Integrated sequencing-batch method for treating sewage by plant micro-net dynamic membrane and apparatus therefor

A dynamic membrane and sequencing batch technology, applied in the direction of sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the lack of detailed analysis of DMBR economy, the initial effluent can not meet the standard, and the problems need to be further studied and other problems, to achieve the effect of good sewage treatment, obvious energy saving and emission reduction, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

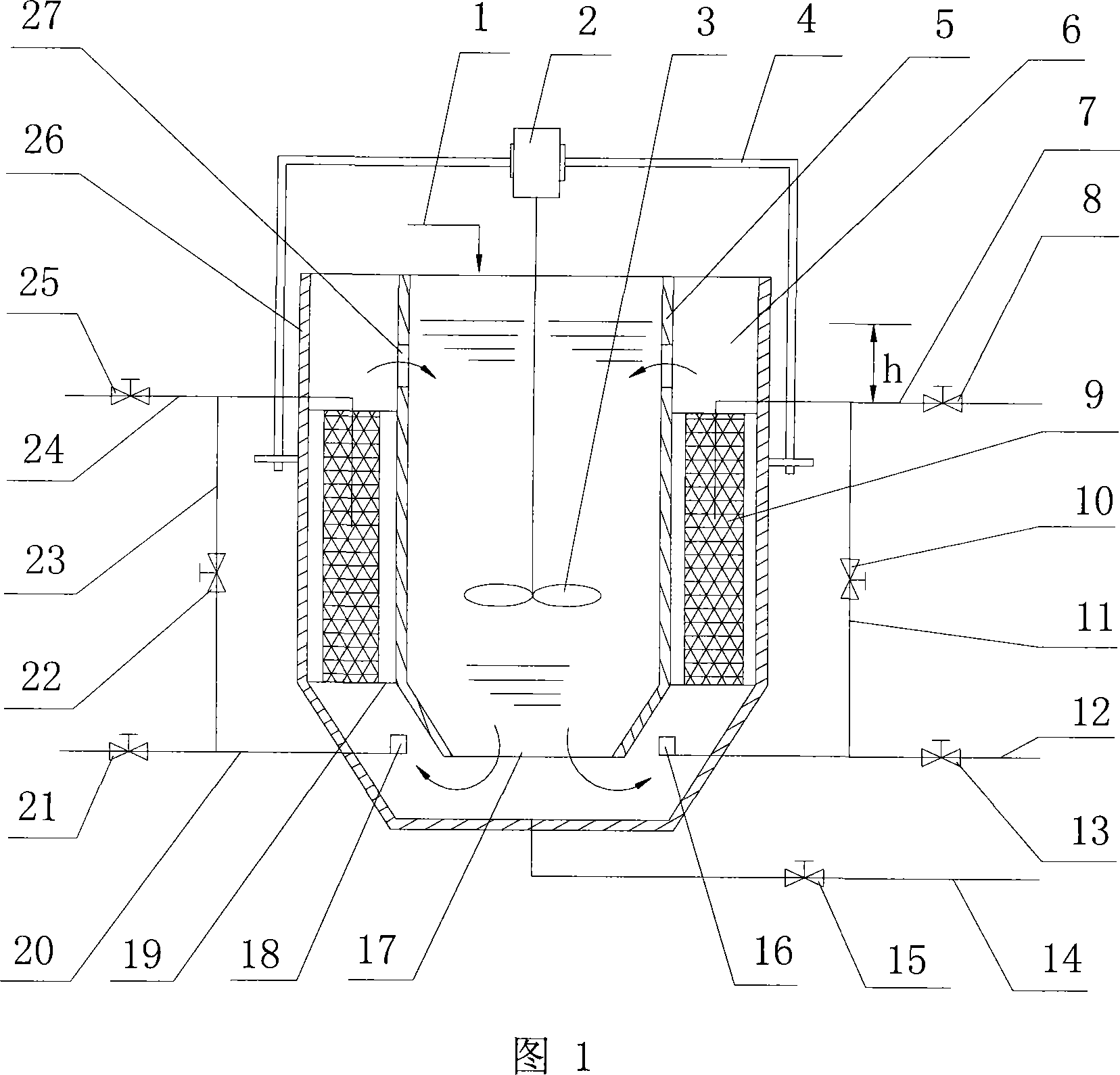

[0024] The method for treating sewage with an integrated sequence-batch type plant micro-network dynamic membrane comprises the following steps:

[0025] 1) Preparation of equipment: set up a partition barrel in the inner cavity of the membrane bioreactor, the upper part of the partition barrel is provided with diversion holes, the bottom of the partition barrel is opened with a bottom opening, and the gap between the partition barrel and the membrane bioreactor body A dynamic membrane filtration chamber is formed, and the upper and lower outer walls of the partition barrel are fixedly connected with the membrane bioreactor body by the upper and lower dynamic membrane fixing brackets respectively, and the dynamic membrane filtration chamber between the upper and lower dynamic membrane fixing brackets is provided with a plant micro-network dynamic membrane; The sewage pipe is communicated with the separation barrel, the stirring paddle of the agitator is set in the separation ba...

Embodiment 2

[0033] The method for treating sewage with an integrated sequence-batch type plant micro-network dynamic membrane comprises the following steps:

[0034] 1) Preparation of equipment: set up a partition barrel in the inner cavity of the membrane bioreactor, the upper part of the partition barrel is provided with diversion holes, the bottom of the partition barrel is opened with a bottom opening, and the gap between the partition barrel and the membrane bioreactor body A dynamic membrane filtration chamber is formed, and the upper and lower outer walls of the partition barrel are fixedly connected with the membrane bioreactor body by the upper and lower dynamic membrane fixing brackets respectively, and the dynamic membrane filtration chamber between the upper and lower dynamic membrane fixing brackets is provided with a plant micro-network dynamic membrane; The sewage pipe is communicated with the separation barrel, the stirring paddle of the agitator is set in the separation ba...

Embodiment 3

[0043] The method for treating sewage with an integrated sequence-batch type plant micro-network dynamic membrane comprises the following steps:

[0044] 1) Preparation of equipment: set up a partition barrel in the inner cavity of the membrane bioreactor, the upper part of the partition barrel is provided with diversion holes, the bottom of the partition barrel is opened with a bottom opening, and the gap between the partition barrel and the membrane bioreactor body A dynamic membrane filtration chamber is formed, and the upper and lower outer walls of the partition barrel are fixedly connected with the membrane bioreactor body by the upper and lower dynamic membrane fixing brackets respectively, and the dynamic membrane filtration chamber between the upper and lower dynamic membrane fixing brackets is provided with a plant micro-network dynamic membrane; The sewage pipe is communicated with the separation barrel, the stirring paddle of the agitator is set in the separation ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com