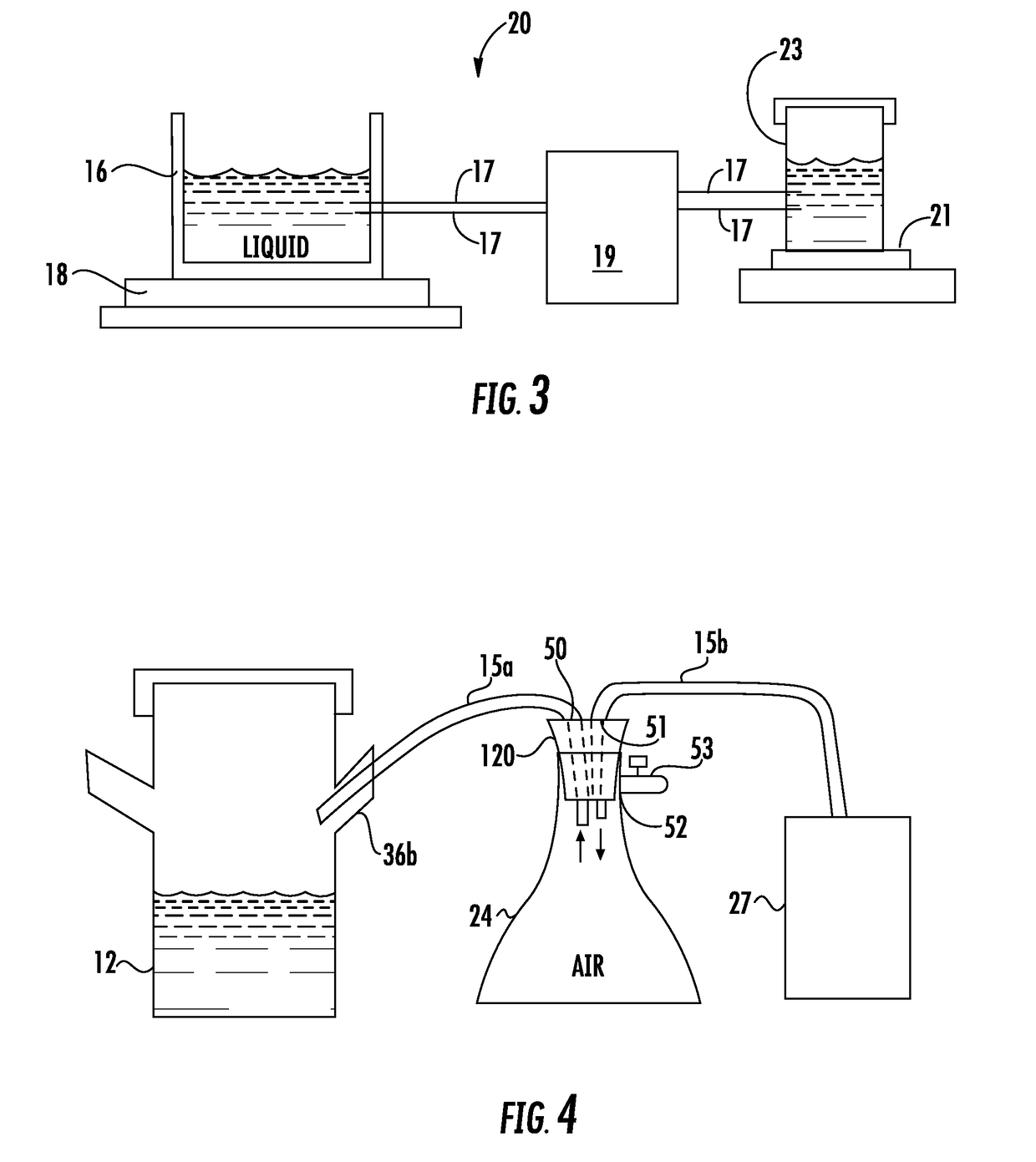

Bioreactor system

ActiveUS20180346863A1Prevent movementBioreactor/fermenter combinationsWater treatment parameter controlImpellerTemperature control

According to various implementations, the bioreactor system includes a bioreactor vessel, an impeller for stirring contents within the vessel, a temperature control source for controlling the temperature of the contents of the vessel, an aeration system for supplying air to the vessel, and one or more data loggers. According to certain implementations, the impeller is a novel impeller design that spins more smoothly and rapidly than known impellers. In addition, the bioreactor system is modular, durable, and relatively inexpensive compared to existing bioreactor systems, which allows for bench-scale implementation, use with differently sized bioreactor vessels, and accessibility to more educational programs, according to some implementations.

Owner:GEORGIA STATE UNIV RES FOUND INC

Micro-net dynamic membrane bioreactor for continuously updating dynamic membrane

ActiveCN101492202BLow priceImprove water qualitySemi-permeable membranesWater/sewage treatment bu osmosis/dialysisVena contracta diameterMicrogrid

The invention relates to a bench-scale dynamic membrane bioreactor capable of continuously updating a dynamic membrane, which is characterized in that: a container is divided into an upper aerobic zone and a lower anoxic zone by a separating orifice plate, and an aerator group is arranged on the separating orifice plate; a microgrid component consists of a wave curve-shaped microgrid net body, a casing, a bottom net, 2 to 3 layers of spherical porcelain granules uniformly spread on the bottom net, a backwash nozzle, an air-jet wash-out brush head, a hollow shaft tube, and a rotation driving mechanism, wherein backwash nozzle and the air-jet wash-out brush head are arranged above and under the net body respectively and are positioned on the same plane, and the hollow shaft tube and the rotation driving mechanism drive the backwash nozzle and the air-jet wash-out brush head to rotate continuously; the microgrid component is arranged on the top of a tank horizontally; and the center of the microgrid net body is provided with the hollow tube the inside of which has a built-in separating plate, the part, above the separating plate, of the shaft tube is connected with the rotation driving mechanism, a water source and the backwash nozzle, the part, blow the separating plate, of the shaft tube is connected with an air source and the air-jet wash-out brush head, and the lower end of the hollow shaft tube rotates and is connected with the aerator group in a sealing mode. The invention has the advantages of improving denitrification and dephosphorization effect, achieving microfiltration solid-liquid separation effect, ensuring effluent flux and optimizing and simplifying power and control systems.

Owner:北京创未环境工程技术有限公司

Bench scale apparatus to model and develop biopharmaceutical cleaning procedures

Owner:WYETH RES IRELAND LTD

Intelligent aggregate proportioning platform scale

ActiveCN111256796BReduce labor intensityImprove conveniencePreparing sample for investigationRoads maintainenceStructural engineeringProcess engineering

Owner:HENAN HIGHWAY ENG GROUP +1

Mounting-free electric hoist energy efficiency test bench

PendingCN108680377ACompact structureReasonable structureStructural/machines measurementSustainable buildingsEngineeringTest bench

Owner:SPECIAL EQUIP SAFETY SUPERVISION INSPECTION INST OF JIANGSU PROVINCE

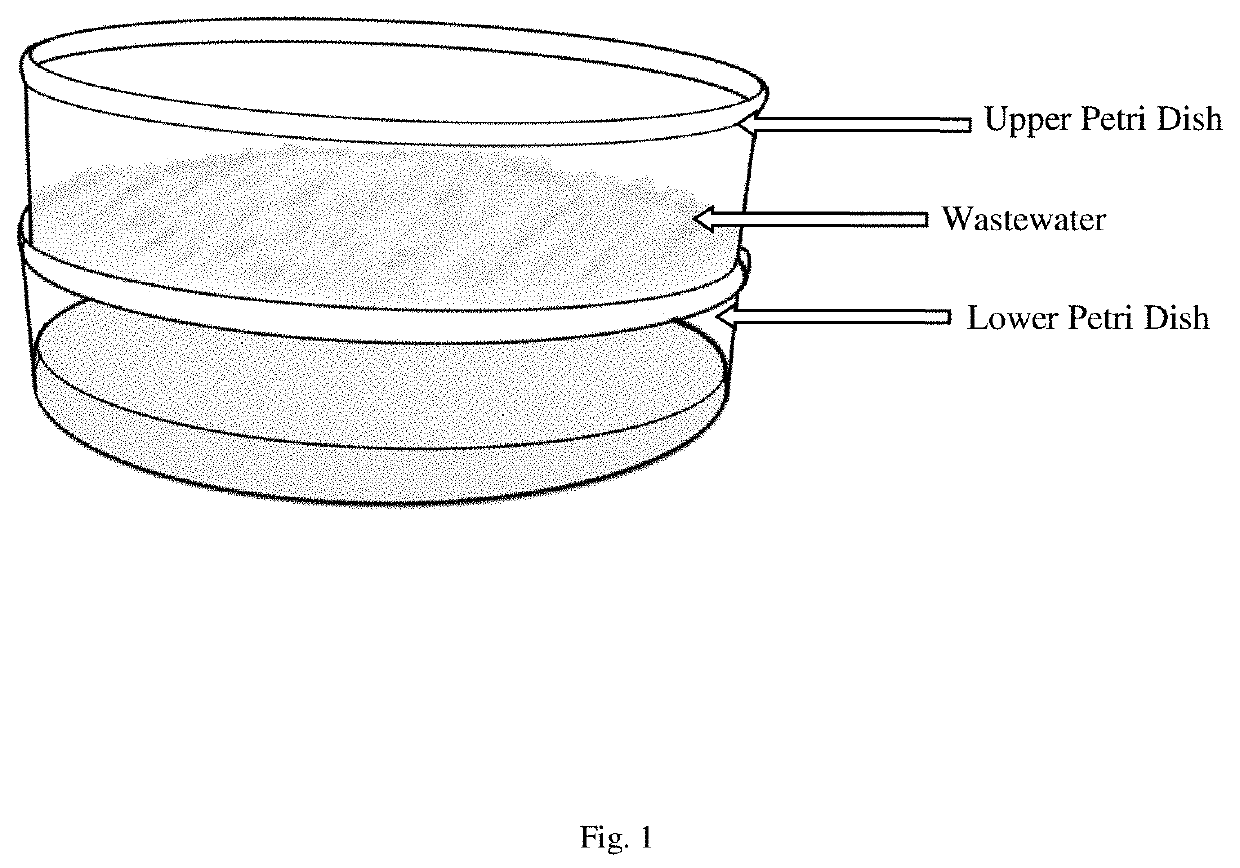

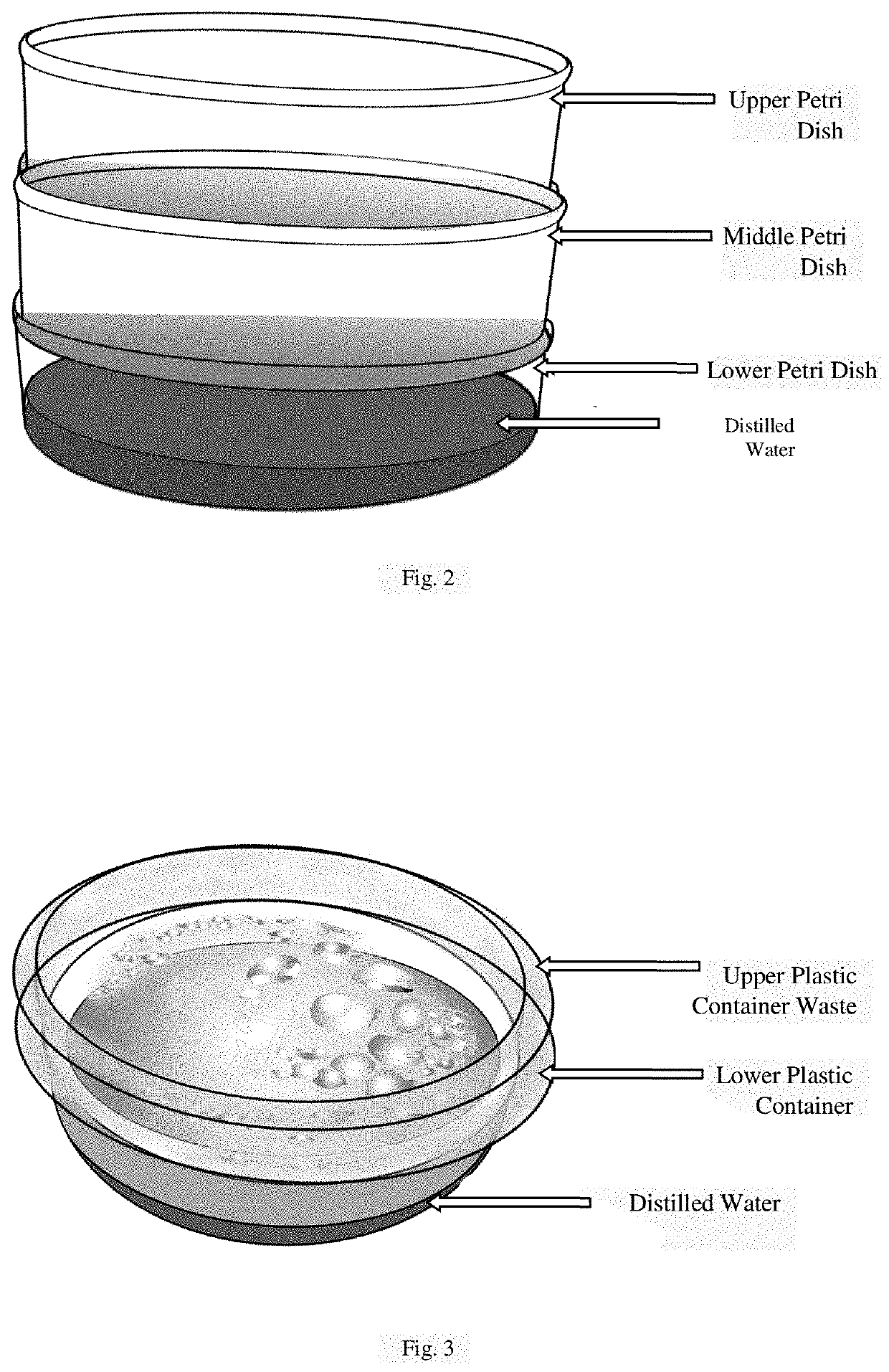

New Device of Wastewater Treatment using Renewable Energy

InactiveUS20220055919A1General water supply conservationDispersed particle separationPetri dishExposure sunlight

Treatment of wastewater and particularly relates to a technique for wastewater treatment using renewable energy (RE) which is sole solar energy (SE). In bench scale experiment, a device is constructed to consist of two fixed upper and lower glass Petri dishes. Another device consists of plastic containers and both devices with the same volume of wastewater in the upper and distilled water in the lower container. The first device is placed on the bench beside a window to be exposed to sunlight at room temperature and the other device is put outdoors under direct sunlight during daytime. A build-up of small circular water droplets starts to appear on the external bottom of upper container. Water droplets are allowed to fall freely in the lower container, pH of droplets water is about 7.1. Yield of freshwater is at a rate of approximately 300 ml freshwater from 400 ml wastewater per 48 hours.

Owner:ALI ALI FADLELMULA MOHAMED

Method for preparing diethyl oxalate by coupling CO

ActiveCN101143821BNo pollution in the processImprove efficiencyPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsCyclic processContinuous use

Owner:TIANJIN UNIV

Grams-grade packaged commercial chlorine gas

The invention discloses a manufacturing method of gram-grade package chlorine, and belongs to the technology field of water disinfector. The technical proposal is as follows: (1) liquid chlorine in steel bottle package is carried out of a copper tube from a gaseous chlorine opening, and put into a chlorine buffer tank; (2) a plastic hose is connected from the top of the chlorine buffer tank to a 500ml plastic bottle; (3) a bench scale for metering is arranged below the plastic bottle; the time for filling the chlorine into the plastic bottle can be measured according to pressure and flow, the mass indication of the bench scale are used as standards in case of bench scale; (4) the plastic bottle is tightly covered with a sealing ring and a bottle cover; and (5) the plastic bottle is labeled. The commercial gaseous chlorine has the advantages of simple structure, convenient manufacture, low cost, and safety and applicability for water disinfection in rural areas or disaster-hit areas. Furthermore, chlorine in a steel bottle with one ton volume can be packed into 632911.30 plastic bottles, the cost of each plastic bottle of chlorine is RMB 0.00316 if each ton of liquid chlorine values at RMB 2000.

Owner:吴欢

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com