Novel technology for manufacturing hot melt resin from waste and old polystyrene foam

A technology of waste polystyrene and foamed plastics, applied in the directions of graft polymer adhesives, adhesive types, adhesives, etc., can solve problems such as methods for direct copolymerization of polystyrene and vinyl acetate that are not reported in the literature , to achieve the effect of excellent performance, simple process and good monodispersity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

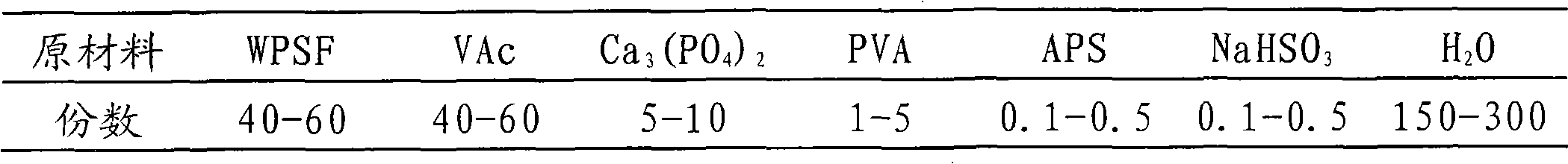

Embodiment 1

[0029] Using waste polystyrene plastic (WPSF) and monomer vinyl acetate (VAC) as raw materials, ammonium persulfate (APS) and sodium bisulfite as redox initiators, tricalcium phosphate and polyvinyl alcohol (PVA) as The dispersant is obtained through suspension polymerization to obtain vinyl acetate / polystyrene graft copolymer, which can be directly used as high-temperature-resistant hot-melt adhesive.

[0030] Step (1): Wash the waste polystyrene foam with deionized water, pulverize and dry it, then add monomer vinyl acetate into the reactor with a speed-regulating stirrer, insert a rotational viscometer into the reaction device , adjust the rotation speed of the agitator, so that the rheology of the polymerization system monitored online or a certain shear rate 20S -1 The viscosity at the bottom is 300-400mPa (the same below), connect the reactor to the condenser, thermometer, gradually add the polystyrene portion, mechanically stir to make it dissolve evenly.

[0031] Step...

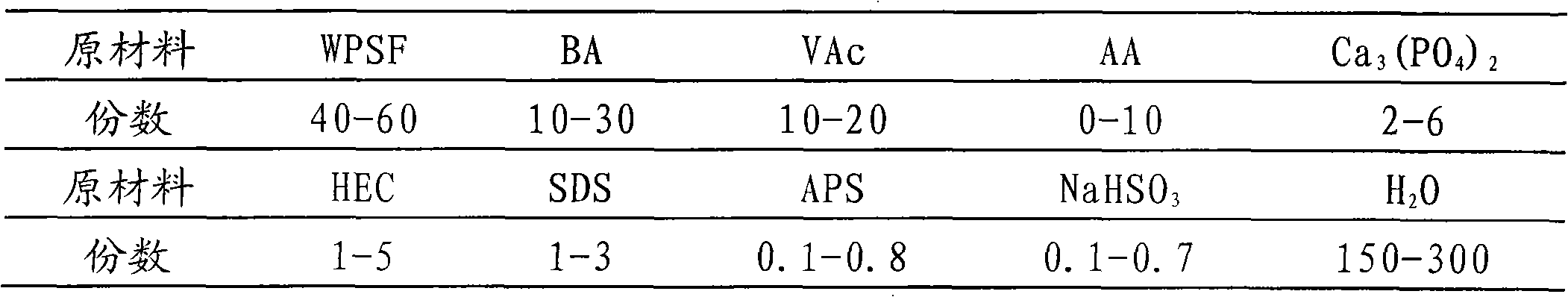

Embodiment 2

[0038] Using waste polystyrene plastics, monomer butyl acrylate and vinyl acetate, and functional monomer acrylic acid as raw materials, ammonium persulfate and sodium bisulfite as initiators, tricalcium phosphate and hydroxyethyl cellulose as dispersants, The acrylate / styrene graft copolymer is obtained by suspension polymerization, which can be used as a hot-melt adhesive for book binding and paper packaging, and can also be used as a coating base material and adhesive after being dissolved in an organic solvent.

[0039] Step (1): first wash the waste polystyrene foam with deionized water, crush it, and dry it, then add monomer butyl acrylate (BA), vinyl acetate, functional monomer acrylic acid (AA) into the reactor, The reactor is connected with a condenser and a thermometer, and 35 parts of polystyrene is gradually added, and mechanically stirred to make it dissolve evenly.

[0040] Step (2): Add 1 part of sodium dodecylbenzenesulfonate, 3 parts of tricalcium phosphate an...

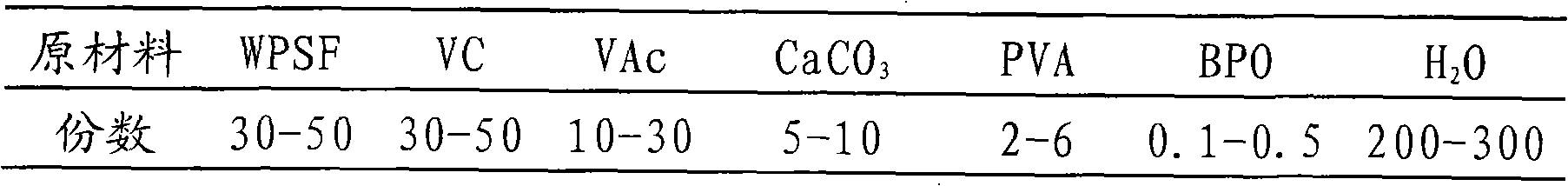

Embodiment 3

[0047] Using waste polystyrene plastics, vinyl acetate, and vinyl chloride as raw materials, benzoyl peroxide as an initiator, calcium carbonate and polyvinyl alcohol as a dispersant, the vinyl chloride grafted polystyrene powder is obtained through suspension polymerization Resins that can be used as high-impact plastics or plastic additives.

[0048] Step (1): washing waste polystyrene foam with deionized water, pulverizing and drying. Add monomer vinyl acetate and vinyl chloride into the reactor, insert a condenser tube and a thermometer on the reactor, gradually add polystyrene, and mechanically stir to dissolve them evenly.

[0049] Step (2): Add 5 parts of calcium carbonate and 3 parts of polyvinyl alcohol into the reactor, add 250 parts of water, continue stirring, and heat the system in a water bath to start heating up.

[0050] Step (3): When the temperature rises to 60°C, add 0.2 parts of the initiator benzoyl peroxide to the system, stir well, and turn on the conde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com