Friction test machine for small sample contracting ratio table

A friction testing machine and scaling technology, applied in the direction of testing wear resistance, using mechanical devices, measuring devices, etc., can solve the problems of low testing accuracy and automation level, low braking force control accuracy, poor reliability, etc., to improve the comparability performance level, reduced test costs, reduced geometry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

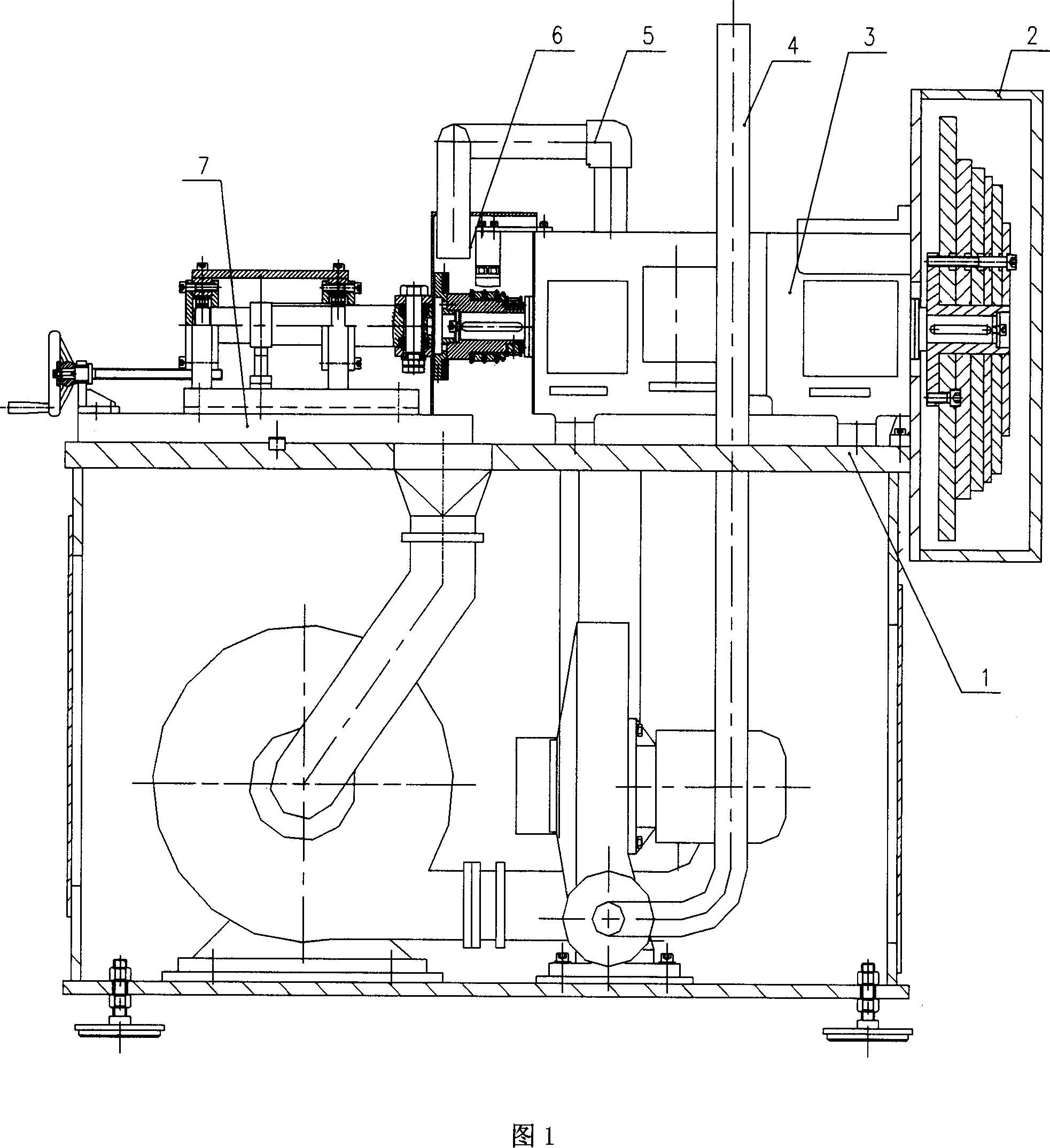

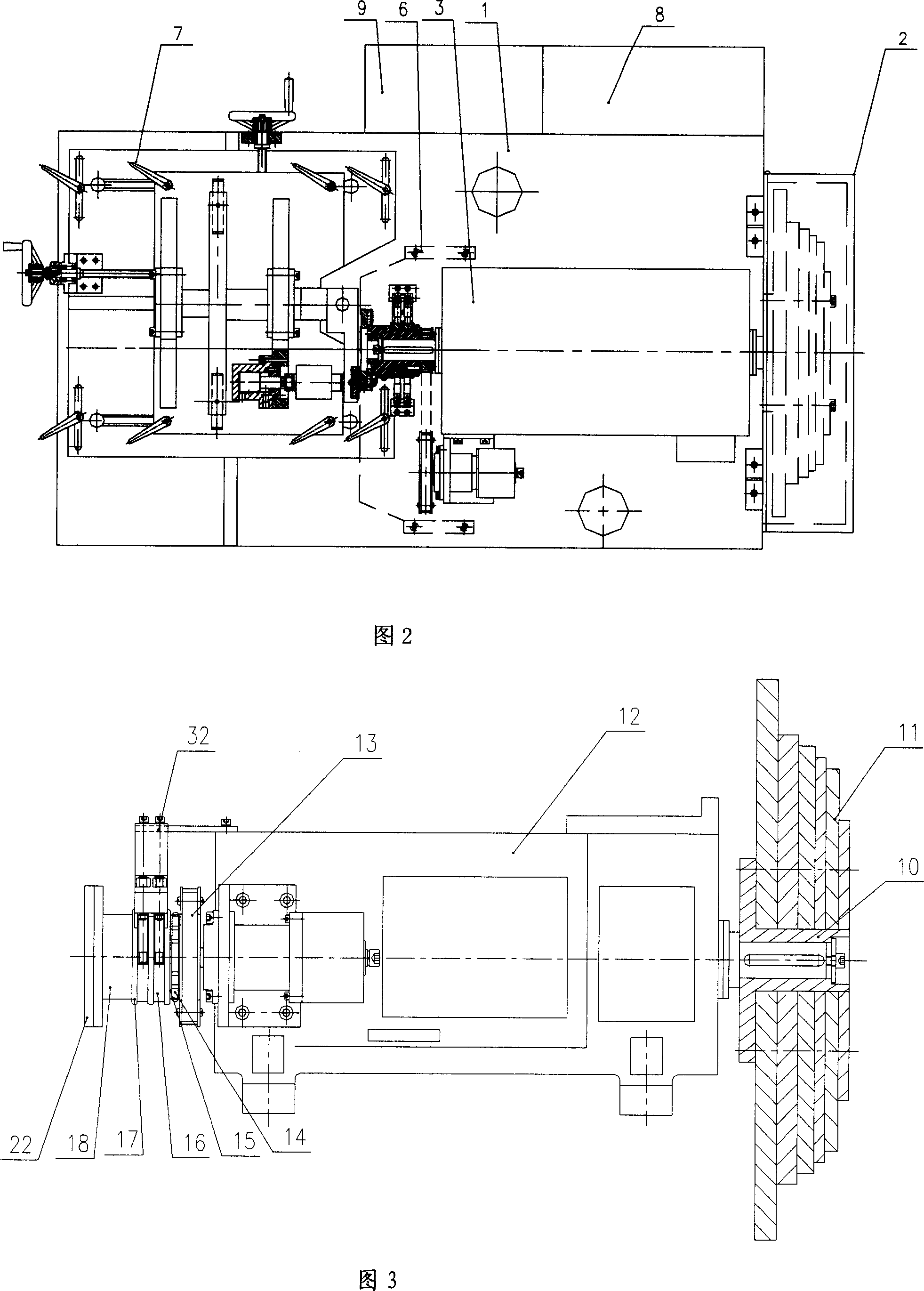

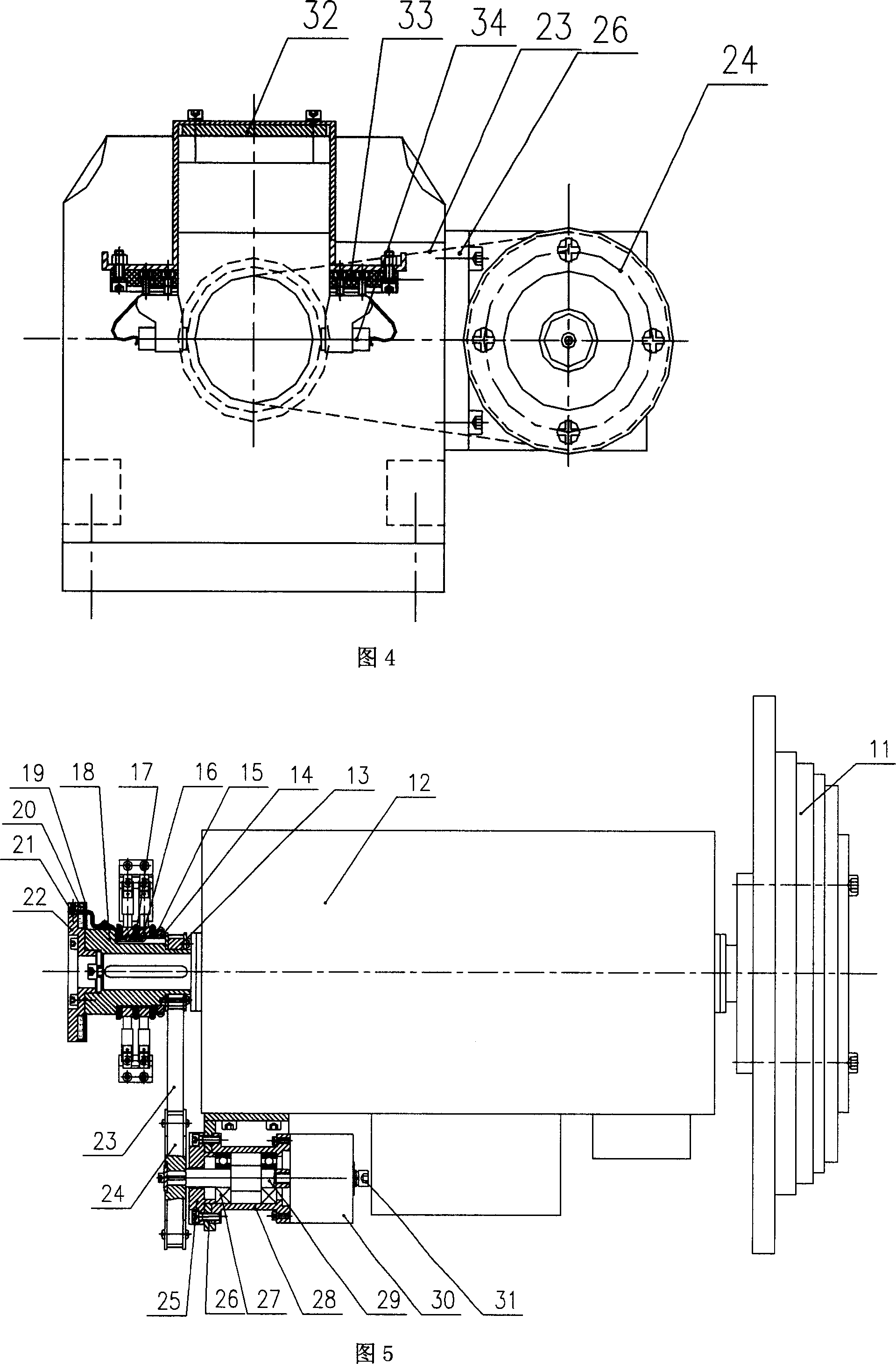

[0034] Referring to Fig. 1 and Fig. 2, a small-scale bench friction testing machine adopts an overall structure, mainly consisting of a box-type machine base 1, a spindle drive system 3, a dust removal assembly 4, a blower cooling assembly 5, and a sliding table system 7 , computer control system and electrical control box 8, pressure control loading device 9 components. The box-type base 1 can be welded by profiles and steel plates according to the size of the production batch, or it can be assembled by casting in parts and then fixed. No matter which method is used, it must have sufficient rigidity and strength. The working surface shall be machined, and a keyway shall be machined longitudinally. First, the sliding table system 7 used to determine the relative position of the friction material sample 84 to be tested and the friction brake disc 22 is connected via a key. The longitudinally moving flat plate 40 in the system 7 can move longitudinally on the upper working surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com