Bench-scale experiment device for nitrogen containing organic waste gas heat storage type incinerator

A technology of organic waste gas and experimental equipment, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems that cannot be adapted to the treatment of organic waste gas, and achieve the effect of reasonable overall structure setting, eliminating interference and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

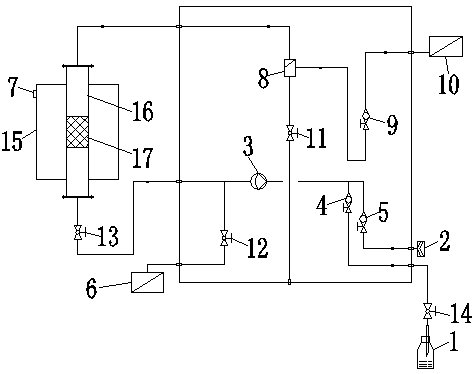

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0013] Such as figure 1 As shown, a small-scale experimental device for a nitrogen-containing organic waste gas regenerative incinerator according to the present invention includes an organic waste gas generator 1 and an air filter 2, and the machine waste gas generator 1 passes through the intake pipe I is connected to the air pump 3, and the air filter 2 is connected to the air pump 3 through the air intake pipe II. A flow meter I4 is provided on the air intake pipe I, and a flow meter II5 is provided on the air intake pipe II. The air pump 3 is connected to the simulated incinerator through the main pipe, and the waste gas VOC detector 6 is connected to the main pipe between the air pump 3 and the simulated incinerator through the branch pipe I. A temperature regulator 7 is provided on the simulated incinerator. The simulated incinerator is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com